Flexible strip material caching device and flexible strip material processing and production line thereof

A flexible belt and production line technology, applied in the field of textile dyeing and finishing, can solve the problems that the continuity of the water press and the setting machine cannot be guaranteed, the integrity of the fabric is affected, and the production efficiency is low, so as to solve the problem of the retention of the flexible belt and maintain the overall performance, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

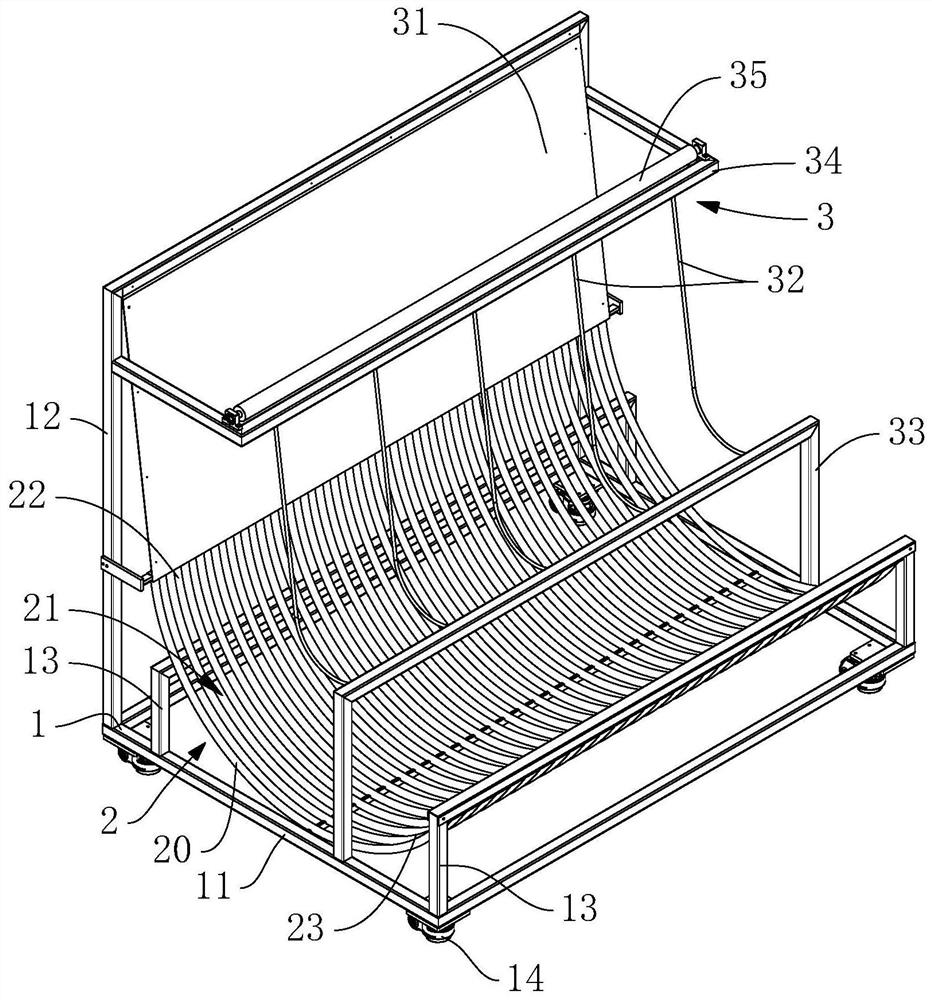

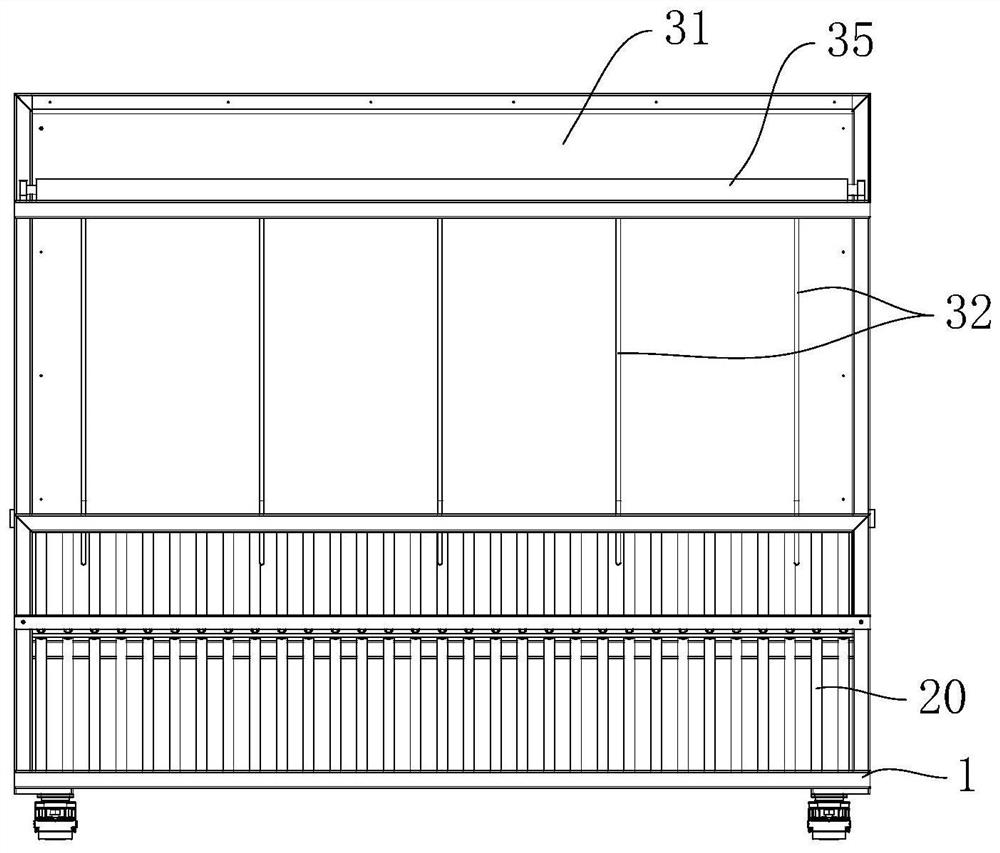

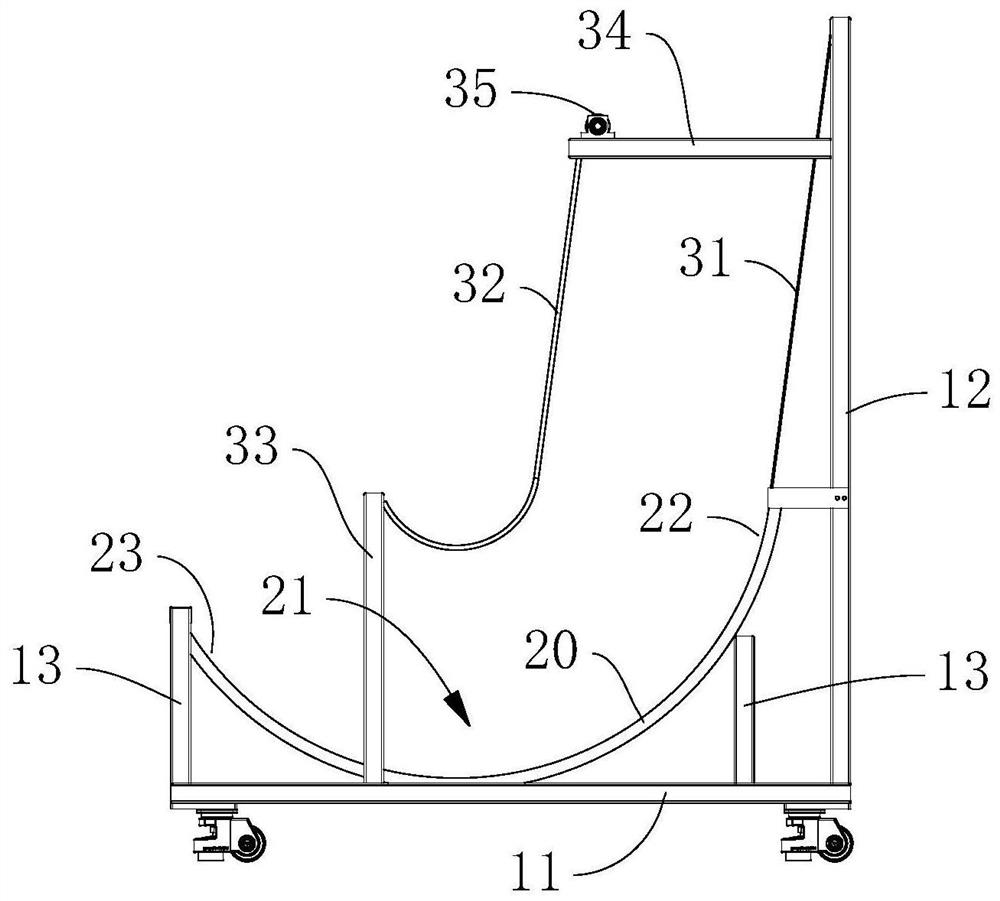

[0028] see Figure 1 to Figure 3 , The invention provides a flexible strip material buffering device, which can be used to guide the cloth for buffering, so as to solve the problem of cloth retention between the water press and the setting machine. The flexible strip buffering device includes a frame 1 and a strip guide structure 2 arranged on the frame 1. The strip guide structure 2 is formed with an arc-shaped chute 21, and the opening of the arc-shaped chute 21 is upward for the cloth to pass The feed end 22 of the arc-shaped chute 21 slides into and is stacked in the arc-shaped chute 21 , and the cloth slides to the discharge end 23 of the arc-shaped chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com