Method for recycling copper, silver and gold step by step by using waste printed circuit board

A printed circuit board and copper recovery technology, applied in the field of copper, gold and silver recovery, can solve the problems of difficult to meet the requirements of resource utilization and market, complex nature, etc., and achieve short reaction time, simple operation and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

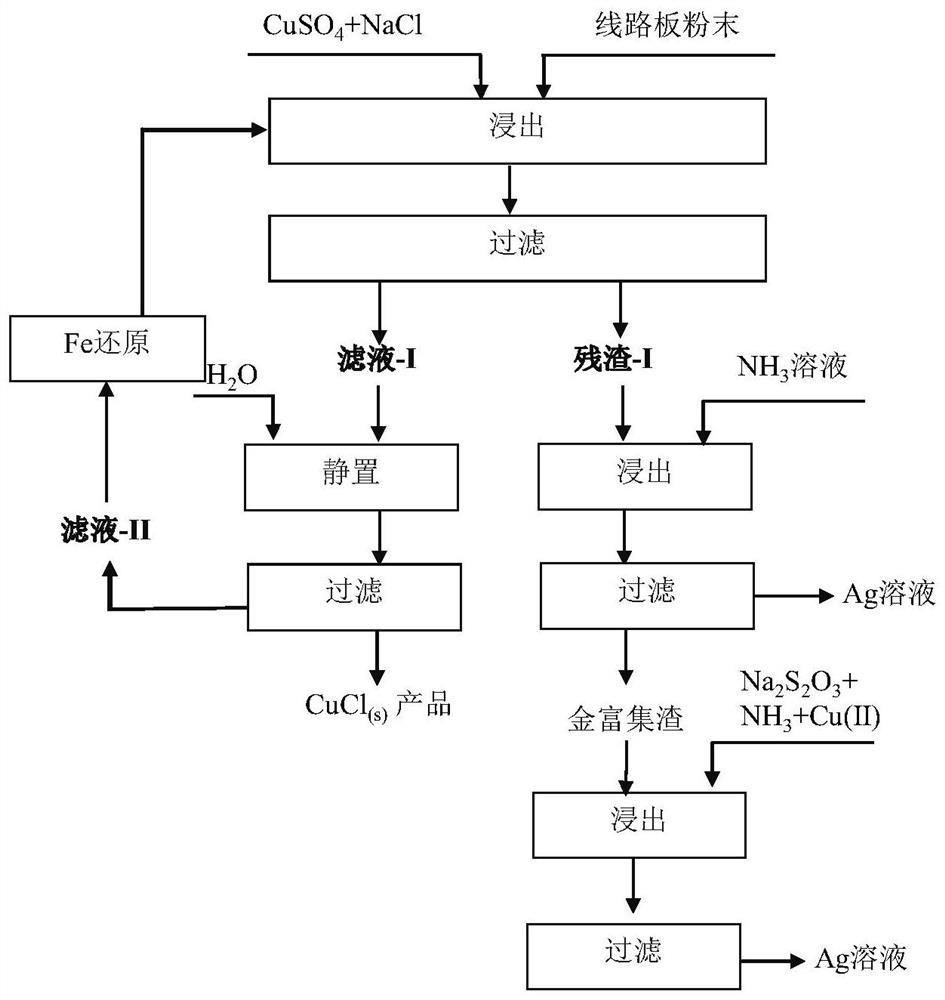

[0027] The relationship and scheme flow chart of Examples 1-3 refer to figure 1 . Among them, Example 1 is used to illustrate the preparation of CuCl and gold and silver enrichment from waste printed circuit boards, Example 2 is used to illustrate the leaching and recovery of silver, and Example 3 is used to illustrate the leaching and recovery of gold.

[0028] Example 1

[0029] a. Pretreatment of waste printed circuit boards: Crush the waste circuit boards to obtain circuit board powder of less than 30 meshes.

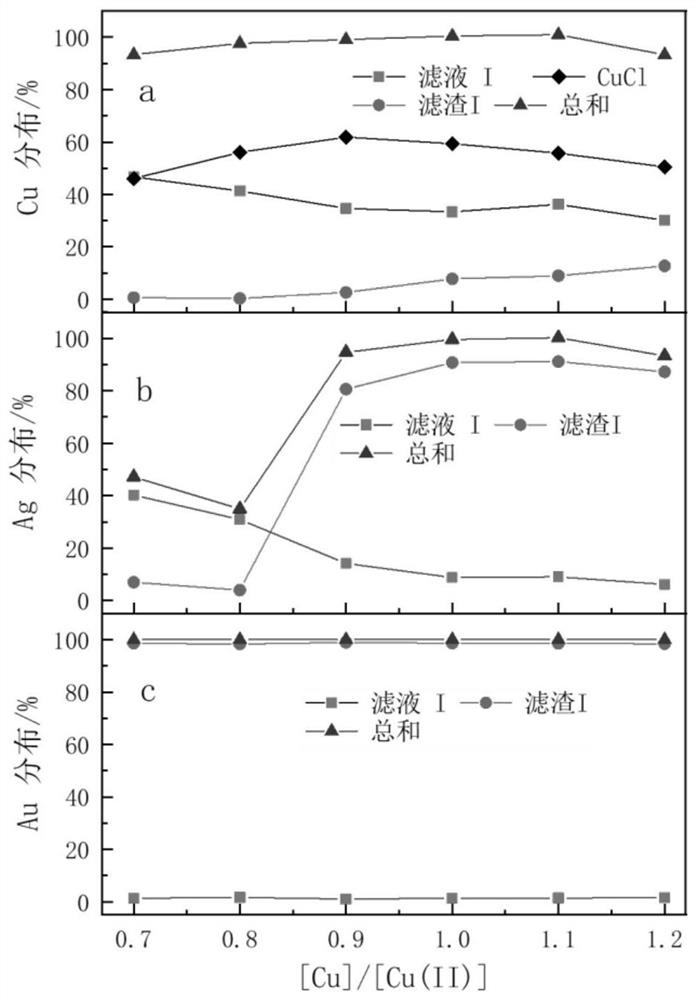

[0030] b. Selective dissolution of copper and enrichment of gold and silver: CuSO 4 ·5H 2 O and saturated sodium chloride were mixed in a mass-volume ratio of 1:5 (g / mL), and the CuSO 4 ·5H 2 After the O is completely dissolved, add the circuit board powder to control the copper and CuSO in the circuit board powder 4 ·5H 2 The molar ratio of copper ions in the O / NaCl mixed solution was 0.7:1-1.2:1, and the reaction was stirred at a temperature of 60° C. for 3...

Embodiment 2

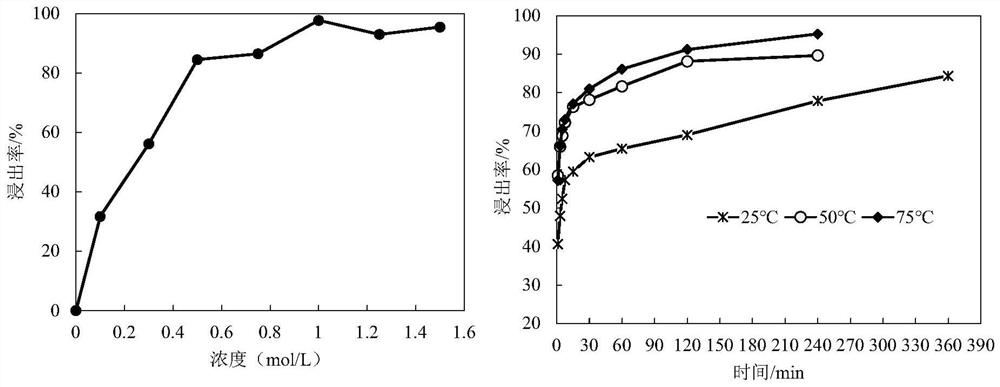

[0034] Example 2 continued to use the gold and silver enriched residue obtained in Example 1, namely residue I. Ammonia solution of 0.1-1.5mol / L was added to the gold and silver enriched slag obtained in step b of Example 1, and the liquid-solid ratio of the ammonia solution to the gold and silver enriched slag was 100:1, and the reaction temperature was 25-75 mol / L. ℃, the reaction time is 2 minutes to 6 hours, and the silver solution and gold enriched slag are obtained after filtration.

[0035] For the data of silver leaching recovery rate in this example, see image 3 . from image 3 It can be seen that the concentration of ammonia water, leaching time and temperature have obvious effects on the leaching of silver. When the ammonia concentration is greater than 0.5, the silver leaching rate can reach more than 80%. The leaching rate is positively correlated with time and temperature. Under the conditions of 25℃, 50℃, and 75℃, the silver leaching rate can reach more tha...

Embodiment 3

[0037] In Example 3, the gold-enriched slag obtained in Example 2 was used. The gold-enriched slag obtained in Example 2 was added to Cu 2+ –NH 3 –Na 2 S 2 O 3 The mixed solution was stirred and leached, in which Na 2 S 2 O 3 The concentration is 0.09-0.13mol / L, NH 3 The concentration is 0.1-0.4mol / L, Cu 2+ Concentration 0.015-0.03mol / L, Cu 2+ –NH 3 –Na 2 S 2 O 3 The liquid-solid ratio of the mixed solution and the gold-enriched slag is 100:1, the reaction temperature is 20-60° C., and the gold solution is obtained by filtration after the reaction time.

[0038] For the data of gold leaching recovery rate in this example, see Figure 4 , Figure 5 . from Figure 4 It can be seen that Cu 2+ –NH 3 –Na 2 S 2 O 3 The concentration of the different components in the gold all affect the leaching rate of gold. when Na 2 S 2 O 3 The concentration is 0.1mol / L, 0.125mol / L, NH 3 Concentrations are 0.1mol / L, 0.2mol / L, 0.3mol / L, 0.4mol / L, Cu 2+ Concentration 0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com