Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

a technology of high purity lead and electrode paste, which is applied in the field of reclaiming high purity lead compound from impure mixtures, can solve the problems of high cost of impure starting materials, complex treatment plants, and high energy requirements, and achieve the effect of reducing the cost of lead reclaiming and simplifying the all wet lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

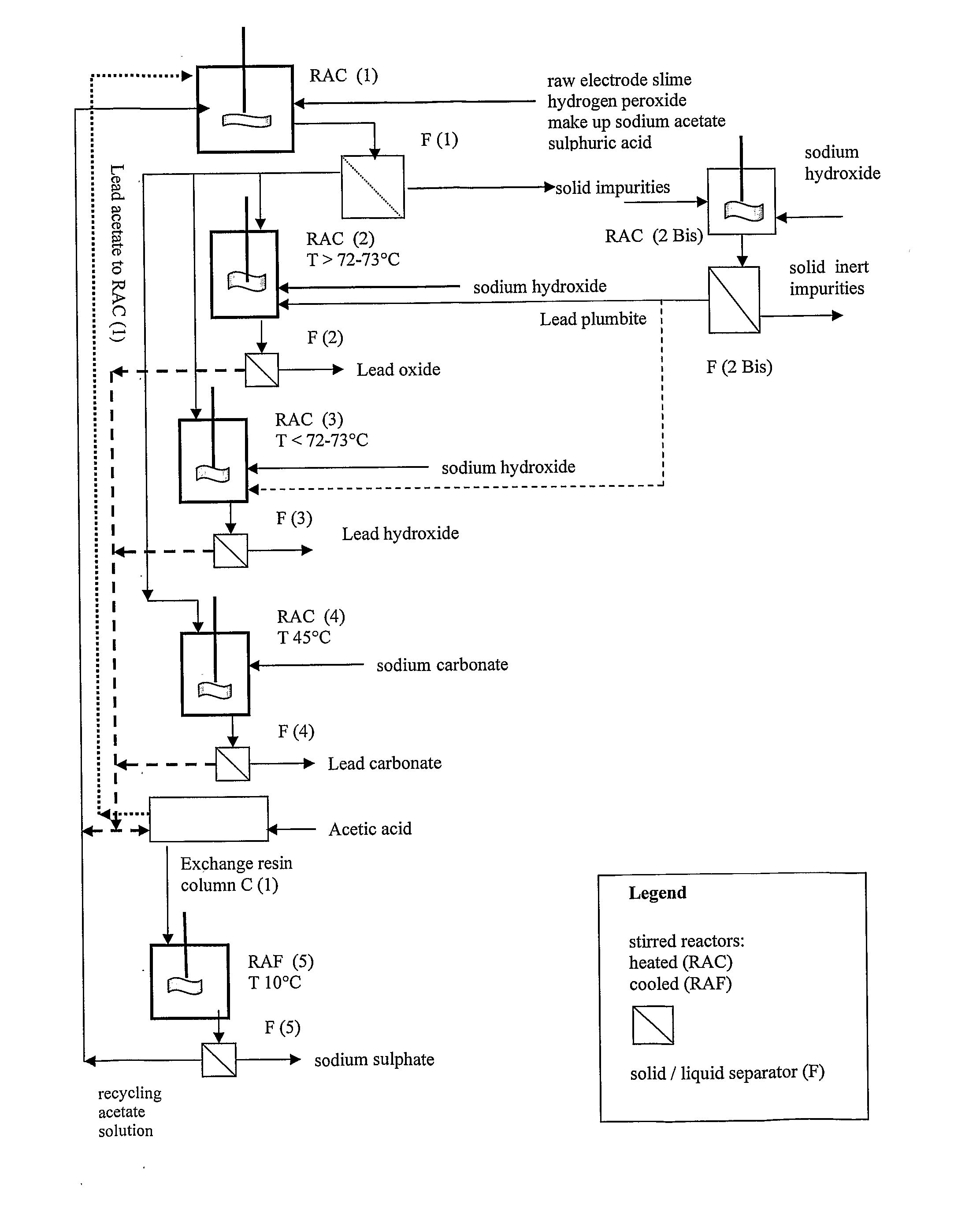

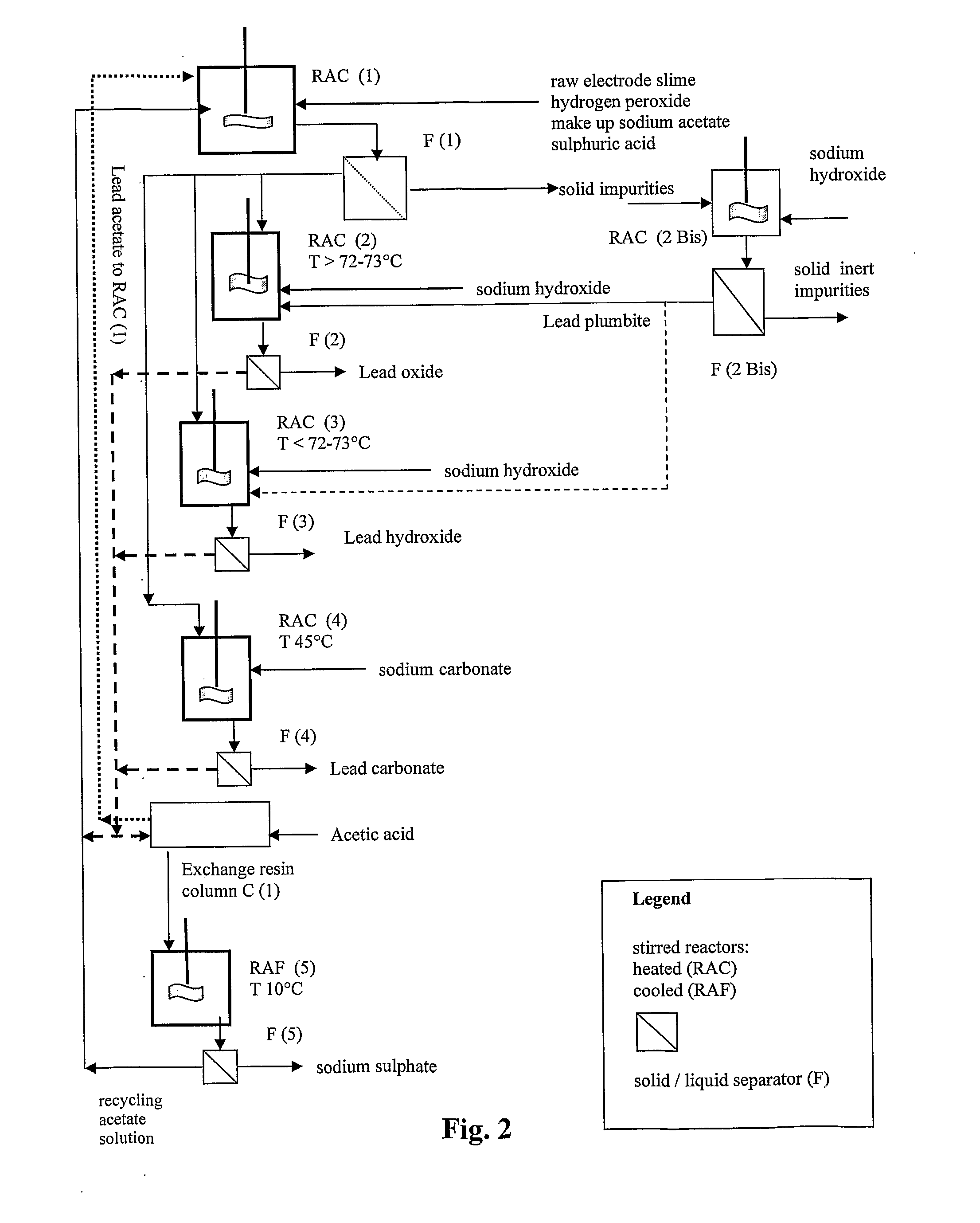

Method used

Image

Examples

example 1

[0038]80 g of recovered dried electrode paste having a lead content, expressed as metal equivalent, of 72% was treated under stirring with 1000 ml aqueous solution of tri-hydrated sodium acetate at 37.5% by weight, with the addition of g 12.2 of concentrated sulphuric acid at 94-96% by weight, at the temperature of 83° C. Successively, hydrogen peroxide at 32% by weight was slowly added to the suspension (dropwise for about 10 minutes) until no further clarification of the suspension was observed.

[0039]The hot suspension was then filtered and the separated solid phase was constituted by insoluble lead compounds and lead compound concretions, electrode grid fragments and various additives used for making the electrode paste such as carbon black, barium sulphate, fibers, etc. and impurities such as sand, plastic materials, etc. The amount of this dark grey solid phase was about 4-12% by weight of the solid mass of the dry electrode paste.

[0040]The filtered limpid solution containing l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com