Patents

Literature

35results about How to "Environmental recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

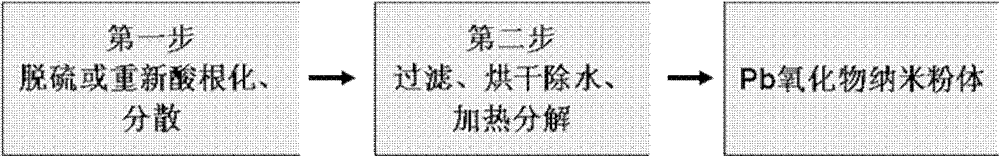

Preparation method of Pb oxide nano powder for recovery and manufacture of lead acid battery

ActiveCN102689921AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologyDecompositionLead salt

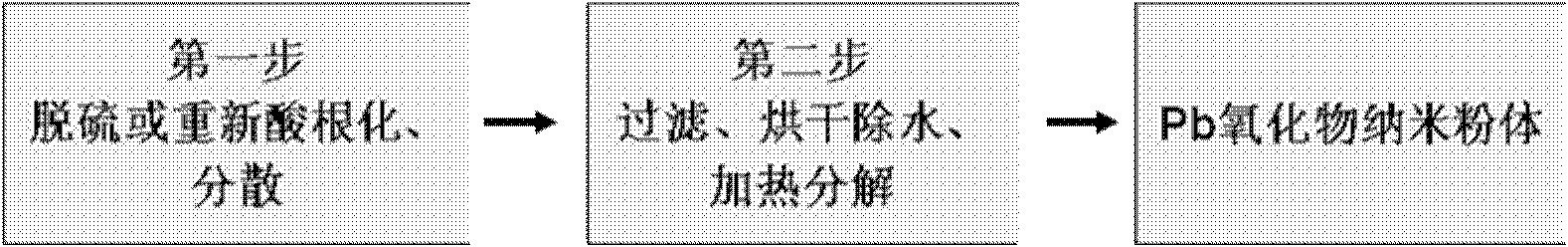

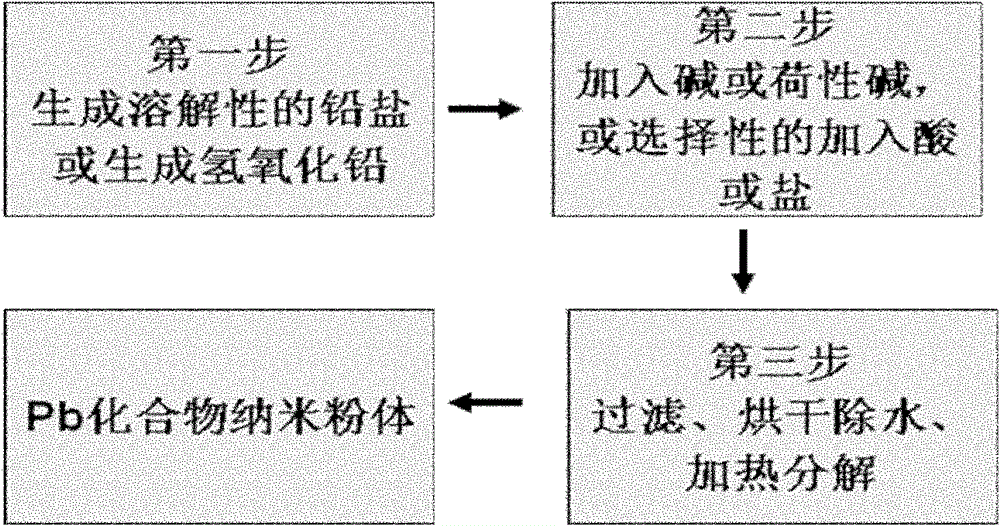

The invention discloses a preparation method of a Pb oxide nano powder for recovery and manufacture of a lead acid battery. The method comprises the steps of: (1) reacting lead salt or waste lead acid battery lead paste with an organic or inorganic compound capable of complexing with Pb atom / ion, so as to realize desulphurization or reloading of acid radical; and (2) carrying out treatment processes of filtering, drying for removing water and heating for decomposition, so as to obtain the Pb oxide nano powder. The method of the invention realizes an environment-friendly and energy-efficient recovery and production process with substantially reduced production cost; meanwhile, the prepared Pb oxide powder is beneficial for enhancement of product performance.

Owner:杨春晓

Waste rigid polyurethane foaming plastic recycling and use method

ActiveCN109776119AWide range of usesEnvironmental RecyclingBio-organic fraction processingGrowth substratesEnvironmental resistanceAbsorption rate

The invention provides a waste rigid polyurethane foaming plastic recycling and use method which comprises the following steps: firstly, carrying out shearing crushing, grinding, adding a surfactant in the shearing crushing and grinding process, and continuously grinding till the particle size of obtained waste rigid polyurethane foaming plastic powder is smaller than or equal to 40 [mu]m, the volume water absorption rate is greater than or equal to 100% and the aperture ratio is greater than or equal to 90%. Under coactions of a mechanical action and a chemical action, closed cell foams are changed into opened cell foams, then the foams have water-absorbing quality and can be used as a water absorption powder material; the material can be mixed with fermentation culture seeds, carbohydrate and excrement below livestock beds in net bed breeding, and a composted fertilizer can be prepared through direct in-situ fermentation; the material can be also used as a medium of medium cultivation of soilless culture; the water absorption powder material has very wide application, and thus waste rigid polyurethane foaming plastics can be recycled and used with environmental protection, energyconservation and high efficiency.

Owner:山东新亚科技服务有限公司

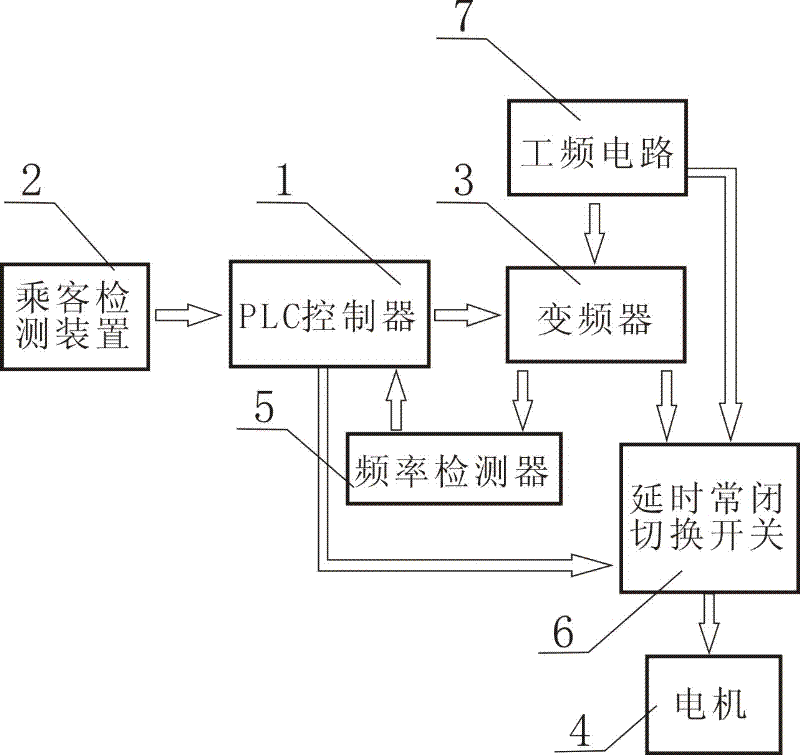

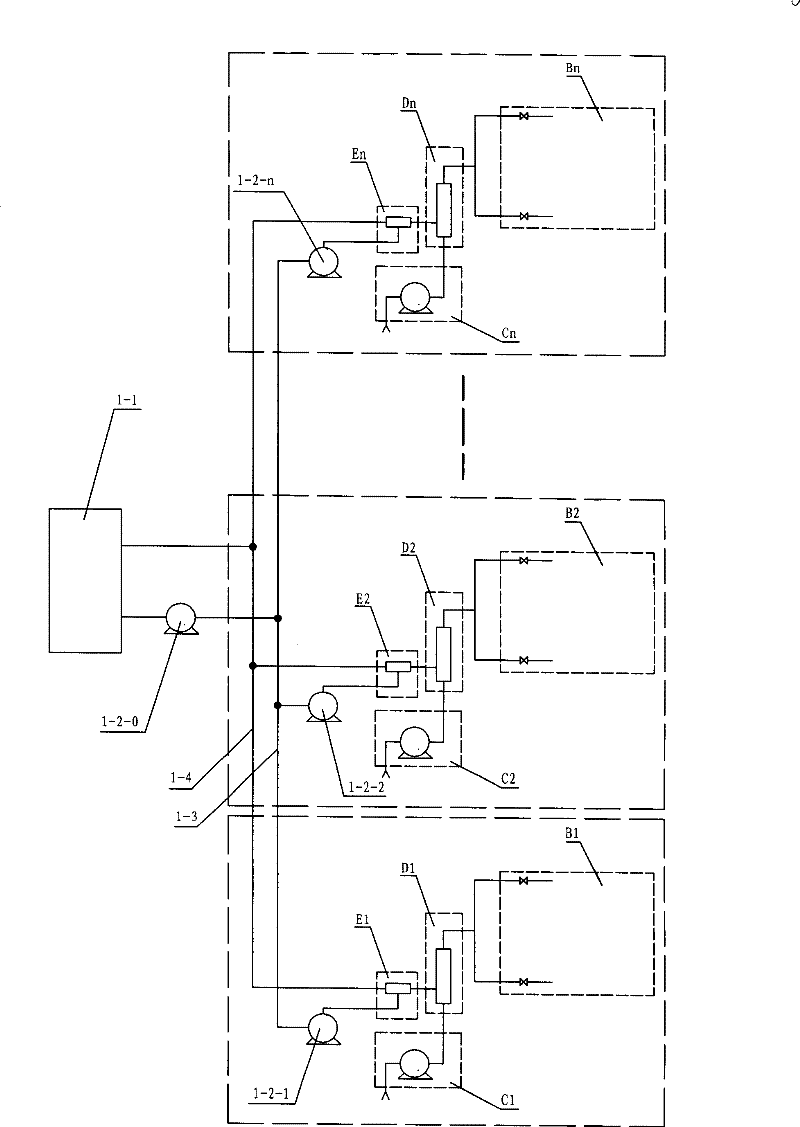

Energy-saving efficient escalator control system

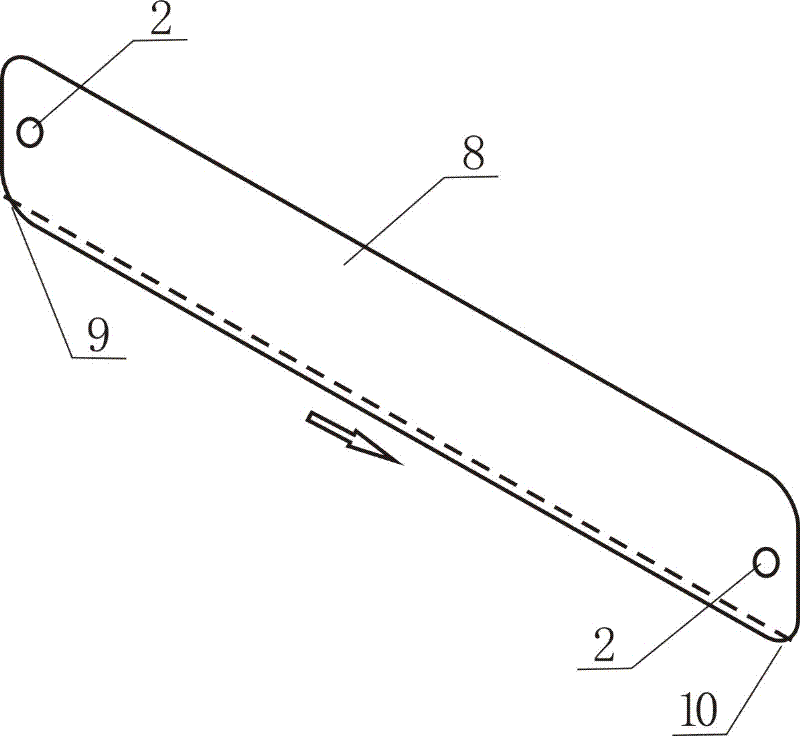

InactiveCN102556825AExtended service lifeEnvironmental recyclingEnergy efficiency in escalatorsEscalatorsFrequency changerStopped work

The invention discloses an energy-saving efficient escalator control system, which comprises a PLC (programmable logic controller), a passenger detector, a frequency changer and a motor. The passenger detector transmits the loading information to the PLC that controls the rotary speed of the motor through the frequency changer. The frequency changer is connected with a frequency detector, a delayed selector switch is arranged on a circuit between the frequency changer and the motor, the frequency detector detects the output power frequency information of the frequency changer and sends the same to the PLC, and the PLC sends a circuit switching command to switch the circuit for the delayed selector switch so that the motor is connected with the power frequency circuit. With adoption of the structural form, when the escalator carries passengers, the escalator advances at full speed and the frequency changer stops working, thereby not only improving the work efficiency, but also prolonging the service life of the frequency changer. In addition, the system further has the advantages of low cost, no noise, energy conservation and environmental friendliness.

Owner:黄德雄

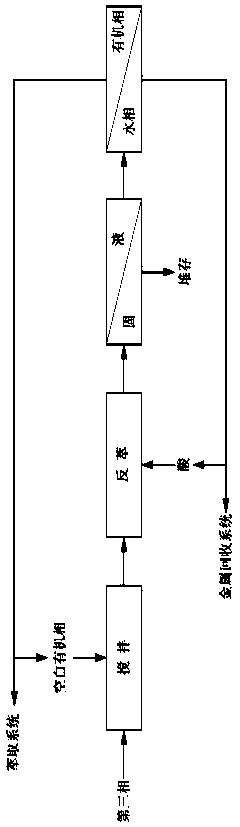

Treatment method of third phases in wet metallurgy extraction system

InactiveCN109112308AReduce lossesEconomic recyclingProcess efficiency improvementPhase splittingThird phase

The invention discloses a treatment method of third phases in a wet metallurgy extraction system. The method is characterized by comprising the following steps that a, extraction agents are added intothe third phases in the wet metallurgy extraction system; stirring is performed; b, acid is added into a mixture obtained in the step a for performing back extraction; c, a mixture obtained after back extraction in the step b is subjected to phase splitting. The treatment method has the advantages that material liquid and organic phases carried by the third phases can be economically, simply andconveniently recovered in an environment-friendly way; the loss caused by a third phase extraction system is reduced.

Owner:广西银亿新材料有限公司

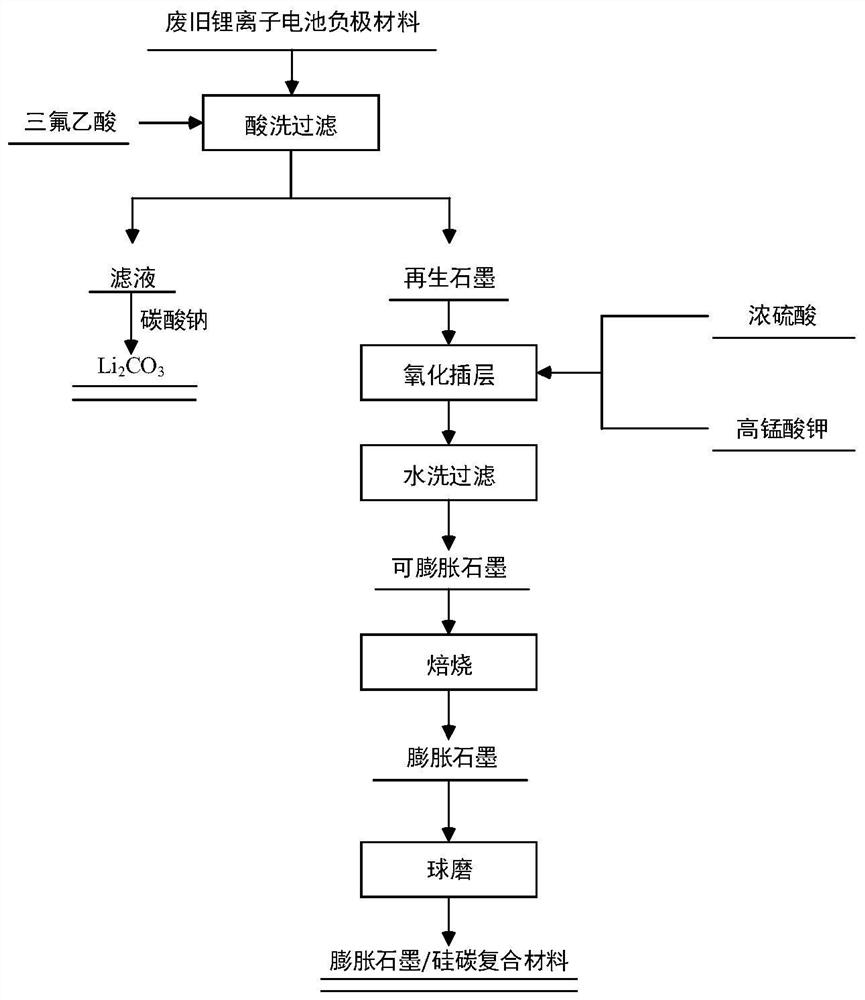

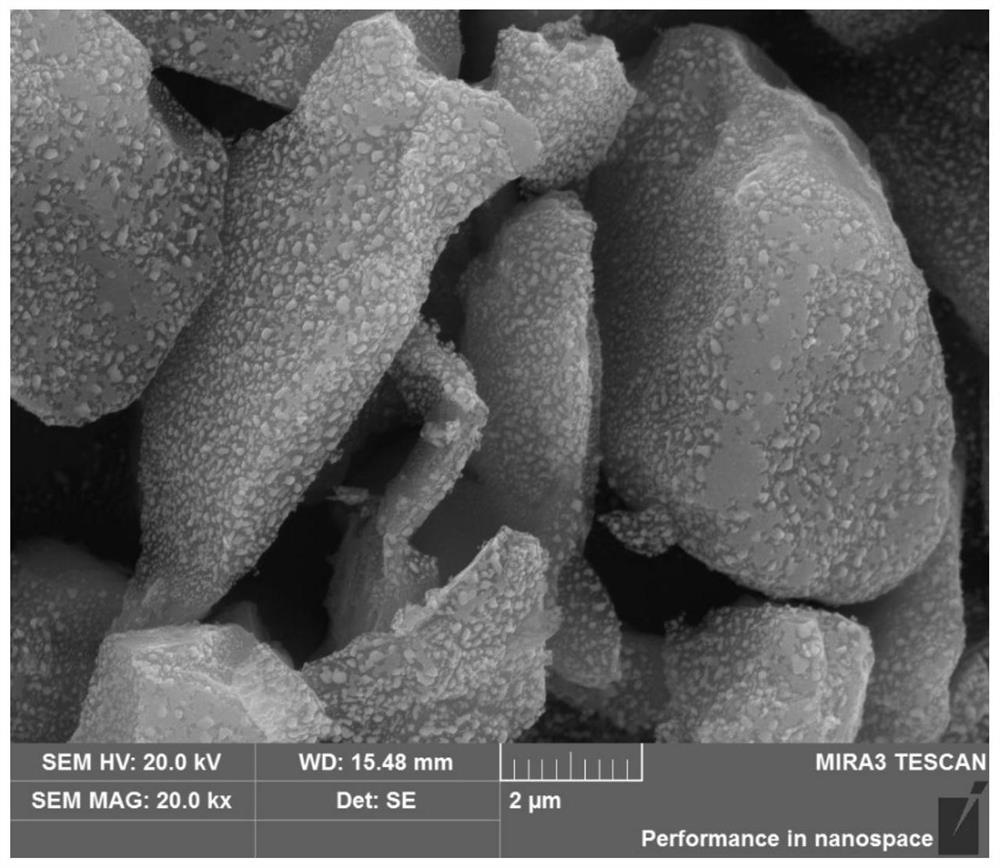

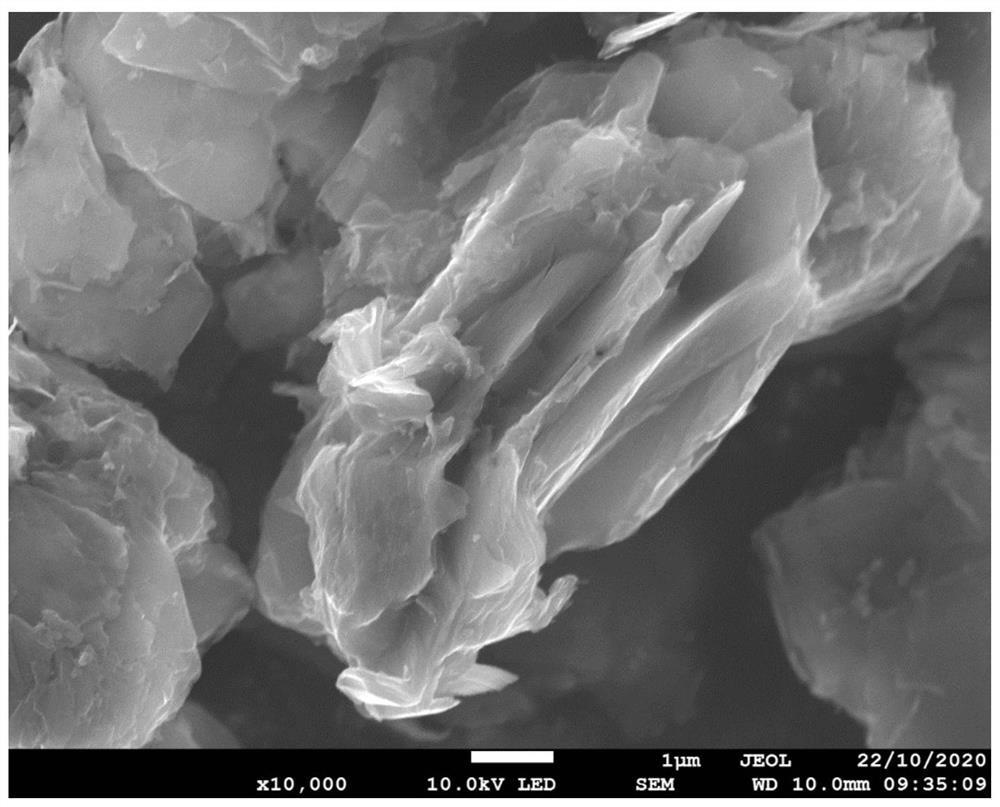

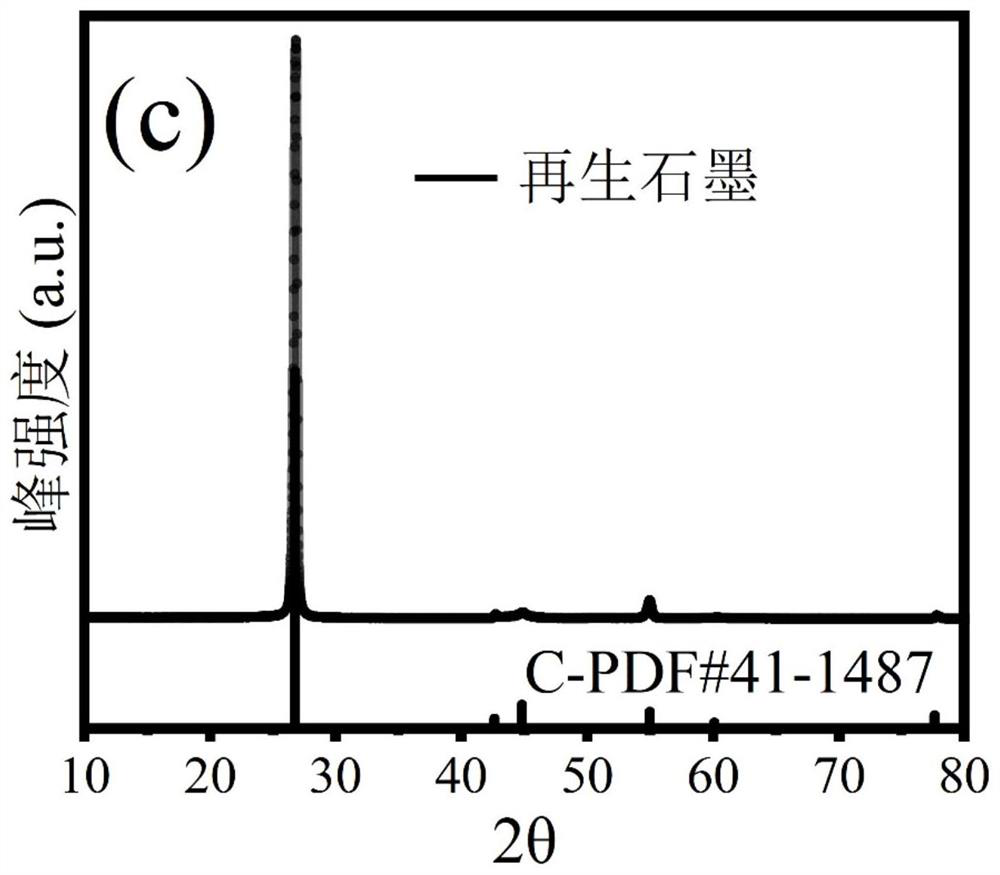

Method for preparing expanded graphite/silicon carbon material from graphite negative electrode of waste battery

InactiveCN111977646AHigh purityHigh mechanical strengthSiliconWaste accumulators reclaimingCarbon compositesGraphite

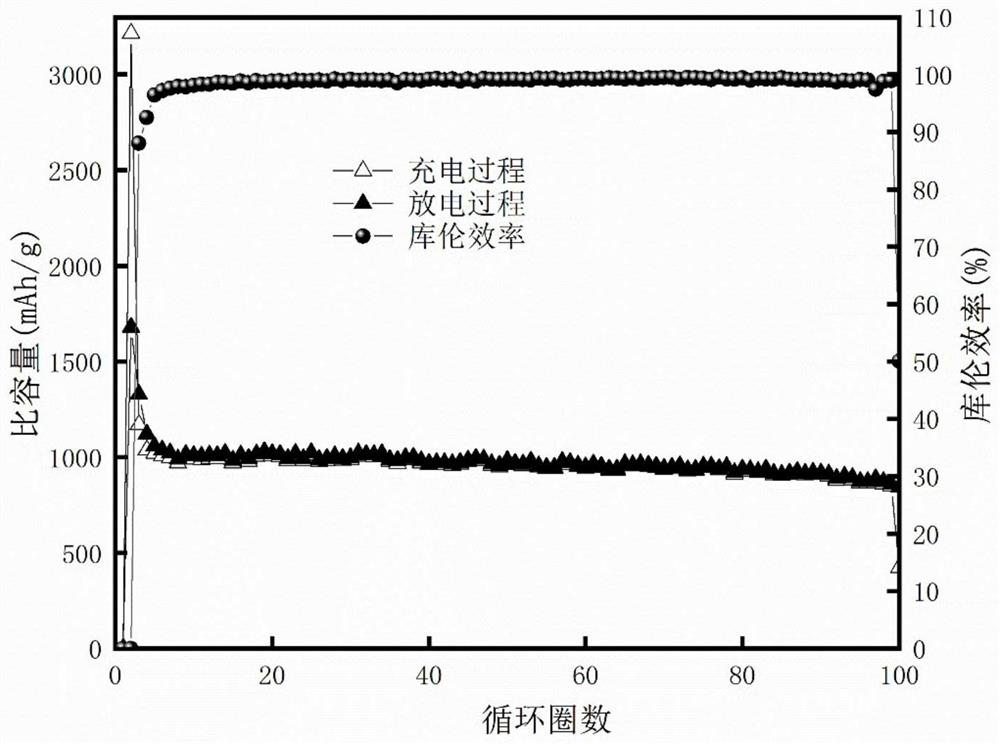

The invention relates to a method for preparing an expanded graphite / silicon carbon material from a graphite negative electrode of waste battery. The method comprises the following steps of (1) takinga waste graphite negative electrode plate, and performing pickling, filtration and drying to obtain a graphite material; (2) mixing the graphite material obtained in the step (1) with an intercalating agent and an oxidizing agent for reaction, and then, performing water washing, filtration and drying to obtain expandable graphite; (3) placing and roasting the expandable graphite in a muffle furnace for a period of time to obtain expanded graphite; and (4) performing ball milling on the obtained expanded graphite and a silicon carbon material, and obtaining the expanded graphite / silicon carboncomposite material after the ball milling. According to the method provided by the invention, the pollution generated by the waste lithium ion battery is effectively reduced, and in addition, the waste graphite material of the negative electrode can be recycled and regenerated into an expanded graphite / silicon carbon composite negative electrode material. The regenerated material has the advantages of excellent mechanical strength and toughness, good cycle performance, great reversible capacity and high capacity retention rate.

Owner:CENT SOUTH UNIV

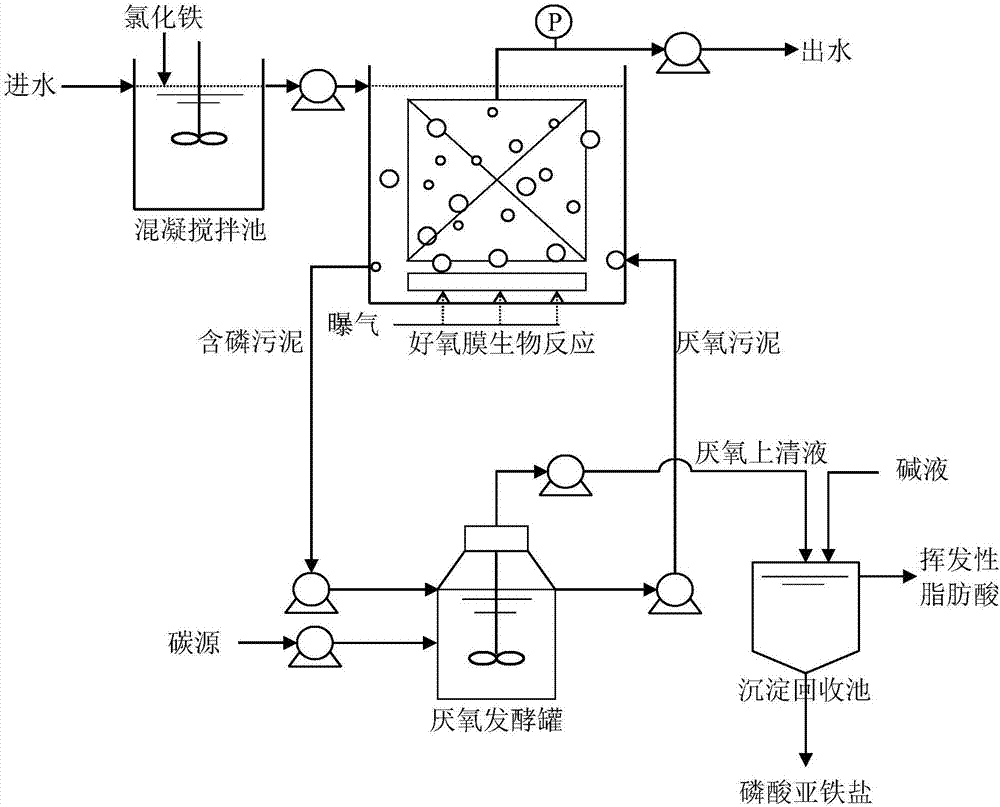

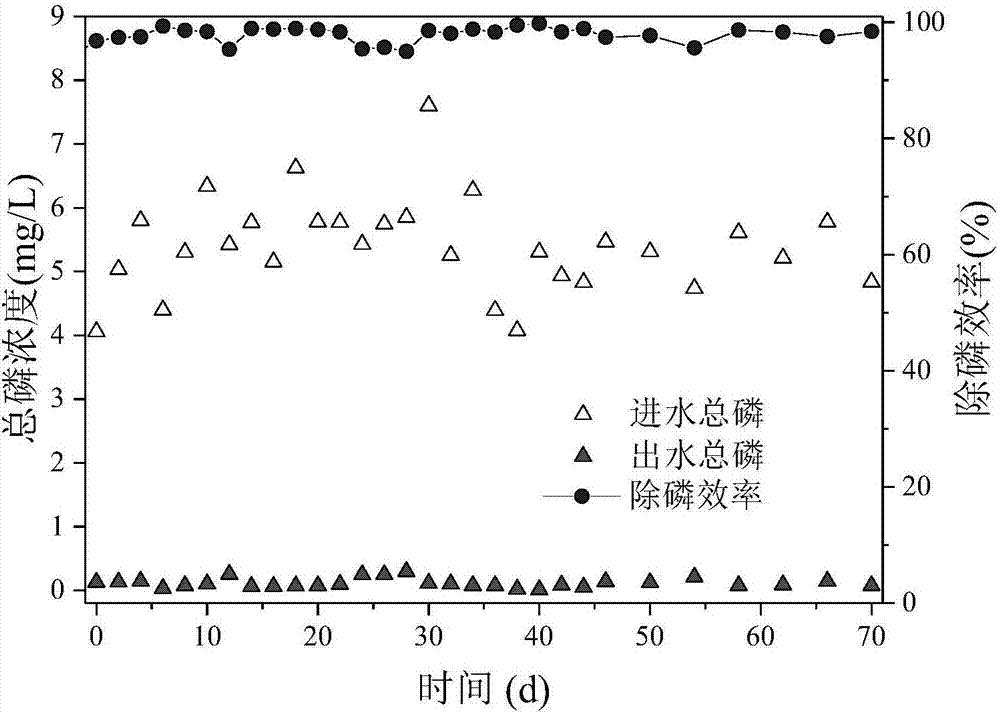

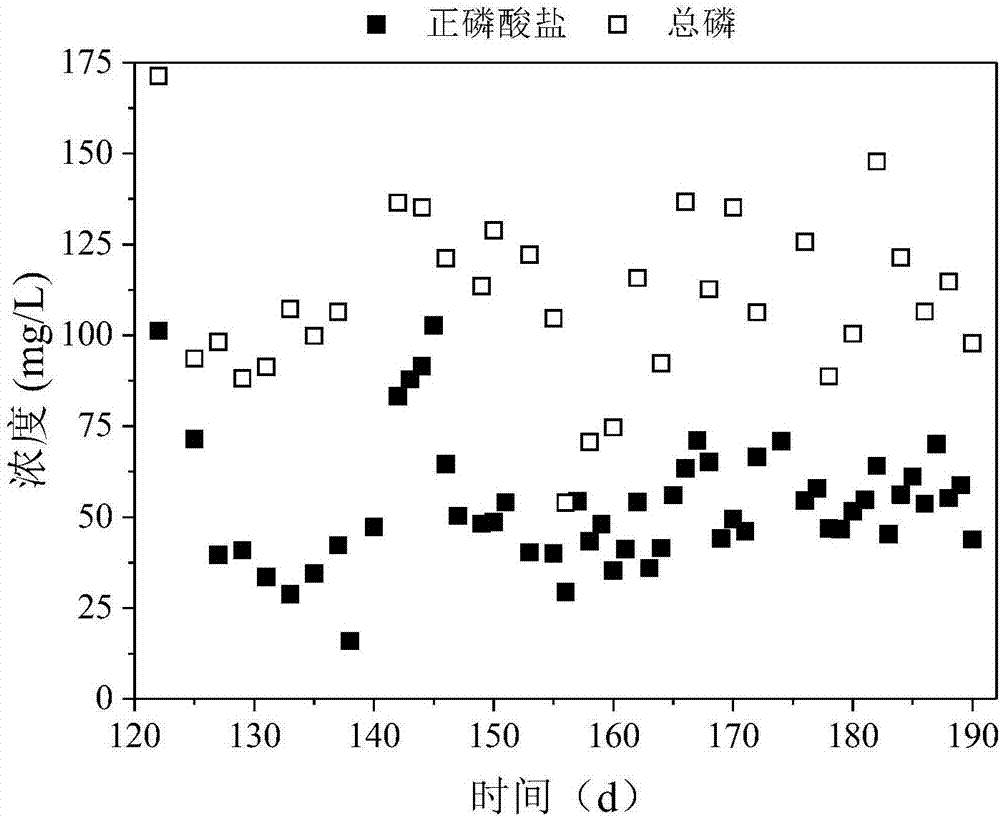

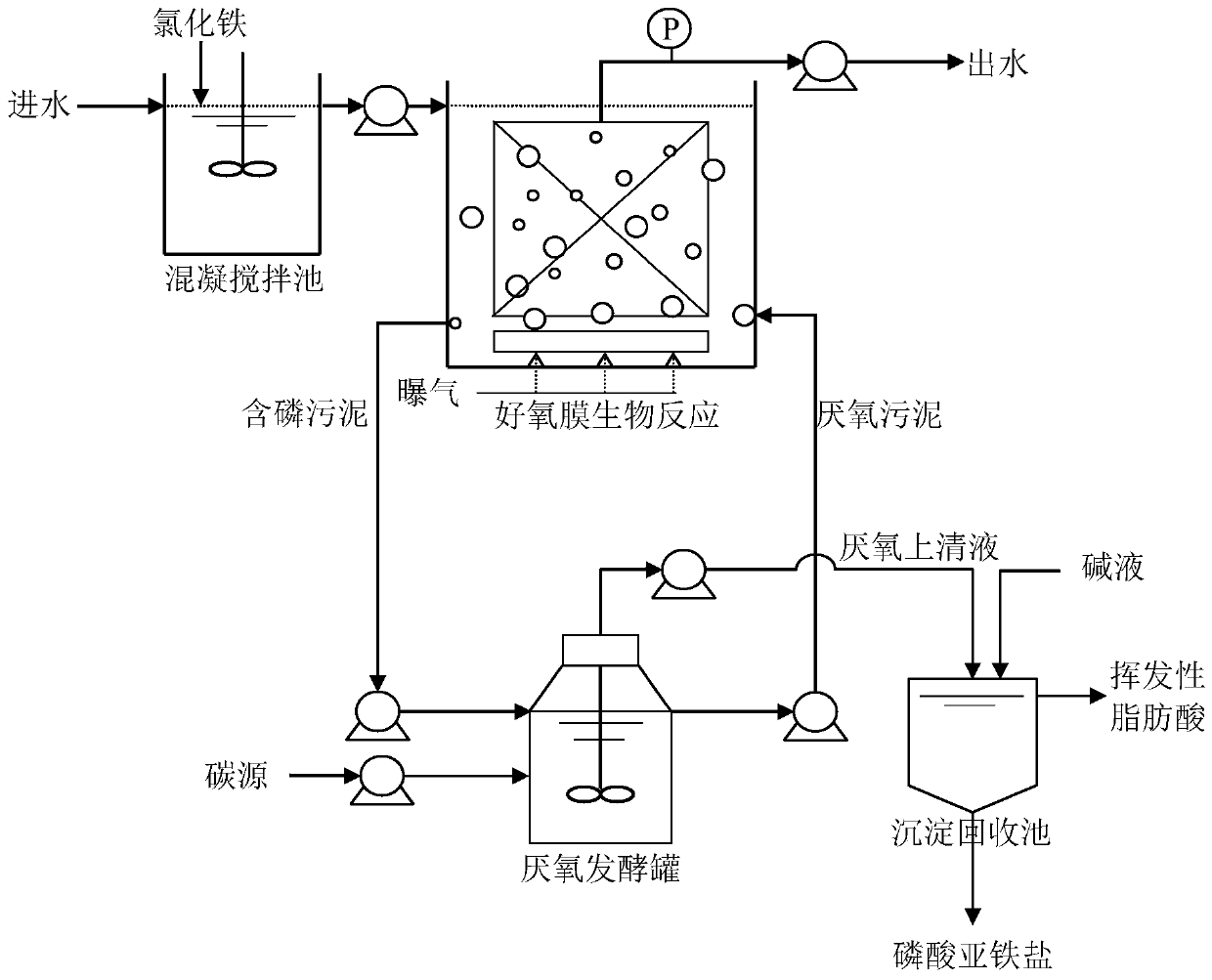

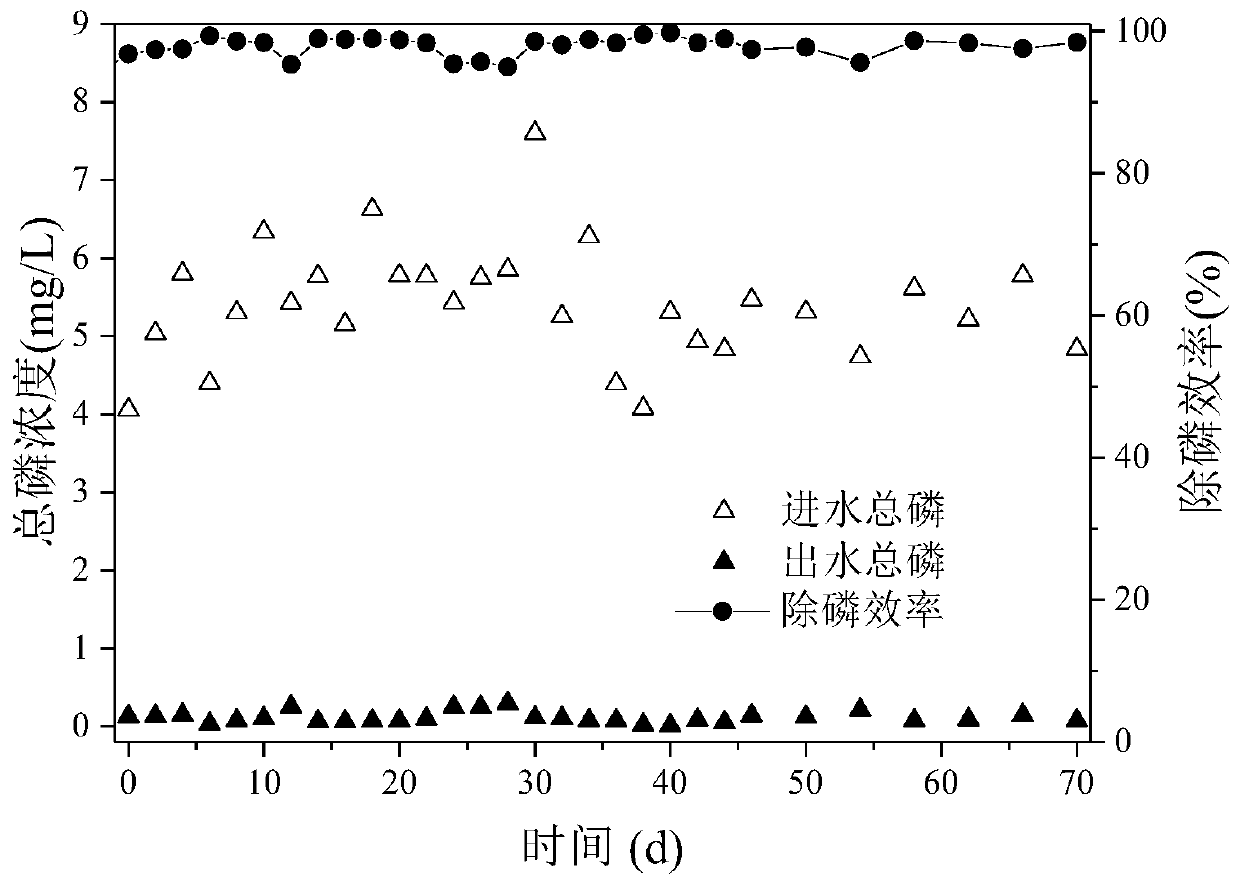

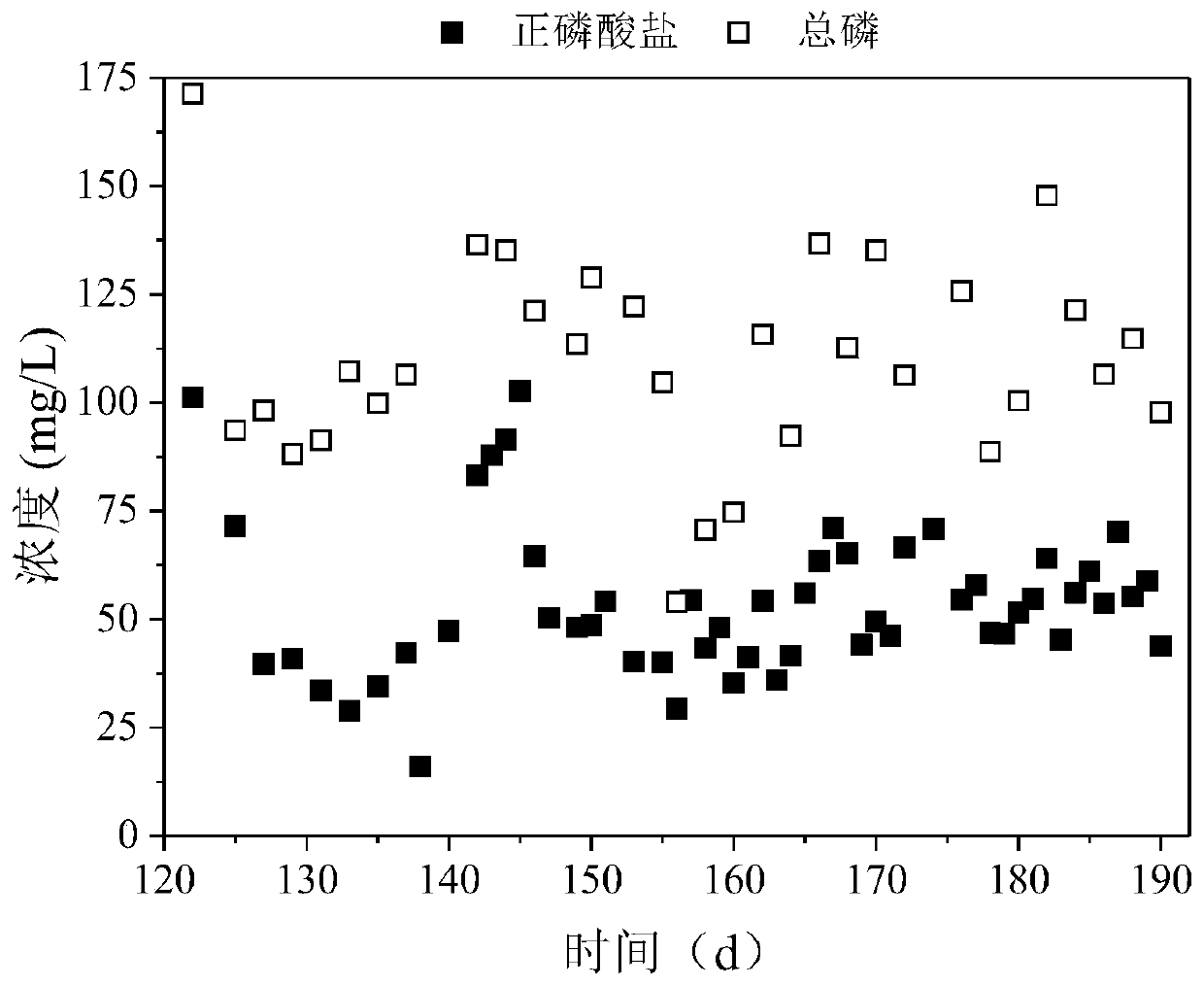

Sewage treatment system and treatment method in combination with membrane bioreactor and phosphorus recovery process

ActiveCN107473370AImprove solubilityReduce usageWater contaminantsSustainable biological treatmentSolubilityActivated sludge

The invention is mainly applied to the technical field of municipal sewage treatment, and mainly relates to a sewage treatment system and treatment method in combination with a membrane bioreactor and a phosphorus recovery process. In combination with a biological method and a chemical method, anaerobic acidification is used for replacing a chemically acidified and dissolved iron phosphate precipitate, and a microorganism dissimilatory iron reduction effect is used for increasing phosphate solubility. The treatment system is applied to activated sludge but not remaining sludge, phosphorus recovery is realized in a weak acid condition, secondary pollution is not caused, inert constituents inside the activated sludge are reduced, the biodegradability of the activated sludge is strengthened, the application of the membrane reactor can realize that the sludge retention time reaches infinity, and the phosphorus recovery efficiency reaches 95% or more. Compared with the chemical method, the treatment method is simple, safe and environmentally-friendly in phosphorus recovery, the application of strong acid and strong base is greatly reduced, and the recovery cost is reduced; and compared with the chemical method, the treatment method is stable and efficient.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

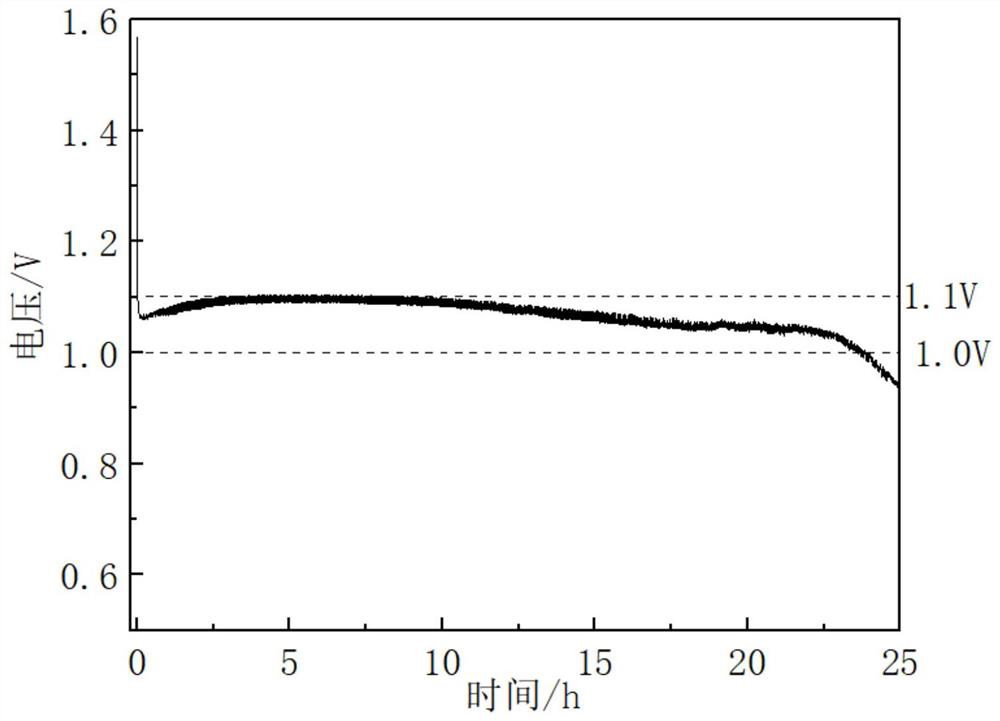

Vanadium pentoxide preparation method

The invention discloses a pentavalent vanadium preparation method which includes the steps: adding hydrogen peroxide into vanadium battery positive electrode and / or negative electrode electrolyte; performing reaction under the action of ultrasonic waves; oxidizing non-pentavalent vanadium in the electrolyte into pentavalent vanadium. The invention further discloses a vanadium pentoxide preparation method which includes the steps: preparing the pentavalent vanadium by the method; adjusting acid; settling vanadium; performing acid washing to obtain vanadium pentoxide. Experimental results indicate that the vanadium yield can reach 68% or more as the vanadium electrolyte is recovered by the method, in the obtained vanadium pentoxide, calcium, magnesium, iron and manganese impurity level is lower than or equal to 0.005%, sodium, silicon and chromium impurity level is lower than or equal to 0.01%, impurity content is low, product purity is high, and the requirement of current vanadium for vanadium battery electrolyte is met. The whole recovery process is simple and environmentally friendly, and industrial production can be realized.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

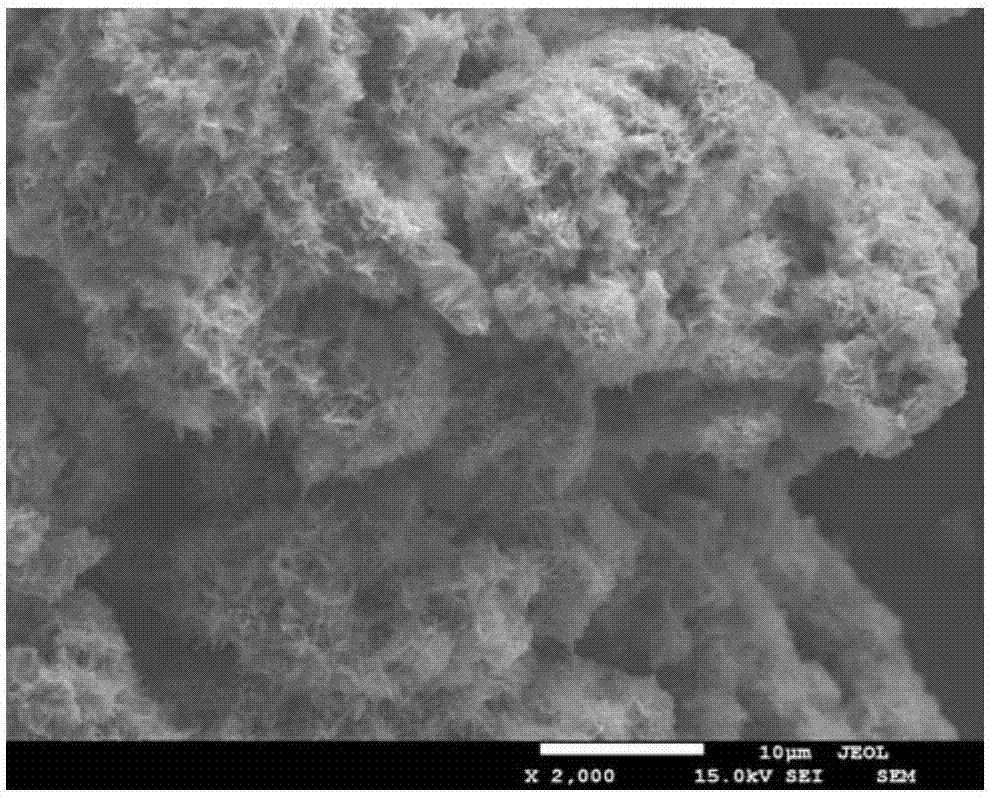

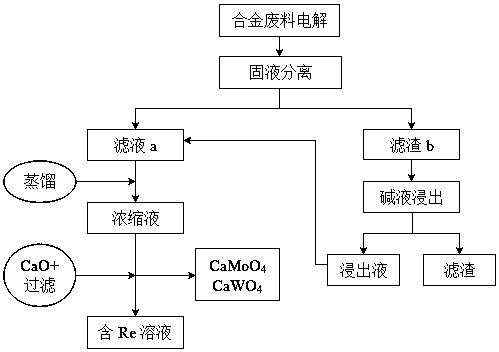

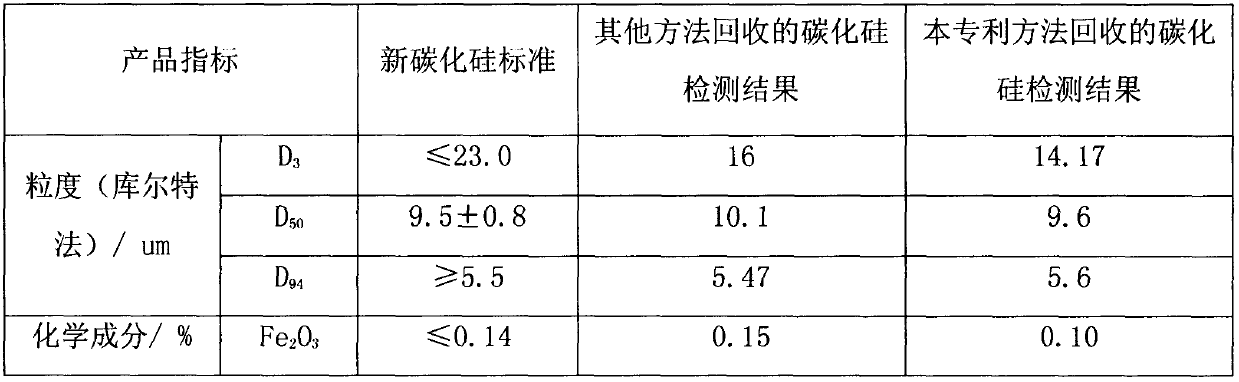

Method for recycling silicon cutting waste mortar

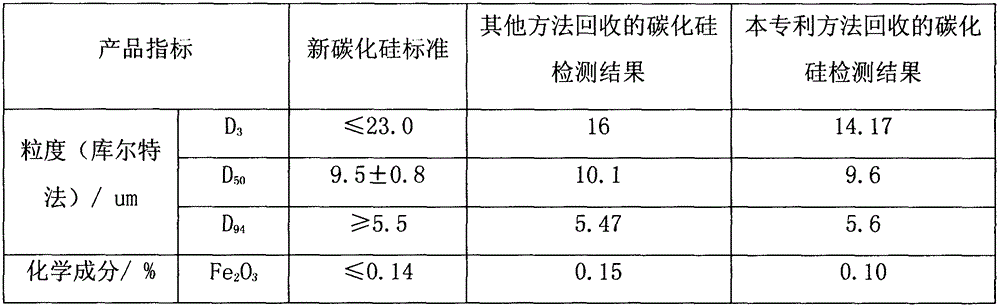

ActiveCN102746935AReduce dosageReduce cost investmentSilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

A method for recovering re from re-containing superalloy waste

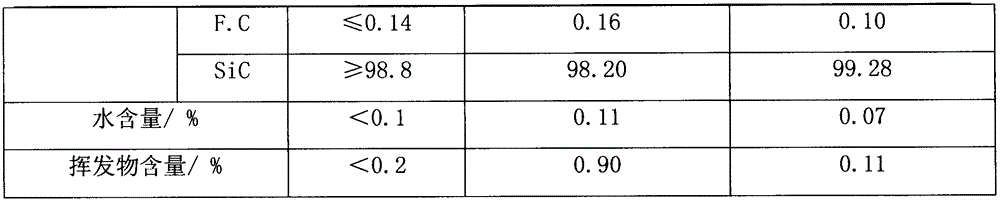

ActiveCN106757156BOvercoming the problem of slow electrolysisImprove electrolysis efficiencyPhotography auxillary processesProcess efficiency improvementPregnant leach solutionElectrolysis

The invention relates to a method for recovering Re from Re-containing high-temperature alloy waste. The method includes the following steps of firstly, carrying out direct-current electrolysis on the high-temperature alloy waste in an organic electrolyte system; secondly, carrying out solid-liquid separation to obtain filtrate a and filter residues b; thirdly, leaching and filtering the filter residues b many times by using an alkaline solution, and extracting the Re element in the filter residues b; fourthly, mixing a leaching solution of the filter residues b with the filtrate a, and then conducting distilling and concentrating; fifthly, adding calcium oxide into a concentrated solution to enable the elements of Mo and W to precipitate, and conducting filtering to obtain a solution only containing Re. The method for recovering the Re from the Re-containing high-temperature alloy waste has the advantages that the steps are simple, implementation is convenient, the investment cost is low, and the required time is short.

Owner:江苏杰之砂新材料有限公司

Production method for recovering regenerated chemical filaments from industrial blankets

InactiveCN105386143AEnvironmental recyclingEasy to useArtificial thread manufacturing machinesMelt spinning methodsFiberUltimate tensile strength

The invention discloses a production method for recovering regenerated chemical filaments from industrial blankets. The production method comprises the following steps of firstly, classifying the waste blankets; secondly, smashing the waste blankets; thirdly, cleaning the surfaces of the blankets; fourthly, grinding the blankets into powder; fifthly, performing cleaning through hot water; sixthly, drying the powder blankets cleaned in the fifth step and storing the powder blankets in the dry environment; seventhly, performing high-temperature melting and filtering on the powder materials; eighthly, enabling melting to pass through a spinneret plate to form multiple columnar fibers; ninthly, performing high-temperature shaping on filament fibers which are stretched to meet the strength requirement so that the filament fibers can meet the requirement for straightness, and feeding the shaped filament fibers into winding equipment for winding and packaging into finished products so as to obtain the regenerated chemical filaments. The production method for recovering regenerated chemical filaments from industrial blankets is capable of recovering the waste industrial blankets in a more environment-friendly mode, wider in application range and better in use effect, reduces waste of resources and is more environmentally friendly.

Owner:WUJIANG SHUANGJIE GLASS STEEL EQUIP CO LTD

Method for recycling silicon cutting waste mortar

ActiveCN102746935BGood dispersionImprove stabilitySilicon carbideSilicon compoundsDistillationPolyethylene glycol

Disclosed is a method for recycling silicon cutting waste mortar. The method comprises the steps of performing solid-liquid separation of the waste mortar; performing solid flow washing and vacuum filtration; drying the obtained filter cake, mixing with deionized water and performing activation reaction; adding water glass and sodium hydroxide successively and performing heating reaction, performing solid-liquid separation of the obtained product, performing ion exchange resin decolorization and distillation of the liquid phase to obtain silica sol, and performing solid phase washing and drying to obtain a silicon carbide raw material; and performing ultra precision filter of obtained liquid phase after solid-liquid separation of the waste mortar, adding a decoloring agent a filter aid to perform solid-liquid separation, reducing the conductivity, and heating and evaporating water to obtain finished polyethylene glycol cutting liquid. According to the technical scheme of the method, the flow line production is achieved, the silicon cutting waste mortar is recycled, the silica sol is prepared effectively, and the environmental pollution is reduced.

Owner:山东网金资源再利用发展有限公司

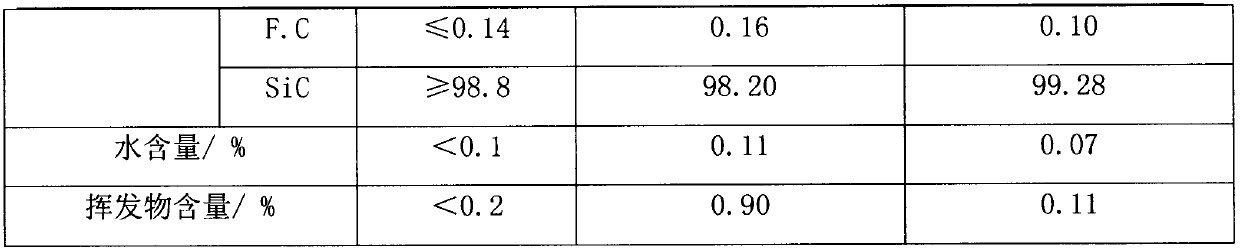

Method for completely recovering valuable components in waste lithium battery

PendingCN114243142AIncrease valueLow costWaste accumulators reclaimingBattery recyclingCurrent collectorPyrolysis

The invention discloses a method for completely recovering valuable components in a waste lithium battery. And carrying out electrified crushing on the disassembled single batteries under the protection of nitrogen atmosphere, and carrying out high-temperature pyrolysis in an anaerobic environment after crushing. Tail gas generated by high-temperature pyrolysis, electrolyte volatilization in the crushing process, metal dust generated by winnowing and acid mist generated by wet stripping are conveyed to an environment-friendly treatment system, and are discharged after being treated to reach the standard through the steps of secondary high-temperature combustion and the like. The pyrolyzed material passes through a multi-component screening and sorting system, and positive and negative pole pieces, a magnetic conductive shell and a pile head, and a non-magnetic shell and a pile head are sorted out. The sorted positive and negative pole pieces pass through a material wet stripping system, pole powder and copper-aluminum foil are separated, and copper and aluminum separation is achieved through color sorting. The recovery rate of the pole powder is 98% or above, the grade of the pole powder is high, copper and aluminum foil current collectors are recovered at the same time, metal shells and pile heads made of different materials are recovered in a classified mode, the recovery rate is high, the output value of the recovery process is increased, and the recovery process is environmentally friendly.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

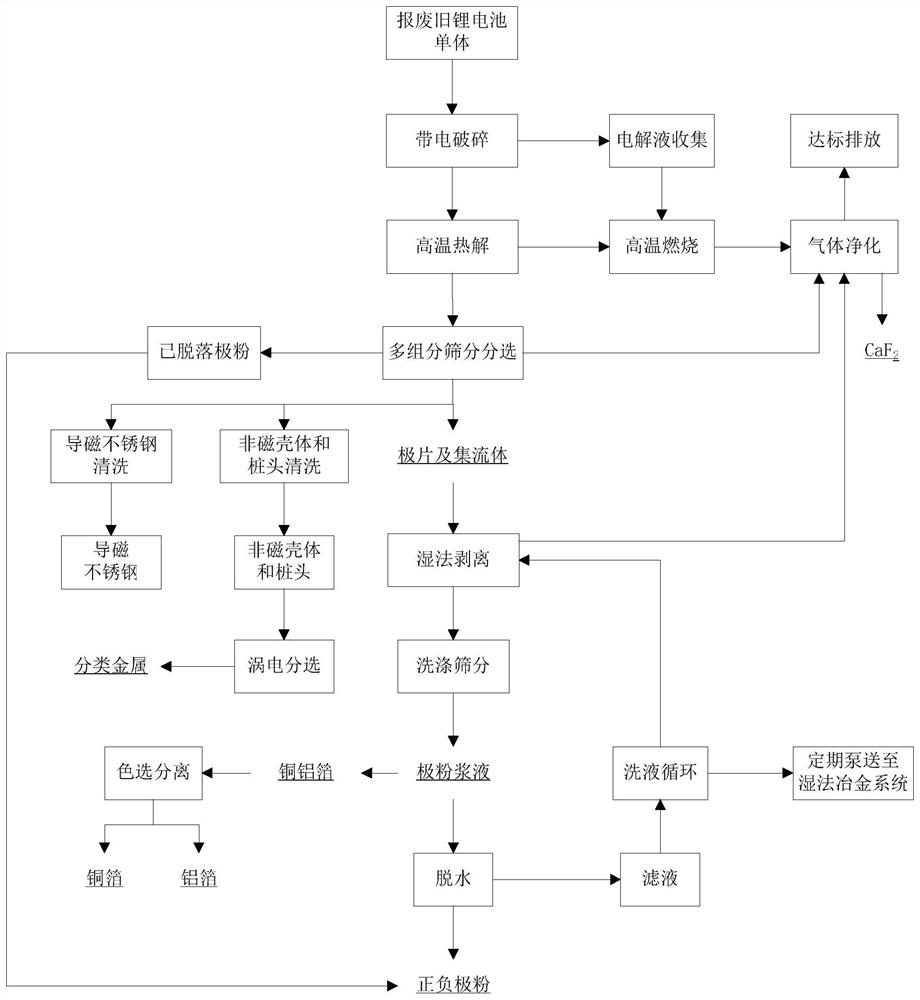

Method for completely recovering valuable metal components of waste lithium battery by stripping pole powder by hydrodynamic separation wet method

PendingCN114381603AHigh recovery rateLess metal impuritiesWaste accumulators reclaimingSortingPyrolysisMetallurgy

The invention discloses a method for completely recovering valuable metal components of a waste lithium battery by stripping pole powder by a hydrodynamic separation wet method. According to the invention, the disassembled waste lithium battery is directly crushed in an electrified manner and then is subjected to high-temperature pyrolysis in an anaerobic environment, and waste gas generated in the process is discharged after reaching the standard through secondary combustion and the like; performing hydrodynamic separation on the pyrolyzed material to separate a shell, a pile head, pole powder and positive and negative pole pieces; and performing wet stripping on the positive and negative pole pieces to strip residual pole powder, drying and granulating the separated copper-aluminum foil, performing color sorting, and separating out copper and aluminum particles. And combining the stripped residual pole powder with the pole powder obtained by cleaning the shell and the pile head, the pole powder obtained by hydrodynamic separation and the pole powder obtained by washing and screening the pole piece, filtering, dehydrating and drying to obtain positive and negative pole powder products, and further separating the shell and the pile head through magnetic separation and eddy current separation. The recovery rate of the polar powder reaches 98% or above, the grade of the polar powder is high, the recovery rate of copper and aluminum foil is also high, metal shells and pile heads made of different materials can be recovered in a classified mode, and the recovery and utilization output value is increased.

Owner:HUNAN JIANG YE MECHANICAL & ELECTRICAL TECH CO LTD

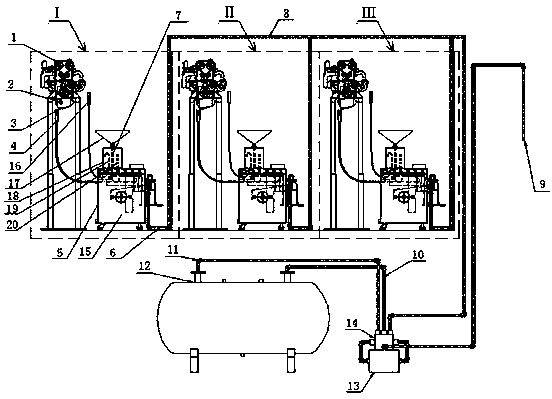

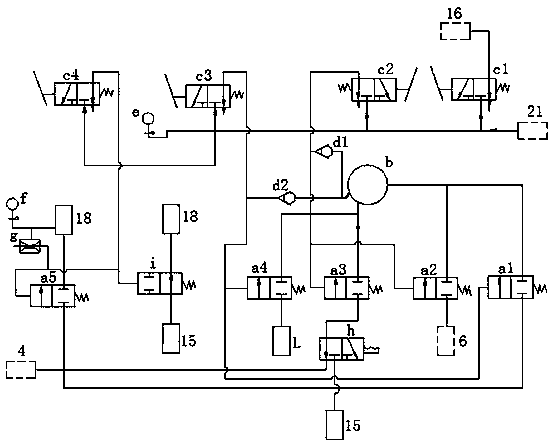

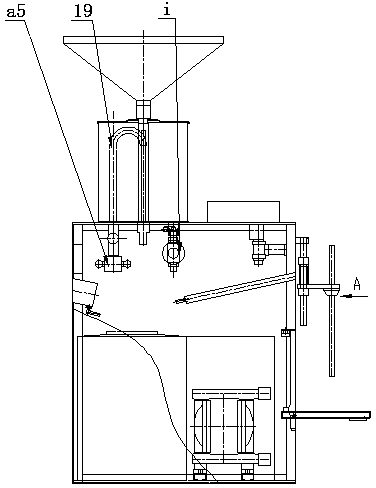

Fluid leaking and filling system

The invention discloses a fluid leaking and filling system. The fluid leaking and filling system comprises at least one working unit; the working unit comprises an oil gun, an oil pumping device connected with the oil gun and an oil injection device, a pressure source connected with the oil pumping device and the oil injection device, a waste oil recycling system connected with the oil pumping device, and an oil storage device connected with the oil injection device. The fluid leaking and filling system combines a plurality of working units into a system; power is uniformly provided by the pressure air source, the waste oil discharged by every working unit is intensively recycled by a waste oil recycling system, and new engine oil is uniformly provided by an oil storage device; the oil injection and recycling of waste oil are high-efficient, safe and environment-friendly; therefore, the fluid leaking and filling system is widely applied to 4S store or automobile repair shops.

Owner:张学用

Preparation method of pb oxide nanopowder for recycling and manufacturing of lead-acid batteries

ActiveCN102689921BEnvironmental recyclingReduce energy consumptionLead monoxideNanotechnologyDecompositionInorganic compound

The invention discloses a method for preparing Pb oxide nanopowder used in the recovery and manufacture of lead-acid batteries, comprising the steps of: (1) lead salt or lead paste of waste lead-acid batteries and organic compounds capable of complexing Pb atoms / ions; or inorganic compounds to react to achieve desulfurization or re-acidification; (2) perform a treatment process of filtering, drying to remove water, and heating to decompose to obtain Pb oxide nanopowder. The invention makes the recycling and production process environment-friendly, low energy consumption, greatly reduces the production cost, shortens the production cycle at the same time, and makes the prepared Pb oxide powder more conducive to the improvement of the performance of the process product.

Owner:杨春晓

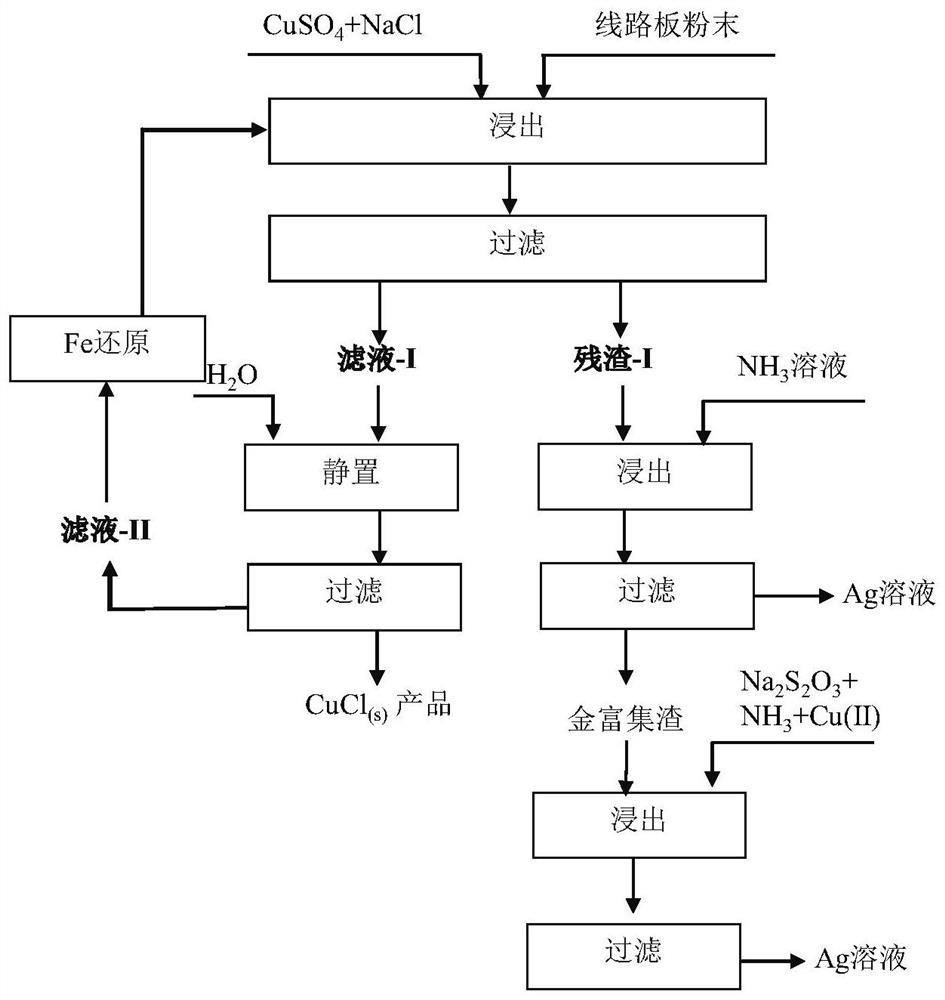

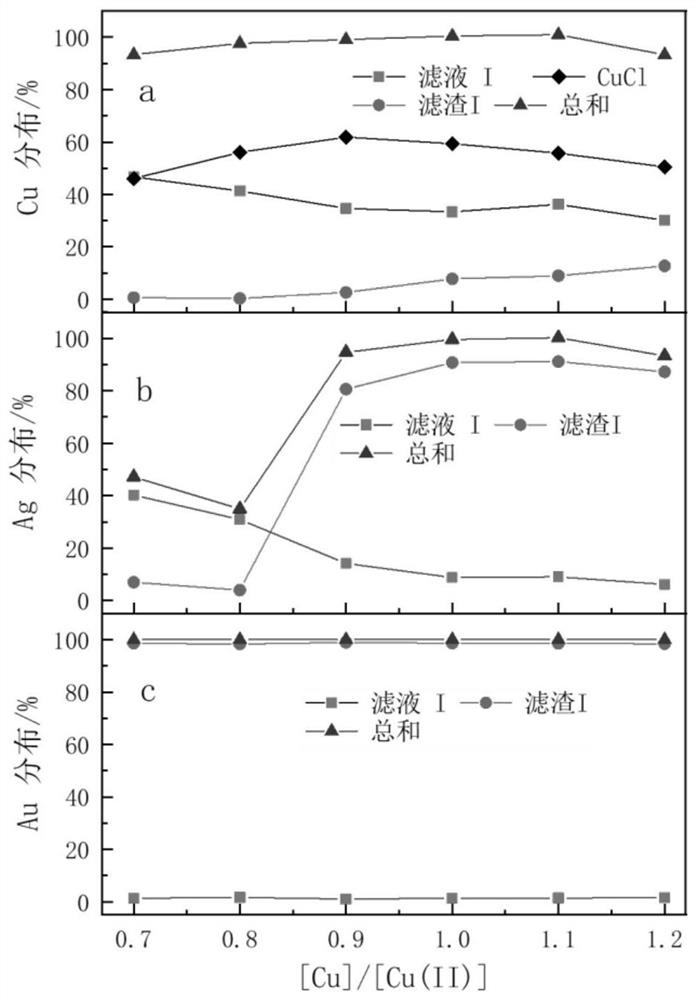

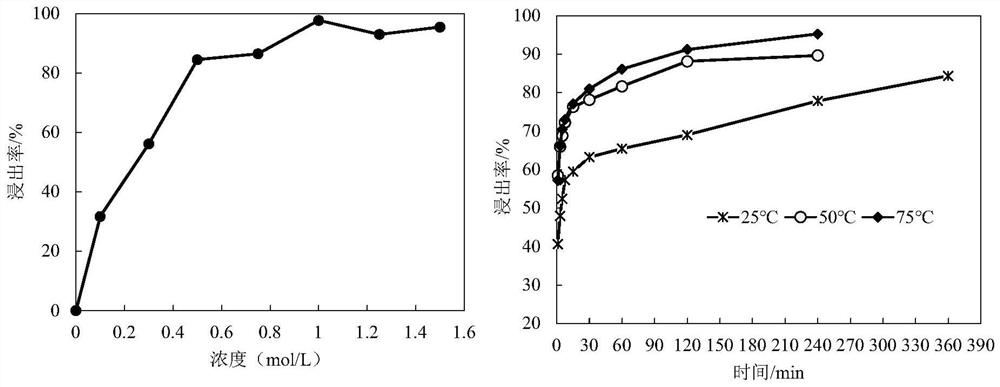

Method for recycling copper, silver and gold step by step by using waste printed circuit board

ActiveCN114717420ARealize step-by-step recyclingAchieve enrichmentProcess efficiency improvementSlagPhysical chemistry

The invention discloses a method for recycling copper, silver and gold step by step by using a waste printed circuit board. The method comprises the following steps: a, pretreatment of the waste printed circuit board: a, crushing of the waste printed circuit board; b, mixing copper sulfate with a saturated sodium chloride solution, adding the circuit board powder, stirring for reaction, and filtering; c, filtering the filtrate in the step b into deionized water, and standing and precipitating to obtain cuprous chloride; d, adding the gold and silver enriched slag obtained in the step b into an ammonia solution, stirring and leaching, and filtering to obtain a silver solution and gold enriched slag; and e, adding the gold-enriched slag obtained in the step d into a Cu < 2 + >-NH3-Na2S2O3 mixed solution, stirring and leaching to obtain a gold solution. According to the method, copper in the waste circuit board is converted into cuprous chloride in the cuprous chloride synthesis process, meanwhile, enrichment of Ag and Au is achieved, step-by-step recycling of copper, gold and silver is achieved, and the method is a simple and environment-friendly method for recycling valuable metal from the waste circuit board.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

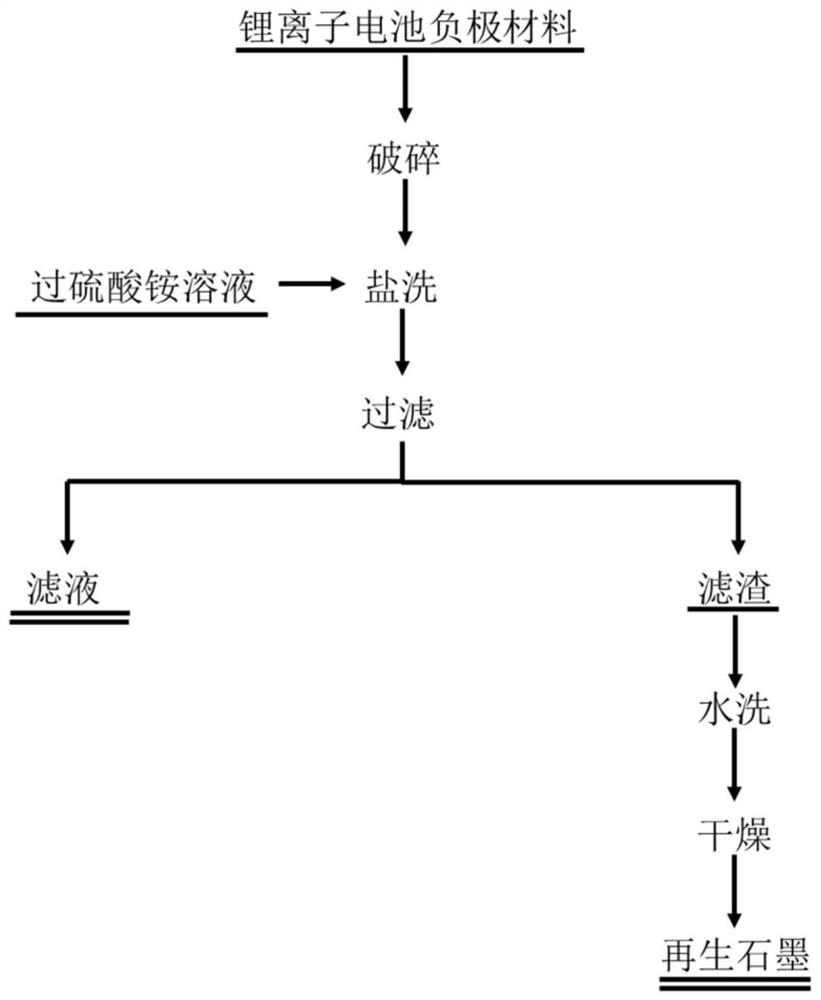

Method for recycling graphite negative electrode of waste battery

InactiveCN113200541ASolve problems that cannot be completely and efficiently separatedNo secondary pollutionCarbon compoundsNegative electrodesMechanical crushingEnvironmental engineering

The invention discloses a method for recycling a graphite negative electrode of a waste battery. The method comprises the following steps of (1) taking a waste lithium ion battery, discharging, disassembling, manually cutting or mechanically crushing to obtain a negative plate, (2) mixing the negative plate obtained in the step (1) with salt which is hydrolyzed to be acidic and has strong oxidizing property, and soaking until copper in the negative plate is completely dissolved, and (3) filtering the solution containing graphite, washing the obtained filter residue with deionized water, and drying to obtain regenerated graphite. According to the method provided by the invention, the pollution generated by the waste lithium ion battery is effectively reduced, and the waste graphite material of the negative electrode can be recycled to regenerate the graphite negative electrode material. The regenerated material has excellent mechanical strength and toughness, good cycle performance, large reversible capacity and high capacity retention rate.

Owner:CENT SOUTH UNIV

Recovery treatment method of waste oil sludge

ActiveCN113717784AEfficient recyclingEnvironmental recyclingFatty/oily/floating substances removal devicesSludge treatment by pyrolysisNitrilotriacetic acidSodium silicate

The invention provides a recovery treatment method of waste oil sludge, which comprises the following steps: preparing a sodium silicate composition from the following raw materials in parts by mass: 90-110 parts of sodium silicate, 5-10 parts of sodium bicarbonate, 2-5 parts of sodium dihydrogen phosphate, 0.2-0.5 part of disodium ethylene diamine tetraacetate, 0.2-0.5 part of nitrilotriacetic acid, 2-4 parts of fatty alcohol-polyoxyethylene ether and 2-5 parts of a demulsifier; and then mixing waste oil sludge, the sodium silicate composition and hot water for primary oil extraction, then mixing primary filter pressing residues, the sodium silicate composition and hot water for secondary oil extraction, then dehydrating, decolorizing and drying primary oil-rich liquid and secondary oil-rich liquid, performing wastewater treatment on primary wastewater and secondary wastewater, and subjecting the secondary filter pressing residues to pyrolysis treatment. The oil product recovery rate exceeds 97 wt%, and water is discharged after reaching the standard.

Owner:GUANGZHOU S SUNNY ENVIRONMENTAL PROTECTION TECH CO LTD

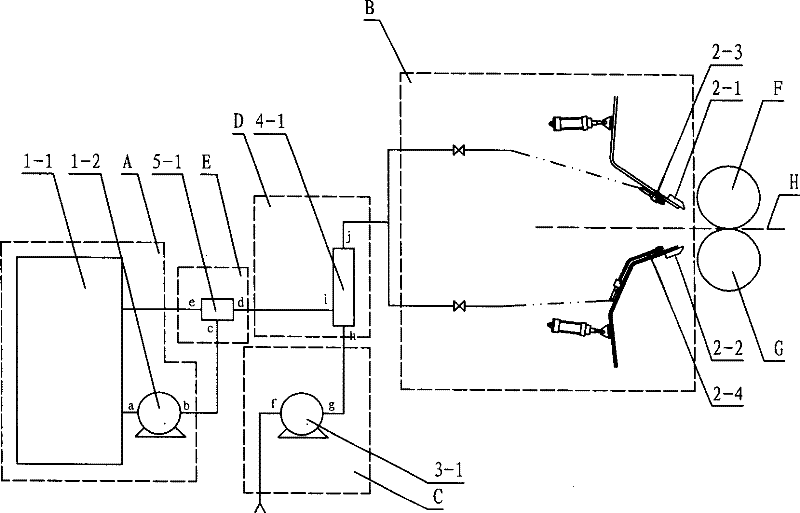

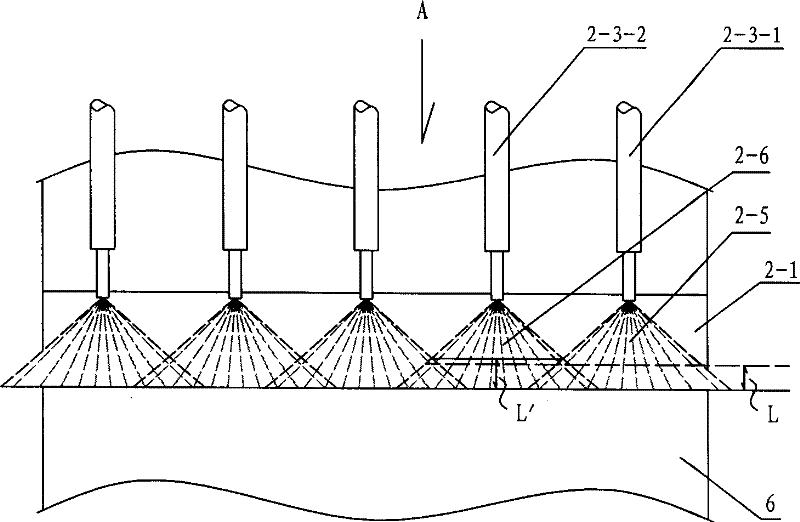

Technological lubricating system of hot mill steel plate continuous milling machine

ActiveCN1911545BAvoid interruptionAdapt to the needs of actual productionRoll mill control devicesWork treatment devicesSheet steelFuel tank

The technological lubrication system for hot rolled steel plate continuously rolling machine belongs to the field of metal rolling technology. The technological lubrication system includes an oil supplying unit, a jetting unit, a connecting pipeline, a water supplying unit and an oil-water mixing unit set between the oil supplying unit and the jetting unit, a controlled direction change unit to the output of the oil supplying unit, and an oil tank connected together. The technological lubrication system can display and record the operation state of the whole technological lubrication system and regulate the oil-water mixture ratio of the jetted liquid conveniently, and may be used in hot continuous rolling machine to raise the production efficiency.

Owner:SHANGHAI ZHUGUANG MACHINERY +1

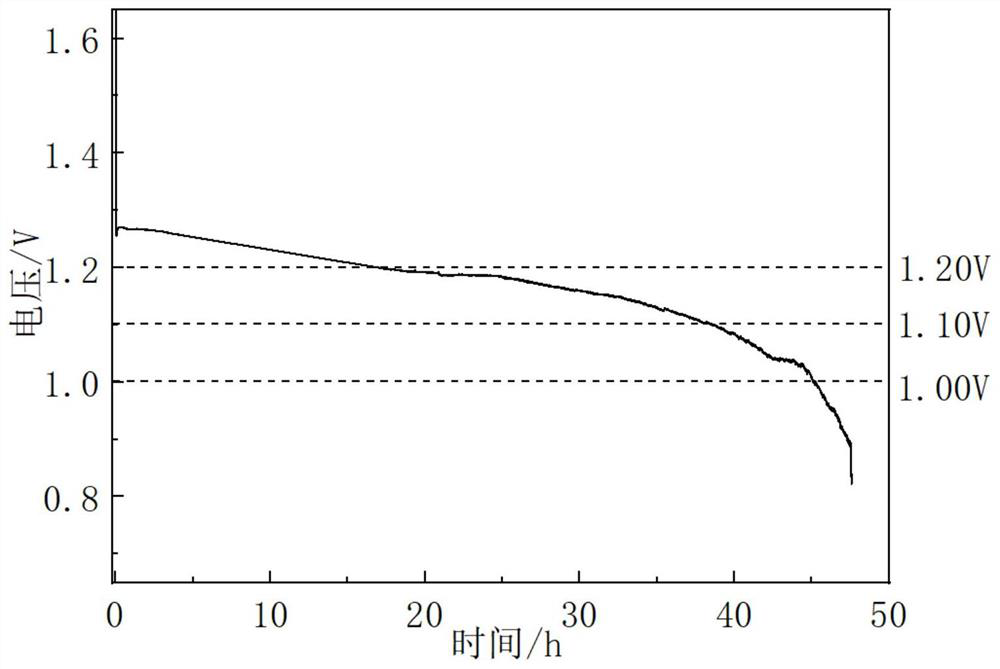

Preparation method of magnesium-based metal air battery, magnesium-based metal air single battery and magnesium-based metal air battery

PendingCN113258171AStrong packageReduce weightFuel and primary cellsJackets/cases materialsComposite materialElectrical battery

The invention discloses a preparation method of a magnesium-based metal air battery. The preparation method comprises the following steps of 1, preparing a positive electrode catalytic material, 2, preparing a battery shell, 3, mounting a positive plate, 4, packaging a battery shell, and 5, assembling the single batteries. The invention also discloses the magnesium-based metal air single battery and the magnesium-based metal air battery which are manufactured by using the preparation method. The composite paper and the magnesium-based metal air battery positive electrode catalytic material are subjected to hot gluing, so that firm packaging can be realized, and the sealing problems of electrolyte leakage and the like are avoided; the composite paper is light in weight, high in strength and good in toughness, so that the packaging weight can be greatly reduced, and enough compression resistance, falling resistance and impact resistance of the battery can be ensured; paper is adopted for packaging, batch and large-scale production is suitable, the production efficiency is obviously improved, and full-automatic heat sealing, folding and liquid injection can be achieved.

Owner:HUNAN HYDRO DYNAMIC NEW MATERIAL CO LTD +1

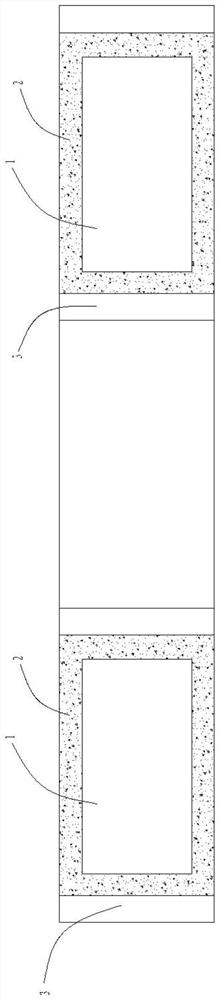

Protective pad for paper finished floor and preparation method thereof

PendingCN111119504AEnvironmental recyclingAccept external pressureBuilding material handlingConstruction engineeringProcess engineering

The invention, which relates to the technical field of indoor daily products, discloses a protective pad for a paper finished floor. The protective pad comprises FSC (Forest Stewardship Council) environmental protection paper and corrugated FSC environmental protection paper from top to bottom in turn. According to the invention, the protective pad prepared with FSC environmental protection paperhas the advantages of high degradability, better environmental protection effect and easy transport and handling, and corrugated structure has greater support and cushioning effect, effectively protecting the finished floor from the risk of heavy impact.

Owner:常州市博安合达包装厂

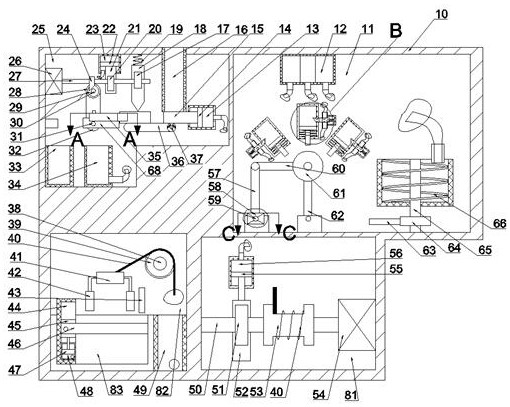

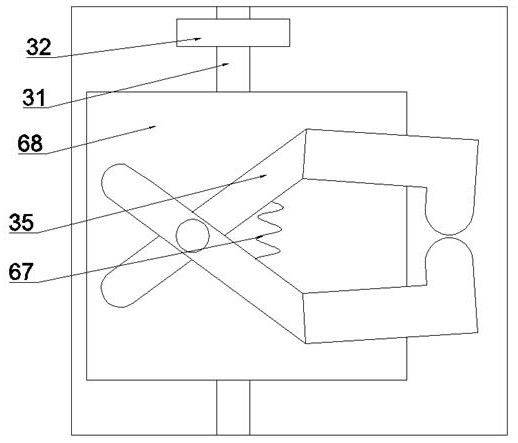

Electric vehicle lead-acid battery slurry recovery equipment

InactiveCN112210798AReduce pollutionEnvironmental recyclingElectrolysis componentsPhotography auxillary processesElectrolysisElectrical battery

The invention discloses electric vehicle lead-acid battery slurry recovery equipment which comprises a shell. A decomposition feeding cavity is formed in the left side of the shell; a decomposition motor is fixed onto the left wall of the decomposition feeding cavity; a decomposition shaft is rotationally arranged on the right side of the decomposition motor; a fan-shaped bevel gear is fixedly arranged on the left side of the decomposition shaft; a feeding wheel is fixedly arranged at the middle section of the decomposition shaft; and a feeding hydraulic cavity is arranged on the upper side wall of the decomposition feeding cavity. According to the electric vehicle lead-acid battery slurry recovery equipment provided by the invention, lead-acid battery pieces in an battery of an electric vehicle can be decomposed and recovered, the shells of the battery pieces are broken, and lead in a slurry is extracted and recovered through electrolysis and oxidation reduction methods, so that the recovery process is environmentally friendly, the energy consumption is low, the extraction purity is high, the environmental pollution is reduced, the lead can be continuously utilized, the sustainable development is achieved, and the economic loss is reduced.

Owner:福州勃楠电子科技有限公司

A sewage treatment system and treatment method combining membrane bioreactor and phosphorus recovery process

ActiveCN107473370BImprove solubilityReduce usageWater contaminantsSustainable biological treatmentSolubilityActivated sludge

The invention is mainly applied to the technical field of municipal sewage treatment, and mainly relates to a sewage treatment system and treatment method in combination with a membrane bioreactor and a phosphorus recovery process. In combination with a biological method and a chemical method, anaerobic acidification is used for replacing a chemically acidified and dissolved iron phosphate precipitate, and a microorganism dissimilatory iron reduction effect is used for increasing phosphate solubility. The treatment system is applied to activated sludge but not remaining sludge, phosphorus recovery is realized in a weak acid condition, secondary pollution is not caused, inert constituents inside the activated sludge are reduced, the biodegradability of the activated sludge is strengthened, the application of the membrane reactor can realize that the sludge retention time reaches infinity, and the phosphorus recovery efficiency reaches 95% or more. Compared with the chemical method, the treatment method is simple, safe and environmentally-friendly in phosphorus recovery, the application of strong acid and strong base is greatly reduced, and the recovery cost is reduced; and compared with the chemical method, the treatment method is stable and efficient.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Lead-acid battery environment-friendly recycling device and using method thereof

InactiveCN113458119AImprove recovery accuracyEnvironmental recyclingSolid waste disposalGrain treatmentsProcess engineeringWaste material

The invention discloses a lead-acid battery environment-friendly recycling device and a using method thereof. A recycling box for compressing and collecting lead-acid batteries is arranged on the table top of a workbench, a washing mechanism is arranged on the recycling box, a lead liquid collecting box for collecting lead liquid for washing the lead-acid batteries is arranged at the bottom of the workbench, a grinding cylinder for processing lead-acid battery waste is arranged on one side of the top of the recycling box, the output end of the grinding cylinder is connected with an iron powder collecting cavity, an output port of the iron powder collecting cavity communicates with a feeding port of the recycling box, a crushing cavity is formed in one side of the workbench, and a crushing roller set is arranged in the crushing cavity. Preliminary crushing in the lead-acid battery recycling process is achieved through the crushing cavity, preliminary crushing and decomposition of the lead-acid battery are achieved, crushed battery waste is further ground through the grinding cylinder, decomposition of ferrous materials in the battery waste is achieved, separation of lead liquid is achieved through water washing of the recycling box, and environment-friendly separation of the lead-acid batteries is realized.

Owner:太和县大华能源科技有限公司

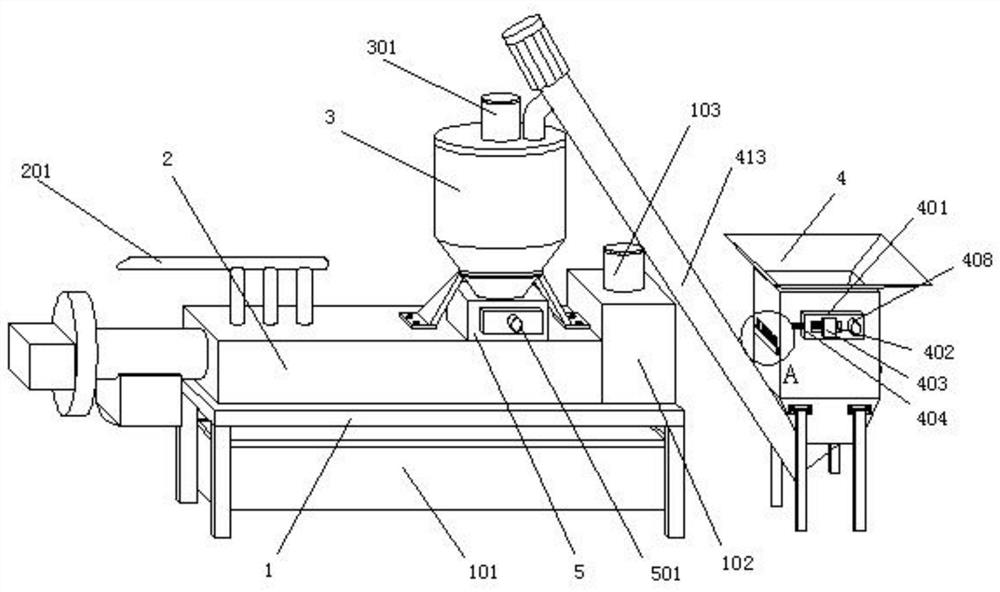

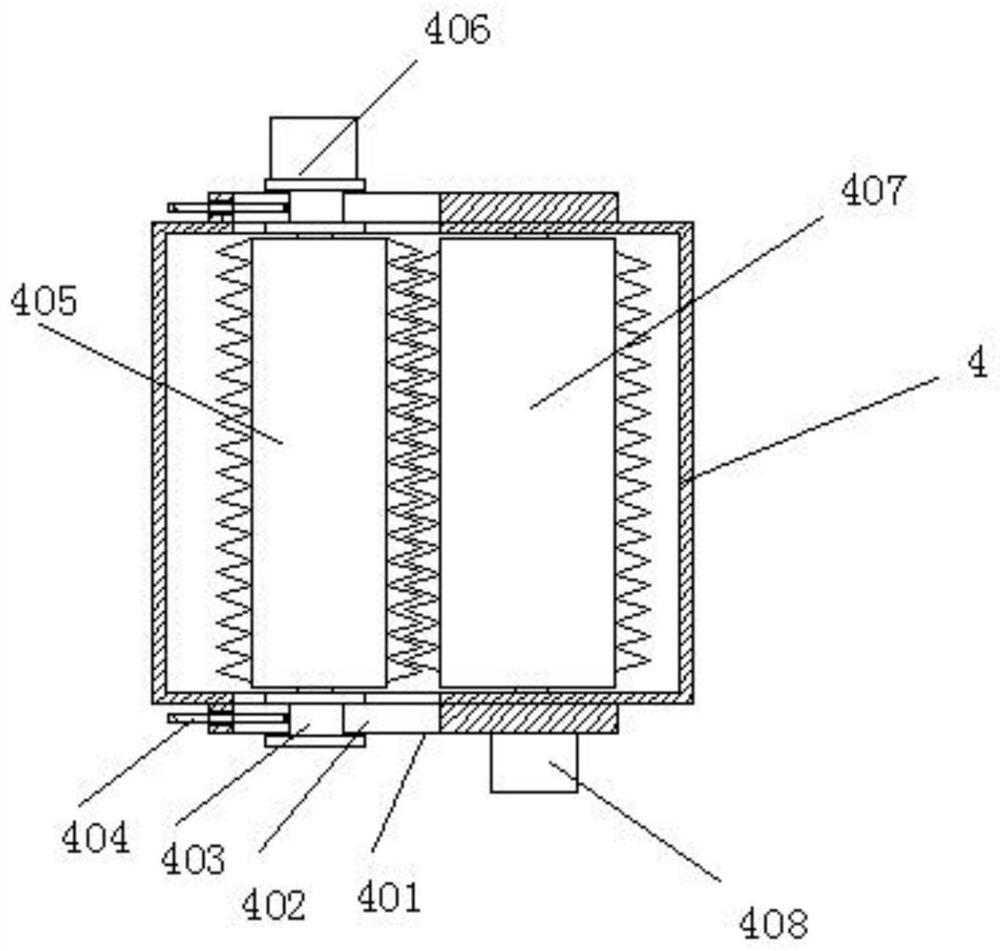

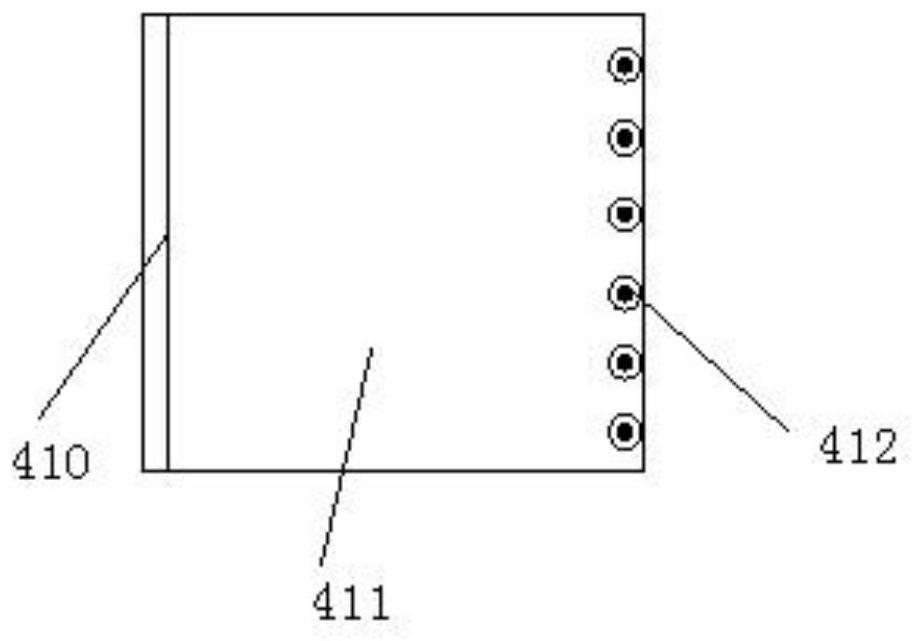

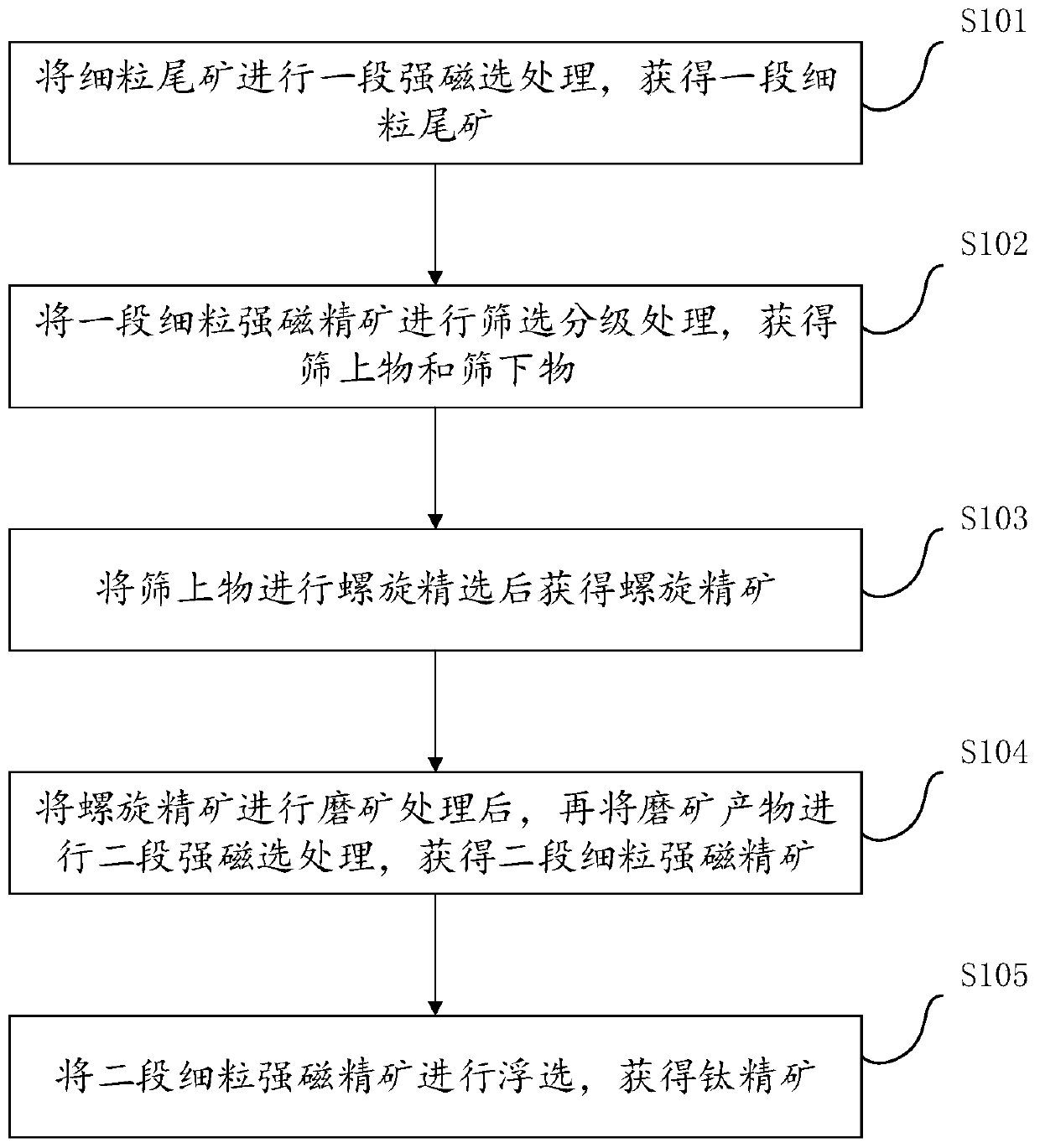

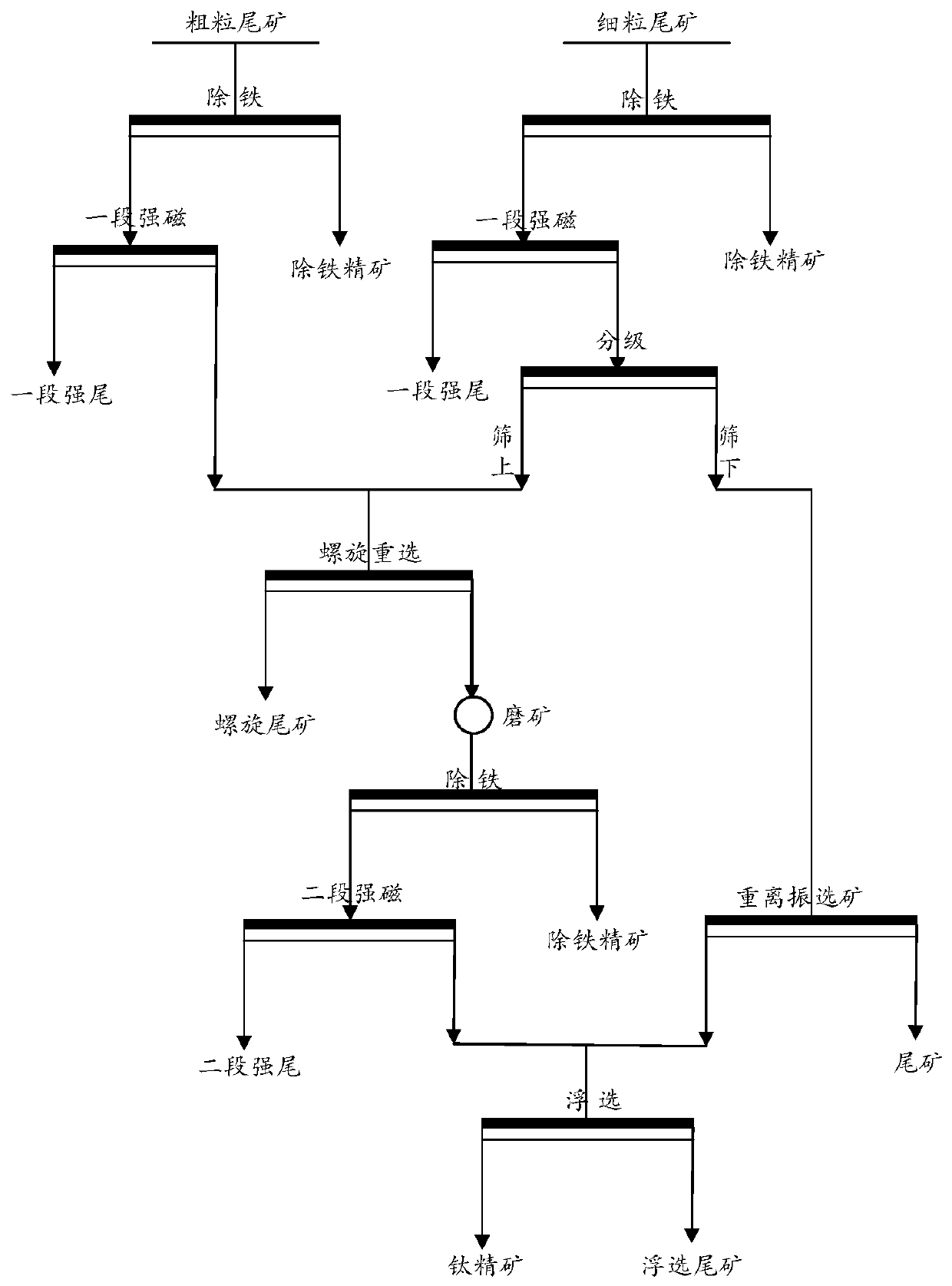

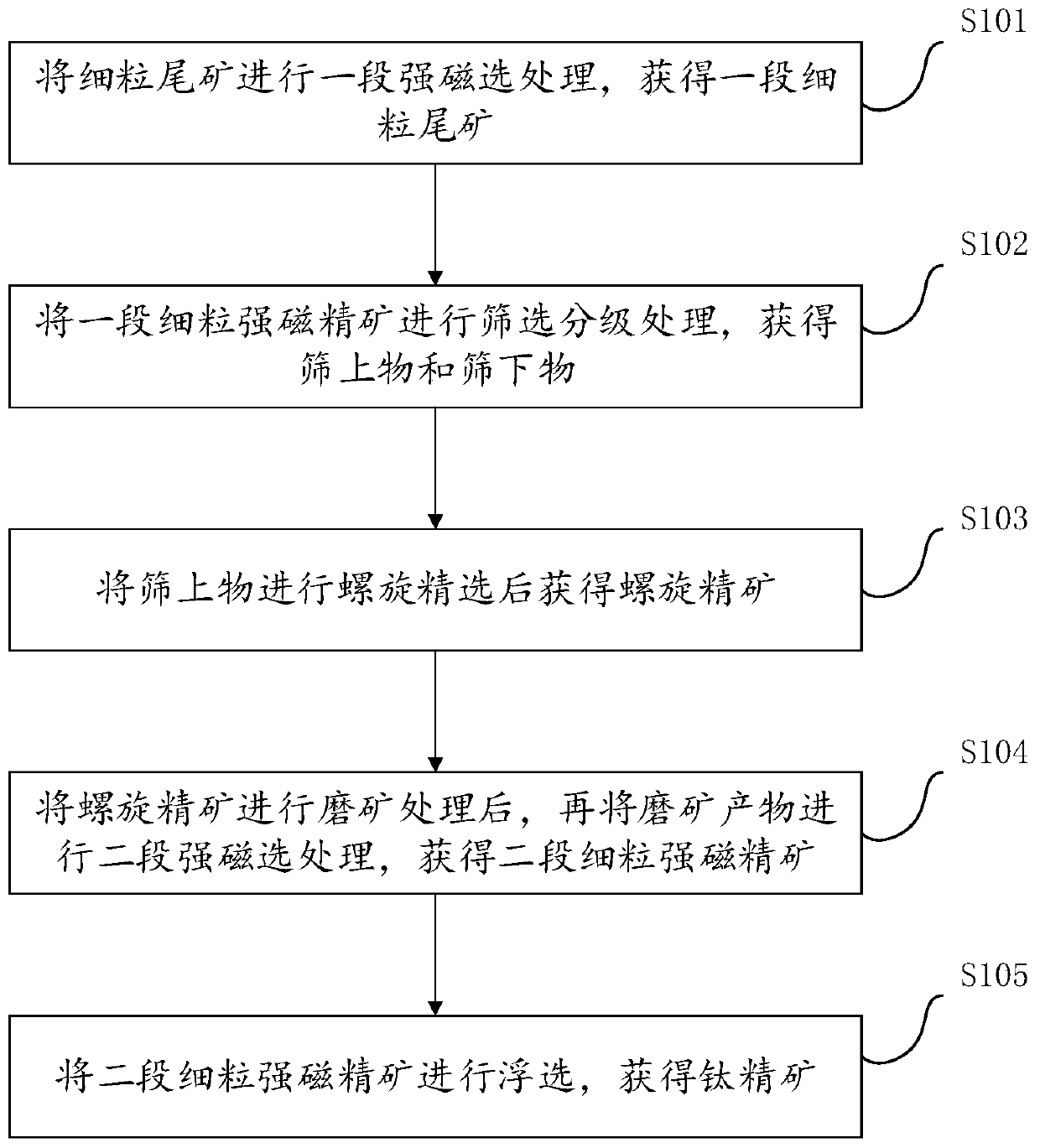

A kind of recovery method of fine-grained ilmenite

The invention discloses a recovery method of fine-grained ilmenite. The recovery method includes the steps that first-section high-intensity magnetic separation treatment is conducted on fine-grainedtailings, and first-section fine-grained high-intensity magnetic concentrate is obtained; screening and classifying treatment is conducted on the first-section fine-grained high-intensity magnetic concentrate, and screen overflow and screen underflow are obtained; spiral concentration is conducted on the screen overflow, and spiral concentrate is obtained; after ore grinding treatment is conductedon the spiral concentrate, ore grinding products are subjected to second-section high-intensity magnetic separation treatment, and second-section fine-grained high-intensity magnetic concentrate is obtained; and flotation is conducted on the second-section fine-grained high-intensity magnetic concentrate, and titanium concentrate is obtained. By means of the recovery method of the ilmenite, the effect of enrichment operation can be effectively improved, the operation cost of recovery can be reduced, and the industrial environment-friendly and high-efficiency recovery of limburgite type low-grade ilmenite is achieved.

Owner:PANGANG GRP MINING

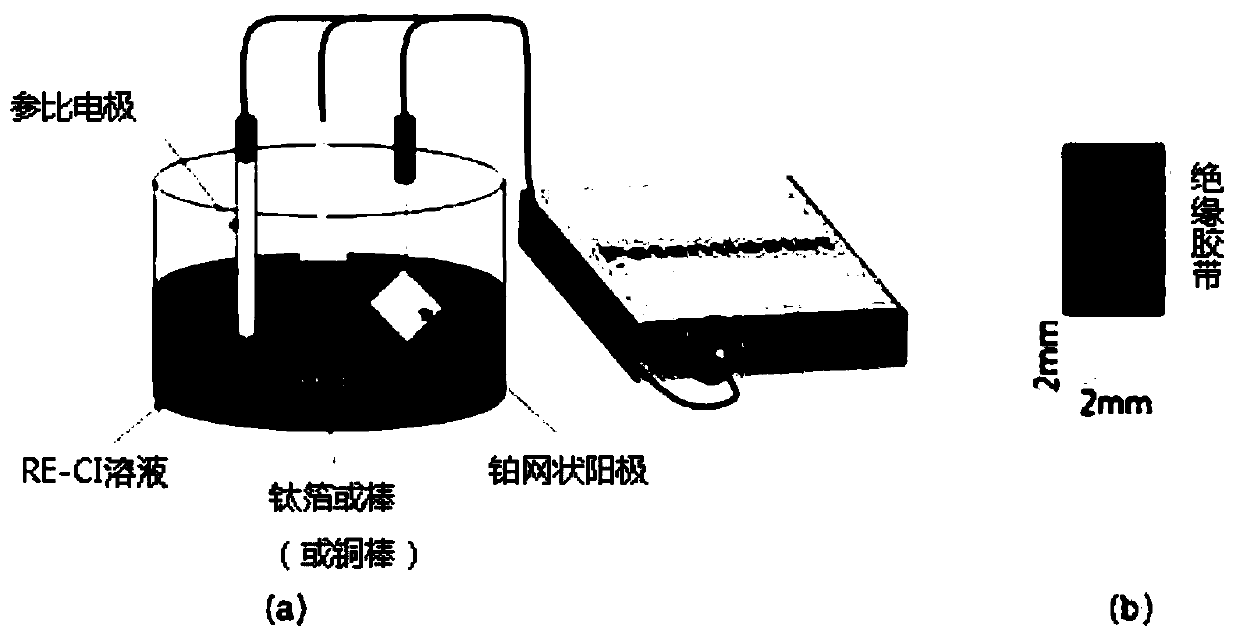

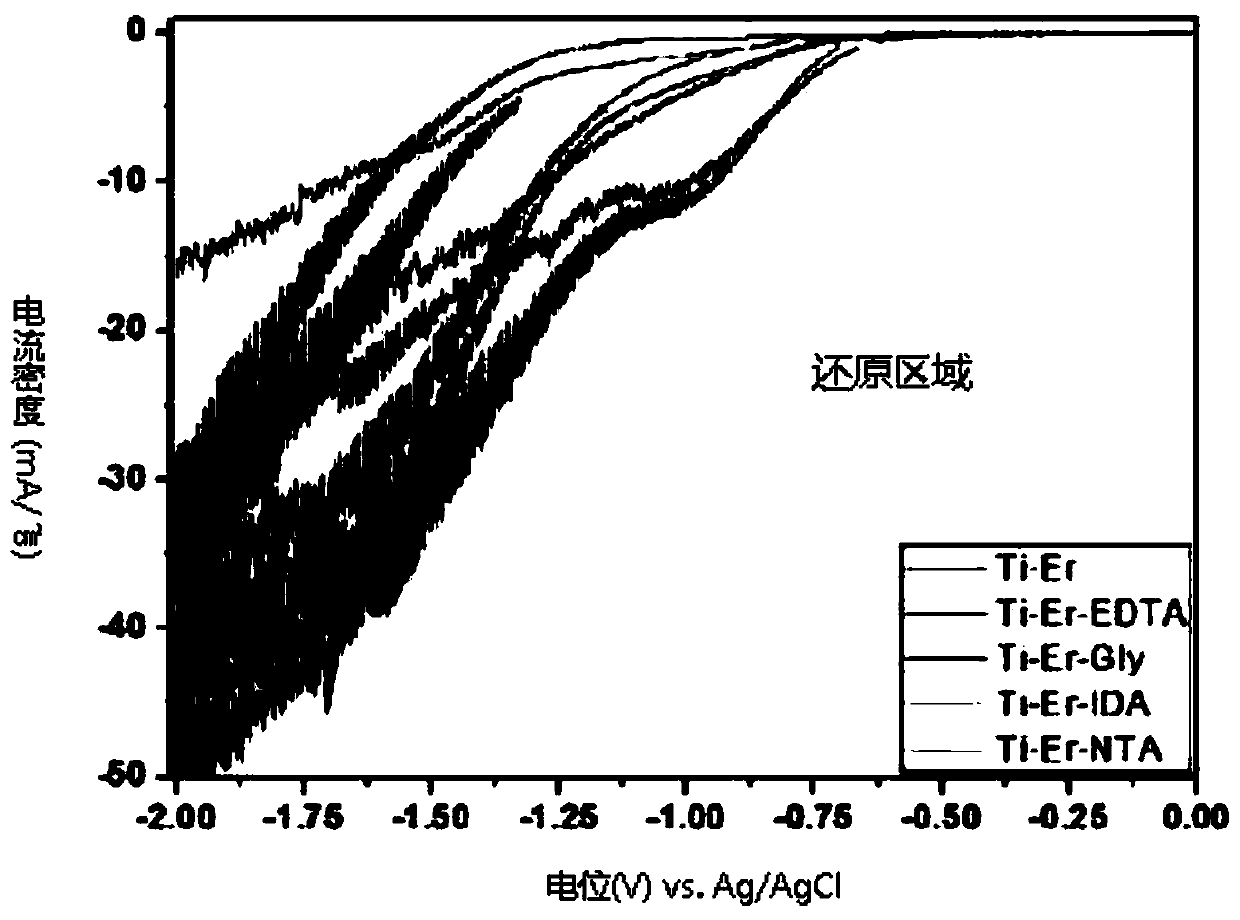

Electrochemical recovery method of heavy rare earth metals

ActiveCN107268031BEnvironmental recyclingHigh yieldPhotography auxillary processesProcess efficiency improvementRecovery methodRare earth

Owner:蔚山大学产学合作部

Preparation process of asymmetric structure pre-oxidized metal filter material for gas turbine

ActiveCN104874233BIncrease concentrationAvoid dissociationGas turbine plantsFiltration separationPorosityFiltration

Owner:江苏华强新能源科技有限公司

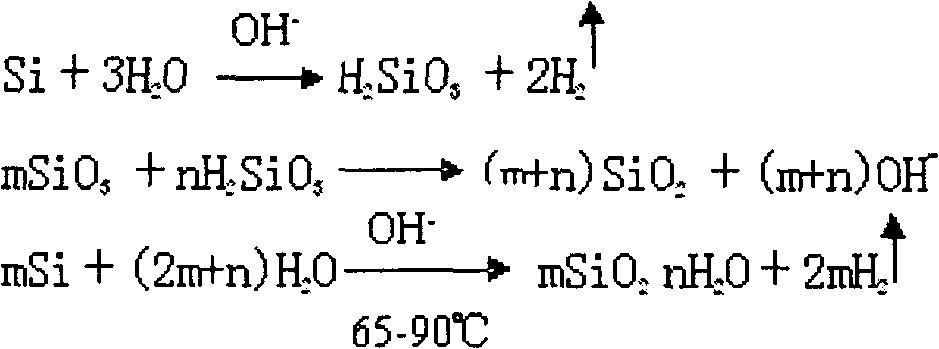

Preparation method of lead compound nanopowder used in the recycling and manufacture of lead-acid batteries

ActiveCN102689922BEnvironmental recyclingReduce energy consumptionLead monoxideNanotechnologyLead saltInorganic chemical compound

The invention discloses a lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery. The lead compound nano-powder preparation method comprises the following steps that 1, lead, a lead salt or waste lead-acid battery lead paste reacts with one or more organic or inorganic compounds to produce a soluble lead salt solution or a lead hydroxide solution; 2, one or more alkalis or caustic alkalis are added into the soluble lead salt solution, or a part or excess amount of H2CO3 or CO2, sulfuric acid, one or more organic acids or their salts are added into the lead hydroxide solution, and 3, lead oxide or lead hydroxide precipitates obtained by the step 2 are filtered and are subjected to drying and pyrolysis to form the lead compound nano-powder. The lead compound nano-powder preparation method realizes environmentally friendly recovery and production, has low energy consumption, greatly reduces a production cost, and shortens a production period. The lead compound nano-powder obtained by the lead compound nano-powder preparation method is conducive to improvement of technical product performances.

Owner:杨春晓

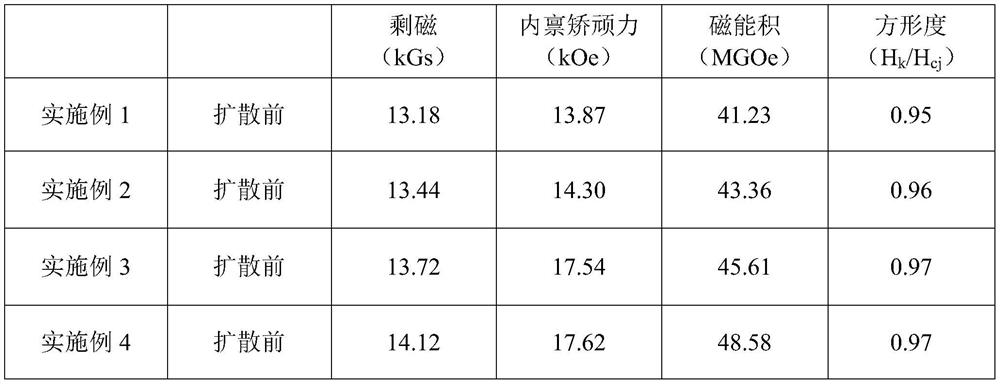

Neodymium-iron-boron rare earth permanent magnet waste regenerated magnet and preparation method thereof

PendingCN113724992ASolve the backlogImprove recycling efficiencyInductances/transformers/magnets manufactureMagnetic materialsAlloyWaste material

The invention provides a neodymium-iron-boron rare earth permanent magnet waste regenerated magnet and a preparation method thereof. The neodymium-iron-boron rare earth permanent magnet waste regenerated magnet comprises main phase crystal grains formed by rare earth waste powder and an R-M alloy layer coating the surfaces of the main phase crystal grains. The preparation method comprises the steps that rare earth waste powder and R-M alloy powder are mixed to obtain mixed fine powder, the mixed fine powder is sequentially subjected to forming, sintering and heat treatment, and the neodymium iron boron rare earth permanent magnet waste regenerated magnet is obtained. According to the invention, the regenerated magnet is prepared by directly utilizing the waste through a short-process controllable preparation process, new materials do not need to be added, the recovery efficiency is greatly improved, the recovery cost is reduced, introduction of chemical reagents in the production process is omitted, the recovery process is more environmentally friendly, a large amount of Ce-containing waste is utilized, and the problem that a large amount of Ce-containing waste is overstocked at present is solved.

Owner:赣州综保华瑞新材料有限公司

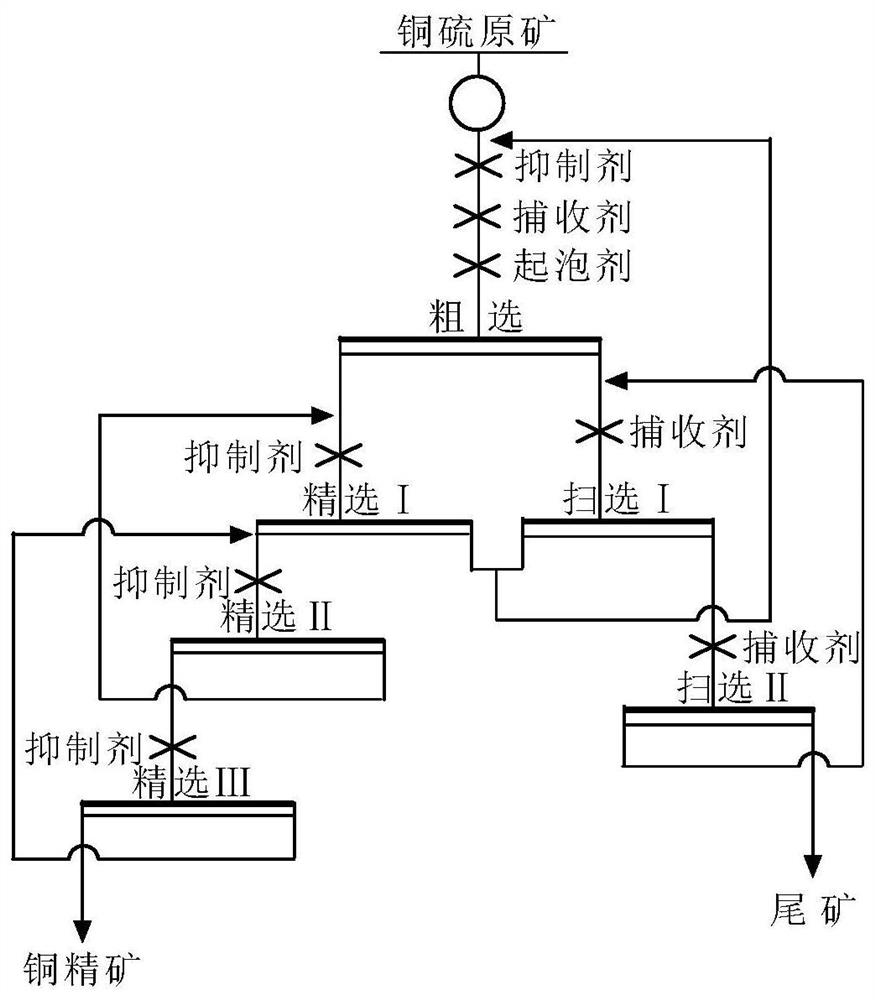

Copper-sulfur separation inhibitor, lime-free copper-sulfur flotation separation method and application thereof

PendingCN112604816AStrong inhibitory abilityGood choiceFlotationSodium acid carbonateAmmonium sulfate

The invention provides a copper-sulfur separation inhibitor, a lime-free copper-sulfur flotation separation method and an application thereof, and relates to the technical field of mineral treatment. The copper-sulfur separation inhibitor comprises sodium carbonate, ammonium sulfate, calcium chloride and sodium hydroxide raw materials, the copper-sulfur separation inhibitor prepared from the raw materials according to a specific dosage ratio has the characteristics of strong inhibition capability, good selectivity and the like, and a good inhibition effect can be achieved by using a small dosage in the copper-sulfur beneficiation process; the copper-sulfur separation inhibitor can replace a traditional lime inhibitor, environment-friendly and efficient recovery of copper-sulfur resources is achieved under the lime-free condition, and the defects that due to the fact that lime is adopted as the inhibitor, foam becomes sticky, the grade of copper concentrate is not high, pipelines and equipment are calcified and corroded, the pH value of tailing water is high, and the environment is polluted are overcome. The invention further provides the lime-free copper-sulfur flotation separation method. In the flotation process of the copper-sulfur raw ore, the specific copper-sulfur separation inhibitor and a collecting agent are adopted, so that efficient separation of copper and sulfur is achieved.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com