Patents

Literature

60results about How to "Save fresh water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

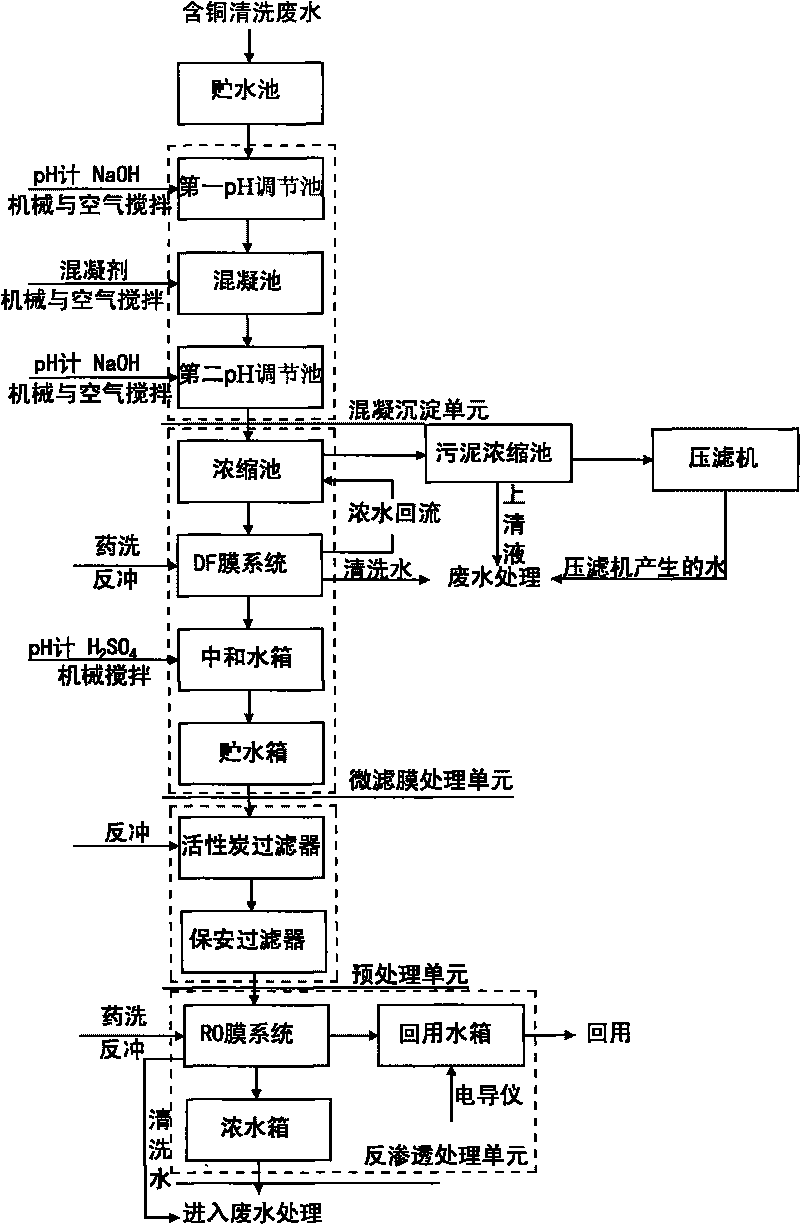

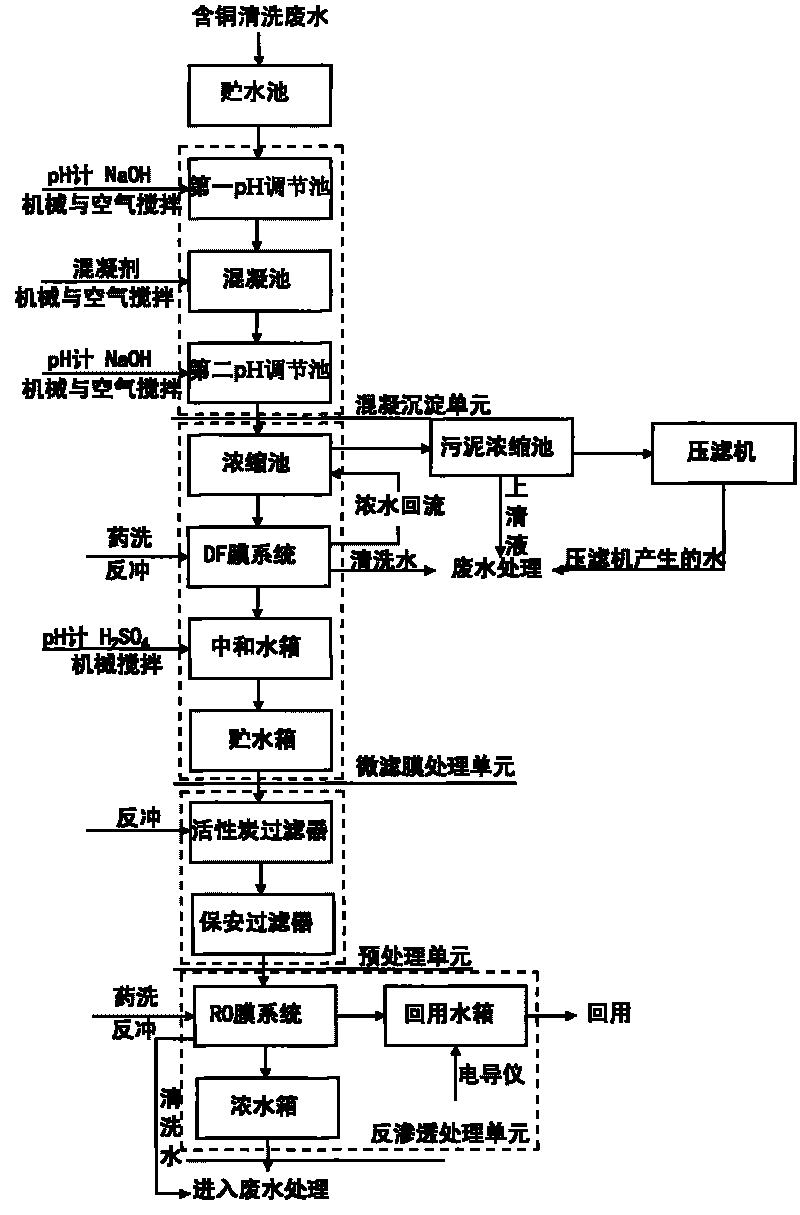

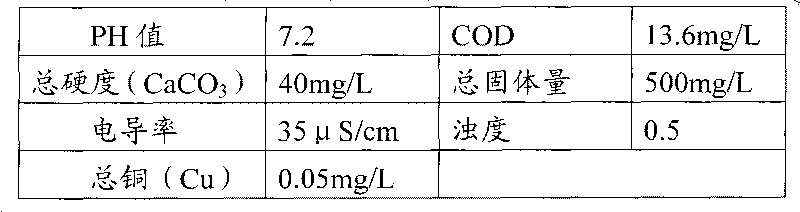

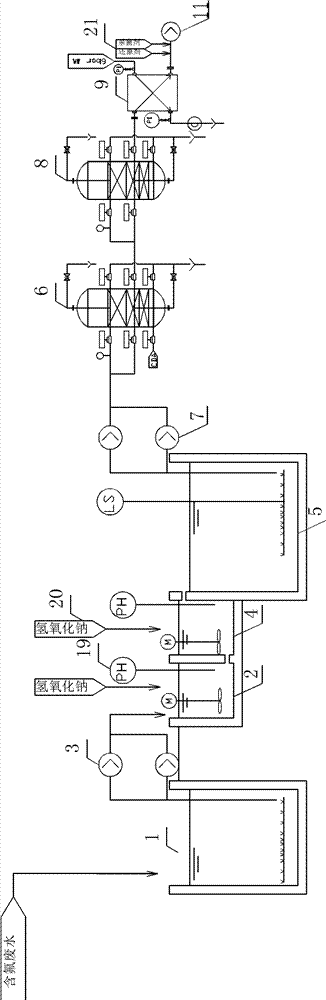

Electronic electroplating wastewater recycling advanced treatment technology

InactiveCN101734815AImprove coagulation and sedimentation effectAvoid easy cloggingWaste water treatment from metallurgical processMultistage water/sewage treatmentMembrane technologyReverse osmosis

The invention relates to an electronic electroplating wastewater recycling advanced treatment technology. The technology uses a large amount of rinse-wastewater with heavy metals in the production process of the electronic electroplating industry as the main object, adopts a combined technology of pH adjustment-microfiltration membrane treatment-pretreatment-reverse osmosis membrane treatment, is mainly characterized by the joint application of DF membrane technology and RO membrane technology and can achieve the aim of reusing wastewater and reducing the emission of heavy metals; and the reuse water reaches the production demand of process water, thus saving the fresh water consumption of the industry, effectively reducing the production cost of the industry, solving the pollution problem of heavy metals, increasing the clean production level of the electronic electroplating industry and having remarkable social environmental and economic benefits.

Owner:苏州市环境工程有限责任公司

Treatment process for sewage water generated from medium-low temperature carbonization of coal

InactiveCN101492223AAvoid pollutionSave resourcesFatty/oily/floating substances removal devicesMultistage water/sewage treatmentHigh concentrationElectrolysis

The invention relates to the field of coal chemical industry and environmental engineering, in particular to a process for treating sewage generated by coal moderate-low temperature carbonization, which comprises processing steps of oil removal, micro electrolysis, ammonia blowing, strain biological treatment, mud-water separation and coagulation treatment. The process is performed according to the sequence, performs intensified pretreatment on the sewage by the physical and chemical actions of the oil removal, the micro electrolysis and the ammonia blowing so as to remove pollutants such as oil, COD, ammonia nitrogen, higher phenols, and the like in the high concentration sewage generated by the coal moderate-low temperature carbonization with the removal rate up to more than 60 percent so that the pretreated sewage reaches the biochemical treatment requirement, and then performs the mud-water separation and the coagulation treatment on the sewage so that the water quality after the treatment reaches the discharge requirement.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

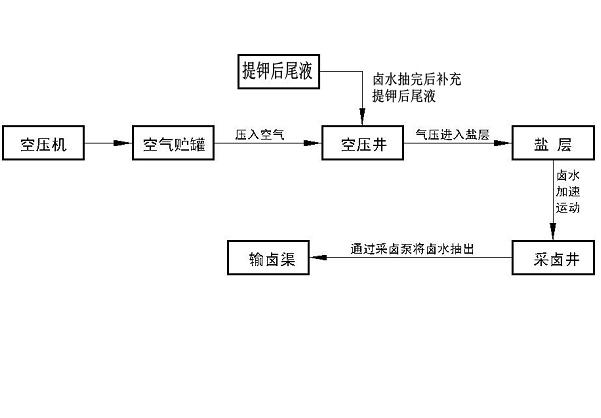

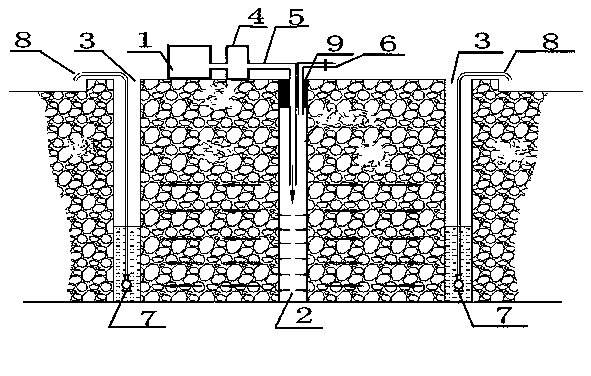

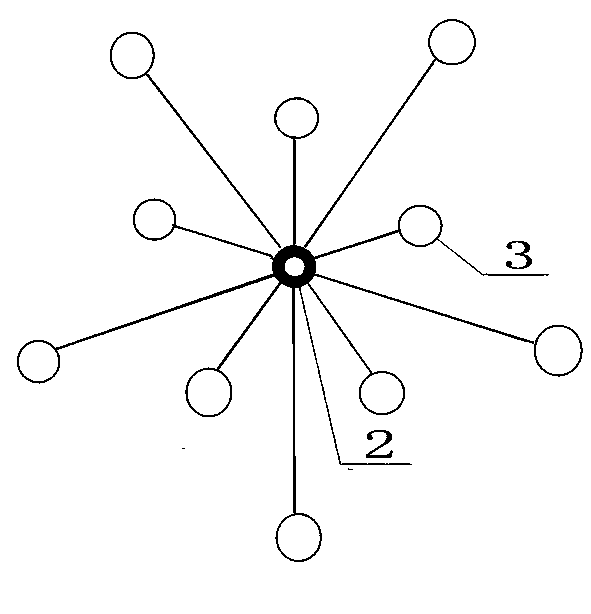

Method for extraction of deep-seated intercrystalline bittern of salt lake mining area

ActiveCN102659139AIncrease collection rateMaintain dynamic balanceAlkali metal chloridesSalt lakeMining engineering

The invention relates to a method for extraction of deep-seated intercrystalline bittern of a salt lake mining area. The method comprises the following steps of 1, excavating a gas-injection well, brine mining wells and a brine transportation channel on a salt lake ore bed, arranging an air compressor on the salt lake ore bed, arranging a brine tail liquid injection pipe in the gas-injection well around which the brine mining wells each provided with a brine transportation pipe in the interior are uniformly arranged; and arranging a brine mining pump in each one of the brine mining wells, wherein the brine mining pump is connected to one end of the brine transportation pipe of which the other end is connected to the brine transportation channel, 2, continuously pumping compressed air into the salt lake ore bed by the air compressor so that deep-seated intercrystalline bittern gushes out, 3, pumping out the deep-seated intercrystalline bittern from underground by the brine mining pumps and outputting the deep-seated intercrystalline bittern to the brine transportation channel, 4, injecting a brine tail liquid subjected to potassium extraction into the salt lake ore bed in the gas-injection well so that the brine tail liquid reaches a salt bed and forms novel potassium-containing brine, and 5, repeating the steps of 2-4 so that a cycle is finished. The method utilizes compressed air to realize extrusion of intercrystalline bittern and deep-seated bittern so that resources are fully utilized.

Owner:MANGYA XINGYUAN POTASH FERTILIZER +2

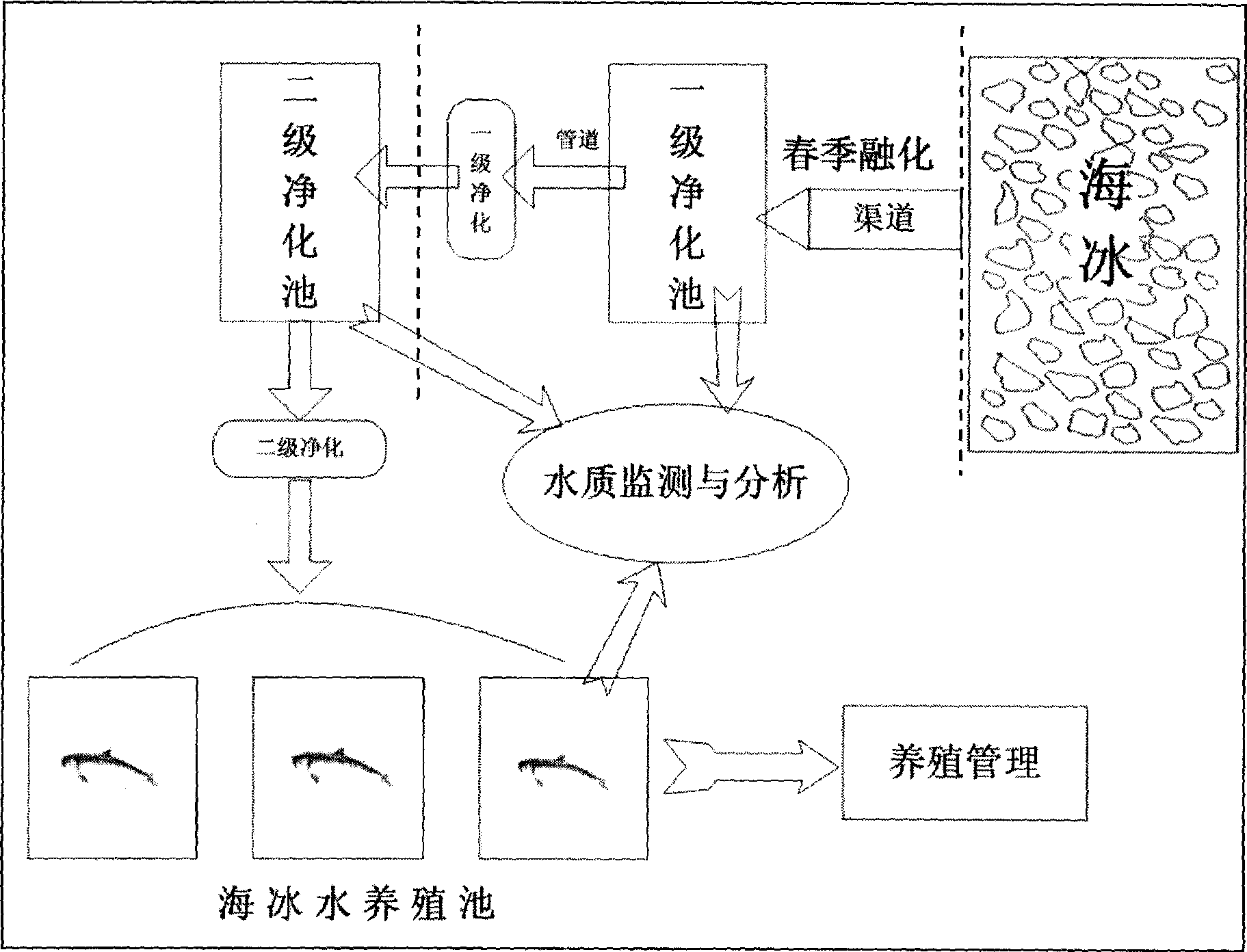

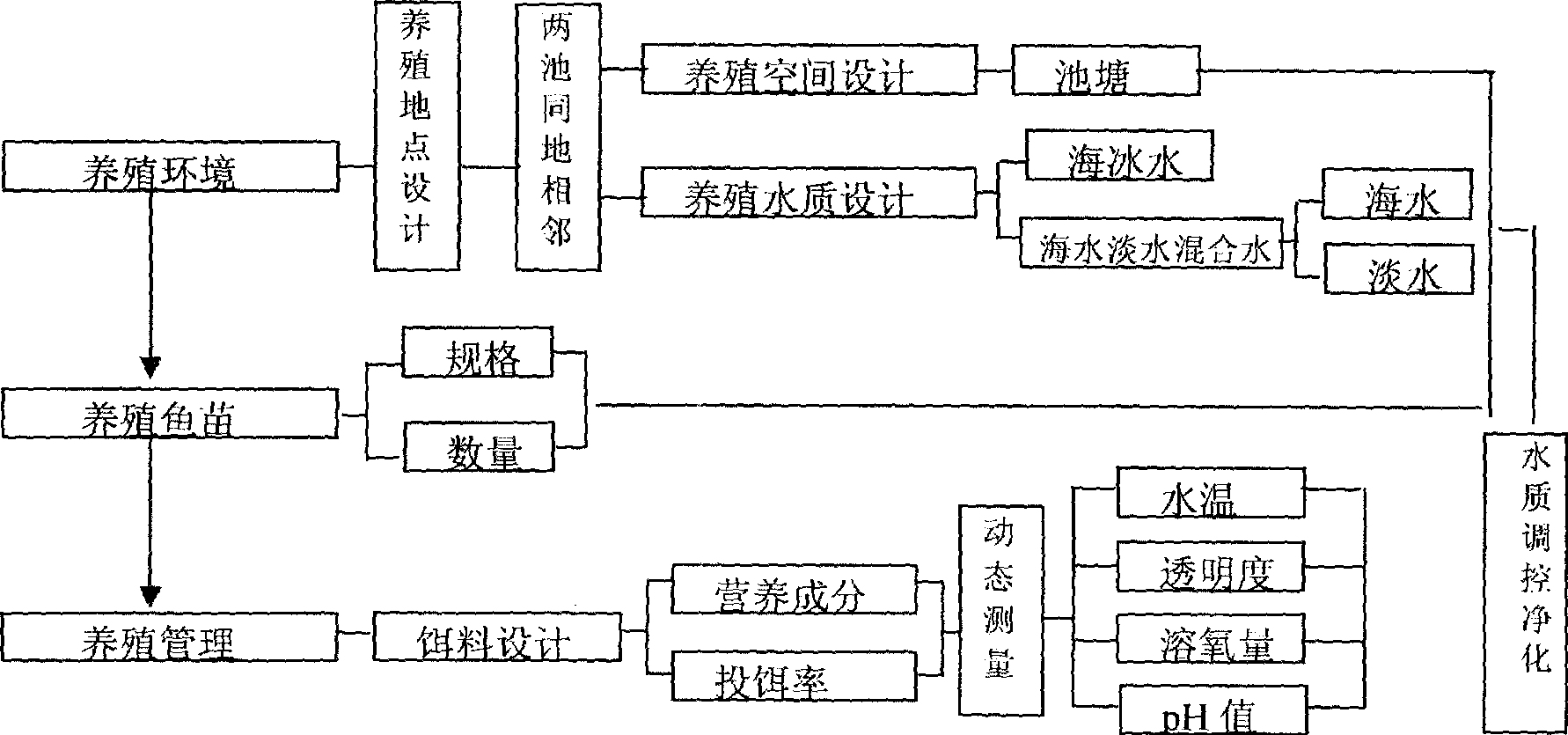

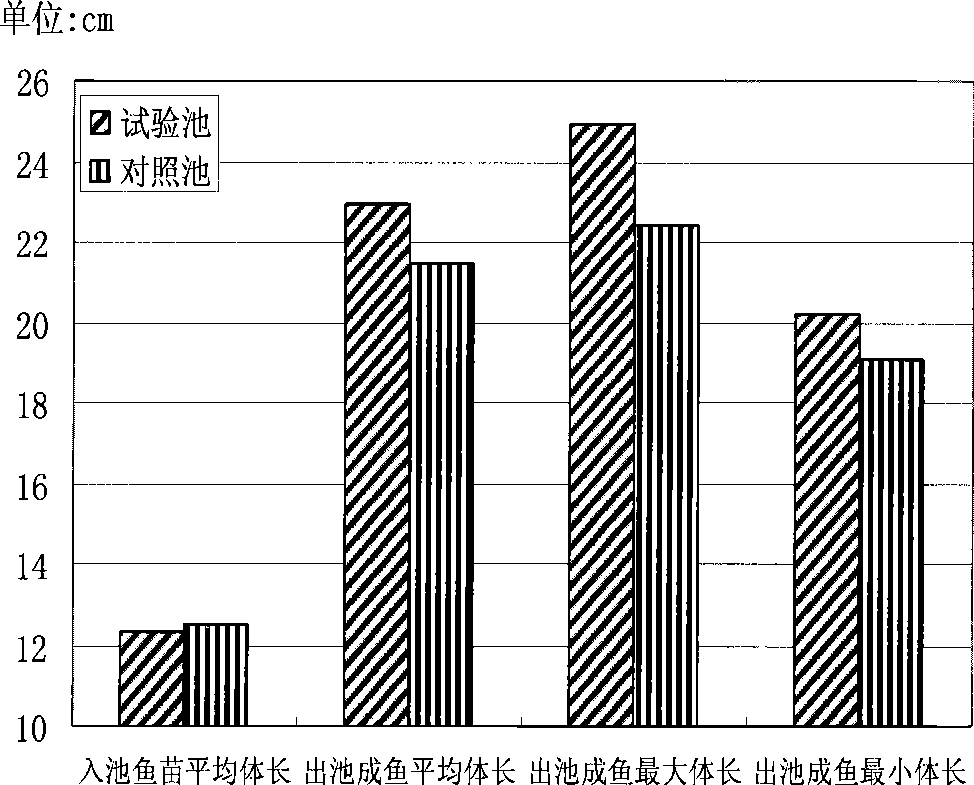

Method for cultivating tilapia by sea ice water

InactiveCN101543190ASolve water problemsImprove purification effectClimate change adaptationAnimal feeding stuffWater storageTilapia

A method for cultivating tilapia by sea ice water comprises the following steps: (1) after seawater is frozen in winter, sea ice is collected into a shoreside water storage pond; (2) after the sea ice is melted to form sea ice water in spring, the sea ice water is delivered into a first-stage purifying pond; (3) the sea ice water carries out first-stage edulcoration, purification and filtration in the first-stage purifying pond and then is delivered into a second-stage purifying pond; (4) the sea ice water carries out second-stage edulcoration, purification and filtration and then is delivered into an alexipharmic sea ice water cultivation pond; (5) tilapia fries are placed into the alexipharmic sea ice water cultivation pond and cultivated; and (6) water quality monitoring and cultivation management are carried out in the cultivation process. Novel water source sea ice water has good purification action in the freezing process, and the salinity of melted sea iced water is between 7g / L and 11g / L so that the melted sea ice water is just an optimal water environment for the growth of the tilapia, thereby the invention opens a new way for the sea ice water on the agricultural multipurpose use of coastal beaches and low-lying alkaline lands.

Owner:BEIJING NORMAL UNIVERSITY

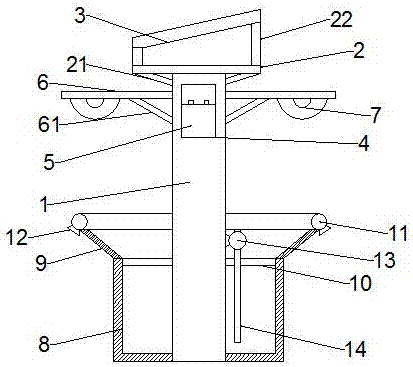

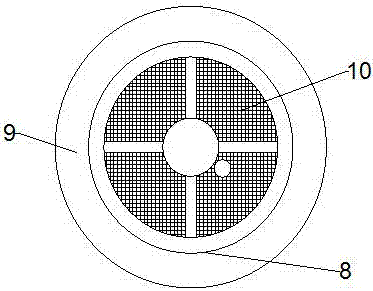

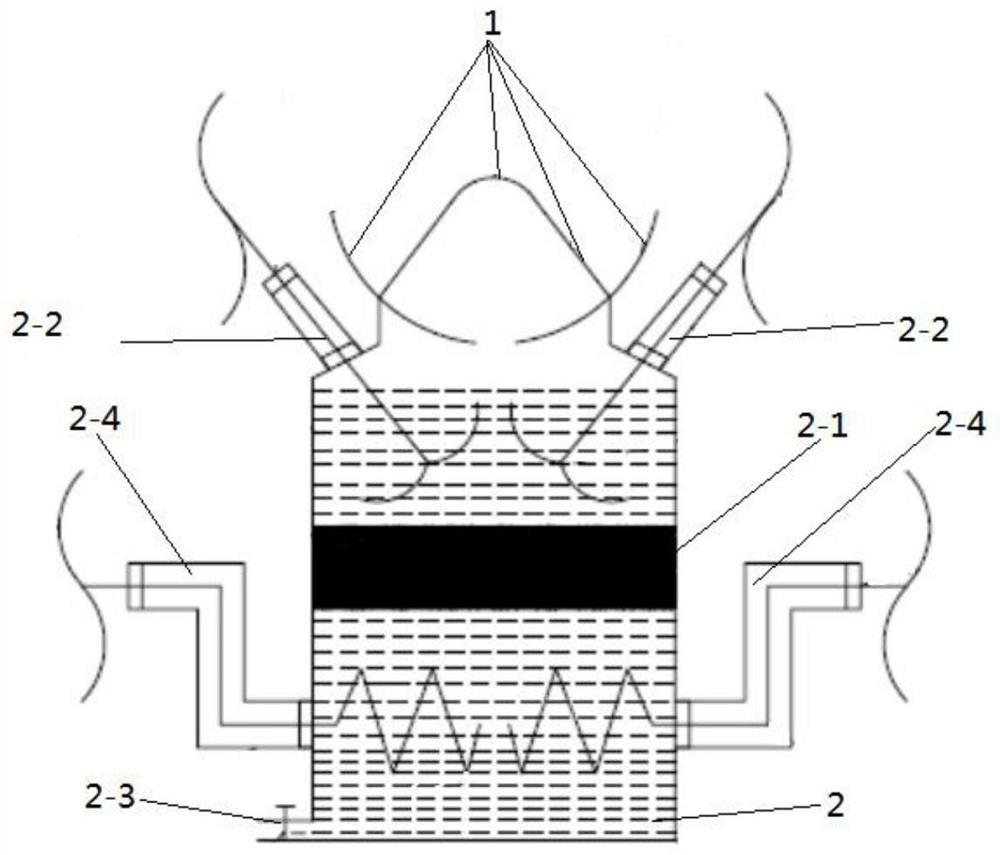

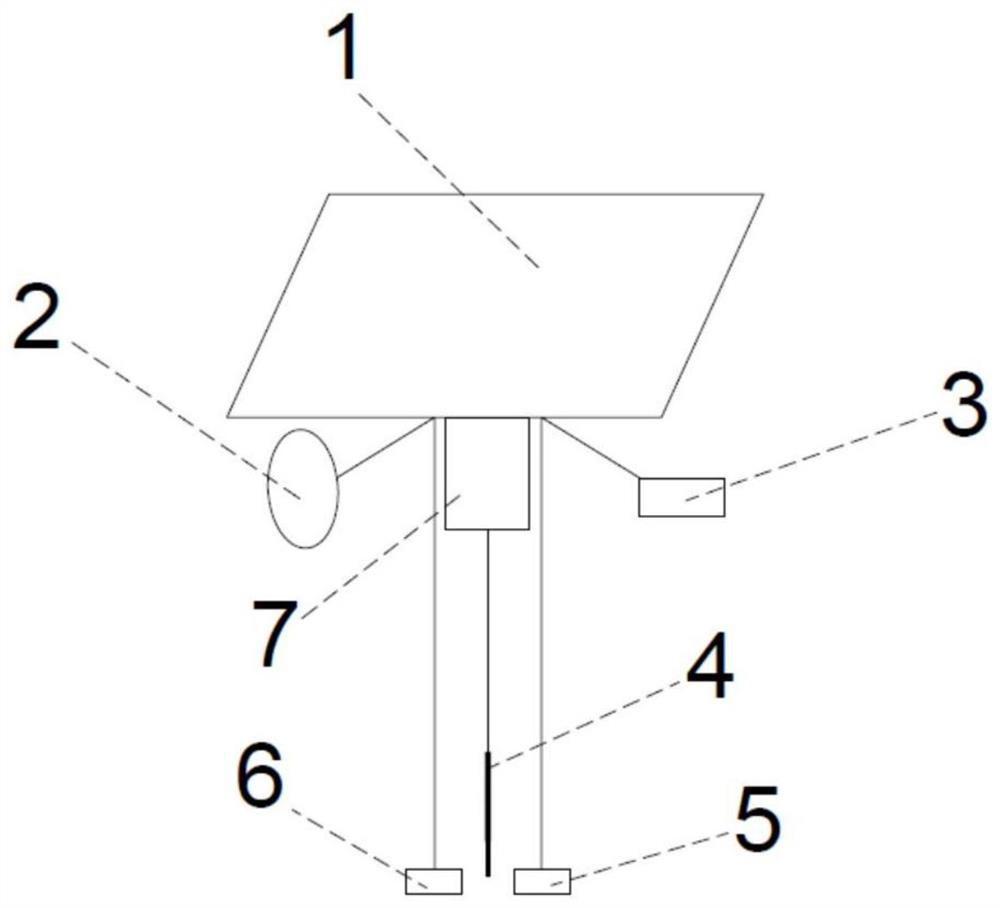

Solar street lamp capable of collecting water for irrigation for park

InactiveCN107013878AGuaranteed lighting effectsSave fresh waterMechanical apparatusLighting support devicesWater irrigationEngineering

The invention discloses a solar street light capable of collecting water for irrigation in gardens, which comprises a street light pole, a solar electric panel, a storage battery, a street light, a water storage tank, a spray pipe, a wide-angle nozzle and a water pump, and the street light pole is provided with a placement plate , reinforcing ribs, placement racks and solar panels; the front of the street light pole is equipped with a waterproof cover and batteries; both sides of the street light pole are equipped with horizontal light frames, light frame reinforcement ribs and street lights; the lower part of the street light pole is equipped with a water reservoir and a drainage ring Plates, screen plates, sprinkler pipes, wide-angle nozzles, water pumps and suction pipes. The present invention adds an annular water storage pool to the solar street light for gardens, collects fresh water in rainy weather, and can be used for watering at ordinary times. It is convenient to use, simple in structure, easy to clean, and more environmentally friendly and practical.

Owner:谷武

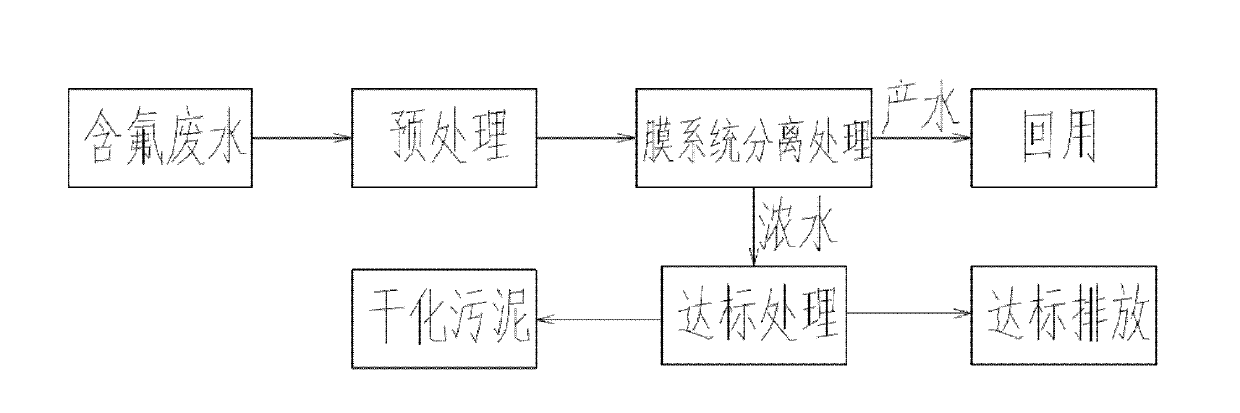

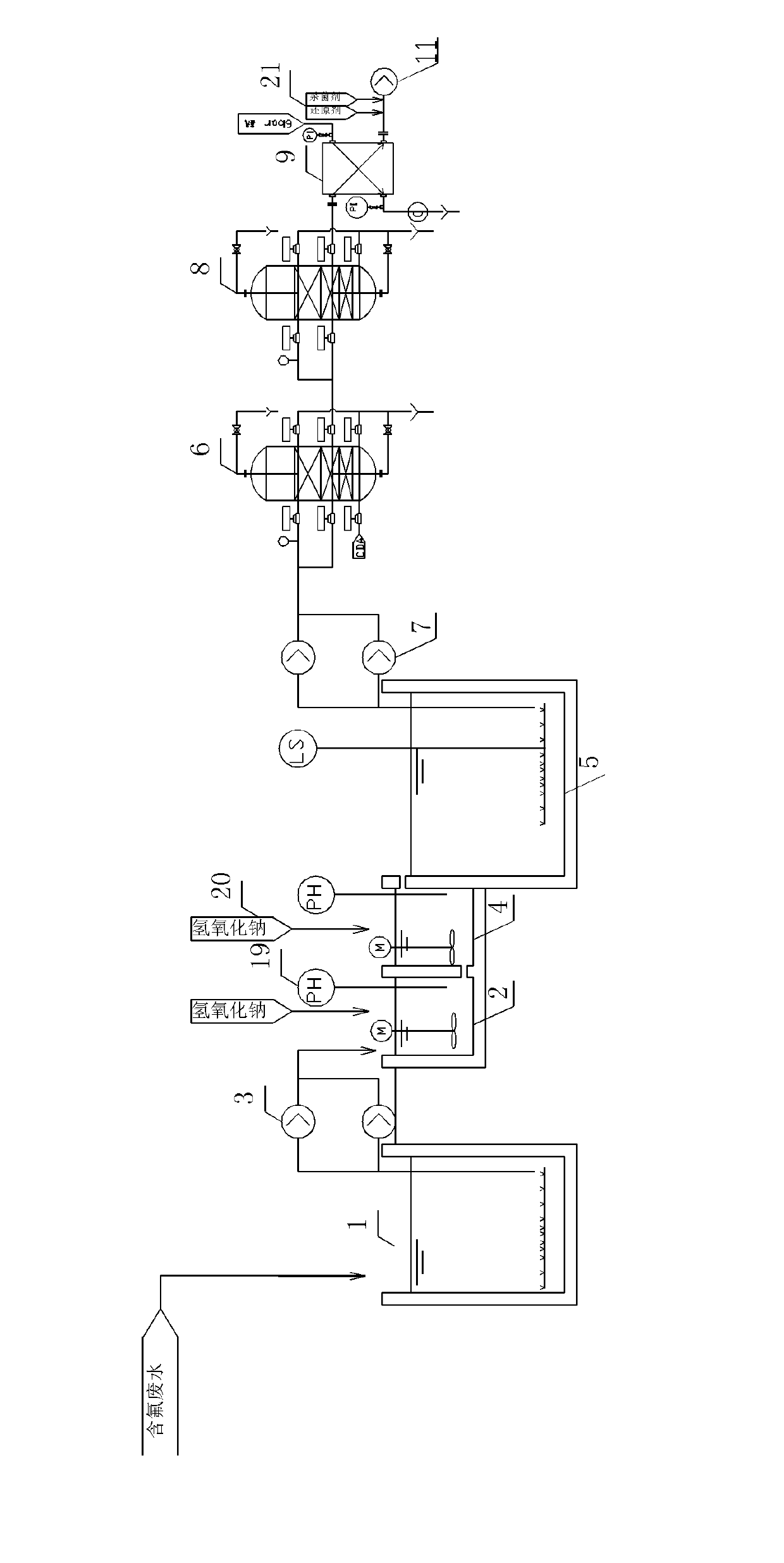

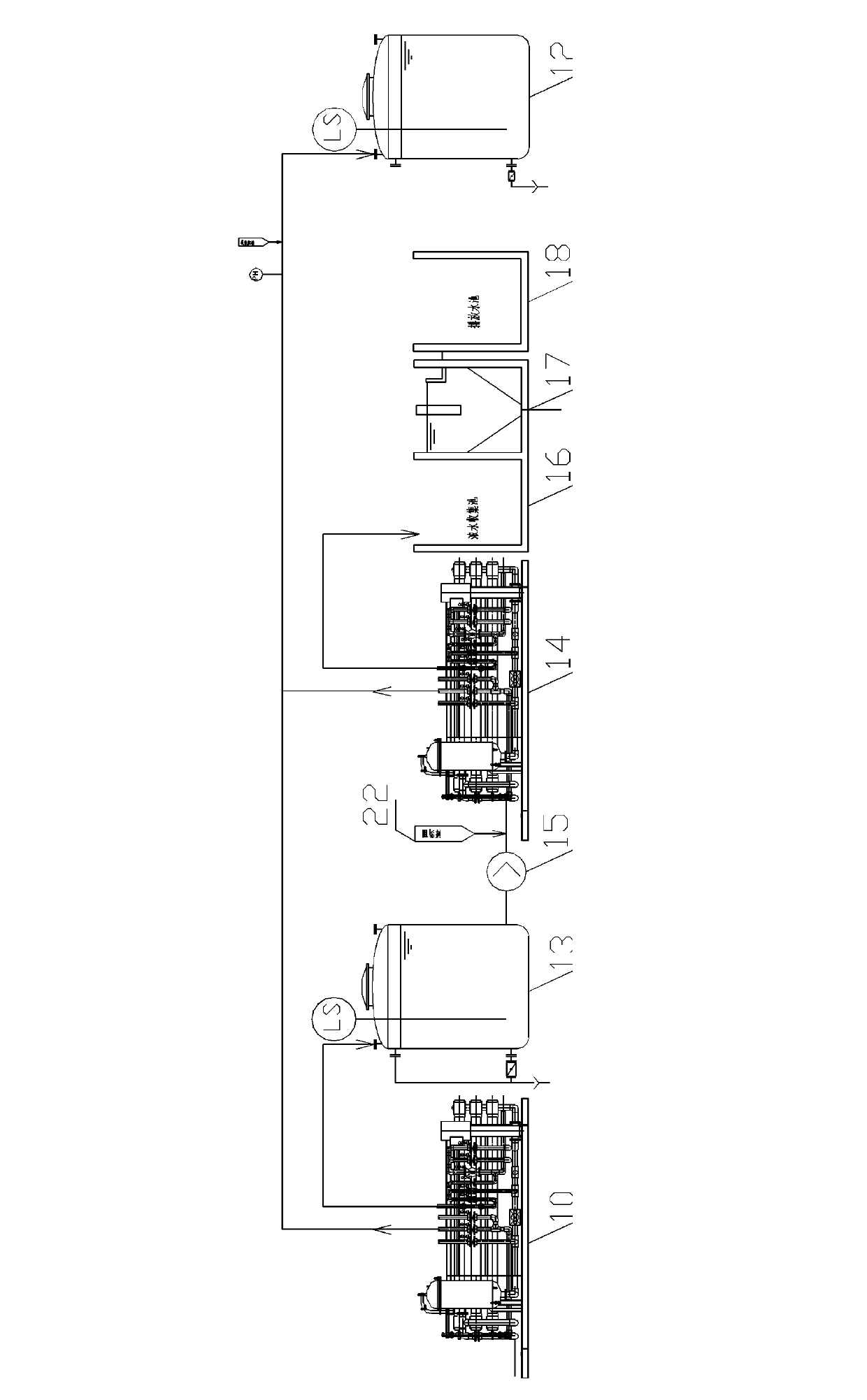

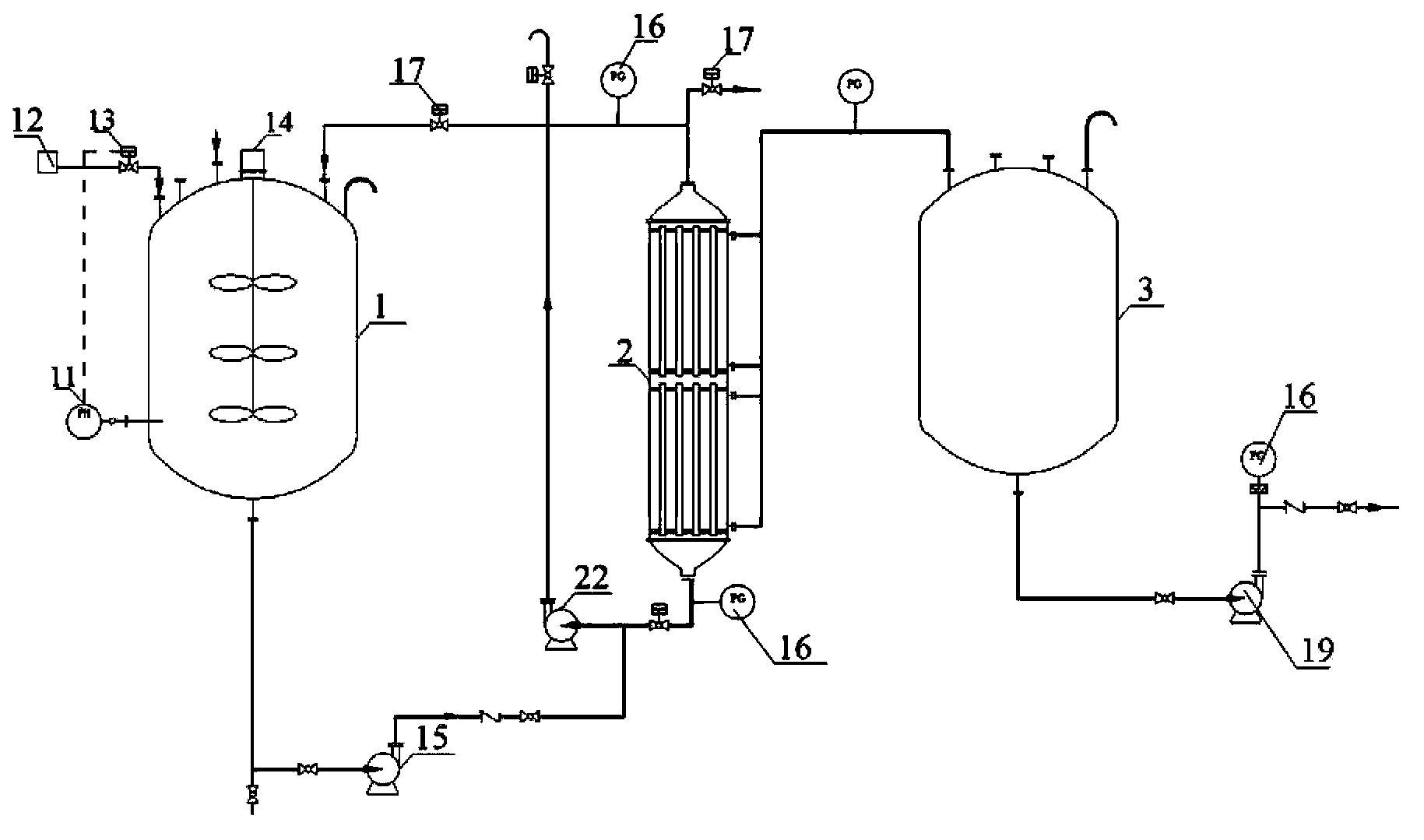

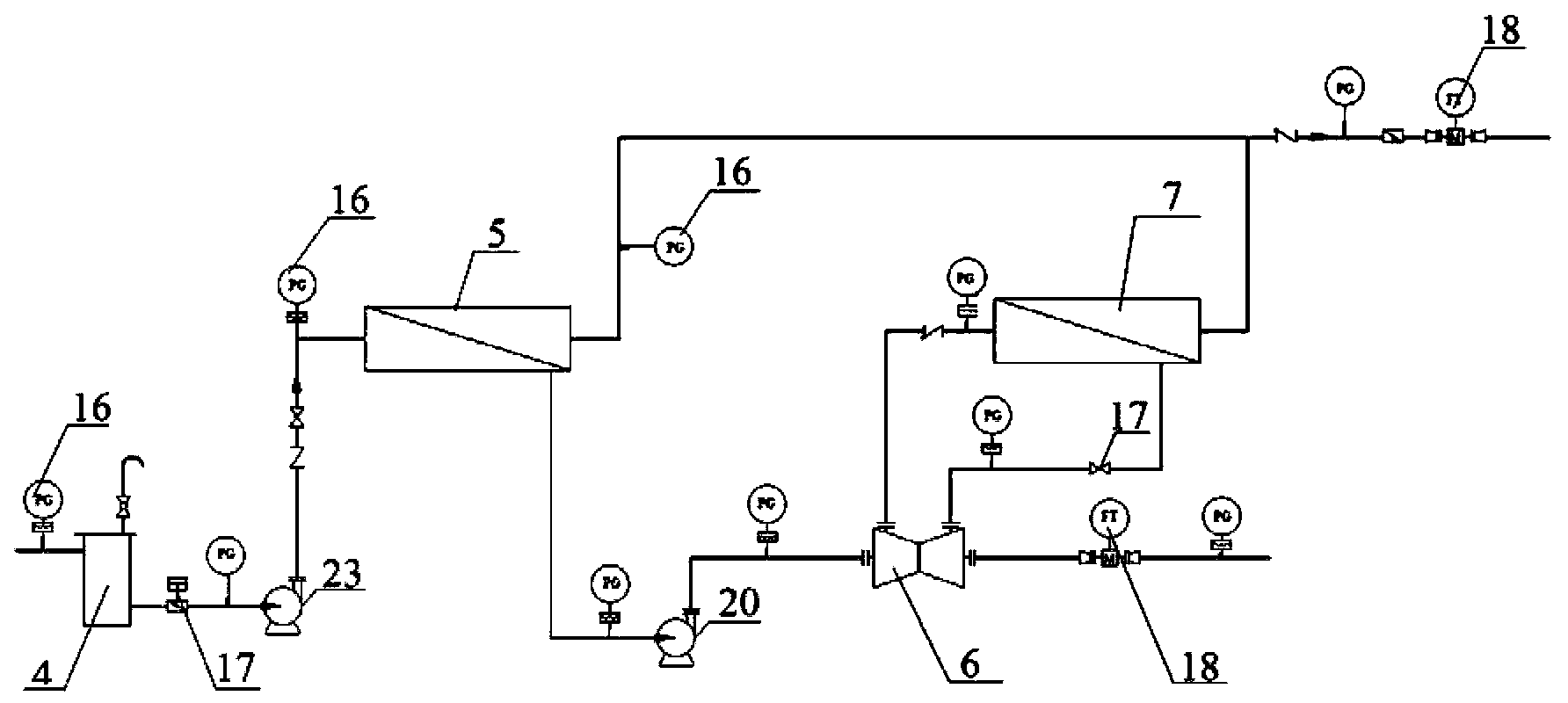

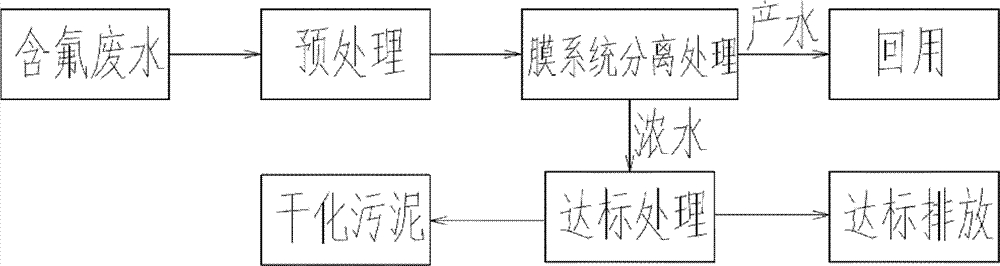

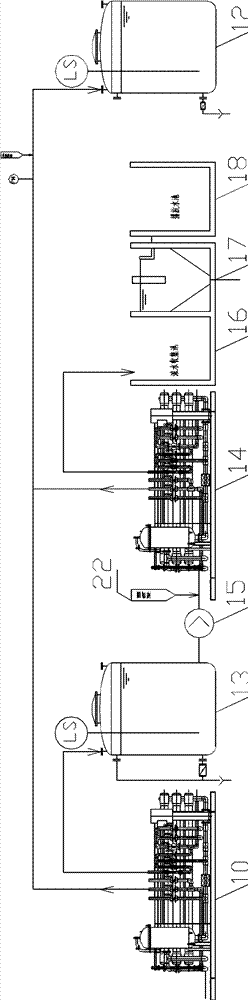

Membrane-method high-powered recycling process for fluoride-containing wastewater generated by photovoltaic industry and dedicated system of membrane-method high-powered recycling process

ActiveCN103373774AReduce the amount of waterReduce pretreatment costsWater contaminantsScale removal and water softeningPhotovoltaic industrySludge

The invention provides a membrane-method high-powered recycling process for fluoride-containing wastewater generated by the photovoltaic industry. The membrane-method high-powered recycling process is characterized by comprising the following steps of: firstly, pre-treating the collected fluoride-containing wastewater; then, introducing the pretreated fluoride-containing wastewater to a membrane separation treatment system, and carrying out further purification treatment on the fluoride-containing wastewater to obtain produced water and concentrated water; next, carrying out up-to-standard discharging treatment on the obtained concentrated water, and then, discharging the concentrated water; and finally, drying sludge, and then, outwards transporting the sludge, wherein the sludge is generated in the system purification treatment process. After the membrane-method high-powered recycling process for fluoride-containing wastewater generated by the photovoltaic industry, provided by the invention, is adopted, the produced water is recycled, so that a great deal of fresh water is saved, the high-powered recycling of the fluoride-containing wastewater is realized, the discharged pollutants and the emission are reduced, the resource is saved, and higher economic, social and environmental benefits are created for enterprises.

Owner:SHANGHAI JINGYU ENVIRONMENT ENG

Fracturing flowback fluid recovery treatment reusing process method

InactiveCN104418450AAvoid emissionsShort processMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationElectrochemistry

The present invention provides a fracturing flowback fluid recovery treatment reusing process method. The technical scheme comprises that: a precipitating agent is added to fracturing flowback fluid wastewater, and filtration is performed to remove harmful components unsuitable for fluid re-preparation, such that the harmful components can not affect the reuse and the fluid re-preparation, wherein the precipitating agent can be one or a plurality of materials selected from sodium hydroxide, sodium carbonate, aluminum sulfate, aluminum ferric sulfate silicate, polyacrylamide and polymeric aluminum ferric chloride; the precipitated flowback fluid is subjected to an electrochemical treatment so as to be subjected to actions such as oxidation, reduction, air flotation and flocculation; and the electrochemically-treated flowback fluid is subjected to an active carbon felt filtration treatment, such that the purpose of the reuse and the fluid re-preparation are achieved. According to the present invention, the useful components and the harmless components are not destroyed, the process is shortened, the cost is low, the operation is easy, and the high promotion application value is provided; and the method is based on the fracturing flowback fluid recycling and the fluid re-preparation, the sewage emission is avoided, the fresh water is saved, and the high environmental protection value is provided.

Owner:DONGYING TUOPU INFORMATION IND

System for extracting deep intercrystalline brine in salt lake mining area

ActiveCN103373736AIncrease collection rateMaintain dynamic balanceAlkali metal chloridesSalt lakePotassium

The invention relates to a system for extracting deep intercrystalline brine in a salt lake mining area. The system comprises an air compressor which is arranged on a salt lake mining layer, and an air-injection well, brine collecting wells and a brine conveying channel, which are formed in the salt lake mining layer in a digging manner, wherein the air compressor is connected with a high-pressure air pipe by an air reservoir; the high-pressure air pipe extends into the air-injection well; a brine tail liquid injection pipeline is arranged in the air-injection well; the brine collecting wells are distributed around the air-injection well; a brine conveying pipeline is arranged in each brine collecting well; a brine collecting pump is arranged in each brine collecting well and is connected with one end of the corresponding brine conveying pipeline; the other end of each brine conveying pipeline is connected with the brine conveying channel; sealing materials are arranged between the high-pressure air pipe and the brine tail liquid injection pipeline, between the high-pressure air pipe and the wall of the air-injection well, and between the brine tail liquid injection pipeline and the wall of the air-injection well respectively. According to the system, intercrystalline brine and deep brine can be pressed out by using compressed air, and simultaneously tail liquid after potassium extraction can be used for resolving low-grade solid potassium or high-grade solid potassium after dilution, so as to realize the aim of fully utilizing resources.

Owner:MANGYA XINGYUAN POTASH FERTILIZER +2

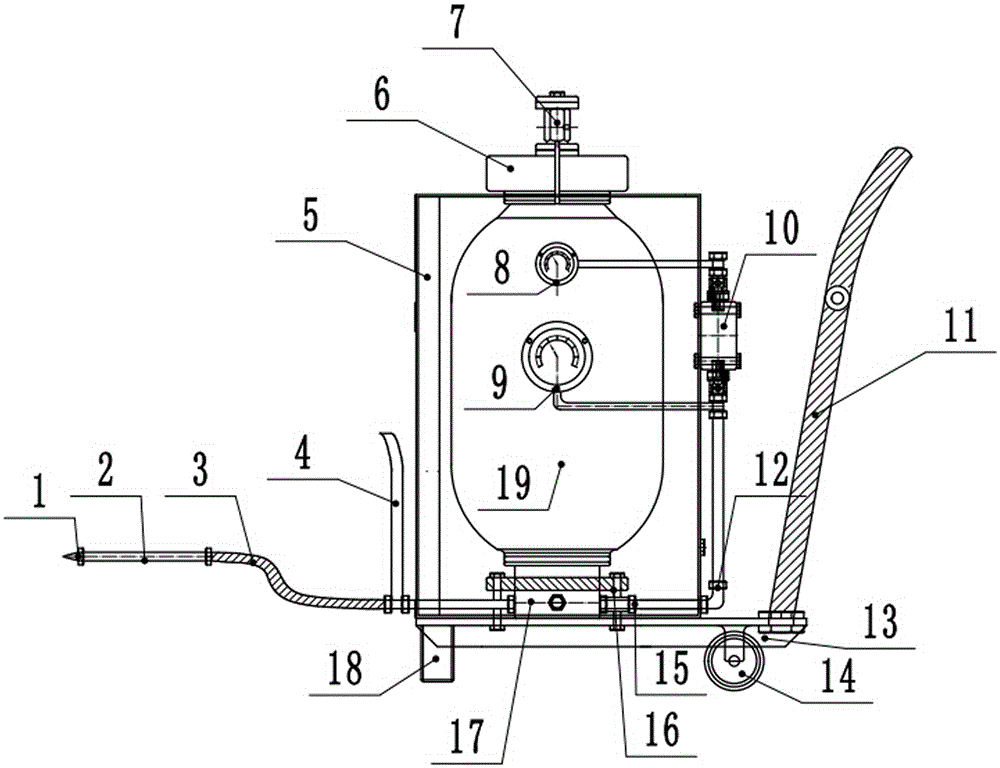

Cleaning, de-rusting and cutting automatic conversion all-in-one machine for offshore oil platform

InactiveCN105081983AReduce trafficRelieve pressureAbrasive feedersAbrasive machine appurtenancesWorking pressureSpray nozzle

The invention discloses a cleaning, de-rusting and cutting automatic conversion all-in-one machine for an offshore oil platform. The cleaning, de-rusting and cutting automatic conversion all-in-one machine for the offshore oil platform comprises a jewel orifice, a spraying gun handle, a high-pressure rubber pipe, a sand amount adjustment handle, a protective shield, an end cover, a pressure relief valve, a liquid inlet pressure gauge, a work pressure gauge, a pressure flow amount control valve, a pushing handle, a high-pressure liquid inlet pipe, a base, a trundle, a one-way valve, a balance water adjustment button, a mixing valve assembly, a supporting leg, an abrasive tank and other parts. After pressure water is subjected to pressure flow amount adjustment through the pressure flow amount control valve, the pressure water enters the mixing valve through the high-pressure liquid inlet pipe. Abrasives in the abrasive tank enter the mixing valve, are mixed with the water and then enter the jewel orifice through the high-pressure rubber pipe. The jewel orifice accelerates the mixed water and sprays the water on an object on the platform. The function of automatic conversion of cleaning, de-rusting and cutting is realized by adjusting the diameter of the jewel orifice.

Owner:天津艾浮瑞特科技有限公司

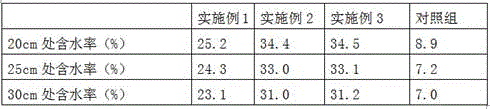

Preparation method of seawater mixing cemented soil

The invention provides a preparation method of seawater mixing cemented soil. The preparation method comprises the steps of adding seawater and cement into a mixing tank to be mixed together at first, and then pouring the mixed liquid into a stratum to be mixed with sludge, wherein the using amount of the cement accounts for 10-20% of the amount of the sludge, and the mass ratio of the seawater to the cement is (1-1.2):2; adding superfine silica fume with the fineness of 0.1 micronmeter-0.2micronmeter as a doping material in a mixing process, wherein the mass ratio of the doping material to the cement is 1:(4-5); and with a compound which is formed by mixing sodium bicarbonate and sodium hydrogen phosphate according to the mass ratio of 1:(1-2) as an exciting agent and a corrosion inhibitor, dissolving the compound into the seawater according to that the ratio of mass g to volume ml in the seawater is 0.5-1%, and then feeding the mixture into the mixed sludge. Compared with the prior art, the seawater mixing cemented soil has a comprehensive inhibiting effect on the erosion of sulfates, chlorine salts and magnesium salts in the seawater to the cemented soil, the expansion growth is not more than 10%, the strength of the obtained cemented soil is not only not influenced but also improved by about 50%, and the erosion of the seawater to machines and tools can also be eliminated.

Owner:ZHEJIANG OCEAN UNIV +1

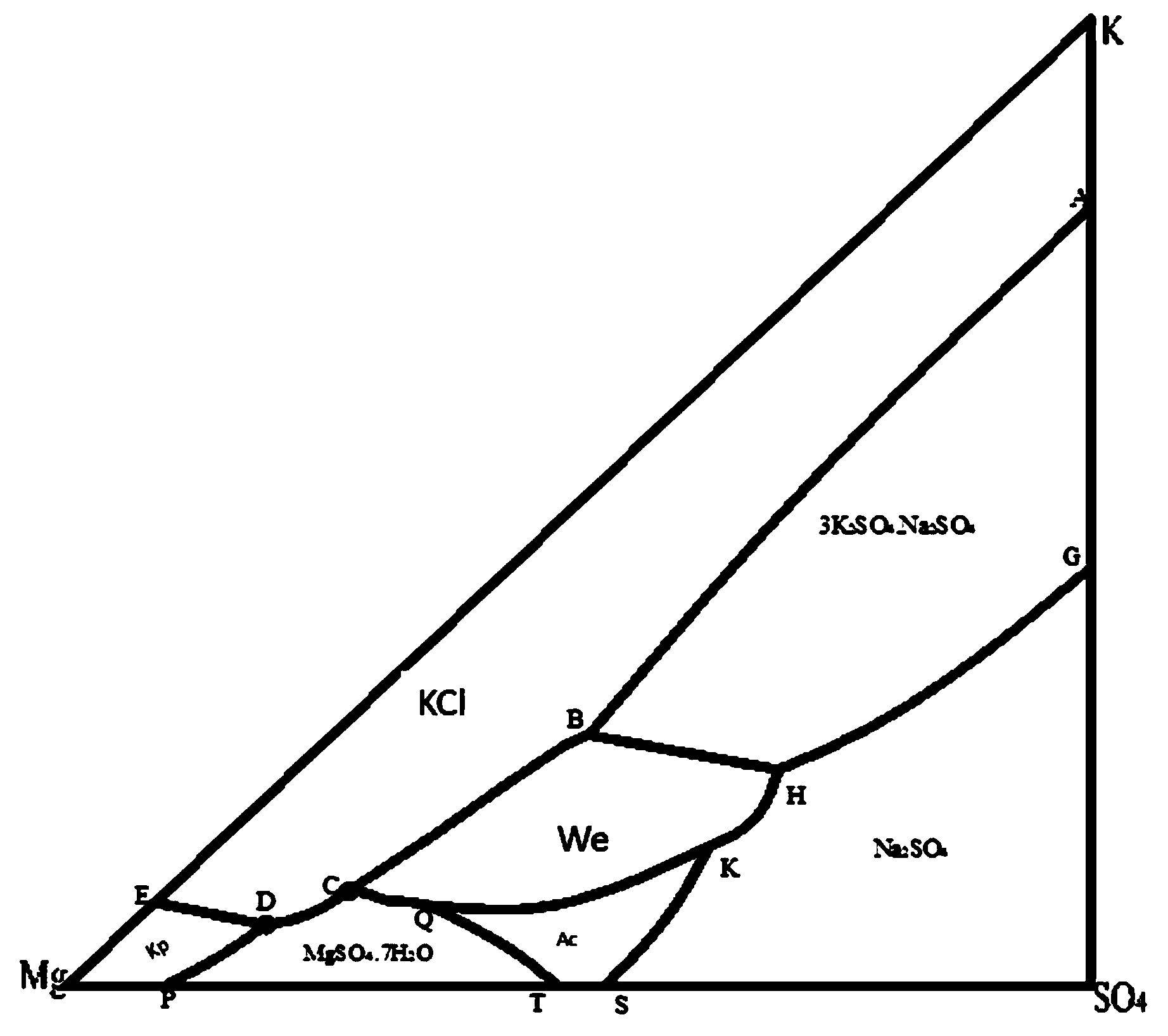

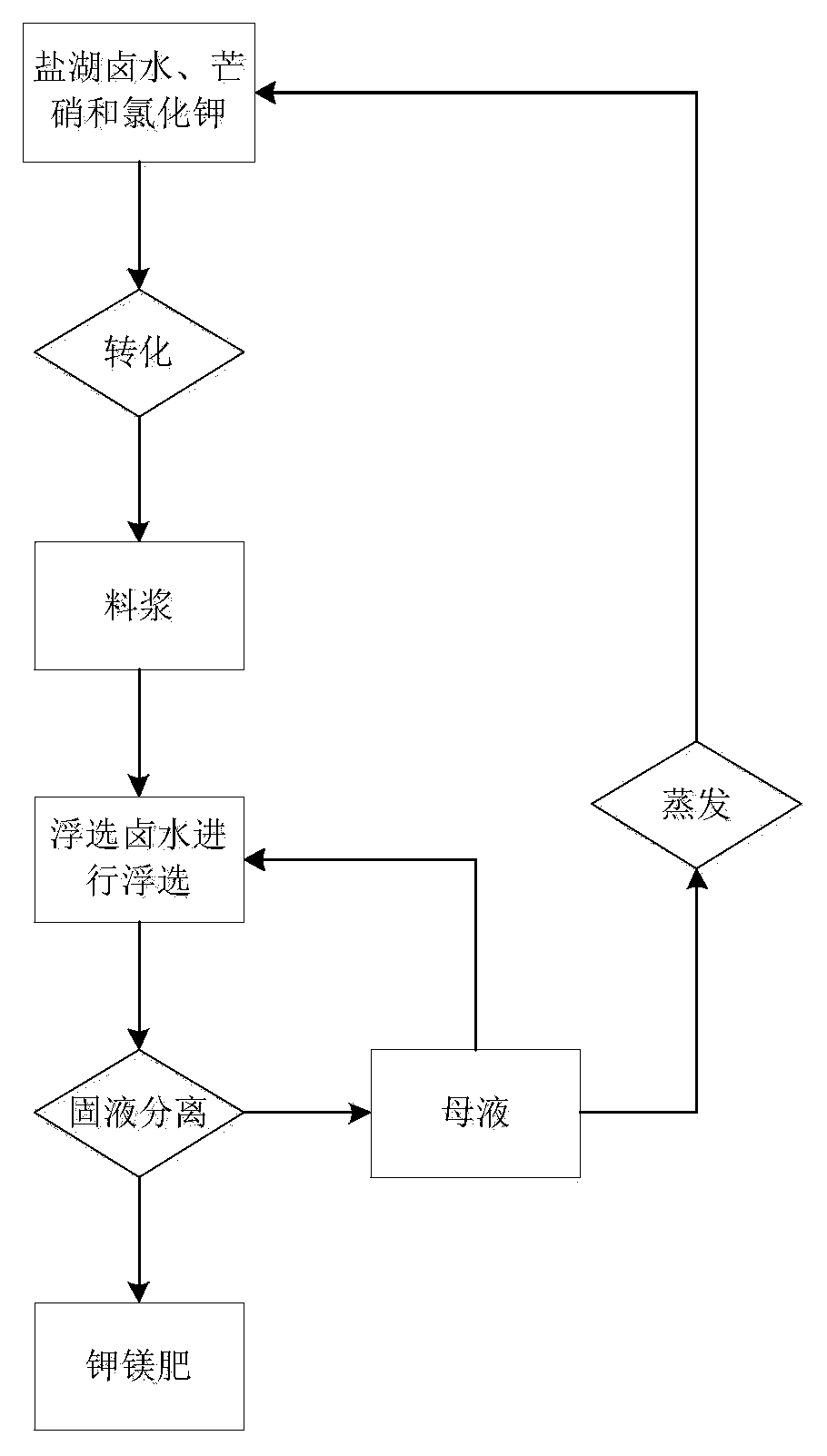

Method for preparing potassic-magnesian fertilizer

ActiveCN104261940ASave raw materialsSave fresh waterMagnesium fertilisersPotassium fertilisersRevolutions per minuteFertilizer

The invention discloses a method for preparing a potassic-magnesian fertilizer. The method comprises the following steps: (1) mixing potassium chloride, mirabilite and high-magnesium salt lake brine according to a mass ratio of (1-2):(1-2):(5-15), stirring and reacting at the room temperature for 0.5-1.5 hours, and controlling the stirring rate to be 350-400 revolutions per minute, so that the raw materials are fully reacted and converted to obtain slurry; (2) adding the slurry obtained in the step (1) into flotation brine according to a mass ratio of 1:(4-6), adding a flotation reagent, performing two-refining one-sweeping flotation separation, washing, thereby obtaining a high-grade potassic-magnesian fertilizer and a mother solution; and (3) returning the mother solution to a salt pan, evaporating the mother solution to serve as high-magnesium salt lake brine, reacting with the mirabilite and potassium chloride, or directly taking the mother solution as the flotation brine to be used for flotation separation. The method disclosed by the invention is low in energy consumption, low in cost, simple in process flow, short in production period and convenient for industrial production, and the produced potassic-magnesian fertilizer is high in grade.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

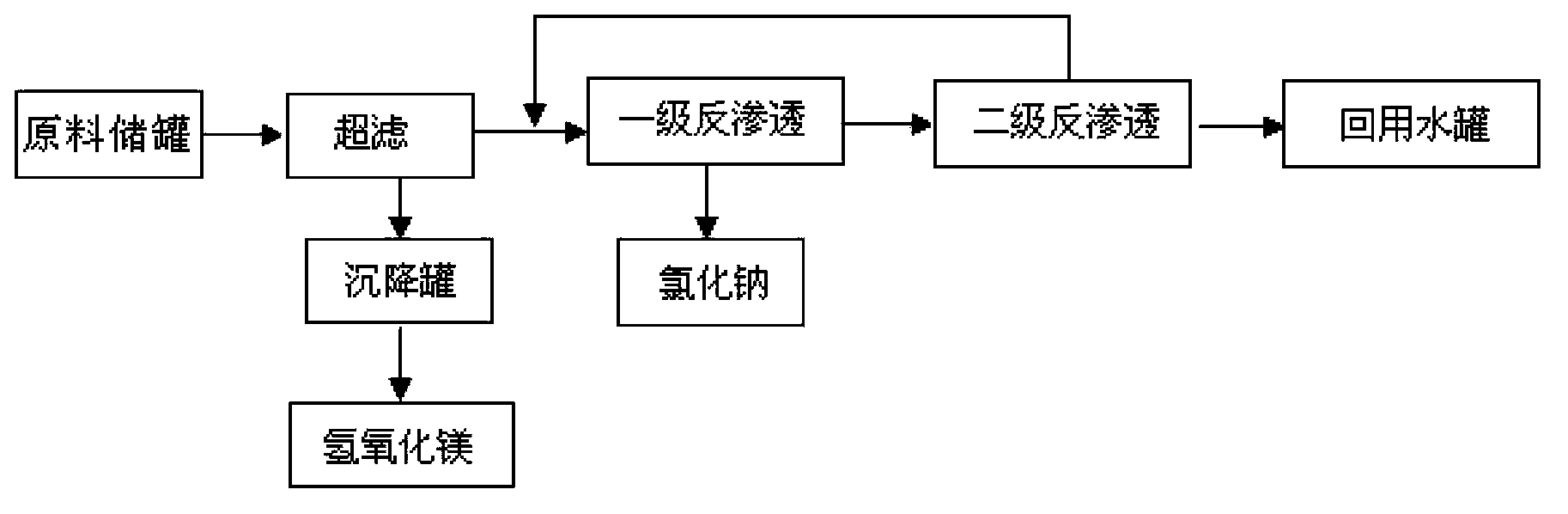

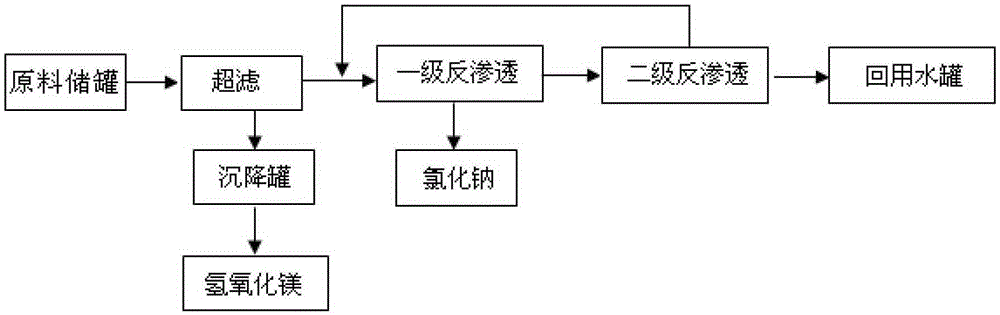

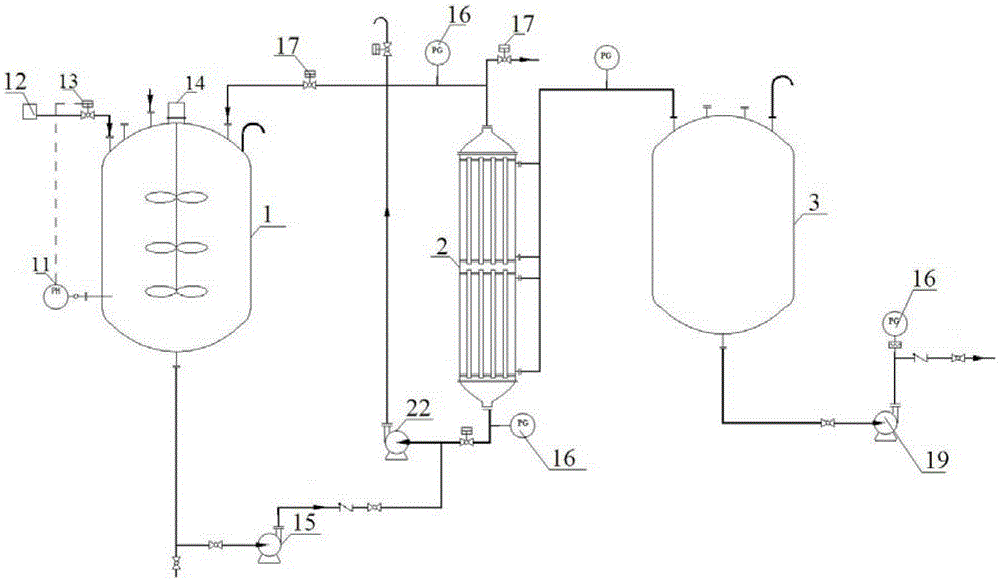

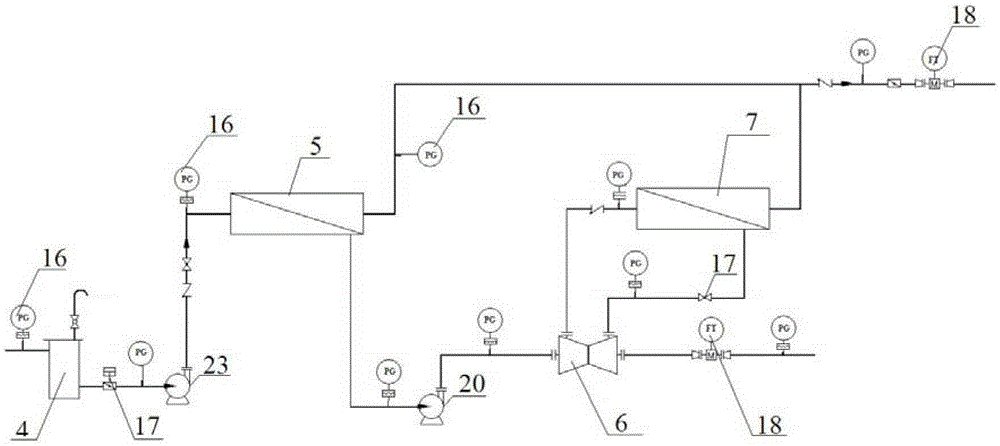

Magnesium hydroxide washing water recovery technology

ActiveCN103979702AEasy to meet environmental protection requirementsTo achieve the goal of energy saving and emission reductionSemi-permeable membranesChemical industryParticulatesReverse osmosis

The invention relates to a magnesium hydroxide washing water recovery technology which comprises the following steps: magnesium hydroxide washing water is led into a raw material storage tank, an alkali liquid is added into the raw material storage tank to regulate the pH value to enable the magnesium hydroxide washing water to produce magnesium hydroxide colloid; the magnesium hydroxide washing water flowing out from the raw material storage tank is filtered by a super / microfiltration unit, the magnesium hydroxide colloid and fine particle matters are trapped in the super / microfiltration unit, sodium chloride-containing filtrate leaves the super / microfiltration unit to enter into a reverse osmosis unit; in the reverse osmosis unit, sodium chloride is concentrated and introduced into a sodium chloride concentration solution storage tank, and filtrate penetrating the reverse osmosis unit is industrial water. Compared with the prior art, by use of the technology, 99.9% of magnesium hydroxide and 99% of sodium chloride and 60-80% of water can be recovered, the production cost of production enterprises can be reduced, wastewater emissions and solid waste emissions can be greatly reduced, energy-saving emission reduction targets of the enterprises can be achieved.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

Membrane-method high-powered recycling process for fluoride-containing wastewater generated by photovoltaic industry and dedicated system of membrane-method high-powered recycling process

ActiveCN103373774BReduce the amount of waterSmall footprintWater contaminantsScale removal and water softeningPhotovoltaic industrySludge

The invention provides a membrane-method high-powered recycling process for fluoride-containing wastewater generated by the photovoltaic industry. The membrane-method high-powered recycling process is characterized by comprising the following steps of: firstly, pre-treating the collected fluoride-containing wastewater; then, introducing the pretreated fluoride-containing wastewater to a membrane separation treatment system, and carrying out further purification treatment on the fluoride-containing wastewater to obtain produced water and concentrated water; next, carrying out up-to-standard discharging treatment on the obtained concentrated water, and then, discharging the concentrated water; and finally, drying sludge, and then, outwards transporting the sludge, wherein the sludge is generated in the system purification treatment process. After the membrane-method high-powered recycling process for fluoride-containing wastewater generated by the photovoltaic industry, provided by the invention, is adopted, the produced water is recycled, so that a great deal of fresh water is saved, the high-powered recycling of the fluoride-containing wastewater is realized, the discharged pollutants and the emission are reduced, the resource is saved, and higher economic, social and environmental benefits are created for enterprises.

Owner:SHANGHAI JINGYU ENVIRONMENT ENG

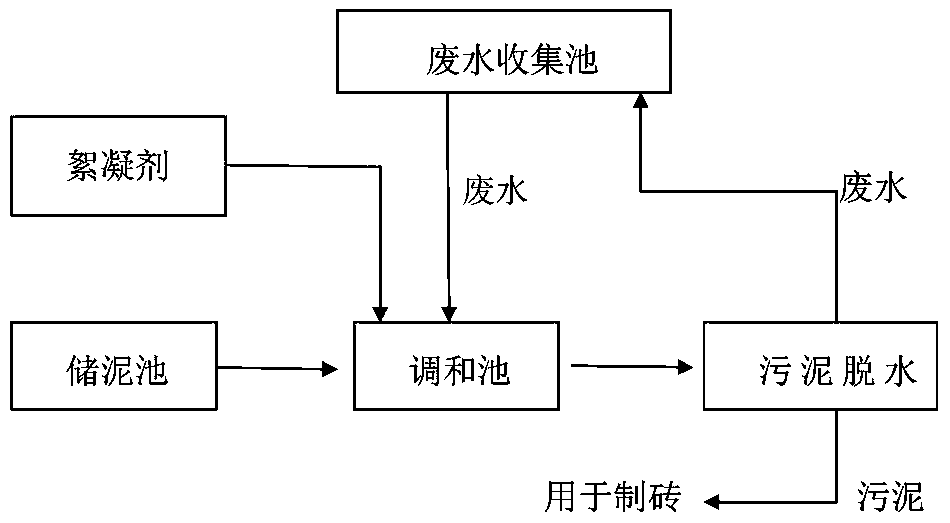

Method for cyclically applying sludge wastewater to sludge dehydration

The invention discloses a method for cyclically applying sludge wastewater to sludge dehydration. The method comprises the following steps: 1) collecting wastewater: precipitating wastewater generatedafter sludge enters a filter press and is dehydrated, then centrally collecting the precipitated wastewater; (2) diluting and pulping: putting sludge with the water content of 80% into a conditioningtank, adding the wastewater collected in the step (1) into the conditioning tank, diluting the sludge until the water content is 93+ / -1%, adding a uniformly stirred liquid flocculating agent, fully mixing, standing for 10 min, starting to settle the sludge, separating mud and water, and sinking into the bottom of the conditioning tank; and 3) sludge dehydrating: conveying the sludge slurry prepared in the step 2) into the filter press through a high pressure and low pressure variable frequency screw pump to obtain a sludge cake with the water content of 50-55% and wastewater, feeding the wastewater into the step 1), centrally collecting and recycling, and using the sludge cake for brick making. The high-molecular cationic polyacrylamide flocculant is adopted, the dehydration efficiency ishigh, the wastewater obtained by sludge removal is used for dilution slurrying of the sludge, and the tap water consumption and the sewage treatment cost are saved.

Owner:湖北玉鑫新型墙材有限公司

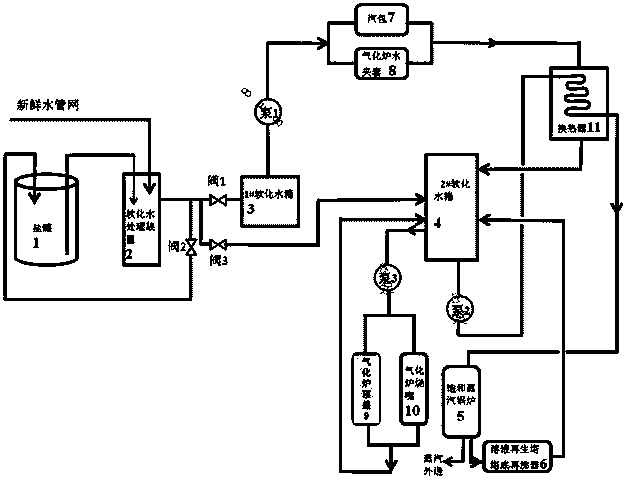

Softened water treatment system and method

InactiveCN103979640ASave fresh waterReduce water consumptionChemical industryWater/sewage treatment by ion-exchangeSoftened waterEngineering

The invention relates to the field of treatment of industrial water and provides a softened water treatment system. The system comprises a salt tank, a softened water treatment device, a plurality of softening water tanks, a heat exchanger, a steam boiler, an external to-be-cooled device and an internal l to-be-cooled device, wherein the softened water treatment device is connected with the salt tank through a first valve, the softened water treatment device is respectively connected with the softening water tanks through a plurality of second valves, one or more softening water tanks feed the softened water into the to-be-cooled devices through one or more pumps, and the softened water heated by the to-be-cooled devices enters into one or more softening water tanks or the softened water after heat exchanger enters into one or more softening water tanks. One or more softening water tanks feed the softened water to the heat exchanger through one or more pumps and feed the softened water after heat exchange by the heat exchanger to the steam boiler, steam output by the steam boiler is fed to the to-be-cooled devices and the softened water cooled by the to-be-cooled devices enters into one or more softening water tanks.

Owner:SHENWU TECH GRP CO LTD

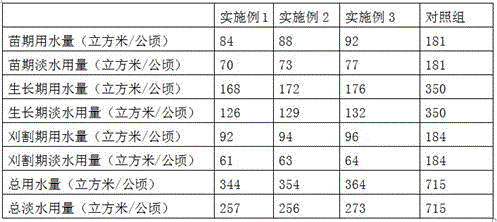

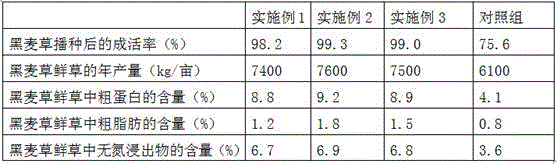

Evaporation reducing water-saving method using iron-containing fertilizer and application thereof in planting saline-alkali soil oleander

InactiveCN106105675AIncrease moisture contentSatisfy moistureAlkali orthophosphate fertiliserClimate change adaptationNerium oleanderAlkali soil

The invention relates to an evaporation reducing water-saving method using iron-containing fertilizer. The method comprises: laying a sprinkling irrigation system and performing sprinkling irrigation. Sprinkling irrigation includes sprinkling irrigation in a seedling stage, sprinkling irrigation in a growing period, and sprinkling irrigation in a cutting stage. The sprinkling irrigation in a growing period uses a mixed sprinkling irrigation method of using iron-containing fertilizer salt water and fresh water. The iron-containing fertilizer contains components in the following parts by weight: 21-23 parts of monoammonium phosphate, 15-17 parts of monopotassium phosphate, 10-13 parts of ammonium bicarbonate, 8-10 parts of ammonium phosphate, 5-7 parts of ammonium chloride, 3-5 parts of Fe-chelate, 2-4 parts of grape vinegar, 1-3 parts of fulvic acid potassium, 0.2-0.4 parts of silybum marianum extract, 0.1-0.3 parts of simazine, 0.1-0.3 parts of paclobutrazol, 0.1-0.3 parts of chlorothalonil, 0.1-0.3 parts of fenaminosulf, 1-3 parts of 5-nitroguaiacol sodium salt, 1-3 parts of urethane, and 50-52 parts of water.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

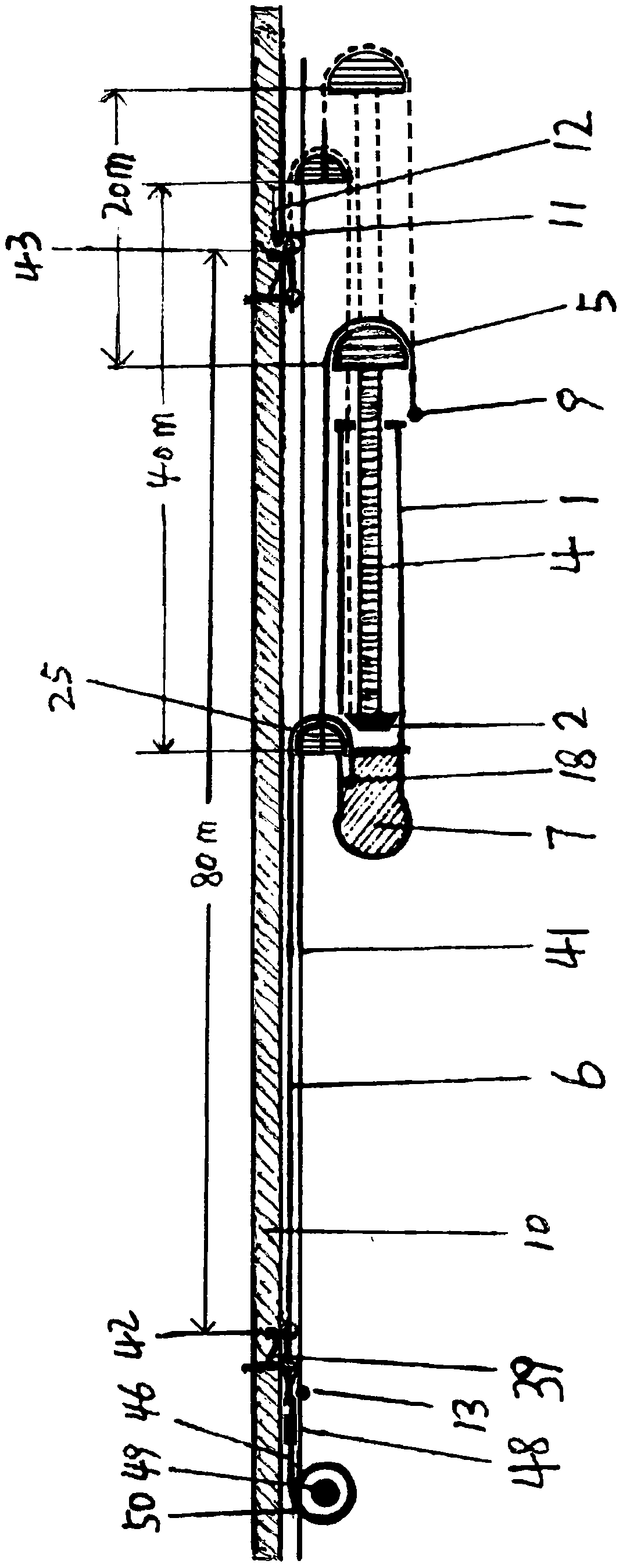

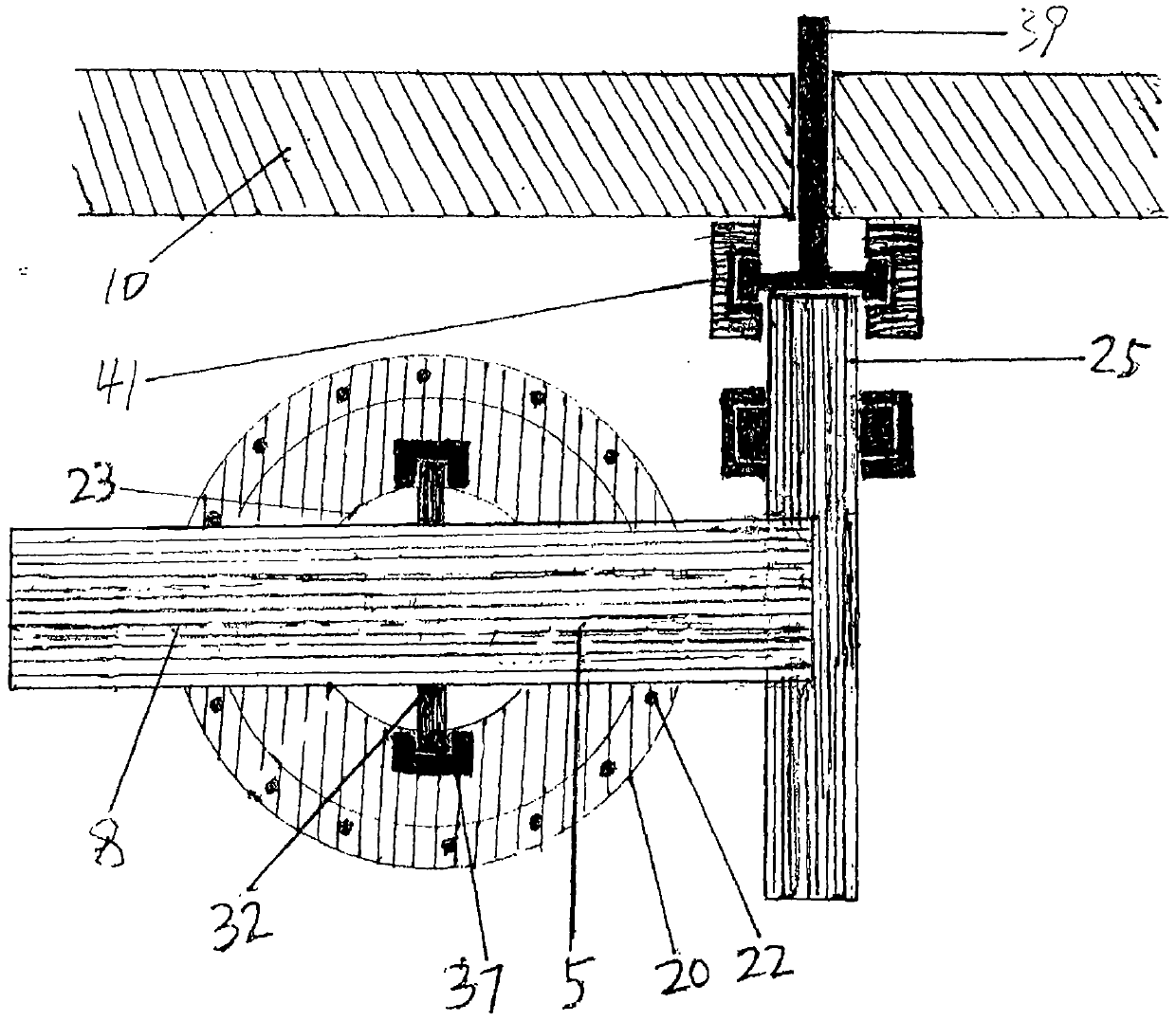

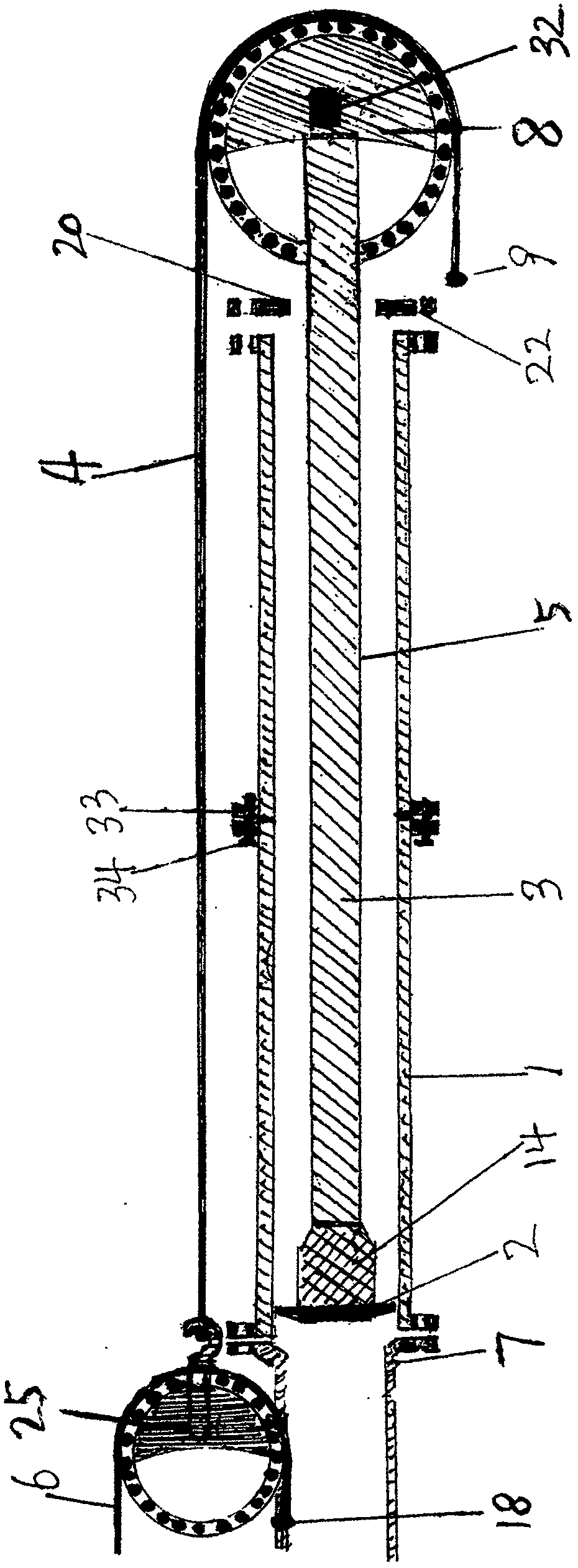

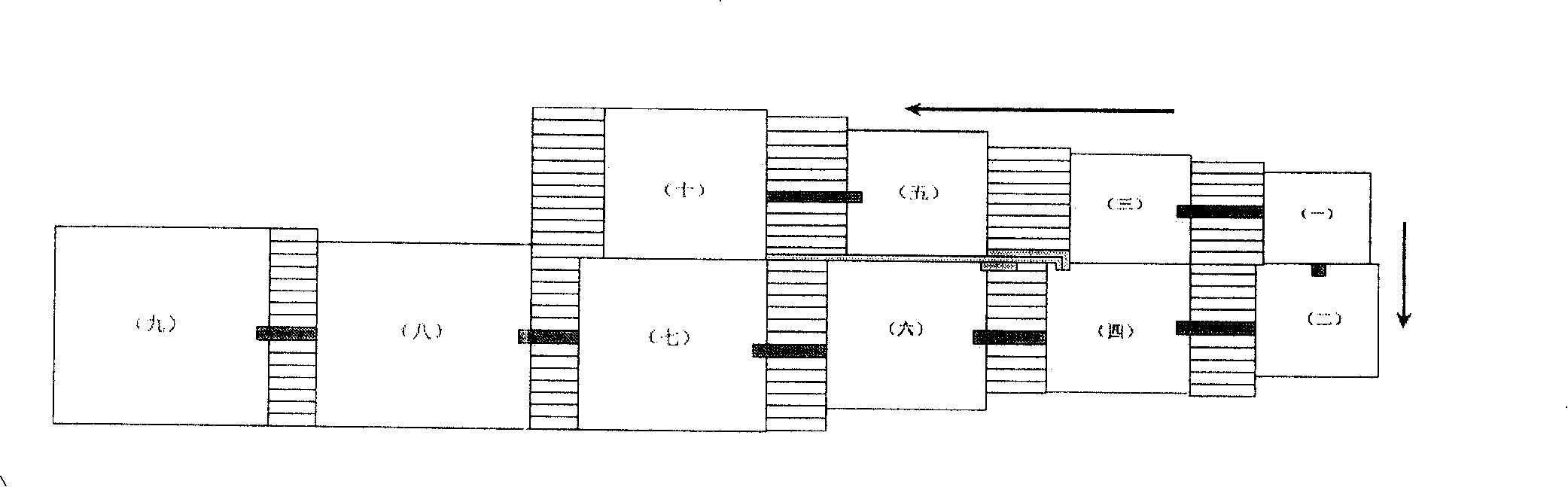

Shipboard aircraft oil wedge two-stage type catapult

InactiveCN110435912ASmall buffer brakeReduce energy consumptionLaunching/towing gearCatapultHigh pressure

A shipboard aircraft oil wedge two-stage type catapult pushes a piston (2) in a cylinder barrel (1) by using high pressure gas; the piston (2) pushes a first-stage slide block assembly (5) so that a first-stage steel strip (4) on the first-stage slide block assembly (5) pulls a second-stage oil wedge slide block (25); and a second-stage steel strip (6) on the second-stage oil wedge slide block (25) is also enabled to pull a catapulting slide shuttle (39) to catapult a shipboard aircraft in an accelerated manner. During accelerating, the speed of a moving part is 1 / 4 of the speed of the catapulted shipboard aircraft, the accelerating energy consumption of the material of the moving part per kg is only 1 / 16 of that of the catapulted shipboard aircraft per kg, and the steel strip in the accelerating stage has no mass accelerating energy consumption. After catapulting is finished, an energy storage winch (53) is driven by aircraft carrier power to pull the catapulting slide shuttle (39) back to a catapulting starting point (42); and at the moment, the high pressure gas is also compressed back into a high pressure gas storage cylinder (7) by using the piston (2) so that the high pressure gas is used in circulation to catapult the shipboard aircraft. Compared with the work-efficiency of a steam catapult using high pressure and high-thermal non-expanding gas to catapult for one time,the work-efficiency of the shipboard aircraft oil wedge two-stage type catapult is improved by multiple times. The shipboard aircraft oil wedge two-stage type catapult has the advantages of simple structure and safe permanent use.

Owner:侯小红

Bactericide used for preventing and treating gray mold and its preparation method and use method

InactiveCN1589626ADoes not increase humidityImprove the effect of disease preventionBiocideAnimal repellantsBoiling pointDiluent

A bactericide in the form of smoking agent for preventing and treating the gray mold of vegetables is perpared from the carbendazim, diethofencarb, surfactant, diluent with high boiling point and antifreezing agent through proportionally mixing. It is applied by use of aerosol generator to spray it.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

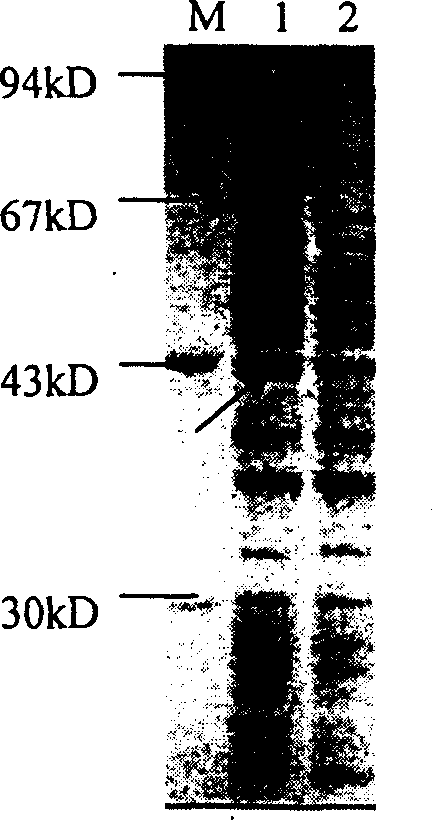

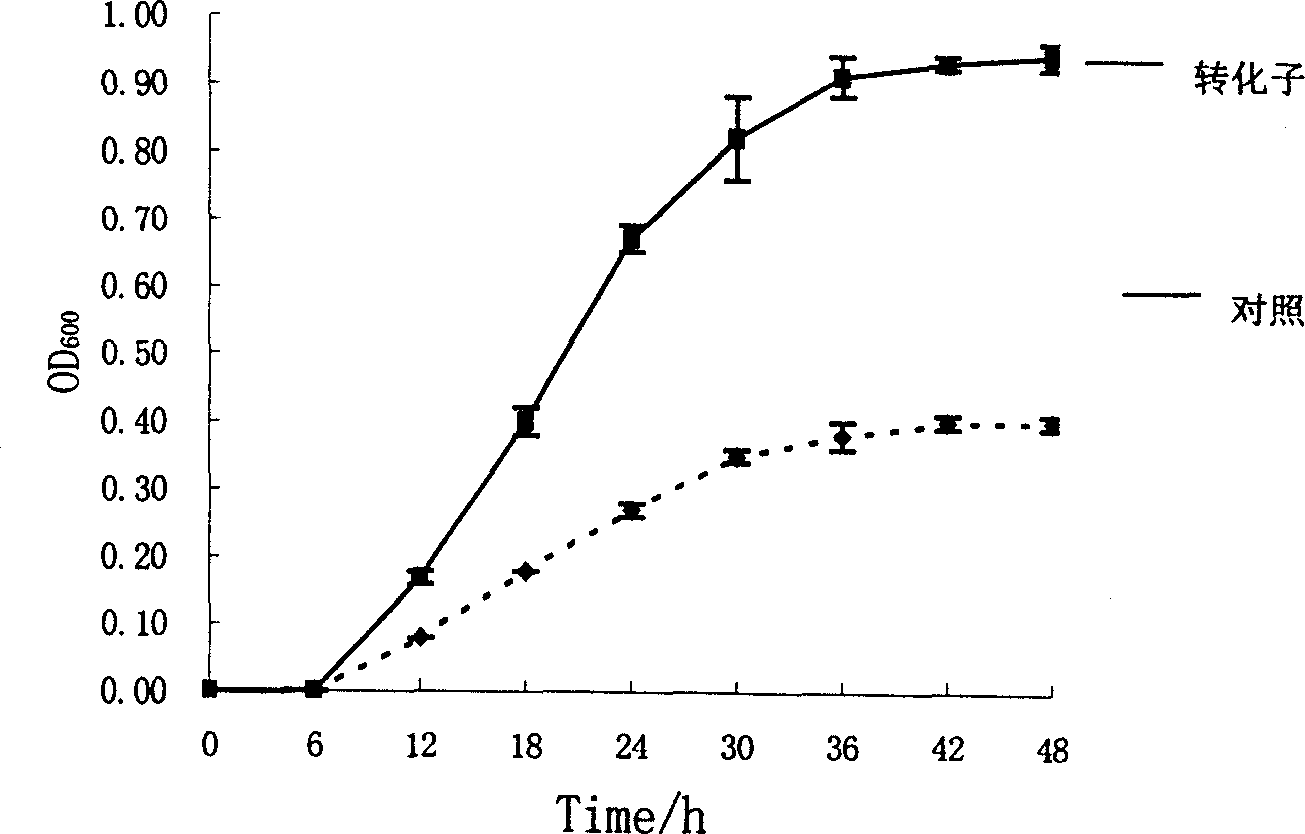

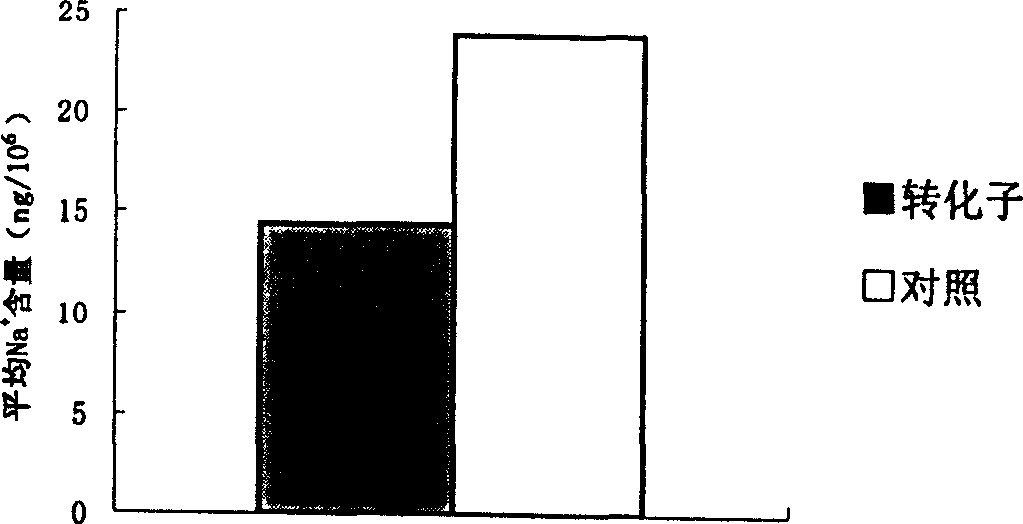

Pseudomonas Na+/H+ antiporter protein gene and its cloning process

InactiveCN1667122AImprove salt toleranceHighlight the function of pumping out of the cellMicrobiological testing/measurementFermentationAntiporterPseudomonas

This invention is fake unicell bacteria Na+ / H+ antiport albumen gene and its clone method, it relates to one kind of gene clone. One kind of fake unicell bacteria Na+ / H+ antiport albumen structure gene and one kind of quickly and economic clone method are provided, gene length is 1089bp, coding 362 amino acids. Procedures are that extra anti-salt fake unicell bacteria is inoculated and cultivated, whole DNA is extracted, primer is designed, PCR reaction and amplified product is gel imaged system sweep record, then the amplified about 1.1kb tripe is cut down. One gland piao lin deoxyribonucleotide (A) is added to end of PCR product, above clear liquid is abandoned, and 20muL weight distilled water is added to dissolve DNA. Carrier is connected with DNA to form single colony. White colony is selected and recombination particle is extracted by caustic cracking solution. Goal gene is identificated and anti-salt level of transformant is detected, clone gene of transformant is sequenced and weight plasmid of transformant is identificated, then colone gene is estimated.

Owner:XIAMEN UNIV

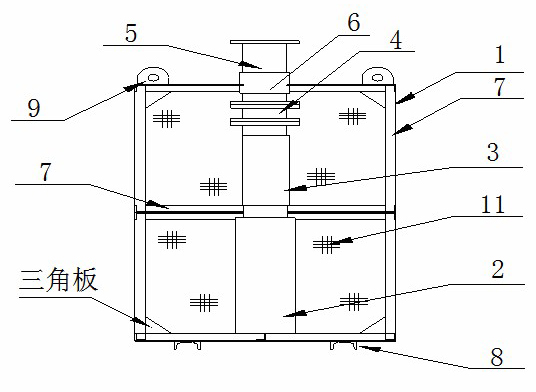

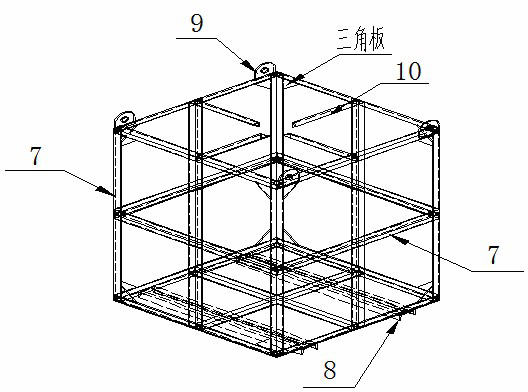

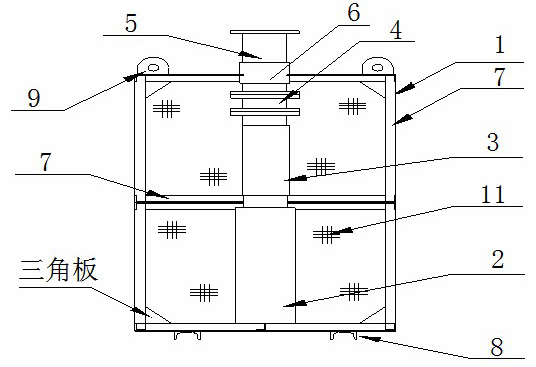

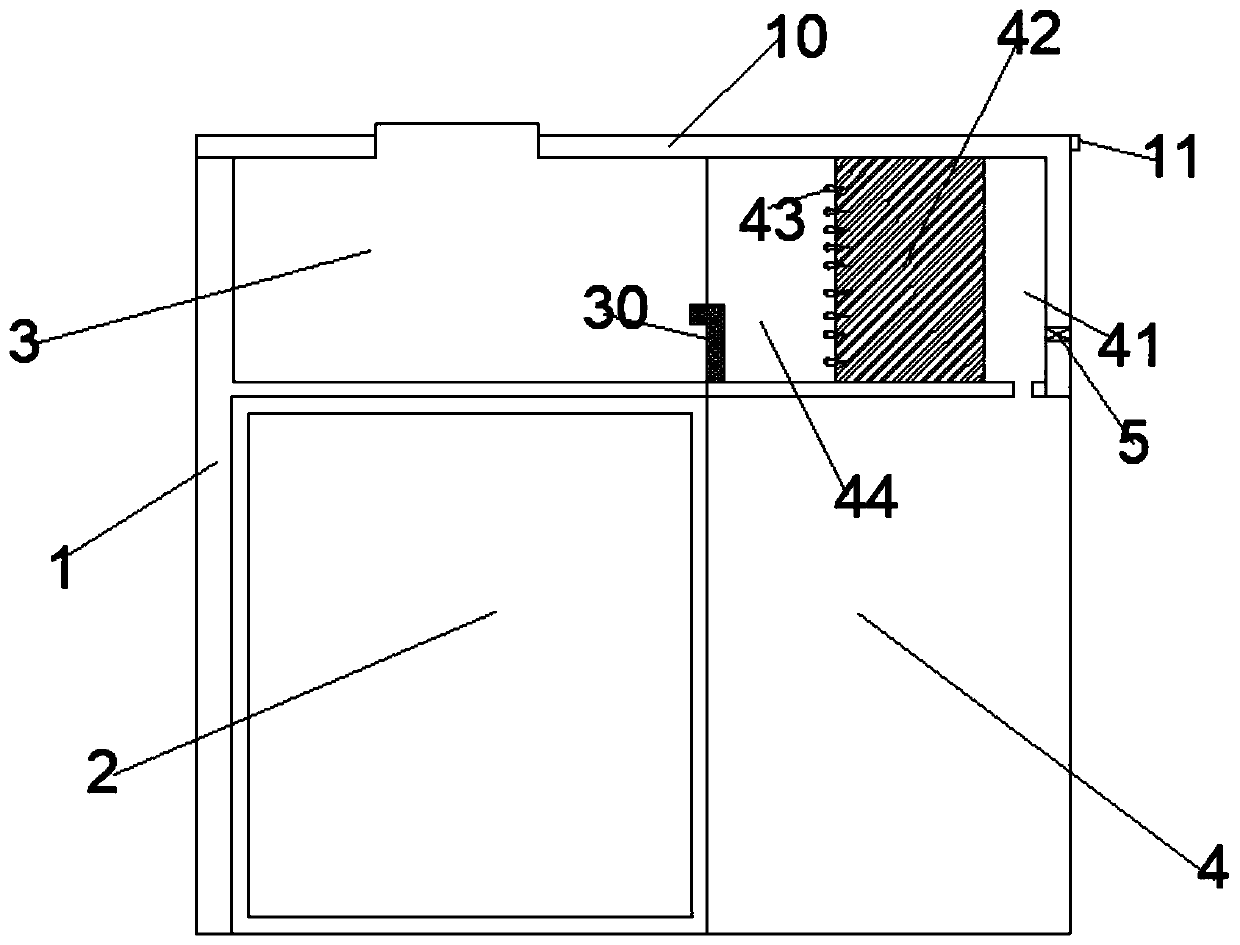

Device for providing cooling water and manufacturing method thereof

InactiveCN102381456ASolve the problem of not being able to debug in the dockShorten the debugging cycleDry-dockingSlipwaysSteel frameEngineering

The invention discloses a device for providing cooling water, which comprises a steel frame and a submersible pump arranged at the center of the steel frame. A water outlet end of the submersible pump is connected with a rubber hose. The other end of the rubber hose is connected with a water inlet end of a regulating steel pipe through a flange. A water outlet end of the regulating steel pipe is connected with a water inlet end of a connecting steel pipe through a flange. A sleeve is arranged outside the connecting steel pipe. The sleeve is fixedly connected with the steel frame. When the cooling water is required for debugging ship equipment in a dock, the device is suspended in a river and is connected with a main cooling water suction pipeline on a ship; and after the submersible pump and a cooling water pump on the ship are started, the cooling water can be provided for debugging equipment on the ship in the dock, so that the production efficiency is improved, the wharf period is shortened and fresh water in the dock is saved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Garbage can capable of growing flowers and plants

PendingCN111268326ASave fresh waterHydrophilicSelf-acting watering devicesRefuse receptaclesBotanyAgronomy

The invention discloses a garbage can capable of growing flowers and plants. The garbage can comprises a garbage can body; a water receiving disc, a garbage bin, a growing cavity, a water tank and a condensate water device are arranged on the garbage can body; the water receiving disc is located at the top of the garbage can body; the garbage bin is located on the lower left portion of the garbagecan body; the growing cavity is located on the upper left portion of the garbage can body; the water tank is located on the lower right portion of the garbage can body; the water receiving disc communicates with the upper portion of the water tank; a one-way valve is disposed on a communicating pipeline between the water receiving disc and the upper portion of the water tank; the condensate waterdevice comprises a water vapor cavity, a water capturing cavity and a condensate water cavity; the water capturing cavity is filled with sponge; and small tapered thorns are inserted into the water capturing cavity on one side of the condensate water cavity side by side. The garbage can capable of growing flowers and plants has the characteristics of being reasonable in design, good in fog dispersal effect and the like.

Owner:孟小艳

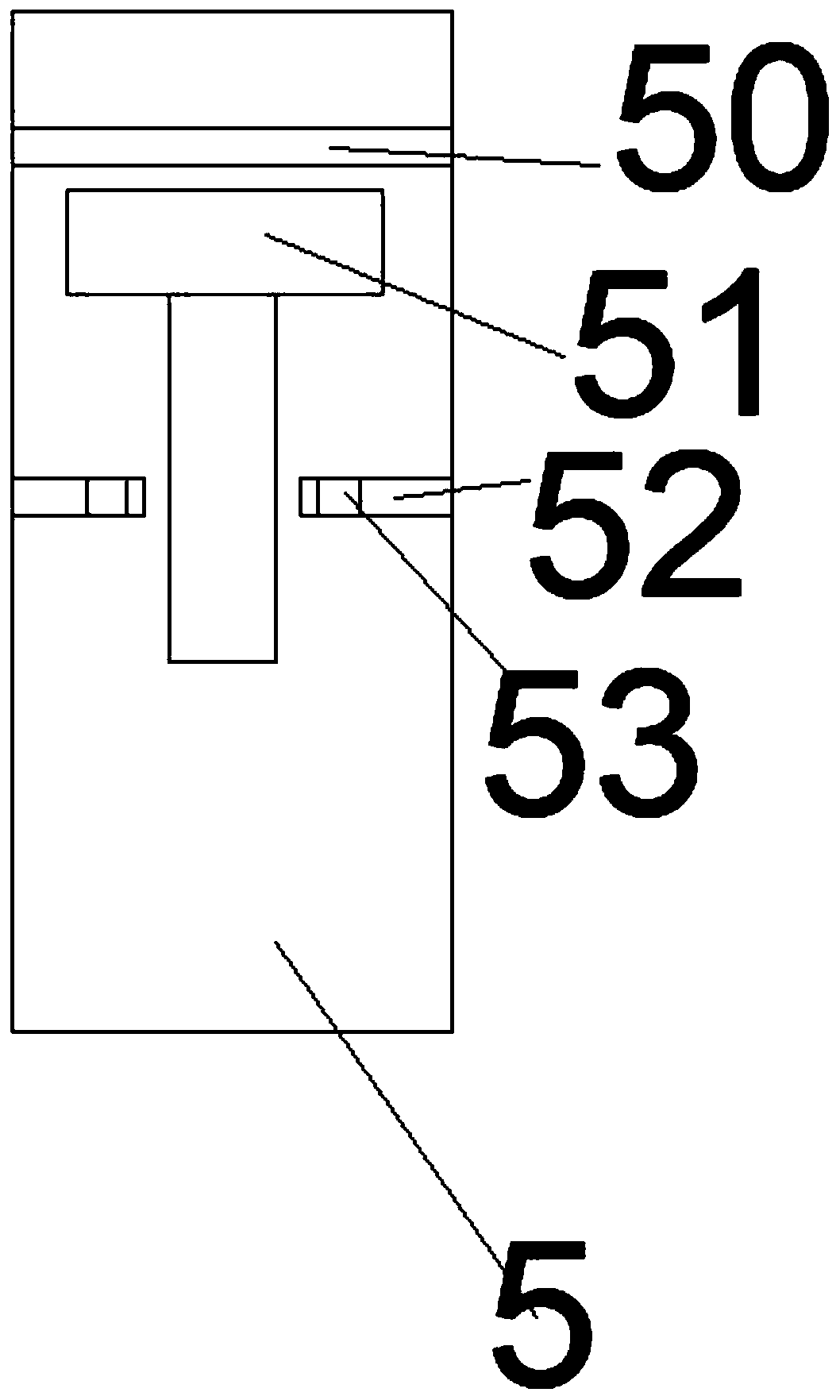

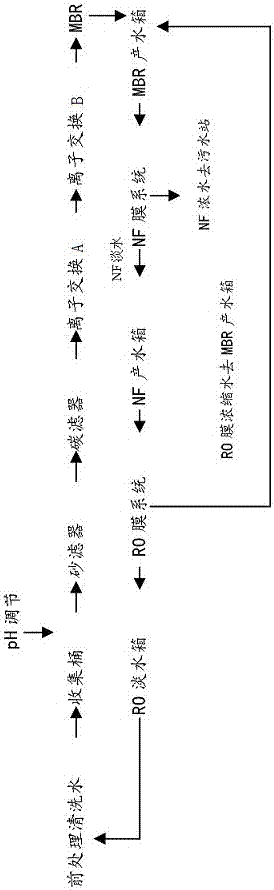

Electroplating pretreatment waste water online reuse technology

ActiveCN107162346AAchieve recyclingReduce dosageWater contaminantsWaste water treatment from metallurgical processIon exchangeFresh water

The invention discloses an electroplating pretreatment waste water online reuse technology. The technology comprises the following steps: 1, pretreatment cleaning water is collected; 2, the pH value of the obtained wastewater is adjusted to 8-9; 3, a quantitative amount of the wastewater is pumped into a sand filter through a pump, and the wastewater enters a carbon filter; 4, the wastewater is pumped into an ion exchange resin tank A, and then enters an ion exchange resin tank B; 5, metal ion removed wastewater flows into an MBR membrane system; 7, wastewater in an MBR produced water tank enters an NF membrane system through a pump; and 7, freshwater in an NF produced water tank enters an RO membrane system through a pump. The electroplating pretreatment waste water online reuse technology combines ion exchange with the MBR membrane system, the NF membrane system and the RO membrane system, so the cycle use of the wastewater is realized, the use amount of freshwater is reduced, the emission reduction purpose is reached, and the use amount of the freshwater is saved by 85%.

Owner:东莞市逸轩环保科技有限公司

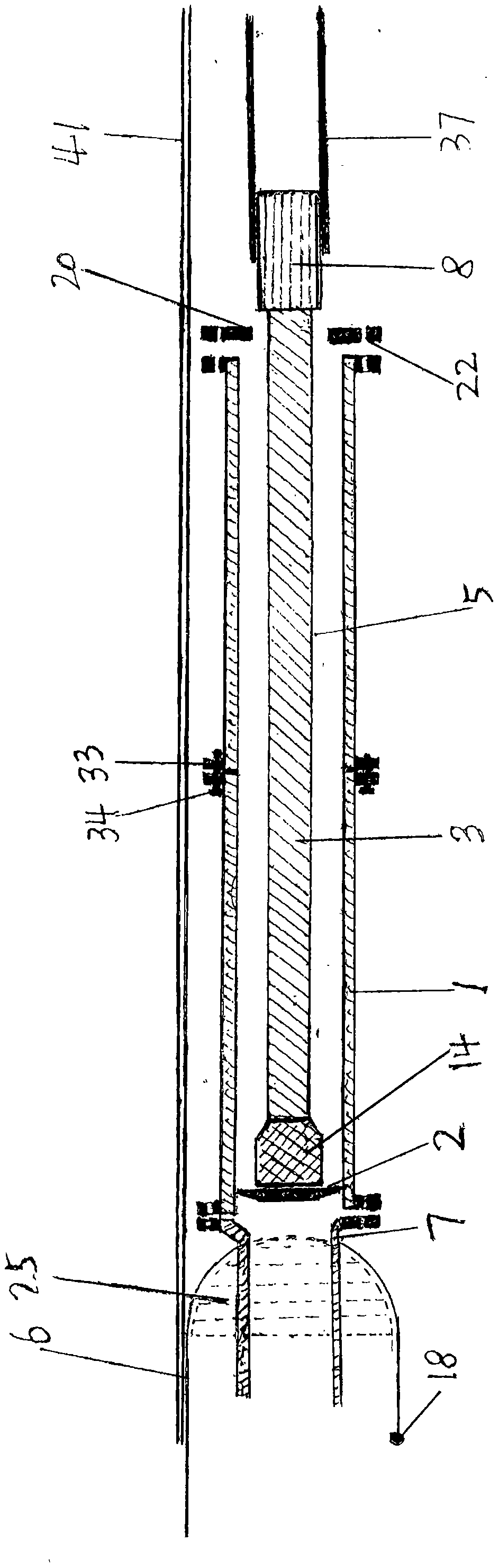

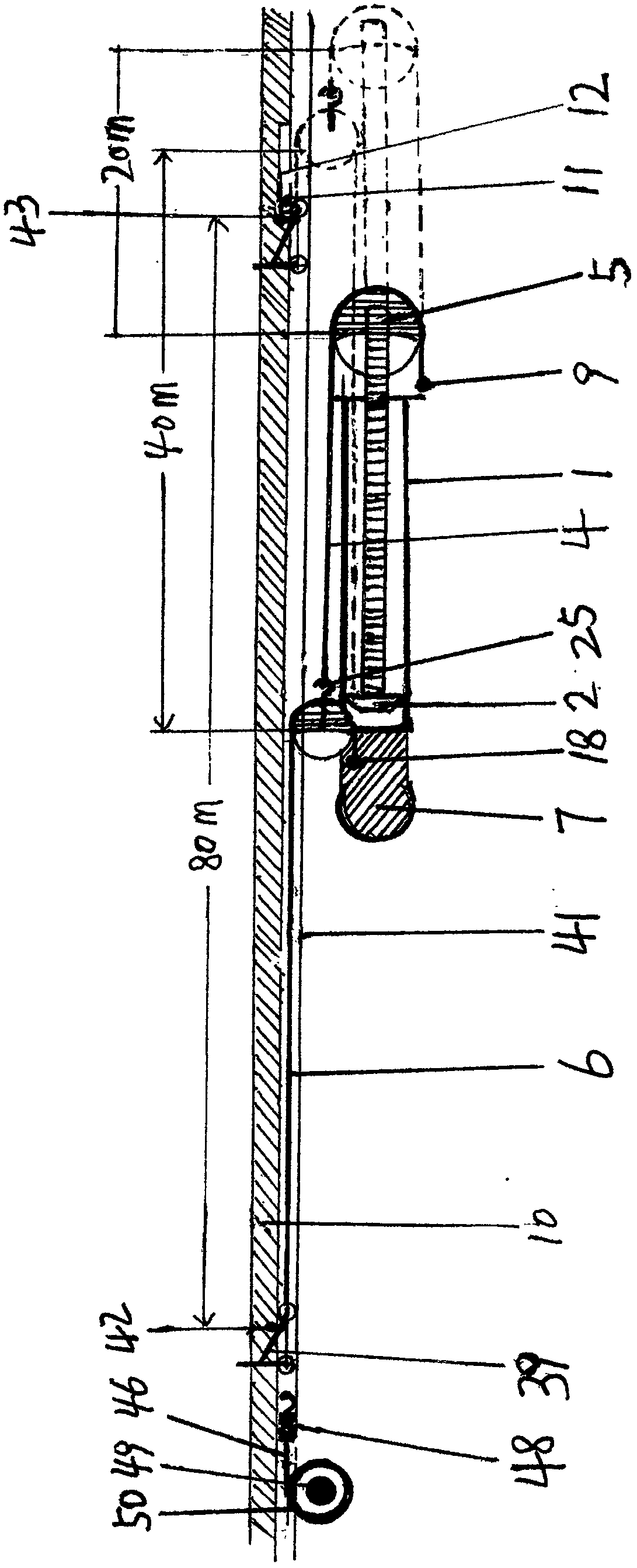

Two-stage type pulley block catapult of carrier-based aircraft

InactiveCN108569414AAvoid the hassle of leaksAcceleration energy consumption is smallLaunching/towing gearBlock and tackleCatapult

Disclosed is a two-stage type pulley block catapult of a carrier-based aircraft. According to the catapult, pistons (2) and first-stage pulleys (5) are pushed by high-pressure gas to enable first-stage ropes (4) to pull second-stage pulleys (25) and enable second-stage ropes (6) on the second-stage pulleys (25) to pull catapulting sliding shuttles (39) to achieve accelerated catapulting of the carrier-based aircraft. The speed of a self-running part of a pulley block during acceleration is 1 / 4 of that of the catapulted carrier-based aircraft, the mass acceleration energy consumption of the self-running part per kilogram is just 1 / 16 of that of the catapulted carrier-based aircraft per kilogram, and the ropes at the acceleration sections do not have mass acceleration energy consumption. After catapulting is completed, energy storage winches (53) are driven by power of an aircraft carrier to pull the catapulting sliding shuttles (39) back to catapulting starting points (42), at this time, the high-pressure gas is pressed by the pistons (2) back into high-pressure air storage cylinders (7) to complete catapulting energy storage, and the carrier-based aircraft is catapulted again. Thehigh-pressure gas is recycled, and the work doing efficiency is improved multiple times compared with that of a steam catapult for catapulting through one-time use of high-pressure high-heat non-expanding gas. The catapult is simple in structure, convenient to use and safe.

Owner:侯小红

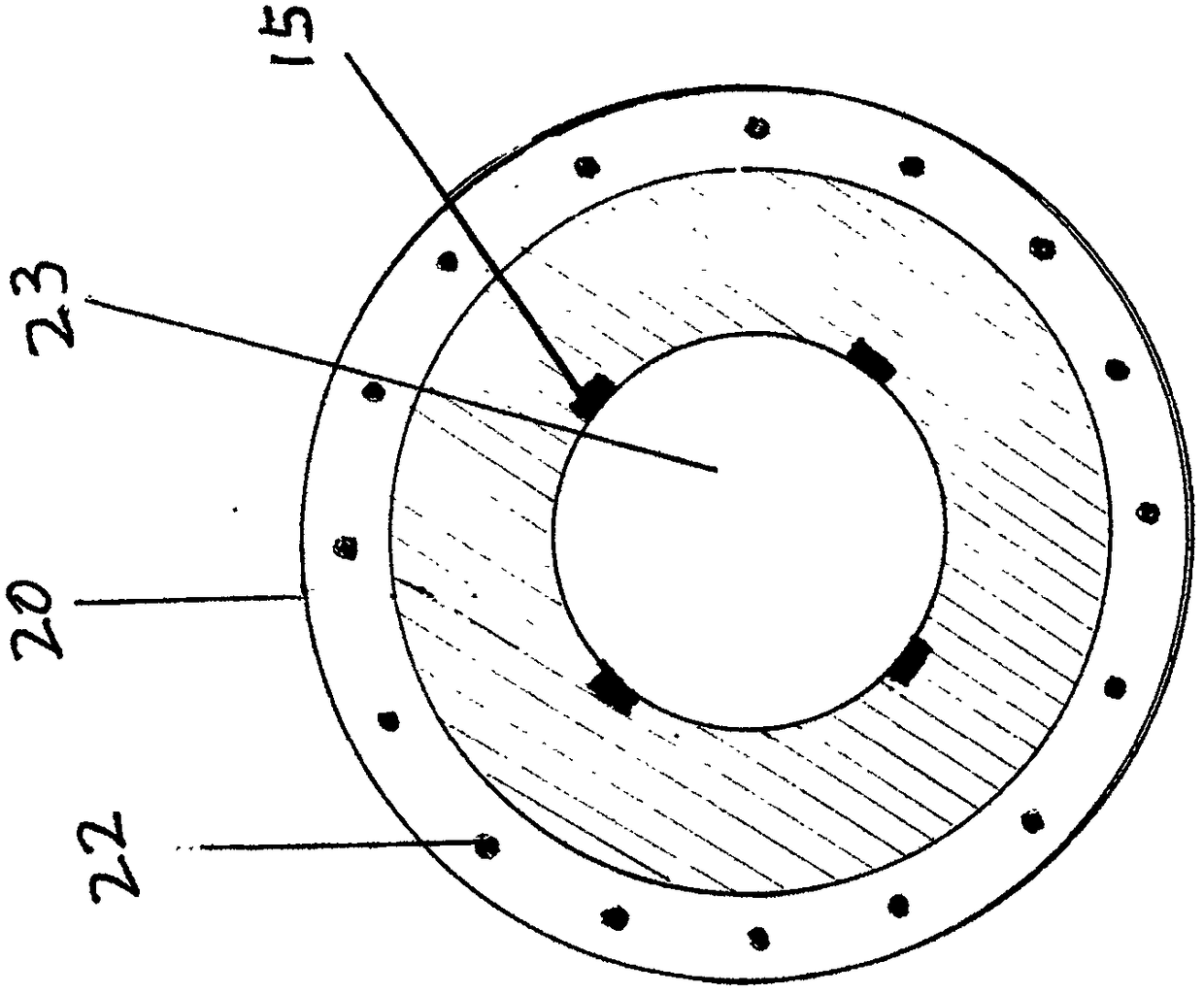

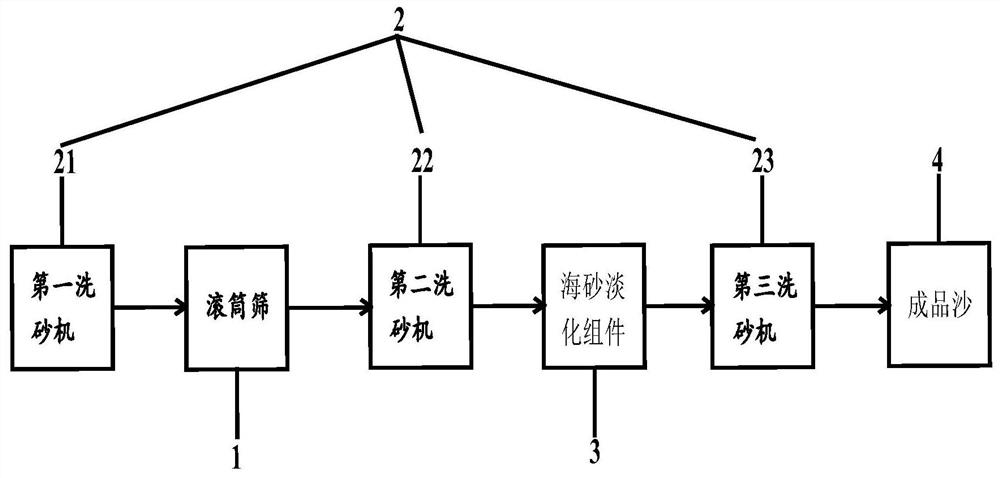

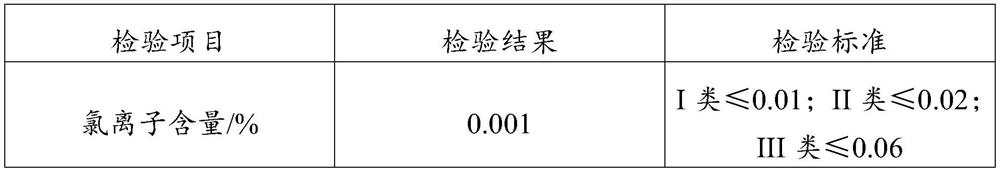

Desalted sea sand production method and device

InactiveCN112174560ATake advantage of material propertiesCause secondary pollutionElectrolysisDesalination

The invention relates to the technical field of sea sand treatment, in particular to a desalted sea sand production method and device. According to the desalted sea sand production device, a drum screen used for screening out impurities in sea sand is arranged so that subsequent removal and catalytic decomposition of chloride attached to the surface of the sea sand are more convenient; a sea sanddesalination assembly comprises an electrolysis device, a plasma generation device and a stirring device, and the electrolysis device is used for electrolyzing water in the sea sand desalination assembly to obtain oxygen; a plasma generation device is used for converting the oxygen obtained by electrolysis into active particles; a stirring device is used for stirring the sea sand to enable the active particles to strongly permeate and strongly oxidize the sea sand, and chloride on the surface of the sea sand is decomposed and stripped, so that the material characteristics of the sea sand are fully utilized, and the sea sand is subjected to chemical pollution-free and biological pollution-free treatment by adopting an environment-friendly and non-toxic desalination technology; secondary pollution to the environment is avoided, water is saved, and the efficiency is high.

Owner:黄俊雄

Composition and process of making an amino silicone based delayed antifoam for use in laundry detergent

InactiveUS20170198239A1Good effectEnhanced inhibitory effectInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsDefoamerPersonal care

A delayed antifoam composition used in laundry detergent comprising an amino silicone antifoam fluid that selectively use alkyl groups selectively being R and R2 where R is a monovalent C1- to C6-alkyl radical, and R2 is a monovalent C2- to C6-alkyl radical, when in selective combination with a water soluble filler material sufficiently and effectively depresses foam at the rinsing stage without even affecting the foam depression in the washing stage. The process of making delayed antifoam detergent composition. The composition is used in diverse applications such as personal care, hair care, textile, and release and alike.

Owner:WACKER METROARK CHEM PVT

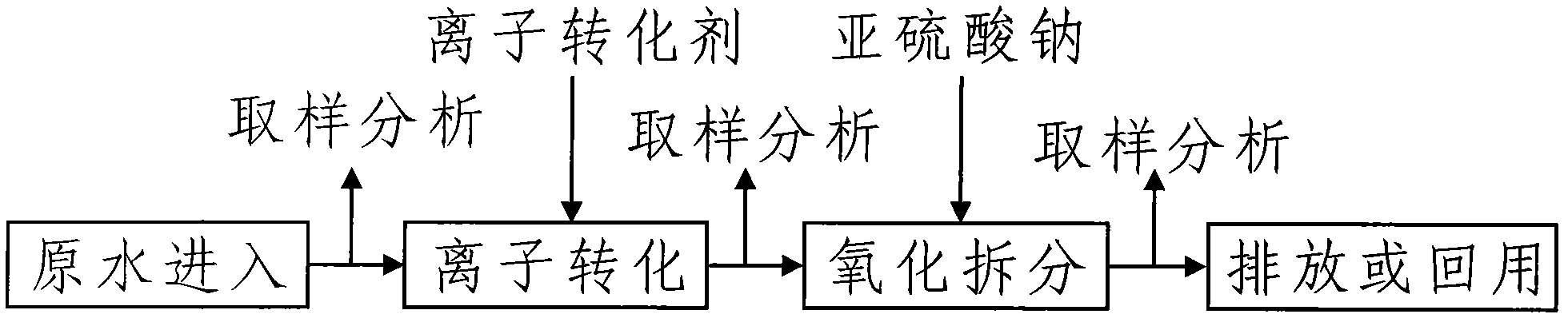

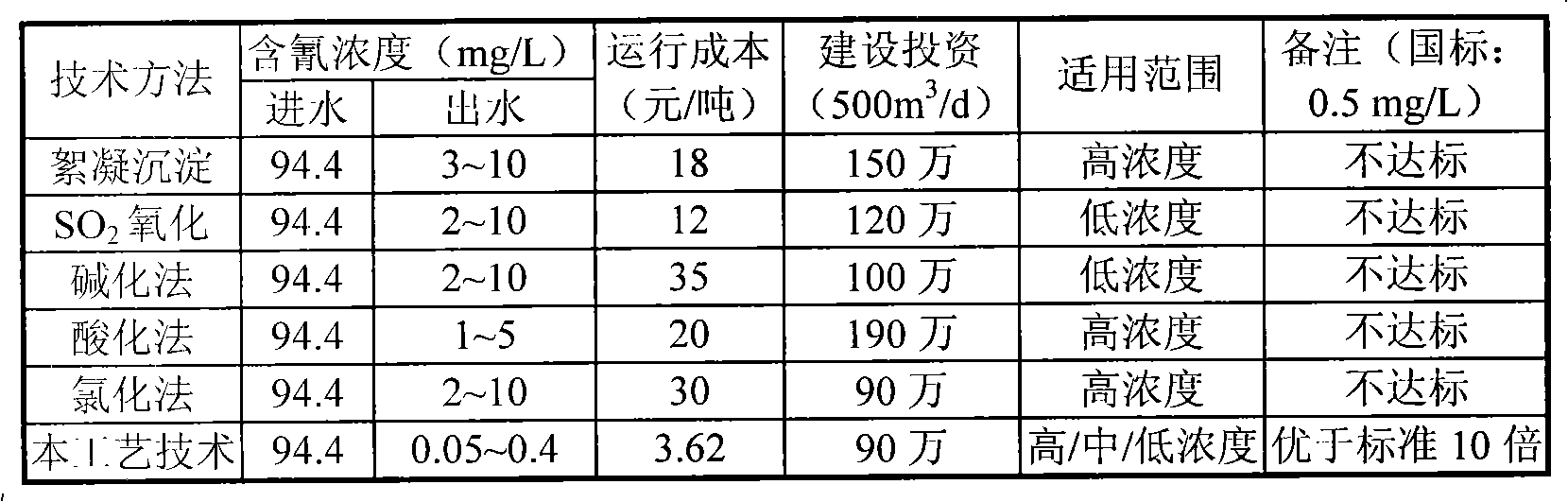

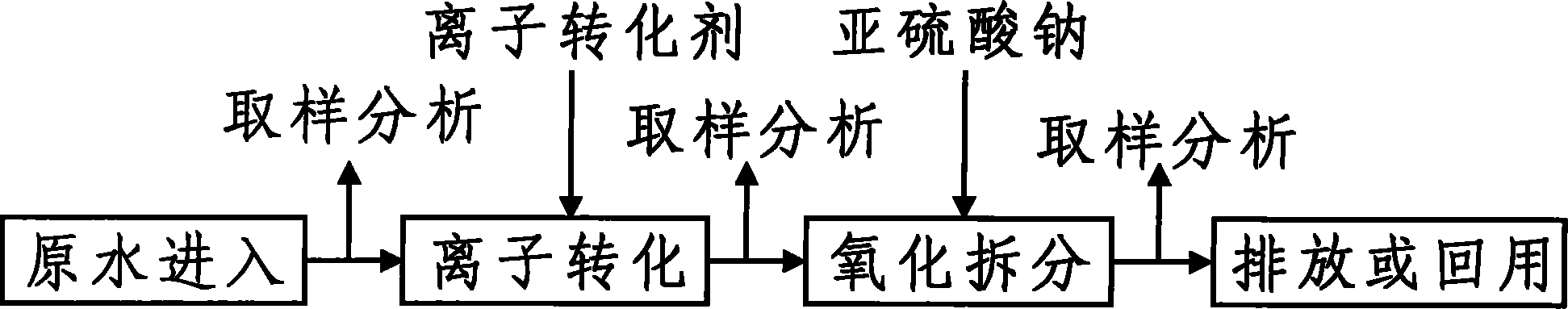

Method of removing total cyanide in sewage by using ionic transformation and oxidative disassembling

ActiveCN102464414AReduce dosageGood effectWater contaminantsMultistage water/sewage treatmentHigh concentrationCyanide

The invention discloses a method of removing total cyanide in sewage and especially relates to a method of removing total cyanide in sewage by using ionic transformation and oxidative disassembling, which belongs the field of environmental protection. According to the method, based on chemical characteristics of different cyanogen compounds, different removing technologies are used for a variety of cyanides of different forms; that is, a two-stage progressive SIF method of strong ionic transformation and targeted breaking is adopted for free cyanogen, high-concentration complicated cyano complexes, complex derivatives hard to degrade and coupled cyanogen; the method enables a breaking rate of total cyanogen in cyanogen-containing waste water produced by industries related to cyanogen to reach 99.99%, thereby allowing the cyanogen-containing waste water to stably meet or be superior to level 1 discharge standard as prescribed in Integrated Wastewater Discharge Standard (GB8978-1996). The method is applicable to treatment of cyanide pollutants in waste water produced and discharged in a plurality of industries, e.g., mining and mineral separation, metallurgy, mechanical processing, electroplating, chemical engineering and leather making, and has industrial popularization and application prospects.

Owner:河南省新悦环境科学技术研究发展有限公司

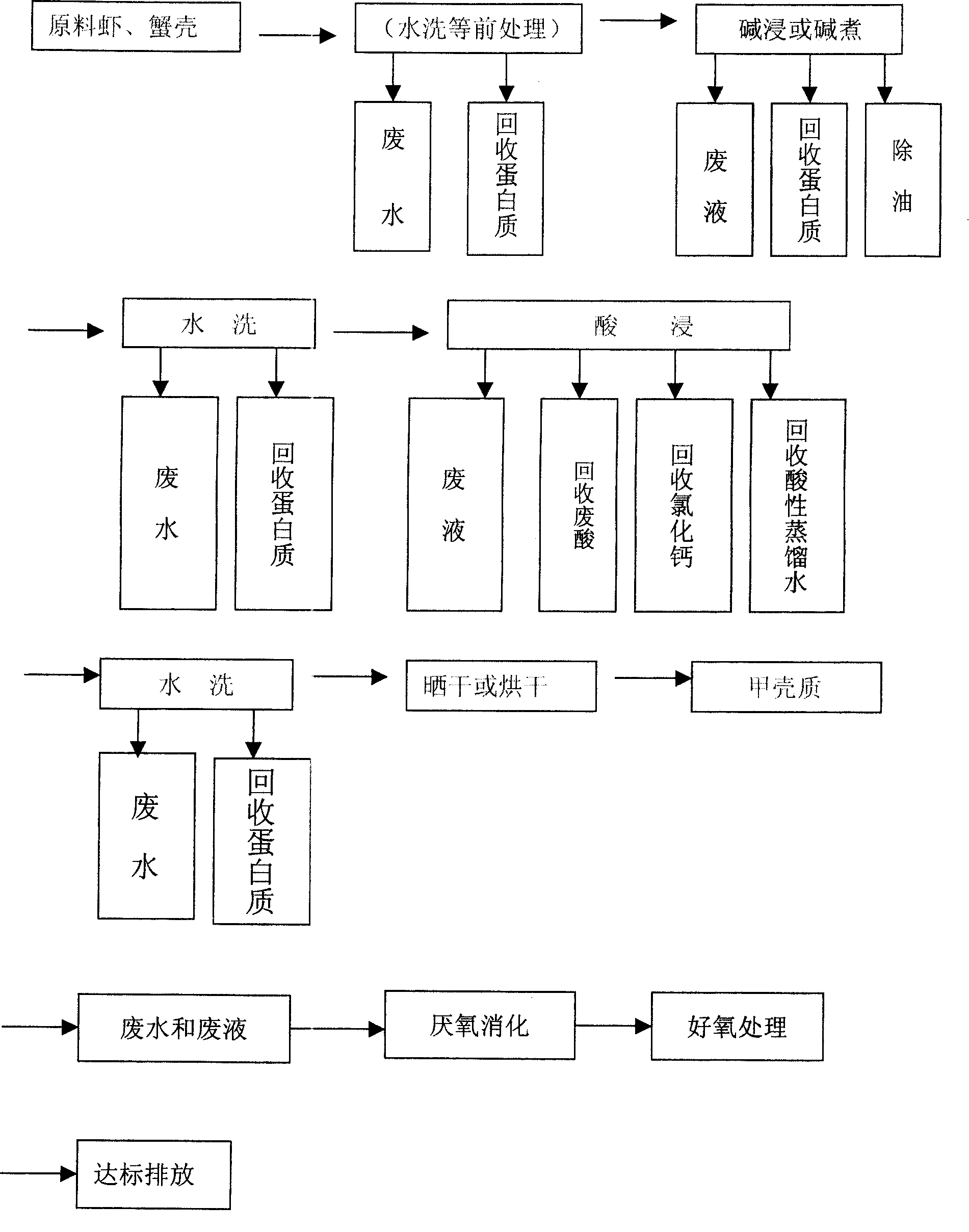

Sewage treating method for chitin production process

InactiveCN100402445CSolve problems that cannot be treated by conventional methods such as biochemical methodsEfficient use ofCalcium/strontium/barium chloridesMultistage water/sewage treatmentWater useChitin formation

The invention discloses a sewage treatment method during chitin production process, which includes the raw material pretreatment, craft steps such as acid pickling processing and alkali treatment, the characteristic is separately in disposal basin center which carries on waste water processing in each processing craft stage, the recycling waste, after carried on various crafts stage processing waste water uses again, the merit lay in the traditional terminal processing method in each craft stage distinction alone for the sewage treatment, remove the pollution like protein in the alkali treatment waste liquid during the alkali treatment craft stage , the fat, the pigment and so on, which make it cannot enter the acid pickling craft stage, and avoided the overlapping pollution.

Owner:NINGBO UNIV

A kind of sea sand desalination tank and using method thereof

ActiveCN110372242BSimple structureEffective structureSolar heating energyGeneral water supply conservationInorganic saltsDesalination

The invention provides a sea sand desalination tank and a using method thereof, belonging to the field of sea sand desalination. The sea sand desalination tank provided by the invention makes full use of solar energy, wind energy and wave energy to promote the operation of the sea sand desalination tank, and the desalination tank has a simple structure, high efficiency, environmental protection and low carbon, and is convenient for replacement and maintenance. The use method of the sea sand desalination tank provided by the present invention is simple and efficient, fully utilizes the solar energy, wind energy and wave energy on the sea surface, and rationally converts them into the stirring mechanical energy and thermal energy required for sea sand desalination. The greater the solubility of inorganic salts related to chloride ions and the more active the ions, the same amount of fresh water can dissolve more chloride ions in sea sand faster, saving fresh water for desalination sea sand, effectively improving the efficiency of sea sand desalination, and significantly reducing sea sand Downplaying the cost has considerable economic and social benefits.

Owner:SHENZHEN UNIV

Mn-Zn. cymoxanil smoking agent and its preparation method

InactiveCN1443450ASolve the problem that can not be made into aerosolImprove the effect of disease preventionBiocideAnimal repellantsActive agentSurface-active agents

The present invention relates to a smoking agent for controlling downy mildew of vegetable, specially for controlling downy mildew of greenhouse vegetable. Its composition includes mancozeb, cymoxanid, diluent, antifreezing agent and compound surfactant. Its preparation method includes the following steps: mixing mancozeb and cymoxanial together, using several surfactants, and adopting ultramicropulverizing process and making them disperse and suspended in the high boiling point diluent so as to obtain the invented product.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

A kind of recovery process of magnesium hydroxide washing water

ActiveCN103979702BTurn waste into treasureTo achieve the purpose of reducing pollution and increasing efficiencySemi-permeable membranesChemical industryReverse osmosisParticulate material

The invention relates to a magnesium hydroxide washing water recovery technology which comprises the following steps: magnesium hydroxide washing water is led into a raw material storage tank, an alkali liquid is added into the raw material storage tank to regulate the pH value to enable the magnesium hydroxide washing water to produce magnesium hydroxide colloid; the magnesium hydroxide washing water flowing out from the raw material storage tank is filtered by a super / microfiltration unit, the magnesium hydroxide colloid and fine particle matters are trapped in the super / microfiltration unit, sodium chloride-containing filtrate leaves the super / microfiltration unit to enter into a reverse osmosis unit; in the reverse osmosis unit, sodium chloride is concentrated and introduced into a sodium chloride concentration solution storage tank, and filtrate penetrating the reverse osmosis unit is industrial water. Compared with the prior art, by use of the technology, 99.9% of magnesium hydroxide and 99% of sodium chloride and 60-80% of water can be recovered, the production cost of production enterprises can be reduced, wastewater emissions and solid waste emissions can be greatly reduced, energy-saving emission reduction targets of the enterprises can be achieved.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com