Dredging type tubular heat exchanging device for sewage or surface water

A tubular heat exchange and surface water technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc. The structural steel consumption is large and other problems, and the overall performance is remarkable and reliable, the amount of water leakage accidents is small, and the pressure bearing capacity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

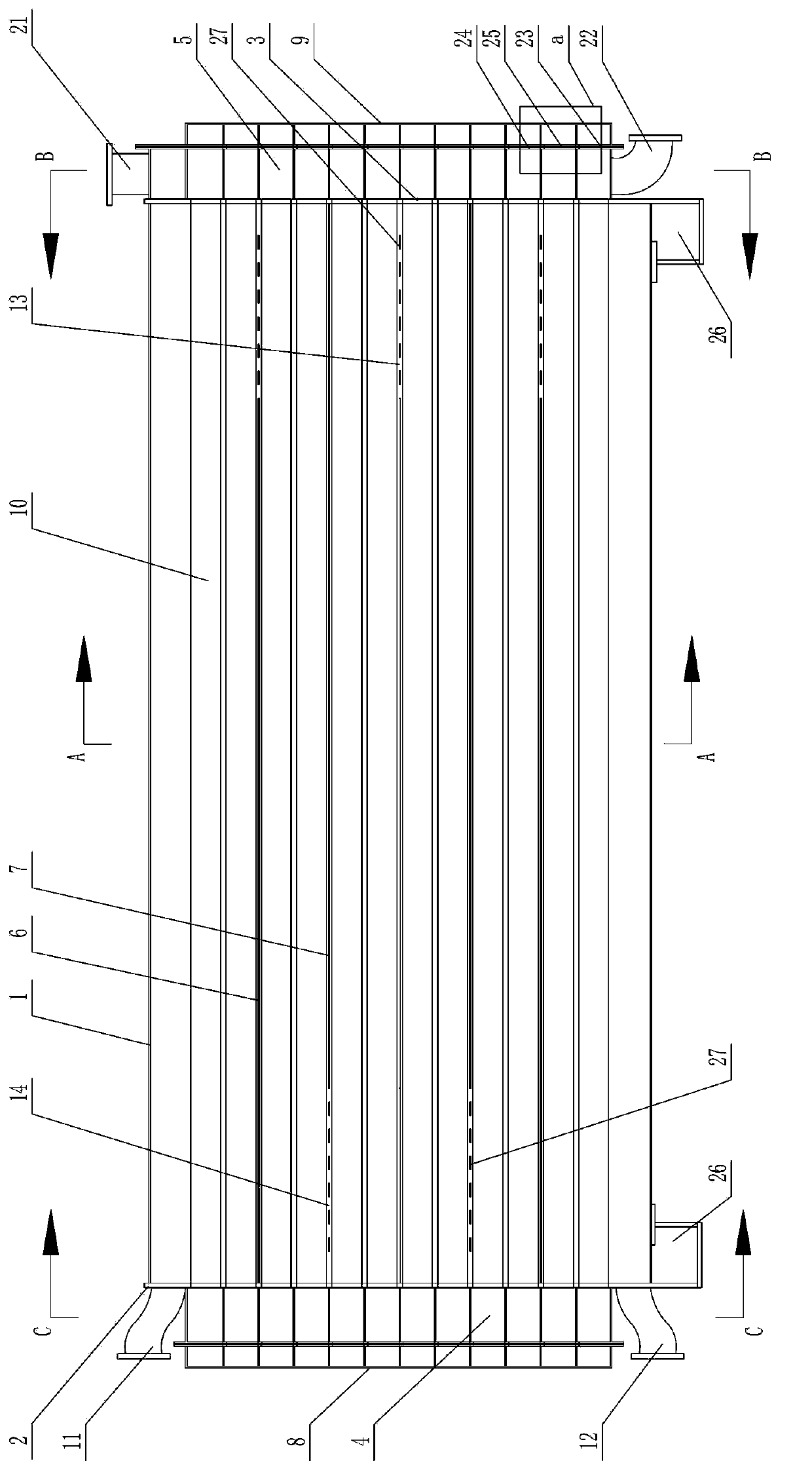

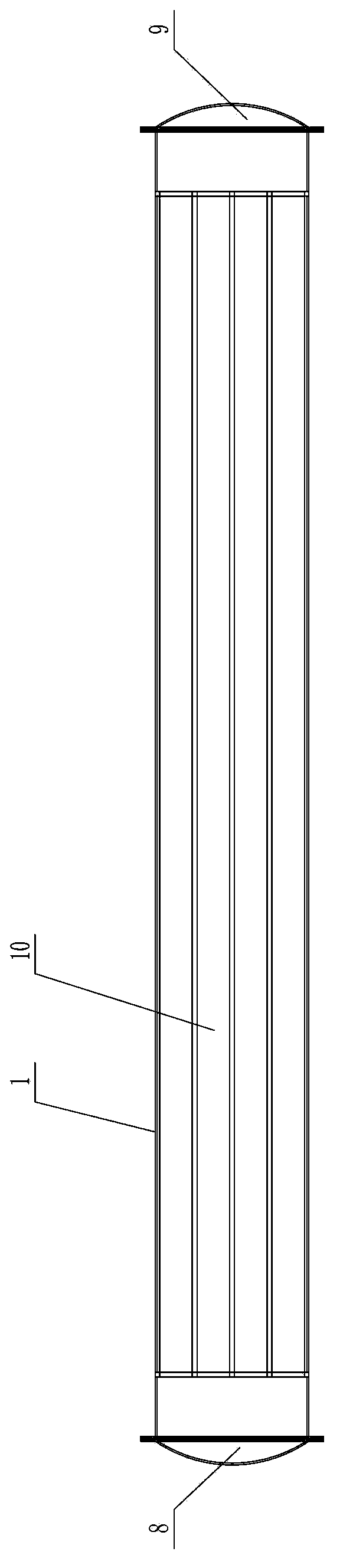

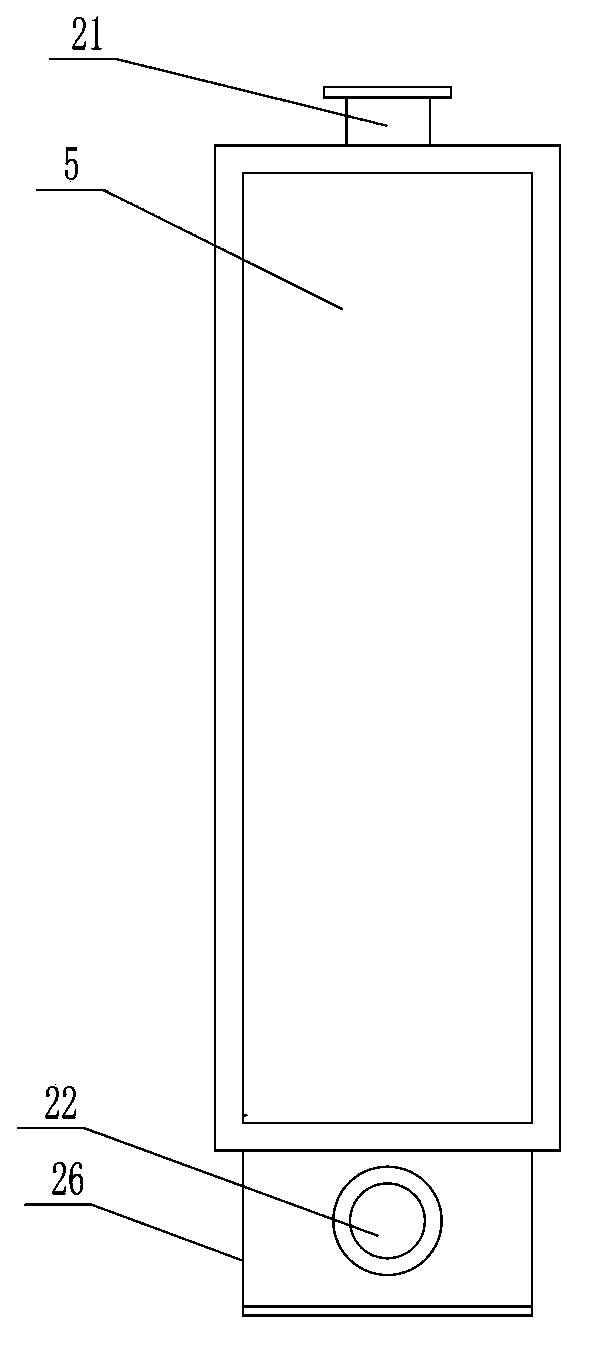

[0029] Specific implementation mode one: as Figure 1-Figure 8As shown, a drainage type tubular heat exchange device for sewage or surface water in this embodiment, the heat exchange device includes a shell 1, multi-layer heat exchange tubes 10, two tube sheets, two cylinders, Two sewage or surface water seal heads and multiple clean water partitions, the two tube sheets are the left tube sheet 2 and the right tube sheet 3, the two cylinders are the left cylinder 4 and the right cylinder 5, and multiple clean water The clapboard comprises a plurality of left clear water clapboards 6 and a plurality of right clean water clapboards 7, and the two sewage or surface water seal heads are respectively the sewage or surface water left seal head 8 and the sewage or surface water right seal head 9, multi-layer replacement The heat pipe 10 is arranged in the housing 1, the left end of the multilayer heat exchange tube 10 is fixedly connected to the left tube plate 2 by welding, the righ...

specific Embodiment approach 2

[0034] Specific implementation mode two: as Figure 6-Figure 8 As shown in the specific embodiment 1, a dredging tube heat exchange device for sewage or surface water, the heat exchange tube 10 is a round tube with a diameter of 70-150mm, which can ensure that the sewage or surface water Water can pass through the heat exchange tube smoothly.

specific Embodiment approach 3

[0035] Specific implementation mode three: as figure 1 and Figure 5 As shown in the specific embodiment 1 or 2, a drainage type tubular heat exchange device for sewage or surface water, the left end surface of the sewage or surface water head 8 and the right end surface of the sewage or surface water head 9 A connecting flange 23 is respectively arranged on the top by welding, and the left cylinder body 4 and the sewage or surface water left head 8 adjacent end faces and the right cylinder body 5 and the sewage or surface water right head 9 adjacent end surfaces are respectively provided with There is a connecting flange 2 24, between the left cylinder body 4 and the sewage or surface water left head 8 and between the right cylinder body 5 and the sewage or surface water right head 9 respectively through the connection flange 1 23 and the connection flange Two 24 and the sealing ring 25 arranged between the two are detachably sealed and connected (connected by bolts). The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com