Patents

Literature

46 results about "Lead hydroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead(II) hydroxide, Pb(OH) 2, is a hydroxide of lead, with lead in oxidation state +2. It is doubtful that such a simple compound exists. Lead basic carbonate (PbCO 3 ·2Pb(OH) 2) or lead(II) oxide (PbO) is encountered in practice where lead hydroxide is expected. This has been a subject of considerable confusion in the past.

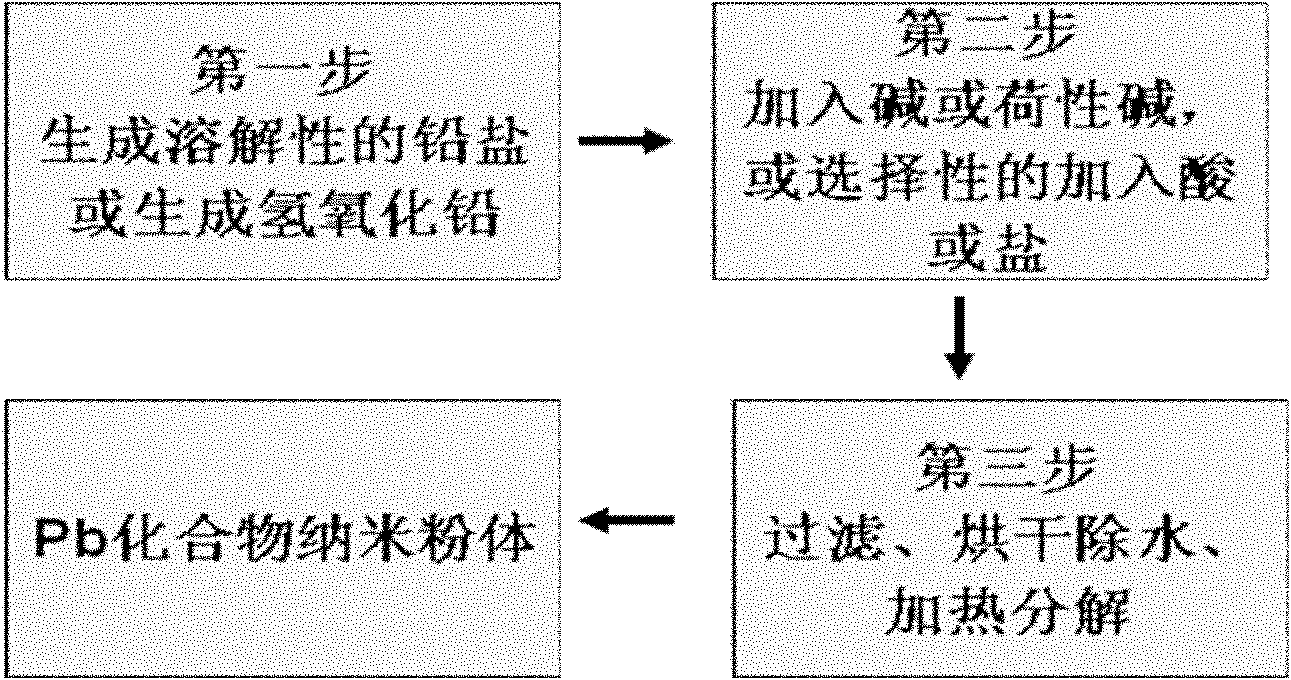

Lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery

ActiveCN102689922AEnvironmental recyclingEnvironmental productivityLead monoxideNanotechnologySolubilityLead salt

The invention discloses a lead compound nano-powder preparation method for recovery and manufacture of lead-acid battery. The lead compound nano-powder preparation method comprises the following steps that 1, lead, a lead salt or waste lead-acid battery lead paste reacts with one or more organic or inorganic compounds to produce a soluble lead salt solution or a lead hydroxide solution; 2, one or more alkalis or caustic alkalis are added into the soluble lead salt solution, or a part or excess amount of H2CO3 or CO2, sulfuric acid, one or more organic acids or their salts are added into the lead hydroxide solution, and 3, lead oxide or lead hydroxide precipitates obtained by the step 2 are filtered and are subjected to drying and pyrolysis to form the lead compound nano-powder. The lead compound nano-powder preparation method realizes environmentally friendly recovery and production, has low energy consumption, greatly reduces a production cost, and shortens a production period. The lead compound nano-powder obtained by the lead compound nano-powder preparation method is conducive to improvement of technical product performances.

Owner:杨春晓

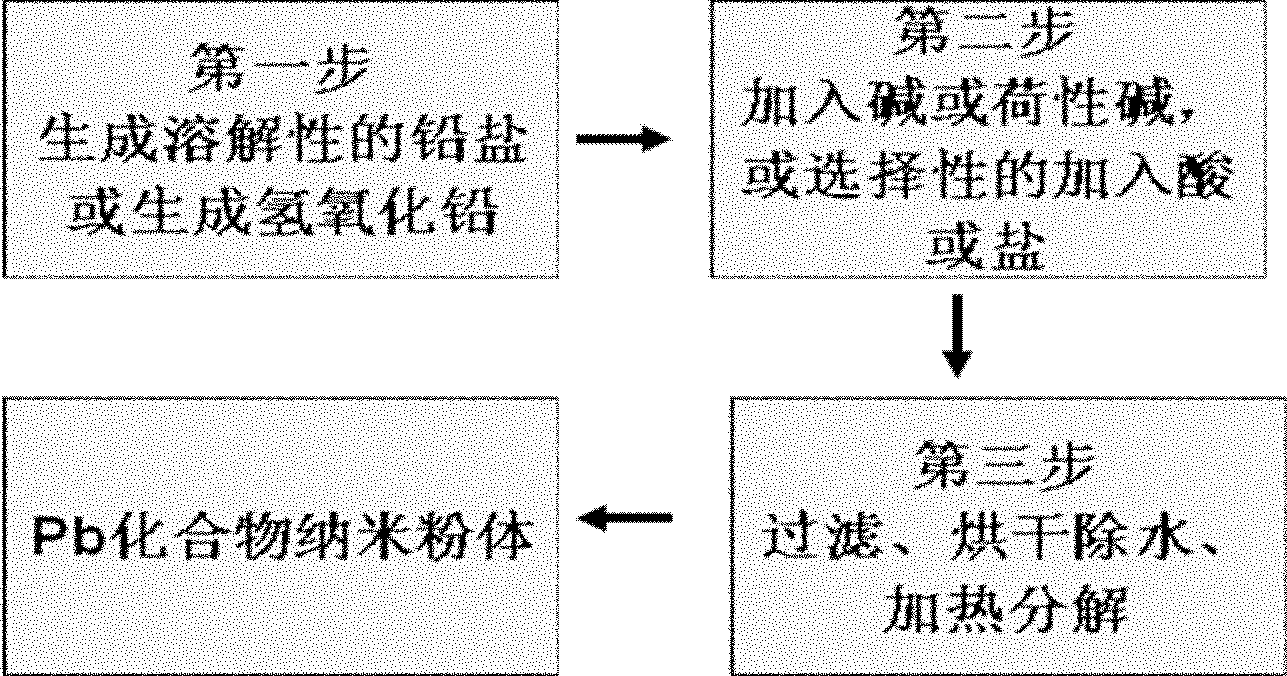

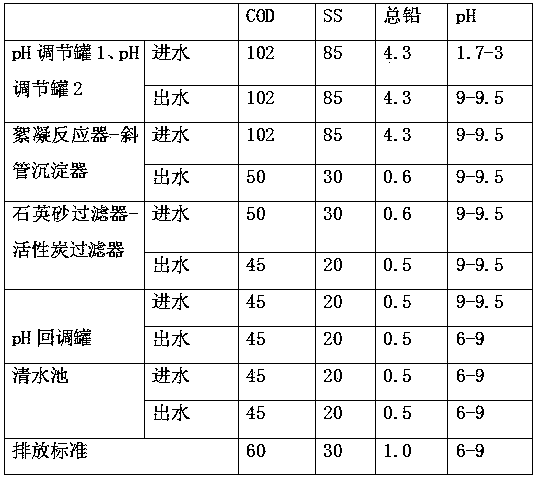

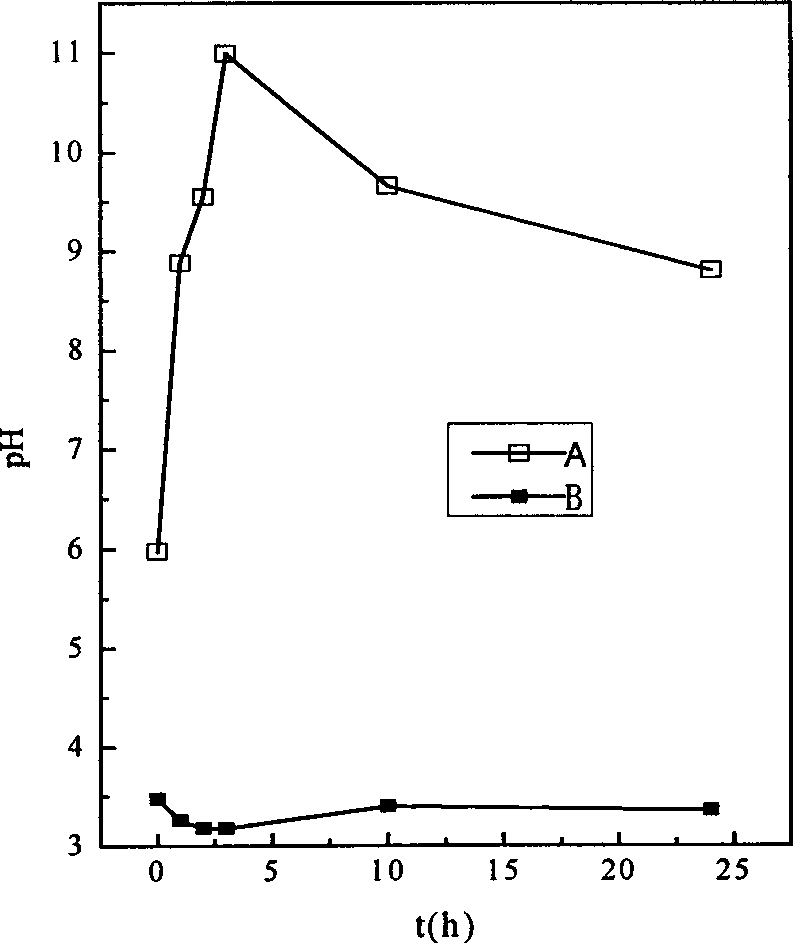

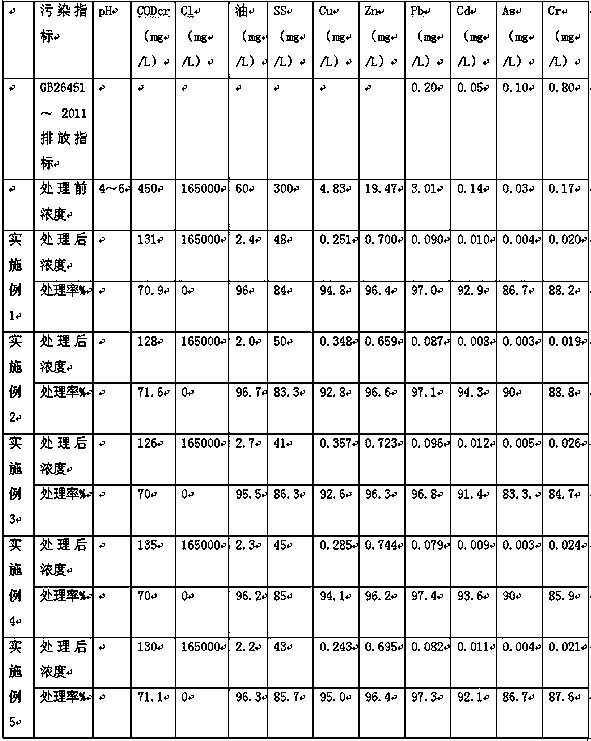

Treatment process for plumbic acid waste water generated in production process of lead storage batteries

InactiveCN103482783ASmall footprintEasy to useSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentActivated carbon filtrationSludge

The invention relates to a treatment process for plumbic acid waste water generated in the production process of lead storage batteries. The treatment process comprises the steps that large-size suspended matter engine oil in the waste water is removed, the waste water enters a water collection pool later, the water quality and water amount are adjusted, alkali liquor is added for adjusting pH of the waste water, the waste water and lead hydroxide sediments enter a flocculation reaction tank, a flocculating agent is added, heavy metal is caught, a colloid is formed, sludge and the water are separated and clarified through an inclined tube precipitator and by means of gravity settling, upper liquor and the sludge are separated, the upper liquor automatically flows to a quartz sand filter through an overflow weir, suspended matter and total lead are removed, then the upper liquor flows to an activated carbon filtering layer, the suspended matter and the total lead are further removed, filtered outlet water enters a pH return tank, diluted hydrochloric acid with the concentration of 10 percent is added to adjust pH to be neutral, and then the filtered outlet water enters a clean water basin and is cycled and reused. According to the treatment process, harmful chemical reagents are not used, the sludge quantity is small, secondary pollution is avoided, the discharged water can be reused, metal in the bacterial sludge can be recovered, the bacterial sludge can be used as fertilizer, and therefore resources and the cost are saved.

Owner:ANHUI GREEN TITAN ENVIRONMENTAL TECH

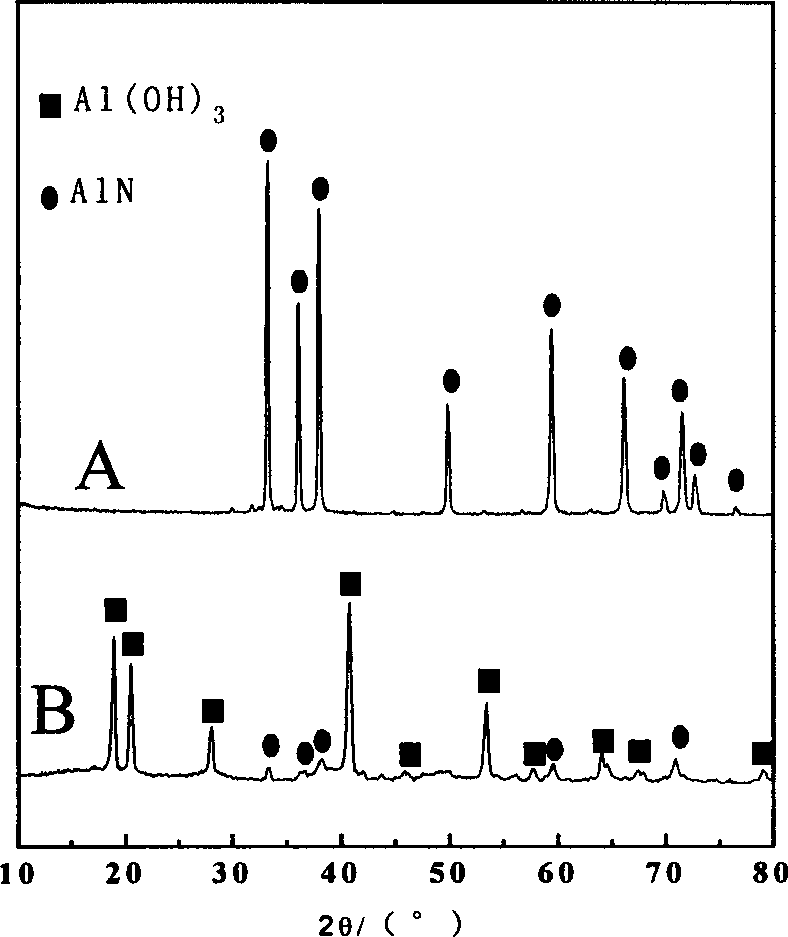

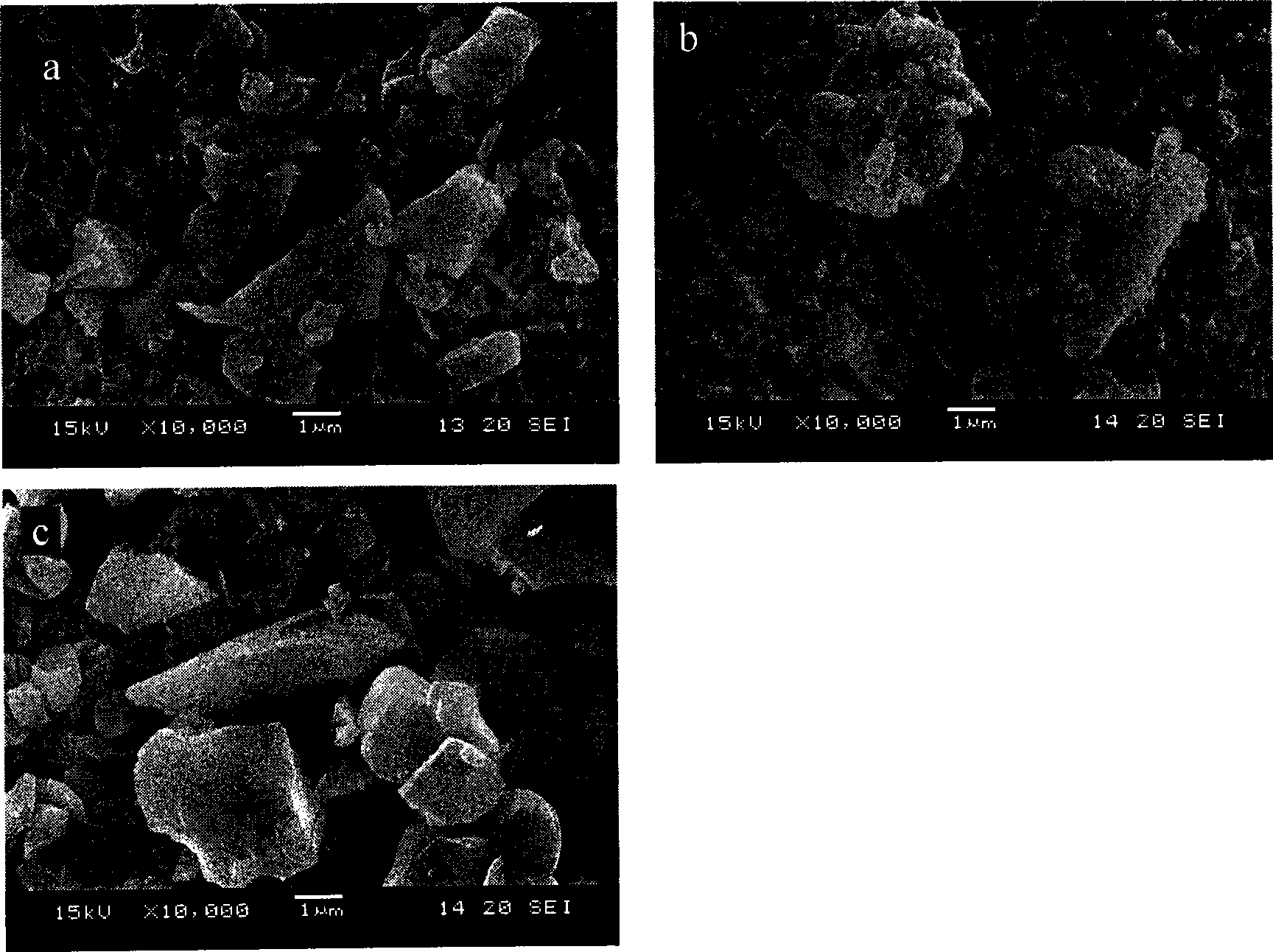

Process for producing hydrolyzation resistant AlN powder

The invention relates to a method for preparing a hydrolysis resistant AIN powder. In the method, the AIN powder is modified by esterification reaction between acid and hydroryl group and hydrolysis of the AIN powder in a humid environment is inhibited to improve hydrolysis resistance thereof. The method comprises the following steps: carrying out ball milling on AIN AI (H2PO4)3 and oxyacid in organic solution for several hours to lead hydroxide radical on surface of the AIN particles to react with acid and form a compact protective layer on the surface of the AIN particles; then washing the AIN powder for numerous times by absolute ethyl alcohol; and drying the washed AIN powder at the temperature of 50-70 DEG C, thus obtaining the hydrolysis resistant AIN powder. The modified AIN powder remains stable at the humid environment with the temperature below 80 DEG C and is free from hydrolysis reaction. The method of the invention is easy to operate with good reproducibility and outstanding anti-hydrating capacity, thus effectively solving the problem that the AIN is extremely prone to be hydrolyzed in the humid environment.

Owner:NANJING UNIV OF TECH

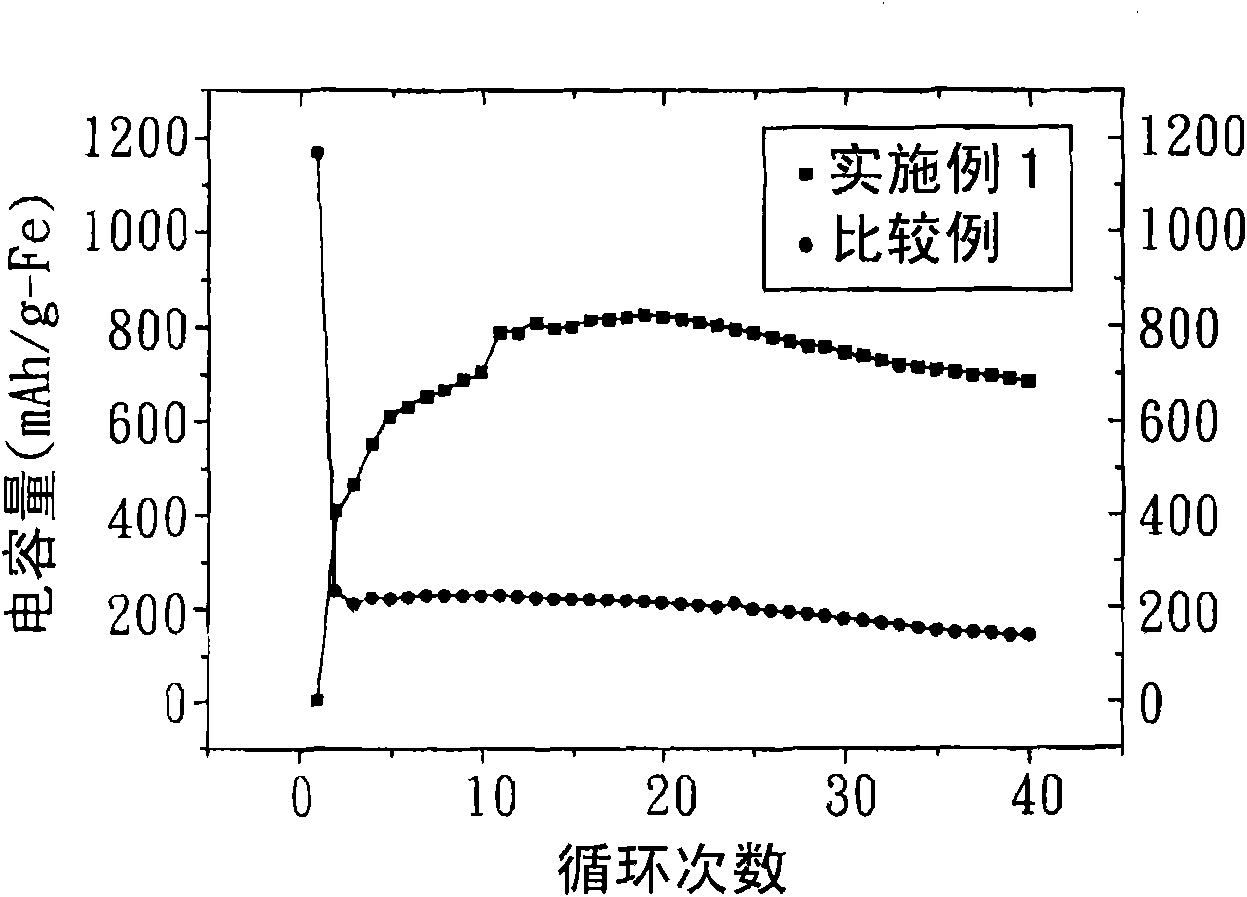

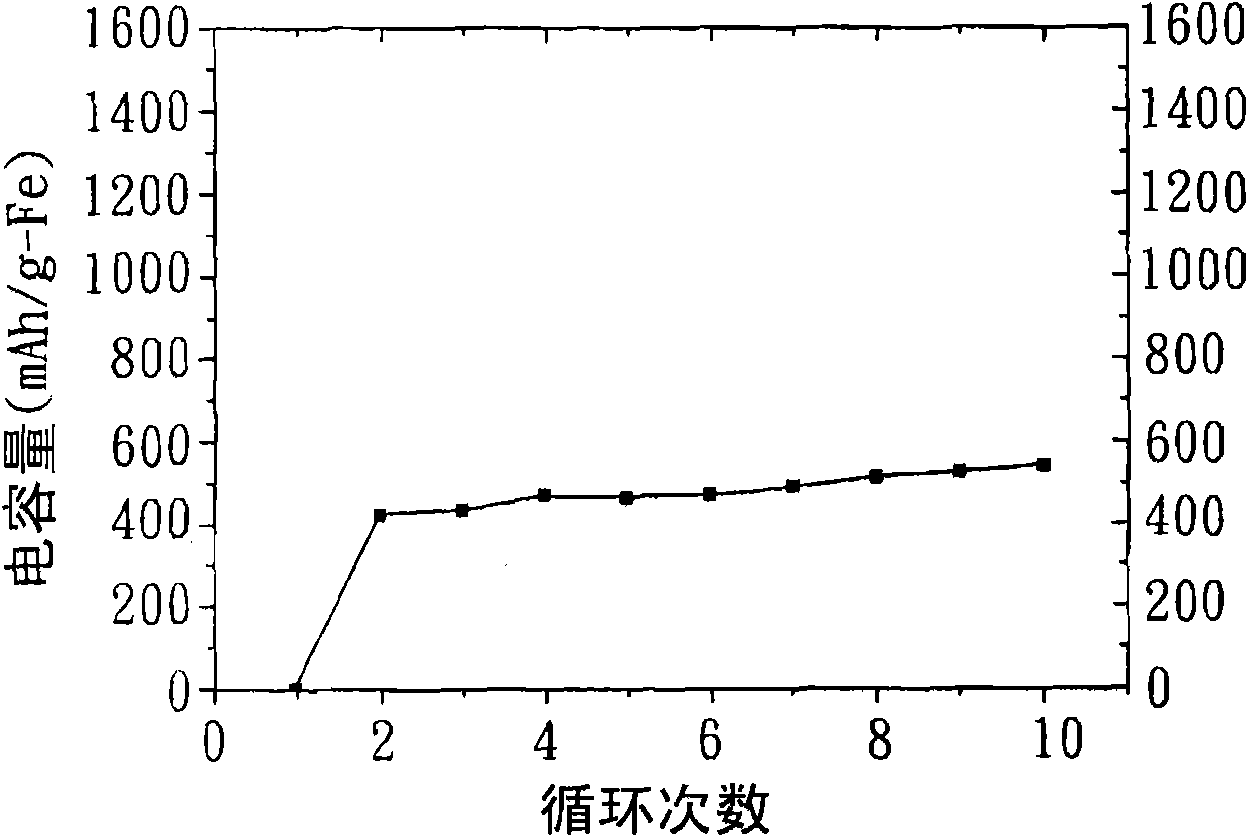

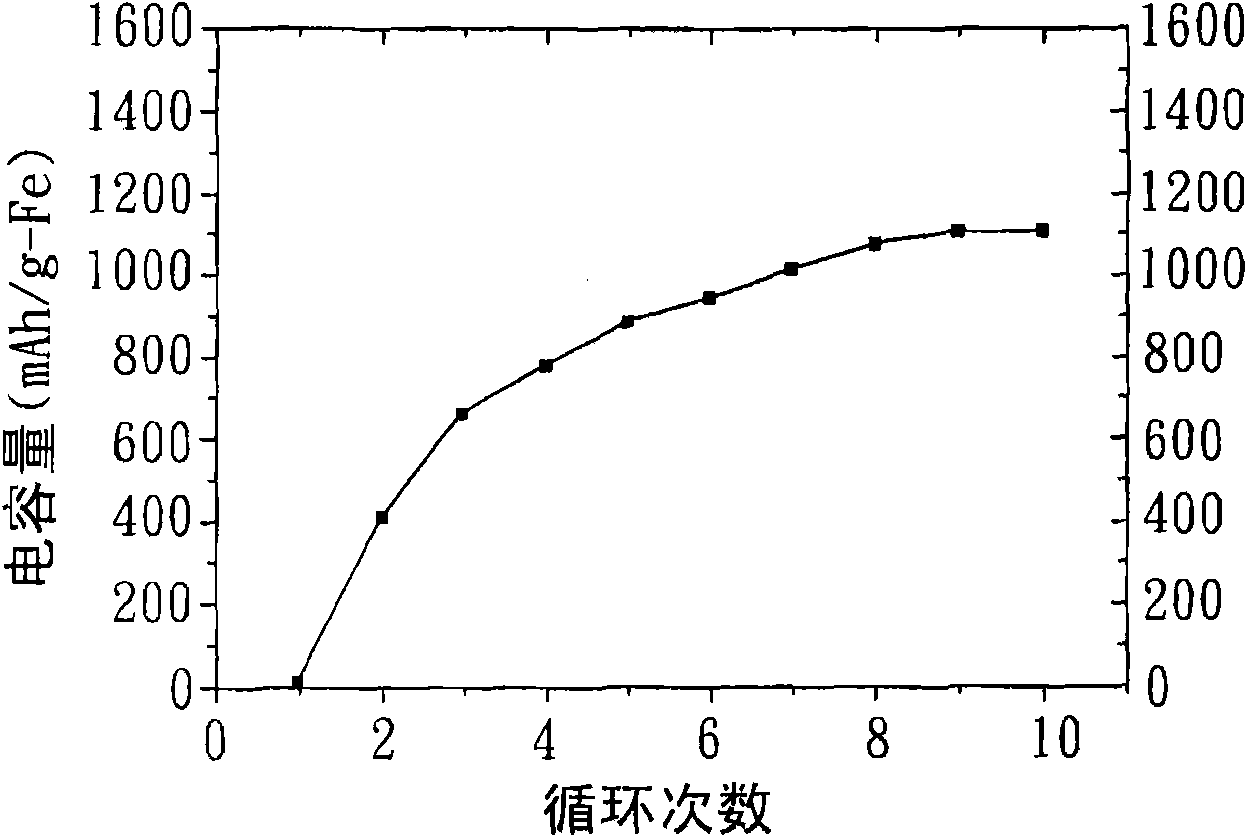

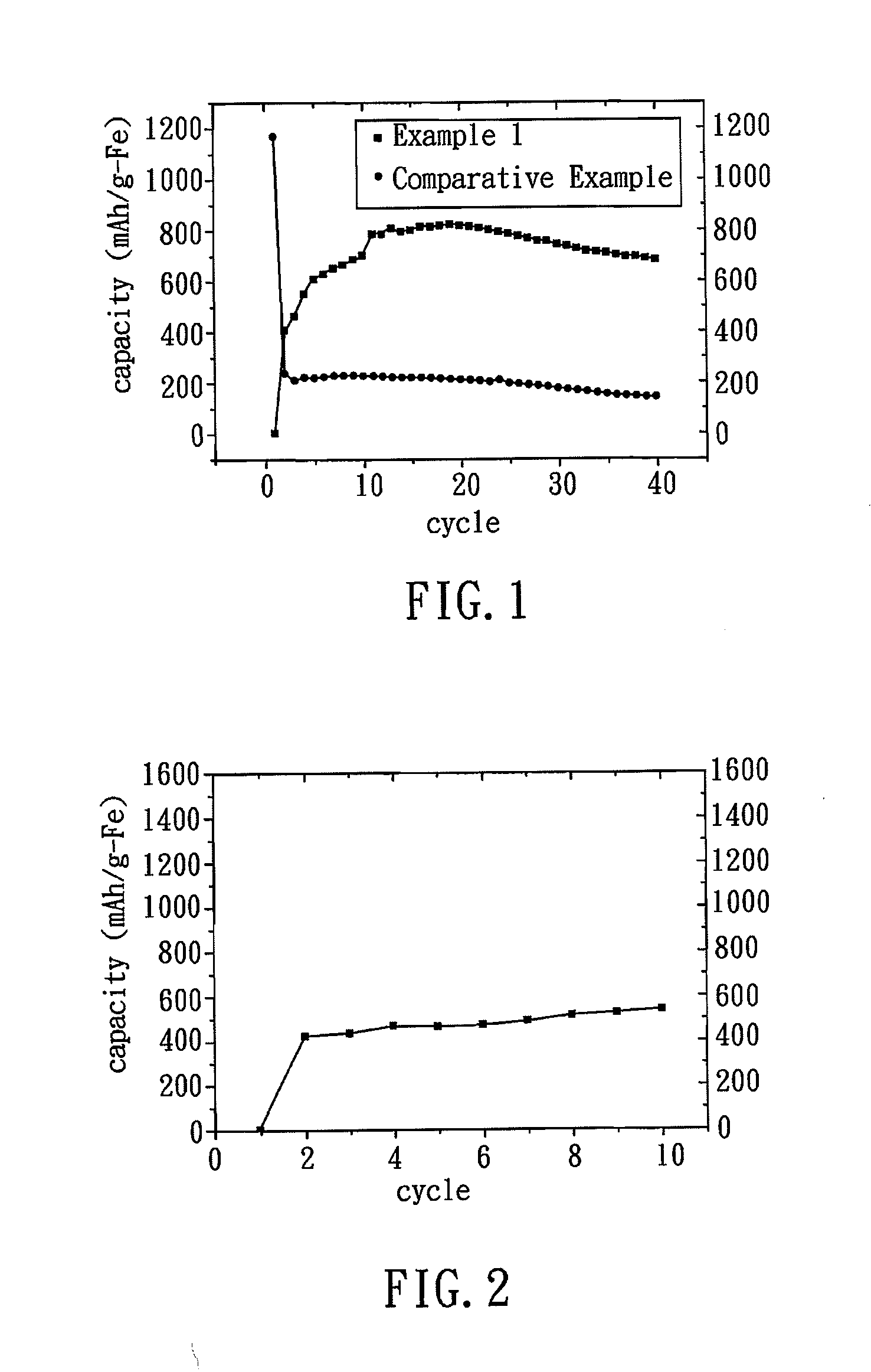

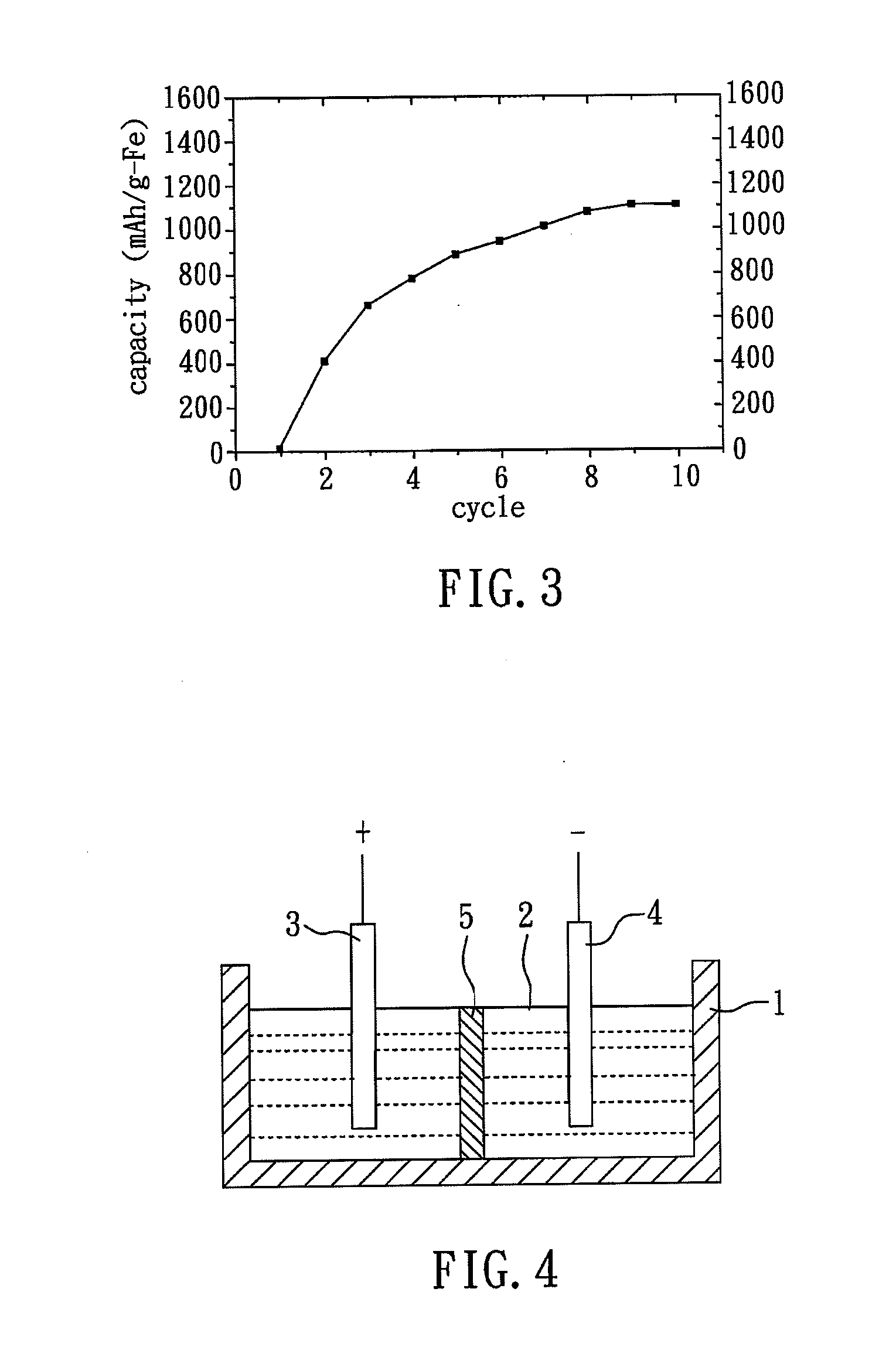

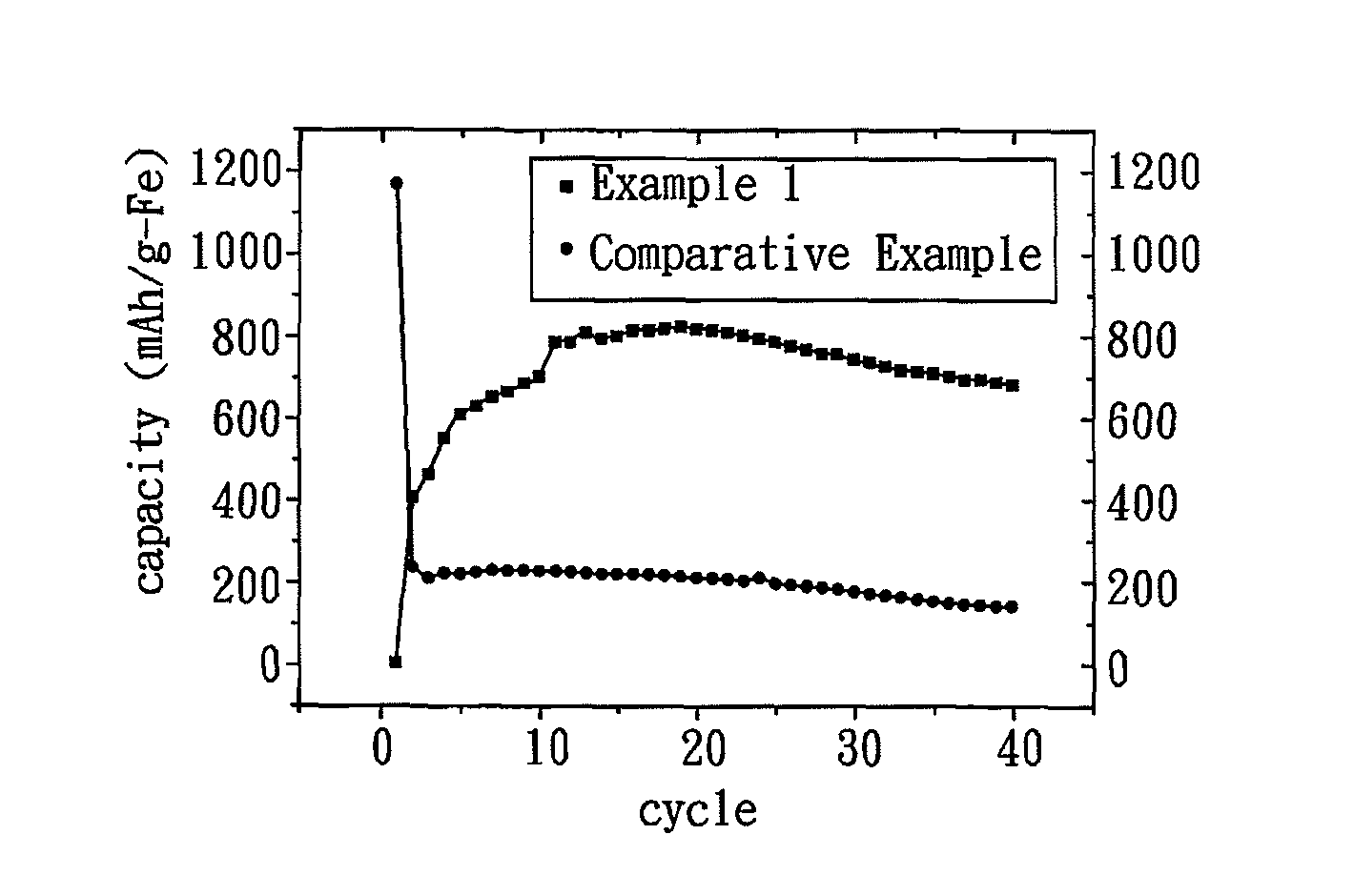

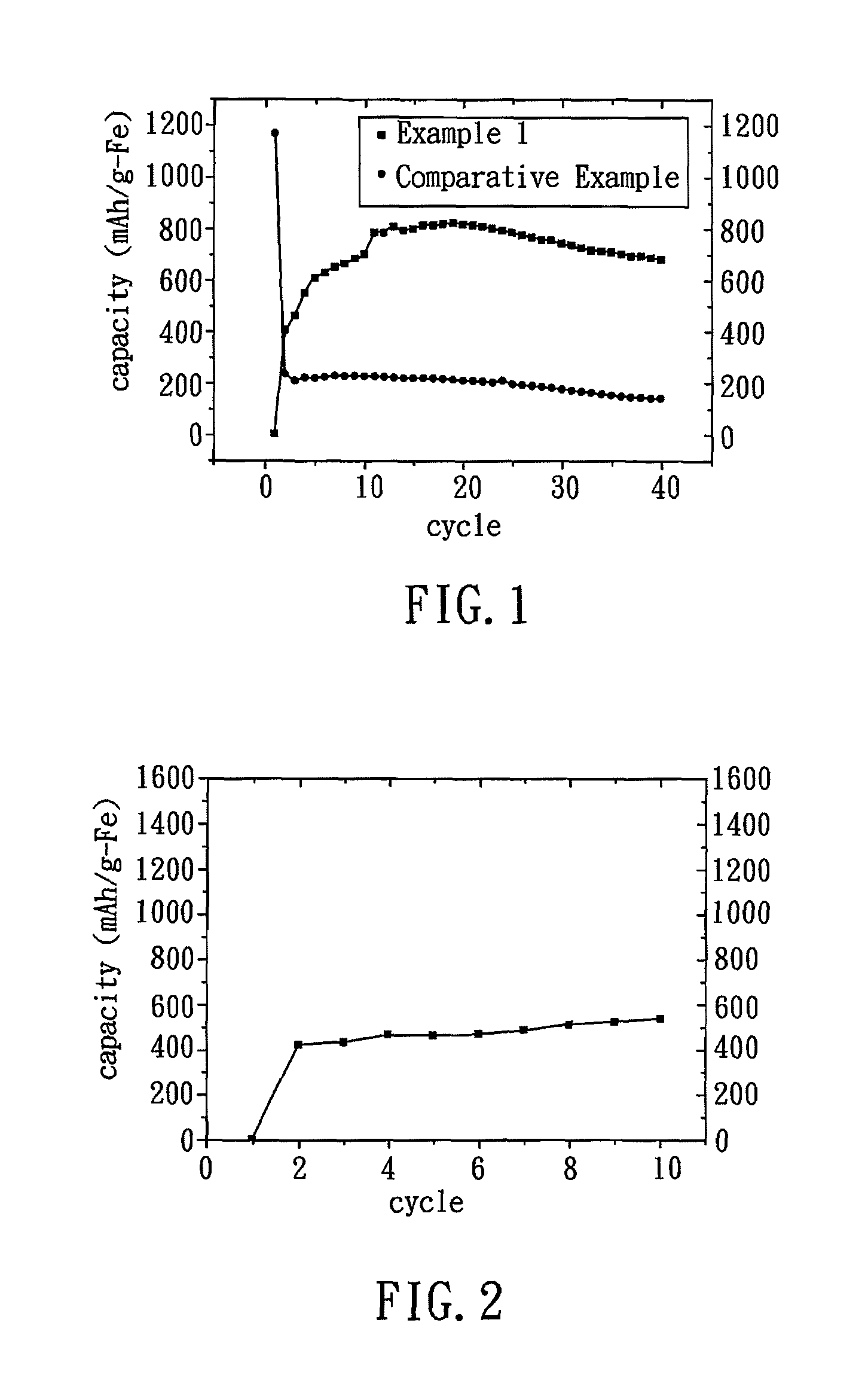

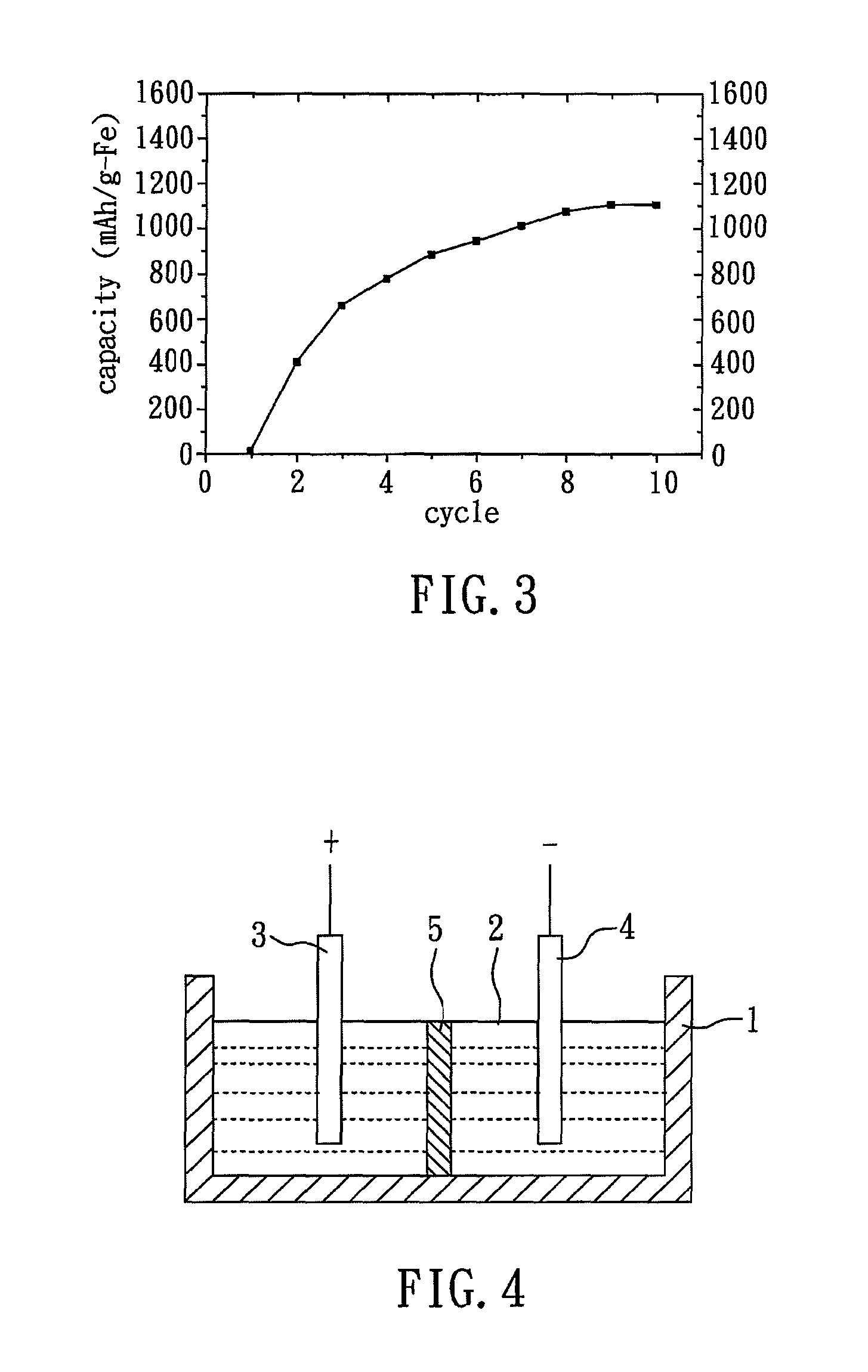

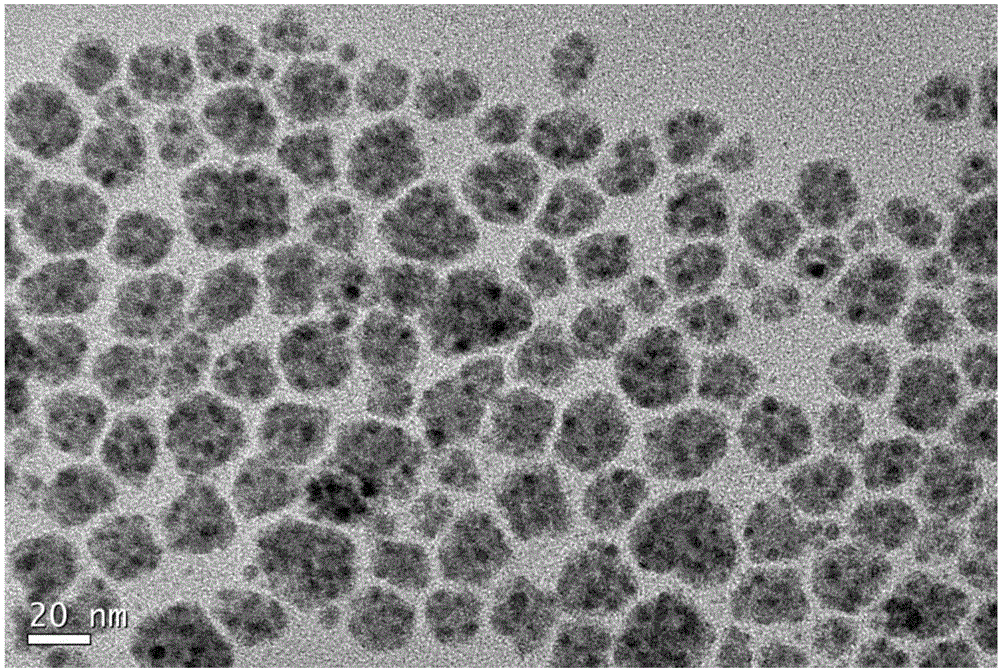

Cathode electrode composite material and preparation method thereof and electrochemical device applying same

InactiveCN102214822ASimple processReduce manufacturing costAlkaline accumulator electrodesNickel accumulatorsIndiumNickel salt

The invention discloses a cathode electrode composite material, which comprises a plurality of ferriferous oxide particles and a conductive aid which is selected from copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, cupric salt, cobalt salt, nickel salt, tin salt, antimonic salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, cupric hydroxide, cobalt hydroxide, nickel hydroxide, tin hydroxide, stibine hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and a group consisting of the combinations. When applied to an electrochemical device, the cathode electrode composite material can show high charging and discharging characteristics and high electric capacity. Moreover, the invention provides a preparation method of the cathode electrode composite material and an electrochemical device applying the same.

Owner:NATIONAL TSING HUA UNIVERSITY

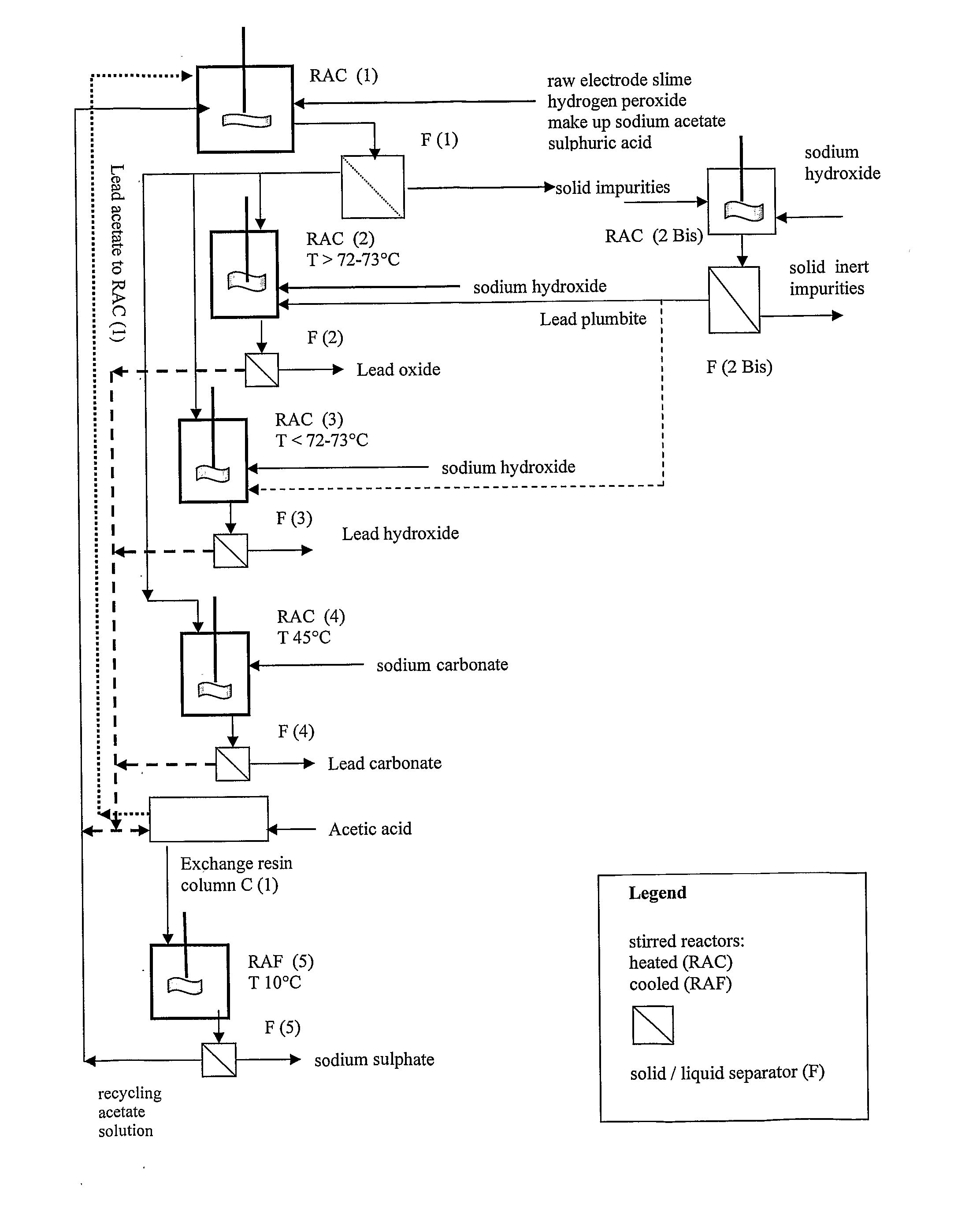

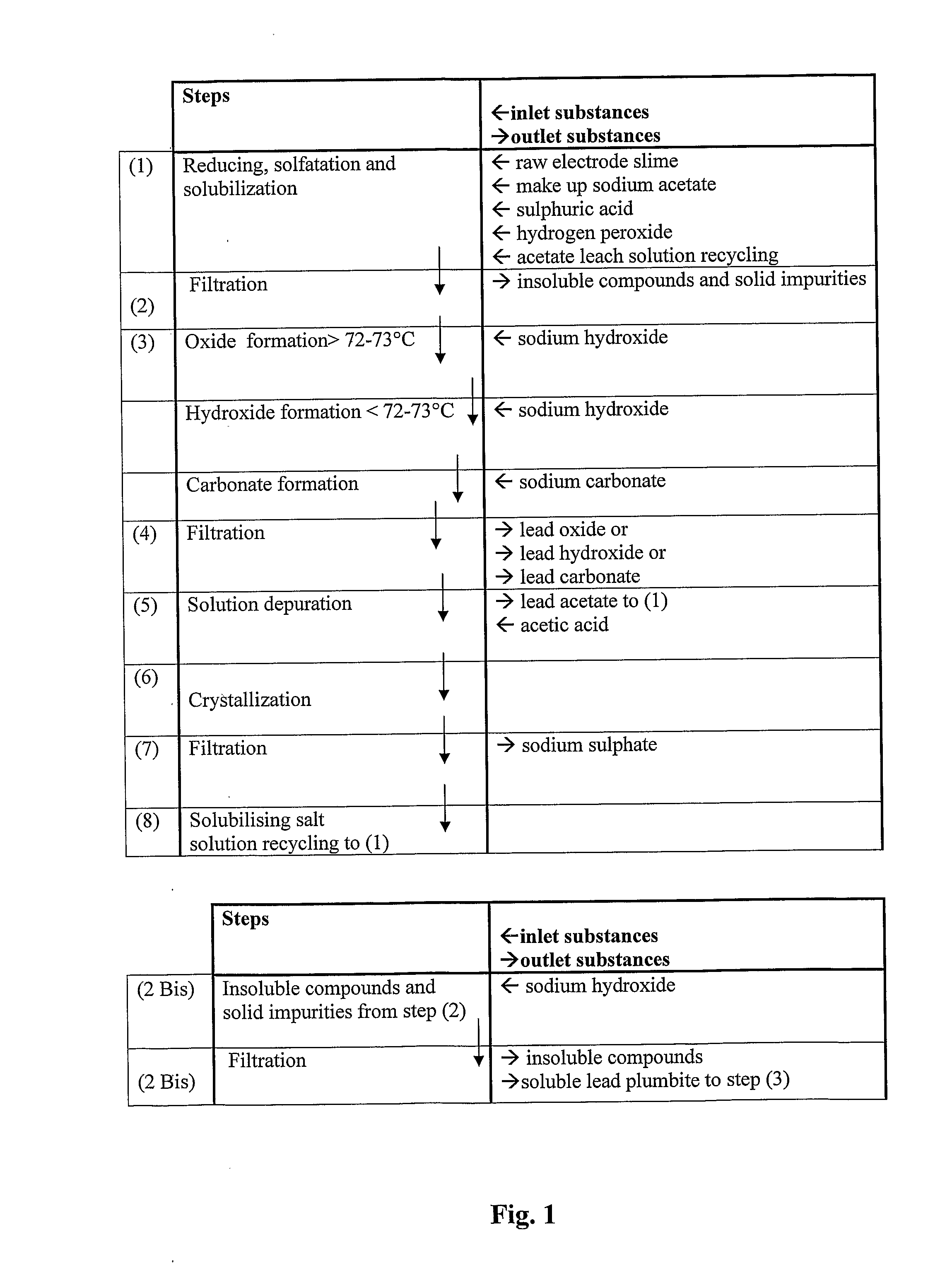

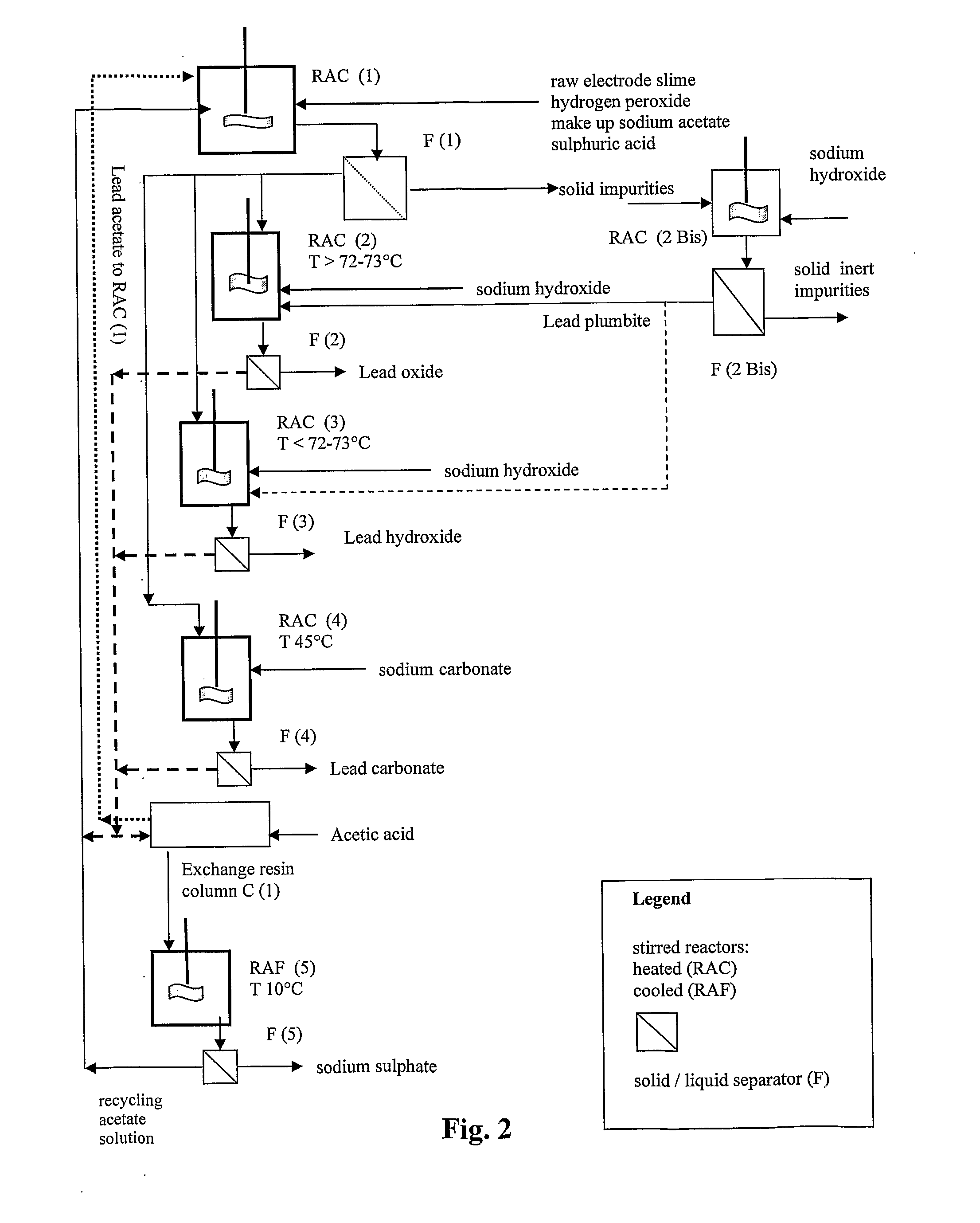

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

InactiveUS20120186397A1Reduce recycling costsEffective simplificationFinal product manufactureWaste accumulators reclaimingInorganic lead compoundSolid phases

An all-wet process for reclaiming the lead content of impure electrode paste or slime from discarded lead batteries and / or lead minerals, in form of high purity lead compound, comprises a) suspending the impure lead containing material in a lead sulphate dissolving aqueous solution of a salt belonging to the group composed of the acetates of sodium, potassium and ammonium; b) adding to the suspension sulphuric acid in an amount sufficient to convert all lead oxides to lead sulphate soluble in the acetate salt solution and slowly adding to the suspension either hydrogen peroxide or a sulphite or bubbling sulphurous anhydride through it, in a measure adapted to reduce any lead dioxide to lead oxide converted eventually to soluble lead sulphate by the sulphuric acid; c) separating a limpid acetate salt solution containing dissolved lead sulphate from a solid phase residue including all undissolved compounds and impurities; d) adding to the separated solution of lead sulphate either carbonate or hydroxide of the same cation of the acetate salt of the lead sulphate dissolving solution for precipitating highly pure lead carbonate / oxycarbonate or lead oxide or hydroxide, respectively, while forming sulphate of the cation, soluble in the acetate salt solution; and e) separating the precipitated high purity lead compound from the acetate salt solution now containing also sulphate of the same cation of the acetate salt. The acetate salt solution containing also sulphate of the same cation of the acetate salt separated from the precipitated compound of lead is re-cycled to step a) and the content of sulphate of the same cation in the solution is maintained below saturation limit by continuously or periodically cooling at least a portion of the solution separated from the precipitated lead compound to cause selective crystallization of sulphate salt of the same cation of the acetate salt and removing it as a by-product. Optionally, the separated solid phase comprising insoluble compounds of lead and / or undissolved concretions of lead compounds is treated in hot concentrated hydroxide of the same cation of the selected acetate salt and converting these compounds of lead and / or undissolved concretions of lead compounds to soluble plumbites, and the separated lead containing alkaline liquor may be added to the limpid acetate solution for precipitating all reclaimable lead in form of high purity lead oxide or hydroxide.

Owner:MILLBROOK LEAD RECYCLING TECH

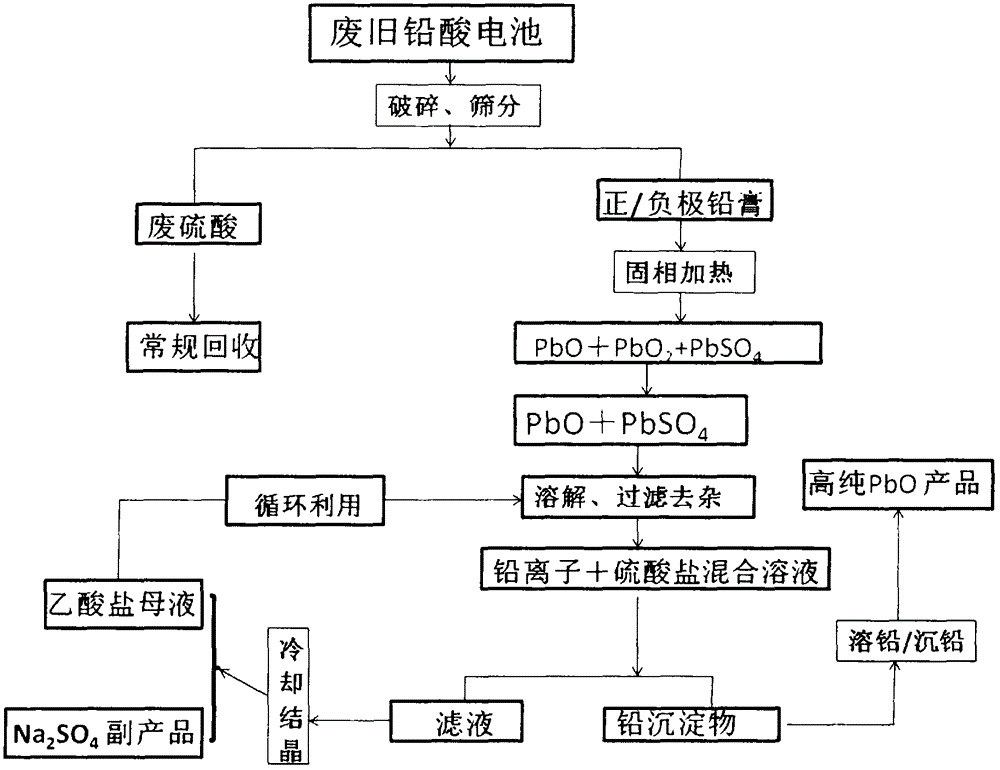

Method for preparing high-purity PbO by cycle wet method

InactiveCN105895983AImprove recycling efficiencyReduce process stepsWaste accumulators reclaimingProcess efficiency improvementHigh energyEngineering

The invention relates to a method for preparing high-purity PbO by a cycle wet method, and provides a method for recycling a waste lead-acid battery to directly produce high-purity PbO and recycling a chemical raw material. The preparation method for the high-purity PbO comprises the following steps of smashing a waste battery, separating positive / negative lead paste, and allowing lead in the lead paste to be completely converted to a lead raw material composed of PbO and PbSO4 through oxidation and reduction reaction of the positive / negative lead pate; immersing the lead raw material with a mixed solution of an organic acid and an organic acid salt to remove impurity, and carrying out lead deposition and desulfuration on the solution, generating a byproduct sodium sulfate to obtain a lead precipitate; purifying the lead precipitate with an alkaline solution by dissolving the precipitation process to obtain high-purity lead hydroxide; and carrying out low-temperature sintering on the lead hydroxide to obtain a high-purity PbO product, wherein an organic acid salt mother liquid can be used for next circulation. By the method, the defects of long process period of a PbO synthesis process, high energy consumption and a large amount of chemical raw materials required to be consumed are overcome, the cost is reduced, and the method is a new technology which has the advantages of high technological additional value, energy saving and environment friendliness, and is suitable for industrial production at a large scale.

Owner:NO 63971 TROOPS PLA

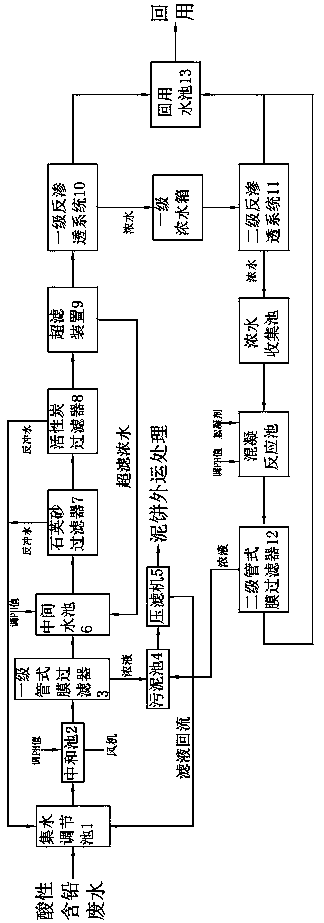

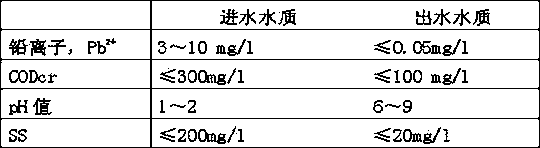

Process and device for processing and recycling leaded wastewater

InactiveCN103466844AEnsure water qualityReduce processing loadGeneral water supply conservationWater contaminantsFiltrationUltrafiltration

The invention discloses a process for processing and recycling leaded wastewater. The process comprises a primary processing part and a deep processing part. The primary processing part is achieved through the chemical neutralization and sedimentation and the primary tubular membrane filtration. The deep processing part is achieved through the ultrafiltration and the secondary reverse osmosis concentration desalination, thick water processed through secondary reverse osmosis is filtered through the secondary tubular membrane filtration, and discharged clean water which is processed through the primary reverse osmosis, the secondary reverse osmosis and the secondary tubular membrane filtration is recycled. Tubular membrane filters are arranged at the water outlet end of a primary processing neutralizing tank and for thick water processing of a deep processing secondary reverse osmosis system, therefore, the occupied area is greatly narrowed, and the device is more compact and simple. The tubular membrane filters can intercept all particles with the diameter greater than 0.1 micrometer, therefore, small lead hydroxide flocs caused by the dosage deviation of a flocculating agent and flocs with the low settling velocity can be intercepted, the quality and the stability of the discharged water can be fully ensured, and the pollution hazards can be avoided.

Owner:宜兴市欧瑞特环保科技有限公司

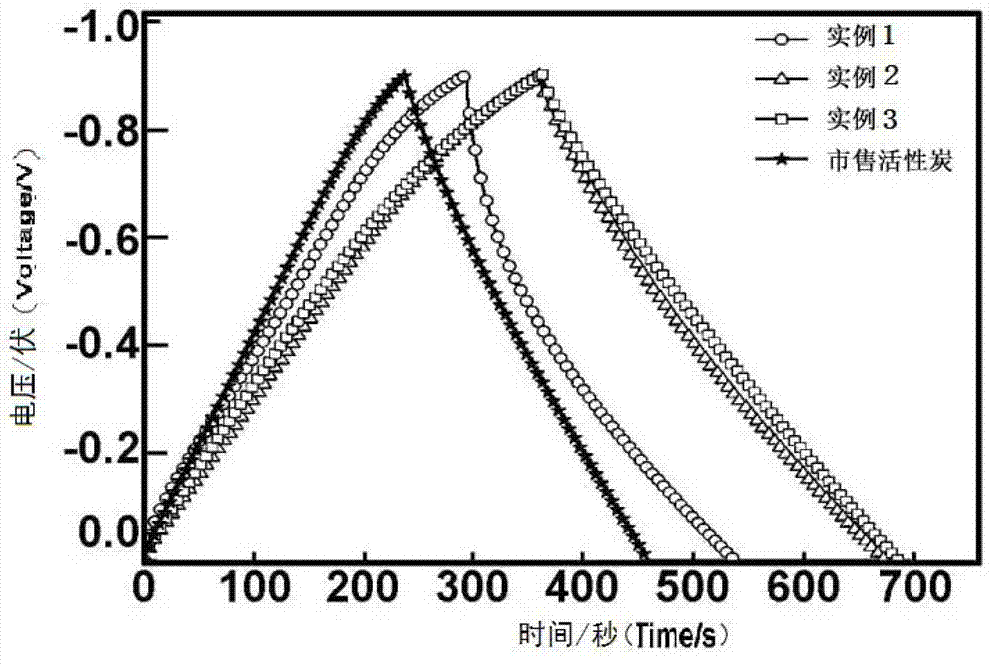

Preparation method for modified actived carbons

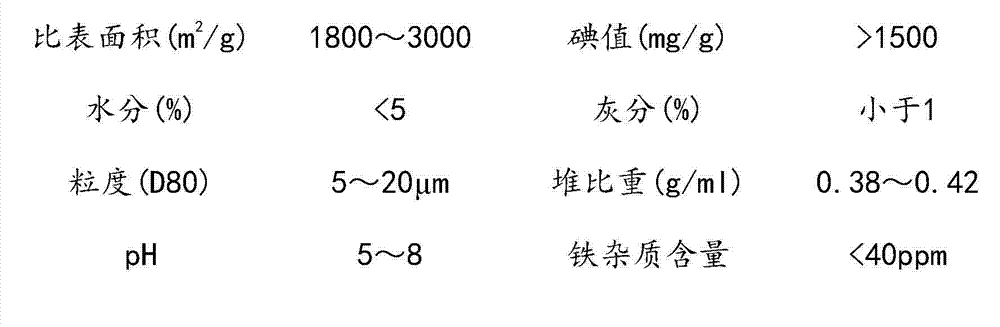

InactiveCN103043659ASimple preparation processShorten the production cycleCarbon compoundsCapacitanceActivated carbon

The invention discloses a preparation method for modified actived carbons. The modified active carbons are actived carbons modified by adopting hydrogen inhibitor; and the hydrogen inhibitor is lead oxide loaded on the surfaces of the actived carbons. The preparation process comprises the following steps: firstly, lead ions are absorbed by using the actived carbons; then the lead ions are deposited on the surfaces of the actived carbons by using alkali; and finally, lead hydrogen is decomposed to lead oxide through the heat treatment, and the lead oxide is loaded on the surfaces of the actived carbons; the actived carbons, lead salt and the alkali are chemically reacted through the ball milling method, and are treated at the high temperature under the protecting air environment to prepare the modified actived carbons. The method has the advantages of simple preparation technique, short production period, facilitation of industrial production, lower equipment investment, environmental friendliness and wide application, and can increase the specific capacitance of the active carbons.

Owner:HUNAN FENGRI ELECTRIC GROUP

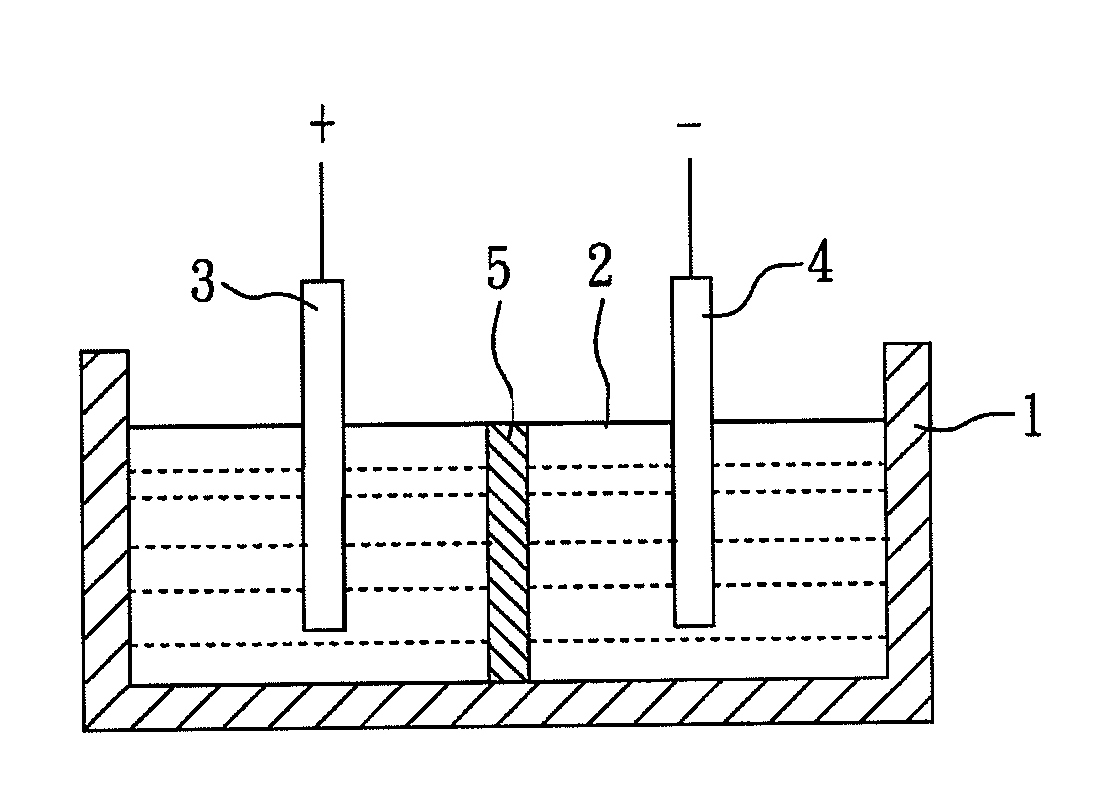

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS20110236747A1Large capacityLarge scaleSilver accumulatorsNon-metal conductorsIndiumNickel salt

The present invention relates to a composite material for a negative electrode, including: a plurality of iron oxide particles; and a conductivity improver, which is selected form the group consisting of copper, cobalt, nickel, tin, antimony, bismuth, indium, silver, gold, lead, cadmium, carbon black, graphite, copper salt, cobalt salt, nickel salt, tin salt, antimony salt, bismuth salt, indium salt, silver salt, gold salt, lead salt, cadmium salt, copper hydroxide, cobalt hydroxide, nickel hydroxide, stannic hydroxide, antimony hydroxide, bismuth hydroxide, indium hydroxide, silver hydroxide, gold hydroxide, lead hydroxide, cadmium hydroxide and the combination thereof. In the case of applying the composite material for a negative electrode according to the present invention in an electrochemical device, the improved charge / discharge characteristics and high capacity can be achieved. In addition, the present invention further provides a method for fabricating the above-mentioned composite material for a negative electrode and an electrochemical device using the same.

Owner:NATIONAL TSING HUA UNIVERSITY

Fine desulfurizer used for removing thiol from liquid hydrocarbon at normal temperature, preparation method thereof and application method thereof

InactiveCN101885981ASolve the lack of technologyRefining with metal saltsAir atmosphereAluminium hydroxide

The invention discloses a fine desulfurizer used for removing thiol from liquid hydrocarbon at normal temperature, a preparation method thereof and an application method thereof. The fine desulfurizer is prepared by blending powder of one to three compounds of copper oxide, zinc oxide, lead hydroxide, nickel oxide, magnesium hydroxide, potassium hydroxide, vanadium pentoxide, manganese dioxide and cobalt oxide with aluminum hydroxide and adhesive CMC, and then extruding the mixture into strips, wherein based on mass percentage, the one to three compounds (in the form of oxide) accounts for 5 to 30 percent, the aluminum hydroxide accounts for 60 to 85 percent and the CMC accounts for 10 percent. The preparation method for the fine desulfurizer comprises the following steps of: blending the powder of one to three compounds, the aluminum hydroxide and adhesive according to the formula, extruding the mixture into strips, drying the strips for 2 to 4 hours at the temperature of 120 DEG C, and baking the mixture for over 3 hours in an air atmosphere at the temperature of 300 to 500 DEG C to prepare the fine desulfurizer. The fine desulfurizer can be widely used for removing the thiol from the liquid hydrocarbon, such as LPG, a solvent oil, a naphtha and the like, can remove the thiol from the liquid hydrocarbon at the temperature of 10 DEG C below zero to 100 DEG C and at an airspeed of 0.01 to 6h-1; the removal rate is over 90 percent; the treated liquid hydrocarbon is guaranteed to meet requirements; and sulfur capacity of the fine desulfurizer is 2 to 6 weight percent.

Owner:HAISO TECH

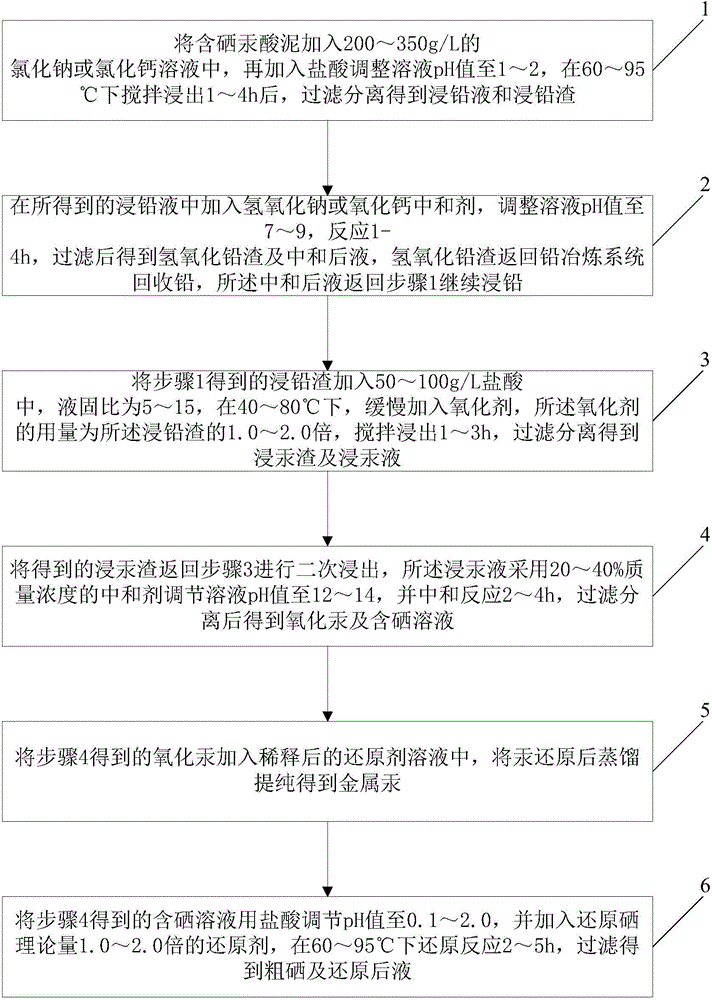

Method for treating selenium/mercury-containing acid mud

ActiveCN104561558ASimple processLess investmentProcess efficiency improvementElemental selenium/telluriumLead smeltingLead hydroxide

The invention discloses a method for treating selenium / mercury-containing acid mud. The method comprises the following steps: adding selenium / mercury-containing acid mud into a sodium chloride or calcium chloride solution, filtering and separating to obtain lead dipping solution and lead dipping residues; adding a sodium hydroxide or calcium oxide neutralizer into the obtained lead dipping solution, filtering, thereby obtaining the lead hydroxide residues and neutralized solution, wherein the lead hydroxide residues return to a lead smelting system to recycle the lead; adding the lead dipping residues into hydrochloric acid, slowly adding an oxidant, filtering and separating to obtain the mercury dipping residues and mercury dipping solution; adding a neutralizer into the mercury dipping solution for precipitating the mercury, filtering and separating to obtain mercuric oxide and selenium-containing solution, adding mercuric oxide into the diluted reducing agent solution, reducing mercury, distilling and purifying to obtain metal mercury, adding a reducing agent into the selenium-containing solution, filtering, thereby obtaining crude selenium and reduced solution. The treatment method is simple in process, low in equipment investment, pollution-free and good in economic benefits, selenium and mercury can be recycled, and lead also can be recycled.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

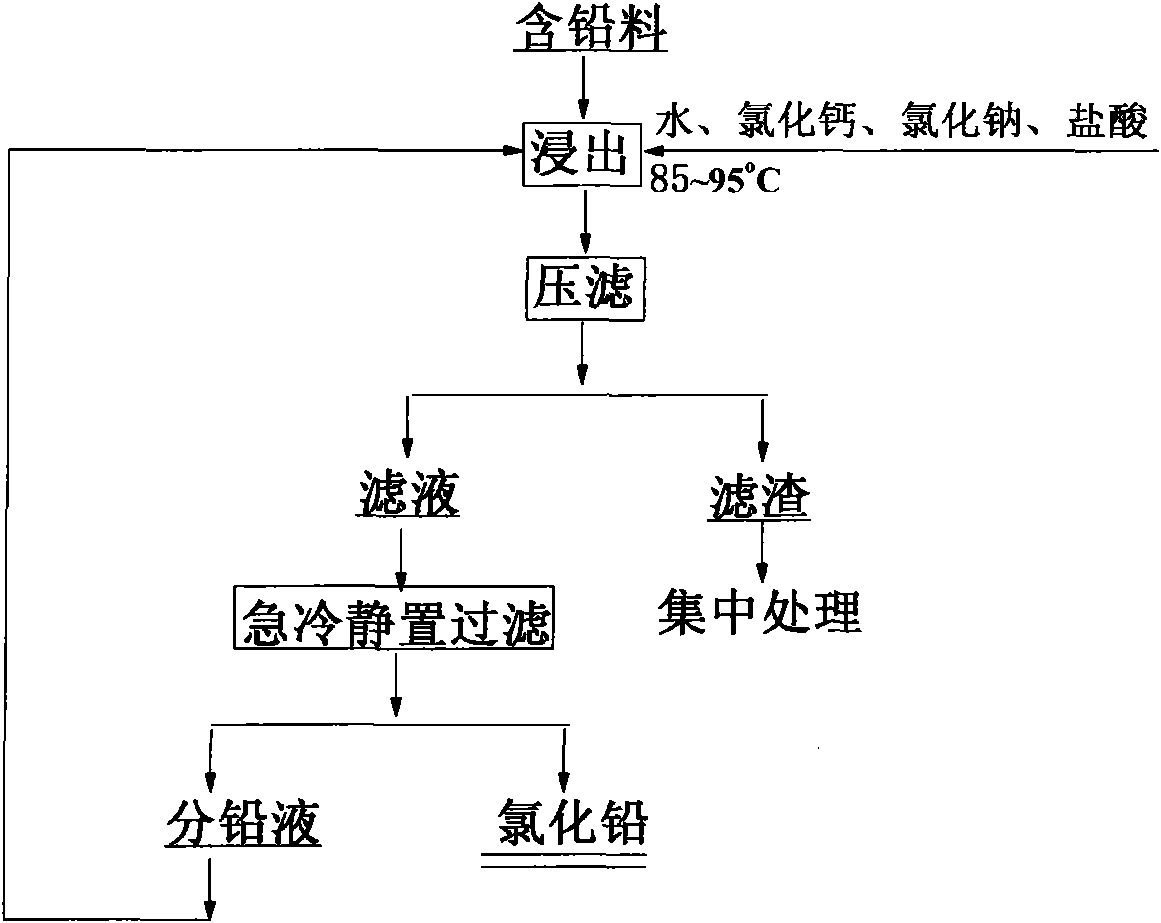

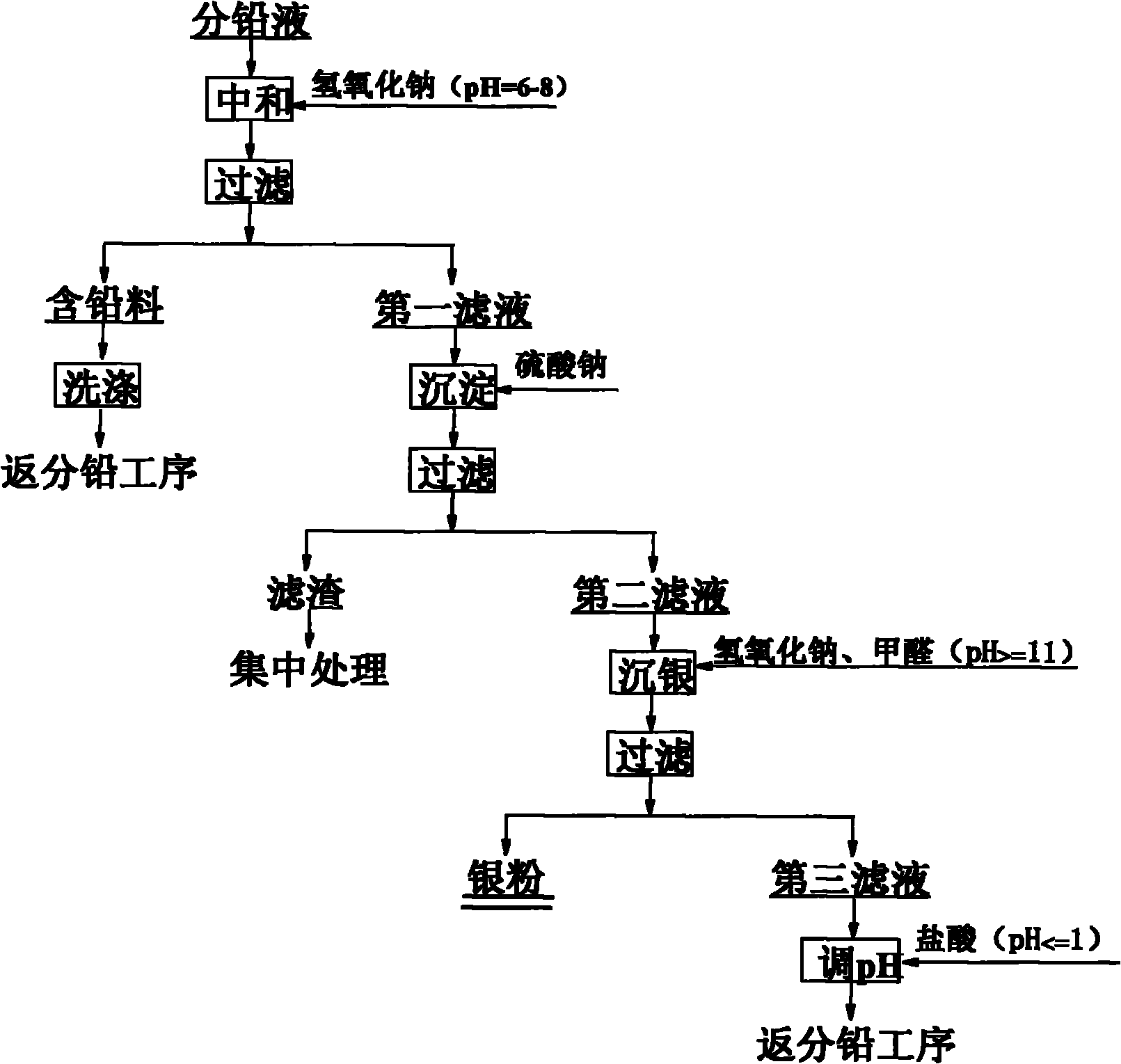

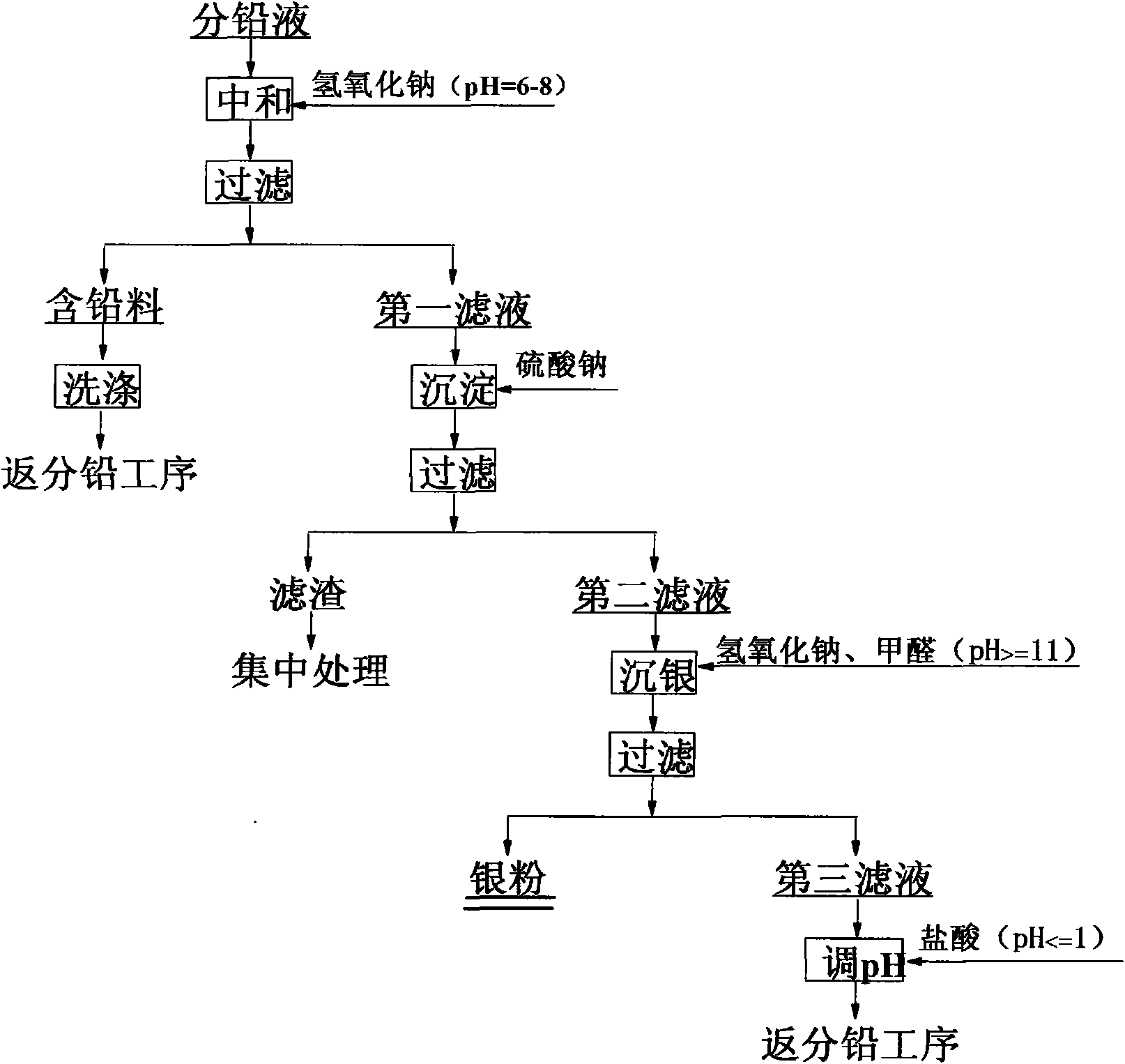

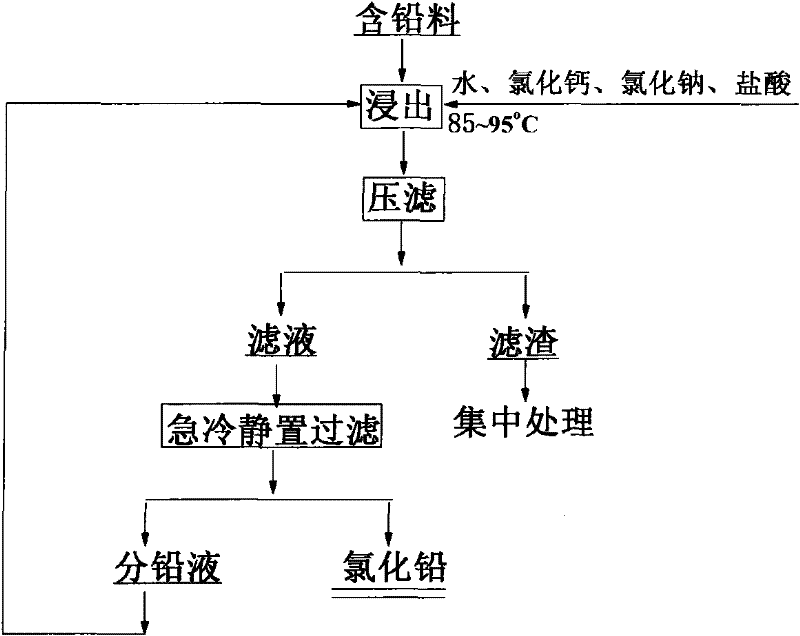

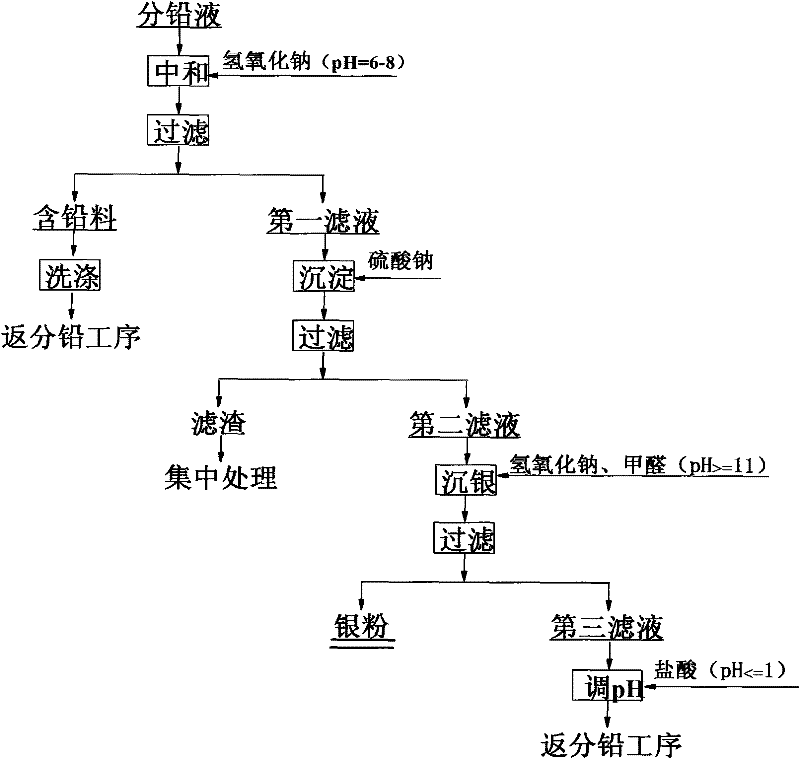

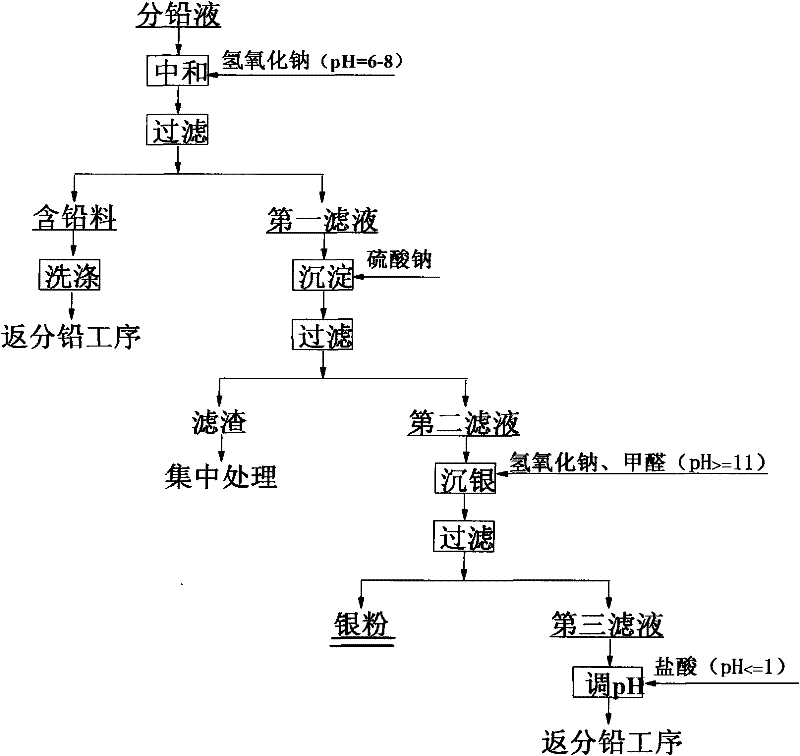

Method for recovering silver from lead-separating liquid of silver-separating residue of copper anode slime

ActiveCN101824546AHigh purityPollution-free production levelProcess efficiency improvementFiltrationSodium sulfate

The invention discloses a method for recovering silver from the lead-separating liquid of the silver-separating residue of copper anode slime, which relates to a method for greenly recovering silver in the lead-separating liquid by adopting a step-by-step precipitation method. The method includes lead-separating process, and also includes the processes that: the lead-separating liquid is poured into a stirring tank, sodium hydroxide is added for neutralization, so that the pH of the lead-separating liquid is regulated to 6 to 8, lead is precipitated in the form of lead hydroxide, lead-containing material and first filtrate are obtained by filtration, and the lead-containing material is washed by water and returns to the lead-separating process to separate lead; sodium sulfate is added in the first filtrate until the solution does not produce precipitate, filter residue and second filtrate are obtained by filtration, and the filter residue is centrally treated; sodium hydroxide is utilized to regulate the pH of the second filtrate to no less than 11, a moderate amount of formaldehyde is added, stirring is carried out for 10 to 30 minutes, silver powder and third filtrate are obtained by filtration, hydrochloric acid is added into the third filtrate to regulate the pH to less than 1, and the third filtrate retunes to the lead-separating process. The method is characterized in that: the technique is simple and easy, the used materials and equipment are common and cheap, the final filtrate is recycled, and no pollution is generated.

Owner:UNIV OF SCI & TECH BEIJING +1

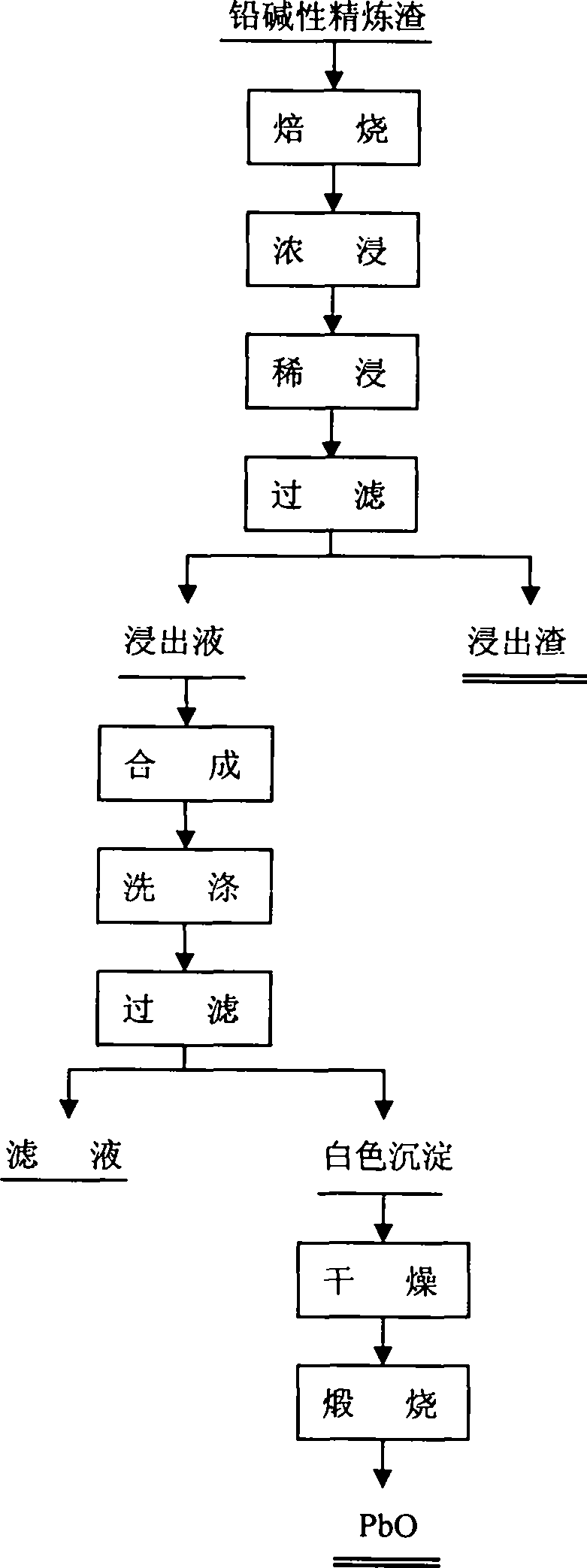

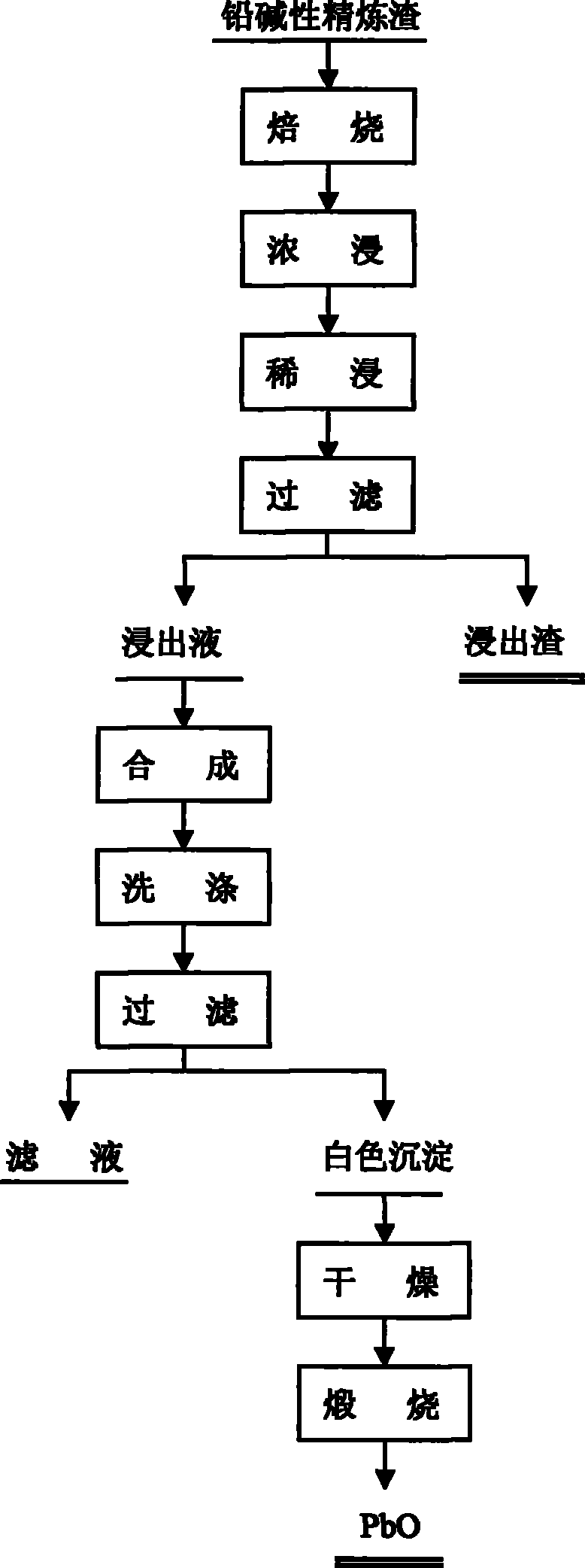

Method for comprehensive recovery of lead and tin from alkaline refining slag of lead

ActiveCN101768668AReduce the difficulty of refining tin removalAchieve separationLead monoxideProcess efficiency improvementLead nitrateSlag

The invention relates to a method for comprehensive recovery of lead and tin from alkaline refining slag of lead, comprising the following steps: 1. oxidizing roasting: oxidizing roasting is carried out on the alkaline refining slag of lead for 2-6h at 300-500 DEG C;2. leaching: nitric acid leaching is carried out on roasted slag, the roasted slag is filtered and separated to obtain lead nitrate solution and zinc slag;3. synthesis: lead nitrate solution is precipitated by sodium hydroxide solution, pH value is controlled while the solution is continuously stirred, thus generating white lead hydroxide sediment which is filtered, washed and dried to obtain white lead hydroxide powder;4. calcination: the white lead hydroxide powder is calcinated to obtain yellow powder yellow lead, namely PbO powder. With the method, lead and tin in the alkaline refining slag of lead are effectively recovered and tin can be ploughed in the lead system; in addition, the method has the advantages of reliable technology and high comprehensive recovery rate.

Owner:ZHUZHOU SMELTER GRP

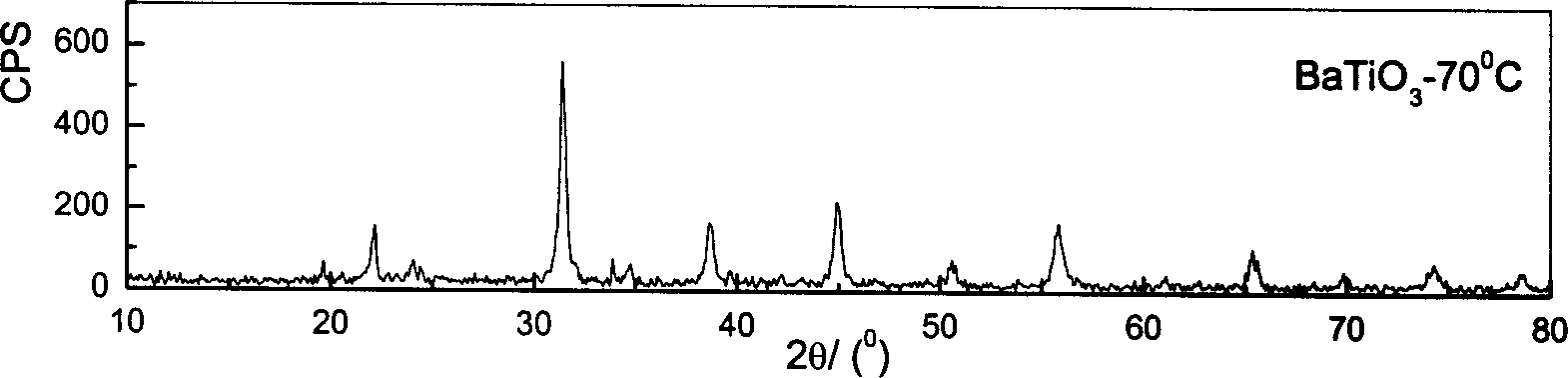

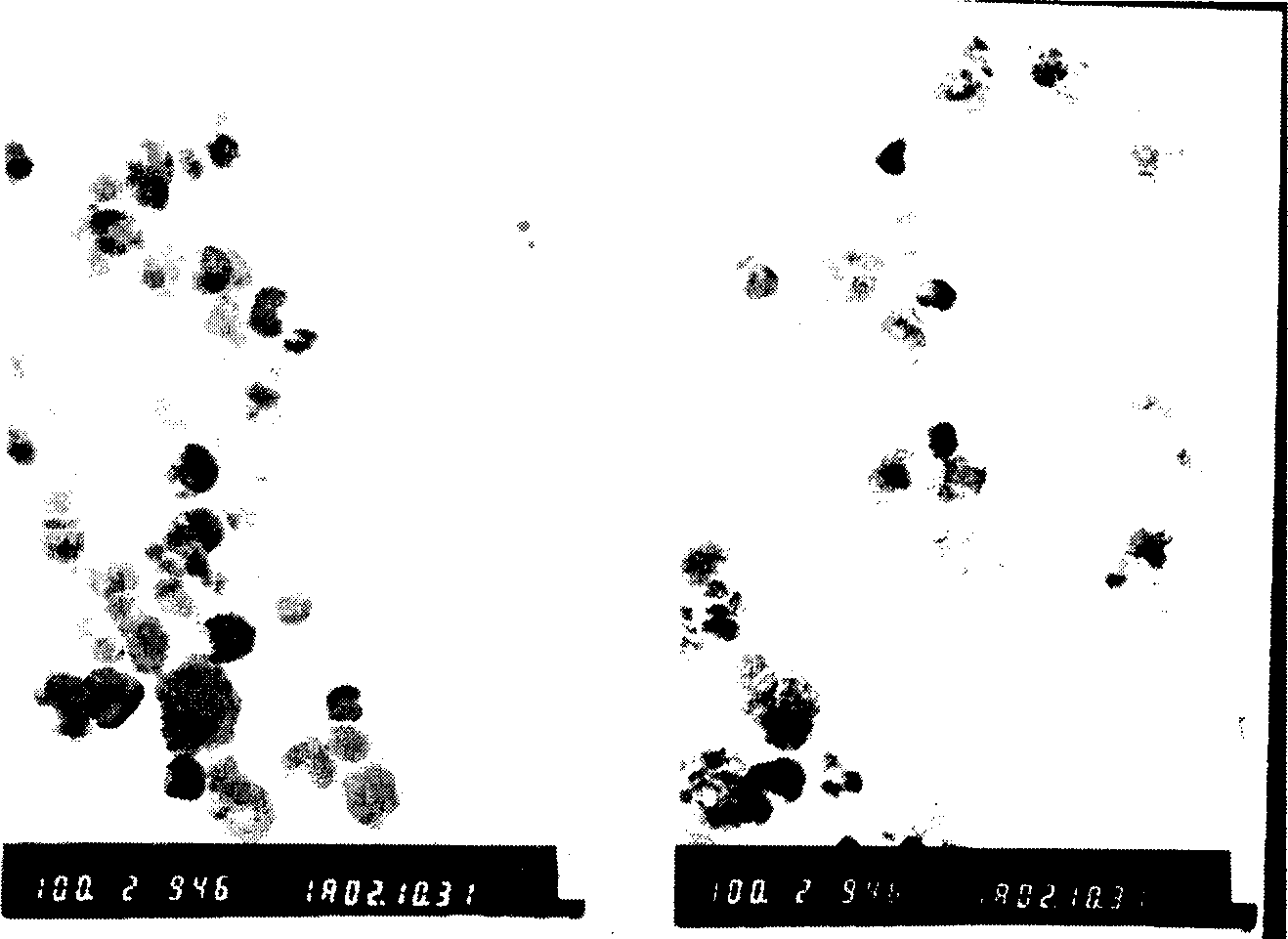

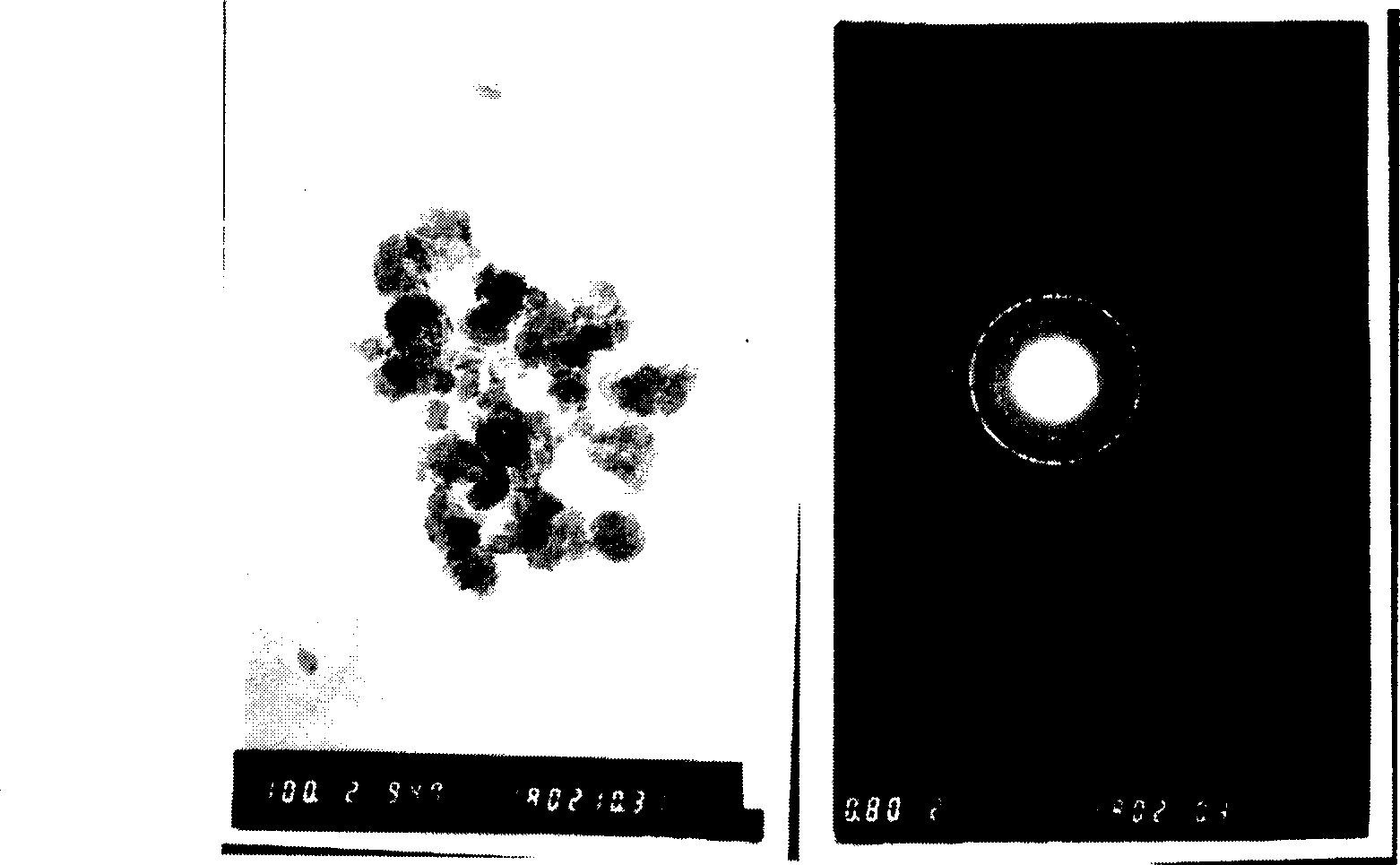

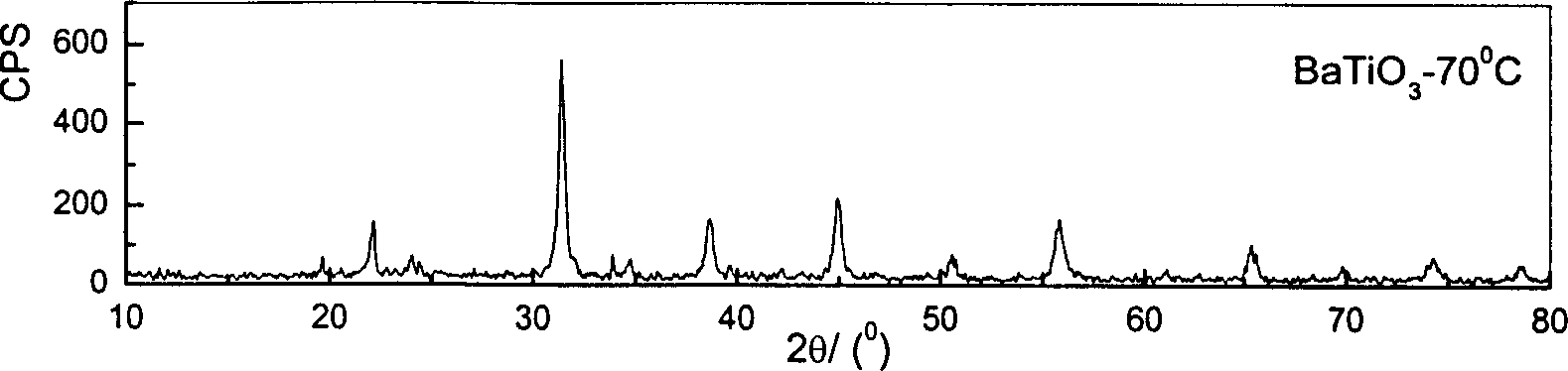

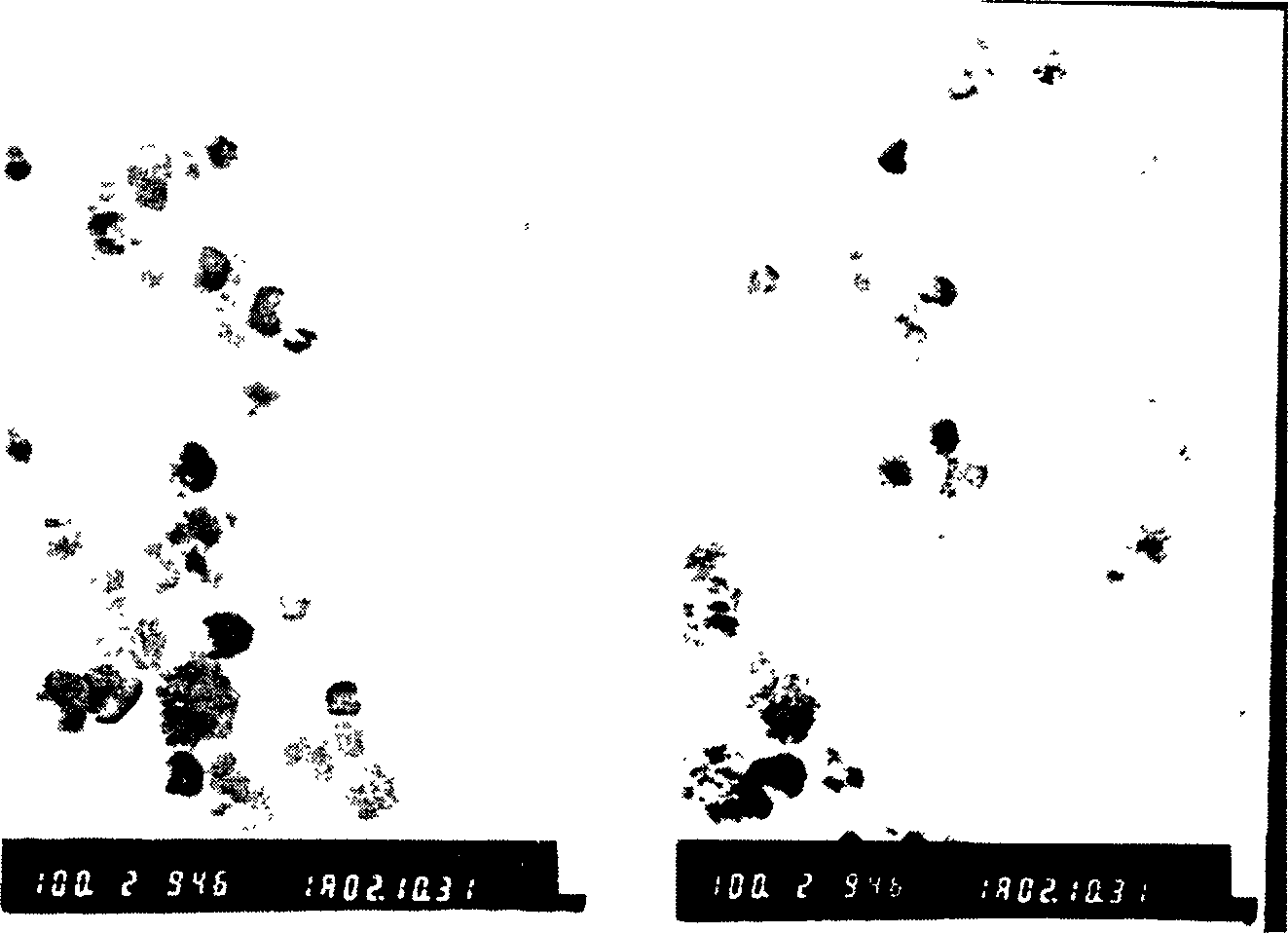

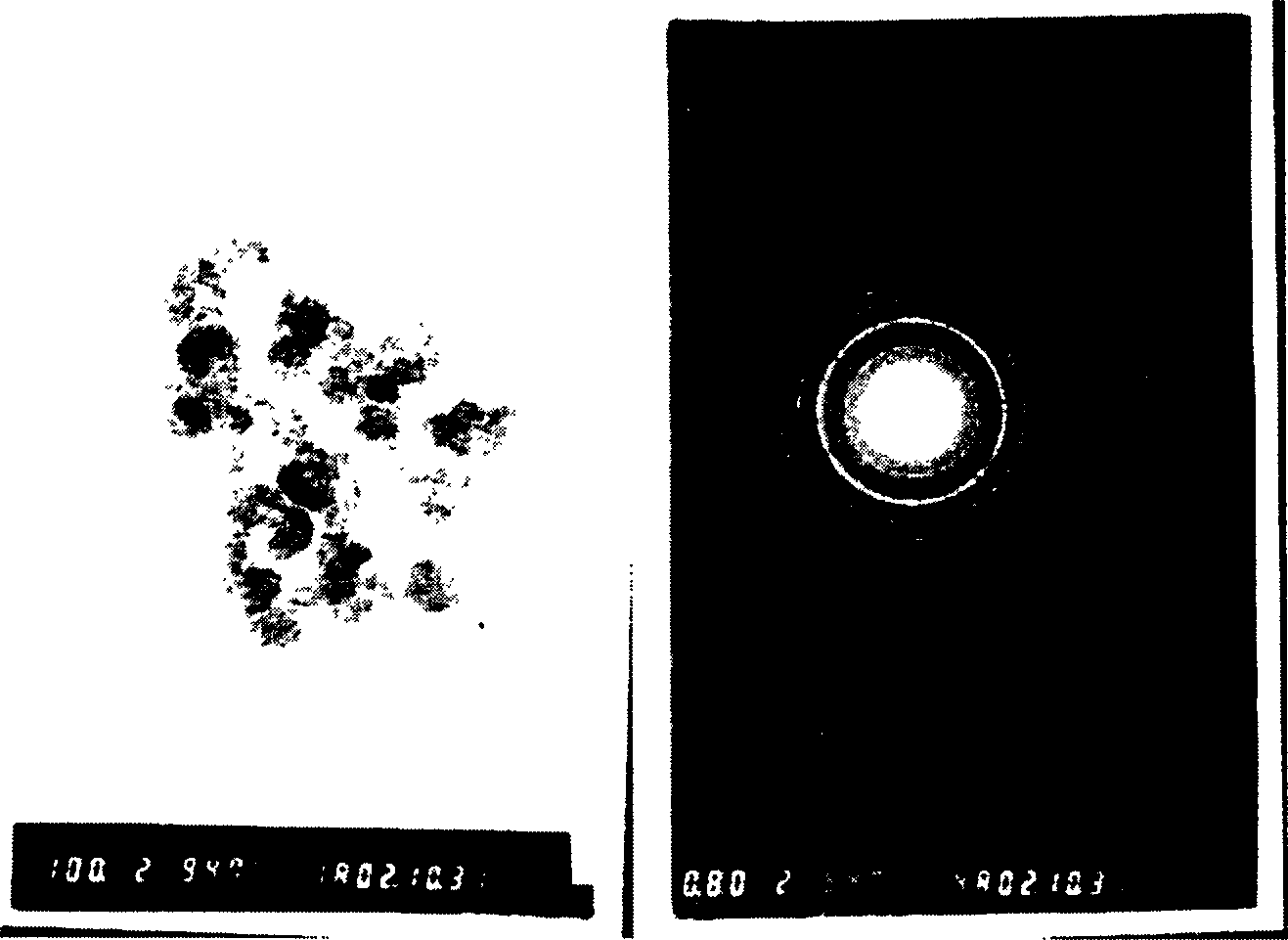

Method of synthesizing nano grade calcium titanium ceramic powder

A process for synthesizing the nanometre-class perovskite ceramic powder under the conditions of temp. lower than boiling point of substrate liquid and normal pressure includes such steps as directlymixing the substrate liquid which is the aqueous solution of barium hydroxide, strontium hydroxide, calcium hydroxide and lead hydroxide with the solution of metallic alkoxide in organic solvent, adding precipitant and disperser, and drying the deposit. Its advantages are high sintering activity, uniformity and stability of Ba / Ti rate, and cubic perovskite structure.

Owner:TSINGHUA UNIV

Method of synthesizing nano grade calcium titanium ceramic powder

Owner:TSINGHUA UNIV

Composite material for negative electrode, method for fabricating the same and electrochemical device using the same

ActiveUS8486563B2Large capacityLarge scaleSilver accumulatorsNon-metal conductorsGold(III) hydroxideIndium

Owner:NATIONAL TSING HUA UNIVERSITY

Production technique for red lead containing rare earth

The invention discloses a production technique for red lead containing rare earth, relating to the technical field of red lead production. The production technique is characterized by comprising the following steps: (1) melting lead at the temperature of 670DEG C and fast pouring into cold water to obtain lead foam; (2) oxidizing the foam lead to obtain lead hydroxide in the presence of an oxidization accelerator; (3) enabling the lead hydroxide to react with 4%-5% acetic acid to obtain lead acetate; (4) adding rare earth elements into lead carbonate; (5) introducing carbon dioxide in the lead carbonate and the rare earth elements at atmospheric temperature to obtain lead carbonate precipitate; and (6) filtering the lead carbonate precipitate and firing at the temperature of 470DEG C to obtain the red lead. The production technique is simple in formula, convenient to control, good in stability, high in formation efficiency, and capable of greatly increasing the early-stage capacity and prolonging the cycle life of a storage battery.

Owner:JIESHOU CITY JUNMA IND & TRADE

Process for treating waste water for car wash and equipment

InactiveCN101306894AEffective filteringEfficient recyclingSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentParticulatesFiltration

The invention relates to a method for processing automobile-washing wastewater, comprising the following steps that: firstly, 100 to 120 grams of calvital is added into the wastewater for aeration treatment and mixed with the wastewater; secondly, cadmium irons and lead irons in the wastewater are converted into lead hydroxide and chromic hydroxide which are then separated and deposited; thirdly, floccule or particulate matter in the water is filtered by a filter screen; fourthly, deposited sludge in a wastewater disposal basin is collected, compressed and dehydrated to form mud cakes; fifthly, the mud cakes are burned or buried; sixthly, wastewater generated in the operations of sludge dehydration and so on can be processed by repeating the steps from the first step to the fourth step. Devices adopted for application of the method include a cleaning device, a slurry processing device, a clear water collection tank, an additional device and a high-pressure water injector. The method not only can separate heavy metal elements from the wastewater and recycles clear water after filtration but also avoids secondary pollution of heavy metal pollutant on the soil.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

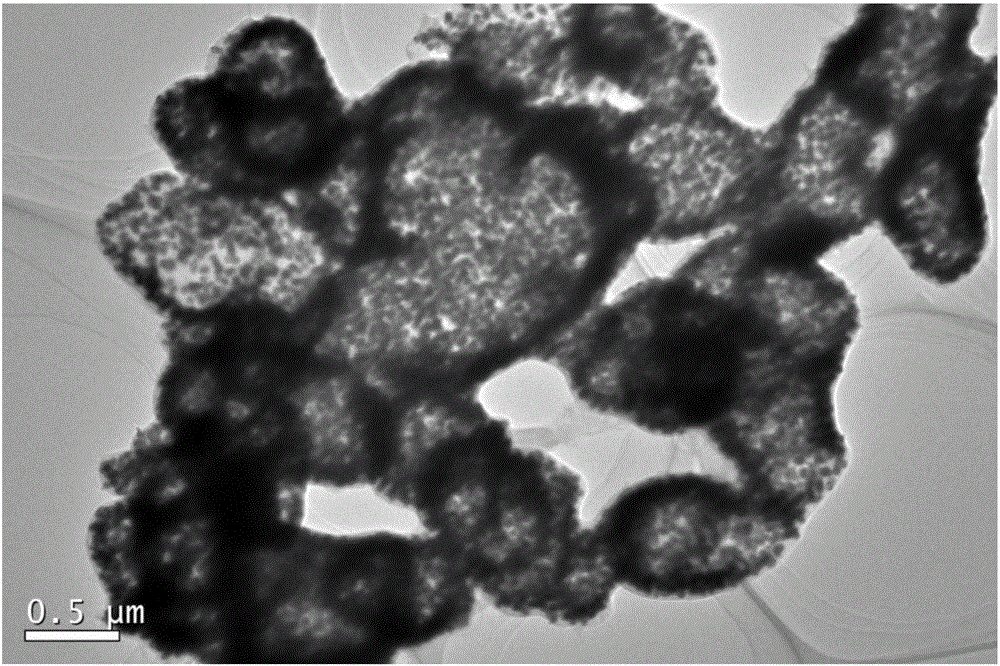

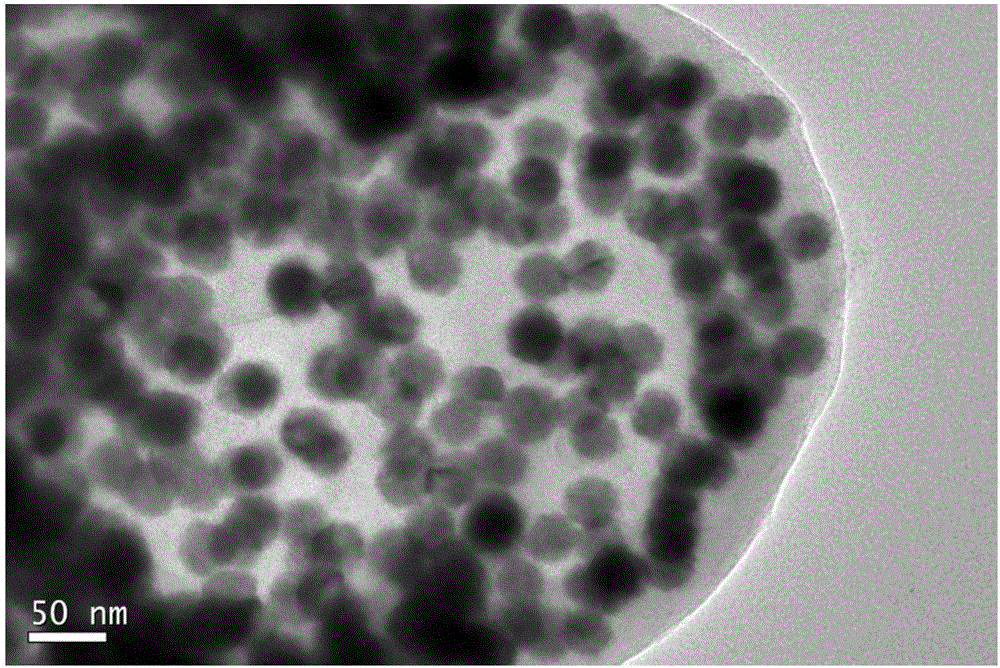

Lead-carbon composite particle and preparation method thereof

The invention discloses a lead-carbon composite particle and a preparation method thereof. The outer layer of the lead-carbon composite particle is a conductive carbon layer, and the inside comprises a plurality of silicon-dioxide-coated Pb&PbO particles. The preparation method comprises the following steps: 1) preparing lead hydroxide; 2) preparing PVP-modified lead hydroxide; 3) preparing silicon-dioxide-coated lead hydroxide; 4) preparing C@[SiO2@Pb(OH)2]; and 5) adding the C@[SiO2@Pb(OH)2] into a zinc chloride solution, impregnating, separating, drying and carrying out carbonization calcination. The outer layer of the lead-carbon composite particle is a high-conductivity carbon layer, and the inside comprises the plurality of silicon-dioxide-coated Pb&PbO particles; the overall density is approximate to that of lead powder; the lead-carbon composite particle can be uniformly mixed with the lead powder in the paste mixing process during lead-acid battery preparation; the lead-carbon composite particle has higher hydrogen evolution overpotential than the conventional carbon material; the addition amount of the lead-carbon composite particle in the lead-acid battery can reach 5 wt%; and the nano silicon dioxide transition layer coated outside the Pb&PbO can effectively isolate the Pb&PbO from the carbon layer, thereby enhancing the stability and use safety in the lead-carbon composite particle preparation process.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for recycling and using medium chrome yellow production wastewater

InactiveCN107010771AEmission reductionEnvironmentally friendlyWater contaminantsTreatment involving filtrationResource utilizationLead nitrate

The invention discloses a method for recycling and using medium chrome yellow production wastewater. The method comprises the following steps: adding sodium hydroxide into medium chrome yellow production wastewater so as to adjust the pH value to 7-9, and precipitating, so as to separate Pb<2+>; carrying out evaporative crystallization on obtained filtrate, so as to separate out sodium nitrate crystals; cooling, so as to further separate out the sodium nitrate crystals; and filtering, and separating, so as to obtain the sodium nitrate crystals and a crystallization solution. The crystallization solution returns to an evaporative crystallization operation stage, the volume ratio of the crystallization solution to the filtrate is 1 to (1-3); and an obtained lead hydroxide precipitate reacts with nitric acid to generate lead nitrate, and lead nitrate is taken as one of the raw materials of a medium chrome yellow production process. The efficient and comprehensive resource utilization of medium chrome yellow process wastewater is realized, the discharging of wastewater is reduced, and a sodium nitrate product is produced, so that the method has an environmental protection benefit, and the economic benefit is increased; and a low-temperature distillation method is simple in process, reaction conditions are mild, new substances are not introduced, and secondary pollution is avoided.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

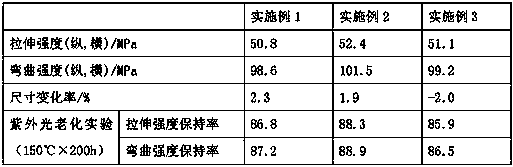

Radiation-resistant plastic flooring and preparation method thereof

InactiveCN107619545AImprove radiation resistanceImprove heat resistancePolyvinyl chlorideLead hydroxide

The invention discloses radiation-resistant plastic flooring and a preparation method thereof. The plastic flooring is made from, by weight part, 46-59 of polyvinyl chloride resin, 31-42 of polyethersulfone, 22-35 of polyisophthaloyl metaphenylene diamine, 22-28 of witherite powder, 16-22 of trioctyl trimellate, 6-11 of ricinoleamide, 18-24 of barite powder, 4-7 of di-n-butyl bis(dodecylthio) tin,14-22 of tritolyl phosphate, 10-15 of high-temperature activated bamboo charcoal powder, and 5-10 of lead hydroxide. Through compounding of polyvinyl chloride resin, polyethersulfone, and polyisophthaloyl metaphenylene diamine, and through addition of raw materials including witherite powder, barite powder, tricresyl phosphate, high-temperature activated bamboo charcoal powder, and lead hydroxide, the plastic flooring is improved in radiation resistance, heat resistance, aging resistance, wear resistance and flame retardance.

Owner:JIANGYIN ZHIYUAN AUTOMOBILE DECORATION PARTS CO LTD

Broad spectrum solar cell material and preparation method thereof

InactiveCN104409640AImprove photoelectric conversion efficiencyImprove stacking effectOrganic semiconductor materialsOrganic semiconductors manufacture/treatmentCyclopenteneScavenger

The invention discloses a broad spectrum solar cell material and a preparation method thereof. The broad spectrum solar cell material is composed of the components in weight parts: 10-20 parts of graphite, 2-5 parts of silicon carbide, 3-8 parts of silicon nitride, 0.8-1.5 parts of erbium oxide, 2-8 parts of quantum dots, 20-30 parts of cyclopentene thiophene, 10-15 parts of diazosulfide, 2-5 parts of 1,8-octane dithiol, 0.15-0.55 part of lead hydroxide oxide sulfate, 1.5-8.5 parts of radical scavenger, 1-5 parts of thermal stabilizer, 3-10 ultraviolet light absorber and 1-3 parts of carbon black. The broad spectrum solar cell material has good electron stacking performance, higher carrier mobility and absorption peaks within the scope of 150-4000 nm, is capable of effectively improving the photoelectric conversion efficiency of solar cells and has broad application prospects.

Owner:WUXI SUNOCEAN

Method for treating magnesium extraction raffinate wastewater

InactiveCN108911325AWater/sewage treatment by centrifugal separationZinc oxides/hydroxidesZinc hydroxidePyrolusite

The invention discloses a method for treating magnesium extraction raffinate wastewater. The method comprises the following steps: recycling an extraction agent from the magnesium extraction raffinatewastewater in an oil separation tank; preparing a demulsifier by guar gum, polyacrylate and polyhydric alcohol; adding the demulsifier to the wastewater after oil removing, performing a demulsification reaction in an ultrasonic environment, and removing an emulsified product; recycling copper hydroxide, zinc hydroxide, and lead hydroxide through multi-stage precipitation; after adding a flocculating agent of Pulullan to the wastewater, performing sand filtering treatment through sand grains, separating a filter residue and clarified magnesium chloride wastewater; performing adsorption treatment on the clarified magnesium chloride wastewater by using pyrolusite, filtering, and removing a pyrolusite residue; conveying the clarified magnesium chloride wastewater to a triple-effect evaporation system, separating a magnesium chloride crystal, and recycling condensate water. Materials used in the method are non-toxic or low-toxicity, and have no secondary pollution to the environment. The magnesium chloride, the copper hydroxide, the zinc hydroxide and the lead hydroxide can be recycled, the effect of removing radioactive elements is good, the recycled extraction agent can be repeatedlyused, and the method is in comply with requirements of green environment-friendly sustainable development.

Owner:广西南宁荣威德新能源科技有限公司

Innocent treatment method of waste solution generated after agricultural product laboratory test

ActiveCN102838245AProtect environmentHazard reductionMultistage water/sewage treatmentWater/sewage treatment by heatingMethylene DichlorideStrong acids

The invention discloses an innocent treatment method of a waste solution generated after an agricultural product laboratory test. The method comprises the steps of treatments of an acetonitrile waste solution, a methylene dichloride waste solution, a strong acid waste solution, a strong base waste solution, a mercury waste solution, a cadmium and lead waste solution and a chrome waste solution; after the treatments, acetonitrile is converted into a ferricyanide complex and stored, mercury is converted into a mercuric sulfide deposit and stored, the cadmium and lead waste solution is converted into an aluminum hydroxide, lead hydroxide and cadmium hydroxide co-precipitate and stored, the chrome waste solution is converted into an iron hydroxide and chrome hydroxide co-precipitate and stored, the methylene dichloride can be recycled after being distilled, strong acid and strong base are neutralized and diluted and then discharged; in this way, the waste solution generated after the laboratory test is almost not directly discharged into water, so that the water environment is protected and the harmfulness of life caused by the waste solution is reduced.

Owner:王冬群

Method for recovering silver from lead-separating liquid of silver-separating residue of copper anode slime

ActiveCN101824546BHigh purityPollution-free production levelProcess efficiency improvementFiltrationLead hydroxide

The invention discloses a method for recovering silver from the lead-separating liquid of the silver-separating residue of copper anode slime, which relates to a method for greenly recovering silver in the lead-separating liquid by adopting a step-by-step precipitation method. The method includes lead-separating process, and also includes the processes that: the lead-separating liquid is poured into a stirring tank, sodium hydroxide is added for neutralization, so that the pH of the lead-separating liquid is regulated to 6 to 8, lead is precipitated in the form of lead hydroxide, lead-containing material and first filtrate are obtained by filtration, and the lead-containing material is washed by water and returns to the lead-separating process to separate lead; sodium sulfate is added in the first filtrate until the solution does not produce precipitate, filter residue and second filtrate are obtained by filtration, and the filter residue is centrally treated; sodium hydroxide is utilized to regulate the pH of the second filtrate to no less than 11, a moderate amount of formaldehyde is added, stirring is carried out for 10 to 30 minutes, silver powder and third filtrate are obtained by filtration, hydrochloric acid is added into the third filtrate to regulate the pH to less than 1, and the third filtrate retunes to the lead-separating process. The method is characterized in that: the technique is simple and easy, the used materials and equipment are common and cheap, the final filtrate is recycled, and no pollution is generated.

Owner:UNIV OF SCI & TECH BEIJING +1

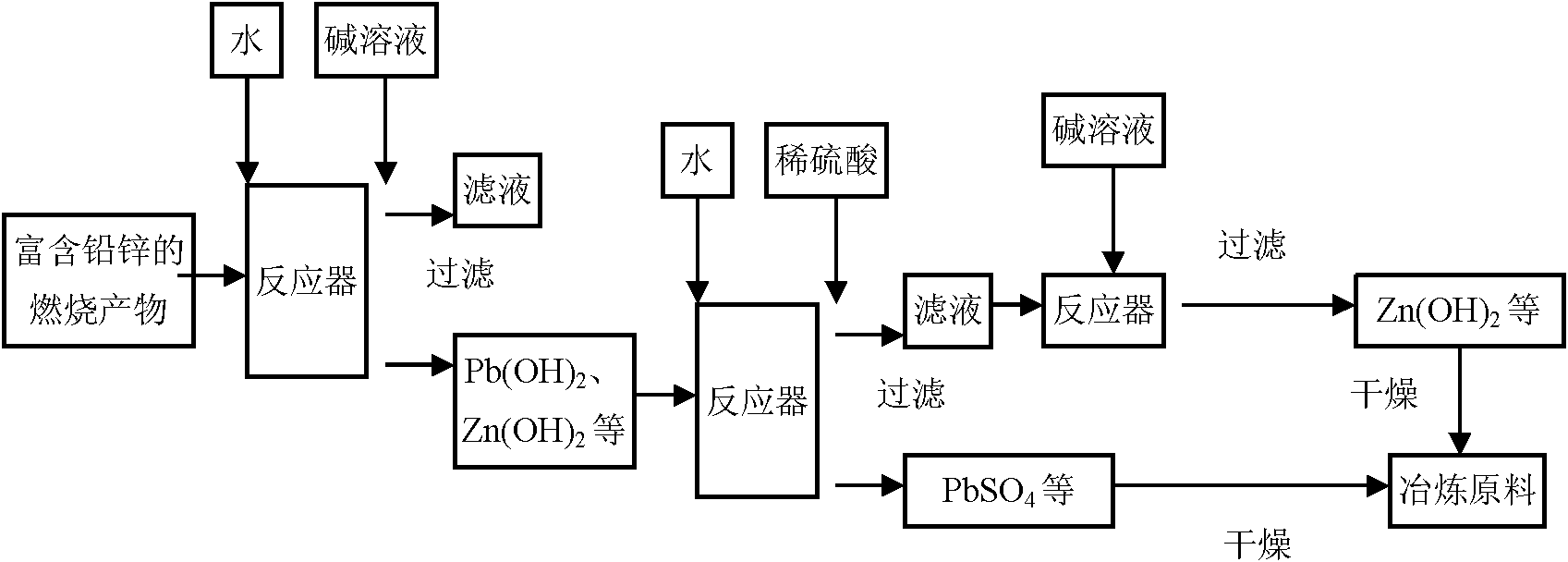

Wet chemical recovery method of lead and zinc in burning solid products

The invention discloses a wet chemical recovery method of lead and zinc in burning solid products, which comprises the following steps of: firstly, using a sodium hydroxide solution for washing fly ash to generate lead hydroxide and zinc hydroxide precipitate; removing chloride ions through being dissolved in water; then, making the precipitate washed in the last work procedure react with sulfuric acid; making the lead hydroxide react with the sulfuric acid to generate lead sulfate precipitate; dissolving the zinc hydroxide into the sulfuric acid to generate a zinc sulfate solution so that the lead and zinc separation can be realized; then, making the obtained solution react with a sodium hydroxide solution; and making the zinc sulfate react with hydroxide to generate zinc hydroxide precipitate for separating out the zinc. The invention can effectively separate out the heavy metal of lead and zinc in the fly ash, can reduce the environment pollution while realize the effect of changing waste materials into resources, and is particularly applicable to the fly ash generated by burning solid waste materials with high lead and zinc content and burning ash of other fuel after the enrichment.

Owner:HUAZHONG UNIV OF SCI & TECH

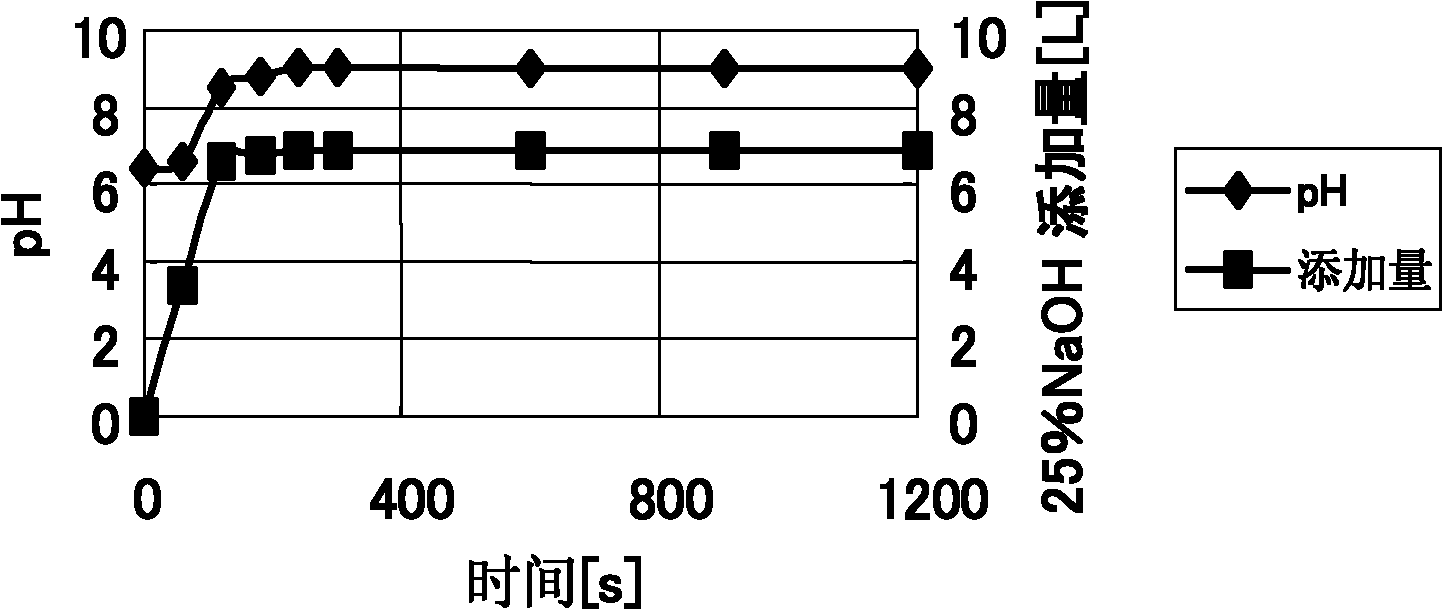

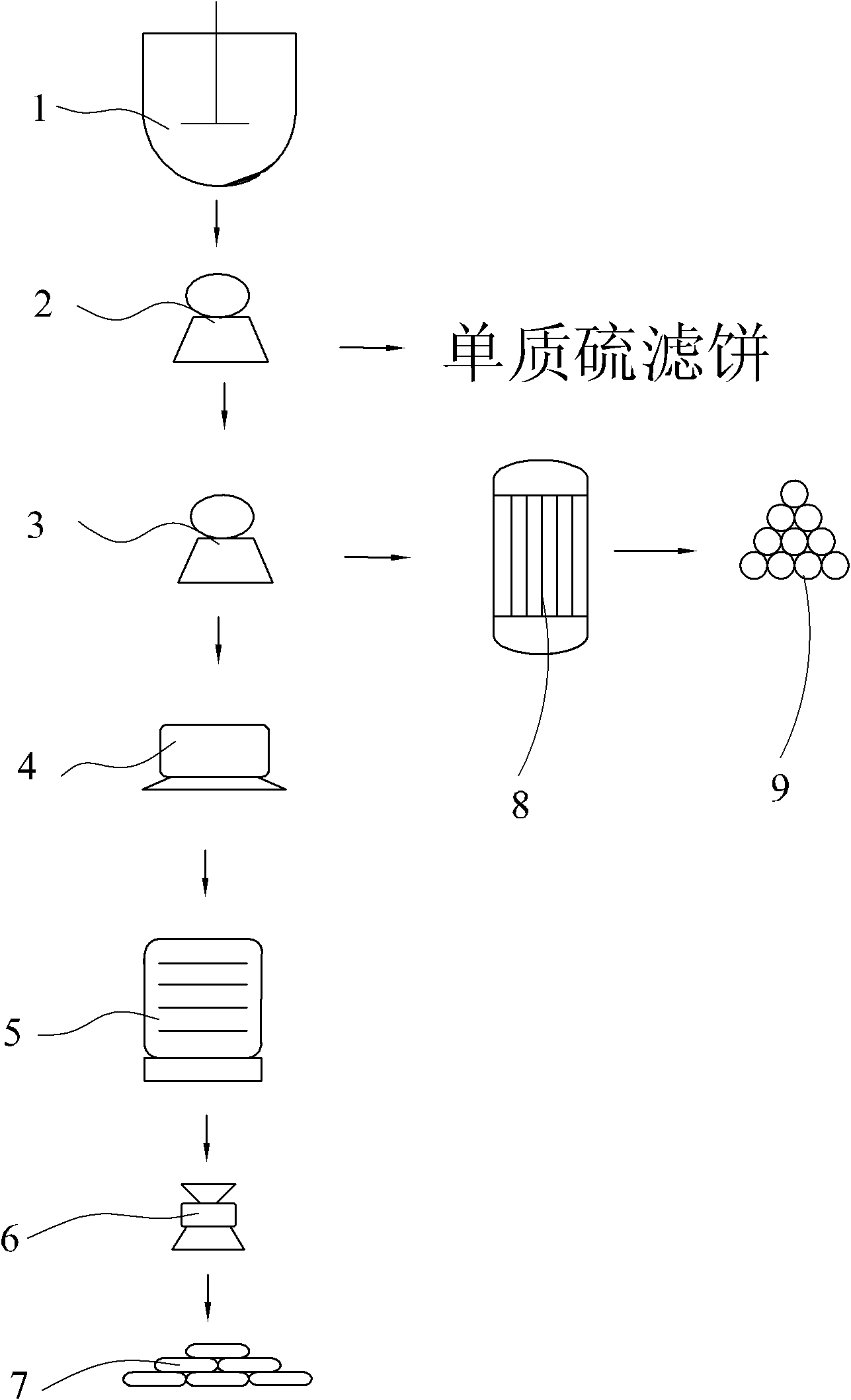

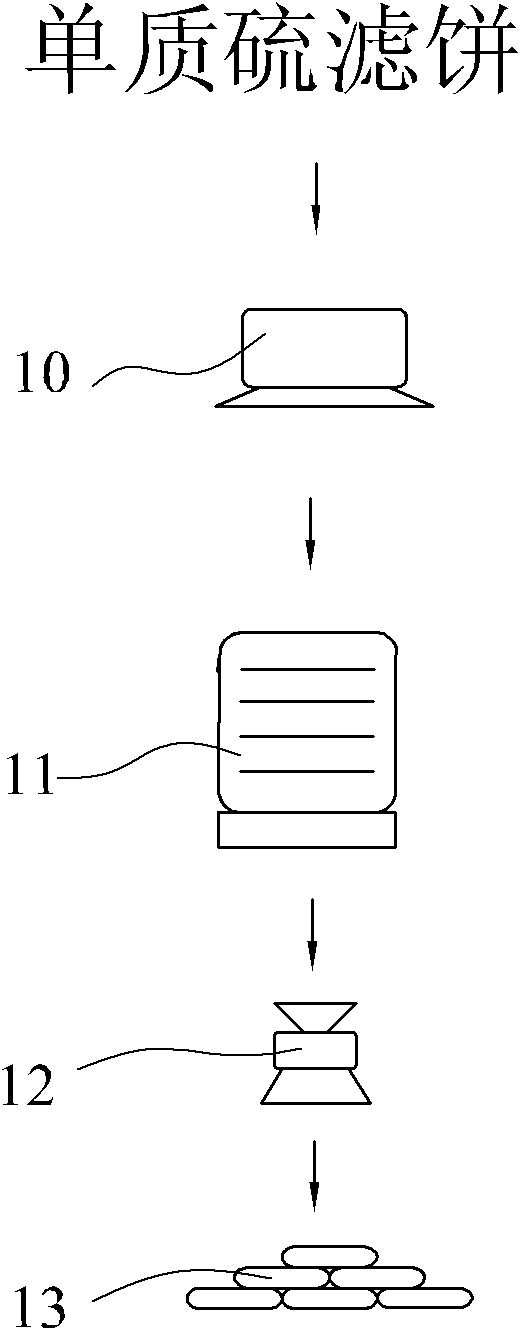

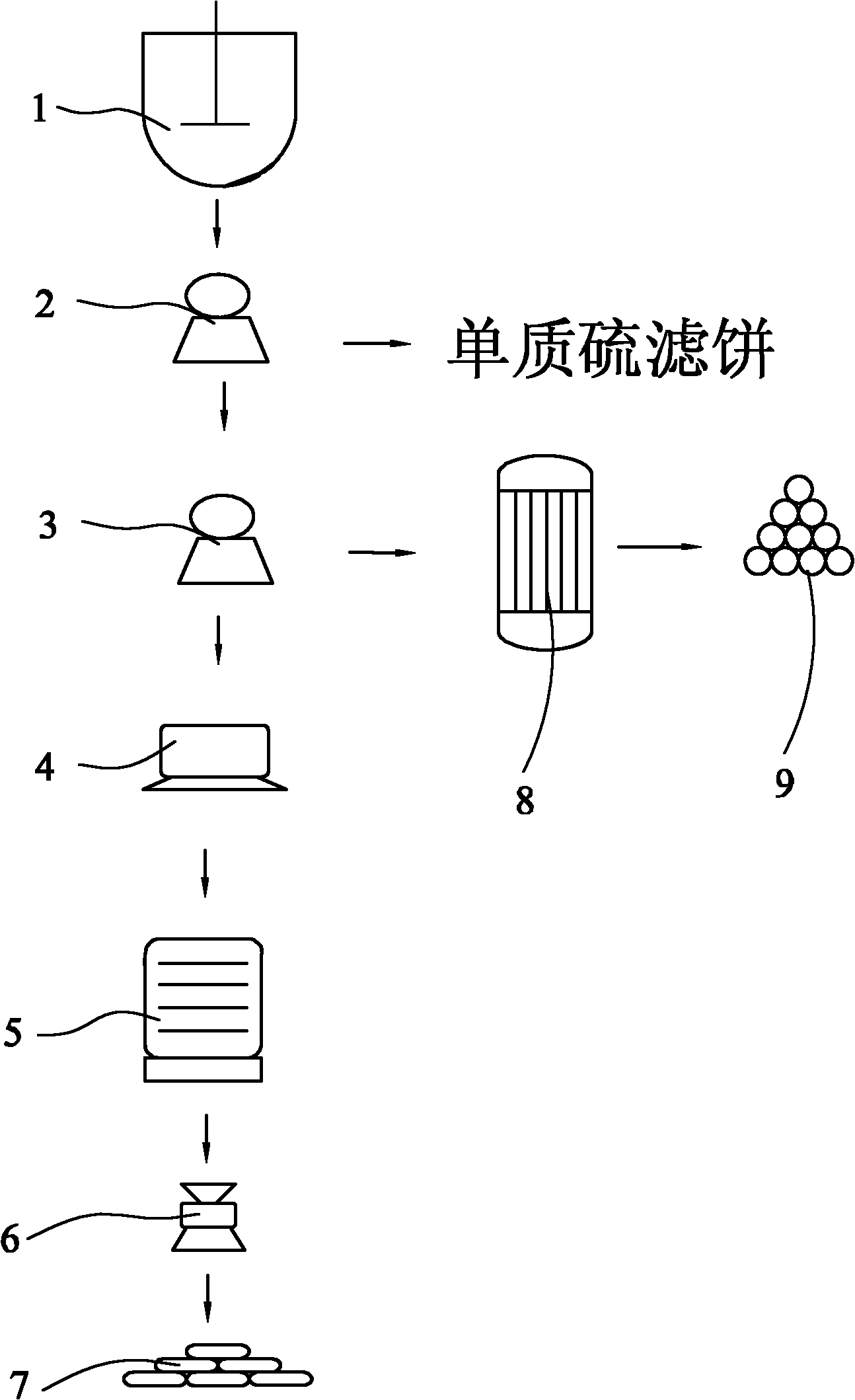

Method for preparing lead hydroxide and silver chloride mixture with waste residues from production of lithopone

The present invention provides a method for preparing lead hydroxide and silver chloride mixture with waste residues from the production of lithopone. The method comprises the following steps of reacting the waste residues from the production of lithopone with sodium hydroxide to obtain a mixture containing lead hydroxide, silver chloride, sodium chloride and elemental sulfur; obtaining clarified micro emulsion and elemental sulfur filter cake after filtering the resultant mixture coarsely; obtaining an elemental sulfur product after subjecting the elemental sulfur filter cake to deep processing; obtaining a lead hydroxide and silver chloride containing filter cake and sodium chloride solution after filtering the clarified micro emulsion finely; obtaining the lead hydroxide and silver chloride mixed product after washing, drying and smashing the lead hydroxide and silver chloride containing filter cake; and obtaining a sodium chloride crystal product by subjecting the sodium chloride solution to distillation and condensation.

Owner:王嘉兴

Internal formation lead plaster preparation process

The invention discloses an internal formation lead plaster preparation process. The internal formation lead plaster preparation process comprises the following steps in sequence: step one. adding dilute sulphuric acid so as to prepare preparatory liquid; step two. pre-preparing a lead hydroxide solution in advance; and step three. mixing the preparatory liquid and the lead hydroxide solution so as to form the lead plaster. According to the internal formation lead plaster preparation process, in order to ensure that additives soluble in acid dissolve in acid in advance, and meanwhile, additives insoluble in acid are uniformly dispersed, firstly short fibers and the additives are sheared and mixed with the dilute sulphuric acid in advance, so that a system is highly dispersed, and then the lead hydroxide prepared in advance is added to the dispersed system. The internal formation lead plaster preparation process has the advantages that the wet process charging is realized, materials can be uniformly dispersed, the uniformity and the consistency of components in the lead plaster are improved, and by adopting a wet-process addition process, the pollution of dust generated during the addition of powder materials to environments is avoided. The self discharge of storage batteries prepared from the lead plaster is obviously reduced, and the heavy current cycle life is obviously prolonged.

Owner:JIANGXI XINWEI POWER ENERGY TECH

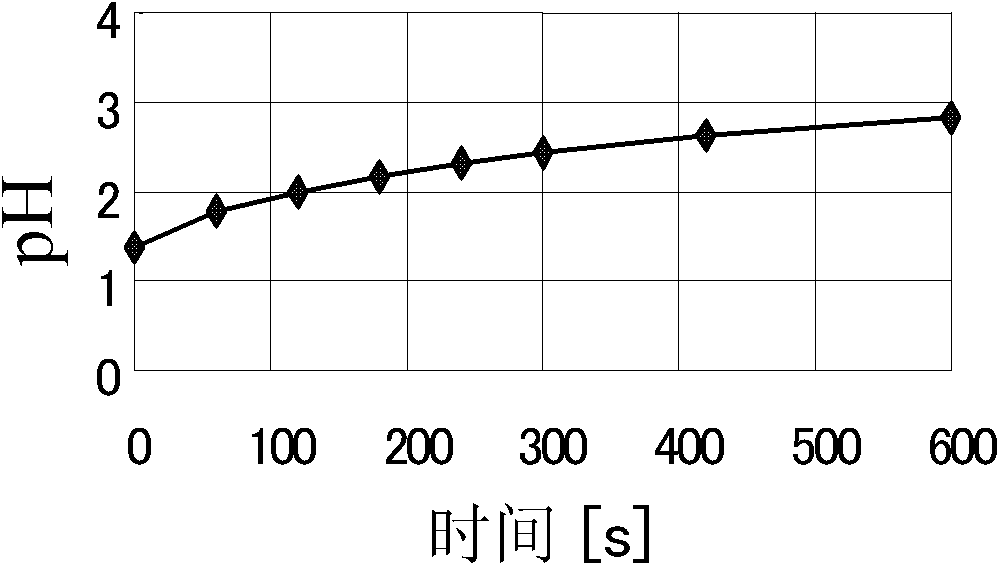

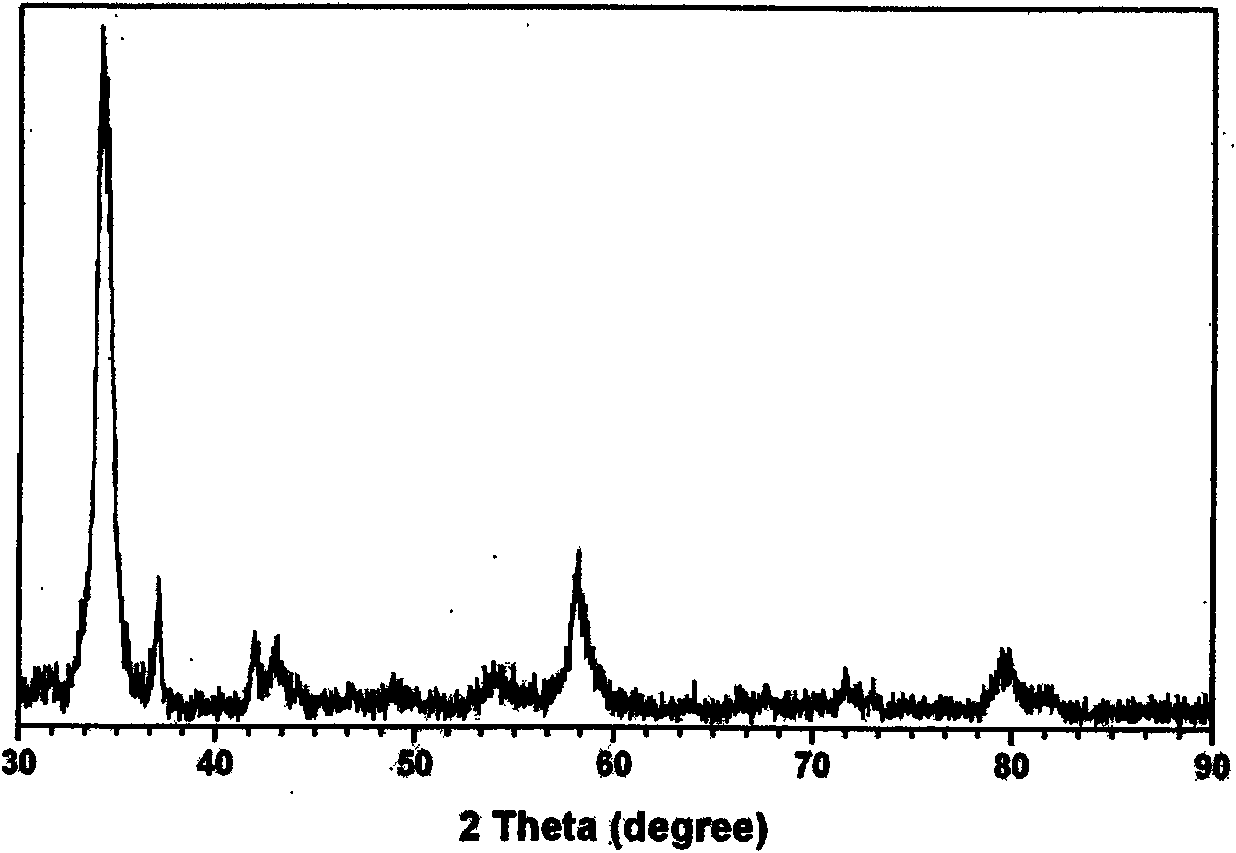

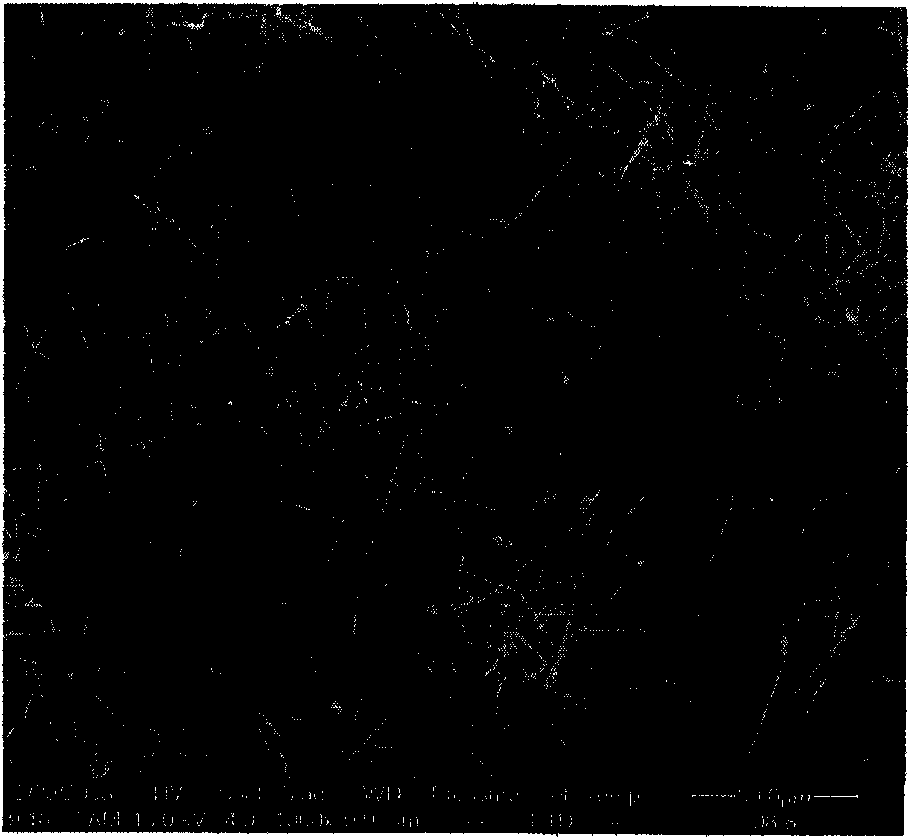

Method for preparing lead hydroxide nano-rod based on liquid-phase chemical reaction

InactiveCN101624211ANo pollution in the processSimple and fast operationLead hydroxidesMaterials preparationChemical reaction

The invention discloses a method for preparing a lead hydroxide nano-rod, belonging to the technical field of nanometer material preparation. The method is characterized in that lead nitrate and soluble chloride are dissolved in de-ionized water according to a mol proportion of 1:1-1:10 to prepare a solution; the solution is heated to 50-90 DEG C; alkali is added into the solution according to the mol proportion of the lead nitrate and the alkali substance of 1:3; the solution is stirred to obtain white participate; the white participate is filtered, washed and dried to obtain the lead hydroxide nano-rod. The lead hydroxide nano-rod is a hexagon structure with the length of about 50 micrometers and the diameter of 20-500 nanometers. The method has simple and convenient operation, high yield and no pollution to the environment.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Method for recycling lead in lead-containing waste water

InactiveCN105417783AEfficient purificationEfficient recyclingWaste water treatment from metallurgical processMultistage water/sewage treatmentReduction treatmentLead oxide

The invention discloses a method for recycling lead in lead-containing waste water. The method comprises the following steps: (1) performing waste water acidizing treatment and causing the pH of the waste water to be between 5.5 and 6; (2) preparing precipitation solution, and preparing sodium hydroxide solution with a concentration of 500 g / L; (3) calculating precipitation capacity ratio; (4) performing precipitation treatment, and performing batch precipitation treatment of acidification pools according to the ratio calculated in the step (3); (5) taking out precipitation; (6) drying the precipitation; (7) performing calcination treatment to decompose lead hydroxide, and obtaining lead oxide; (8) performing reduction treatment, performing reduction treatment on lead oxide in the step (7), and heating charcoal in lead oxide to obtain metal lead through reduction. The recycling method is simple and good in effect.

Owner:永兴县灿阳贵金属有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com