Neodymium-iron-boron rare earth permanent magnet waste regenerated magnet and preparation method thereof

A rare earth waste and rare earth permanent magnet technology, which is used in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of increased production costs, single shape of the blank, waste of materials, etc., to reduce the cost of recycling, recycling The effect of process environmental protection and improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

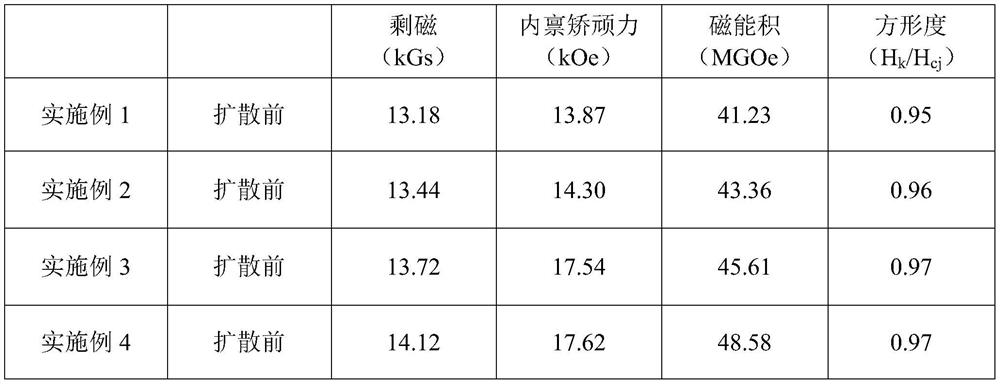

Embodiment 1

[0062] This embodiment provides a method for preparing a NdFeB rare earth permanent magnet waste regenerated magnet. The preparation method specifically includes the following steps:

[0063] (1) Distinguish the mixed waste of grades N35-N40 containing Ce from the mixed waste of grades N48-N52 not containing Ce, and select 5 kg each. The two kinds of waste materials are then pickled to remove surface oil and scale, and then the waste after pickling is rinsed with a high-pressure water gun, and the waste after washing is dried and stored in a glove box. The pickling liquid is hydrochloric acid with a concentration of 1%, and the surface treatment time is 15s;

[0064] (2) Put the waste materials obtained in (1) into the hydrogen breaking furnace respectively, make the waste absorb hydrogen under the hydrogen pressure environment of 0.1-0.2 MPa, and heat it to Dehydrogenation at 550°C, cool down after the vacuum degree in the furnace is less than 10Pa, and then sieve the coarse...

Embodiment 2

[0070] This embodiment provides a method for preparing a NdFeB rare earth permanent magnet waste regenerated magnet. The preparation method specifically includes the following steps:

[0071] (1) Distinguish the mixed waste of grades N35-N40 containing Ce from the mixed waste of grades N48-N52 not containing Ce, and select 5 kg each. The two kinds of waste materials are then pickled to remove surface oil and scale, and then the waste after pickling is rinsed with a high-pressure water gun, and the waste after washing is dried and stored in a glove box. The pickling liquid is hydrochloric acid with a concentration of 1%, and the surface treatment time is 15s;

[0072] (2) Put the waste materials obtained in (1) into the hydrogen breaking furnace respectively, make the waste absorb hydrogen under the hydrogen pressure environment of 0.1-0.2 MPa, and heat it to Dehydrogenation at 550°C, cool down after the vacuum degree in the furnace is less than 10Pa, and then sieve the coarse...

Embodiment 3

[0078] This embodiment provides a method for preparing a NdFeB rare earth permanent magnet waste regenerated magnet. The preparation method specifically includes the following steps:

[0079] (1) Distinguish the mixed waste of grades N35-N40 containing Ce from the mixed waste of grades N48-N52 not containing Ce, and select 5 kg each. The two kinds of waste materials are then pickled to remove surface oil and scale, and then the waste after pickling is rinsed with a high-pressure water gun, and the waste after washing is dried and stored in a glove box. The pickling liquid is hydrochloric acid with a concentration of 1%, and the surface treatment time is 15s;

[0080] (2) Put the waste materials obtained in (1) into the hydrogen breaking furnace respectively, make the waste absorb hydrogen under the hydrogen pressure environment of 0.1-0.2 MPa, and heat it to Dehydrogenation at 550°C, cool down after the vacuum degree in the furnace is less than 10Pa, and then sieve the coarse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com