Upper driving type no-clean vacuum fryer

A vacuum fryer, no-clean technology, is applied to the utensils for frying things in oil, household utensils, applications, etc., and can solve the problems of laboriousness, easy accumulation of residues at the bottom of the pot body, and complex structure of the bottom of the pot body, etc. The effect of simplifying the connection structure and the internal structure of the pot body, improving the frying effect and product quality, and solving the problem of residue retention and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

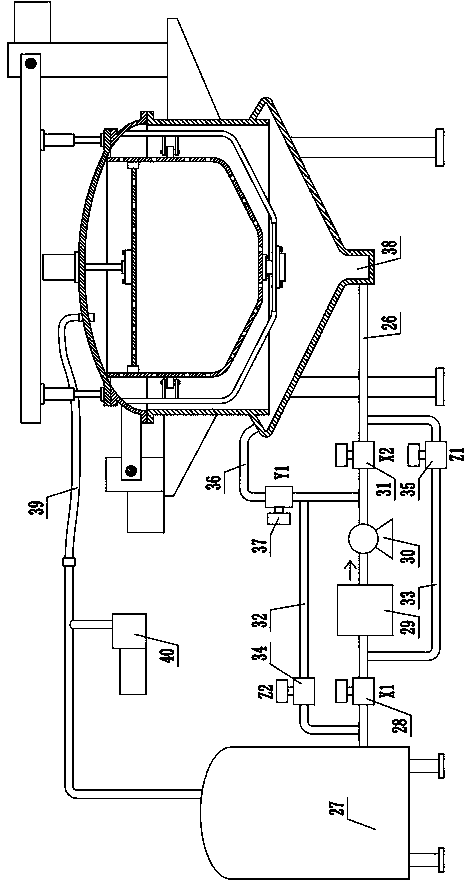

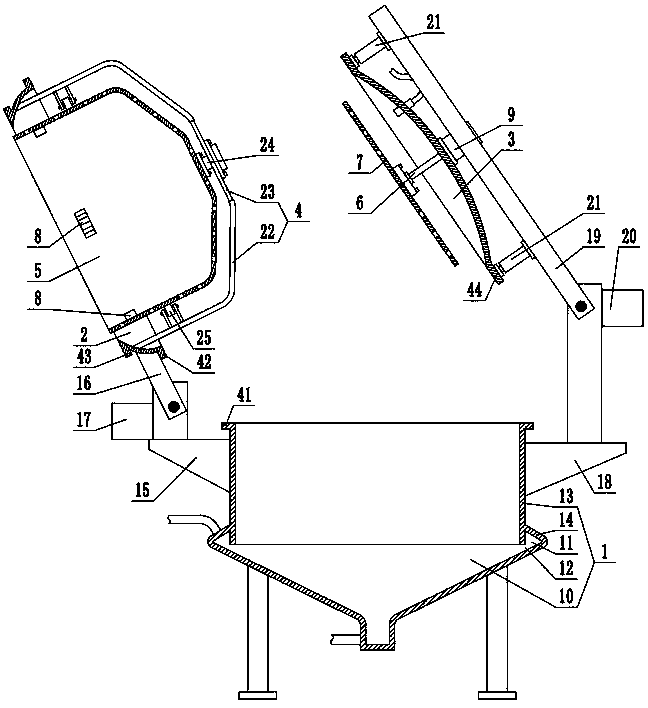

[0022] In order to describe the structure of the present invention conveniently, define now figure 1 The left side is the left side of the present invention, and the definition figure 1 The upper side is the top of the present invention.

[0023] Referring to the accompanying drawings, the upper-driven no-cleaning vacuum fryer includes a pot body 1 with a pot mouth on the top, a ring-shaped pot cover 2 sealed and pressed on the top of the pot body 1, and an opening on the ring-shaped pot cover 2 sealed and pressed. The circular pot cover 3; wherein, the ring-shaped pot cover 2 is roughly in the shape of a cone with a small diameter at the upper end and a large diameter at the lower end. Of course, the ring-shaped pot cover can also be cylindrical. Secondly, in order to improve the pot Body 1, annular pot cover 2 and circular pot cover 3 contact area and tightness, preferably the upper end of pot body 1 is annularly welded with radially outwardly protruding lower flange 41, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com