Patents

Literature

46results about How to "Solve the retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester paint of high solid for coiled material and lithographed sheet

InactiveCN1415682AIncreased irregularitySmall molecular weightLiquid surface applicatorsPolyester coatingsChemistryBoiling point

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

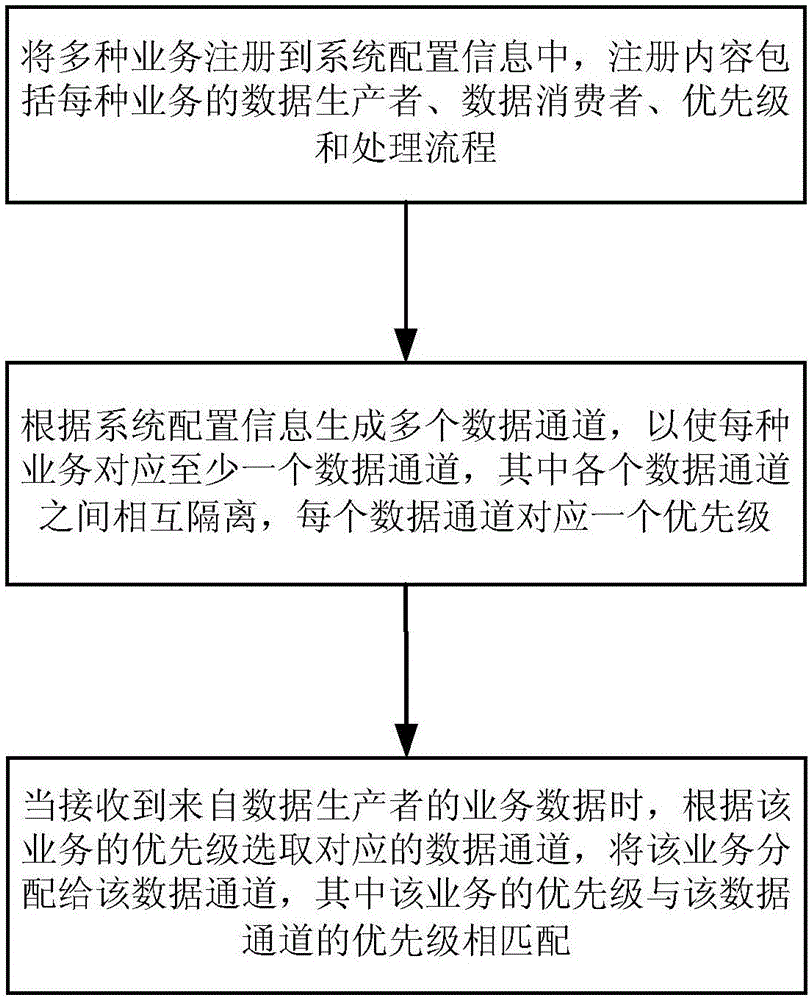

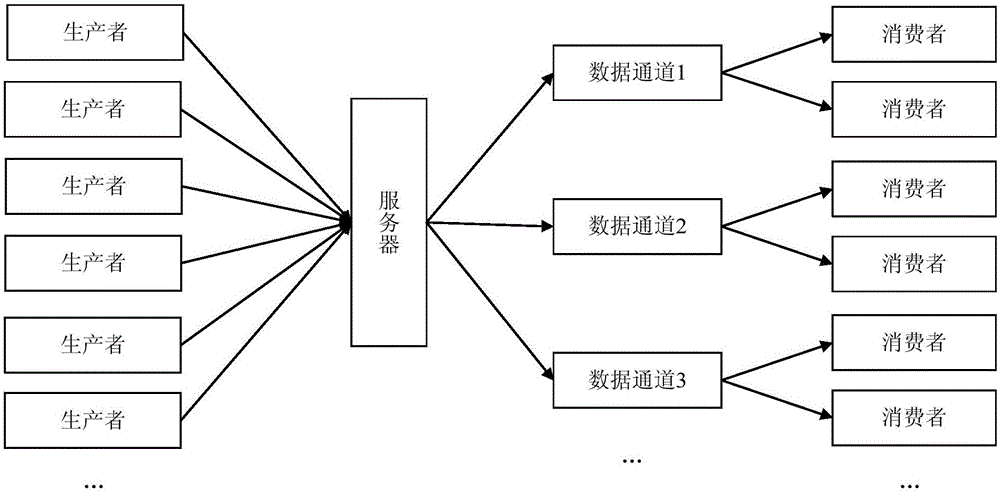

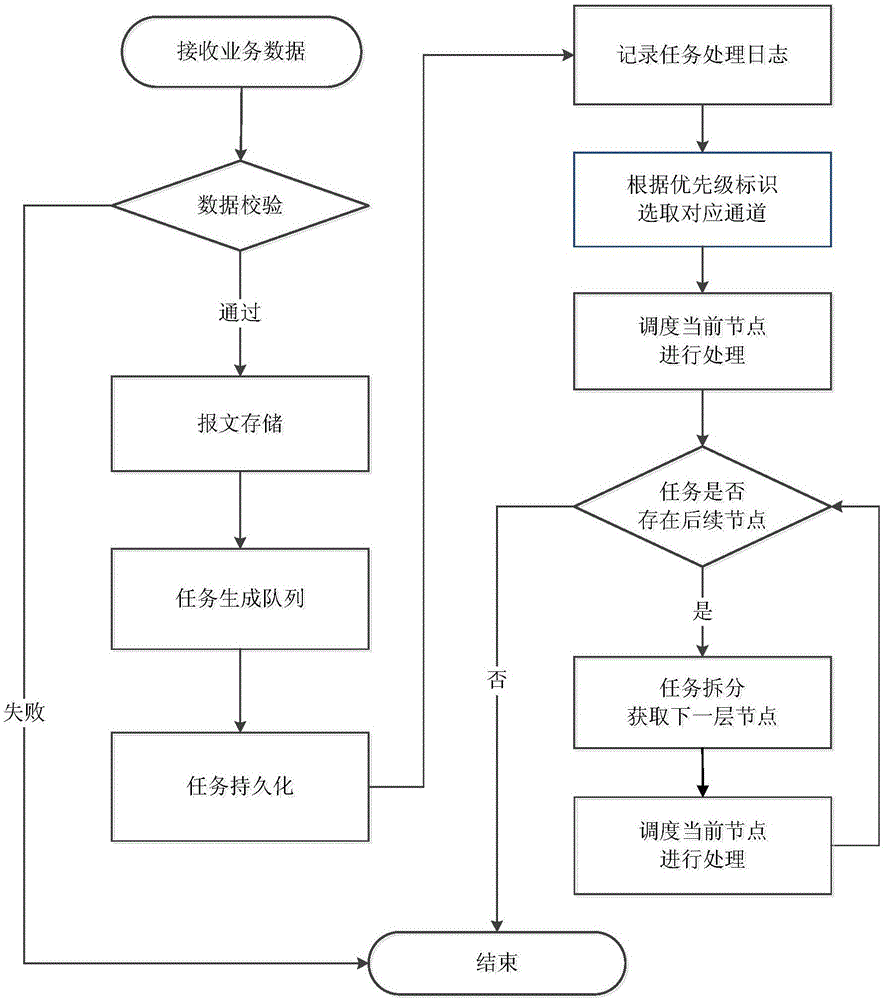

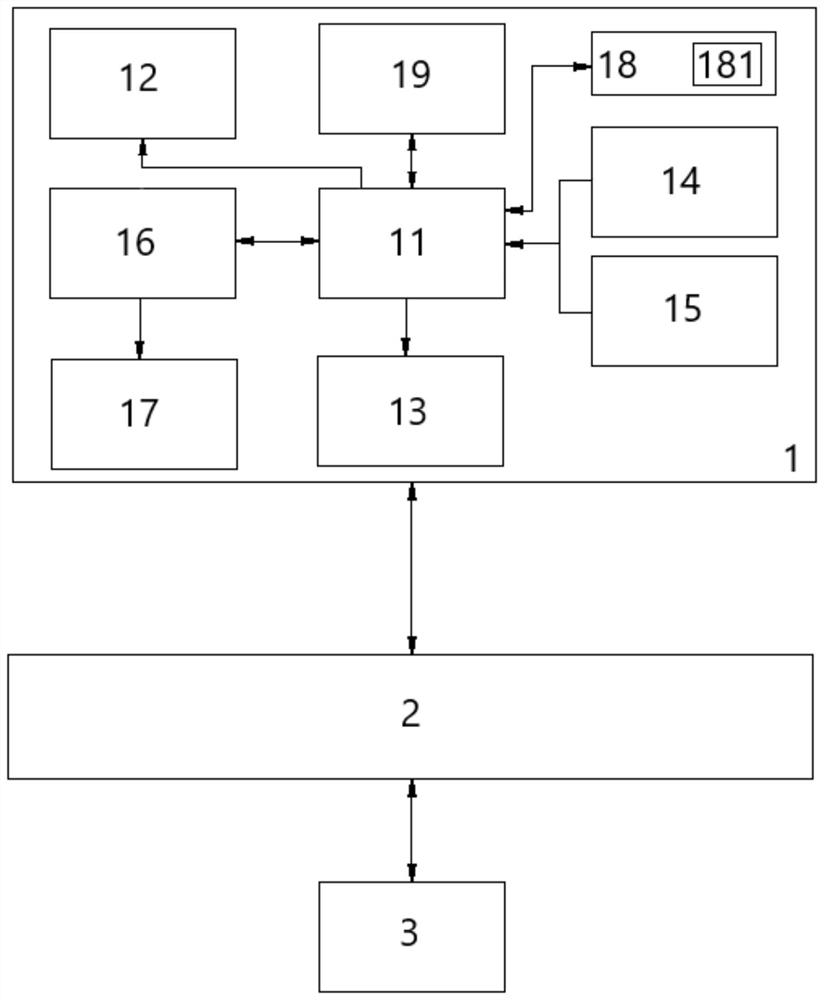

Business distribution method and business distribution device based on channel separation

ActiveCN105094956ASolve the impact of other dataSolve the retentionMultiprogramming arrangementsDistribution methodBusiness data

The invention discloses a business distribution method based on channel separation. The business distribution method comprises the following steps: registering businesses, that is, registering a plurality of businesses in system configuration information, wherein registered contents comprise a data producer, a data consumer, a priority and a treatment scheme of each business; creating channels, that is, generating a plurality of data channels according to the system configuration information so that each business at least corresponds to one data channel, wherein the data channels are mutually isolated, and each data channel corresponds to one priority; and distributing the channels, that is, when receiving business data coming from the data producer, selecting one corresponding data channel according to the priority of the business, and distributing the business to the data channel, wherein the priority of the business is matched with the priority of the data channel. By utilizing the business distribution method, data with high requirement on timeliness can be processed preferentially.

Owner:BEIJING JINGDONG ZHENSHI INFORMATION TECH CO LTD

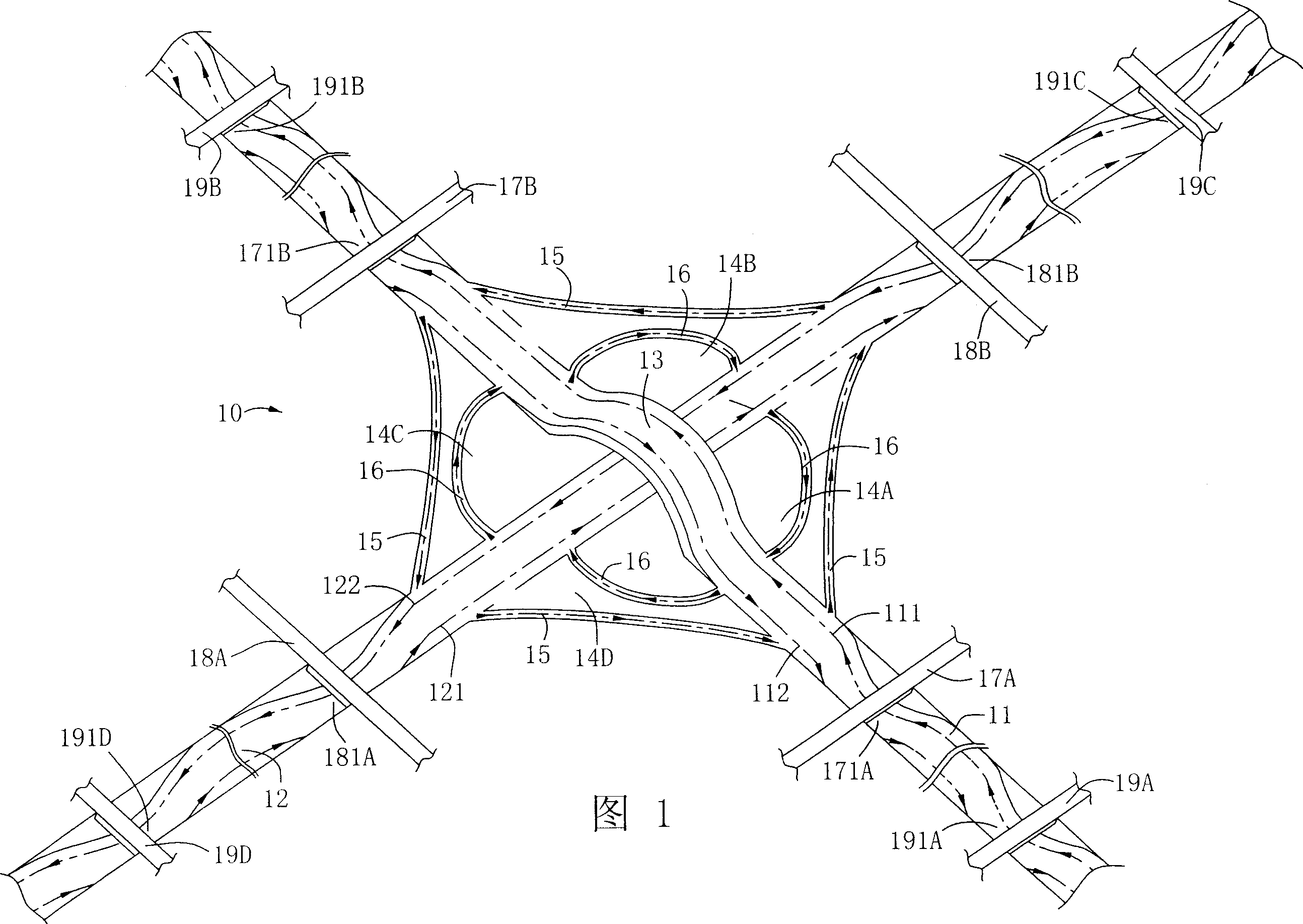

Non-obstacle cross road structure without traffic light

The invention relates to a crossroad without traffic light, which comprises crossed longitudinal and horizontal roads, which are solid crossed, and one of them is extended to the horizontal road at the back of another road via the horizontal road at the front of cross part; the longitudinal or horizontal roads of horizontal plane have right bend channel at the crossed part to connect the vertical road and a passage horizontal channel near the crossed rod. The invention can improve the traffic efficiency, to separate the crosswalk and the vehicle channel, to confirm the safety.

Owner:彭振华

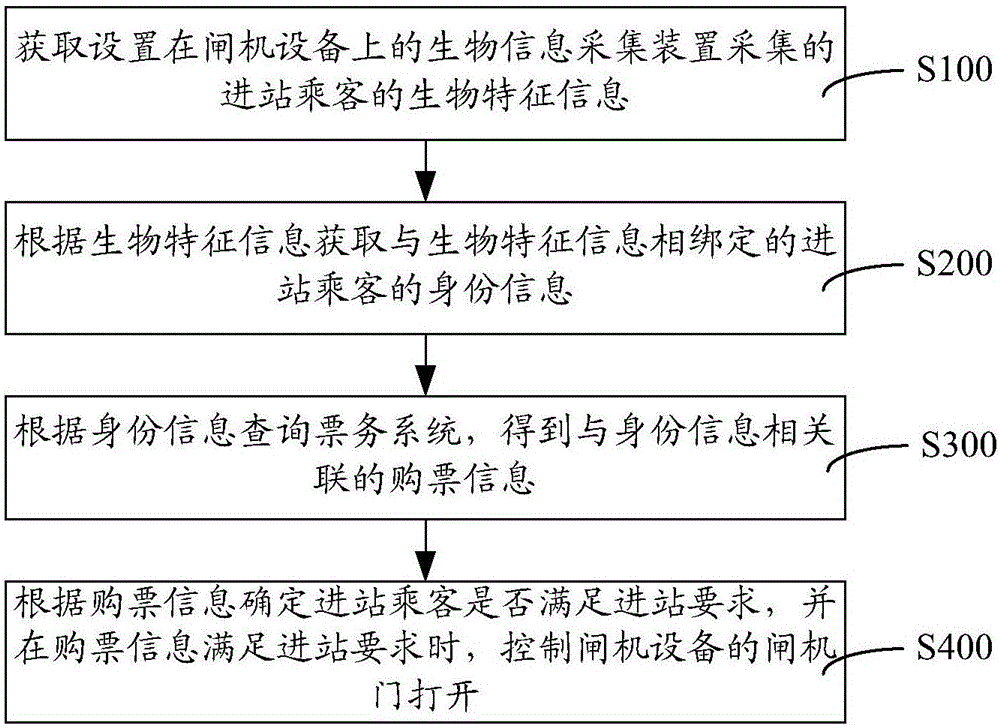

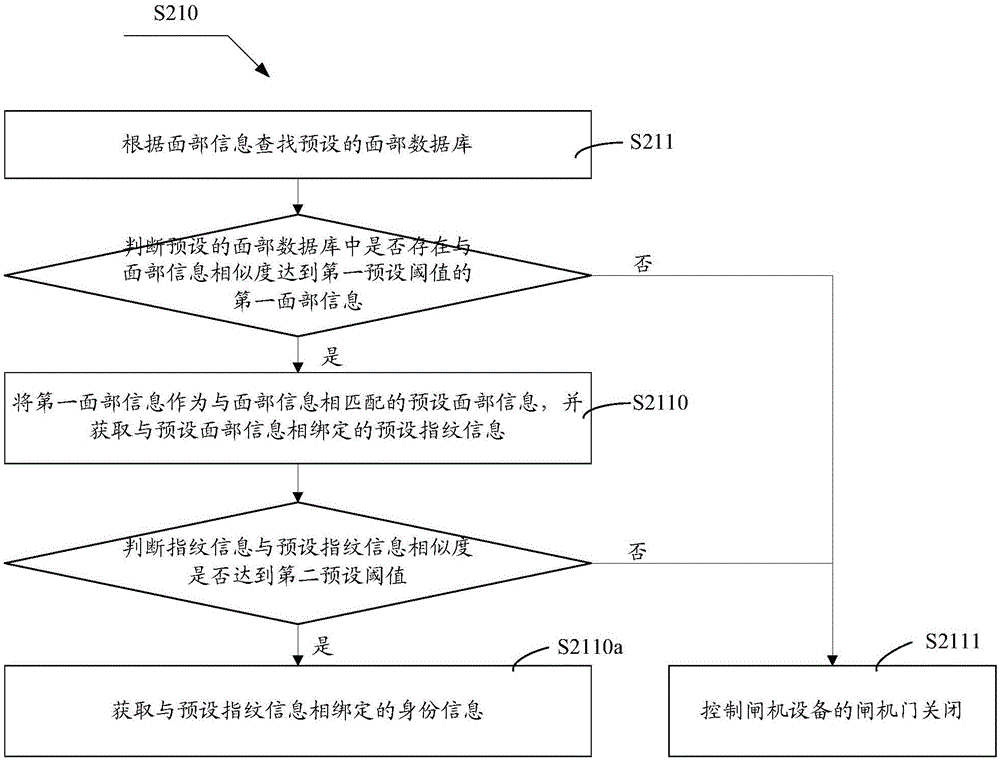

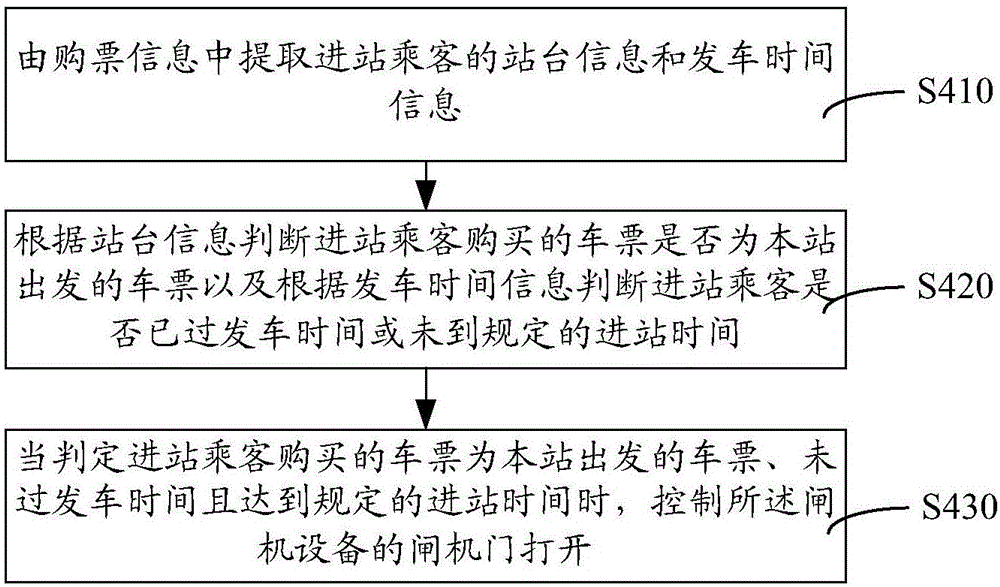

Control method and device of gate machine equipment

InactiveCN106780909AEasy accessSolve the retentionTicket-issuing apparatusIndividual entry/exit registersComputer science

The invention provides a control method and device of gate machine equipment, wherein the method comprises the following steps of obtaining biological characteristic information, of pull-in passengers, collected by a biological information collecting device arranged on the gate machine equipment; obtaining identity information of the pull-in passengers bonded with the biological characteristic information according to the biological characteristic information; inquiring a ticketing system according to the identity information; obtaining ticket buying information relevant to the identity information; determining whether the pull-in passengers meet the pull-in requirements or not according to the ticket buying information; when the ticket buying information meets the pull-in requirements, controlling a gate machine of the gate machine equipment to be opened. The equipment automatic ticket checking is used for replacing the conventional manual ticket checking mode; the labor cost is greatly reduced; in addition, high efficiency, convenience, high speed and reliability of the station ticket checking can be realized; meanwhile, passengers do not need to show tickets, identity cards and the like; convenience is brought for the passenger pull-in; the pull-in speed of the passengers is greatly accelerated; the maintenance of the station order is facilitated.

Owner:CRSC COMM & INFORMATION GRP CO LTD

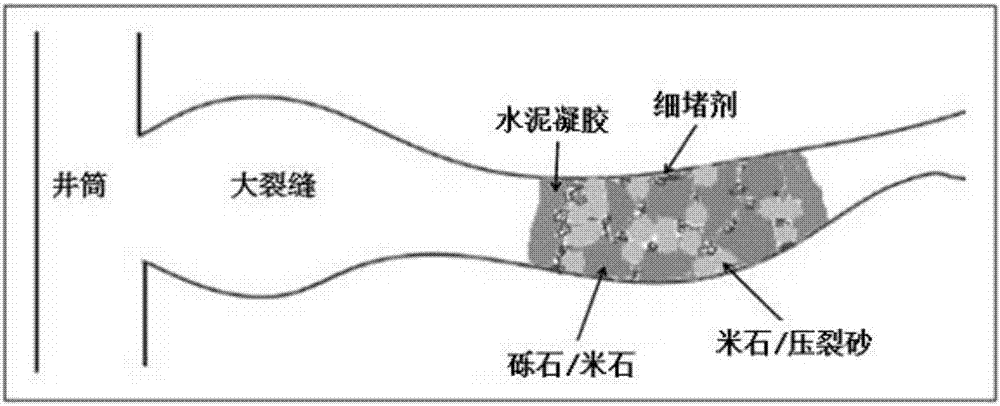

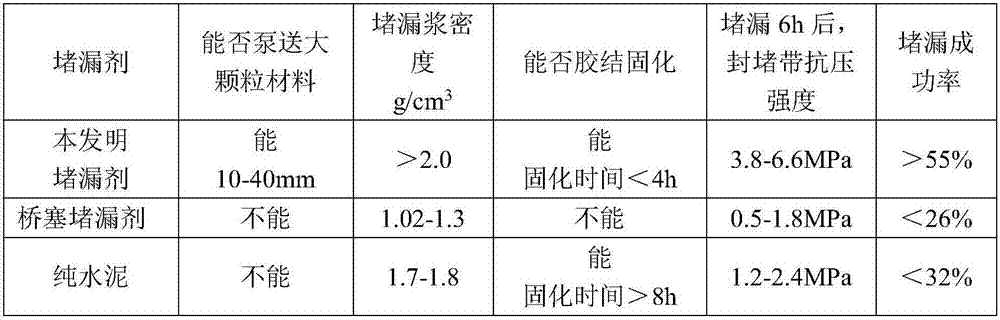

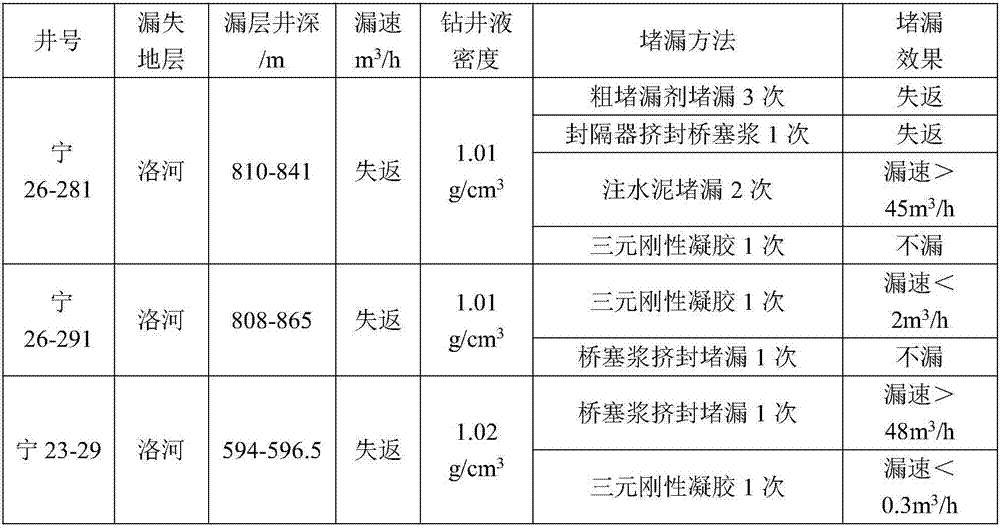

Lost circulation additive for plugging severe mud loss formation fracture and preparation method of lost circulation additive

ActiveCN107235691ALow costReduce manual labor intensityDrilling compositionGranolithicLost circulation

The invention provides a lost circulation additive for plugging severe mud loss formation fracture and a preparation method of the lost circulation additive. The lost circulation additive comprises the following components in percentage by mass: 45-56% of oil well grade-G cement, 8-12% of gravel, 12-15% of granolithic, 15-20% of fracturing sand, 6-9% of a thin plugging agent, 1-2% of a fluid loss agent and 2-4% of an admixture. According to the lost circulation additive disclosed by the invention, large fractures and large holes of the severe mud loss formation can be well plugged, the problem that the plugging agent cannot be bridged, remained, filled and reinforced in the large fractures can be well solved, and the requirements on drilling construction and environment friendliness are met. Moreover, the preparation method is simple, the operability is high, the severe mud loss plugging effect is obvious, the plugging operation cost is effectively reduced, and the plugging operation time is saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

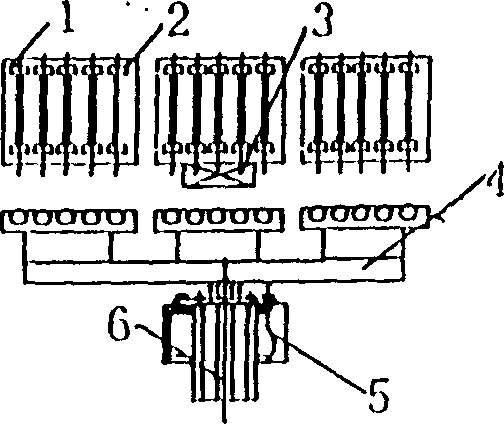

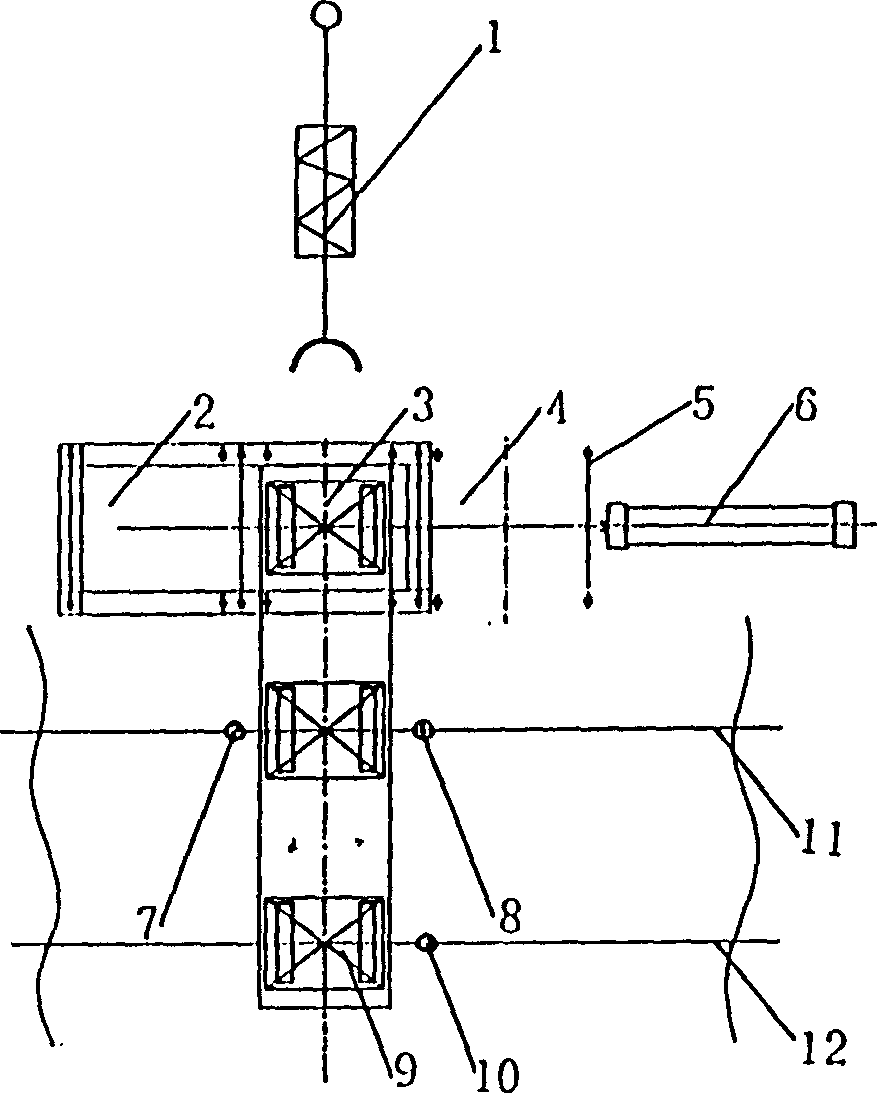

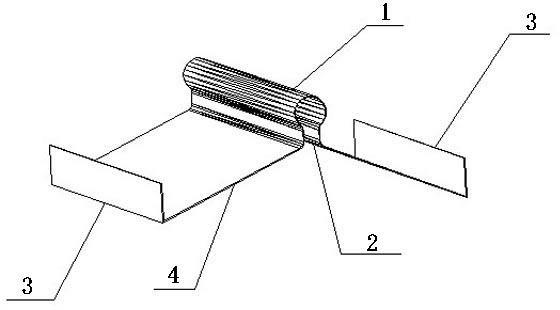

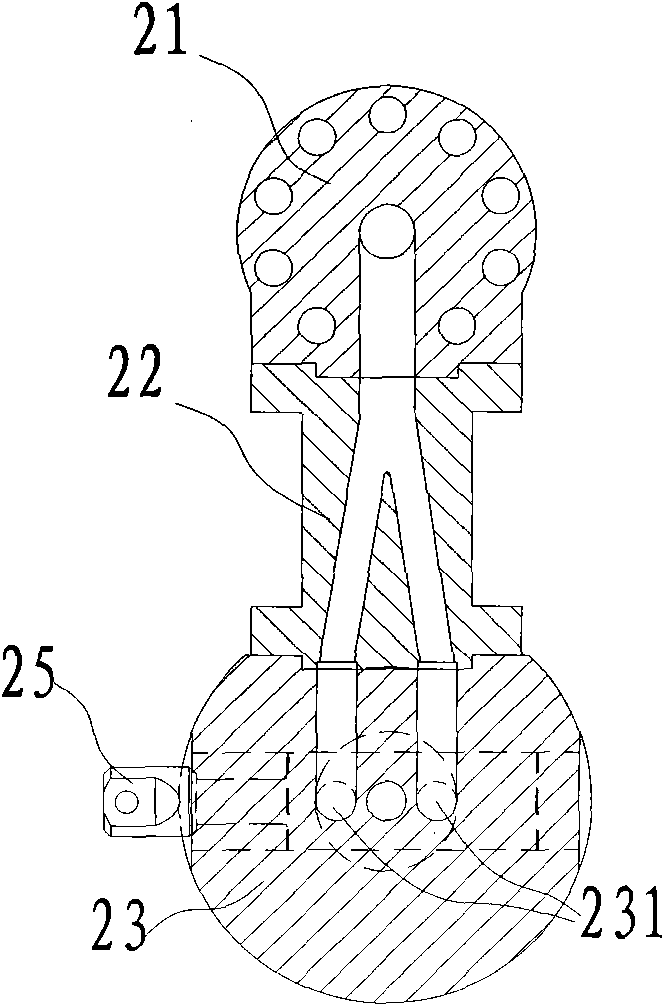

Triple motion device for striding multiple lines using in delivery lines

The invention relates three-position carryover machine used for transmission line. A cylinder pushes three carryover facing bars out of the line surface, the pallet is uplifted, driving motor drives the roller on carryover plate, and the pallet can be moved; the carryover mechanism is used for three-row or multi-row carryover; one position of carryover machine is also operating platform. The conveying work-piece can arbitrarily move and leave the transfer passage for next work-piece, improving the availability. It can arrange many treatment work-pieces on the same station, avoiding adopting many lines. The machine improves the transfer efficiency and saving the resource.

Owner:郑卫星

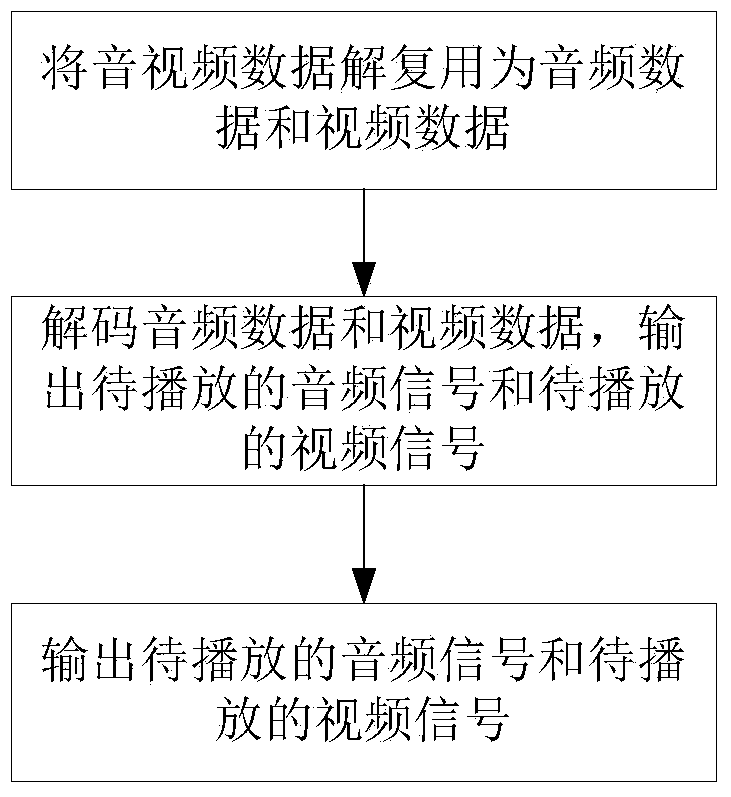

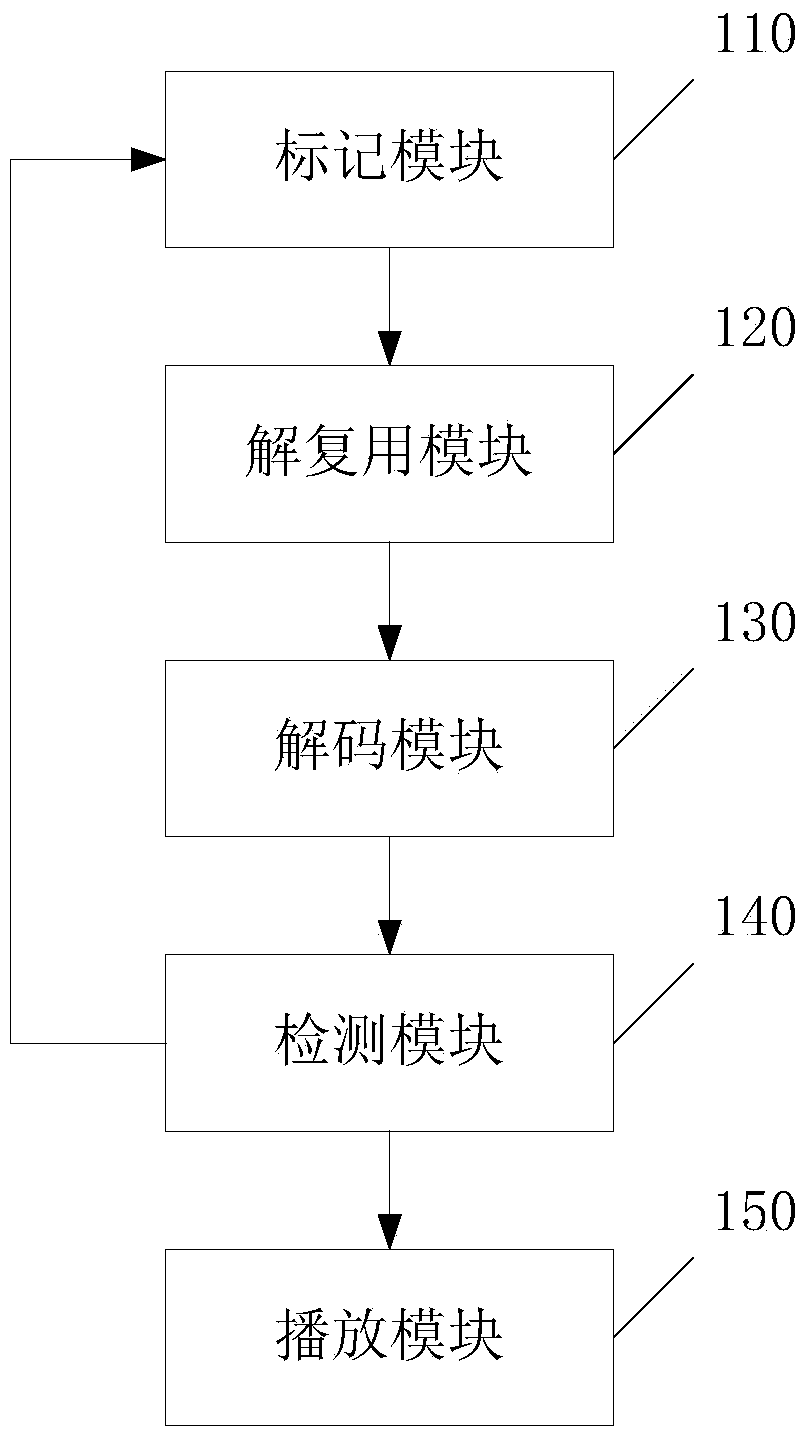

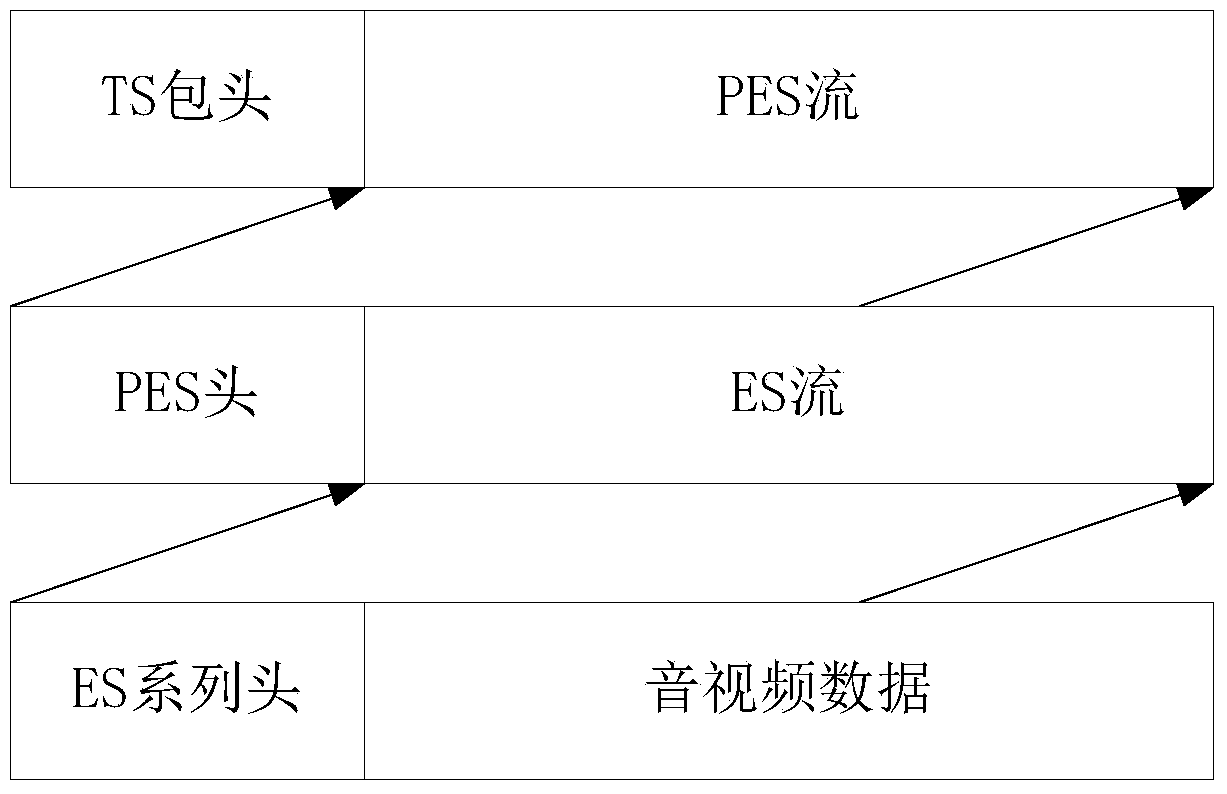

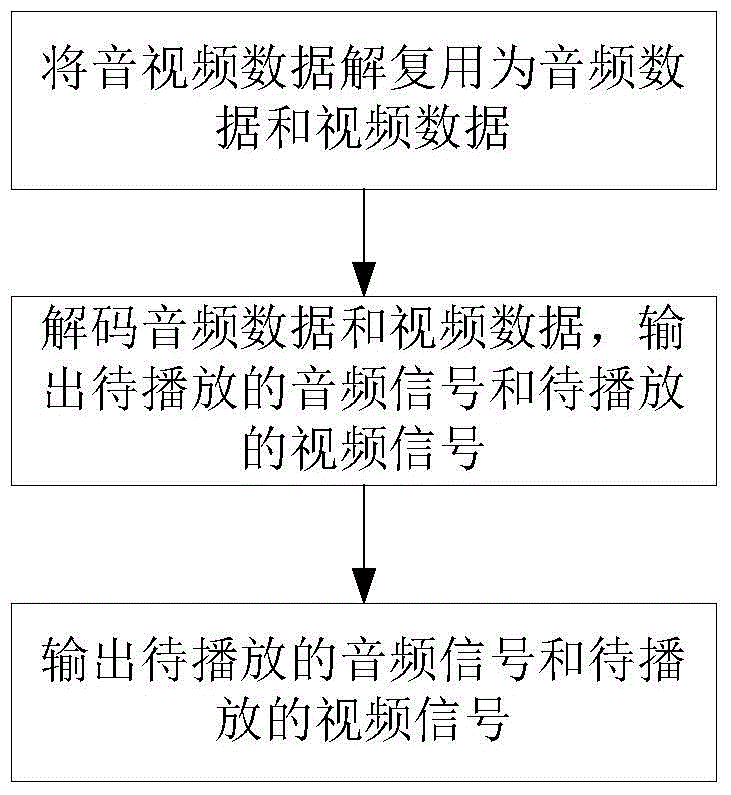

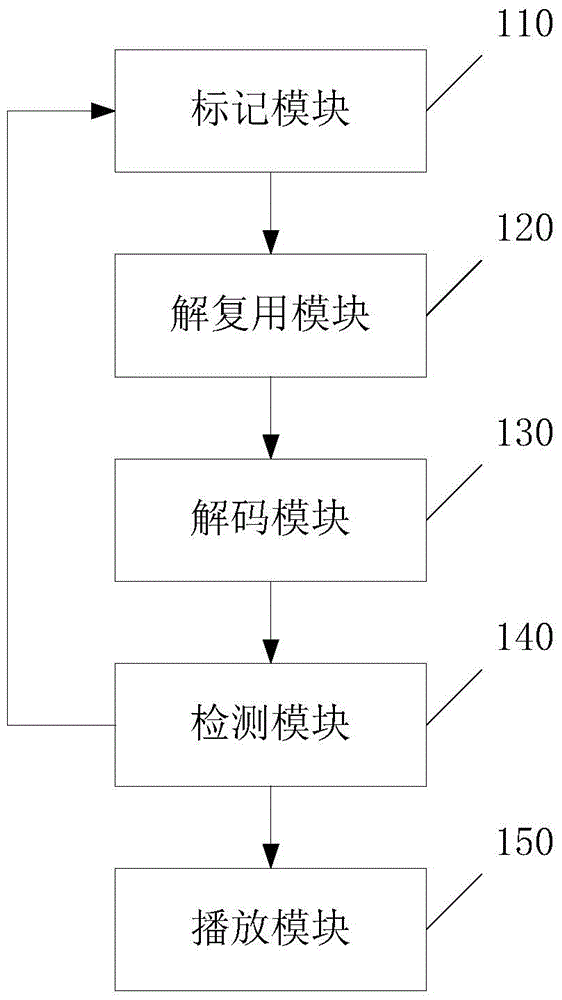

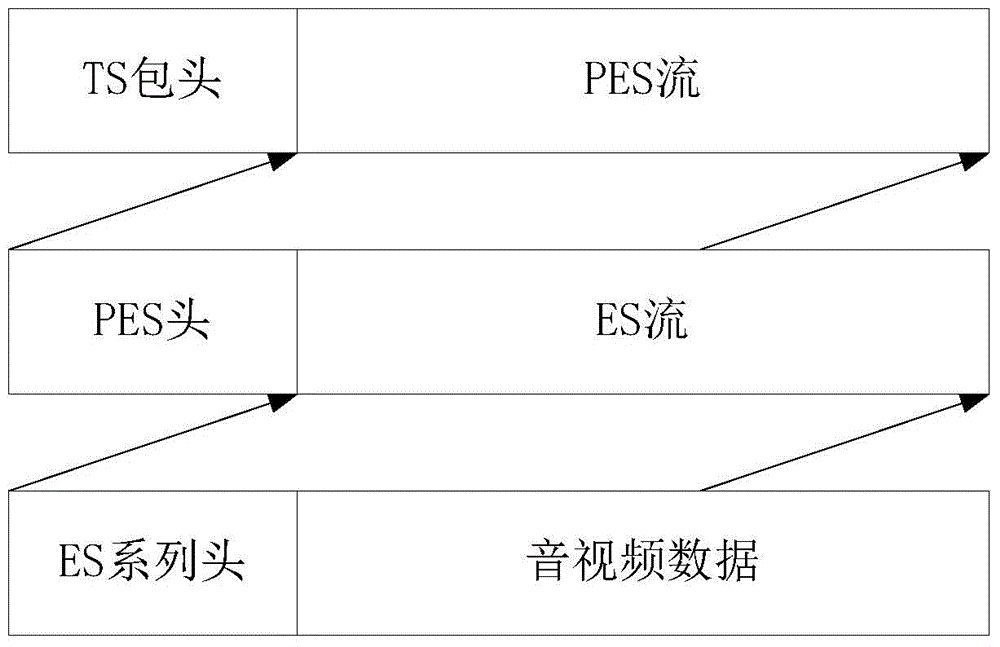

Audio and video synchronization device and method based on HLS protocol

ActiveCN103648011ASolve the retentionOutput synchronizationSelective content distributionComputer hardwareTimestamp

The invention provides an audio and video synchronization device and method based on an HLS protocol. The method comprises: after receiving a synchronization request, adding a synchronization mark to audio and video data obtained first; demultiplexing the audio and video data into audio data and video data, and updating timestamps of the audio data and / or video data based on the synchronization mark; decoding the audio data and video data and outputting an audio signal to be played and a video signal to be played; detecting whether the timestamps carried in the audio signal to be played and the video signal to be played are consistent, and sending the synchronization request when the timestamps carried in the audio signal to be played and the video signal to be played are not consistent; and controlling the audio signal to be played and the video signal to be played to be output synchronously based on the synchronization mark. Through the technical scheme in the invention, the problem of picture or sound retention due to continuous nonsynchronization of the audio and video is solved.

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

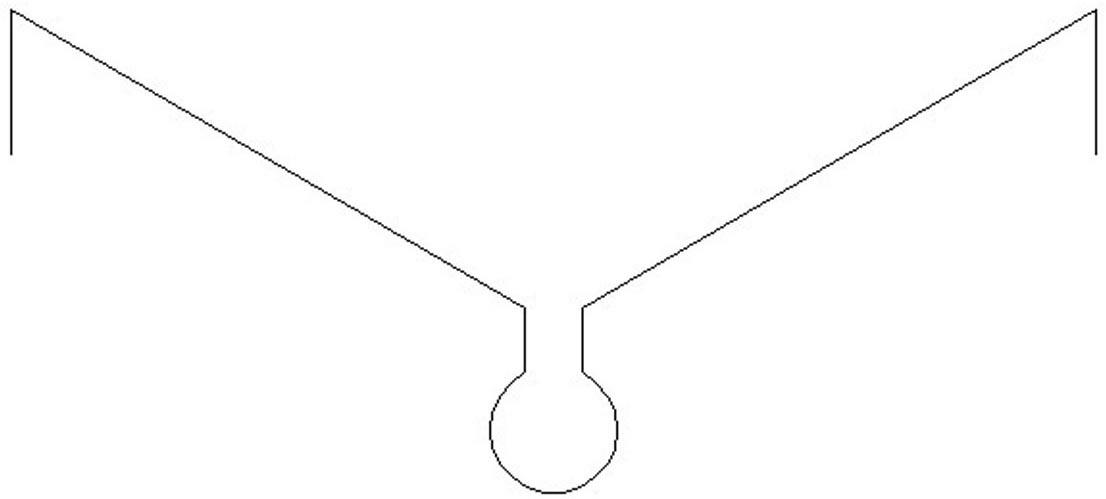

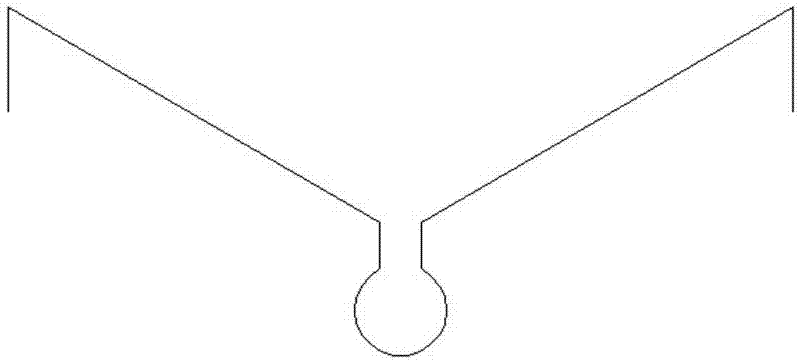

Seaming method of underground diaphragm wall

ActiveCN102155010AThe sinking position is accurateEasy to pull outBulkheads/pilesSlurry wallDevice form

The invention relates to underground buildings, in particular relates to a seaming method of an underground diaphragm wall. The method comprises the following steps that: an approximately V-shaped platy structure is mounted at the seam crossing of unit walls; hinge pipes are arranged at the top end of the V-shaped platy structure so as to realize a guide function; corresponding guide rollers are matched for guiding when a wall brushing device is used for cleaning, and enabling the wall brushing device to vertically brush the wall along a guide device formed by the hinge pipes, thereby ensuring mud brushing effect and greatly reducing the working load of leak prevention; or the corresponding guide rollers are also can be used for the guide device when locking notch tubes are submerged so as to ensure the accurate submergence position of the locking notch tubes and improve the working efficiency and the project quality; simultaneously, due to the presence of wing plates and flanged parts, the contact surface of the firstly-cast groove section has continuous and smooth planes except the local openings of the hinge pipes; therefore, the surface of the firstly-cast groove section is conveniently cleaned and brushed; and the locking notch tubes are conveniently pulled. According to the method of the invention, the problems of retention of the contact surface of the firstly-cast groove section or difficult clamped mud cleaning and brushing are excellently solved so that the seam crossing is closer; and the leakage in the seam is prevented.

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

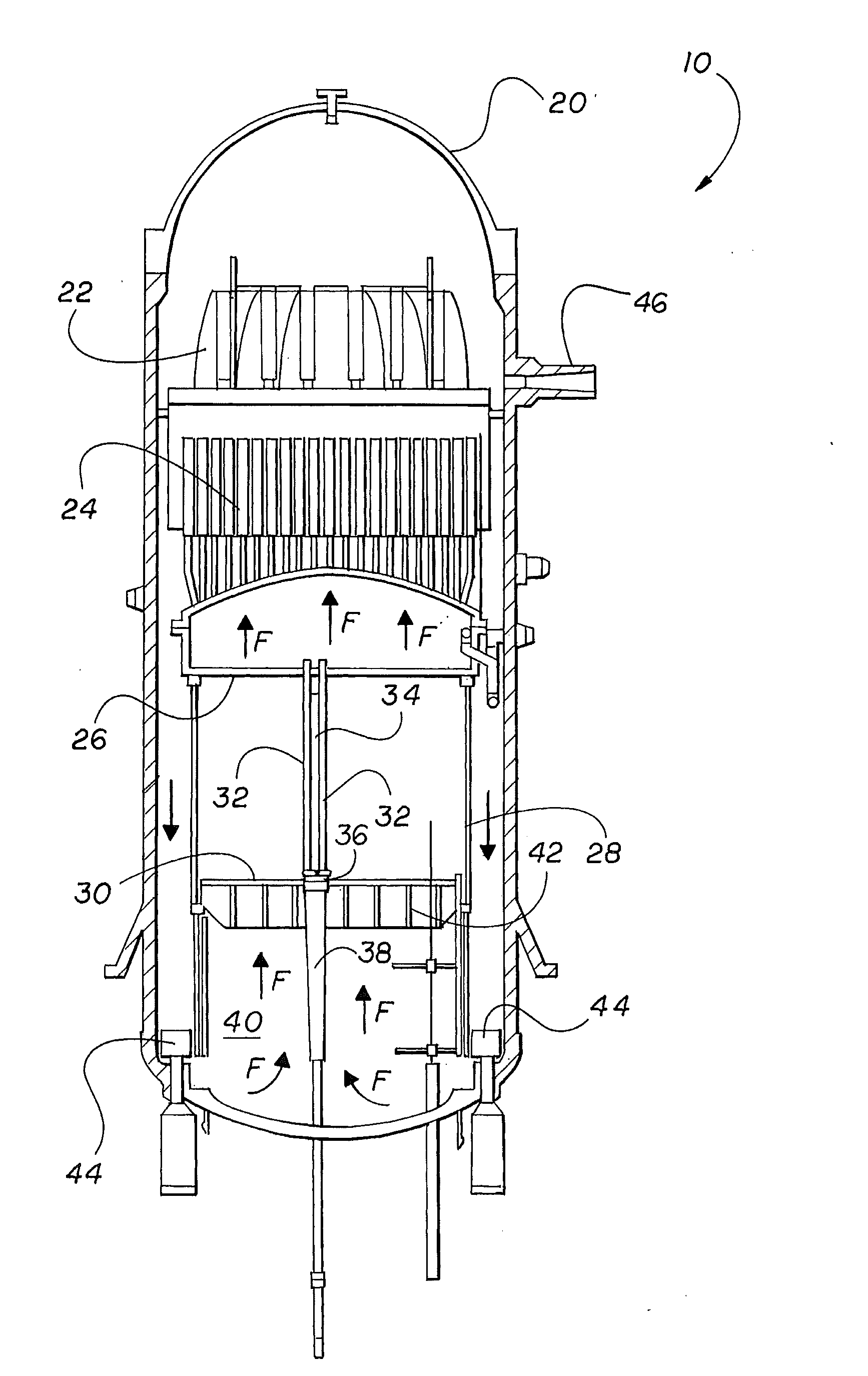

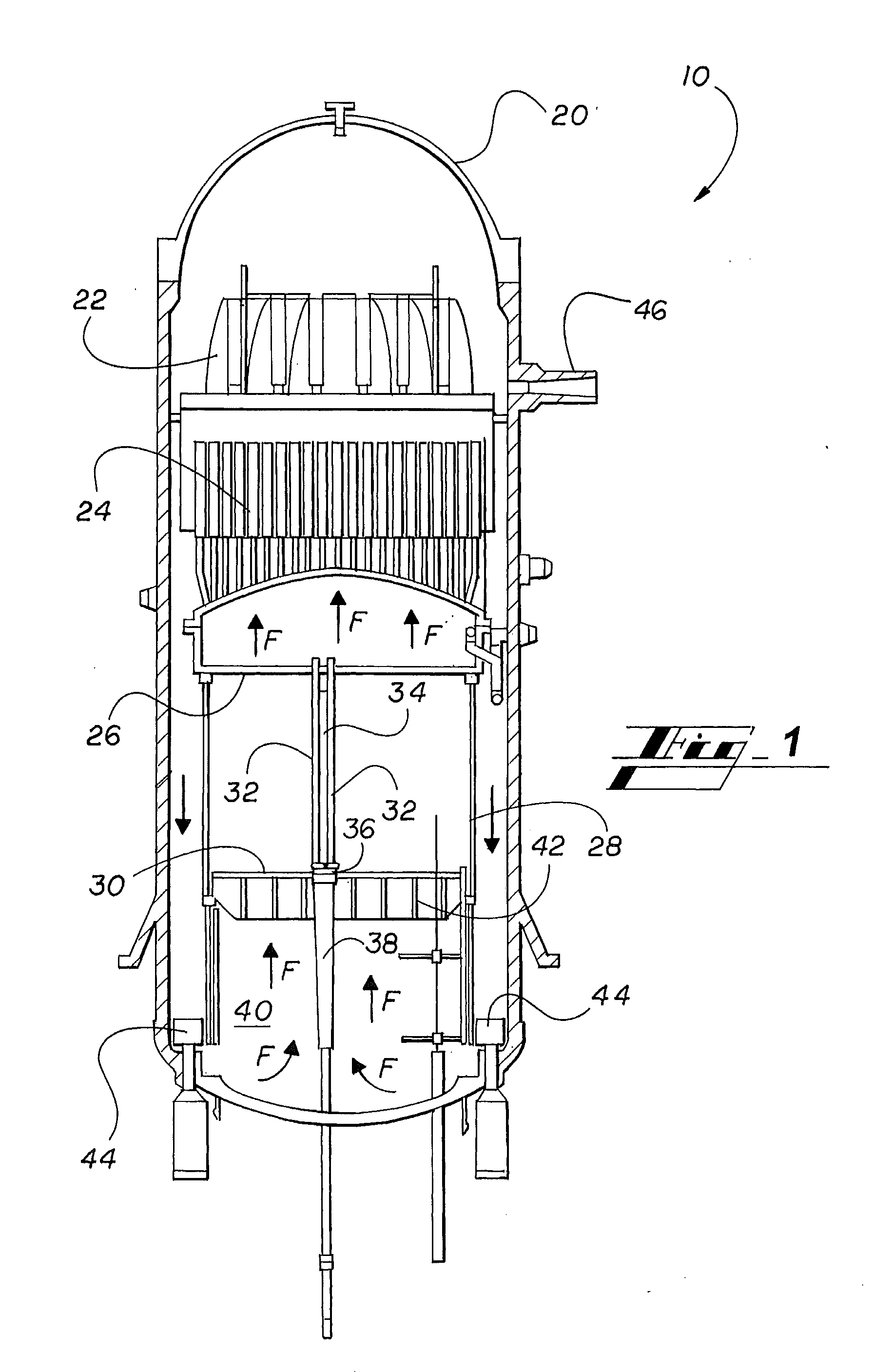

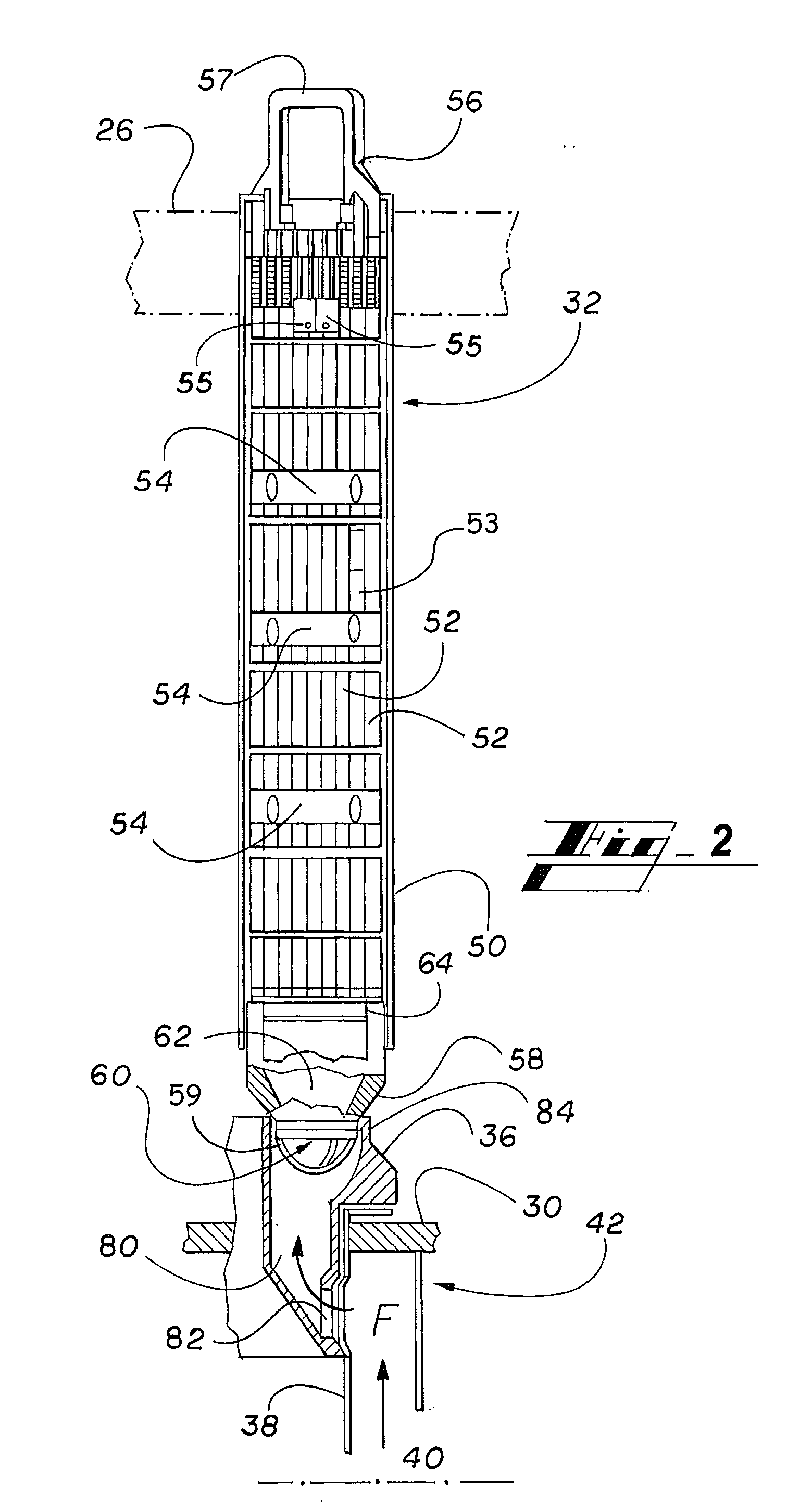

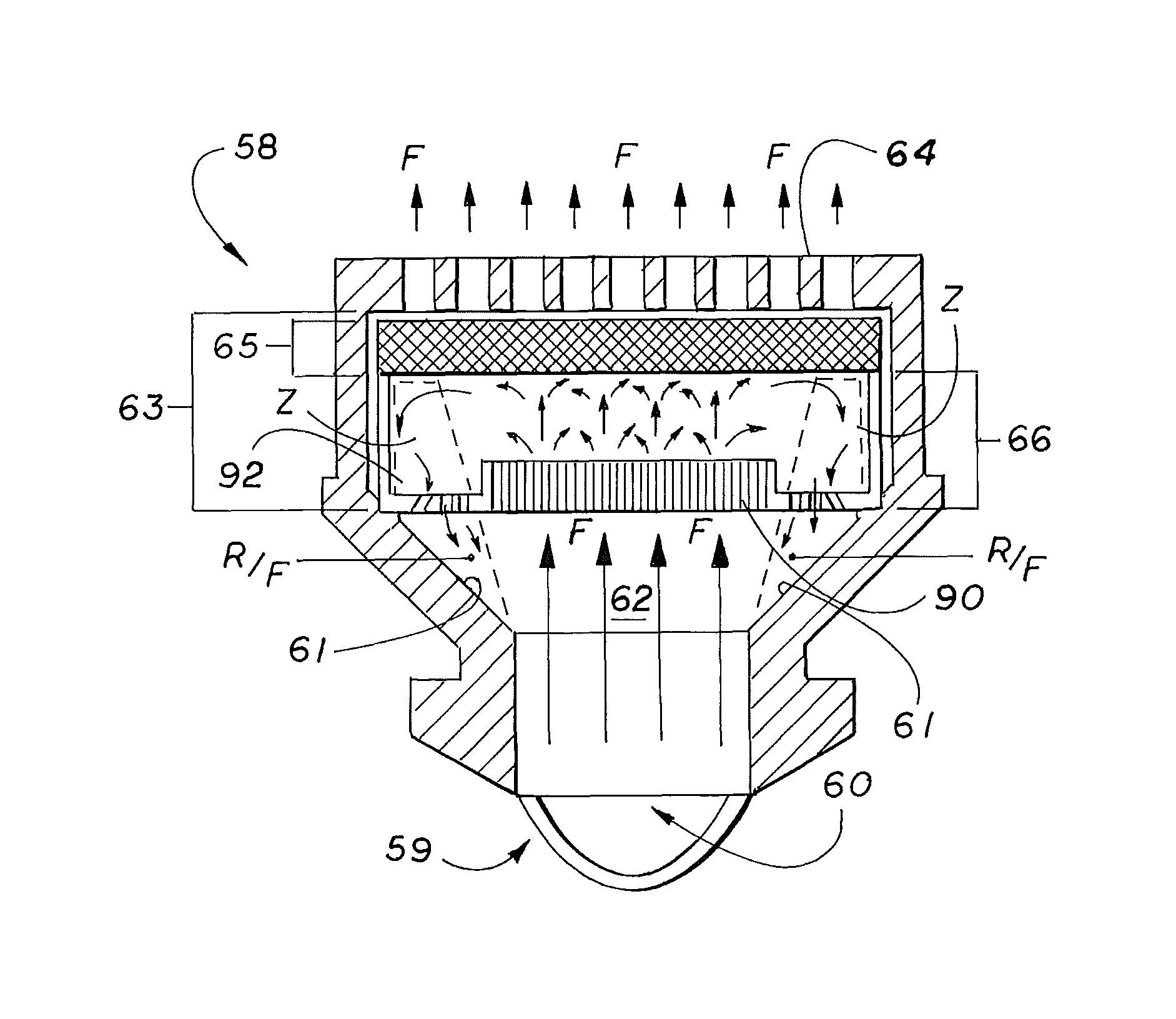

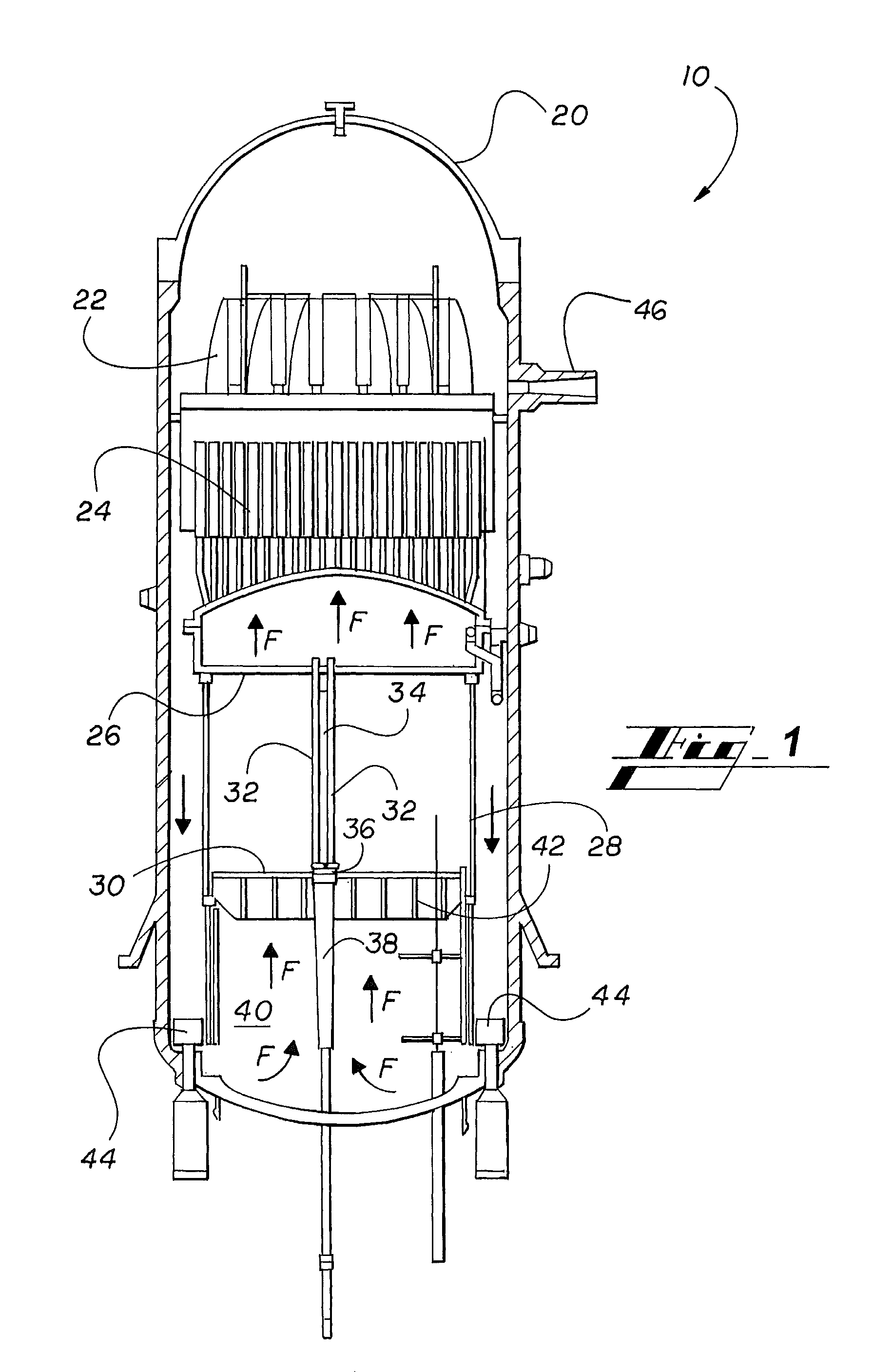

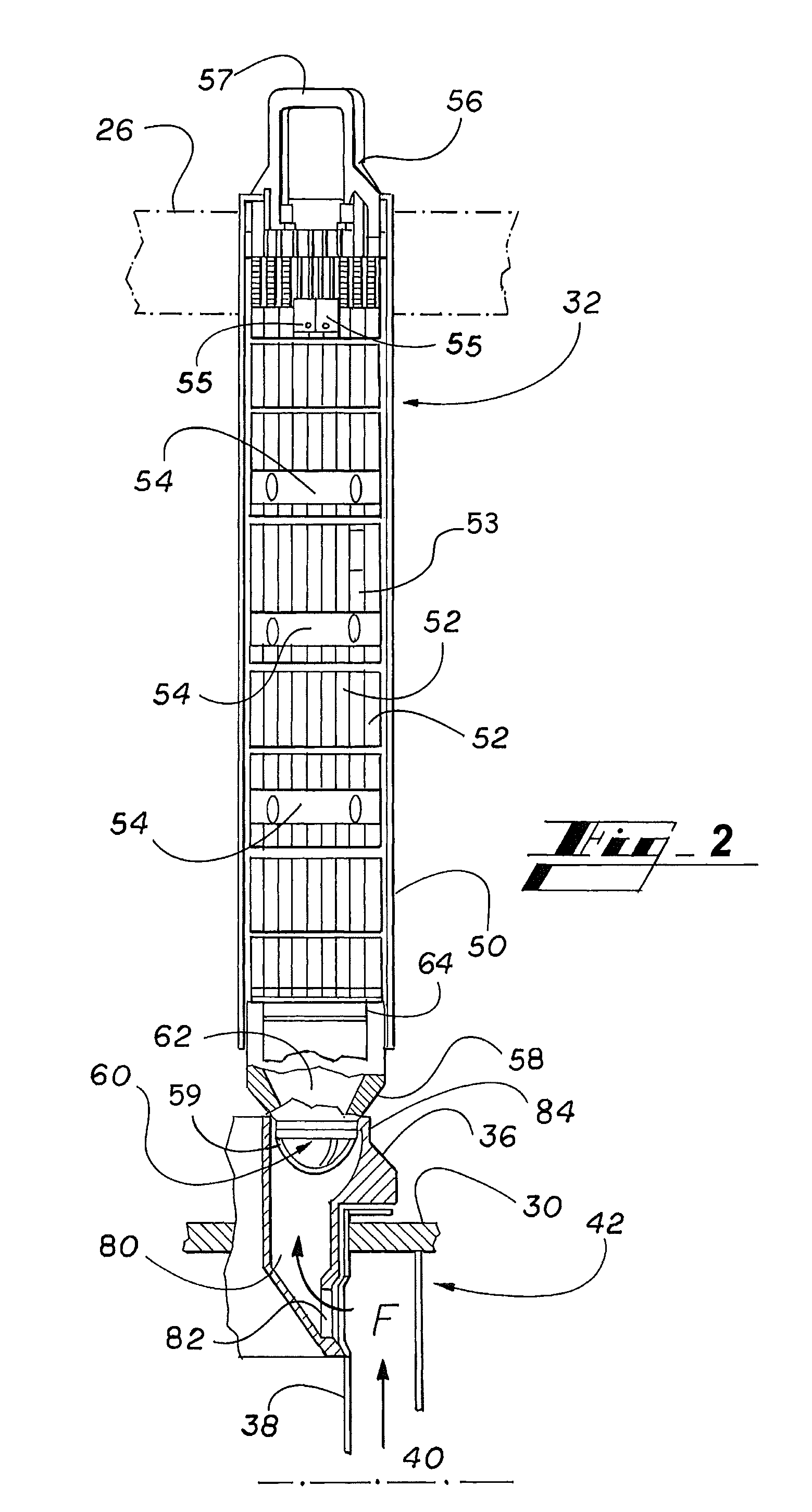

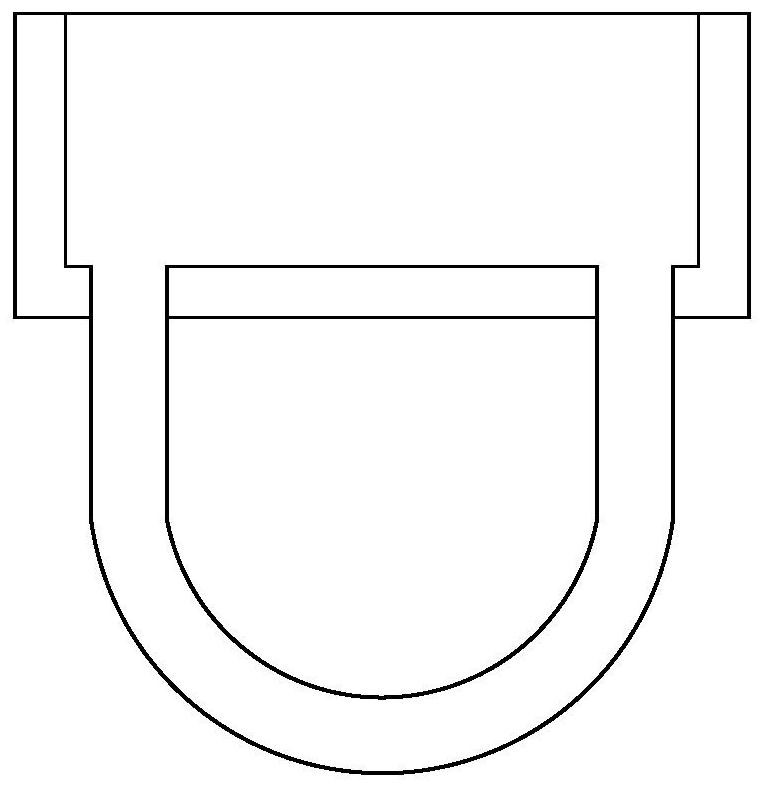

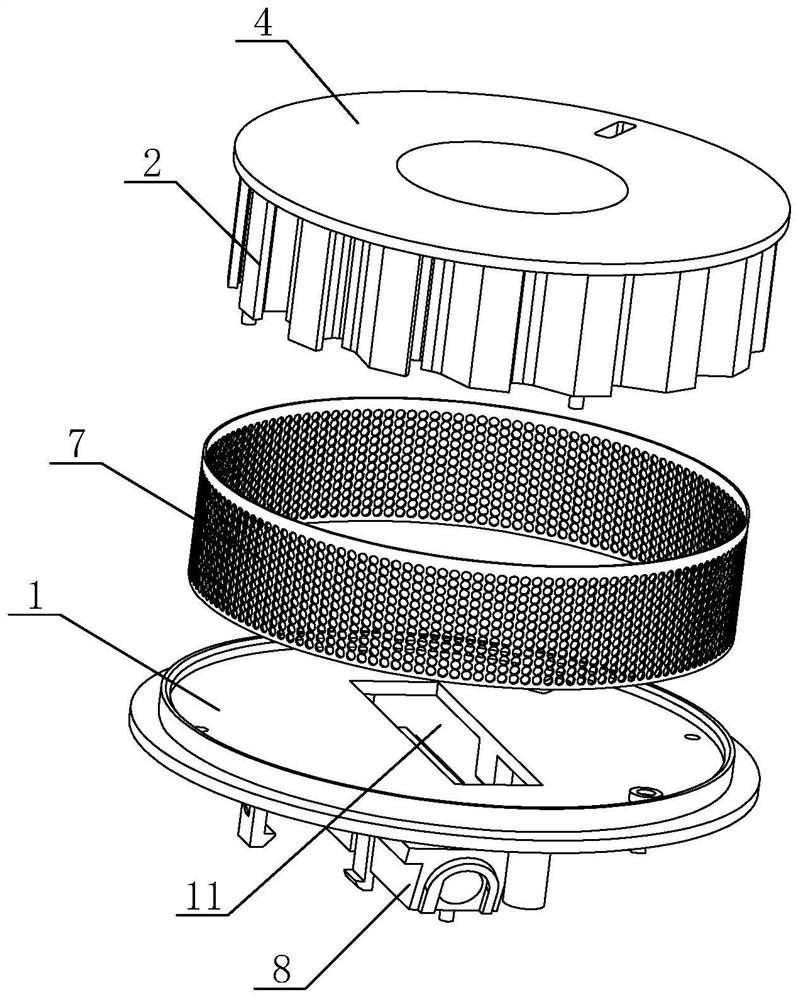

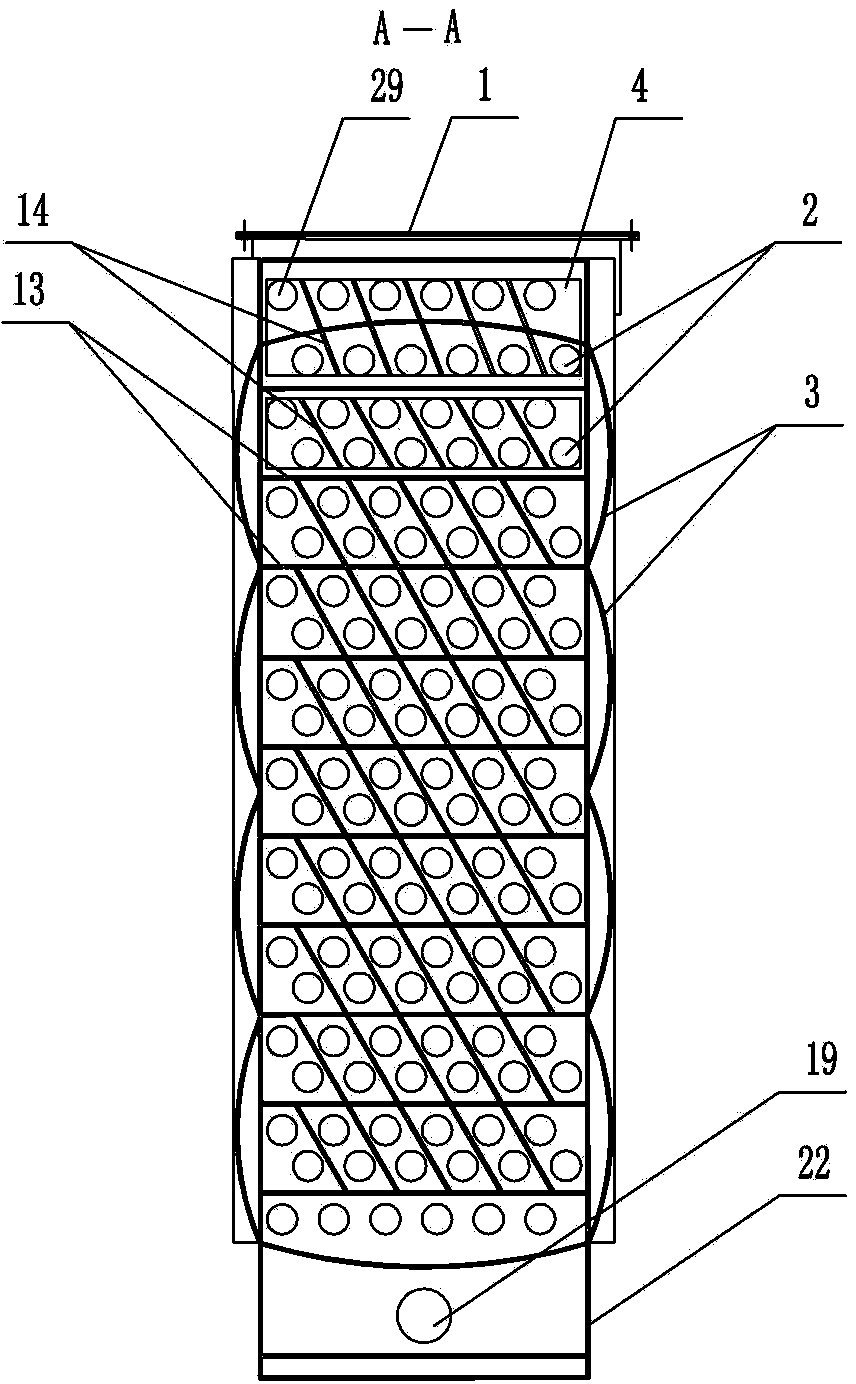

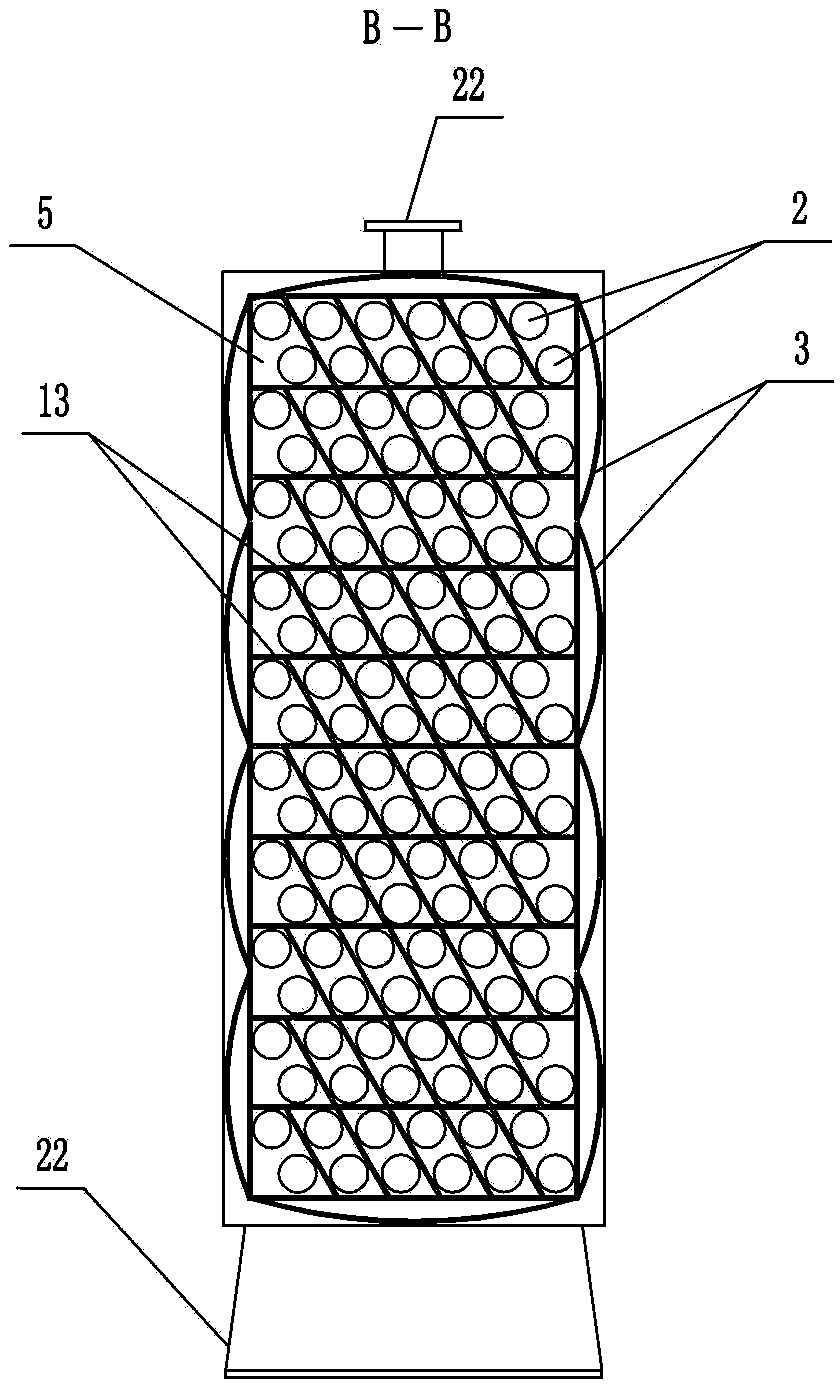

Debris Exclusion and Retention Device for a Fuel Assembly

ActiveUS20120207262A1Mitigating undesirable levelMinimal impact on the pressure drop in the coreNuclear energy generationFuel element assembliesPoint of entryEngineering

A debris exclusion and retention device traps and retains foreign material within the lower tie plate of the fuel assembly utilizing the existing flow paths within the lower tie plate, and without redirecting coolant flow. Flow through the inlet nozzle of the lower tie plate into an enlarged lower tie plate housing creates strong jet impingement against the center of the lower tie plate grid or debris filter, if present, which has a tendency to push debris to the periphery of the lower tie plate. Low flow zones around the periphery of the lower tie plate allow debris to fall back toward the inlet nozzle. The retention device traps and retains debris in these low flow zones without impacting existing flow patterns in the lower tie plate. Thus, the retention device has minimal or no impact on lower tie plate pressure drop.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

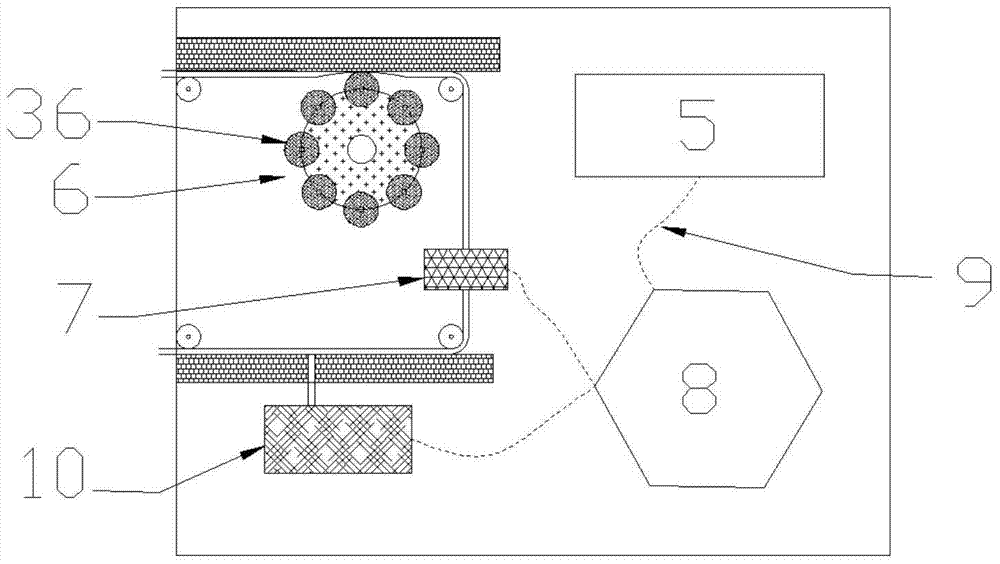

Rotary cleaning device for production of roller shaft seat and one-way wheel of fax machine

ActiveCN107755313AChange direction of rotationAchieve cleaning effectCleaning using toolsDrive wheelGear wheel

The invention discloses a rotary cleaning device for production of a roller shaft seat and a one-way wheel of a fax machine. The rotary cleaning device comprises supporting legs, wherein a support table is fixedly connected to the top of the supporting legs; a first support rod is fixedly connected to the lower surface of the support table; a first motor is fixedly connected to the middle of the first support rod; an output shaft of the first motor is fixedly connected with a first rotating shaft through a coupling; and a driving wheel is fixedly connected to the surface of the first rotatingshaft. According to the rotary cleaning device for production of the roller shaft seat and the one-way wheel of the fax machine, the effect of cleaning the surfaces of the roller shaft seat and the one-way wheel is achieved; a second rotating shaft and a third rotating shaft rotate to drive cleaning brushes to scrub and clean the surfaces of the roller shaft seat and the one-way wheel; meanwhile,as the outer surface of a driven gear meshes with that of a driving gear, the rotating direction of the third rotating shaft can be changed, swirling is prevented, and accordingly, the problem that acommon roller shaft seat and one-way wheel cleaning device has high probability of causing retention of oil dirt and impurities is effectively solved.

Owner:佛山市常捷粉末冶金科技有限公司

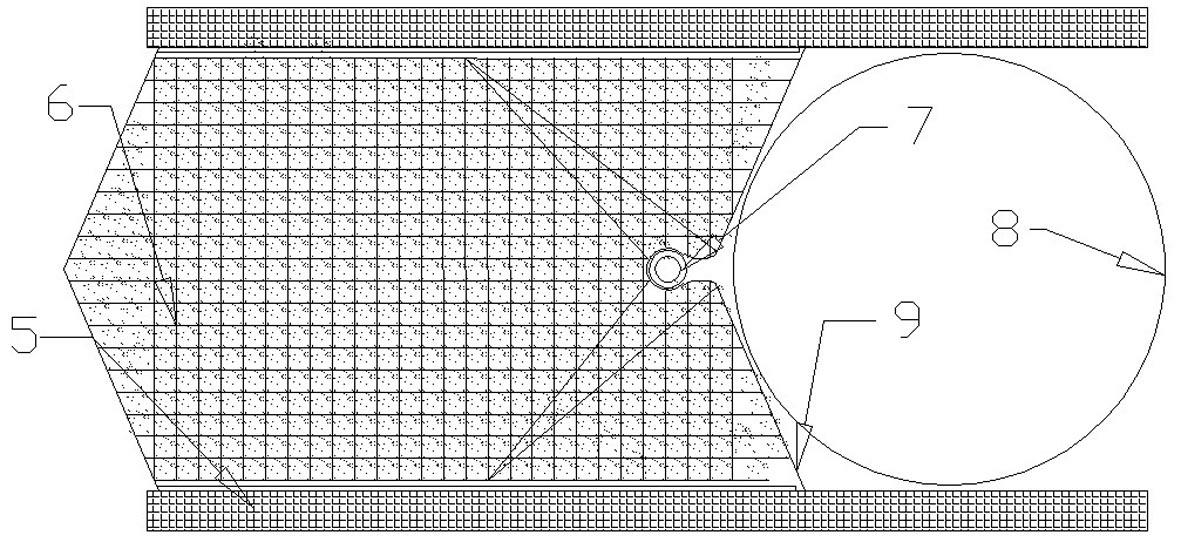

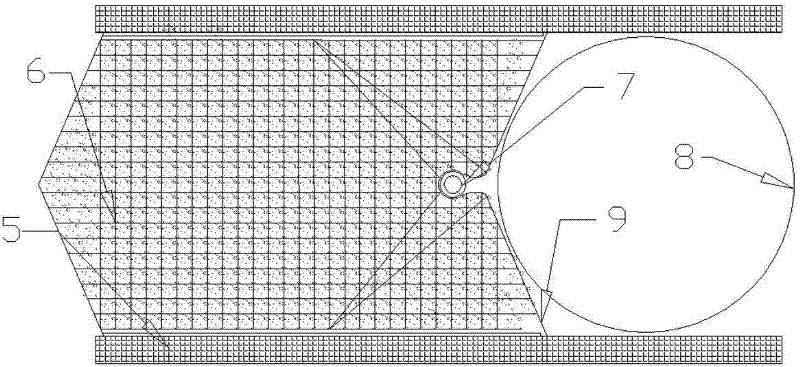

Anode with gas exhausting hole for aluminum electrolysis

InactiveCN101348923ASolve the retentionLower resistanceElectricityElectrical resistance and conductance

An anode with an exhaust hole used for aluminium electrolysis relates to an anode block used for aluminium electrolysis. The anode block comprises the structure that the anode block is provided with an exhaust hole; the exhaust hole can be a through hole, a vertical through hole or an oblique through hole forming an angle with a vertical line; moreover, the exhaust hole can also be a semi through hole which does not reach an anode bottom, and the distance between the bottom of the semi through hole and the bottom of the anode bottom is between 1 and 30 centimeters; and a high temperature-resistant antioxidizing nonmetallic pipeline or a metal pipeline is arranged above the exhaust hole. The anode block has the advantages that the anode block can effectively solve the problem of retention of gas bubbles accumulated on the anode bottom, and ensure that gas bubbles under the anode bottom can be smoothly discharged outside a cell, thereby reducing cell resistance and preventing the generation of effect; moreover, the anode block reduces both set voltage and working voltage of an electrolytic cell so as to reduce electricity consumption, thereby saving 60 to 150KWH of electricity when manufacturing one ton of aluminum ingot.

Owner:秦晓明

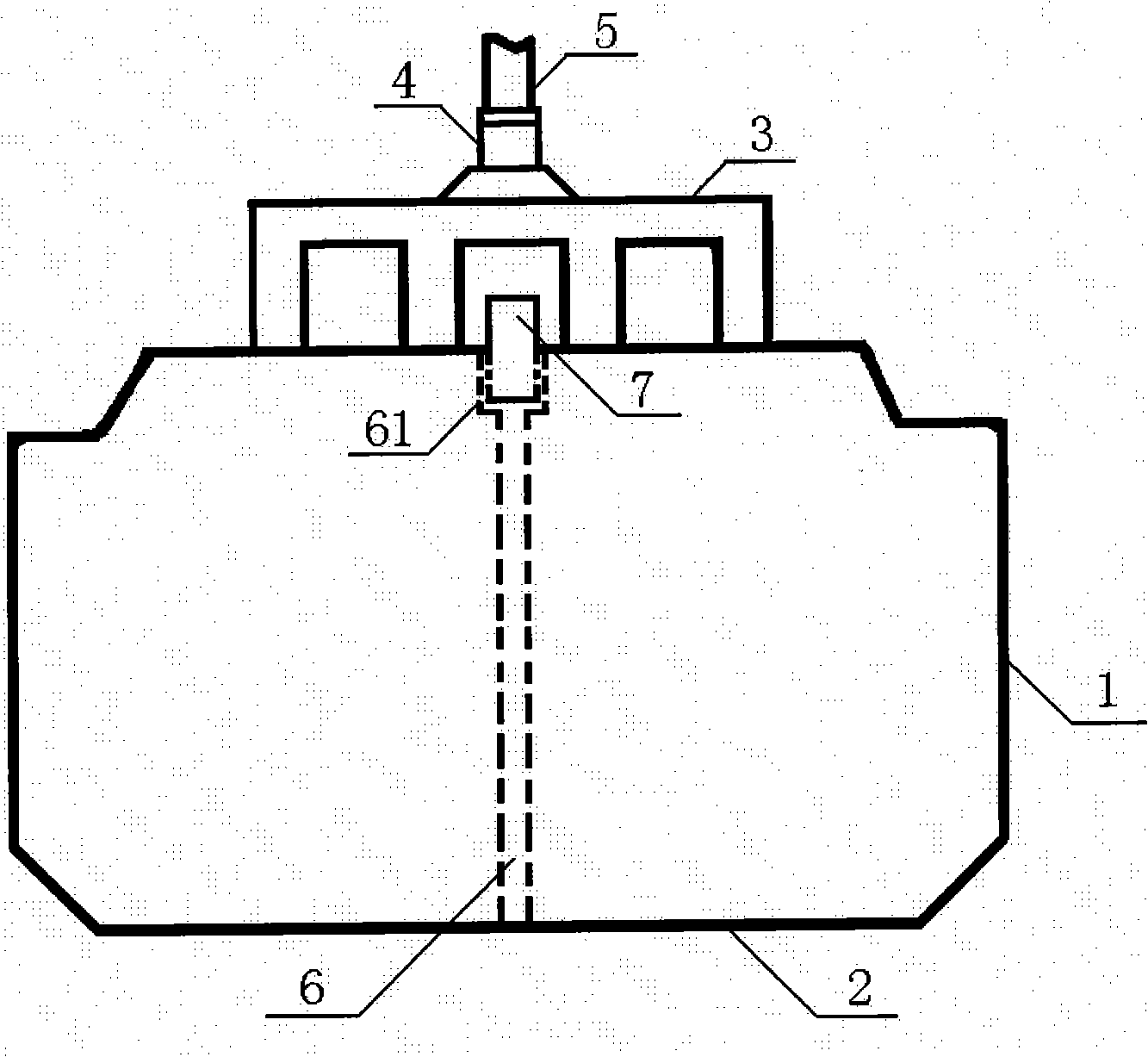

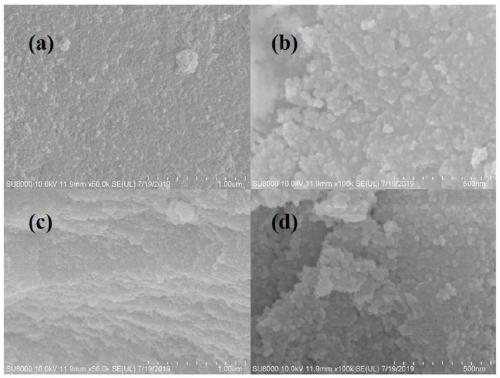

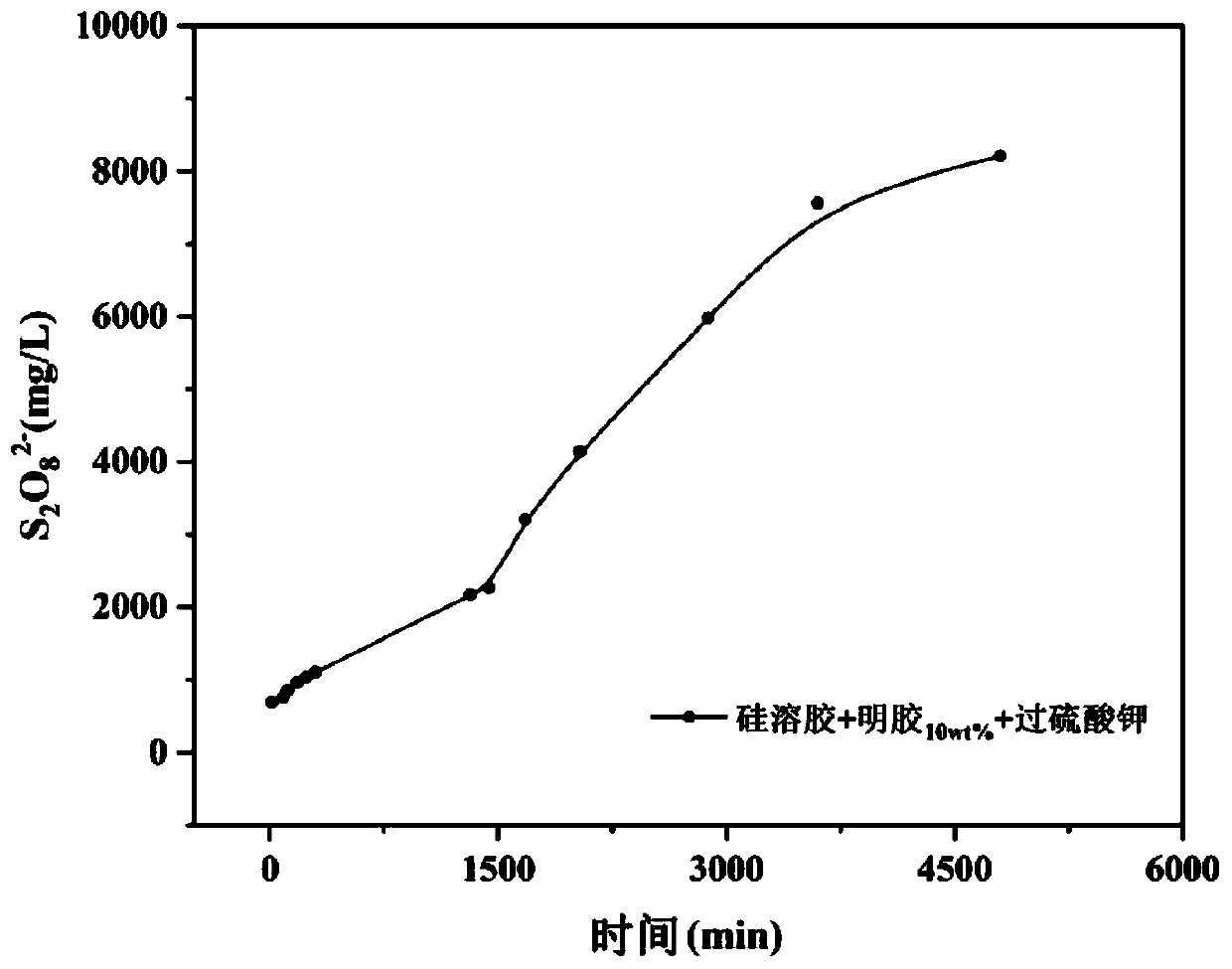

Persulfate gel slow-release agent as well as preparation method and application thereof

ActiveCN111547832ASolve the retentionEasy to wrapWater contaminantsContaminated groundwater/leachate treatmentCross linkerEnvironmental engineering

The invention discloses a persulfate gel slow-release agent. A gelatin-silica sol composite gel system is used as a coating material, persulfate is used as an inner core, and the persulfate gel slow-release agent comprises the following components in percentage by mass: 20%-40% of alkaline silica sol, 1.25%-5% of an oxidizing agent, 2%-15% of gelatin, 0.2%-1% of a cross-linking agent and 0.1%-1%of an emulsifying agent, wherein the volume ratio of gelatin to alkaline silica sol is 1: (3-6). The invention also discloses a preparation method of the persulfate gel slow-release agent and application of the persulfate gel slow-release agent in degradation of organic pollutants in underground water. According to the invention, the low-viscosity liquid can be directly injected into the aquifer,and a gel state with a slow release function is gradually formed in the migration process of the aquifer, so that persulfate is continuously released to repair organic pollutants in underground water.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

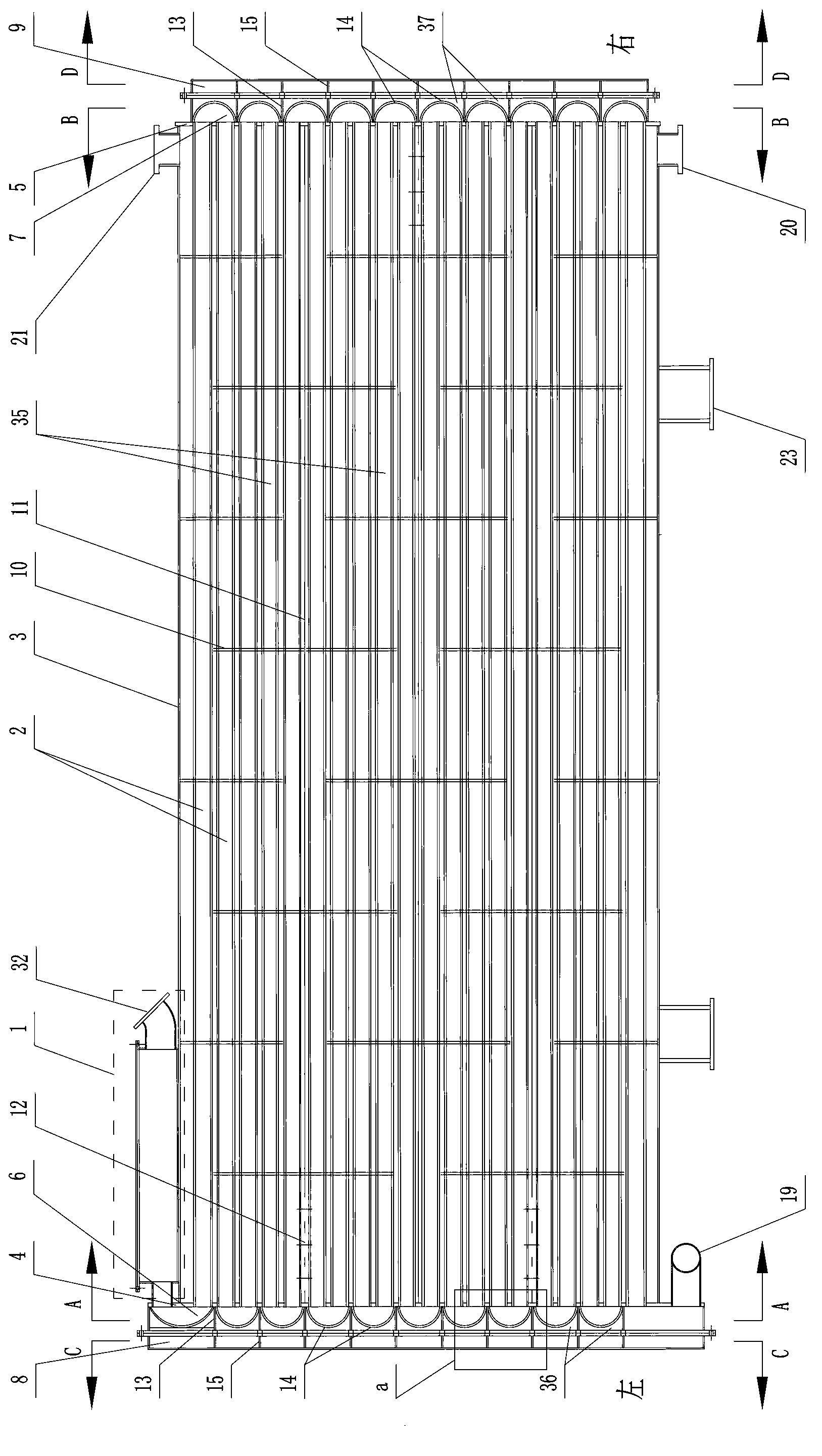

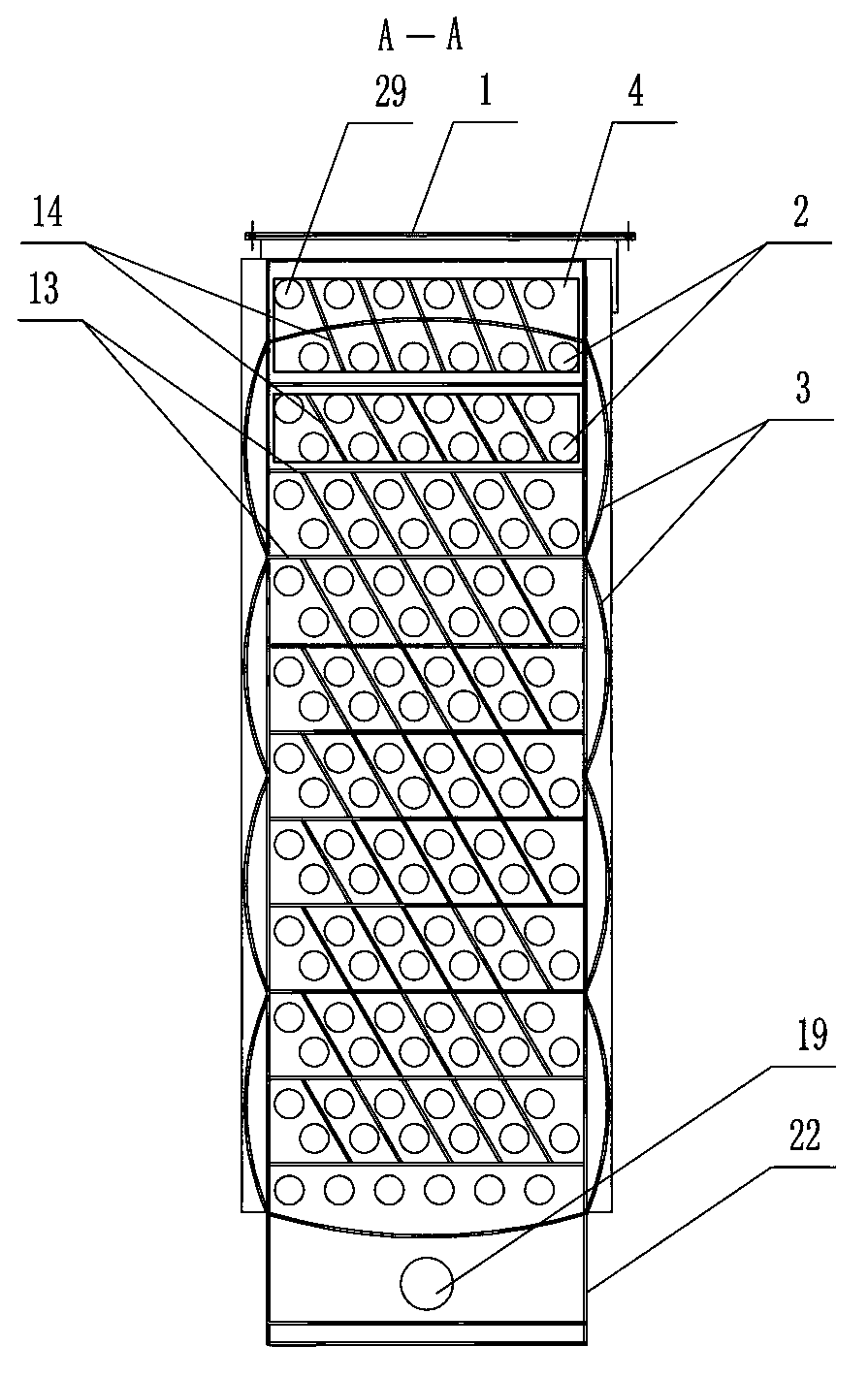

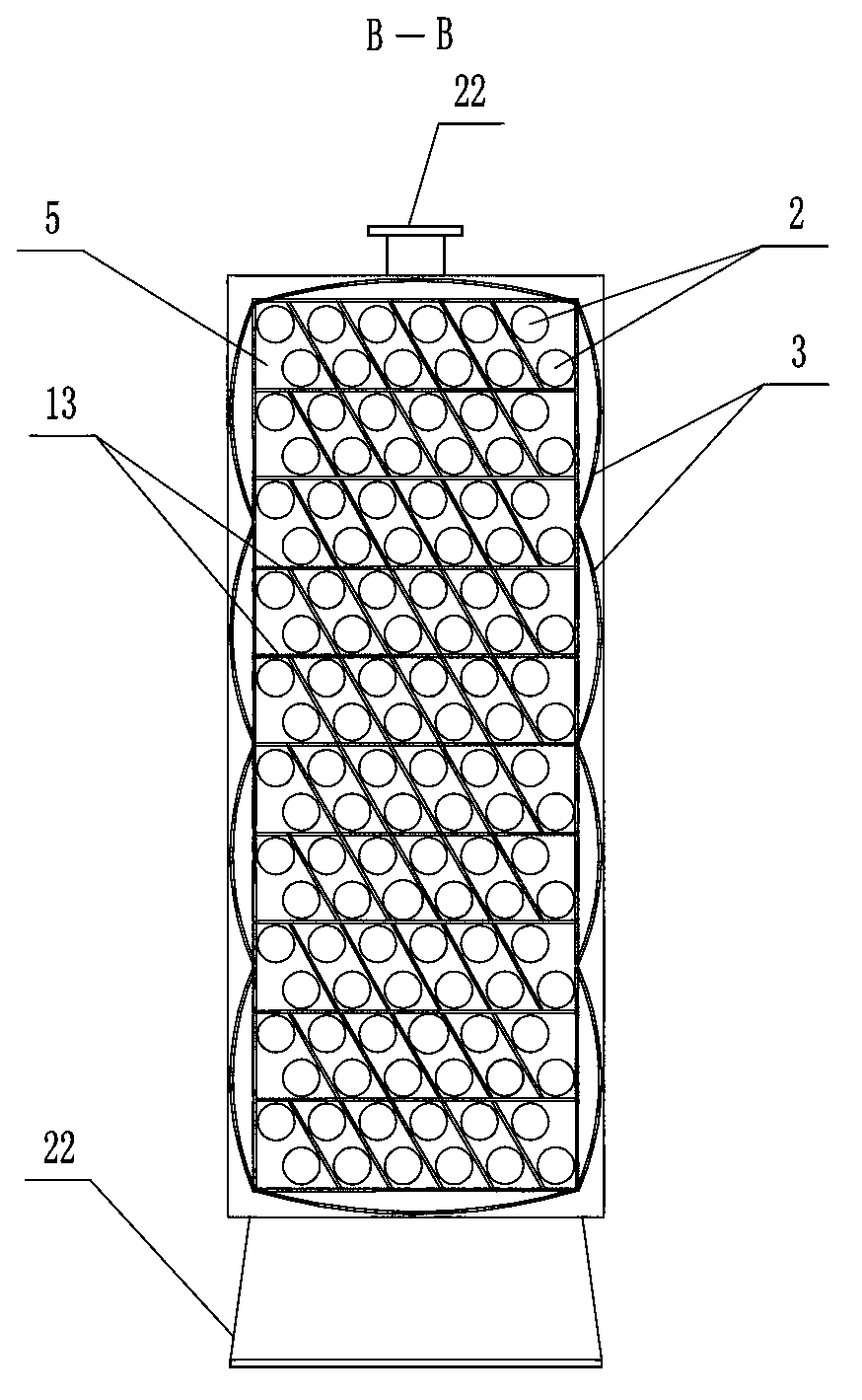

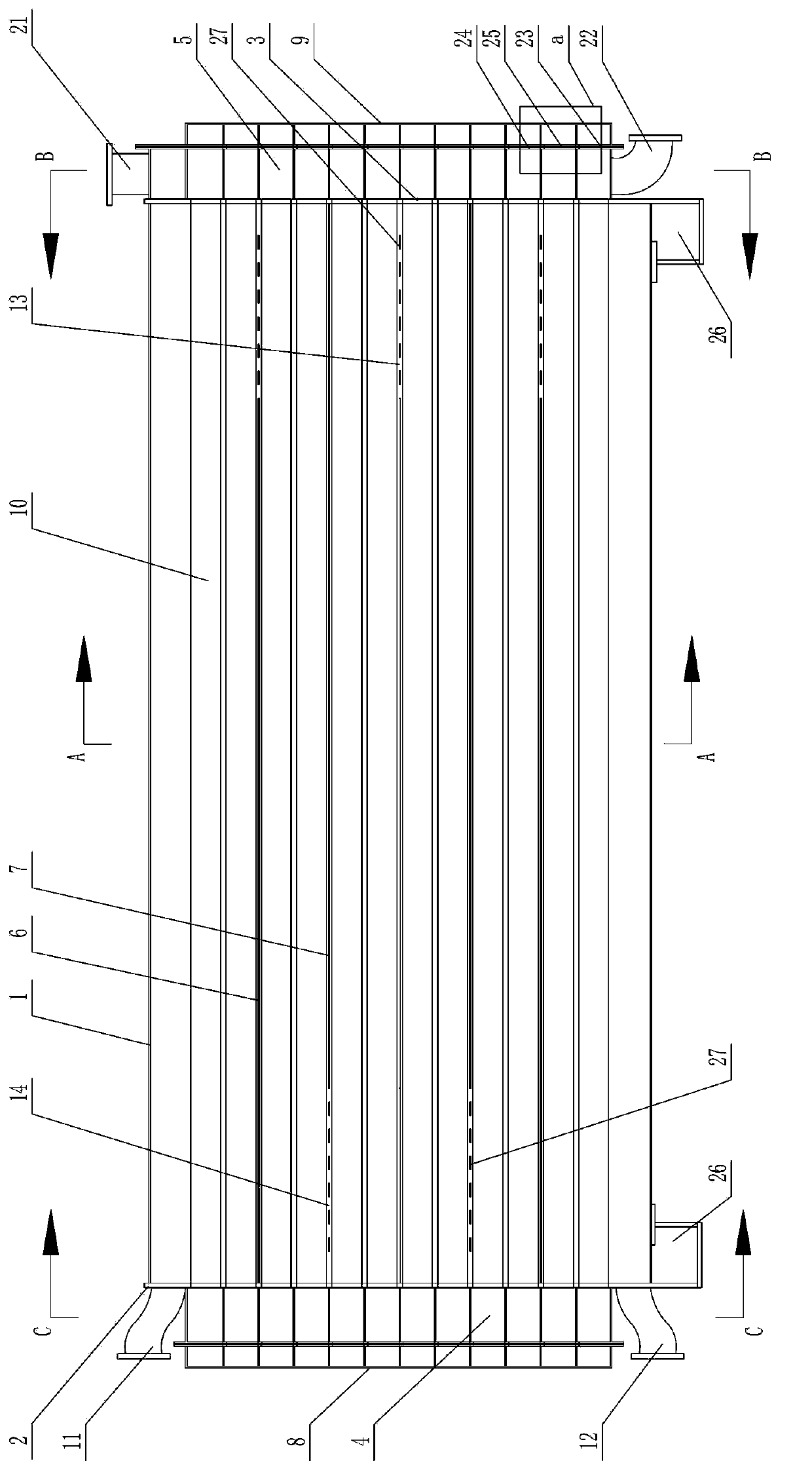

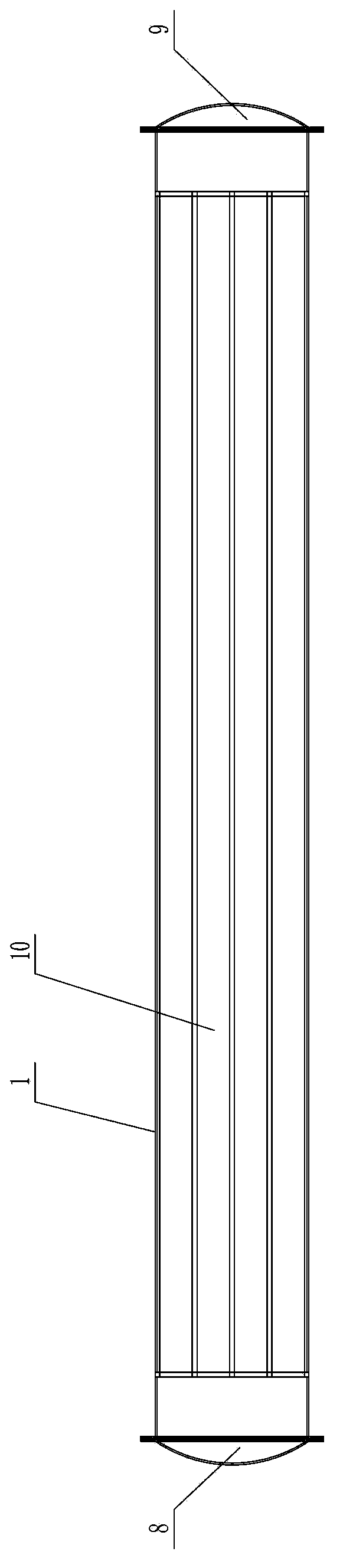

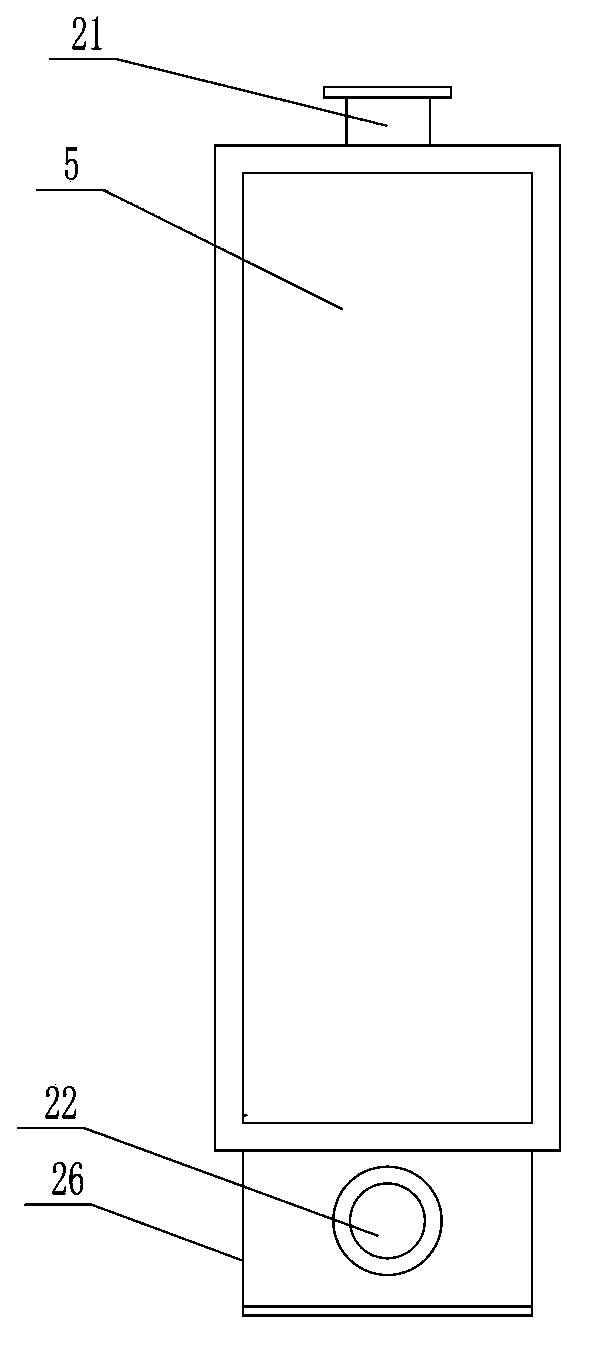

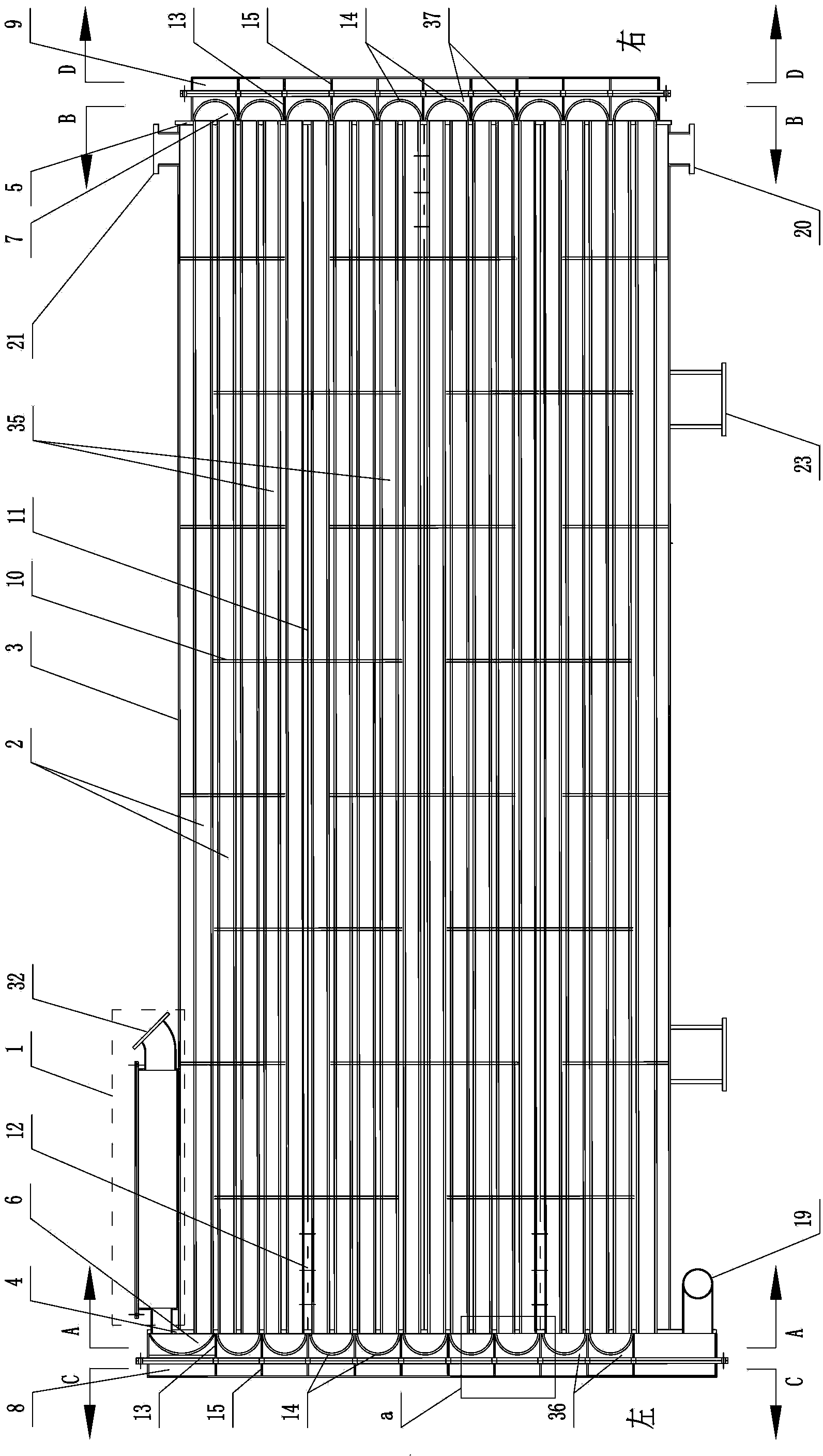

Forcible dredging type tubular heat exchange device for sewage or surface water

ActiveCN103063063AAchieve non-cloggingHeat exchange without clogging and high efficiencyHeat exchanger casingsStationary tubular conduit assembliesWater leakageEngineering

Owner:青岛科创蓝新能源股份有限公司

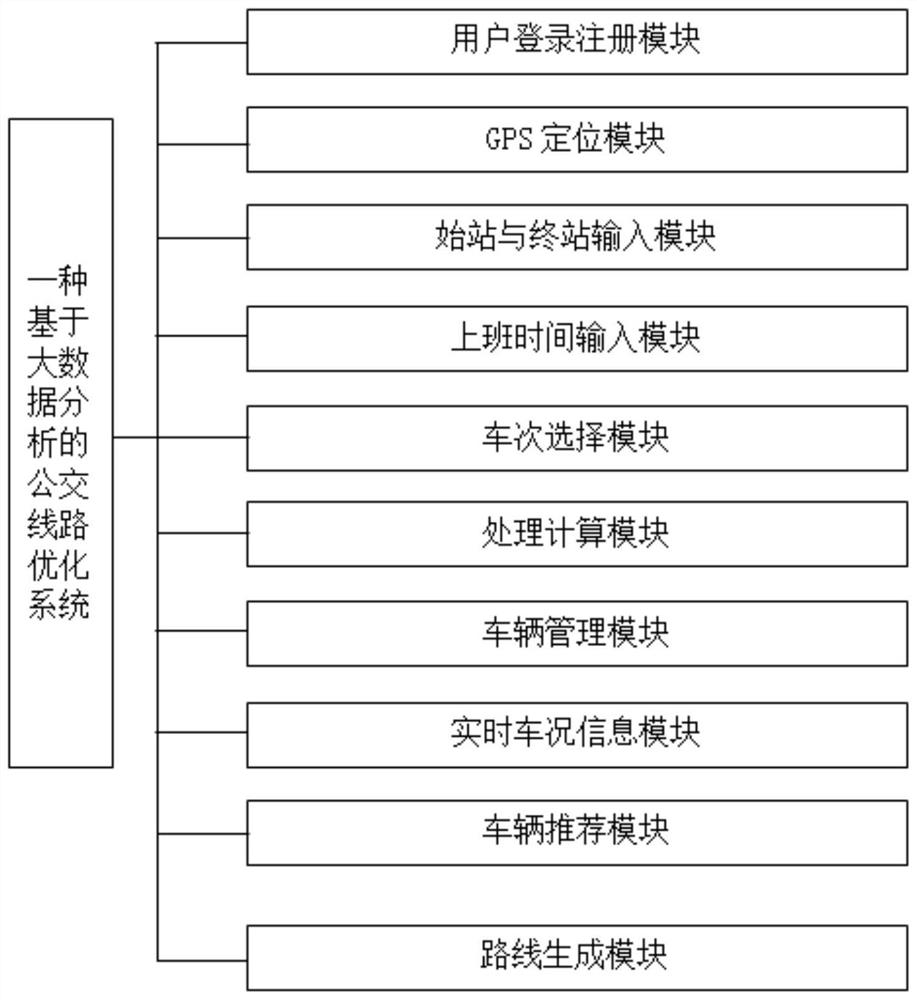

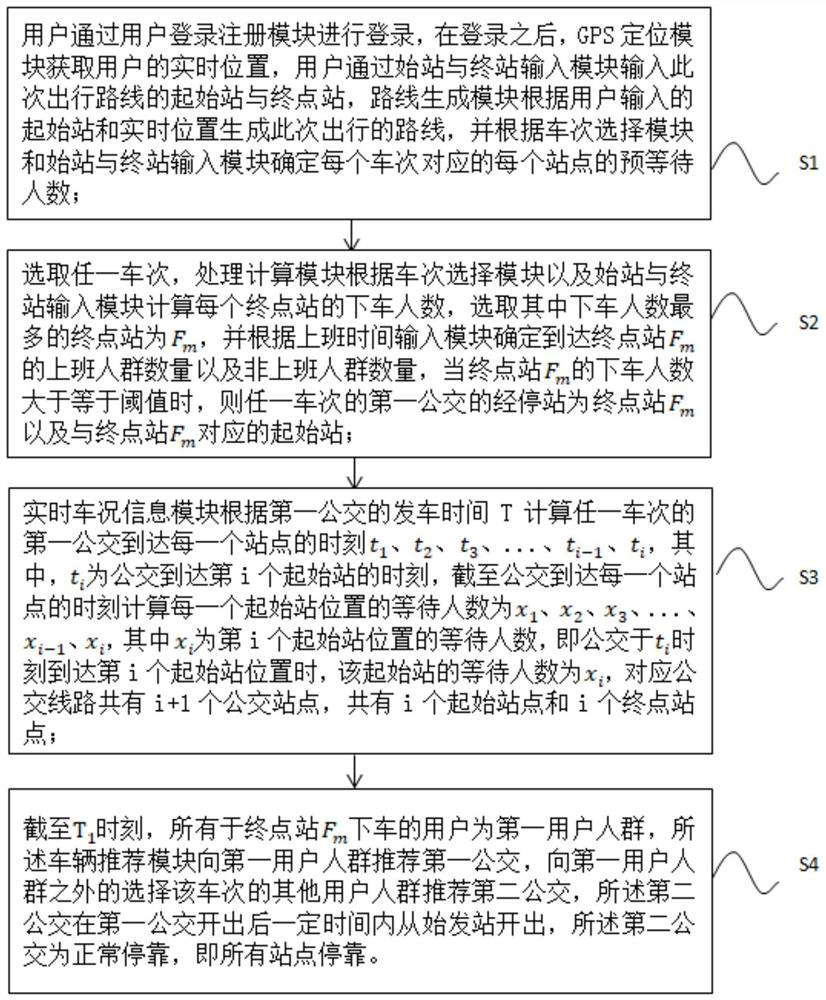

Bus route optimization system and method based on big data analysis

ActiveCN112465177AReduce the number of stopsSolve the retentionInternal combustion piston enginesReservationsOffice workersTransit bus

The invention discloses a bus route optimization system and method based on big data analysis, and the system comprises a user login registration module, a GPS positioning module, an initial station and final station input module, an on-duty time input module, a bus number selection module, a processing calculation module, a bus management module, a real-time bus condition information module, a bus recommendation module, and a route generation module. The beneficial effects of the invention are that the method carries out the batch passenger transportation according to the number of users in each work time period, achieves the substation parking, solves a problem that the number of passengers in a work peak period is large and the departure frequency is not enough to meet the demands of passengers, the problem that office workers are late due to the fact that the current vehicle is full and waits for the next vehicle takes a lot of time is solved. According to the method, two continuous stations of which the average daily number of users is smaller than the threshold are cancelled, and a new station is arranged between the two stations, so that the bus stop frequency is reduced, and the service quality is improved.

Owner:SUZHOU YUDESHUI ELECTRIC TECH CO LTD

Debris exclusion and retention device for a fuel assembly

ActiveUS8611488B2Mitigating undesirable levelMinimal impact on the pressure drop in the coreNuclear energy generationFuel element assembliesForeign matterPlate pressure

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

Underground Diaphragm Wall Hinged Joints

InactiveCN102296635AThe sinking position is accurateEasy to pull outArtificial islandsUnderwater structuresSlurry wallExact location

The invention relates to underground buildings, in particular to a hinged joint of an underground diaphragm wall, which is fixedly connected to the concave end of the reinforcement cage of the diaphragm wall, and is characterized in that the joint consists of a hinged pipe, wing plates located on both sides of the hinged pipe and It is composed of a hemming part located at the edge of the wing plate. The hinged tube is approximately Ω-shaped with a partial opening. The two ends of the opening are respectively connected to the wing plate. Shaped hinged tube can be used as a guide channel for objects to be placed in the later stage. It can not only be used as a guide when cleaning the wall brusher to ensure the mud brushing effect, but also can be used as a guide device when the lock tube is placed to ensure that the lock tube The accurate sinking position improves the work efficiency and project quality; it is more convenient for cleaning the surface, and it is also convenient for the extraction of the locking pipe, which is a good solution to the problem of stagnation in the contact surface of the first pouring trough or partial mud cleaning. Problems, while making the seams tighter, can better prevent leakage.

Owner:SHANGHAI YUANFANG GROUNDWORK ENG

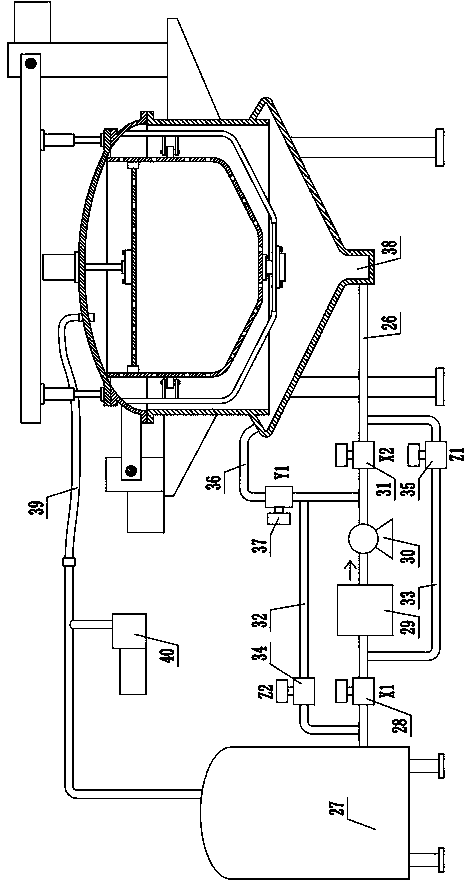

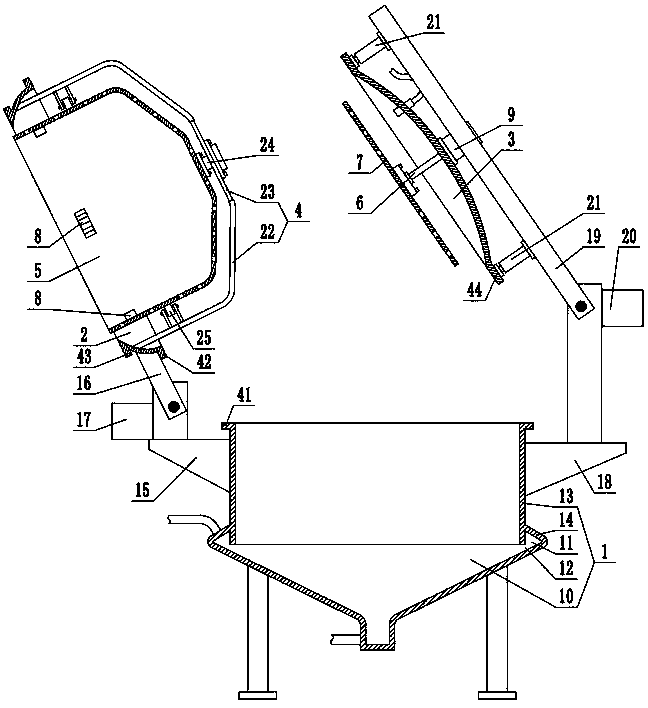

Upper driving type no-clean vacuum fryer

PendingCN111481076AGuaranteed cleanlinessSolve the retentionDeep fat fryersStructural engineeringMechanical engineering

The invention discloses an upper driving type no-clean vacuum fryer comprising a pot body, an annular pot cover pressed on the top of the pot body in a sealed mode, and a circular pot cover pressed onan opening of the annular pot cover in a sealed mode. A bracket extending into the pot body is connected to the inner wall of the annular pot cover, a frying basket with an opening in the top and located in the pot body is rotatably connected to the bracket, and a left driving mechanism capable of driving the annular pot cover to swing leftwards and upwards so as to swing the frying basket out ofthe outer side of the pot body is arranged on the outer side of the pot body; a pressing disc for driving the frying basket to rotate is mounted at the bottom of the circular pot cover; a right driving mechanism for driving the circular pot cover to lift up and down and swing towards the upper right side is arranged at the outer side part of the pot body. The vacuum fryer is simple in structure,the problems of residue retention and accumulation are solved, the residue discharging effect is improved, vacuum frying operation can be achieved, frying work and pan bottom self-cleaning work can beachieved at the same time, the cleanliness of oil in the frying process can be guaranteed, and the frying effect and the product quality are improved.

Owner:张培森

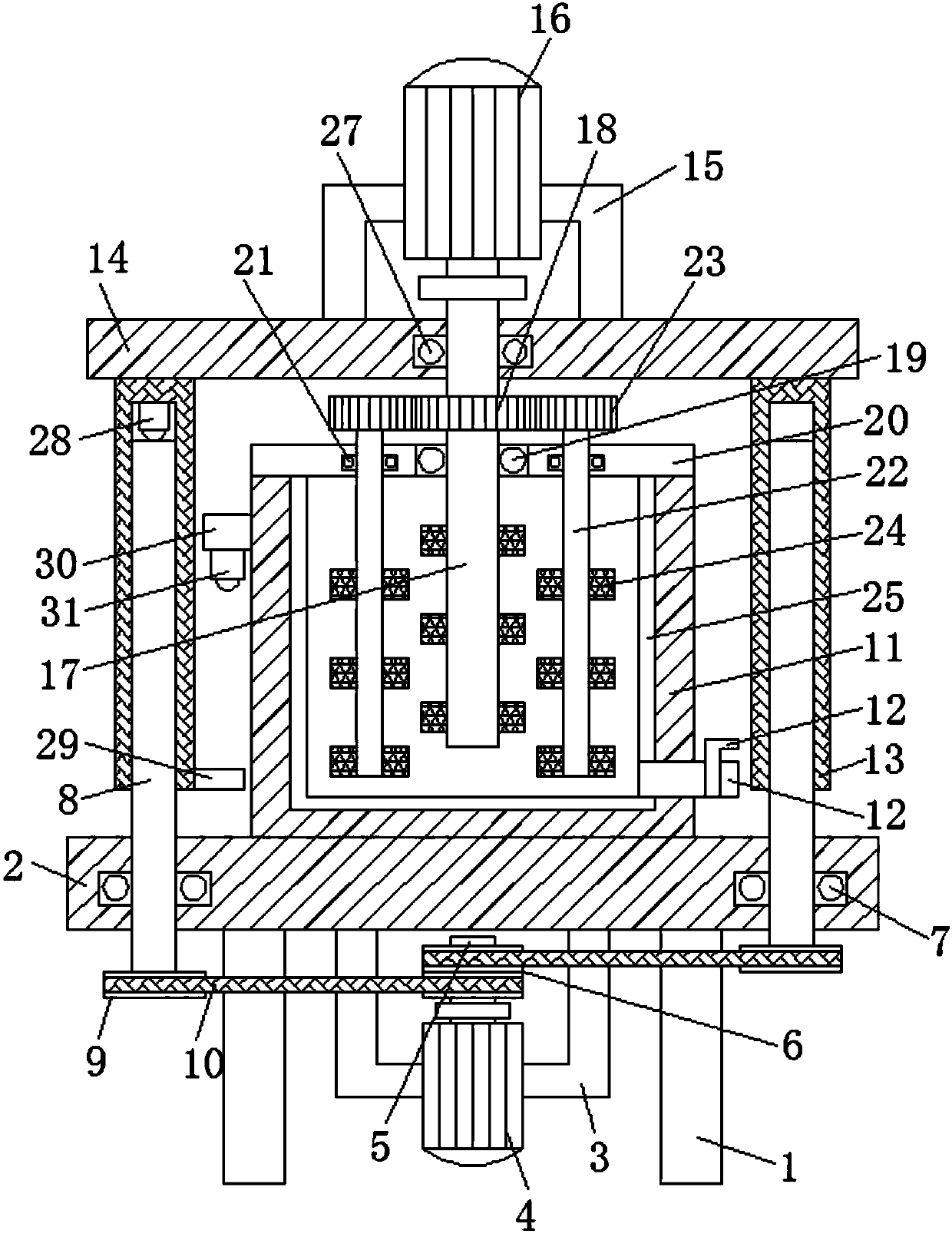

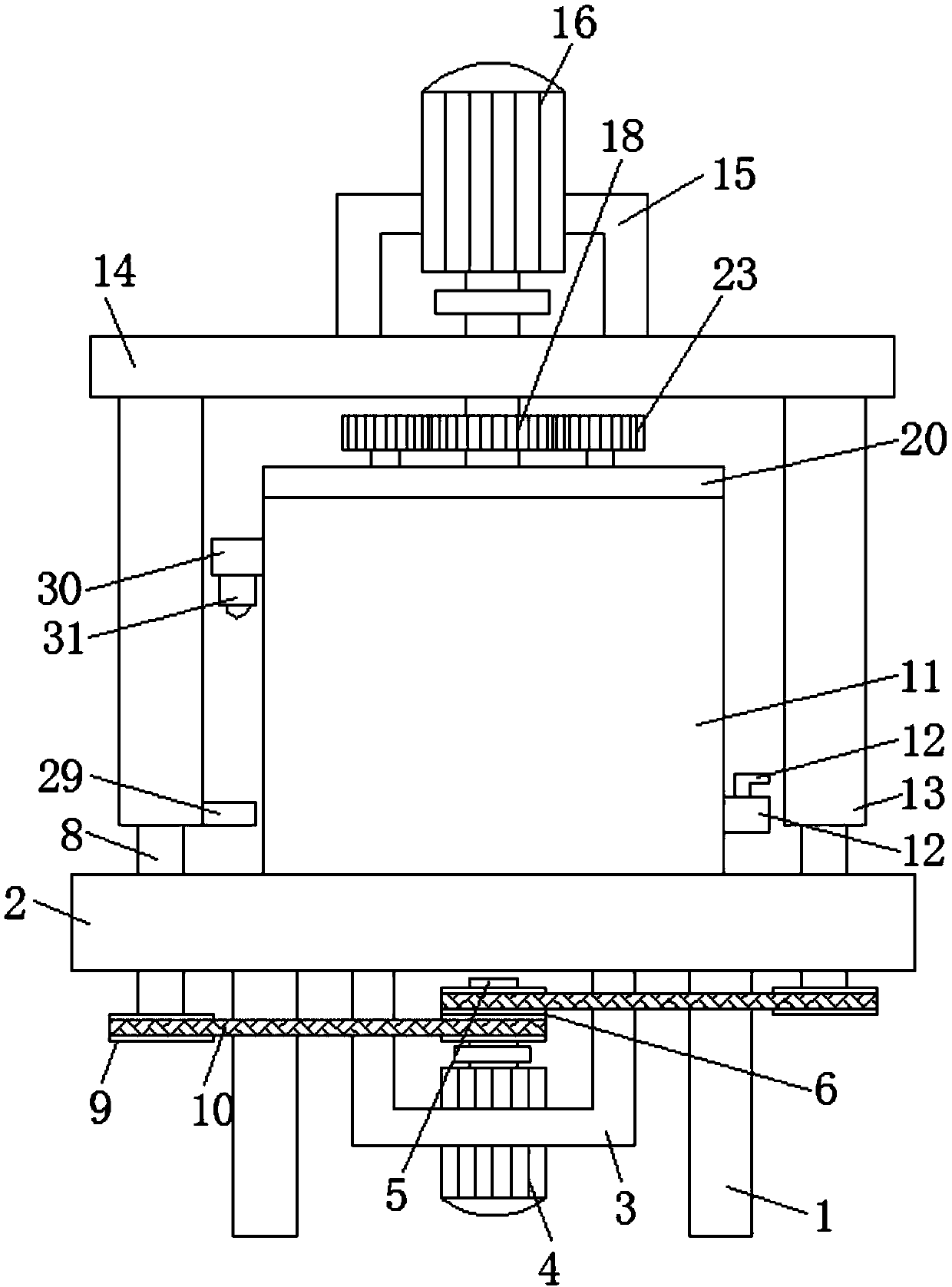

Medicinal material processing device

InactiveCN110179668ASolve the retentionPharmaceutical product form changeDomestic articlesEngineeringMaterials processing

The invention discloses a medicinal material processing device. The medicinal material processing device comprises a shell, a separating mechanism, a stirring mechanism, a heat exchange mechanism anda heating mechanism, wherein the separating mechanism separates an inner cavity of a tank body into a first cavity and a second cavity which are communicated with each other; the heating mechanism ispositioned in the second cavity; the stirring mechanism comprises a first stirring part arranged in the first cavity and a second stirring part arranged in the second cavity; the shell is provided with a heat exchange inlet, a material inlet, a liquid inlet, a liquid outlet and a material outlet; the heat exchange inlet is formed at the top of the shell and is communicated with the heat exchange mechanism; the material outlet is formed at the bottom of the shell; the liquid outlet is formed in the peripheral wall of the shell; and the material inlet and the liquid inlet are formed in the peripheral wall of the first cavity. The medicinal material processing device integrates the medicinal material processing step, omits intermediate equipment, increases the equipment utilization rate and aims to solve the technical problem in the prior art that the medicinal materials cannot be subjected to extraction and concentration or stir-frying treatment.

Owner:古浪县康泰中药材种植专业合作社

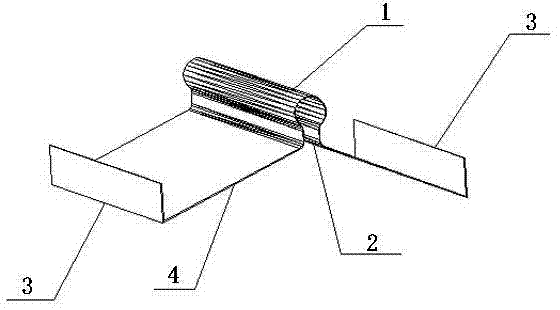

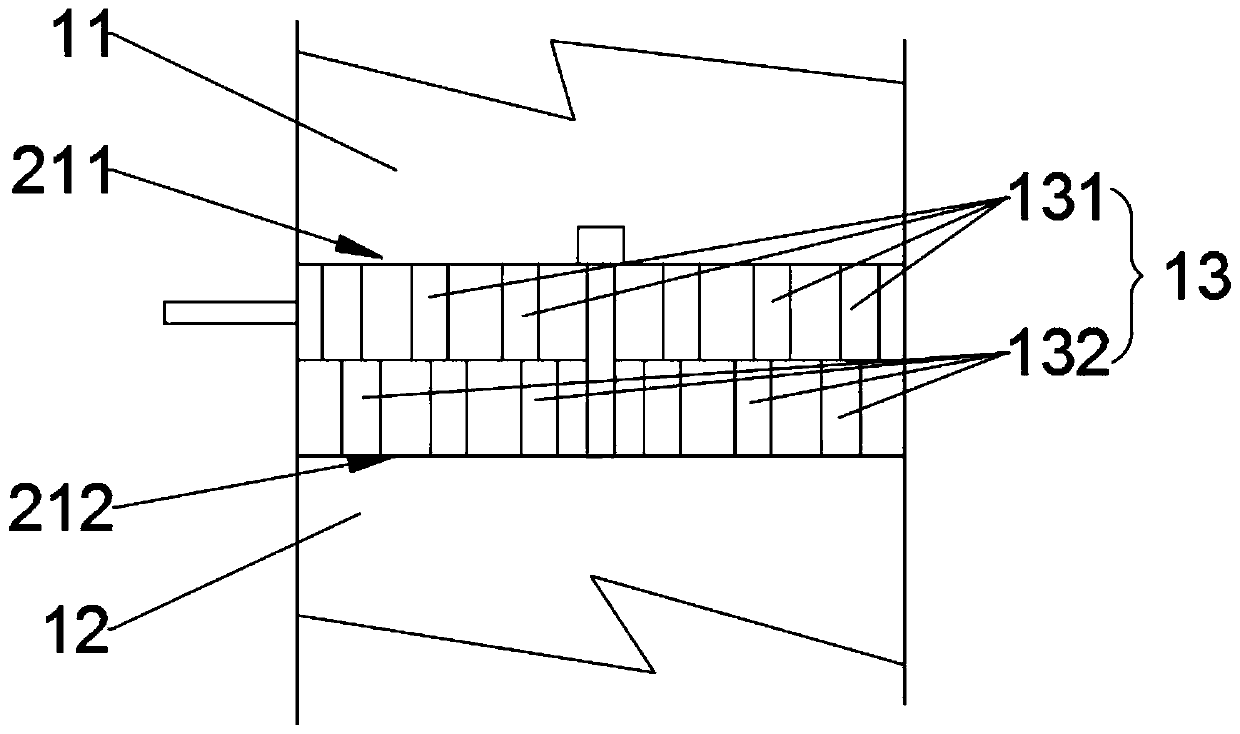

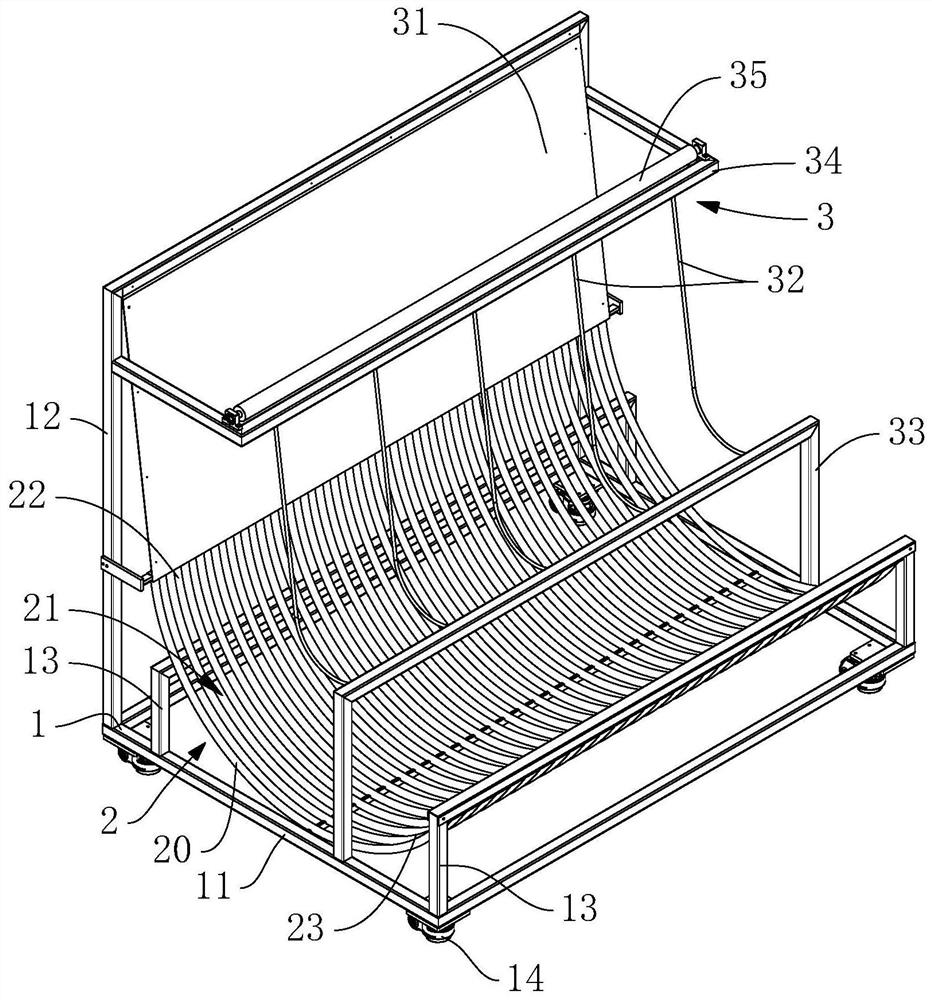

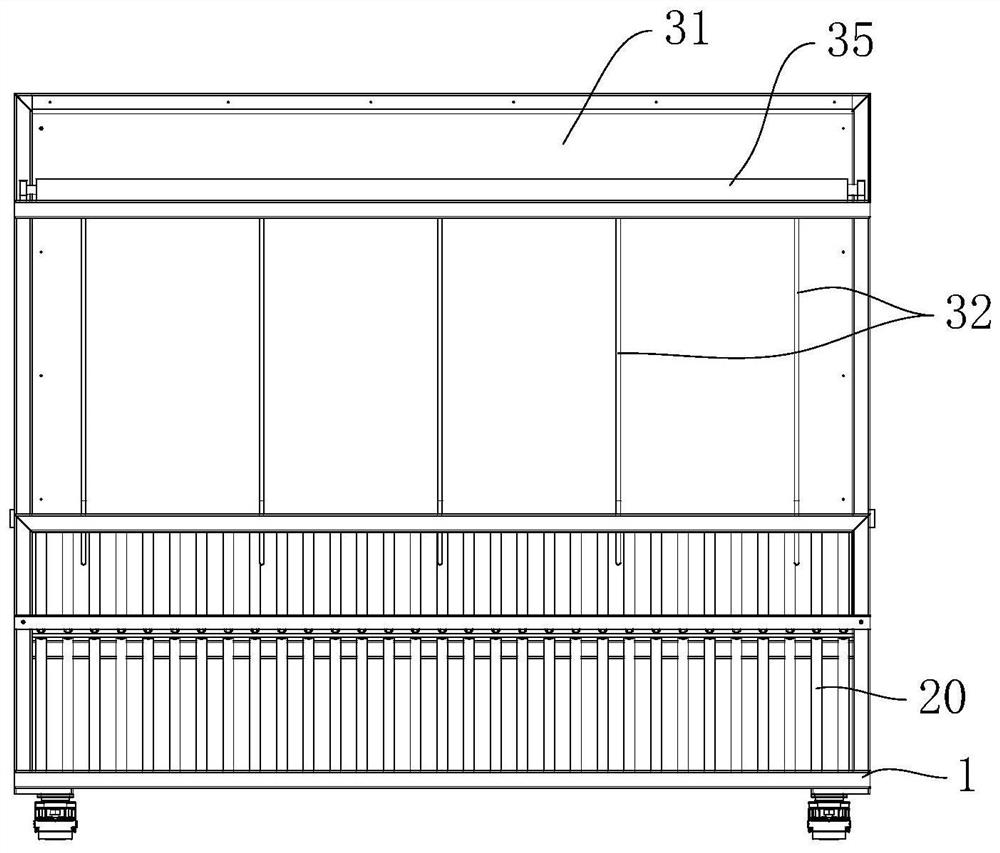

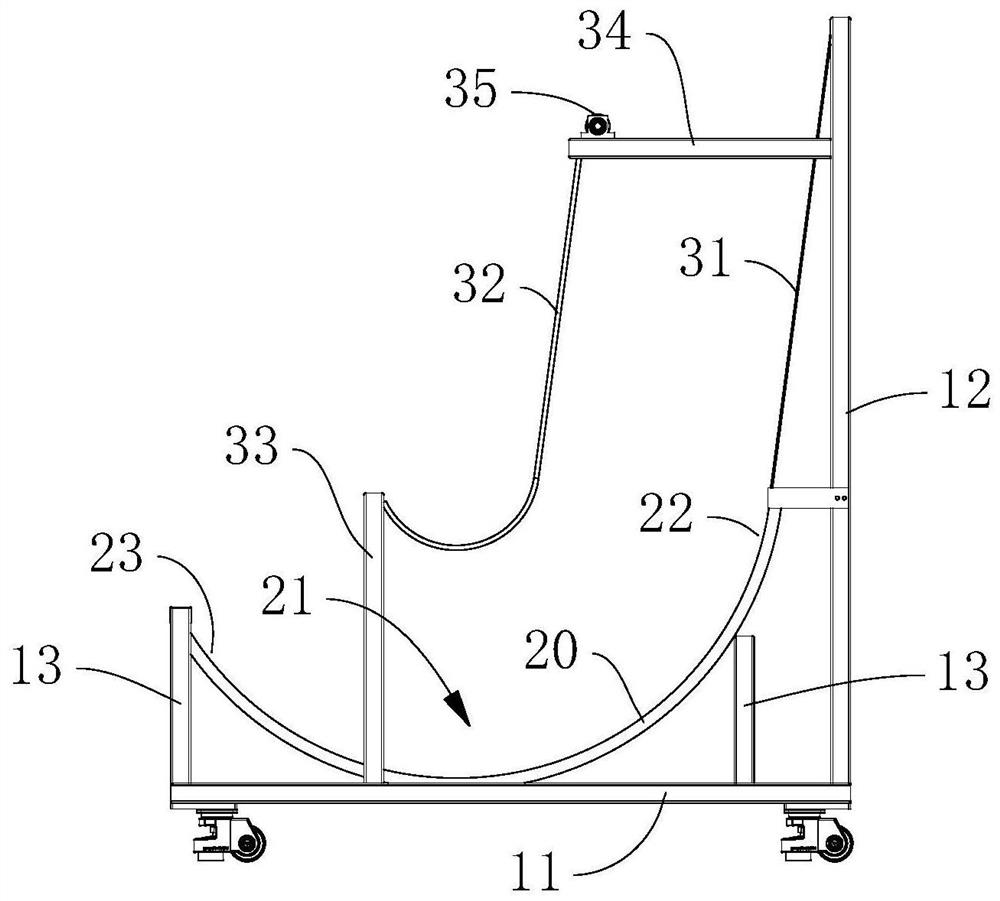

Flexible strip material caching device and flexible strip material processing and production line thereof

PendingCN111924612AGuaranteed integrityImplement sliding stackingWebs handlingStructural engineeringMaterials processing

The invention provides a flexible strip material caching device and a flexible strip material processing and production line. The flexible strip material caching device is used for guiding flexible strip materials to be cached. The flexible strip material caching device comprises a rack and a flexible strip material guiding structure set on the rack. An arched chute is formed on the flexible stripmaterial guiding structure. The opening of the arched chute is upward, so the flexible strip materials slide into the arched chute from a feeding end of the arched chute, and the flexible strip materials are stacked in the arched chute. Under own gravity of the flexible strip materials, the flexible strip materials slide to a discharging end of the arched chute. According to the flexible strip material caching device provided by the invention, the sliding and stacking of the flexible strip materials between two processing devices can be realized, the problem that the flexible strip materialsare stuck between the two processing devices is solved, the continuity of a production process is ensured, the manual operation is reduced, the labor intensity is reduced, and the working efficiency is improved.

Owner:湖南先森智能科技有限公司

Auxiliary system for guide vehicle in large scenic area

PendingCN113516932ASolve the retentionThe leasing process is simple and fastChecking apparatusAdvertisingSimulationTerminal equipment

The invention discloses an auxiliary system for a guide vehicle in a large scenic area. The auxiliary system comprises the guide vehicle, a remote server and a mobile client, the remote server is respectively communicated with the guide vehicle and mobile terminal equipment through a network; the guide vehicle comprises an intelligent central control upper computer, and the intelligent central control upper computer interacts with the remote server through the network and is used for uploading GPS positioning information in real time, conducting scene navigation in real time and conducting scenic spot explanation according to the GPS positioning information. The guide vehicle is leased by scanning a two-dimensional code, the convenience of tourists for visiting the scenic area is improved, time and cost of vehicle operation and maintenance in the scenic area are reduced, meanwhile, a braking module of the guide vehicle can automatically stop when the vehicle encounters obstacles in driving process, and safety problem of driving in open areas in the scenic area is solved.

Owner:北京可视通科技发展有限公司

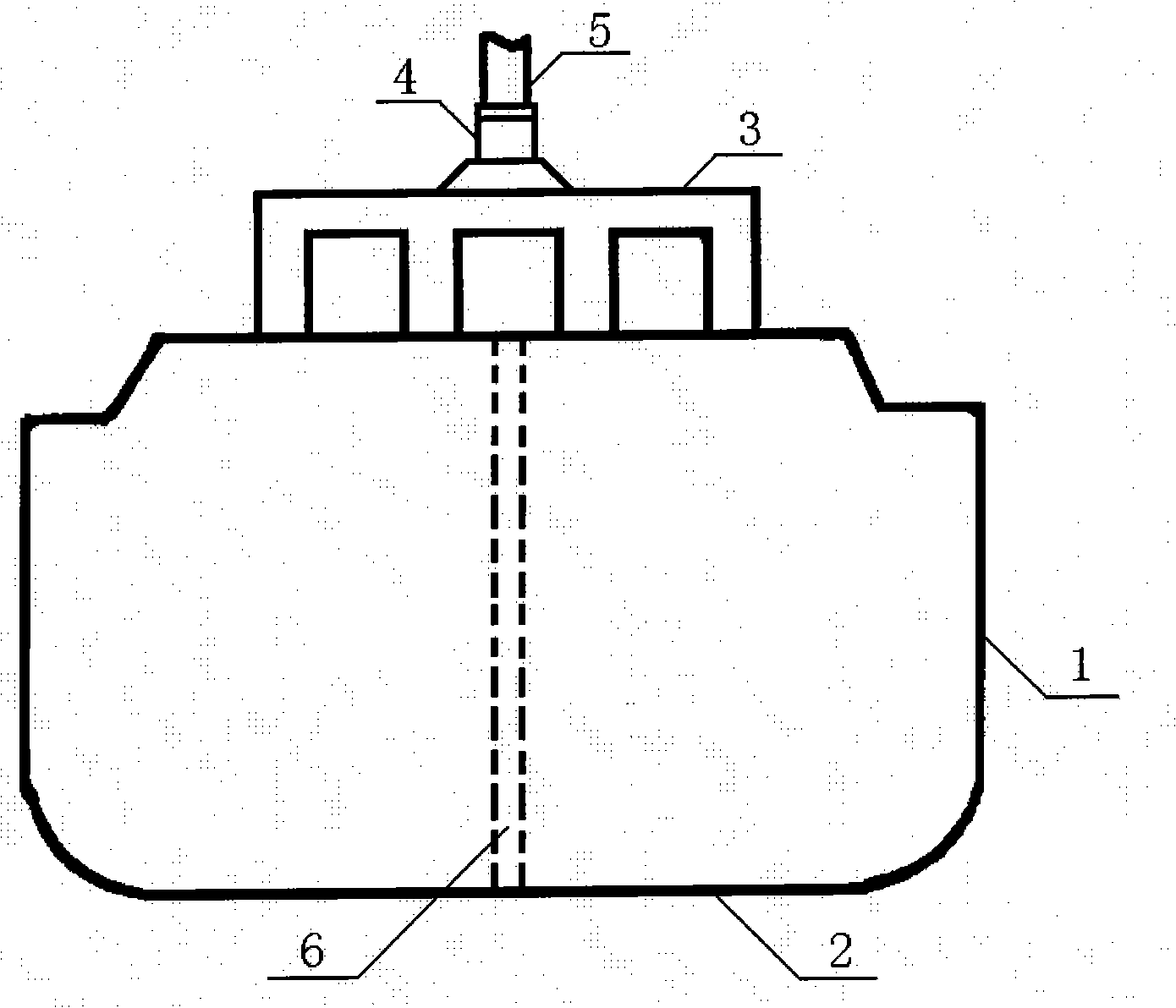

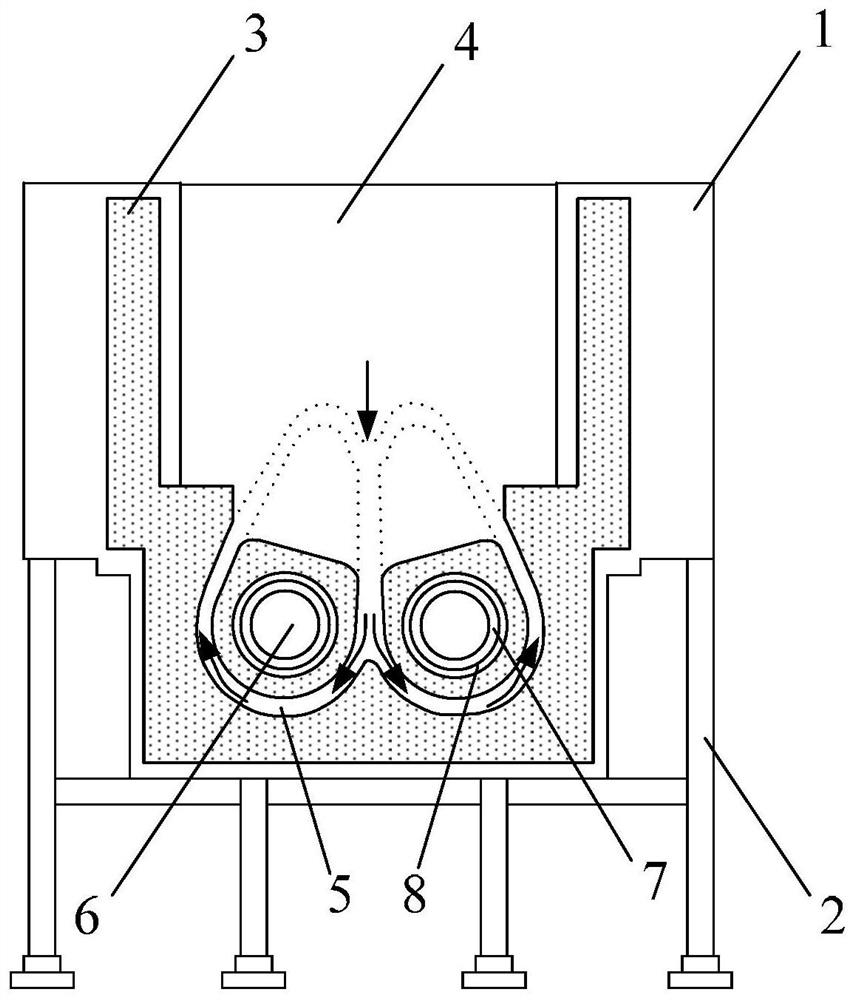

Power frequency furnace with W-shaped melting channel and using method thereof

PendingCN112833667ASmall temperature differencePrevent agingCharge treatment typeCrucible furnacesRefractoryCopper

The invention discloses a power frequency furnace with a W-shaped melting channel and a using method thereof. The power frequency furnace comprises a power frequency furnace body, a furnace body support, a furnace pipe, a melting furnace cavity, the W-shaped melting channel, an iron core, a coil and a water-cooled jacket. A molten melting channel mold is fused with molten copper in the melting furnace cavity, the temperature of the molten copper in the W-shaped melting channel is high, and the temperature of the molten copper in the melting furnace cavity is low. At the moment, the temperature difference between the molten copper in the W-shaped melting channel and the molten copper in the melting furnace cavity is 10-20 DEG C, so that the temperature difference between the molten copper in the W-shaped melting channel and the molten copper in the melting furnace cavity is reduced, the aging of a refractory material in the W-shaped melting channel is avoided, and the service life of the power frequency furnace is effectively prolonged. Under the action of magnetic induction current generated by the coil, the molten copper in the W-shaped melting channel is gradually heated, the density of the molten copper with the high temperature is low, the molten copper is sprayed into the melting furnace cavity from channels on the two sides of the W-shaped melting channel, so that the flowing speed of the molten copper is increased, the circulating speed of the molten copper in the melting furnace cavity is increased, the power consumption is reduced, and the actual service life of the W-shaped melting channel is remarkably prolonged.

Owner:安徽悦波电气设备有限公司

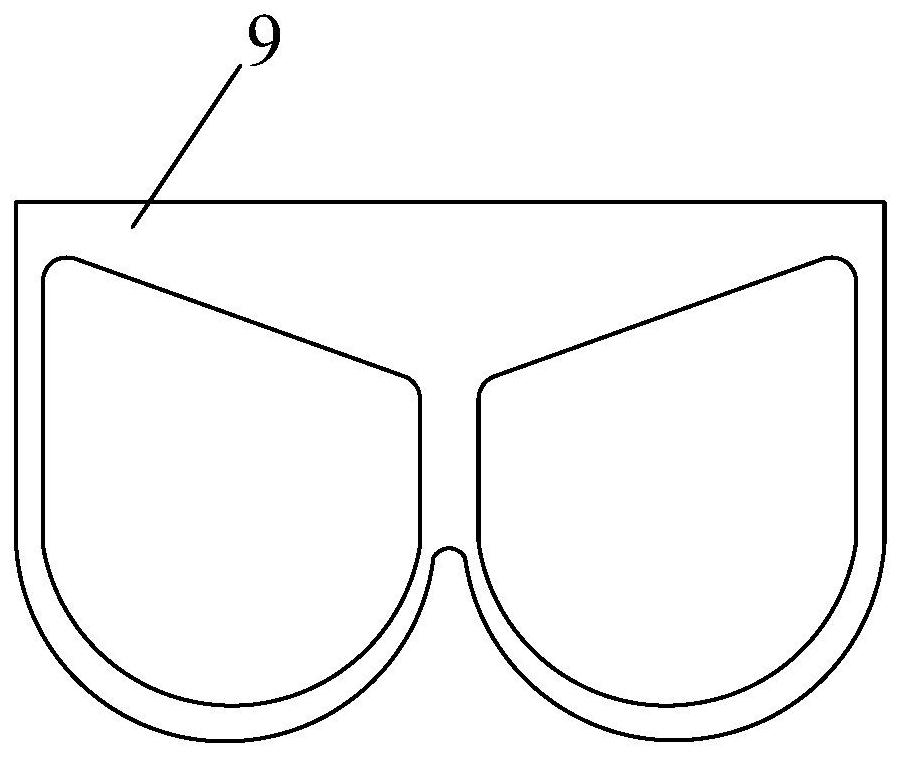

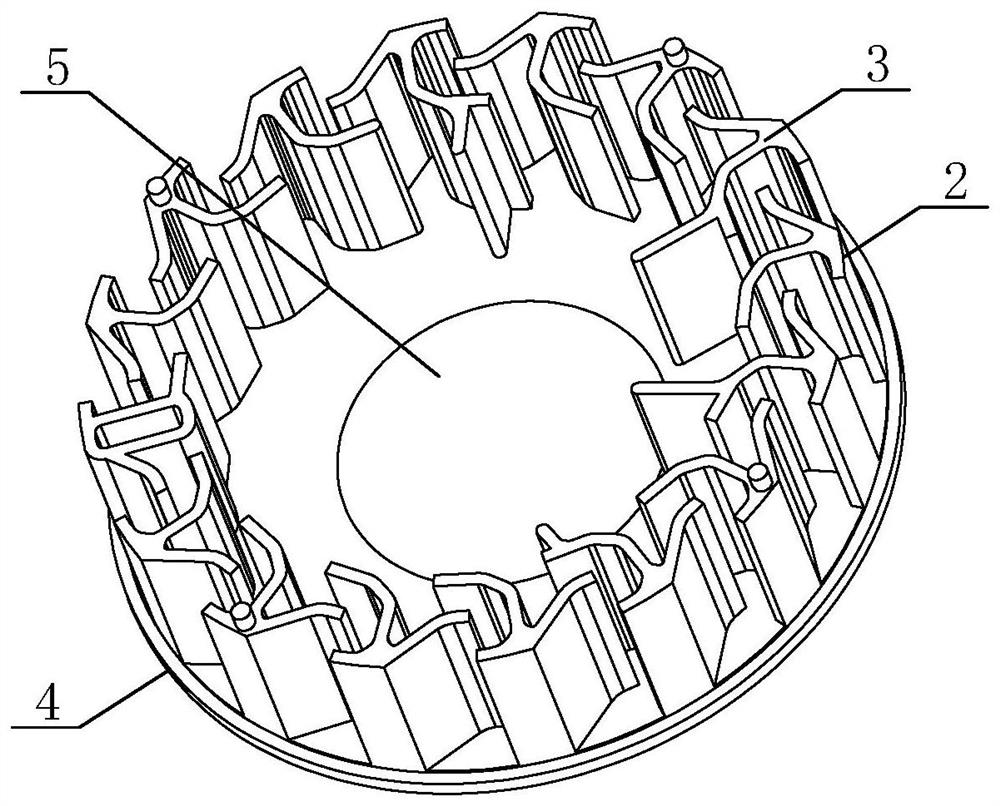

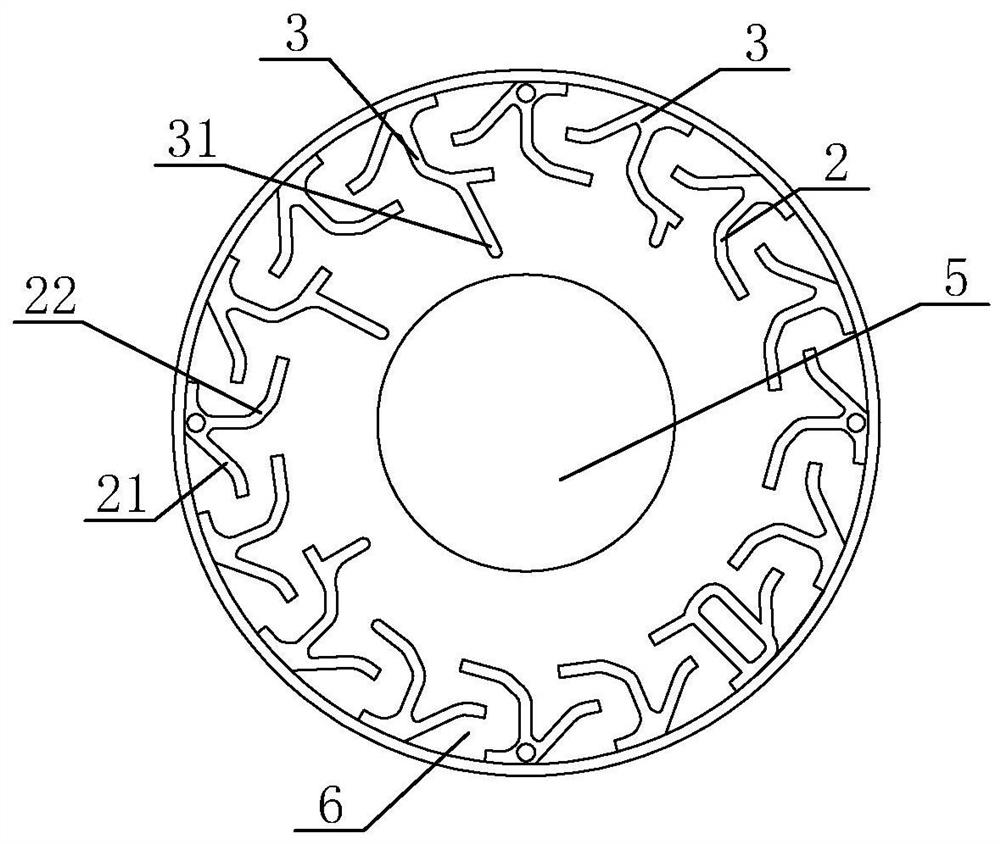

A smoke maze used for smoke detectors and smoke detectors

ActiveCN109166268BImprove anti-interference abilityBalanced smoke effectFire alarmsSmoke detectorsEngineering

The invention discloses a smoke inlet labyrinth for a smoke detector and a smoke detector. The smoke inlet labyrinth comprises a base and an upper cover; a cavity for detecting the concentration of smog is arranged between the base and the upper cover; a plurality of baffle plates are arranged at the periphery of the cavity; the baffle plates are uniformly arranged along the circumferential direction of the periphery of the cavity; a smoke inlet channel for allowing external air to enter the cavity is formed between two adjacent baffle plates; the baffle plates comprise a plurality of specially-shaped plates; convex plates for changing smoke inlet effects of the corresponding smoke inlet channels are arranged on the specially-shaped plates; and the convex plates extend into the cavity. Thesmoke inlet labyrinth can enable the smog in the air to enter or flow out of the detector or the labyrinth more easily; and the structures of the multiple baffle plates arranged in the labyrinth, thesmoke inlet effect of the smoke inlet labyrinth is more uniform.

Owner:浙江巨感物联网科技有限公司

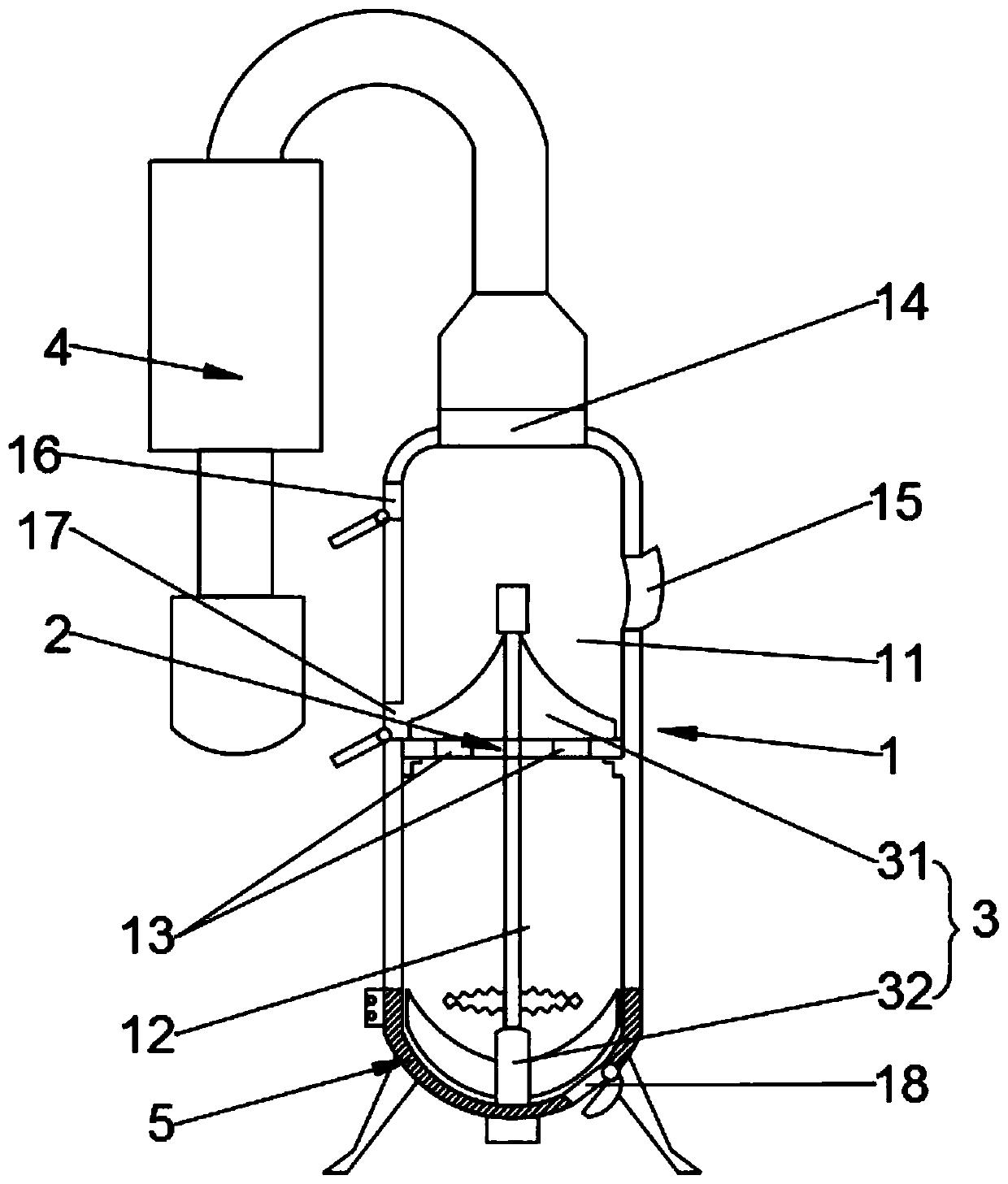

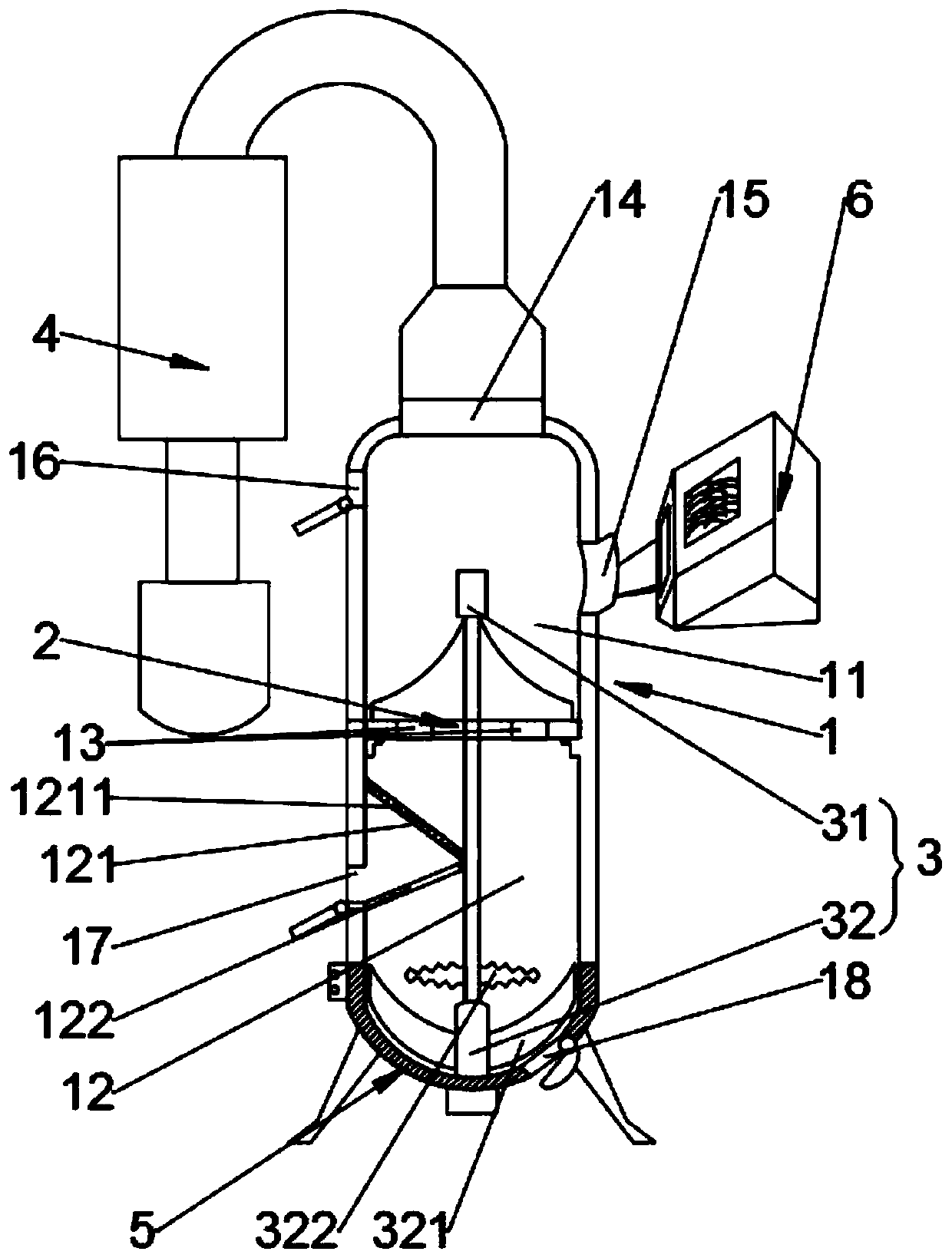

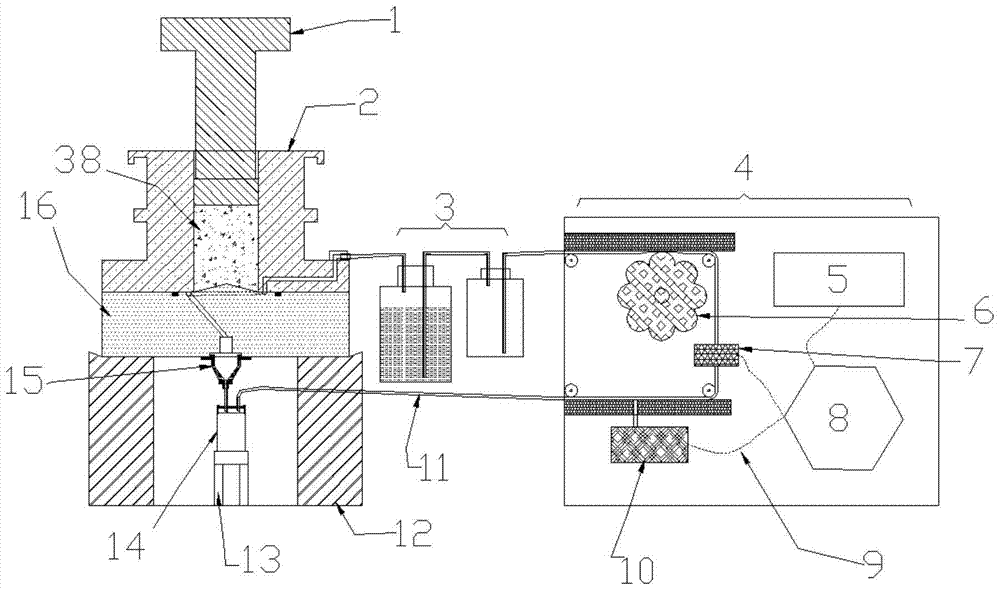

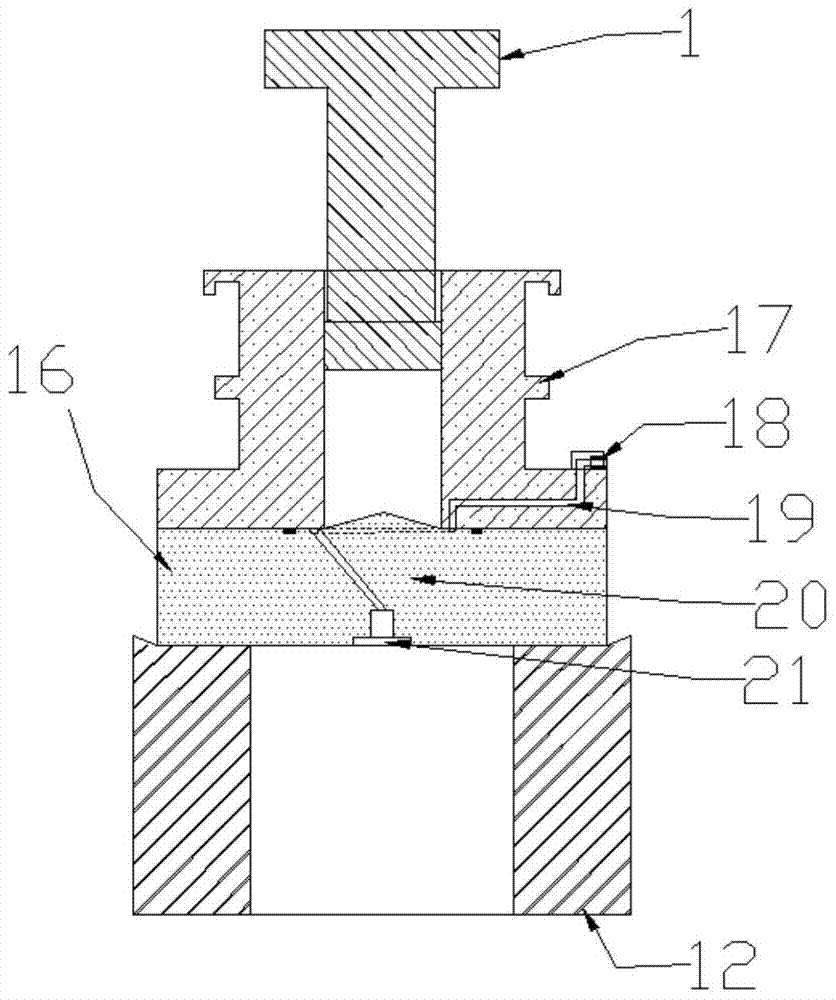

A collection device and collection method for concrete pore solution

ActiveCN105651554BImprove collection efficiencyImprove scienceWithdrawing sample devicesPositive pressureCarbonization

The invention discloses a collection device and a collection method of a concrete pore solution. The collection device of the concrete pore solution comprises a peristaltic gas guide control device, a degassing and pressure buffering device, a concrete pore solution squeezing device, a filter tip, filter paper, a collection bottle, a rubber tube and a connection guide pipe. The collection method of the concrete pore solution comprises the following steps: before squeezing a concrete test piece, starting the peristaltic gas guide control device so as to facilitate air to generate flowing circulation; removing carbon dioxide in air flow through the degassing and pressure buffering device; in a pore solution collection process, forming a pressure difference state that the filter tip has positive pressure and the collection bottle has negative pressure. According to the collection device and the collection method of the concrete pore solution, carbonization-free collection of the concrete pore solution is realized, and efficient collection of the concrete pore solution is realized through a structural design of the concrete pore solution squeezing device.

Owner:JIANGSU SOBUTE NEW MATERIALS

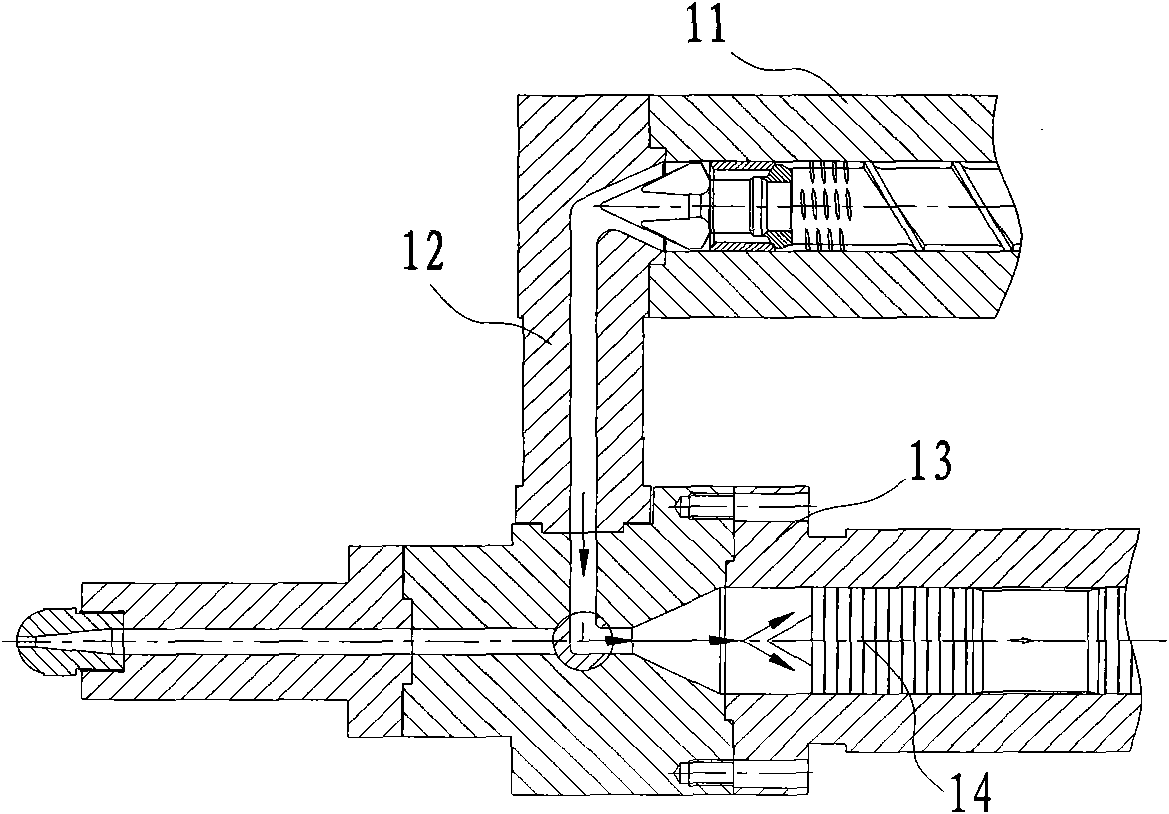

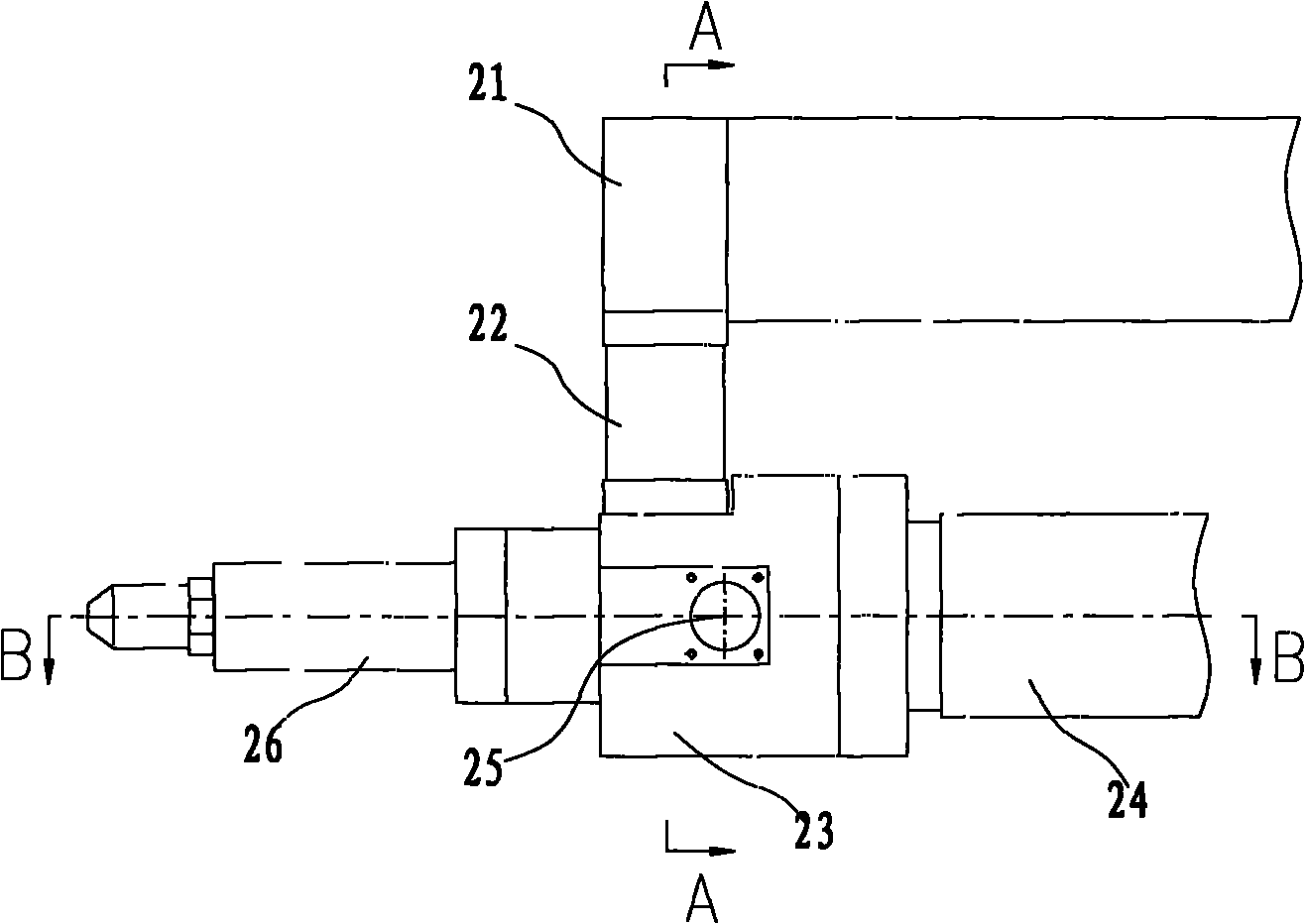

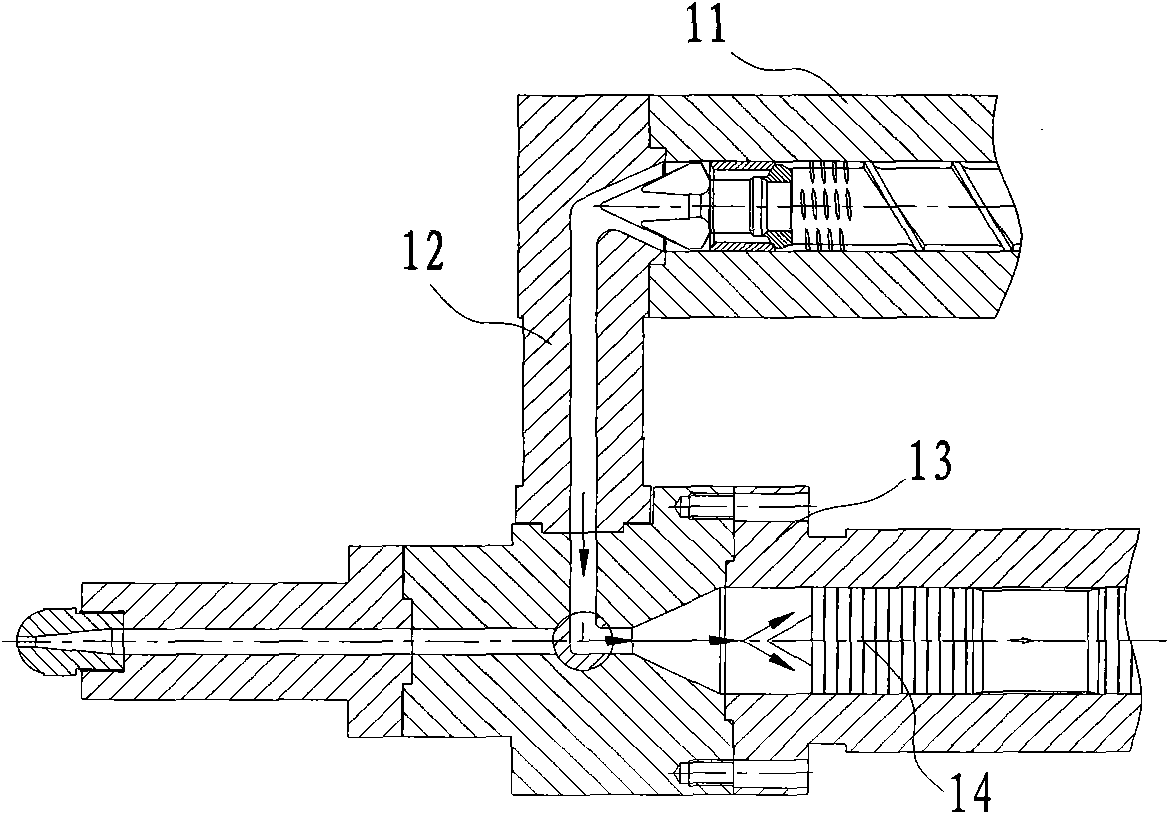

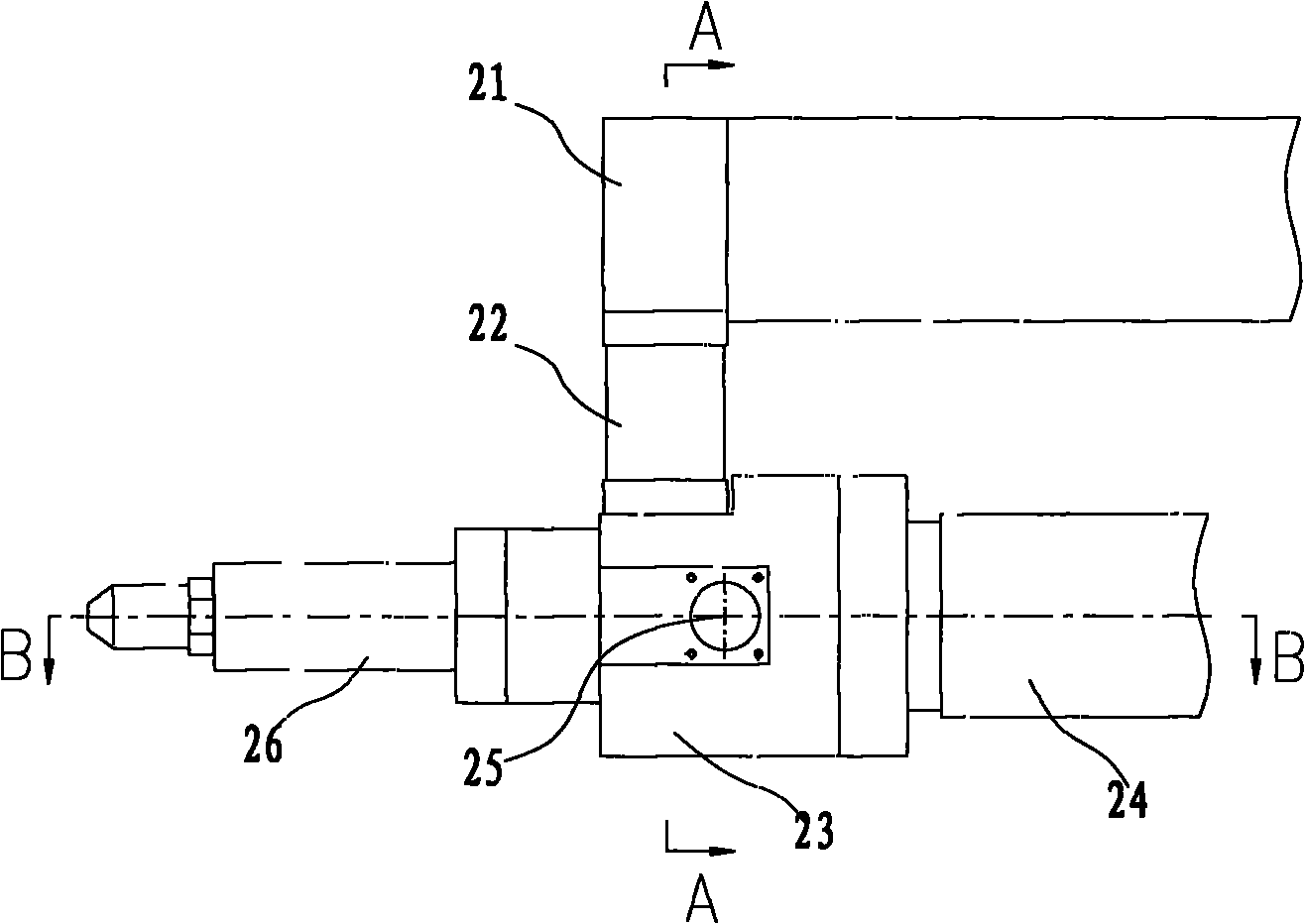

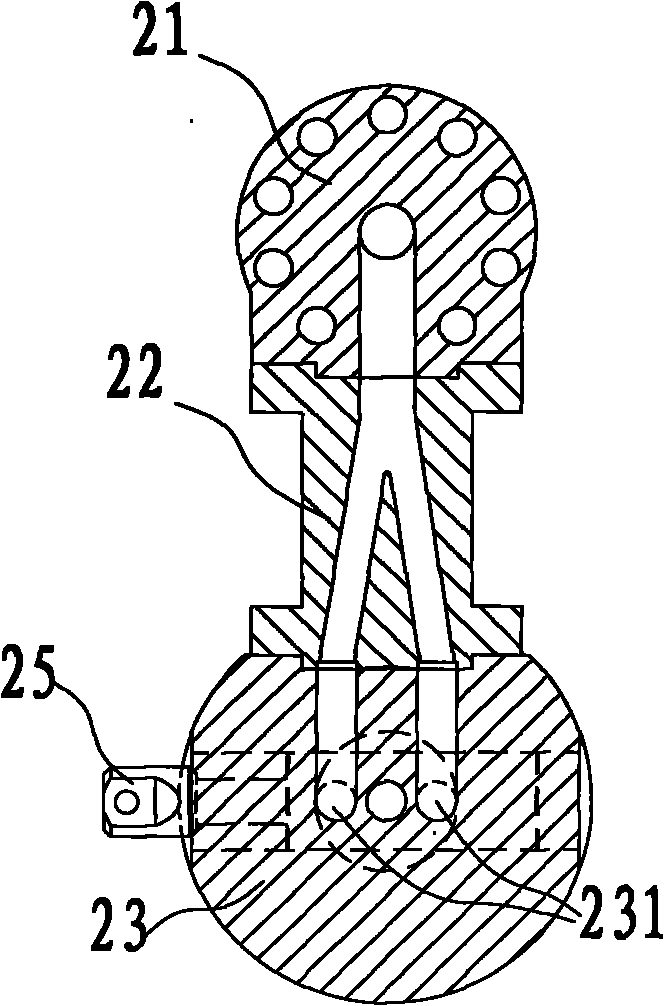

Divided-flow secondary injection flow passage device of ejection forming machine

The invention discloses a divided-flow secondary injection flow passage device of an ejection forming machine, which comprises a machine barrel nozzle, an injection cylinder assembly and a flow passage connector connected to the output end of the machine barrel nozzle and the input end of the injection cylinder assembly; an injection rod capable of moving along the axial direction of the injection cylinder assembly is arranged in the injection cylinder assembly; the injection cylinder assembly is internally provided with two storage flow passages corresponding to the end parts of the injection rod; and the output end of the inner cavity of the flow passage connector comprises interfaces matched with the two storage flow passages. The problem of remaining remainder is radically solved, and the quality of the products is effectively ensured. In addition, the process regulating range is wider, and the production efficiency is favorably improved.

Owner:GUANGZHOU HUAYAN PRECISION MACHINERY

A kind of audio and video synchronization device and method based on hls protocol

ActiveCN103648011BSolve the retentionOutput synchronizationSelective content distributionTimestampAudio frequency

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

Dredging type tubular heat exchanging device for sewage or surface water

ActiveCN102997725BAchieve separationSolve the Darien blockage problemHeat exchanger casingsStationary tubular conduit assembliesEnergy technologyWater leakage

The invention discloses a dredging type tubular heat exchanging device for sewage or surface water and belongs to the technical field of energy. The dredging type tubular heat exchanging device aims at solving the problem that the plate type structure of the existing sewage heat exchanging device is insufficient in loading capacity, severe in water leakage accident, large in steel consumption of a sleeve structure and the like and connection blocking can be caused by suspended solids at an orifice. A multilayer heat exchanging tube is arranged in a casing, two ends of the multilayer heat exchanging tube is fixedly connected with a left tube plate and a right tube plate, the left tube plate, the right tube plate and a left end socket and a right end socket of sewage or surface water define a sewage or surface water left transition cavity and a sewage or surface water right transition cavity, a left clean water channel and a right clean water channel are arranged in the casing, and the sewage or surface water left transition cavity is communicated with the orifice of the heat exchanging tube at the corresponding layer; and the sewage or surface water left transition cavity is divided into two sewage or surface water left transition cavity units through a second vertical partition plate, the top end of the sewage or surface water right transition cavity is provided with a sewage or surface water outlet or inlet, and a sewage or surface water outlet or inlet is arranged at the bottom end of the sewage or surface water right transition cavity. The dredging type tubular heat exchanging device for sewage or surface water is used for blocking-free and efficient heat exchanging between sewage or surface water and clean water during cold energy extracting in the sewage or surface water.

Owner:青岛科创蓝新能源股份有限公司

Forcible dredging type tubular heat exchange device for sewage or surface water

ActiveCN103063063BAchieve non-cloggingHeat exchange without clogging and high efficiencyHeat exchanger casingsStationary tubular conduit assembliesWater leakageEngineering

The invention belongs to the technical field of energy resources and relates to a forcible dredging type tubular heat exchange device for sewage or surface water. The forcible dredging type tubular heat exchange device for the sewage or surface water aims to solve the problems that an existing wide-flow-passage plate type structure is insufficient in pressure bearing capability and severe in water leakage accidents and results in retention of suspended matters and impurities, a tubular structure orifice is prone to blockage and the like. The device comprises a flow passage separation device, header dredging devices, heat exchange tubes, a shell, two tube plates, two headers, two seal heads, baffle plates, diaphragm plates, diaphragm plate holes, a sewage or surface water inlet, a sewage or surface water outlet, a heat exchange media inlet, a heat exchange media outlet and the like. The sewage or surface water flows into the device from the inlet and then flows backwards sequentially by means of blocking of the header dredging devices after being subjected to flow passage separation of the flow passage separation device, and performs heat exchange with heat exchange media outside the tubes during flowing, and after entering the device from the inlet, the heat exchange media baffle and flow in the shell by means of blocking of the diaphragm plates and the baffle plates and performs heat exchange with the sewage or surface water in the tubes during flowing. The forcible dredging type tubular heat exchange device for the sewage or surface water is used for heat exchange of the sewage or surface water with the heat exchange media.

Owner:青岛科创蓝新能源股份有限公司

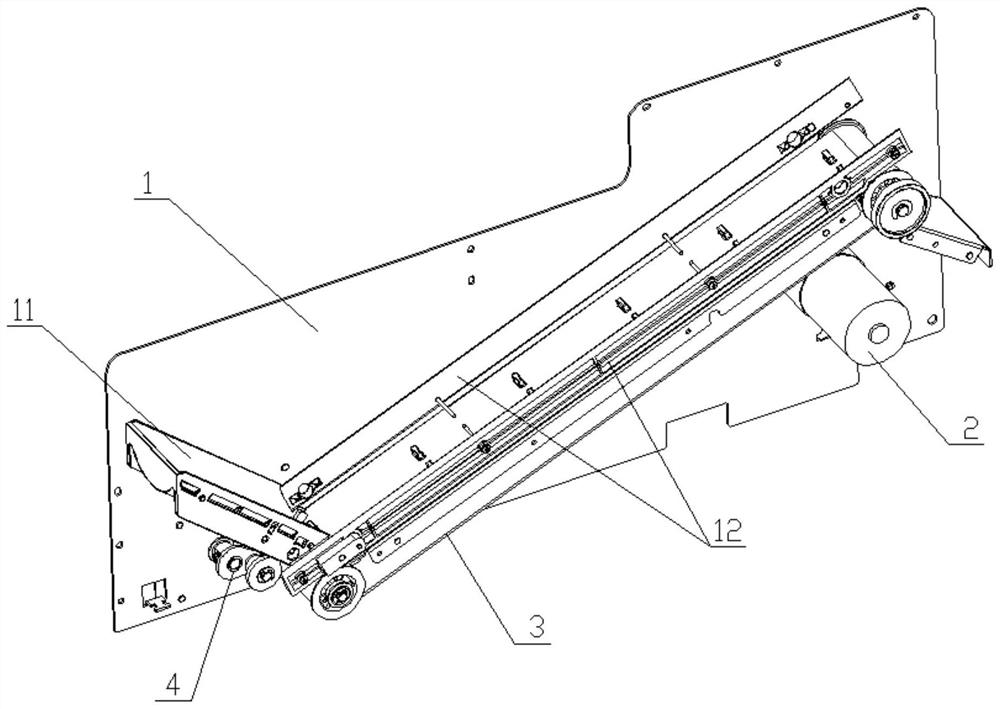

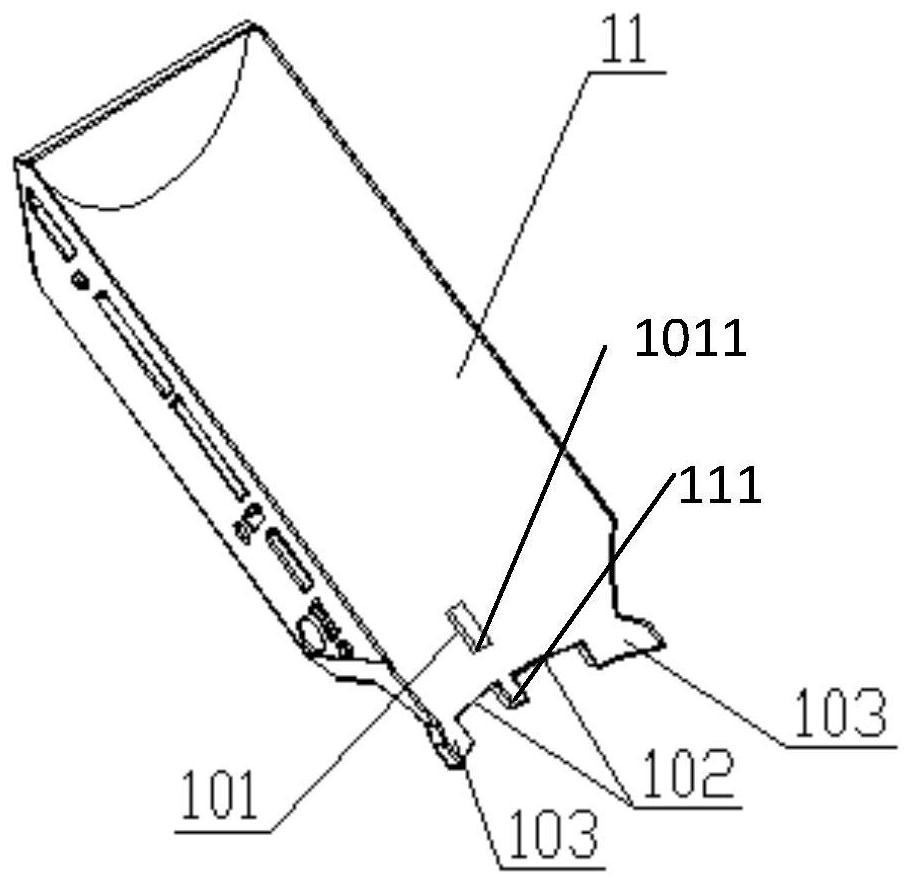

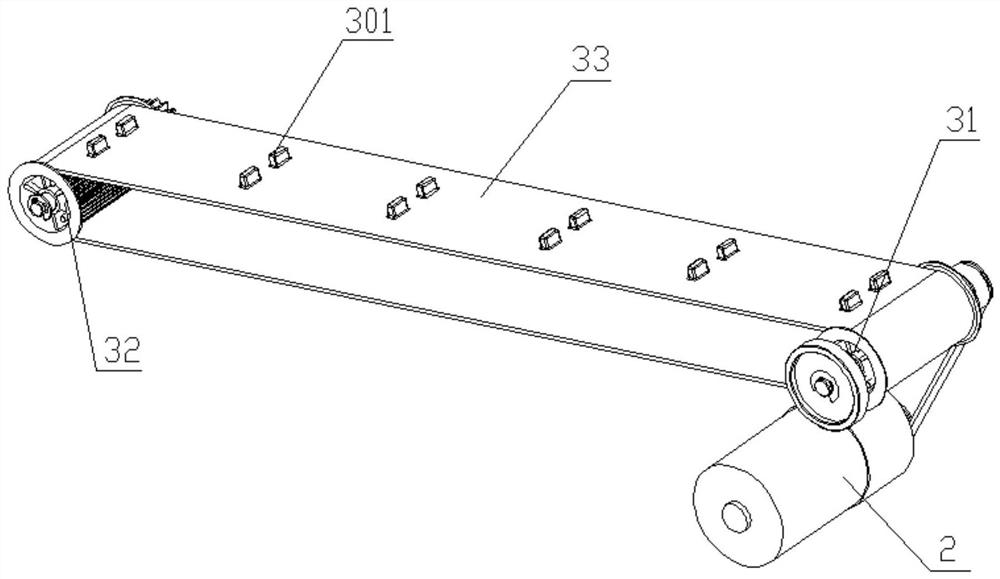

Coin retention prevention device and coin lifting device for preventing coin retention

PendingCN114387721ASolve the retentionImprove experienceCoin/currency accepting devicesStructural engineeringCoin

The invention discloses a coin retention prevention device and a coin lifting device for preventing coin retention, each of the coin retention prevention device and the coin retention prevention device comprises a conveying belt, a chute fixedly arranged at the input end of the conveying belt and a coin shifting device, the coin shifting device comprises a shifting rod driving device and a shifting rod which are arranged behind the chute, the chute is provided with a notch, one end of the shifting rod extends out of the notch, and the other end of the shifting rod extends out of the notch. The poke rod driving device drives the poke rod to stretch out and retract back and forth in the notch in a reciprocating mode. A conveying belt of the coin lifting device comprises a driving conveying belt and a driven conveying belt, the driving conveying belt comprises a transverse moving section moving in the inclined direction and a lifting section moving in the vertical direction, the lifting section of the driving conveying belt is attached to the driven conveying belt, and the belt of the attaching face is in a zigzag Z-shaped trend. The poke rod which stretches out and withdraws back in the notch in a reciprocating mode pokes coins detained on the sliding groove or pokes coins rolling between the sliding groove and the conveying belt, the problem of detained coins when the coins are output is solved, and the device is simple in structure and convenient to maintain.

Owner:NANJING PANDA ELECTRONICS +1

Divided-flow secondary injection flow passage device of ejection forming machine

The invention discloses a divided-flow secondary injection flow passage device of an ejection forming machine, which comprises a machine barrel nozzle, an injection cylinder assembly and a flow passage connector connected to the output end of the machine barrel nozzle and the input end of the injection cylinder assembly; an injection rod capable of moving along the axial direction of the injection cylinder assembly is arranged in the injection cylinder assembly; the injection cylinder assembly is internally provided with two storage flow passages corresponding to the end parts of the injection rod; and the output end of the inner cavity of the flow passage connector comprises interfaces matched with the two storage flow passages. The problem of remaining remainder is radically solved, and the quality of the products is effectively ensured. In addition, the process regulating range is wider, and the production efficiency is favorably improved.

Owner:GUANGZHOU HUAYAN PRECISION MACHINERY

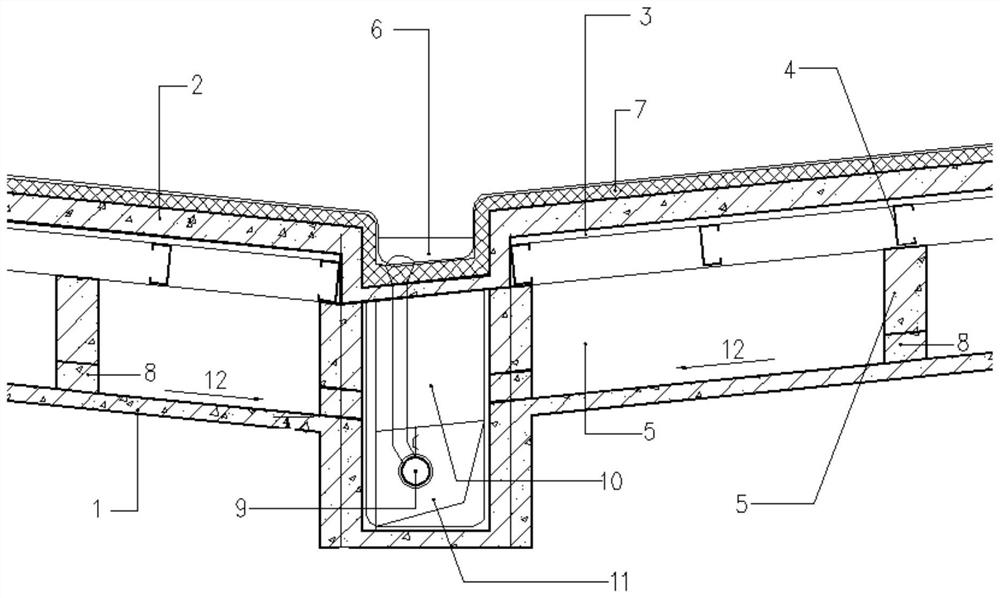

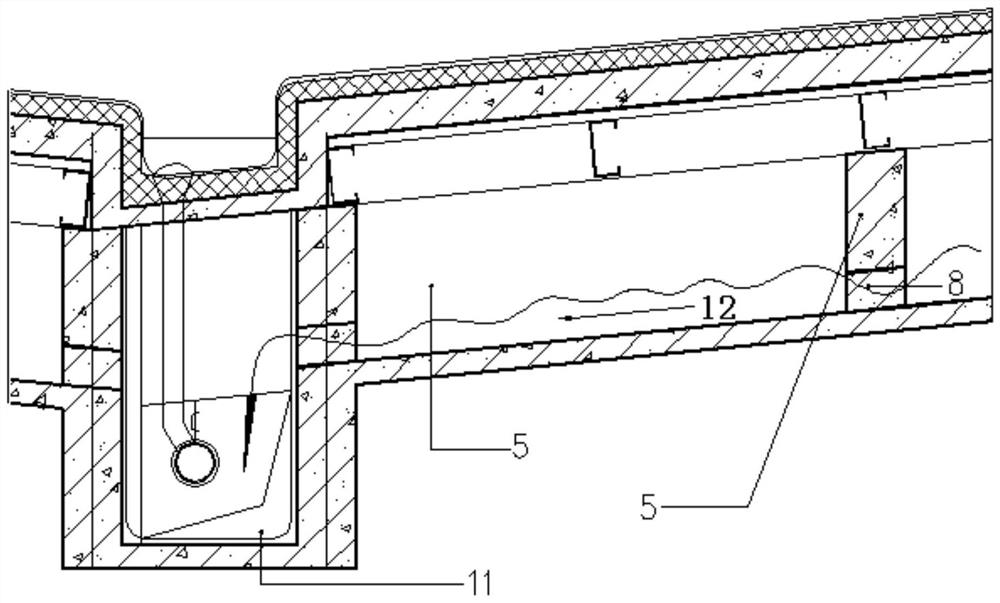

Double-layer waterproof and drainage system on the roof of large-scale hydrogen exhaust plant

ActiveCN106639103BSolve the retentionSolve the problem of indoor water leakageBuilding roofsRoof drainageWater leakDrainage tubes

A double-layer waterproof and drainage system for the roof of a large-scale hydrogen exhaust factory building, including roof panels, roof beams, and purlins, characterized in that: the roof panels are double-layer roof panels, the roof beams are lower upper return beams, and the double-layer roof panels are cast on site Roof slab, the upper roof slab is poured with a roof drainage gutter, the upper roof slab is equipped with a profiled steel plate bottom form, the roof drainage gutter is a maintenance ditch, and the roof internal drainage pipe is set in the maintenance ditch, and the lower return beam Drain outlets are reserved in the interior, and emergency drainage ditches are set within the direction of the drainage pipes in the roof. The drainage pipes in the roof are designed in a closed drainage organization gutter. The beneficial effects of this structure are: 1. The double-layer roof panel structure is adopted, and the roof drainage organization gutter and the accident drainage ditch are respectively arranged on the roof panel, which can solve the problem of indoor water leakage caused by roof leakage. 2. The upper roof panel and the lower roof panel of the double-layer waterproof and drainage system are all cast-in-place roof panels, and a profiled steel plate bottom mold is installed under the upper roof panel to solve the problem of hydrogen retention.

Owner:NORTHEAST ELECTRIC POWER DESIGN INST CO LTD OF CHINA POWER ENG CONSULTING GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com