Membrane-method high-powered recycling process for fluoride-containing wastewater generated by photovoltaic industry and dedicated system of membrane-method high-powered recycling process

A special system and industry-leading technology, which is applied in the field of high-power recovery special system for fluorine-containing wastewater membrane method in the photovoltaic industry, can solve problems such as inability to recycle wastewater, and achieve the effects of easy automatic control, water volume reduction, and investment cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

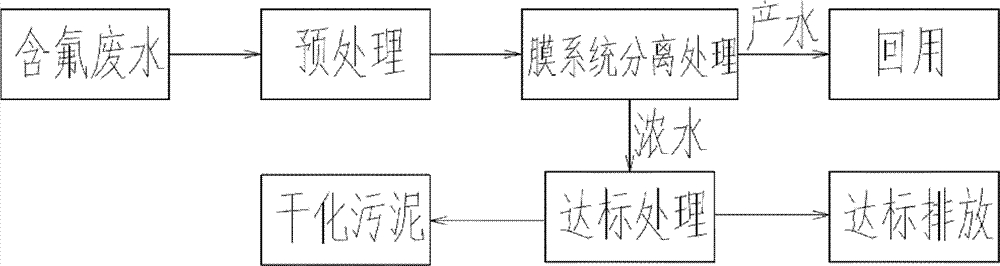

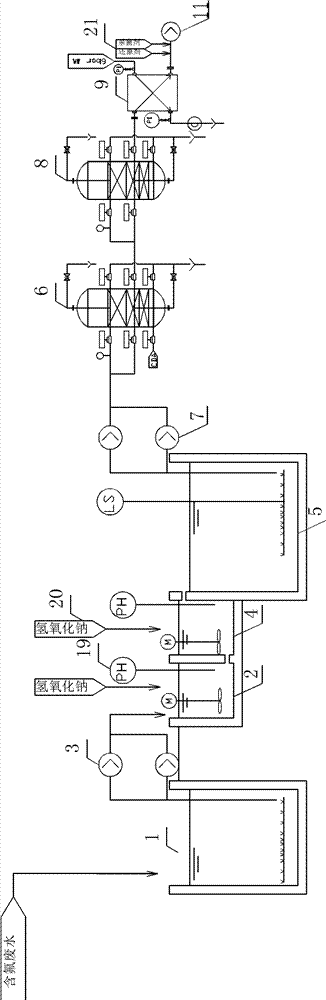

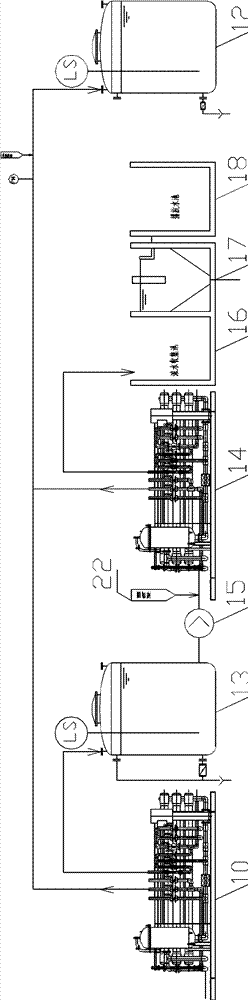

[0031] as attached figure 1 , 2 As shown in and 3, the first embodiment of the present invention is a special system for high-power recovery of fluorine-containing wastewater in the photovoltaic industry by membrane method, which includes a collection pool 1, and the water outlet of the collection pool 1 is connected to the water inlet of the first acid-base reaction pool 2 A first booster pump 3 is installed on the connecting pipeline between the collection tank 1 and the first acid-base reaction tank 2, and the water outlet of the first acid-base reaction tank 2 is connected to the water inlet of the second acid-base reaction tank 4, and the second acid-base reaction tank 4 is connected to the water inlet of the second acid-base reaction tank. The water outlet of the alkali reaction tank 4 is connected to the water inlet of the intermediate pool 5, the water outlet of the intermediate pool 5 is connected to the water inlet of the sand filter 6, and the second booster pump 7 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com