Vanadium pentoxide preparation method

A technology of vanadium pentoxide and pentavalent vanadium, applied in vanadium oxide and other directions, can solve the problems of influence of vanadium product purity, increase recovery cost, difficult to remove, etc., and achieve the effects of low cost, reduced emission and mild reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

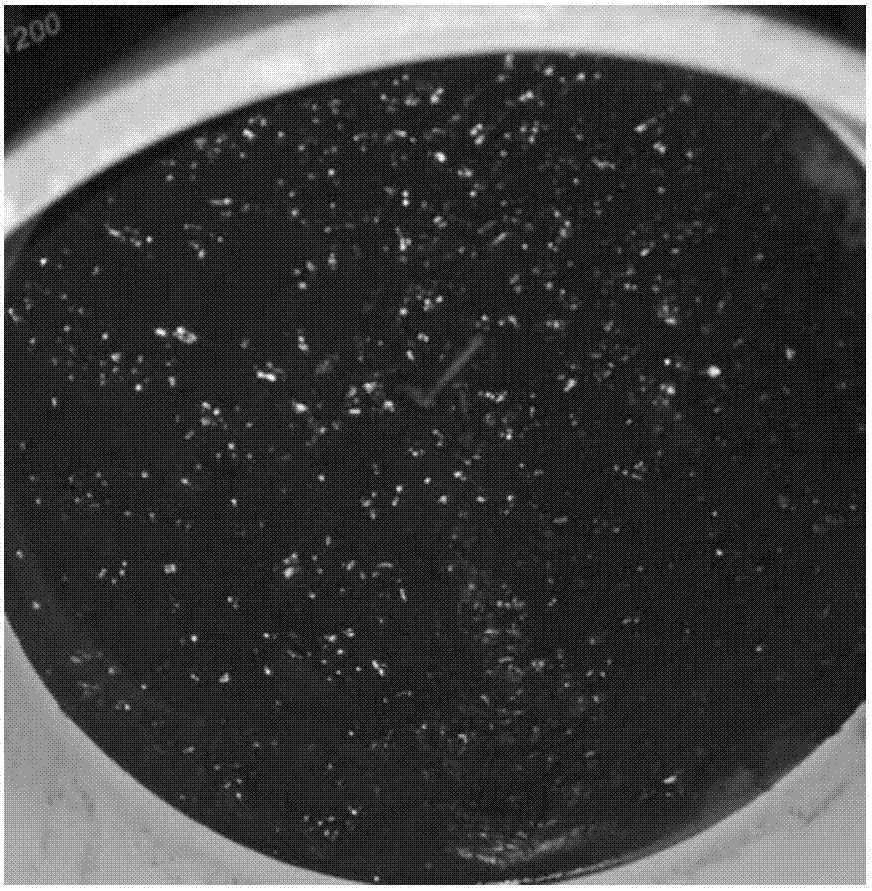

[0038] Embodiment 1 adopts the inventive method to prepare vanadium pentoxide

[0039] 1. Unification of vanadium valence state: take the molar concentration of total vanadium as 1.5mol / L (wherein the molar concentration of non-pentavalent vanadium is 1.0mol / L), H 2 SO 4 Concentration of 3mol / L vanadium battery positive and negative electrolyte 200mL; add hydrogen peroxide 14mL to the electrolyte, and react for 20min under the condition of ultrasonic frequency of 20KHz.

[0040] 2. Adjustment of system acidity: filter, add 1000mL of distilled water to the filtrate, and adjust the pH value to 0.

[0041] 3. Precipitation of vanadium: heat up the electrolyte solution obtained from acid adjustment to 80°C at a speed of 5 rpm, react the system at a speed of 5 rpm, and react for 40 minutes at 80°C, keep the speed constant and stir to cool to room temperature (25 ~30°C), filtered, and the precipitate was taken for pickling.

[0042] 4. Acid washing: Add distilled water with pH=0 ...

Embodiment 2

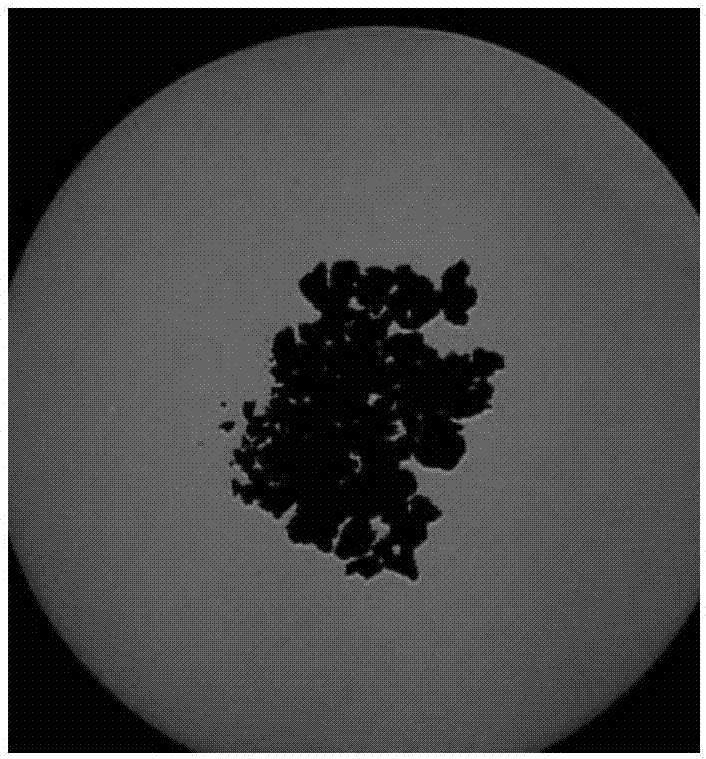

[0046] Embodiment 2 adopts the inventive method to prepare vanadium pentoxide

[0047]1. Unification of vanadium valence state: take the molar concentration of total vanadium as 1.6mol / L (wherein the molar concentration of non-pentavalent vanadium is 1.0mol / L), H 2 SO 4 Concentration of 3mol / L vanadium battery positive and negative electrolyte 200mL; add hydrogen peroxide 17mL to the electrolyte, and react for 15min under the condition of ultrasonic frequency 30KHz.

[0048] 2. Adjustment of system acidity: filter, add 1.2mL of distilled water to the filtrate, and adjust the pH value to 1.

[0049] 3. Precipitation of vanadium: heat up the electrolyte solution obtained from acid adjustment to 90°C at a speed of 10 rpm, react the system at a speed of 10 rpm and 90°C for 30 minutes, keep stirring and cool to room temperature (25 ~30°C), filtered, and the precipitate was taken for pickling.

[0050] 4. Acidic washing: add distilled water with a pH of 1 times the volume of the ...

Embodiment 3

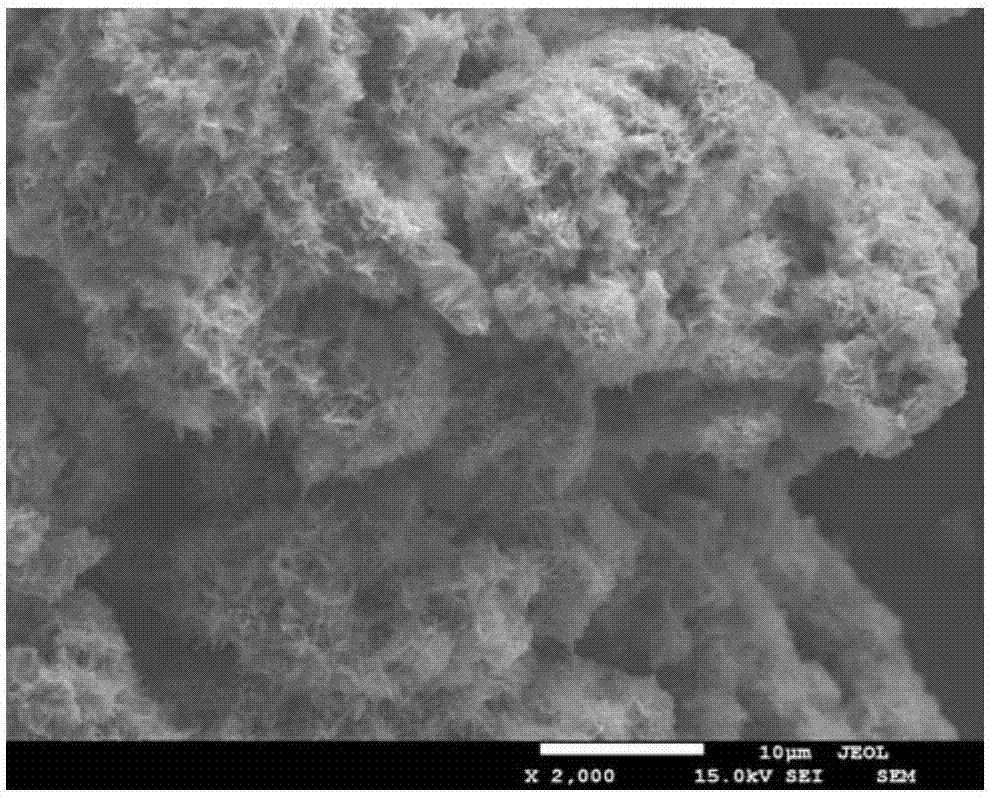

[0054] Embodiment 3 adopts the inventive method to prepare vanadium pentoxide

[0055] 1. Unification of the vanadium valence state: take the molar concentration of total vanadium as 1.7mol / L, of which the molar concentration of non-pentavalent vanadium is 1.0mol / L), H 2 SO 4 Concentration of 3mol / L vanadium battery positive and negative electrolyte 200mL; add hydrogen peroxide 20mL to the electrolyte, and react for 10min under the condition of ultrasonic frequency 40KHz.

[0056] 2. Adjustment of system acidity: filter, add 1.2mL of distilled water to the filtrate, and adjust the pH value to 1.

[0057] 3. Precipitation of vanadium: heat up the electrolyte solution obtained from acid adjustment to 100°C at a speed of 15 rpm, react the system at a speed of 15 rpm and 100°C for 20 minutes, keep stirring at a constant speed and cool to room temperature (25 ~30°C), filtered, and the precipitate was taken for pickling.

[0058] 4. Acidic washing: add distilled water with a pH o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com