Triple motion device for striding multiple lines using in delivery lines

A technology for moving a traveler and a conveyor line, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of long processing time, increase costs, occupy space, waste resources, etc., and achieve institutional solutions, saving resources and saving time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

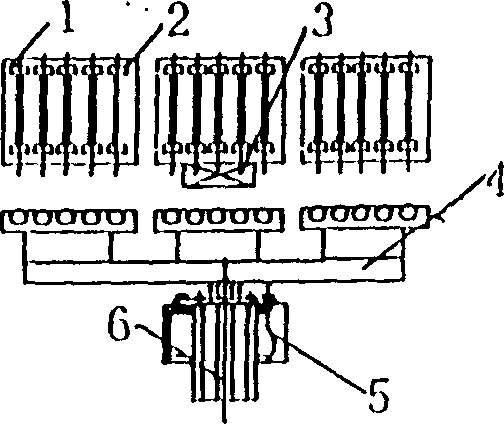

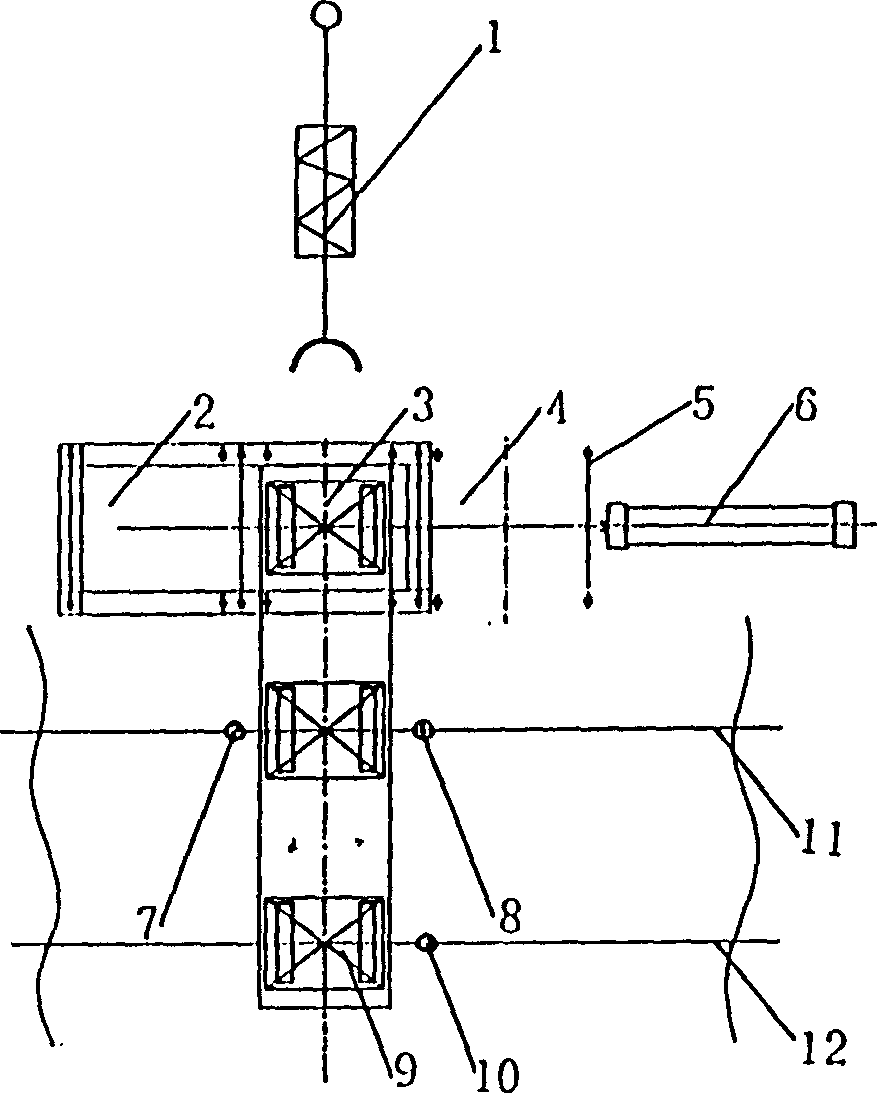

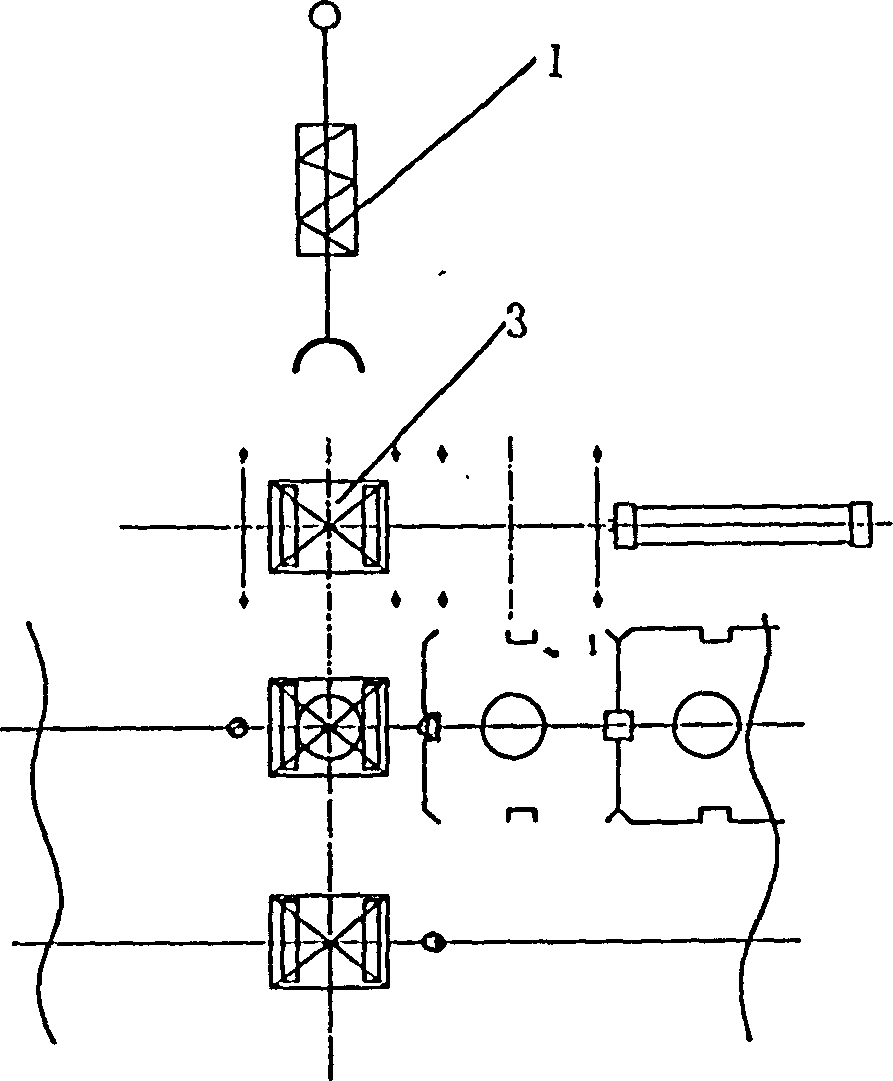

[0020] Control attached figure 1 , its structure is that the jacking cylinder 6 is installed on the jacking cylinder mounting frame 5, and then connects with the three-position connecting device 4, thereby driving the three shifting position support plates 1 to lift. When working, the three-position connecting device 4 ejects the three shifting position support plates 1, and the shifting driving device 3 directly rotates the shifting stick group 2 to shift the tray.

[0021] In the embodiment, one cylinder pushes three traveling supporting plates, pushes the three-moving traveling plates out of the line, lifts up the tray, and drives the motor to drive the stick installed on the traveling plates to move the tray arbitrarily; the traveling mechanism is used for three rows Or a moving device for multiple rows of line bodies; installed at the line body station, one of the positions of the moving machine is also an operating platform. The following is a description of the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com