Preparation method of pb oxide nanopowder for recycling and manufacturing of lead-acid batteries

A nano-powder, oxide technology, applied in battery recycling, lead oxide, nanotechnology and other directions, can solve the problem of unsuitable lead-acid battery recycling and manufacturing process, inconsistent manufacturing process requirements, difficult commercial production and application, etc. problems, to achieve the effect of shortening the production cycle, simplifying the process and related logistics steps, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

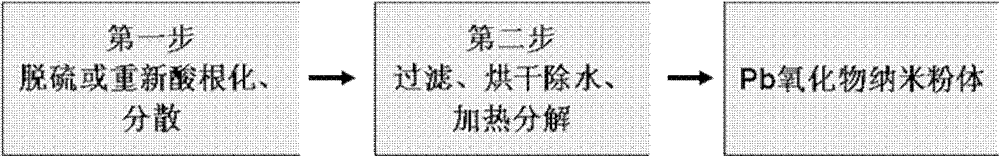

[0032] The preparation method of the Pb oxide nano-powder that is used for lead-acid storage battery recovery and manufacture of the present invention, its schematic flow sheet, as shown in the accompanying drawings of description, its steps comprise:

[0033] (1) Place 0.1kg (0.308mol) of lead acetate in 0.9kg of water, then pass 0.136kg (3.08mol) of CO into the water 2 To form a carbonic acid solution, react with lead acetate at the same time to generate a precipitate, the reaction is carried out at room temperature, the reaction time is controlled until no precipitation continues to occur, and precipitate A is generated;

[0034] In addition, the above-mentioned 1kg lead acetate solution was also prepared, and 0.02kg (0.0308mol) of surfactant Triton X-100 was added thereto, and then the same CO 2 The operation, and the reaction system was supplemented with 30s ultrasound at intervals of 2 minutes during the process, resulting in precipitate B;

[0035] (2) Filter the above...

Embodiment 2

[0037] The preparation method of the Pb oxide nanopowder that is used for lead-acid storage battery recovery and manufacture of the present invention, its steps comprise:

[0038] (1) Mix 0.1kg of lead sulfate (0.33mol) with 1 liter of Na with a concentration of 1.65mol / L 2 CO 3 The aqueous solution is reacted, and the solution is removed after the reaction, and then the precipitate is mixed with 1 liter of Na with a concentration of 1.65mol / L 2 CO 3 The aqueous solution is reacted, so repeated 200 times, that is, 0.1kg of lead sulfate (0.33mol) is mixed with 333mol of Na in total 2 CO 3 Interact, fully remove sulfur, and obtain precipitate A;

[0039] In addition, the same preparation of the above Na 2 CO 3 solution, and 0.007kg (0.0165mol) of surfactant Tween-80 was added thereto, and then the same repeated operation was performed, and the reaction system was supplemented with 30s ultrasound during the interaction (reaction). 2 CO 3 In addition to the interaction, 0....

Embodiment 3

[0042] The preparation method of the Pb oxide nanopowder that is used for lead-acid storage battery recovery and manufacture of the present invention, its steps comprise:

[0043] (1) Place 0.1kg (0.303mol) of lead nitrate in 3kg of water, and then continuously feed 13.33kg (303mol) of CO into the water 2 To form a carbonic acid solution, react with lead nitrate at the same time to generate a precipitate, the reaction is carried out at room temperature, the reaction time is controlled until no precipitation continues to occur, and precipitate A is generated;

[0044] In addition, prepare above-mentioned 0.1kg (0.302mol) lead nitrate solution equally, and add the surfactant lauric acid of 3.02mol (0.6kg) wherein (or it and a certain amount, such as 1kg, ethanol solvent add together), stir simultaneously The reaction system was supplemented with ultrasound, and then the same CO 2 The operation produces precipitate B;

[0045] (2) Filter the above solution or / and oily liquid to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com