Technological lubricating system of hot mill steel plate continuous milling machine

A technology for process lubrication and hot rolling of steel plates, which is applied in the direction of rolling mill control devices, rolls, metal rolling, etc., can solve the problems of unsuitability for rolling mill control, inappropriateness, poor scalability, etc., and achieve simple and simple processing equipment and processes. Small downtime for roll changes, low manufacturing and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

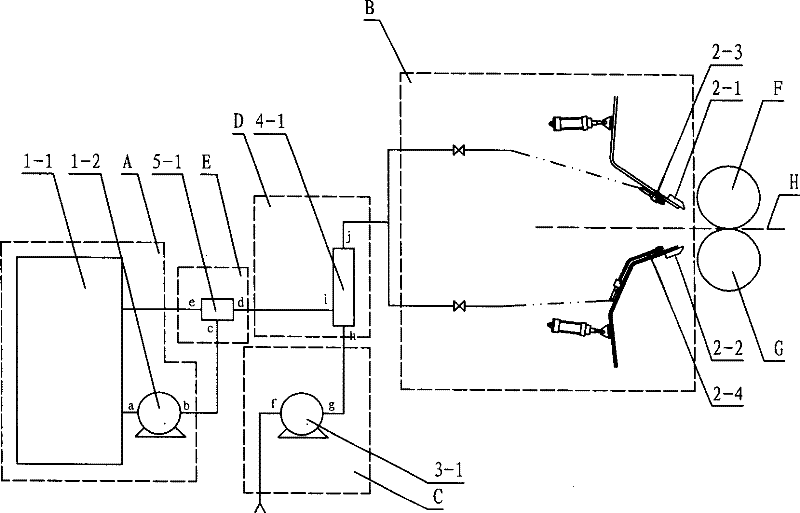

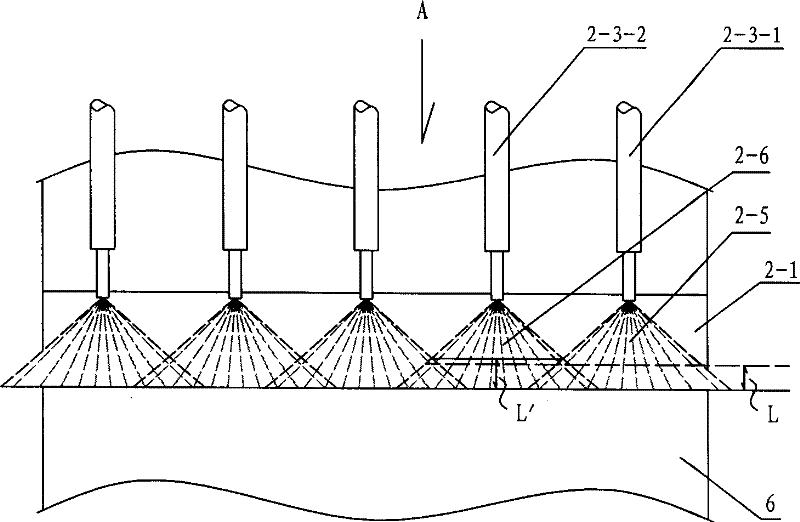

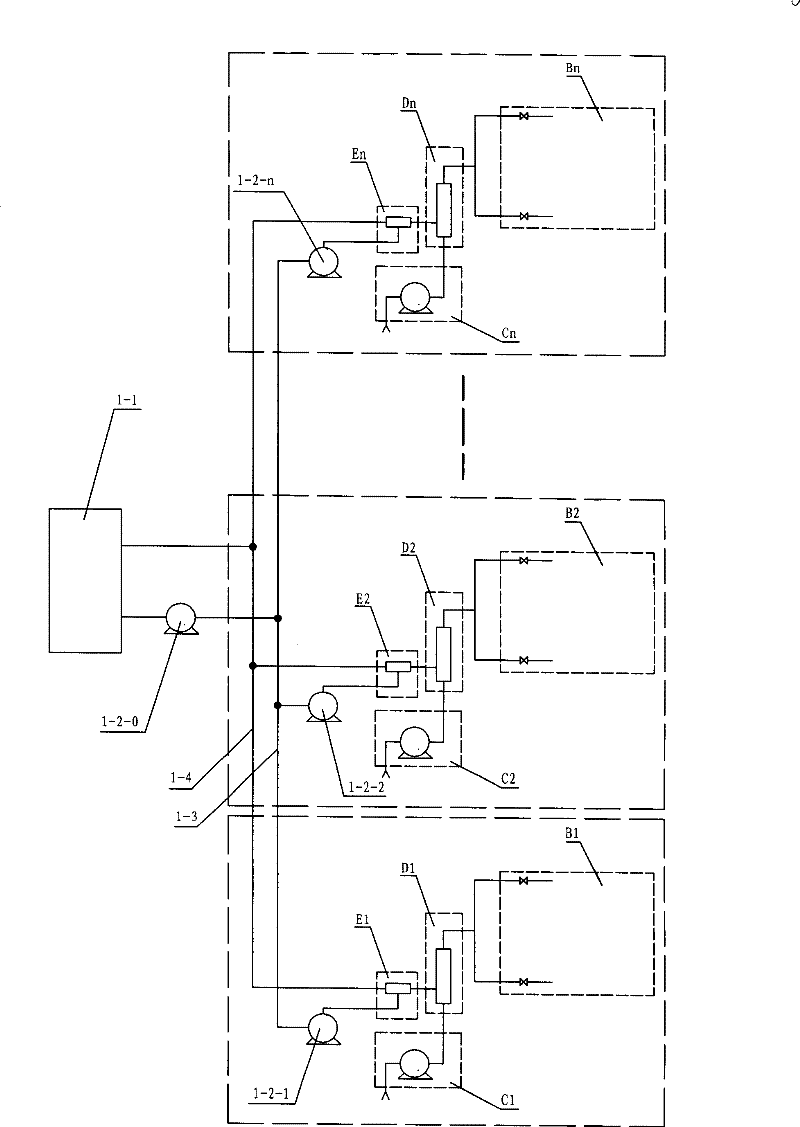

[0038] figure 1 Among them, this technical solution includes an oil supply unit A composed of an oil tank 1-1 and an oil supply booster pump unit 1-2, which is arranged on each roll above the water cutting plate 2-1 / below the lower water cutting plate 2-2 / The upper spray unit B and the pipeline connecting the above components are composed of several spray nozzles 2-3 and 2-4 arranged at intervals. Between the oil supply unit A and the spray unit B, a water pump 3- 1 and the water supply unit C and the oil-water mixing unit D composed of the corresponding connecting pipelines, the electric control reversing module E is set at the output end b of the oil supply unit, and the output end of the oil supply unit passes through one output end of the electric control reversing module d is connected to one input terminal i of the oil-water mixing unit; the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com