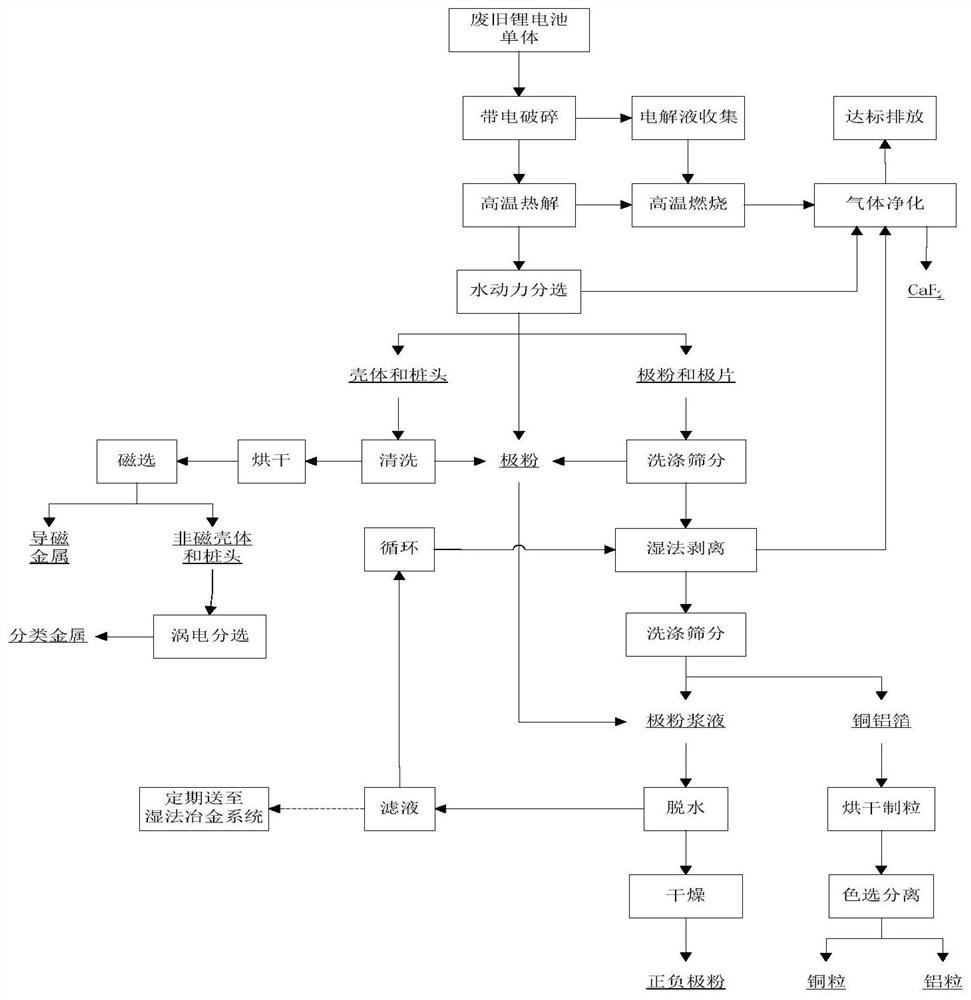

Method for completely recovering valuable metal components of waste lithium battery by stripping pole powder by hydrodynamic separation wet method

A waste lithium battery, wet stripping technology, used in battery recycling, waste collector recycling, recycling technology and other directions, can solve the problem of not involving lithium hexafluorophosphate recycling, unable to remove electrolyte, affecting the accuracy of color sorting, etc., to avoid The effect of polar powder entrainment loss, complete polar powder peeling, and improved environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Under a nitrogen atmosphere, the waste square steel shell ternary lithium battery is put into the crushing system, and the shearing type is used for one-time crushing, and then the crushed material is added to the pyrolysis system, and the rotary kiln type pyrolysis furnace is used at 550 ℃ for high temperature and oxygen deprivation. Pyrolysis in the environment for 1 hour, after pyrolysis, the material is sent to the hydrodynamic sorting system, the screw machine at the bottom of the sorting machine takes out the shell and the pile head, and the positive and negative electrode pieces and the shedding electrode powder mixture are recovered from the second overflow port. A small amount of fine powder is recovered from the first overflow port. Wash and sieve the electrode mixture to obtain the positive and negative electrode materials, and then pass through the wet stripping system, add low-concentration dilute sulfuric acid to soak, the liquid-solid ratio is 20:1, the ma...

Embodiment 2

[0041] In a nitrogen atmosphere, the waste square aluminum shell ternary lithium battery is put into the crushing system, and the shearing type is used for one-time crushing, and then the crushed material is added to the pyrolysis system, and the rotary kiln-type pyrolysis furnace is used at a high temperature of 550 ° C. Pyrolysis under ambient conditions for 1 hour. After pyrolysis, the material is sent to the hydrodynamic sorting system. The screw machine at the bottom of the sorting machine takes out the shell and pile head, and recovers the positive and negative electrode pieces and the electrode powder mixture from the second overflow port. A small amount of light pole powder is recovered from the first overflow port. Wash and screen the electrode mixture to obtain the positive and negative electrode materials, and then pass through the wet stripping system, add low-concentration dilute sulfuric acid to soak, the liquid-solid ratio is 20:1, the mass fraction of dilute sul...

Embodiment 3

[0045] In a nitrogen atmosphere, the waste soft-packed ternary lithium battery is put into the crushing system, and the shearing type is used for one-time crushing, and then the crushed material is added to the pyrolysis system, and the rotary kiln-type pyrolysis furnace is used in a high-temperature anaerobic environment at 550 ° C. After pyrolysis for 1 hour, the material after pyrolysis is sent to the hydrodynamic sorting system, and the screw machine at the bottom of the sorting machine takes out the shell and pile head, and recovers the positive and negative electrode pieces and the powder mixture from the second overflow port. A small amount of fine powder is recovered from the first overflow port. Wash and sieve the electrode mixture to obtain the positive and negative electrode materials, and then pass through the wet stripping system, add low-concentration dilute sulfuric acid for soaking, the liquid-solid ratio is 20:1, the mass fraction of dilute sulfuric acid is 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com