Double-layer waterproof and drainage system on the roof of large-scale hydrogen exhaust plant

A waterproof and drainage, double-layer technology, applied in the direction of roof drainage, roof cladding, roofing, etc., can solve the problems of hydrogen gas discharge, rainwater discharge pipeline maintenance and leak prevention, etc., and achieve the effect of solving hydrogen retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

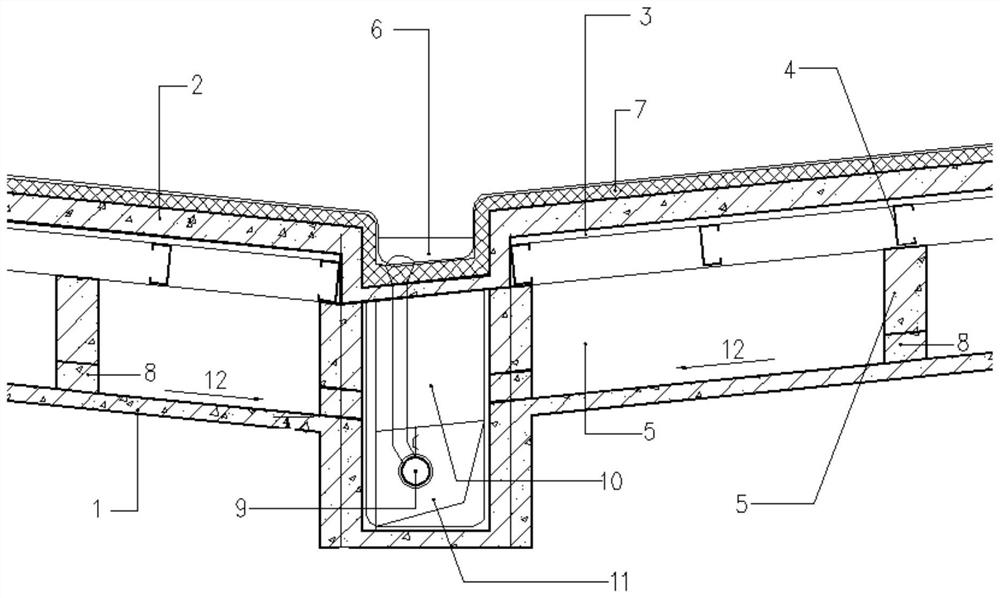

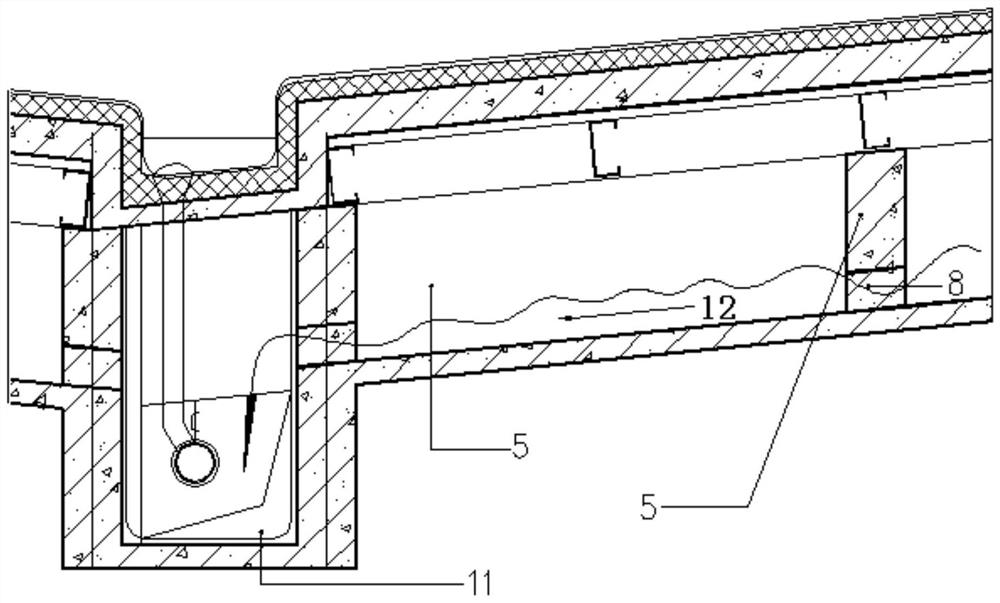

[0011] refer to figure 1 , the present invention includes double-layer roof panels 1, 2, purlins 4, and upper return beams 5 on the lower floor. The double-layer roof panels are all cast-in-place roof panels. There is a profiled steel plate bottom mold 3, and an inspection ditch 10 is set under the gutter of the roof drainage organization. The roof internal drainage pipe 9 is arranged in the inspection ditch, and the drain outlet 8 is reserved in the upper return beam of the lower floor, and emergency drainage is arranged within the direction of the roof internal drainage pipe. Ditch 11, easy to repair the roof internal drainage system, the roof internal drainage pipe is designed in the closed drainage organization gutter, the drainage organization gutter has the function of emergency drainage, and the height of the emergency drainage ditch can meet the maintenance requirements. The upper return beam 5 on the lower floor meets the requirements of smooth hydrogen discharge with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com