Treatment method of third phases in wet metallurgy extraction system

A technology of hydrometallurgy and treatment method, which is applied in the field of third phase treatment, and can solve the problems of slow recovery, long cycle, long treatment cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

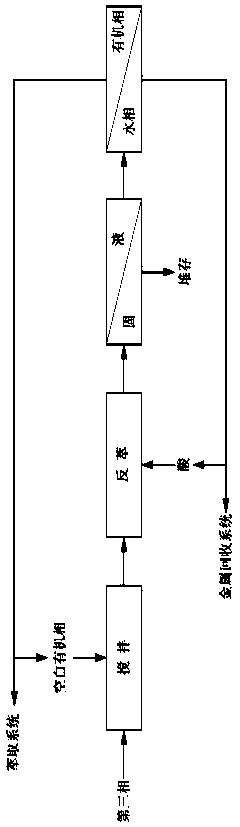

Method used

Image

Examples

Embodiment 1

[0029] Take out 100L of the third phase in the extraction system that uses P507 as the extraction agent to extract nickel and cobalt. In the third phase: the total content of Ni and Co is 1.5wt%, and the organic phase is 20wt%. Add 680L to the extraction system in the reaction tank The unloaded P507 (that is, the P507 not loaded with the extract) (density 0.85g / ml) obtained through the stripping section is mixed with the third phase, heated to 65°C and stirred for 175min, and then added to the reaction tank with a hydrogen ion concentration of 2mol 400L of sulfuric acid per liter, continue to stir for 5min and then leave it still. After 90min, the upper layer organic matter in the reaction tank is used as the blank organic phase for the next treatment of the third phase. A total of 532kg of organic phase is recovered, and the organic phase recovery rate is 88.96%. The water phase is discharged from the lower part and returned to the extraction system to recover a total of 1.30k...

Embodiment 2

[0031] Take out 100L of the third phase in the extraction system that uses C272 as the extraction agent to extract nickel. The third phase contains 2.0wt% Ni and 22wt% organic phase, and add 350L of unloaded nickel obtained through the stripping section in the extraction system to the reaction tank. Mix C272 (that is, C272 without extract) (density 0.80g / ml) with the third phase, raise the temperature to 50°C and stir for 90 minutes, then add 100L of hydrochloric acid with a hydrogen ion concentration of 12mol / l to the reaction tank, and continue stirring Press filter after 18 minutes, and store the solids after they are discharged from the system. After the liquid phase is allowed to stand for 2 minutes, the organic matter in the upper layer is used as a blank organic phase for the third phase in the next treatment. A total of 274 kg of organic phase is recovered, and the recovery rate of the organic phase is 90.73%. The water phase is discharged from the lower part and return...

Embodiment 3

[0033] Take out 100L of the third phase in the extraction system that uses P204 as the extraction agent to extract nickel and cobalt. In the third phase: the Ni and Co contents are 1.5wt% in total, and the organic phase is 15wt%. The unloaded P204 obtained in the extraction section (that is, the P204 not loaded with the extract) (density 0.85g / ml) is mixed with the third phase, heated to 35°C and stirred for 18 minutes, and then added to the reaction tank with a hydrogen ion concentration of 8mol / l 80L of hydrochloric acid, continue to stir for 12min and then stand still. After standing for 40min, the organic matter in the upper layer of the reaction tank is used as the blank organic phase for the next treatment of the third phase. A total of 80.52kg of organic phase is recovered, and the recovery rate of organic phase is 88.00%. The phase is discharged from the lower part and returned to the extraction system to recover a total of 1.25kg of Ni and Co, with a metal recovery rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com