Novel transmission shaft support structure

A supporting structure and transmission shaft technology, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of easy damage, cracking, high rigidity value requirements, high hardness of rubber materials, etc., and achieve extended use The effect of improving the service life, improving the pass rate, and improving the sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

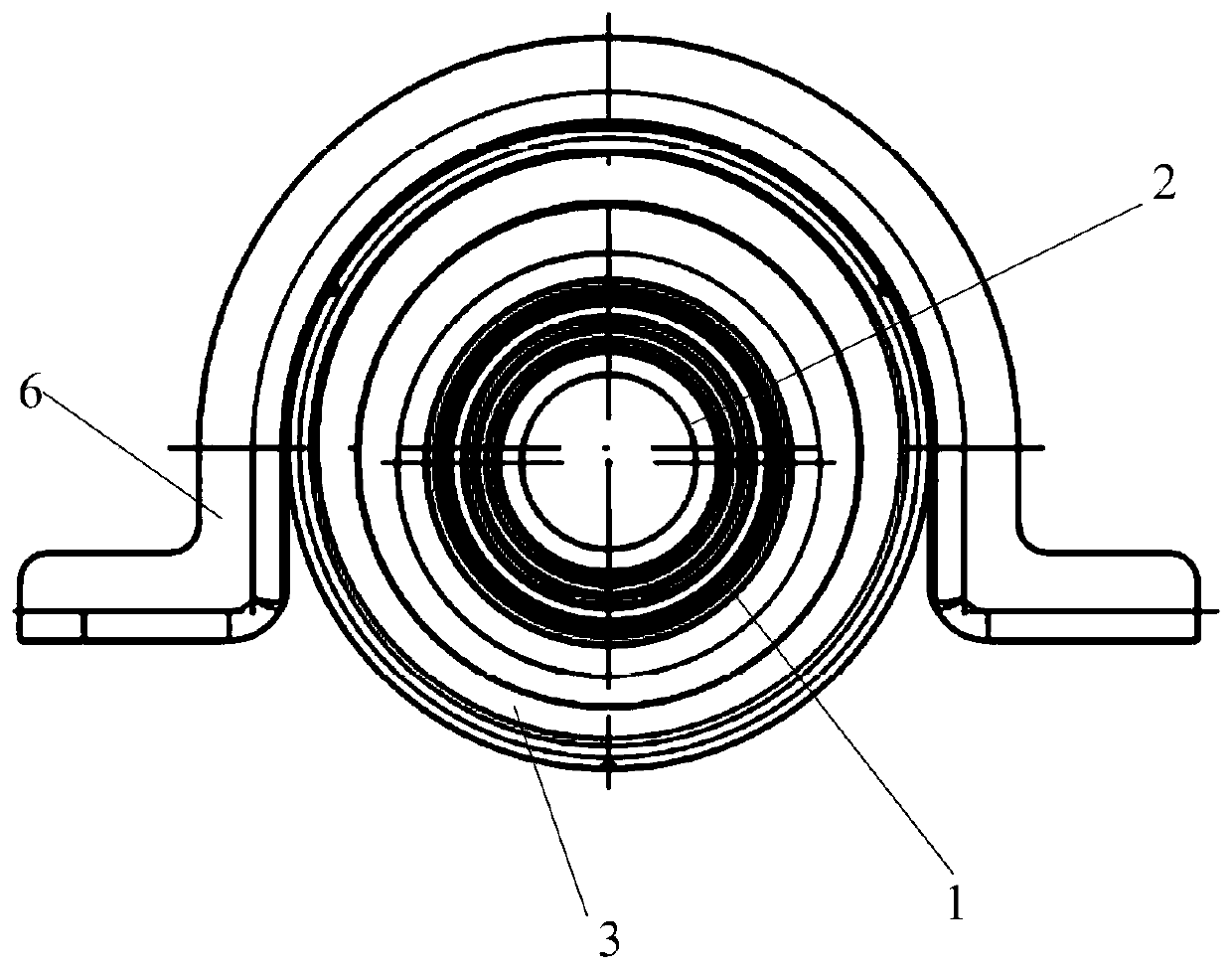

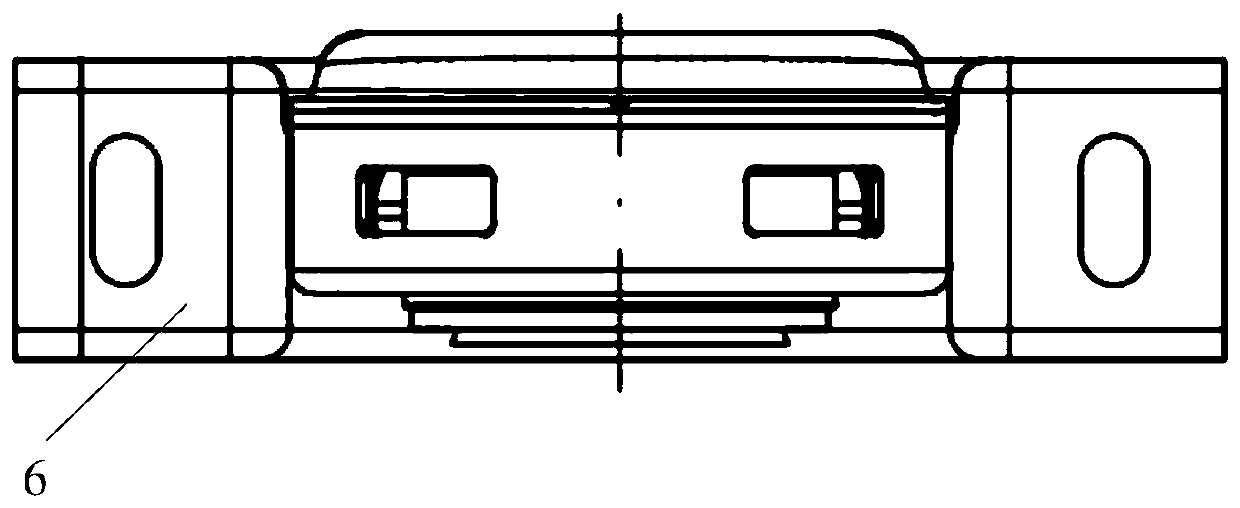

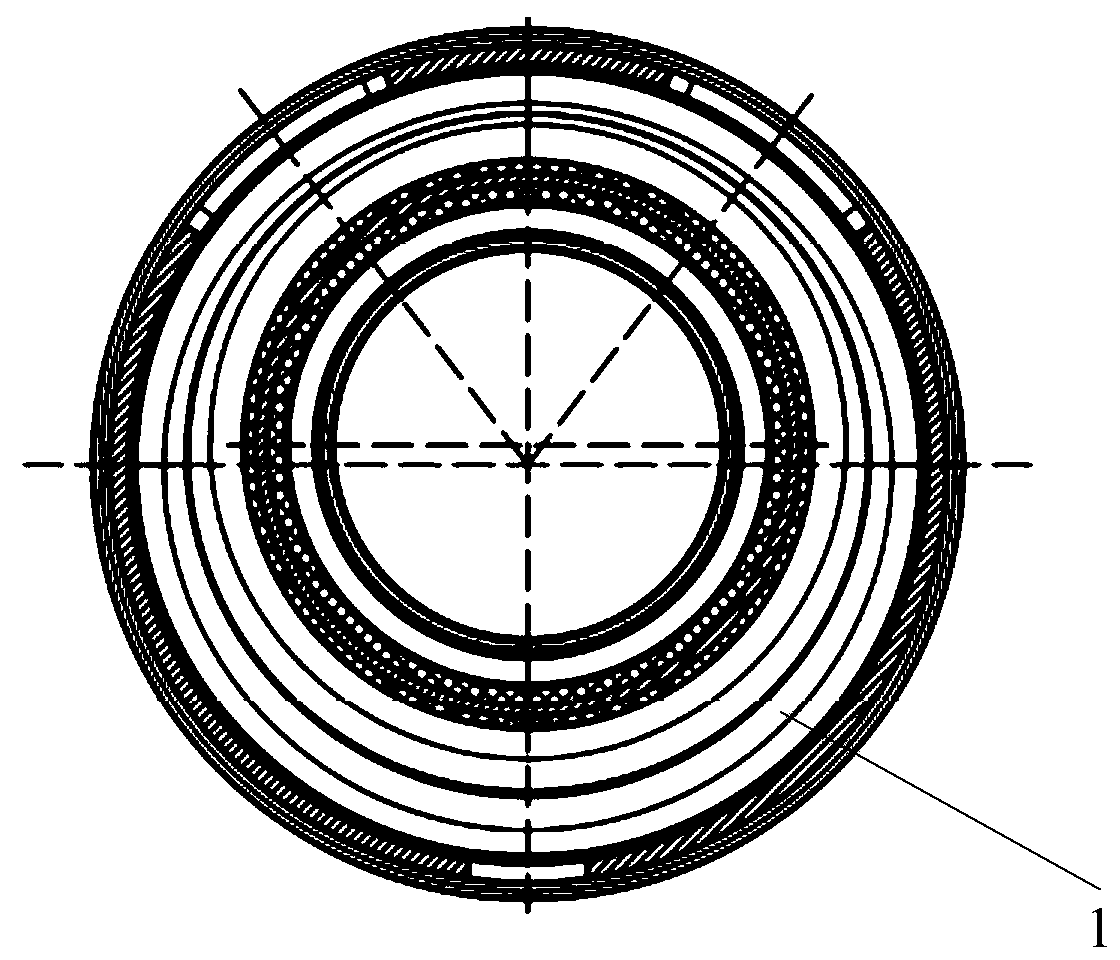

[0028] Such as Figure 1-10 As shown, the present invention discloses a novel transmission shaft supporting structure, comprising a main rubber spring 1, an inner metal part 2 of the main rubber spring, and an outer metal part 3 of the main rubber spring, and the main rubber spring 1 is installed on the main rubber spring Between the inner metal part 2 and the outer metal part 3 of the main rubber spring, the inside of the main rubber spring 1 is hollow in a circular arc, and the inner metal part 2 of the main rubber spring is located at the inner ring of the main rubber spring 1, The outer metal part 3 of the rubber main spring is located at the outer ring of the rubber main spring 1, and the standard bearing 8 is installed on the rubber main spring 1, and its circular arc transition and hollow structure can ensure the rigidity performance of the product; The structure of the main rubber spring 1 is realized by a special rubber vulcanization mold.

[0029] The inner metal pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com