Treatment process for plumbic acid waste water generated in production process of lead storage batteries

A production process, lead-acid battery technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of complex operation process and high energy consumption, and achieve Effect of less sludge amount, less sludge, and reduction of fresh water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments.

[0024] A process for the treatment of lead-acid waste water produced in the production process of lead-acid batteries, comprising the following steps:

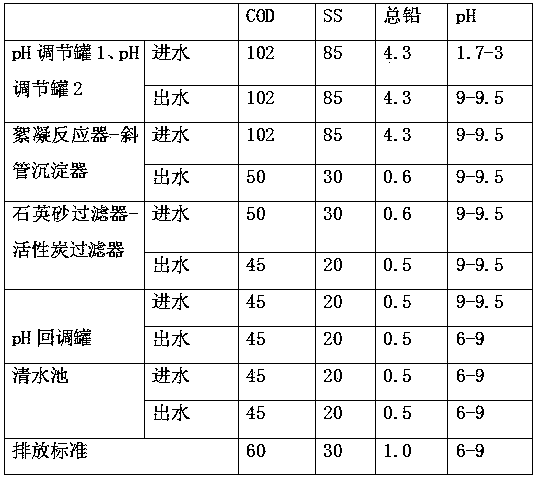

[0025] The wastewater first enters the grease trap to remove the large volume of suspended solids and oil in the wastewater, and then enters the sump to adjust the water quality and quantity. The wastewater is lifted to the pH adjustment tank 1 by the lift pump, and the NaOH solution with a mass concentration of 30% is added and Stir roughly to adjust the pH to between 5-6; the water from the pH adjustment tank 1 flows into the pH adjustment tank 2 by itself, add NaOH solution with a mass concentration of 30%, and stir to further adjust the pH to between 9-9.5, lead ions and hydrogen Oxygen ions generate lead hydroxide precipitation; then enter the flocculation reaction tank, by adding flocculant PAC, PAM, the dos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com