Patents

Literature

296results about How to "Easy to implement automation control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

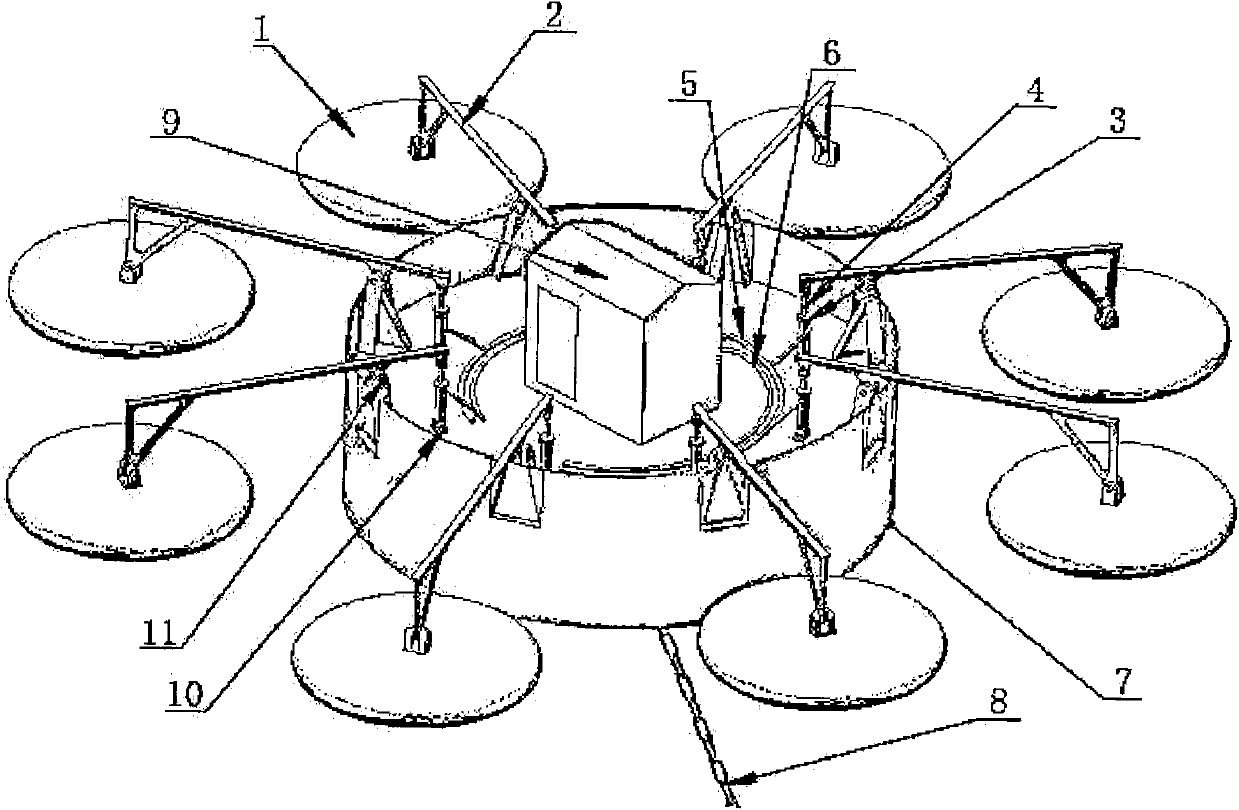

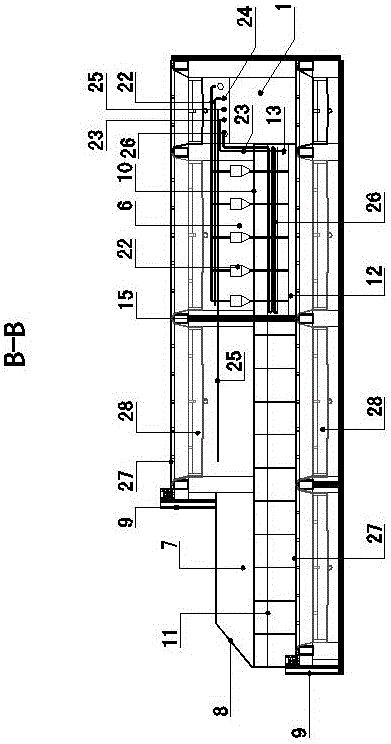

A floating type wave power generation system

InactiveCN102022248AEfficient captureControllable outputMachines/enginesEngine componentsWave power generationMechanical energy

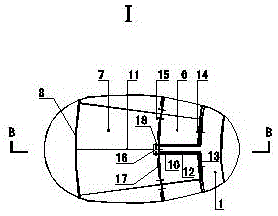

A floating type wave power generation system is characterized in that the system consists of eight sets of lever-type floating bodies and a hydraulic energy accumulation converter with the hydraulic pump function. On a floating workbench 7, eight sets of levers 2 and a floating body 1 are connected through supporting hinge bearers 10 and 11; in this way, the highly undulating displacement caused by waves can be converted to relatively lesser displacement of a piston rod 4, and the minor force that the floating body bears can be converted through the lever to the major force on the piston rod. The piston rod drives a hydraulic tank 3 to switch and transmit the hydraulic energy through a connecting oil pipe5, a high-pressure oil pipe6, a hydraulic oil tank and four no-return valves of each set to a hydraulic motor in a hydraulic power generation control chamber 9; in this way the generator is driven to work. The present system can absorb, convert and accumulate the intermittent unstable wave energy in a highly effective way and can buffer the destructive effect of waves. The floating platform can be suitable to different marine space by adjusting the length of an anchor chain 8. And in various sea conditions, kinetic energy and potential energy possessed by waves in the sea surface can be converted and accumulated as hydraulic mechanical energy by utilization of the wave drop; thus the generator is driven to unremittingly provide electric power.

Owner:杨超

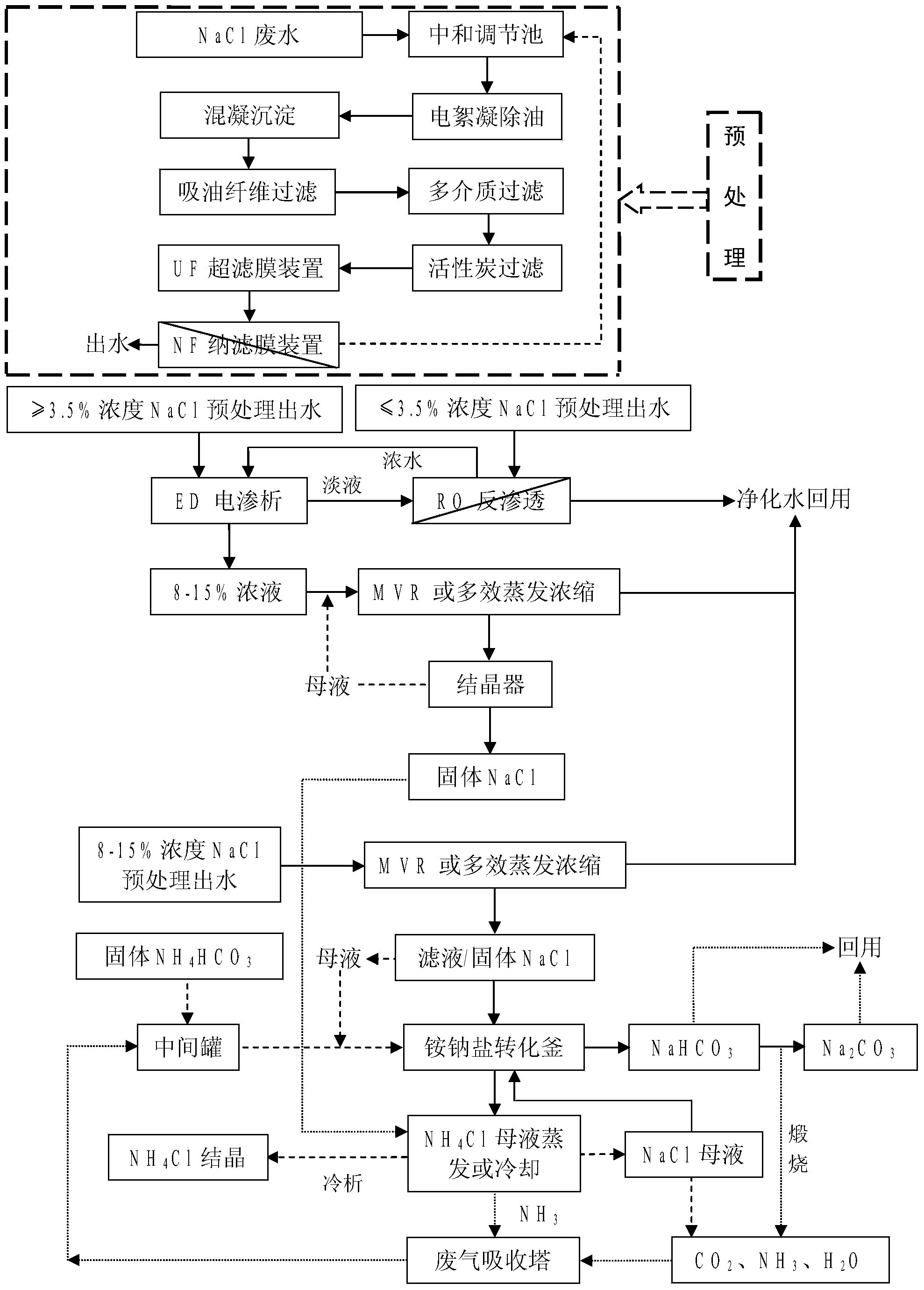

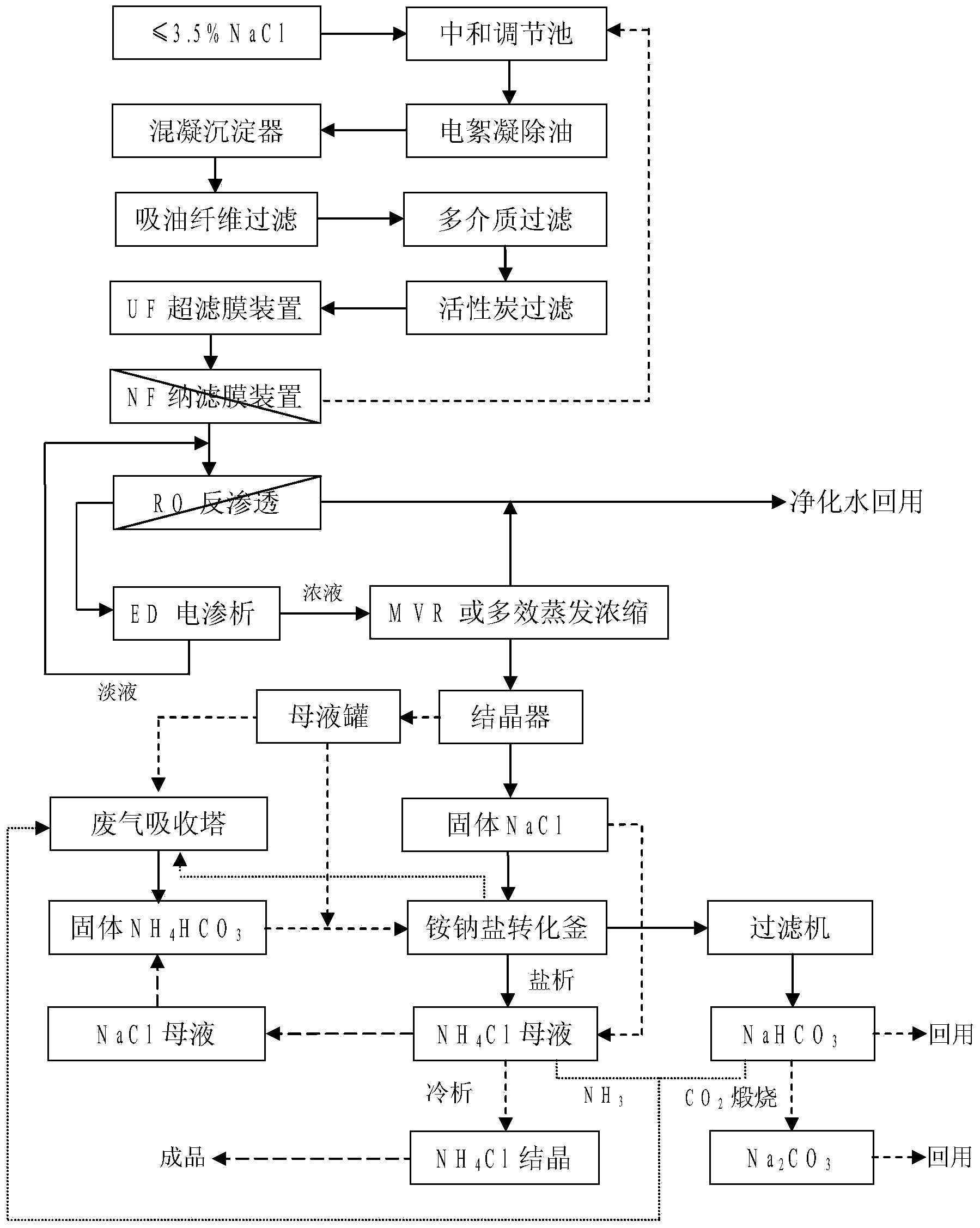

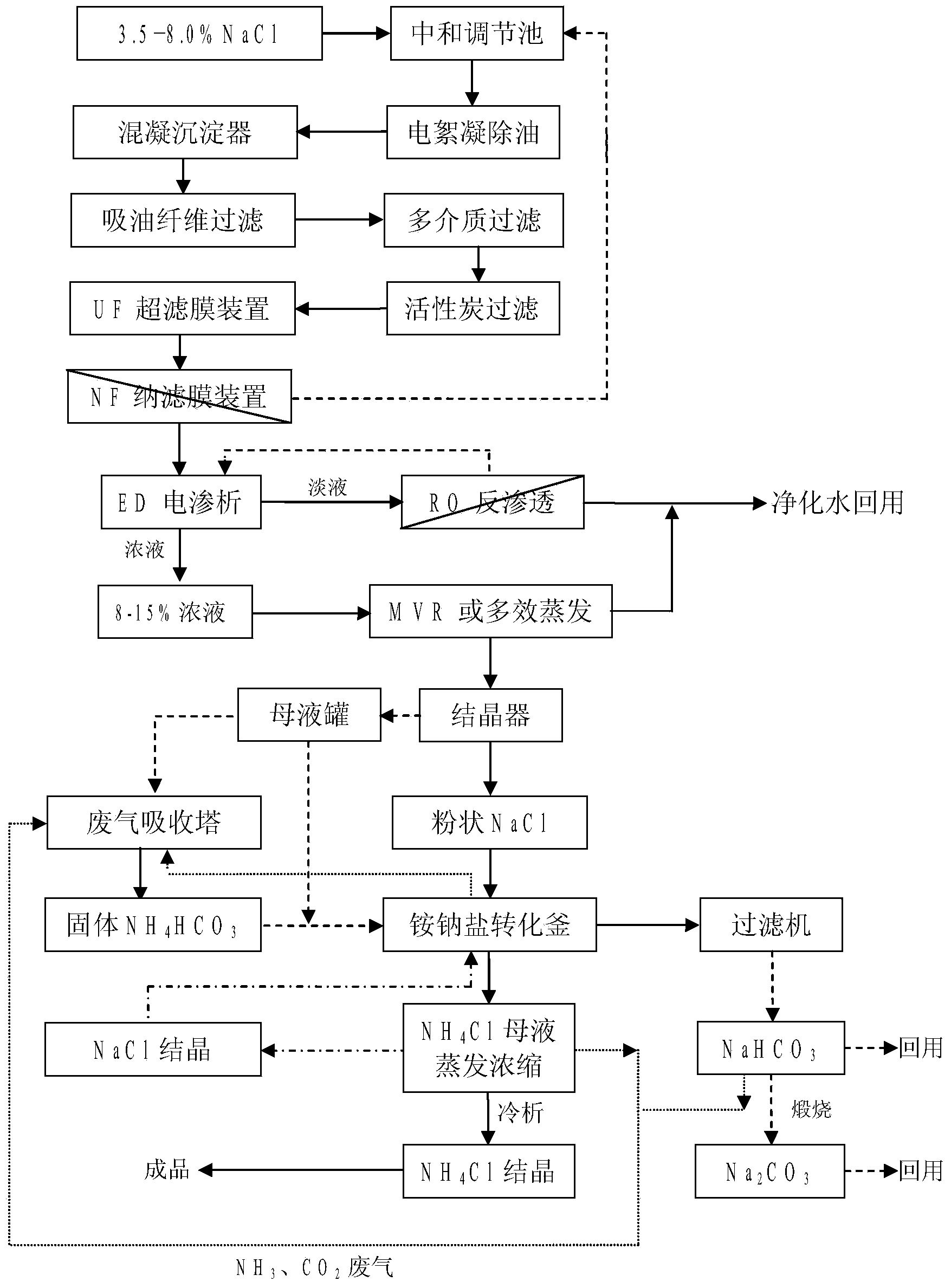

Combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth

InactiveCN103449653AImprove environmental protection measuresAvoid volatile lossGeneral water supply conservationMultistage water/sewage treatmentSodium bicarbonateUltrafiltration

The invention relates to a combined treatment method for sodium chloride-containing wastewater generated in dressing and smelting of rare earth. According to the method, a series of desalination and concentration treatments such as deoiling, neutralizing, homogenizing, aeration, flocculation, ultrafiltration, nanofiltration, reverse osmosis, electroosmosis and MVR (mitral valve replacement) concentration are carried out on the wastewater, so that recyclable purified water is obtained; ammonium bicarbonate is added into the sodium chloride extracted from the wastewater, so that the sodium salt can be converted and regenerated into sodium bicarbonate, sodium carbonate and ammonium chloride products for dressing and smelting of the rare earth. According to the method, the recovery rate of the wastewater is high, the effluent quality is stable, the conversion rate of the sodium salt is high, and no three wastes are discharged; production equipment is compact, simple to operate, and easy to realize automation control; the problem that the sodium chloride-containing wastewater and other similar industrial wastewater generated in dressing and smelting of rare earth are difficult to recycle is solved.

Owner:YANSHAN UNIV

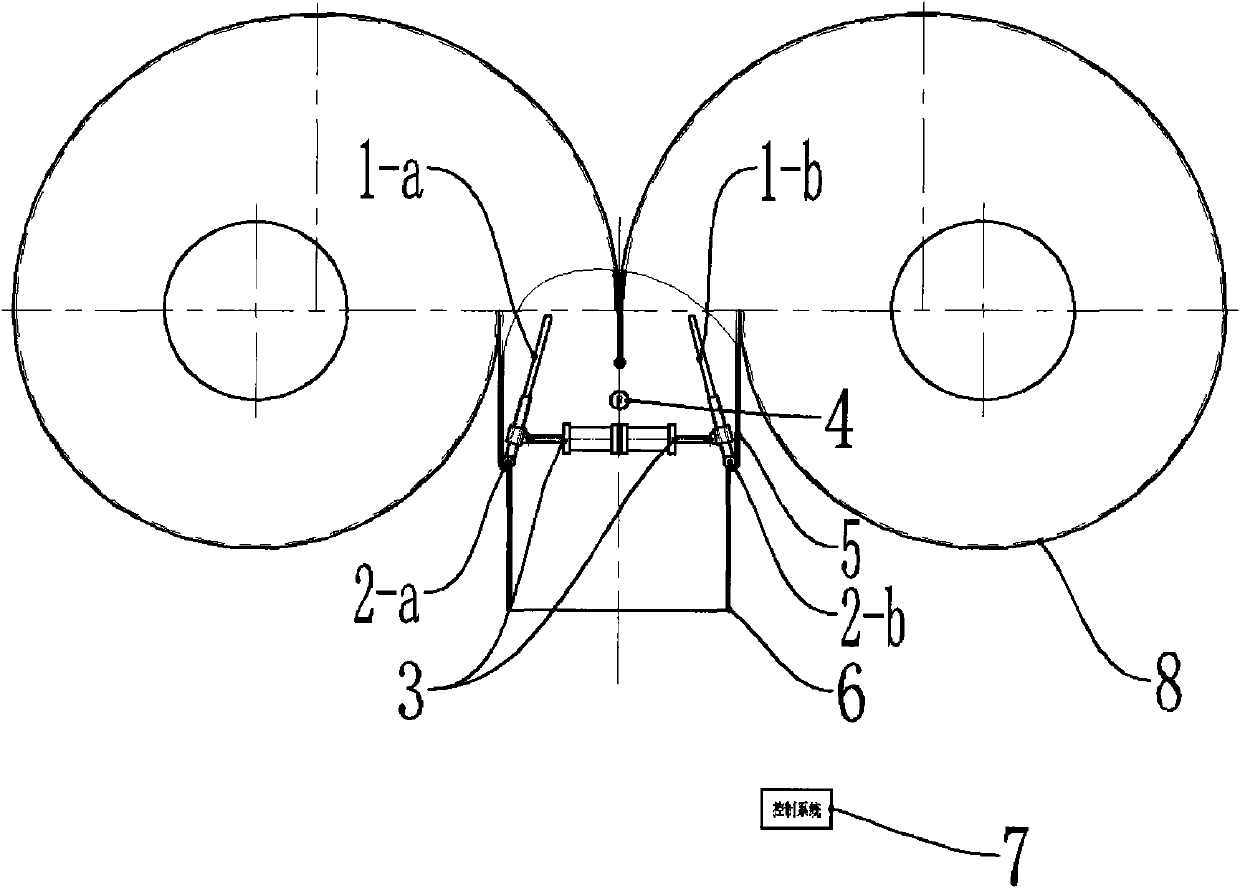

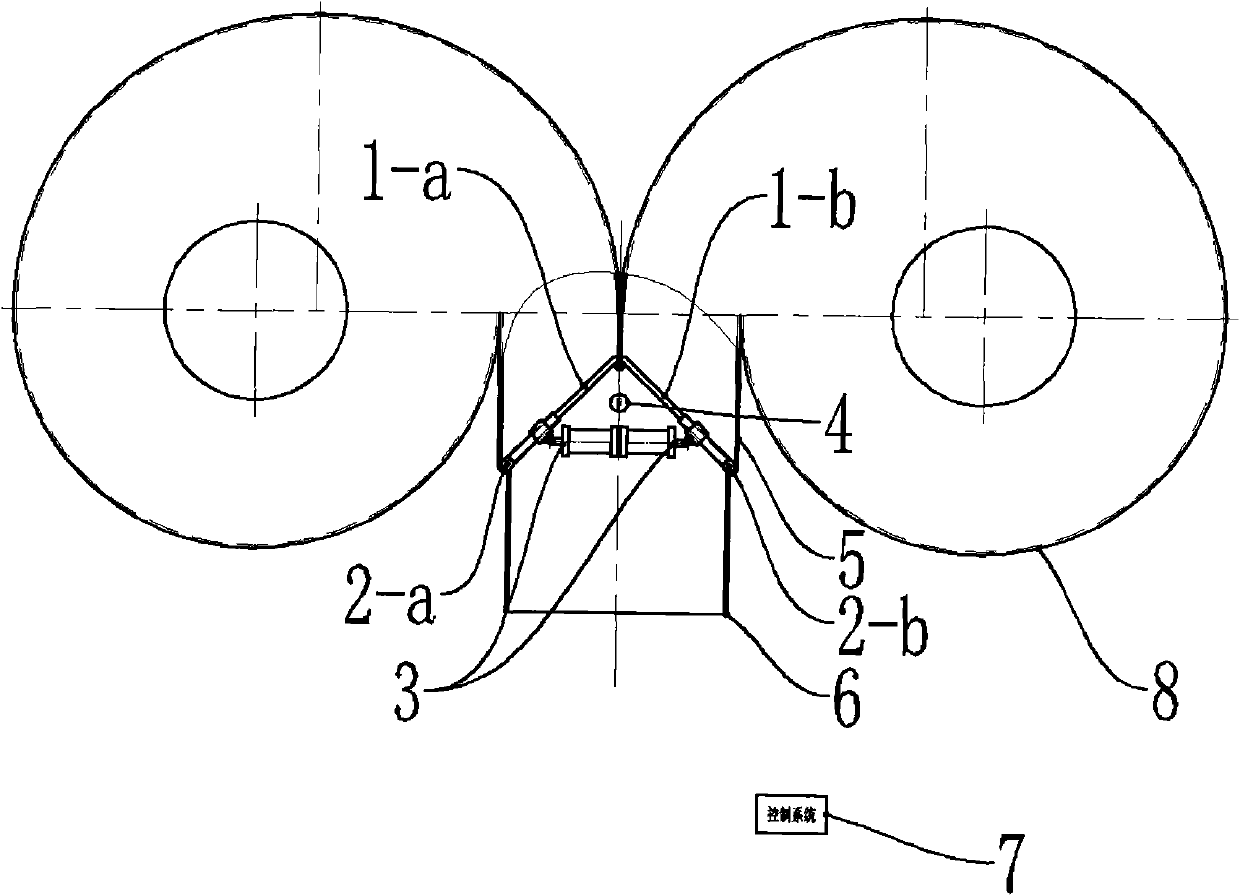

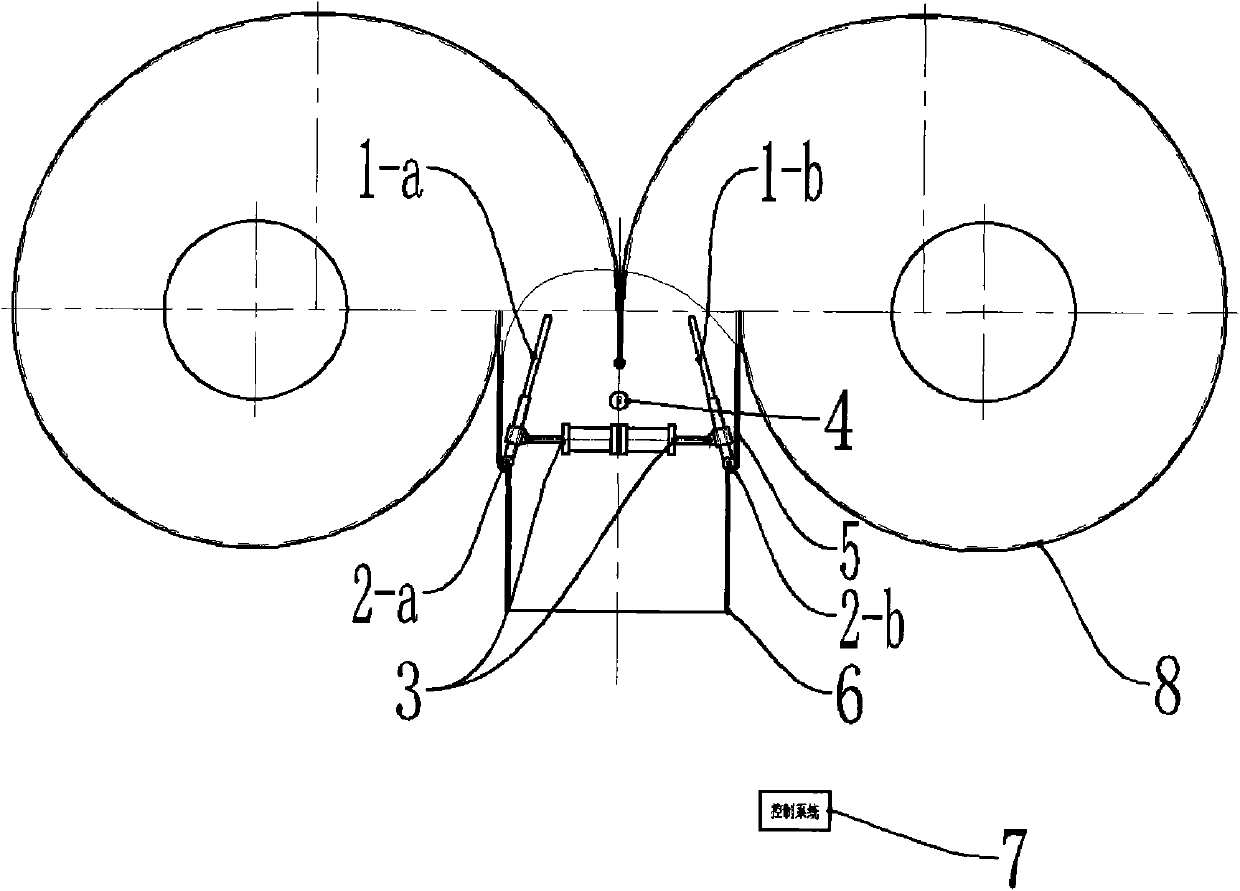

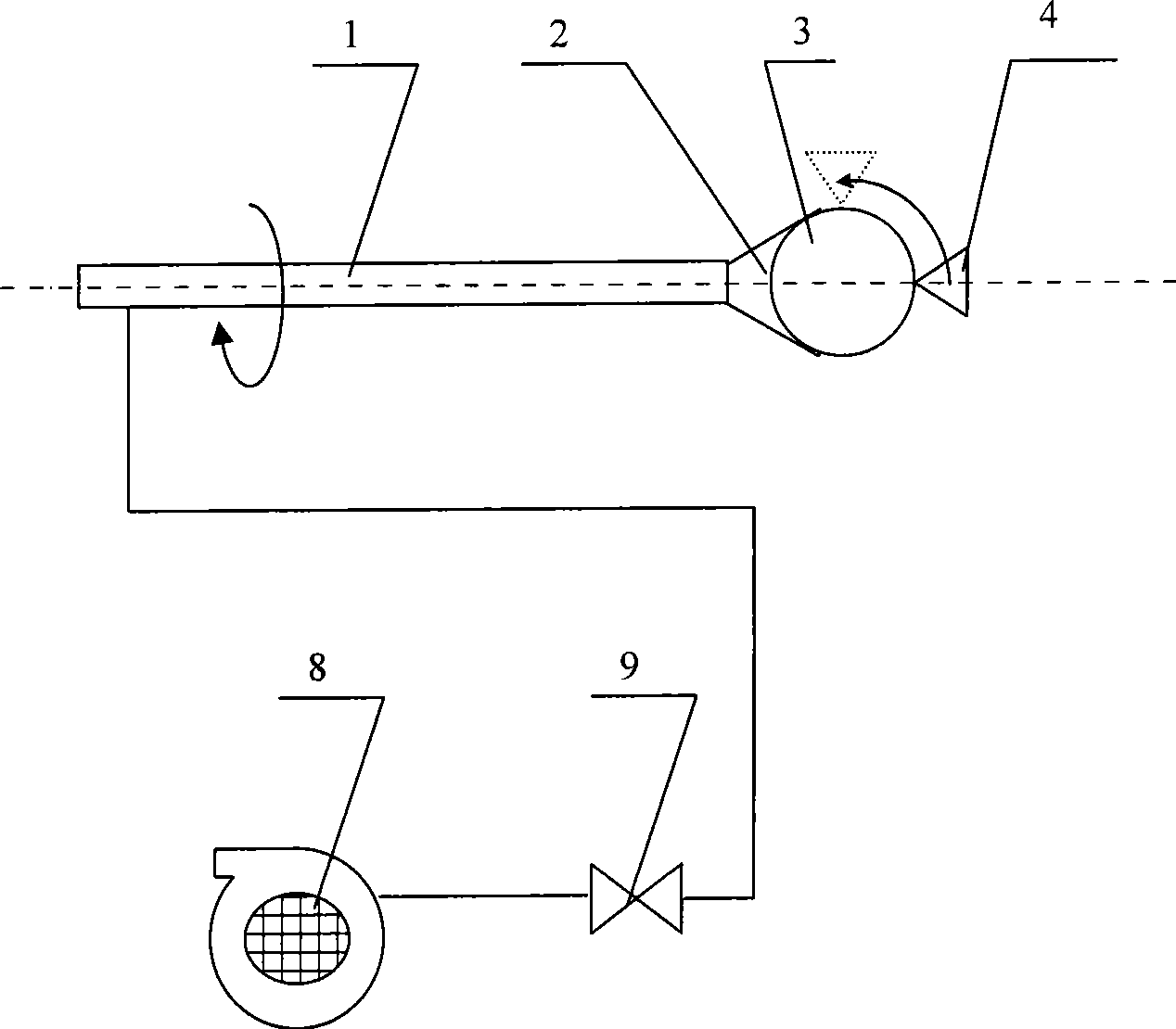

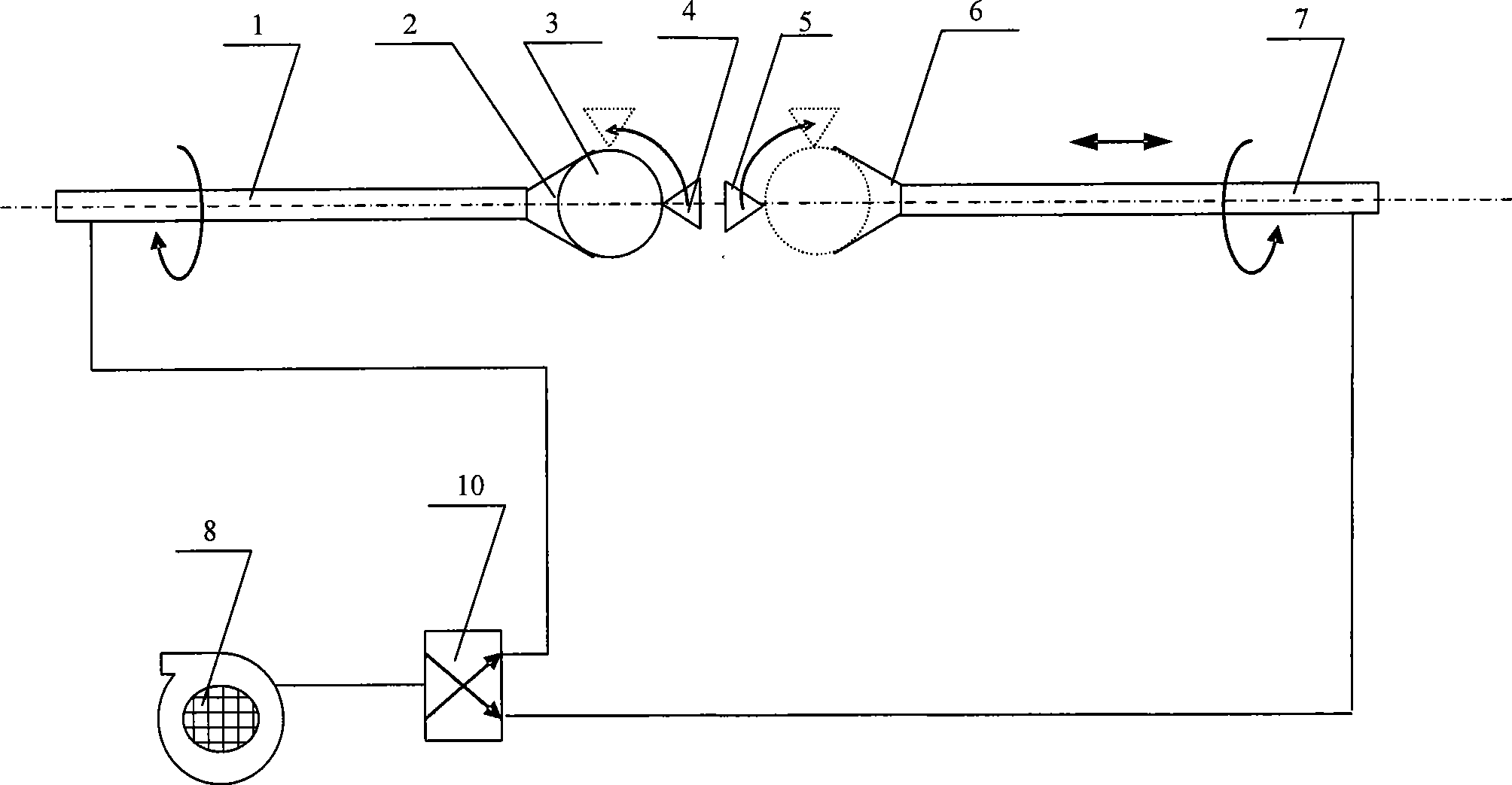

Gas inlet regulating method of double-cyclone dust collector and device thereof

InactiveCN101905196AOptimize the working conditions of the air inletReduce processing loadReversed direction vortexFlue gasControl system

The invention relates to a gas inlet regulating device of a double-cyclone dust collector. Two gas inlets of the double-cyclone dust collector are connected with a flue gas pipeline in parallel. The gas inlet regulating device is arranged at the gas inlet of the double-cyclone dust collector (8) and comprises a first valve plate (1-a), a second valve plate (1-b), a first valve plate rotating shaft (2-a), a second valve plate rotating shaft (2-b), a valve plate opening drive device (3), a gas flow rate monitoring unit (4) and a control system (7), wherein the first valve plate (1-a) and the second valve plate (1-b) are symmetrically positioned on the pipelines of the two gas inlets of the double-cyclone dust collector (8) respectively, the valve plate opening drive device (3) is used for respectively regulating the opening angles of the first valve plate (1-a) and the second valve plate (1-b) by the first valve plate rotating shaft (2-a) and the second valve plate rotating shaft (2-b), the air inlet pipeline is provided with the gas flow rate monitoring unit (4), and the valve plate opening drive device (3) and the gas flow rate monitoring unit (4) are respectively connected with the control system (7).

Owner:北京钢研新冶工程设计有限公司

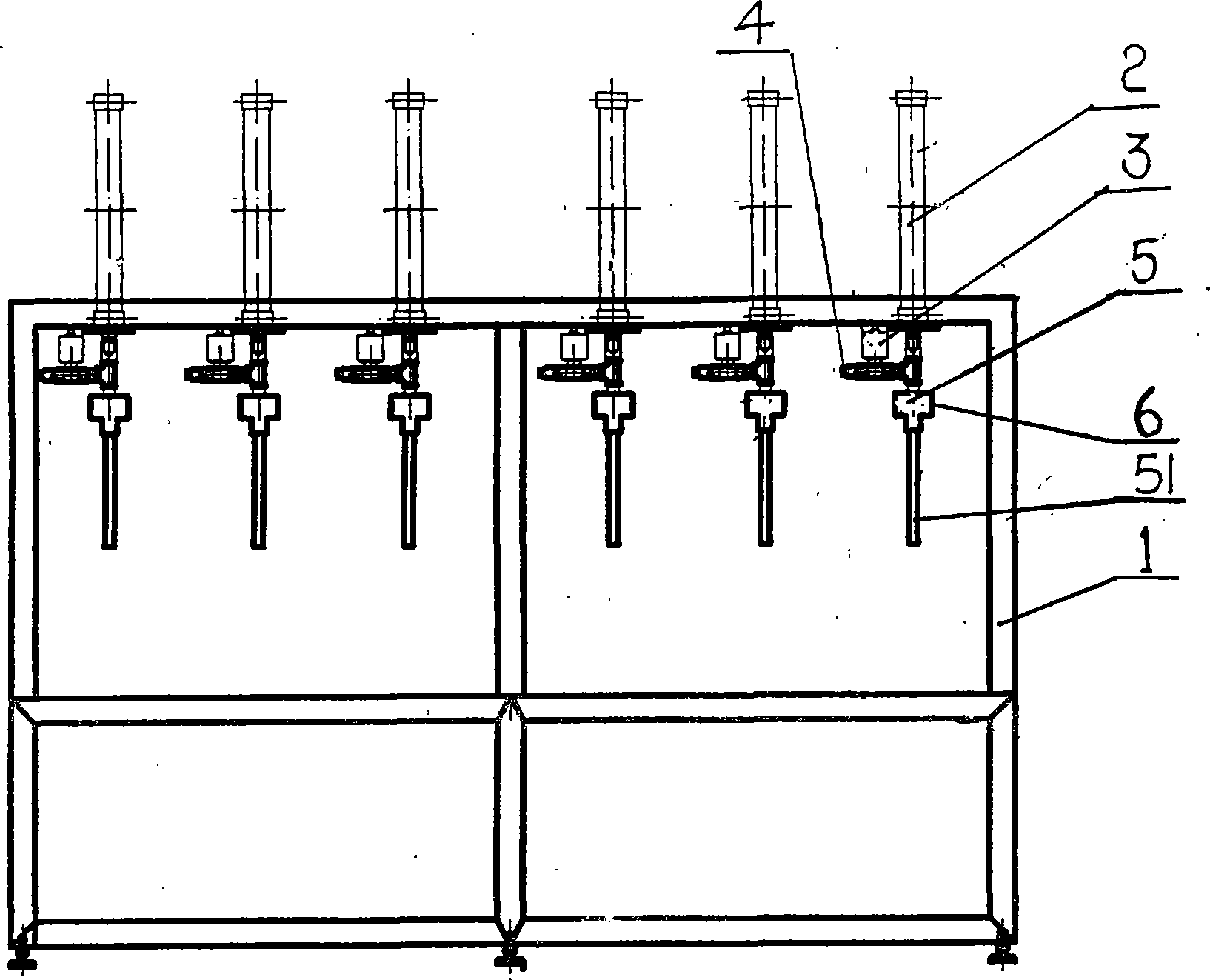

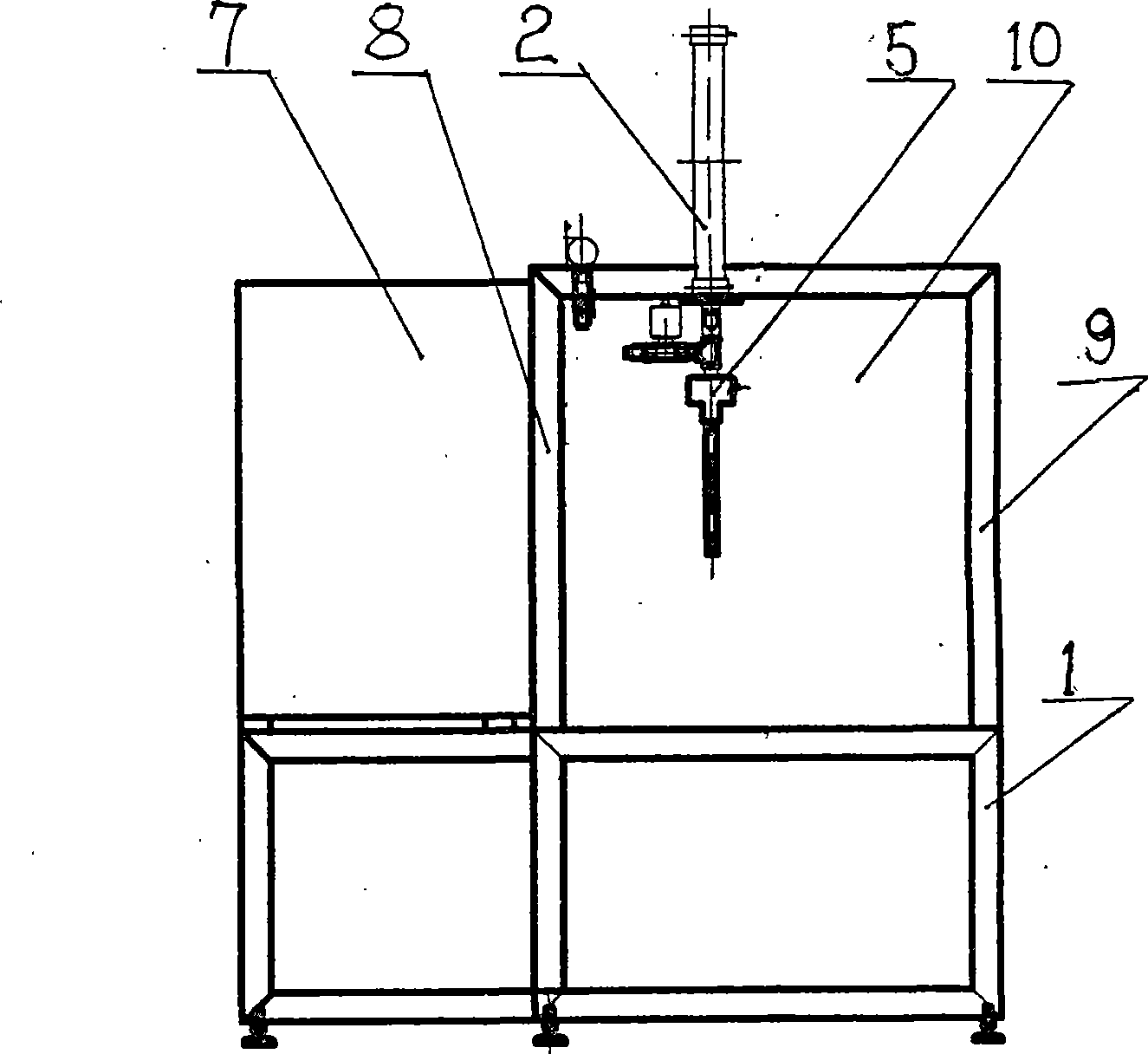

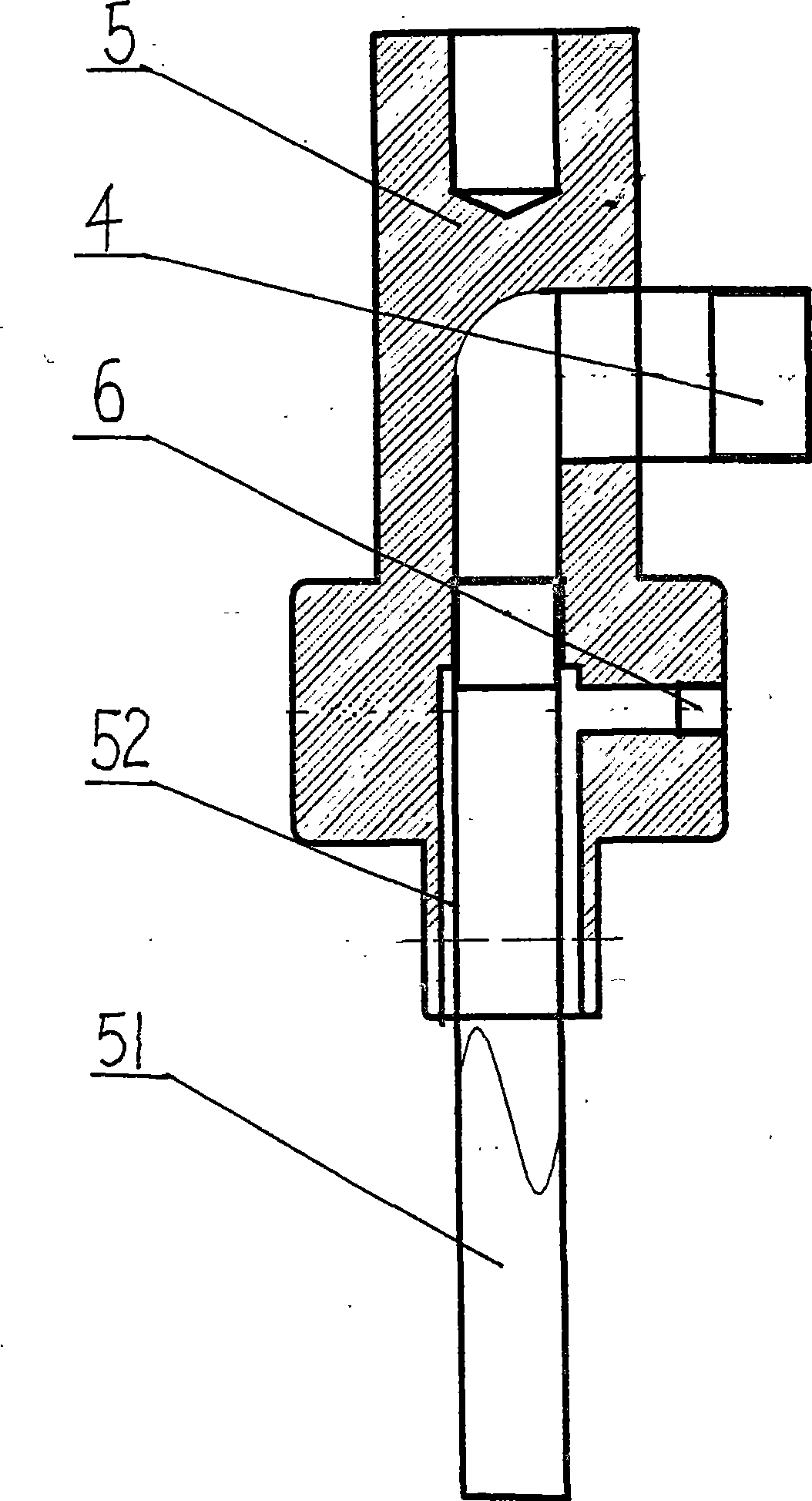

Beer sterilized bottle filler

InactiveCN101391735AReduce usageReduce oxygenationLiquid fillingBottle-handling machinesPositive pressureSolenoid valve

The invention discloses a beer aseptic filling machine which belongs to the light industrial machinery field and aims to solve the defects of the existing equipments that the universality is poor and the cost is high. The beer aseptic filling machine comprises a frame and a filling mechanism arranged on the frame and is characterized in that: the filling mechanism comprises lifting-controllable filling heads; the filling heads are connected with beer inlets controlled by solenoid valves; the beer inlets are communicated with long tubes provided with bottom ends adjacent to bottoms of filling containers; clearances are arranged at the lower ends of the jointing parts between the filling heads and the long tubes and the clearances are communicated with vents arranged on the filling heads; both the filling heads and the long tubes are arranged in the aseptic positive-pressure environment formed by an air outlet of a film filtration fan. The filling machine can realize the automatic aseptic filling and the cleaning is convenient and thorough without dead angles, the universality is better, the cost is low, therefore the beer aseptic filling machine can be applicable to various small and medium size containers for realizing the aseptic filling of beer or beverage.

Owner:济南百脉泉啤酒饮品有限公司

Plasma preparation method of spherical titanium powder for 3D printing

InactiveCN105562700AHigh sphericityUniform particle size distributionAdditive manufacturing apparatusTransportation and packagingPrillSpherical shaped

The invention discloses a plasma preparation method of spherical titanium powder for 3D printing. Titanium powder in an irregular shape is selected as the raw material; argon carries titanium powder particles to be sprayed into a plasma torch through a feeding gun; the titanium powder particles are rapidly heated and fused, and the fused particles form liquid drops with a high degree of sphericity under the action of surface tension; and crushing gas is introduced to crush the fused liquid drops again, the fused liquid drops are rapidly cooled and solidified to form spherical titanium powder particles under the two different progressively increasing temperature gradients, powder is separated from plasma gas due to the efficient filtering gas, and the spherical powder is collected through a powder collection device. The titanium powder prepared by the method is controllable in component, particle size and degree of sphericity; the prepared spherical titanium powder is high in degree of sphericity, good in mobility, uniform in size distribution, little in impurity, high in compactness, high in quality and used for 3D printing; the preparation process is rapid and easy, and one-time molding is achieved.

Owner:LONGYAN ZIJIN INNOVATION RES INST

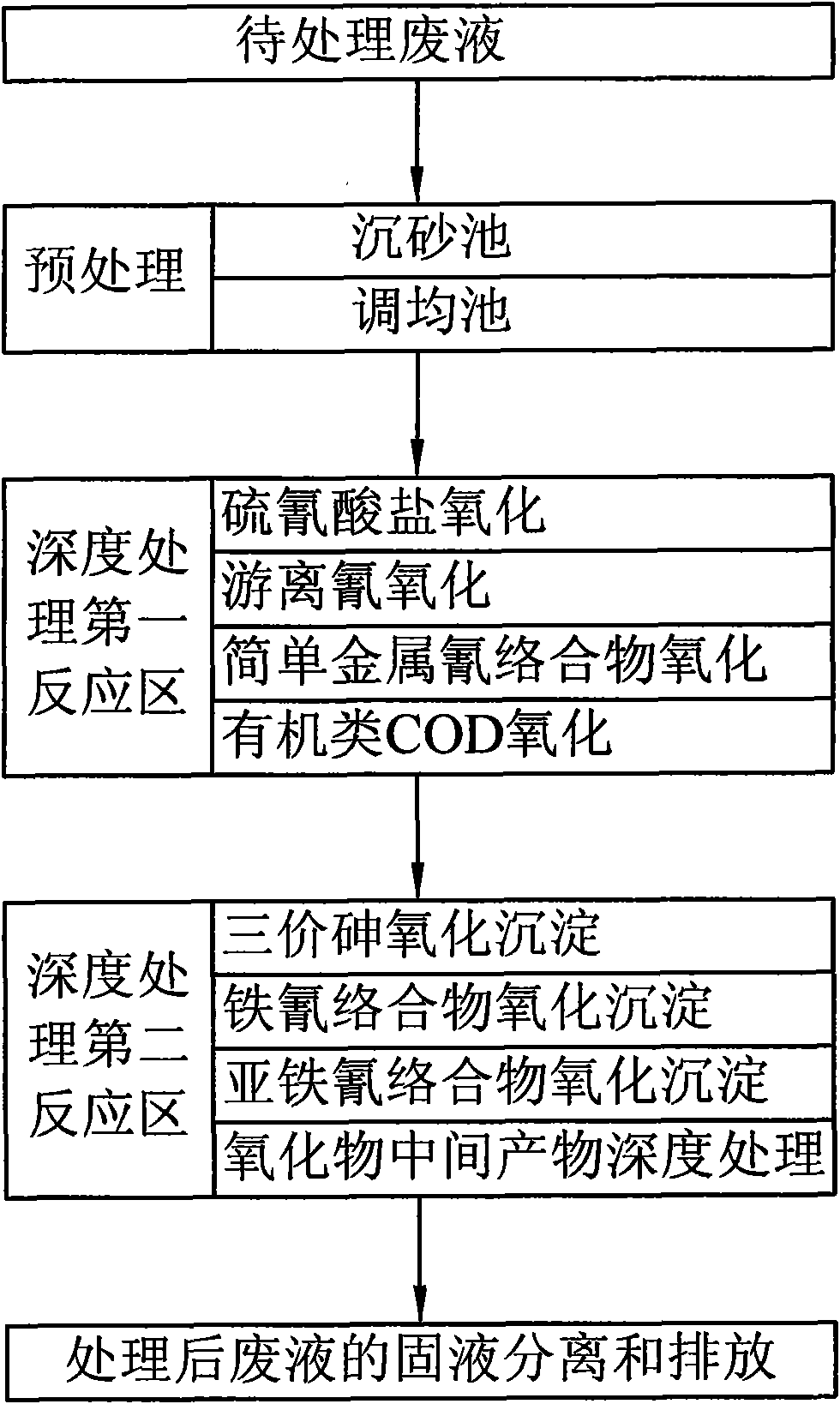

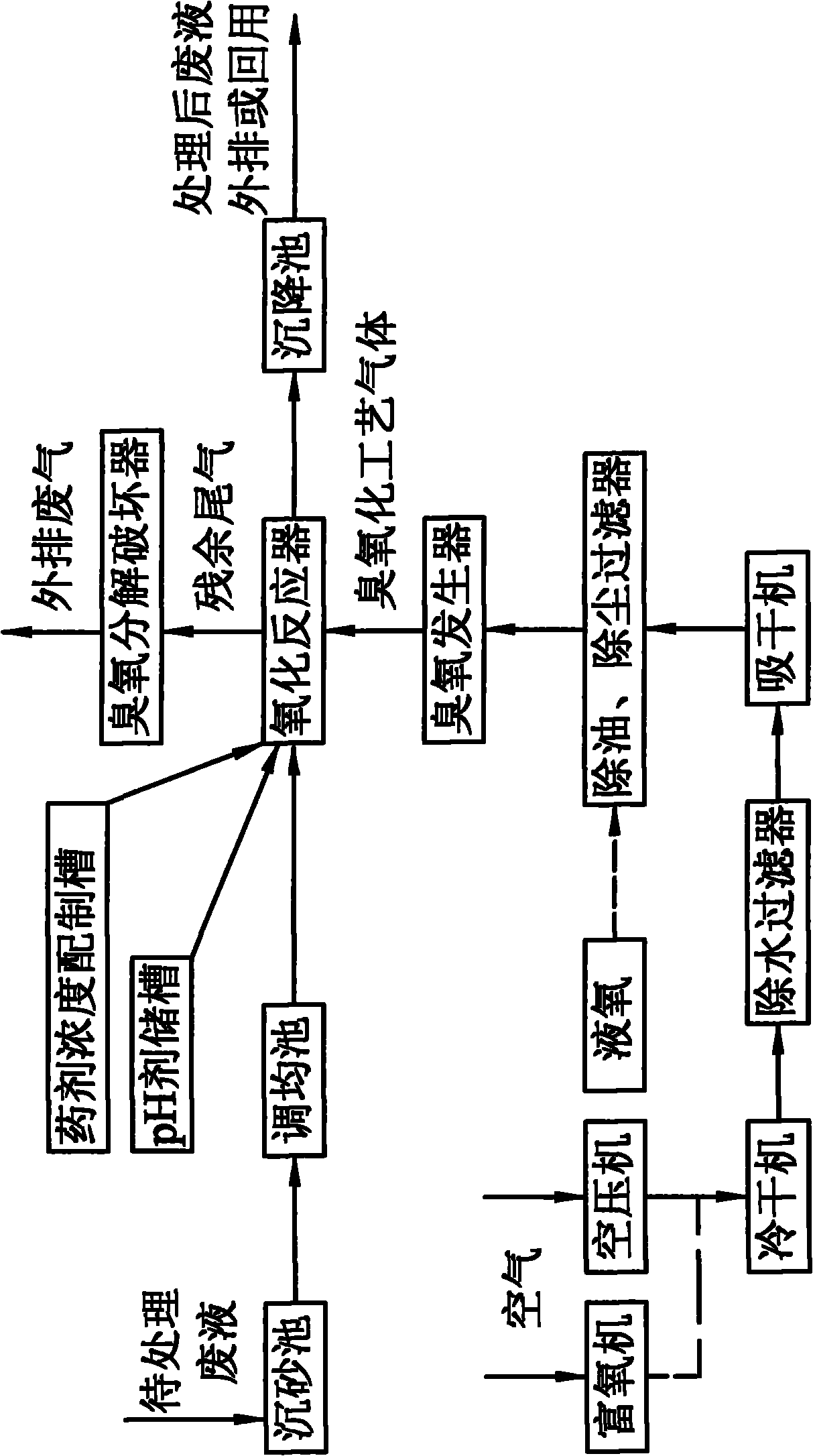

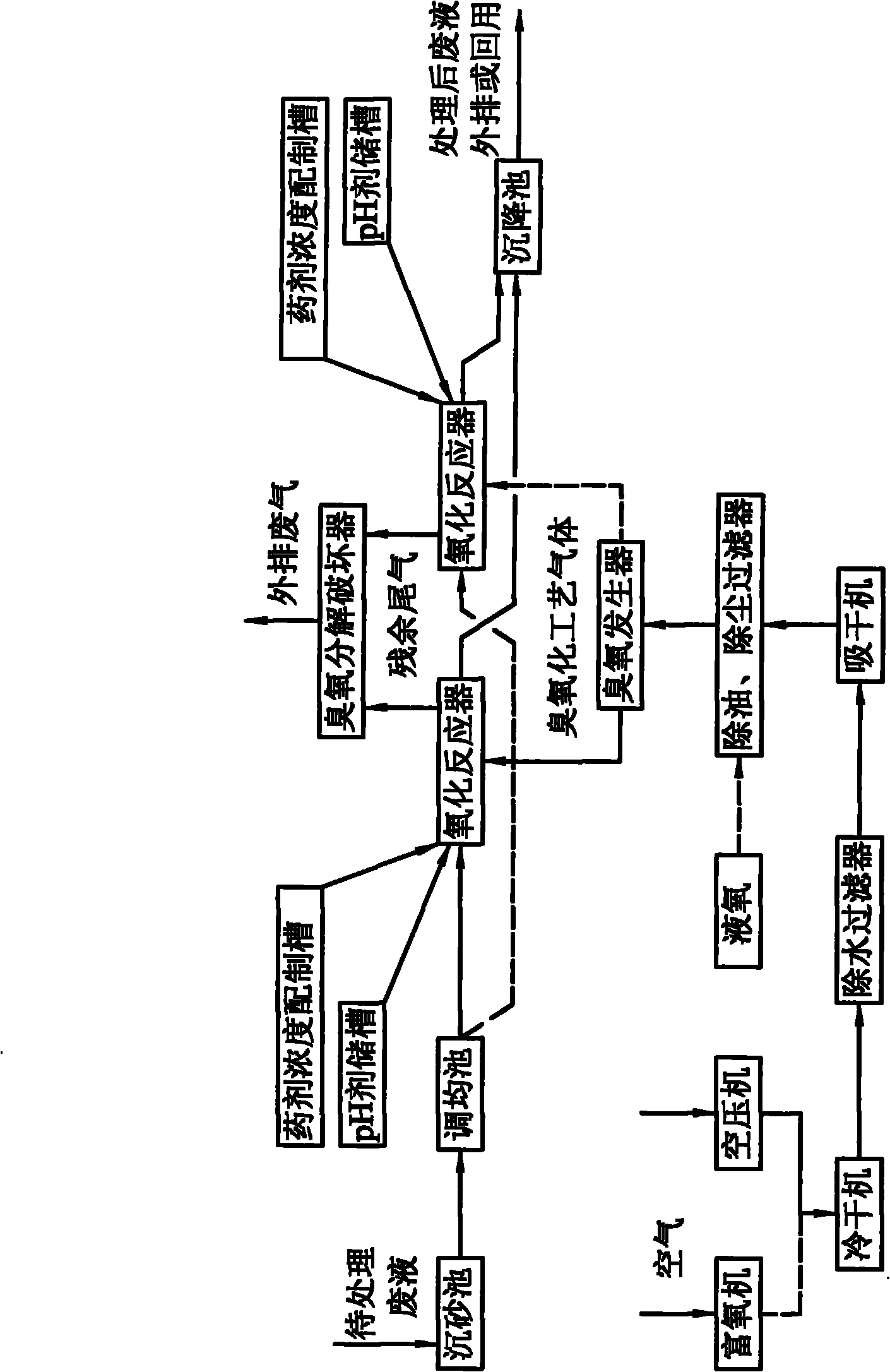

Method for removing cyanide, thiocyanate, COD and arsenic in waste liquid

ActiveCN102070264ALow costReduce complexityWater contaminantsMultistage water/sewage treatmentLiquid wasteThiocyanate

The invention discloses a method for removing cyanide, thiocyanate, COD and arsenic in waste liquid, comprising the following steps: the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid are deeply treated by utilizing ozonized gas, a mode with continuous treatment and direct discharge can be adopted, also a mode with batch treatment and intermittent discharge can be adopted, and the implementation process of the method is easy to control; in the range of the pH value with sectioned control, the generation concentration and mass velocity of ozone do not need to be required strictly, the problem that single technology can not treat the cyanide, the thiocyanate, the COD and the arsenic in the waste liquid deeply can be solved, the cost and the operation complexity of technological equipment are reduced, and the environmental pollution is reduced; solid suspensions (SS) in the treated waste liquid is removed by settlement, and clear liquor is directly discharged outwards or returned to the upstream technology for repeated use; the contents of pollutants in the treated waste liquid are stable, the total content of the cyanide is less than 0.2mg / L(waste water); the content of the thiocyanate is less than 5mg / L(waste water); the total content of the COD is less than 30mg / L; the total content of the arsenic is less than 0.5mg / L(waste water), and no secondary pollutants are generated in the reaction process.

Owner:CHANGCHUN GOLD RES INST +1

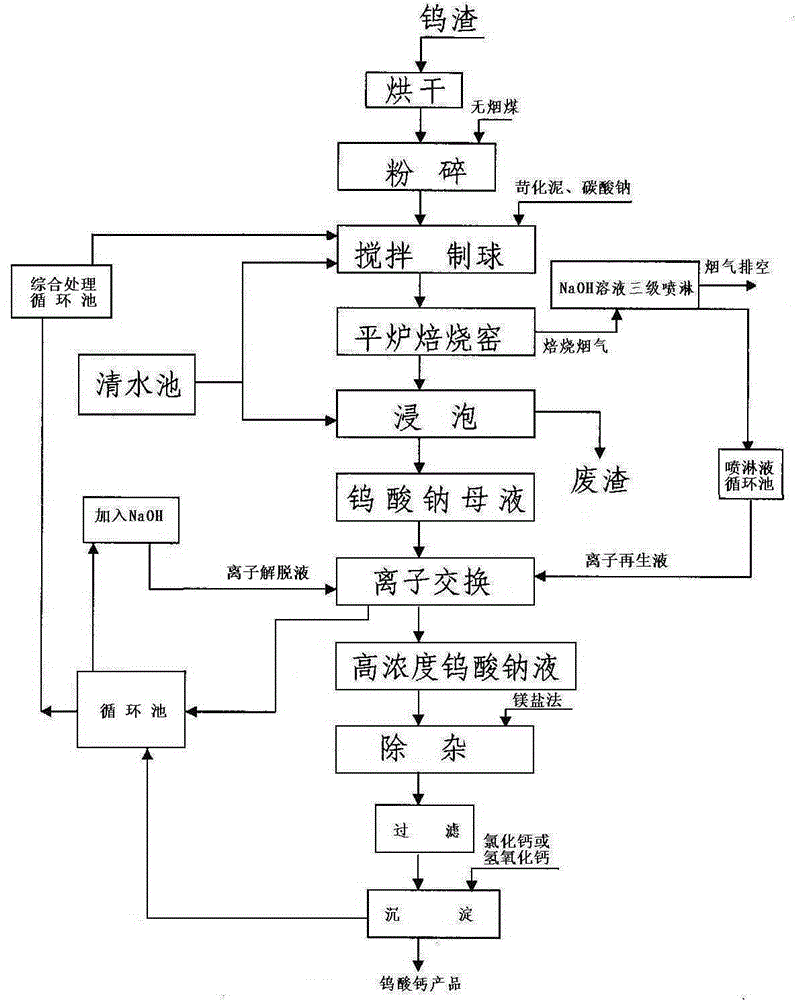

Technology for producing tungsten trioxide by prilling and roasting of tungsten slag

The invention discloses a technology for producing tungsten trioxide by prilling and roasting of tungsten slag. The technology is characterized by comprising the following steps of: (1) baking tungsten slag and then adding blind coal, mixing and crushing the tungsten slag and the blind coal, and then adding lime mud, sodium carbonate and water, priling in a priling disc to prepare the mixed tungsten slag balls; (2) putting the mixed tungsten slag balls into an open hearth kiln to carry out semi-enclosed insulated roasting so as to obtain a tungsten slag clinker; (3) soaking the tungsten slag clinker, and carrying out ion exchange to obtain high-concentration sodium tungstate mother liquor; (4) removing the impurity of the high-concentration sodium tungstate mother liquor, and then filtering, precipitating, leaching the sediment, dewatering and baking the sediment to obtain a calcium tungstate product. The tungsten slag, the blind coal, the lime mud and recycling wastewater are adopted as roasting agents to replace soda ash and burning acid with high price and large consumption for the traditional technology-wet firing method, so that the tungsten production cost of each metal ton is reduced by***, and the transformation rate of WO3 is improved by 25%; the chronic diseases of sodium-process rotary kiln roasting and caking shovel kiln stop production are successfully solved, and about 50% of energy consumption is saved on the traditional technology and wet firing production.

Owner:陈检辉

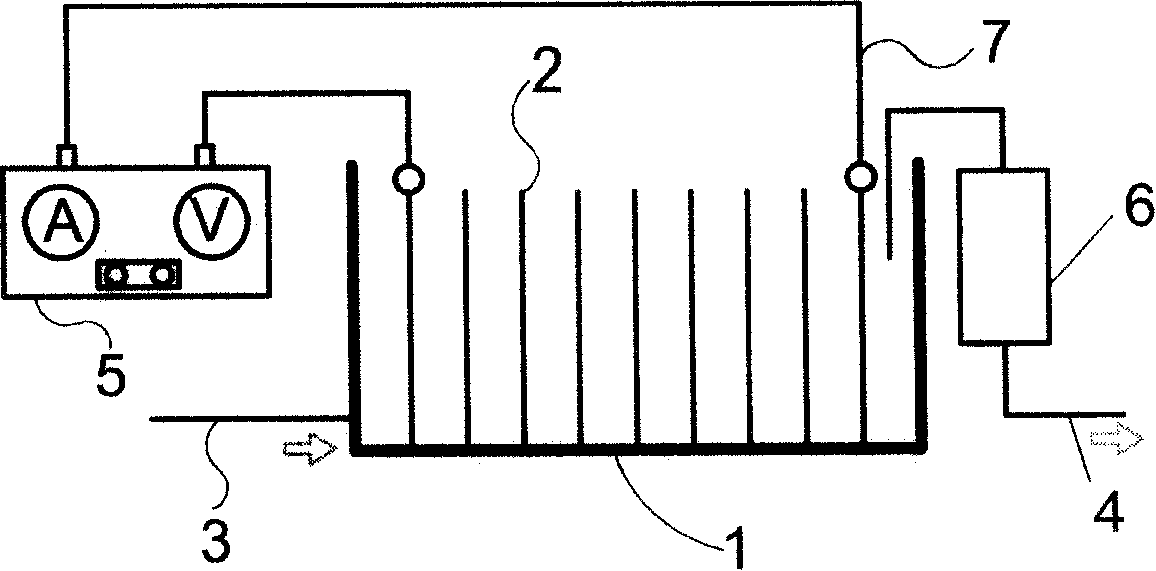

Process of treating fluoride and organic matter in drinking water and its electrical flocculator

The present invention relates to drinking water treatment, and is especially process and electrical flocculator for treating fluoride and organic matter in drinking water. In the combined electric flocculating and microfiltering process, the electrolysis with aluminum or iron plate as electrode produces aluminum salt or iron salt capable of combining with fluorine ion and organic matter in water to form relatively large flocculate, and the subsequent filtering with microfiltering membrane eliminates the flocculate effectively to reach the aim of eliminate fluoride and organic matter from drinking water. The present invention is simple, easy to automatize and suitable for wide use in different places.

Owner:TSINGHUA UNIV

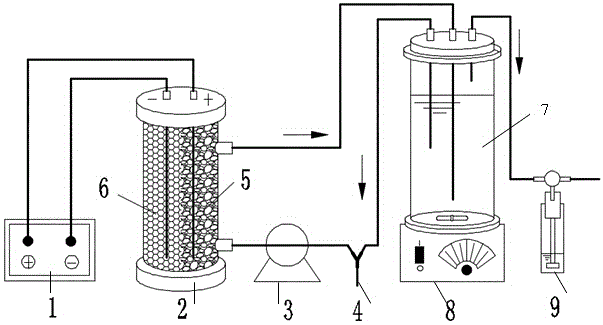

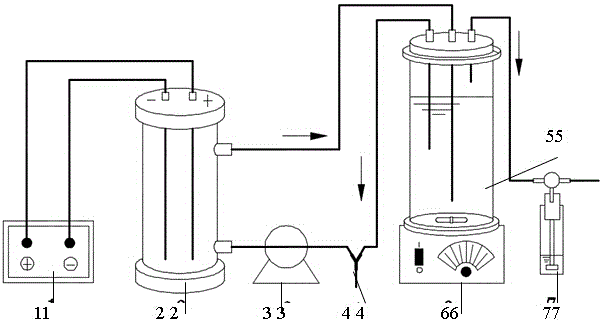

Method and device for removing nitrate nitrogen in water by using three-dimensional electrodes

InactiveCN104163479ARemoval of efficient and environmentally friendlyHarm reductionWater/sewage treatment using germicide/oligodynamic-processActivated carbonElectrolysis

The invention provides a method for removing nitrate nitrogen in water by using three-dimensional electrodes, which comprises the following steps: wastewater is input from a wastewater distribution device into a electrolysis bath, wherein a cathode, an anode and a particle electrode are arranged in the electrolysis bath, the particle electrode is composed of activated carbon and foamed metal copper, the activated carbon and foamed metal copper are filled in an electrode tank, and the electrode tank is connected with a direct current power supply; and after the power is on, the wastewater in the electrode tank is electrolyzed and input into the wastewater distribution device to be circulated, and the gas in the wastewater distribution device is discharged through a gas washer. The invention also provides a device for implementing the method. The double fillers activated carbon and foamed copper are utilized to enhance the mass transport process; and on such basis, the electrochemical redox is utilized to remove the nitrate nitrogen in the water body, thereby reducing the hazard of the nitrate nitrogen to the human body.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

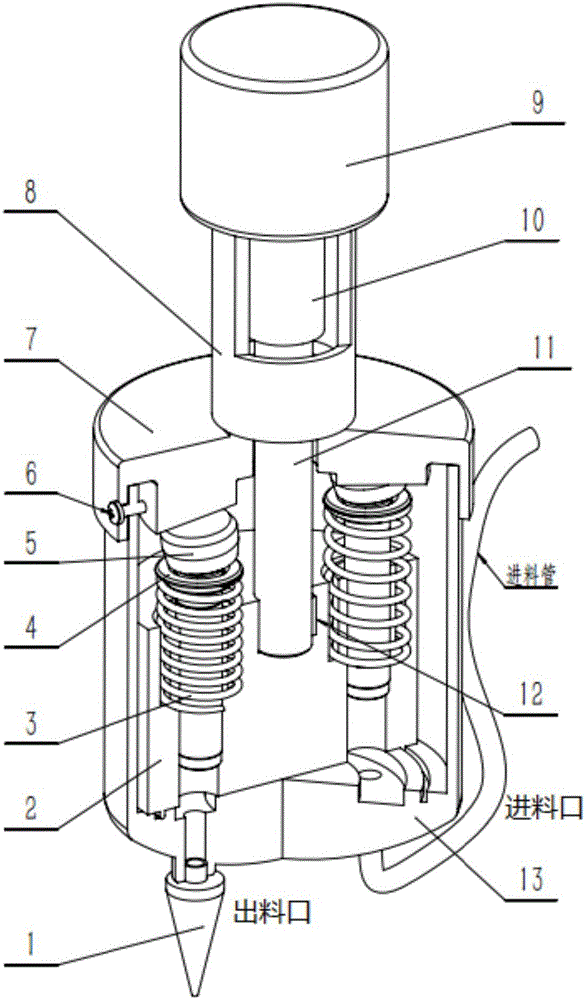

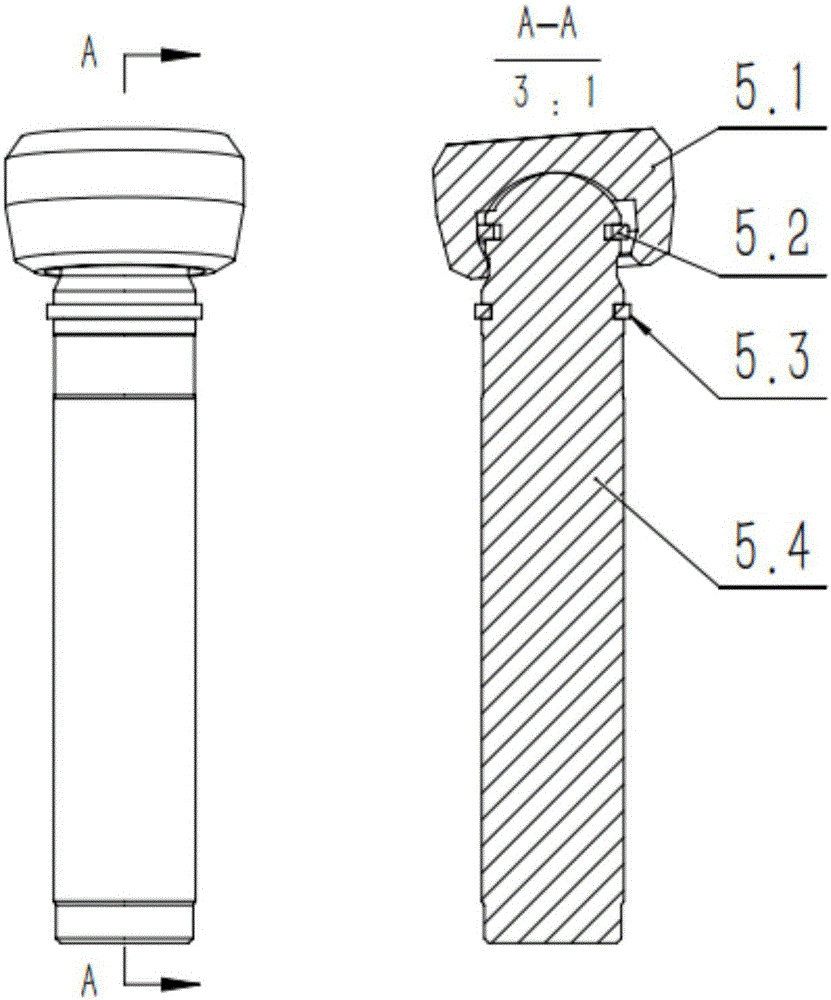

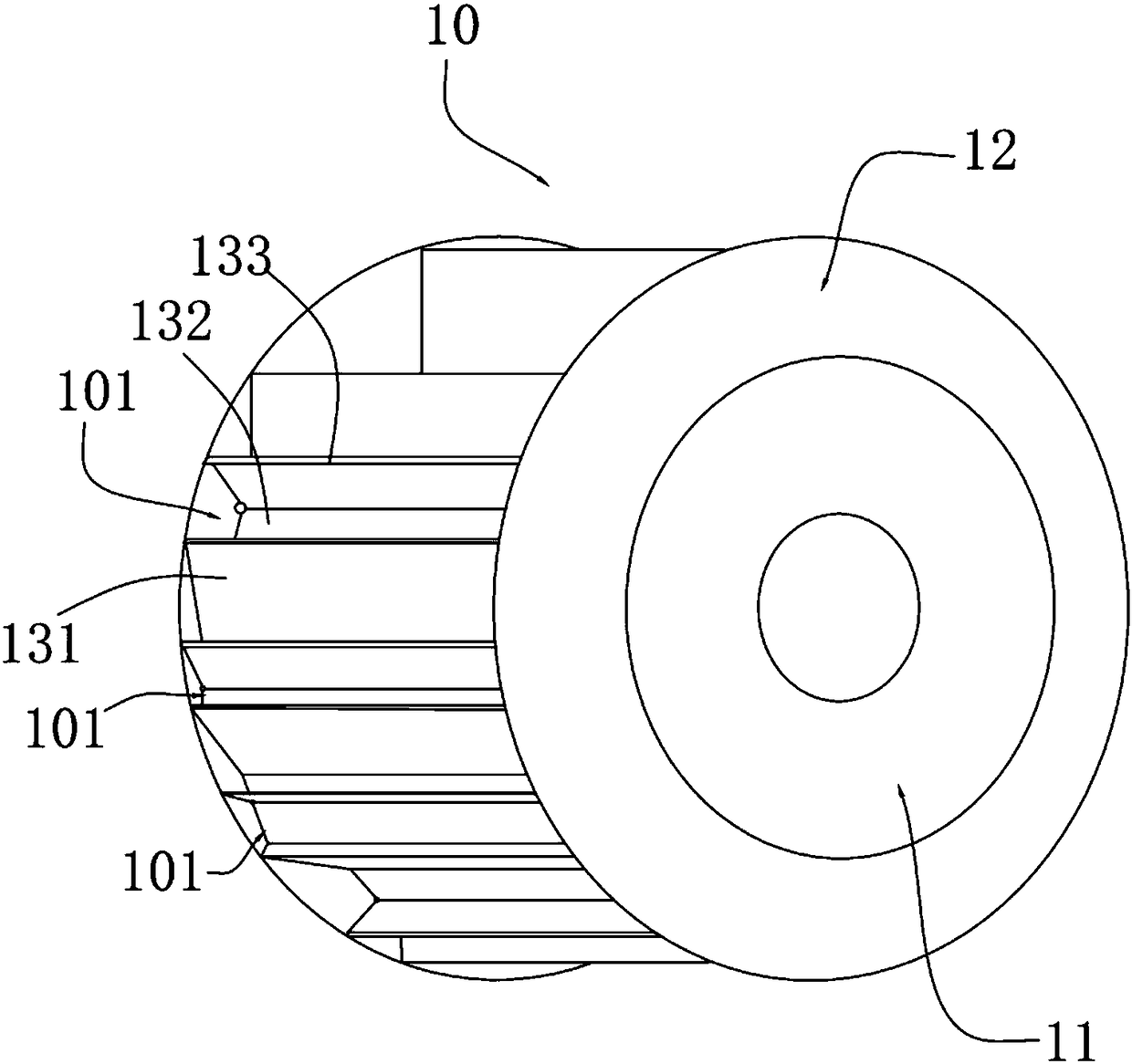

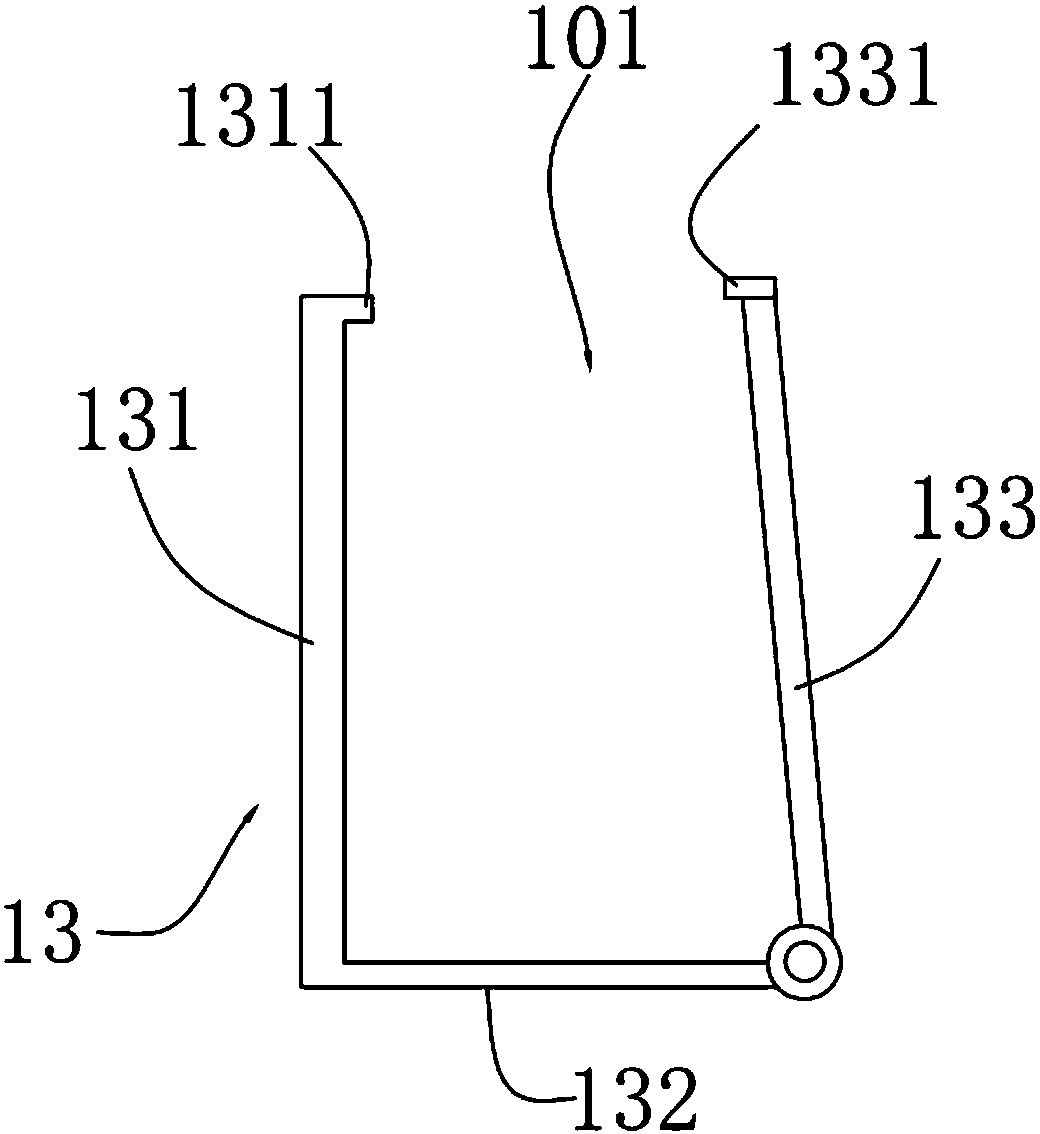

Self-sucking biological 3D printing nozzle device and method thereof

ActiveCN105818389AAutomatic continuityAutomate printing jobsAdditive manufacturing apparatusAutomatic controlTissue material

The invention discloses a self-sucking biological 3D printing nozzle device and a control method thereof, and belongs to the field of tissue engineering and biological 3D printing. The nozzle device is characterized by comprising a nozzle, a plunger cylinder, screws, an inclined disc cover, a motor base, a motor, a coupling, a transmission shaft, a flat key and a flow distribution cylinder. The motor drives the transmission shaft to rotate through the coupling to drive the plunger cylinder coaxially mounted in the flow distribution cylinder to rotate, so that a plunger body on the plunger cylinder moves up and down in a cylinder plunger hole under the combined effect of spring force and an inner inclined surface of the inclined disc cover to realize continuous sucking and pressing actions to finish continuous biological material printing work. The nozzle device effectively prevents the trouble of the need of stopping to replace the nozzle device when being applied to continuous printing of large-size tissue material organs. The nozzle device has the advantages of simple and skillful structure concept, easy realization of automatic control, improvement of the printing efficiency and effective solving of the continuous supply printing problem.

Owner:ZHEJIANG UNIV

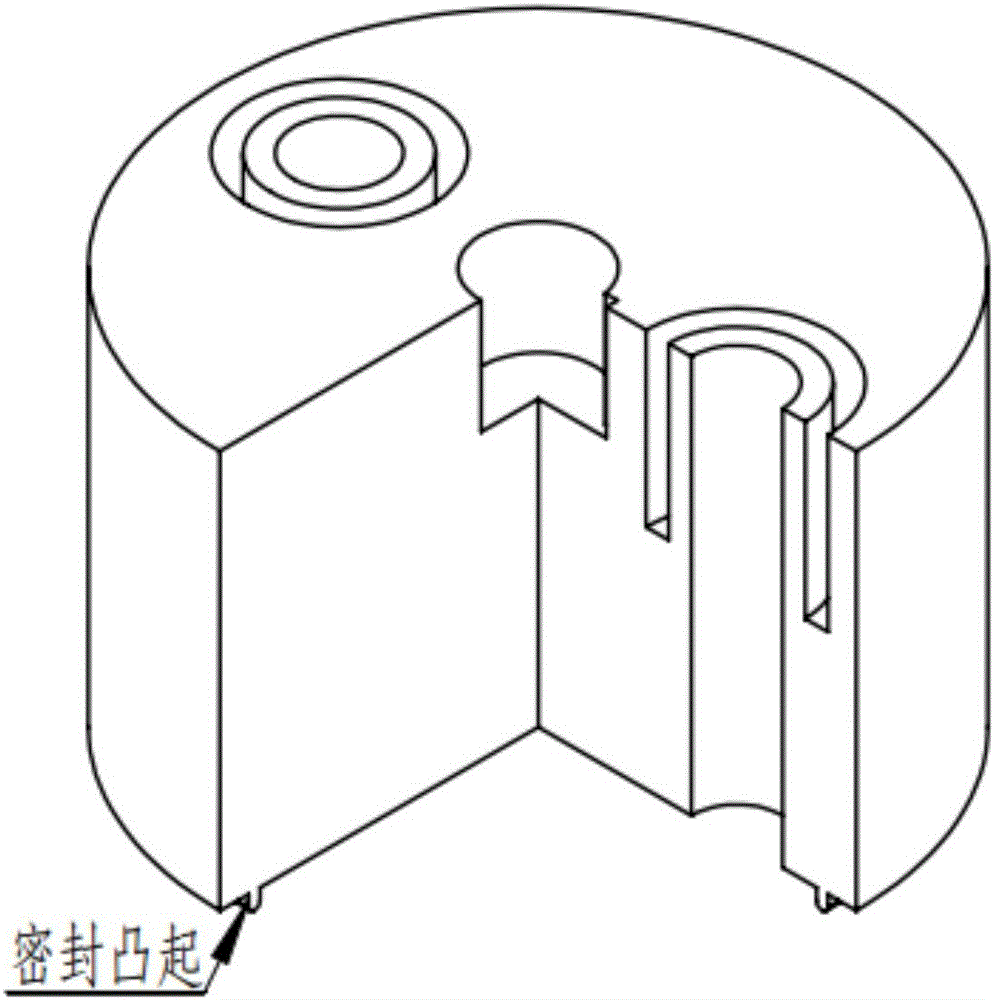

Catalytic ozonation water treatment device

InactiveCN104150578ANot ruled outReduce processing costsWater/sewage treatment by oxidationIndustrial waste waterLiquid state

The invention belongs to the field of industrial waste water deep treatment equipment, and particularly relates to a multi-stage advanced catalytic ozonation water treatment device. The device mainly comprises a titanium microporous aerator, H2O2 feeding systems, liquid-state specific catalyst feeding systems, solid-state specific catalysts, a corrugated plate demister and a tail gas collection and destruction system. Waste water flows in the treatment device through a water inlet pipe, the bottom, the middle part and the upper part of the treatment device are respectively provided with a different amount of ozone feeding systems, H2O2 feeding systems, liquid-state specific catalyst feeding systems, and solid-state specific catalysts, and meanwhile, tail gas is demisted through a corrugated plate and then is collected and delivered to the destruction system for destruction, so as to avoid the pollution to an environment. According to the catalytic ozonation water treatment device, the color and COD in industrial waste water can be effectively removed, the treatment method is simple, and the cost is low and the treatment efficiency is high.

Owner:TAIZHOU INST OF SCI &TECH NUST

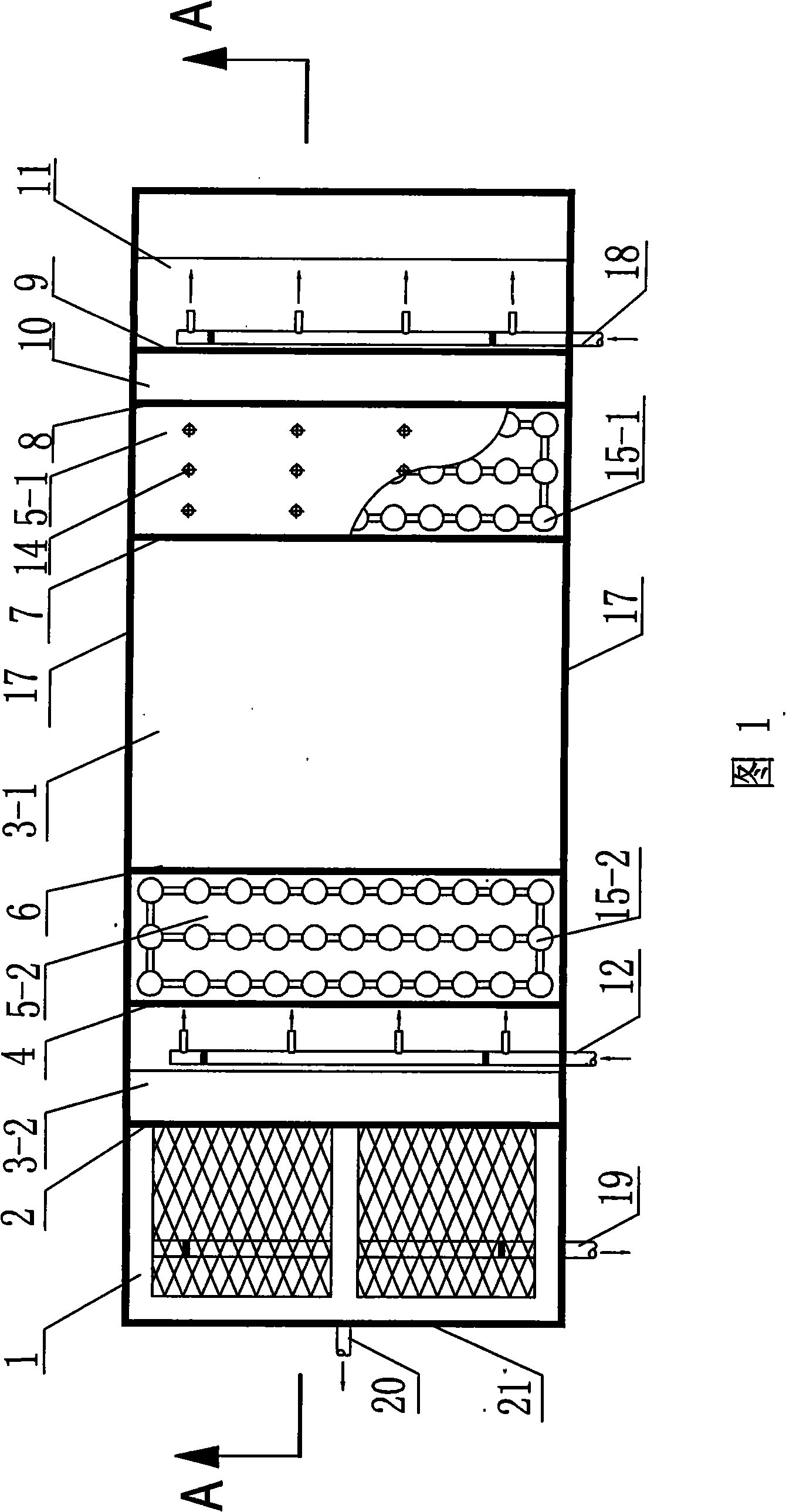

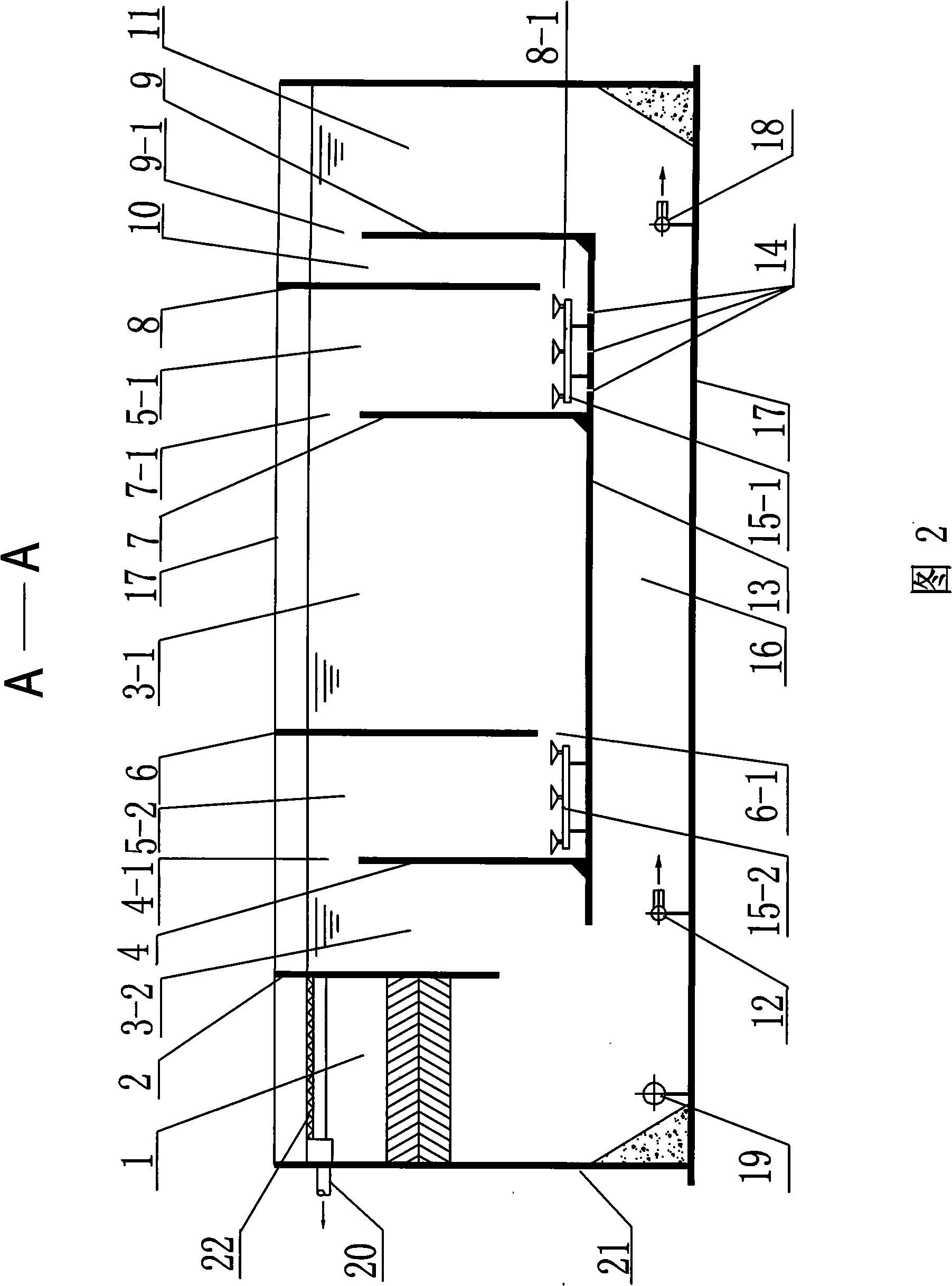

Multilayer three-dimensional breeding system for livestock and poultry

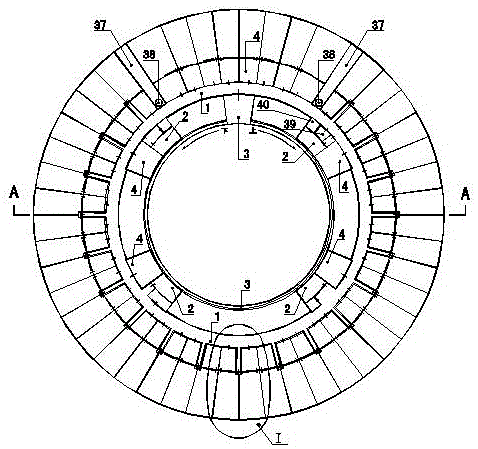

The invention provides a multilayer three-dimensional breeding system for livestock and poultry. The multilayer three-dimensional breeding system comprises an annular building with more than two stories, wherein the outer diameter of each upper-layer annular building is smaller than the outer diameter of each lower-layer annular building, so that the annular building is formed into a step type structure; breeding houses are arranged in the annular step type building respectively, the breeding houses are connected with sports fields, each breeding house is positioned on the inner side of the corresponding annular step type building layer, and all the sports fields are positioned on the outer side of the corresponding annular step type building layer; animal walking surfaces of the breeding houses and the sports fields are hollow surfaces, excrement and urine collecting chambers are arranged under the hollow surfaces and communicated with a sewage treatment pond through pipelines, and excrement cleaning machines are mounted in the excrement and urine collecting chambers; a feed conveying device and a drinking water device are mounted in the annular step type building, the annular step type building is connected with a helical ramp which gradually rises to the top story along each story on the inner side of the annular step type building from the bottom end, and animals walk on the helical ramp and pass in and out of the breeding houses through the helical ramp. The multilayer three-dimensional breeding system disclosed by the invention can solve the problems existing in the prior art.

Owner:姜伟

Nickel base self-lubricating coating on surface of titanium alloy by laser cladding and preparation method thereof

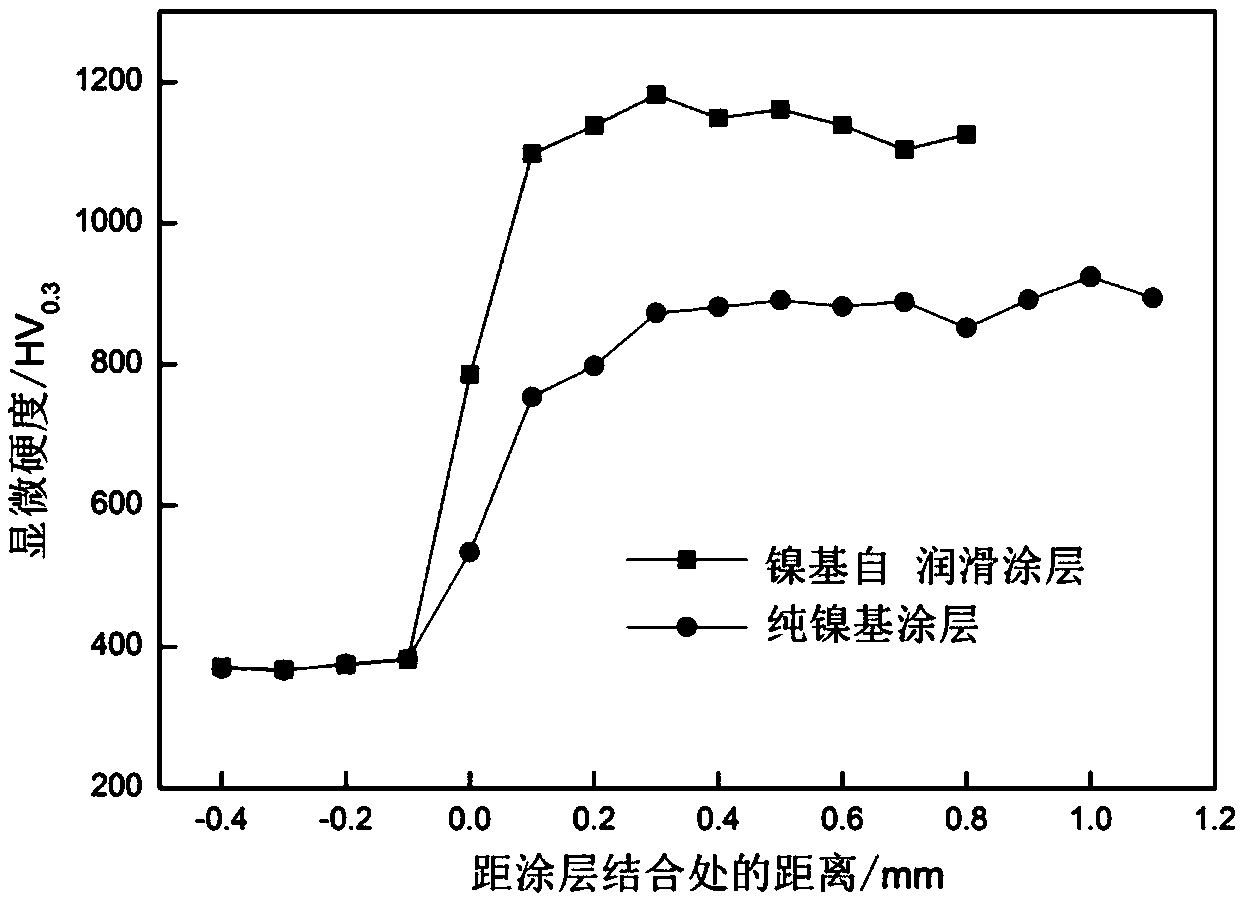

InactiveCN108411300AImprove wear resistanceGood metallurgical bondMetallic material coating processesLubricationTitanium

The invention discloses a nickel base self-lubricating coating on the surface of a titanium alloy by laser cladding and a preparation method thereof. The preparation method comprises the steps that the surface of the titanium alloy is pretreated first; a raw material is prepared, wherein the raw material comprises, by weight, 45-55% of nickel base alloys, 20-30% of titanium and 20-30% of nickel-coated molybdenum disulfide, after uniform mixing, the raw material and a binder are mixed uniformly and are preset on the surface of the titanium alloy, and a binder preset powder layer is formed; anda nickel base self-lubricating composite coating is formed after powder is melted and solidified by laser irradiation. The obtained nickel base self-lubricating coating has good anti-friction and anti-friction lubrication action, and the using requirements of titanium alloy parts under harsh working conditions are met.

Owner:SHANGHAI UNIV OF ENG SCI

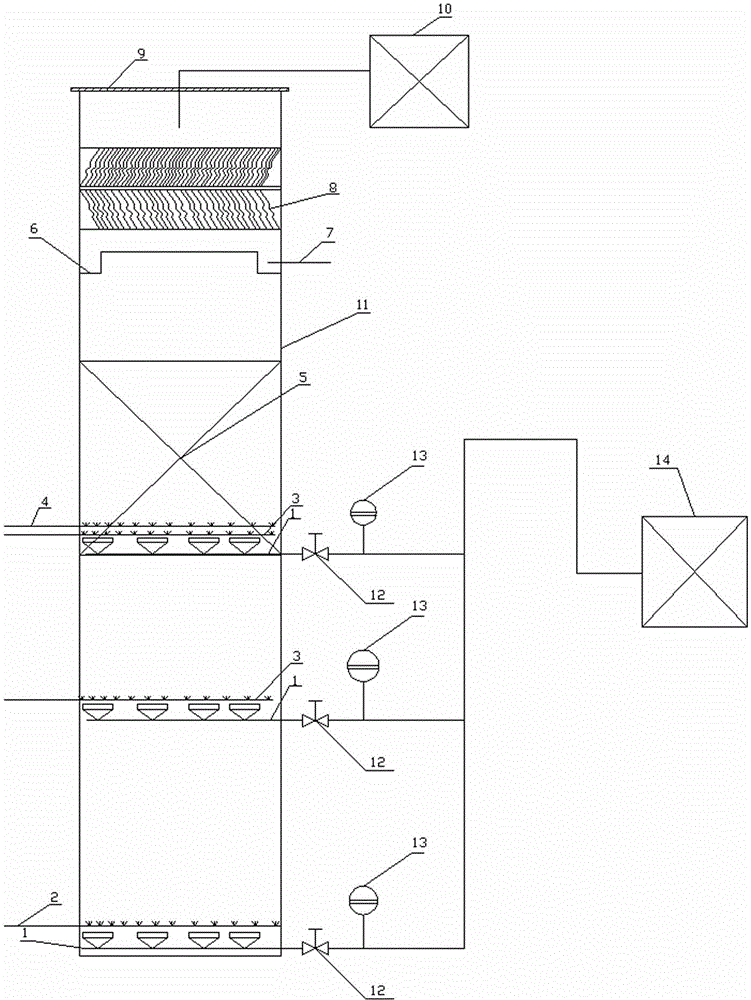

Zanjon type gas-lift stream-pull tridimensional circulation type inversion A<2>O integral co-construction oxidation ditch

ActiveCN101269879AIncrease water depthGood removal effectTreatment with aerobic and anaerobic processesWater qualityEnvironmental engineering

The invention relates to a zanjon air lifting pushing solid circulation inversion A<2>O integrated construction oxidation ditch, which comprises an anoxic zone, an anaerobic zone, an aerobic zone provided with a millipore aerator group and an inversion A<2>O integrated construction oxidation ditch of a solid and liquid separating zone. The solid and liquid separating zone is arranged at the front end of a main ditch, the anaerobic zone is arranged at the tail end of the main ditch, and water inlets are respectively arranged at the front ends of the aerobic zone and the anaerobic zone. The integrated construction oxidation ditch is characterized in that a horizontal partition board which divides the main ditch into an upper groove layer and a lower groove layer is arranged at the middle-lower part of the main ditch, the aerobic zone and the anaerobic zone are respectively arranged at the upper groove layer and the lower groove layer, the aerobic zone is internally provided with n (n is more than or equal to 1) aeration lifting zone (s) which is (are) composed of an inlet water-retaining wall, an outlet water-retaining wall and the millipore aerator group and is (are) provided with a lower water inlet and an upper water outlet, the horizontal partition board of a first grade aeration lifting zone is provided with a plurality of lifting holes, and the aerobic zone is internally divided into n aerobic reaction zone (s) corresponding to the aeration lifting zone (s).The integrated construction oxidation ditch has the advantages that: the yielding water quality, particularly the dephosphorization and denitrification effect, is better, the occupation area is reduced, the equipment is reduced, the operation is simplified, and the operation cost is lowered.

Owner:北京创未环境工程技术有限公司

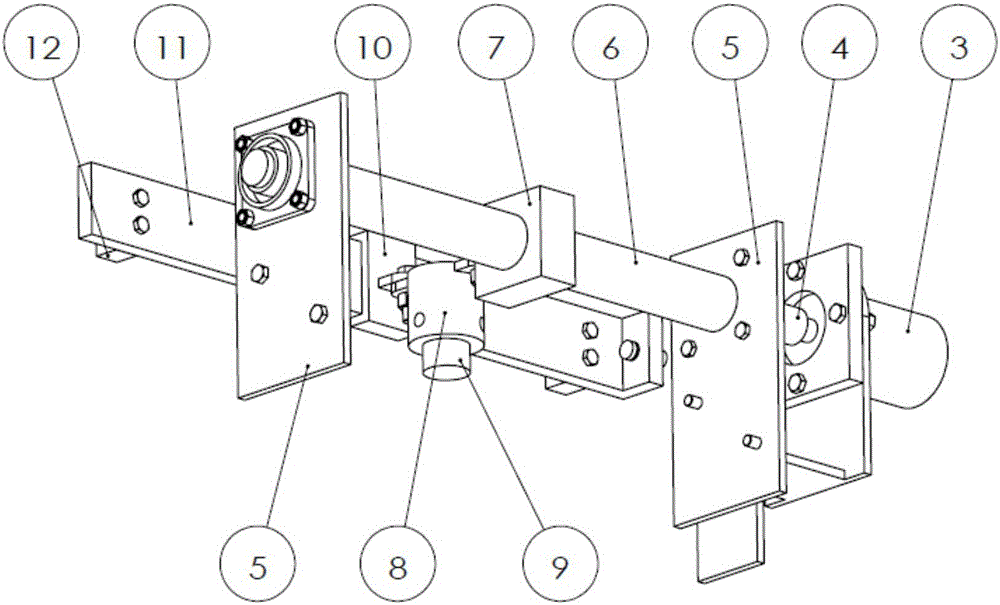

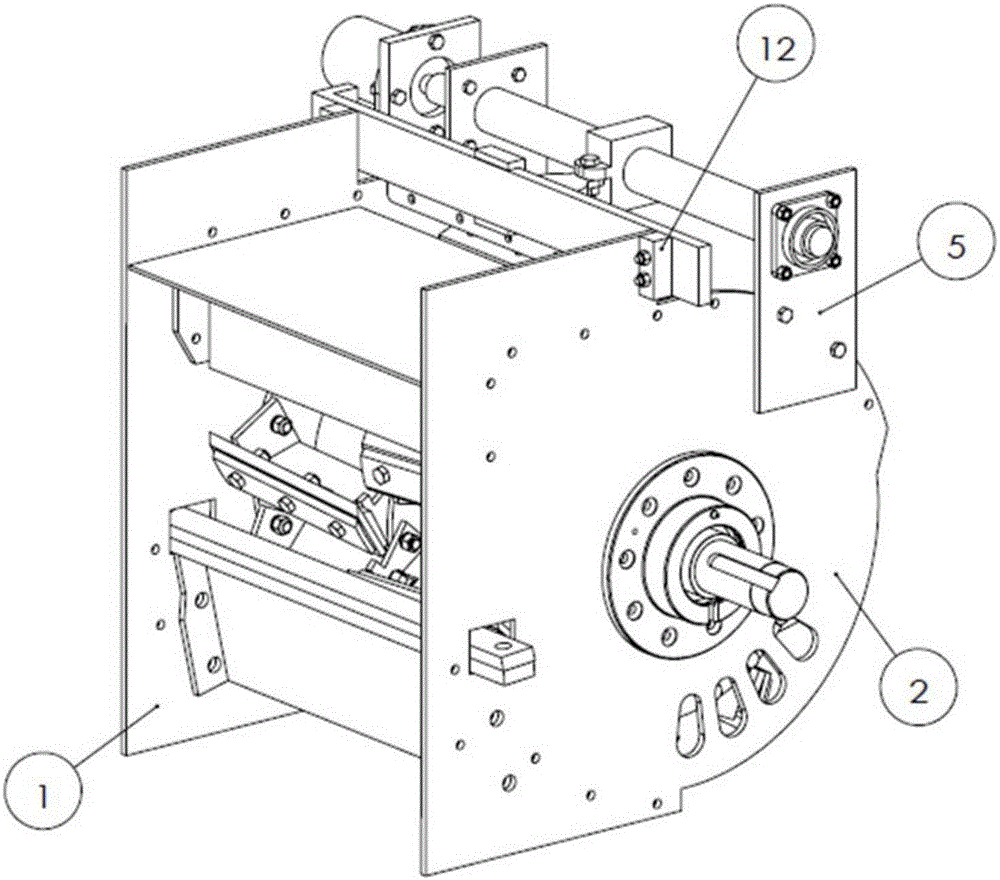

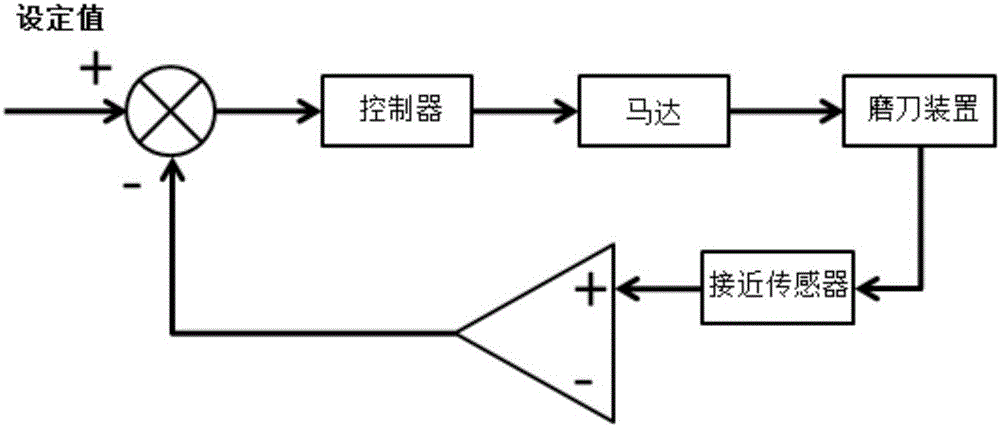

Automatic cutter grinding device of silage maize harvester and silage maize harvester automatically grinding cutters

InactiveCN105773326AEasy to automateSimple structureCuttersOther manufacturing equipments/toolsEngineeringReciprocating motion

The invention discloses an automatic cutter grinding device of a silage maize harvester and the silage maize harvester automatically grinding cutters. The automatic cutter grinding device is installed above chopping rollers of the silage maize harvester and acts on the movable cutters on the chopping rollers. The automatic cutter grinding device comprises a horizontal transmission device, a cutter grinding stone sleeve, a cutter grinding stone, a sliding block, a guide rail and guide rail fixing blocks. One end of the horizontal transmission device and one end of the guide rail are fixed to a left side plate, and the other end of the horizontal transmission device and the other end of the guide rail are fixed to a right side plate. The part, at the upper portion of the cutter grinding stone sleeve, of the horizontal transmission device is connected with the sliding block on the guide rail. The horizontal transmission device drives the cutter grinding stone of the cutter grinding stone sleeve to horizontally reciprocate. The automatic cutter grinding device is simple and ingenious in structural design, the manufacturing difficulty is lowered, the manufacturing cost is reduced, flexible control is easy to achieve, and the work efficiency and stability are improved.

Owner:ZHEJIANG UNIV

Tubular continuous method for preparing cyclopropanecarboxylic acid

InactiveCN101693660AIncrease production capacityHigh yieldOxygen-containing compound preparationOrganic compound preparationContinuous reactorAutomatic control

The invention discloses a tubular continuous method for preparing cyclopropanecarboxylic acid. In the method, gamma-butyrolactone used as a raw material reacts with thionyl chloride and alcohol to produce 4-chlorobutyrate; after the reaction liquid is processed in an acid gas removing way and an alcohol recycling way, the reaction liquid and liquid sodium alkoxide are synthesized to obtain cyclopropanecarboxylate in a tubular reactor; the rectified cyclopropanecarboxylate is firstly hydrolyzed in alkali liquor and then neutralized with acid to obtain crude cyclopropanecarboxylic acid; and the crude cyclopropanecarboxylic acid is rectified to obtain the pure cyclopropanecarboxylic acid. The synthetic technique of the cyclopropanecarboxylic acid adopts the tubular continuous reactor, thereby effectively reducing the equipment investment and enhancing the investment efficiency; the continuous reaction can conveniently realize automatic control, thereby ensuring the continuity and the stability of the production, saving the manual cost, realizing the safe production operation and enhancing the purity and the yield of the product; and the invention adopts a technique of adding solid caustic soda again in the second aqueous phase for recycling, thereby fully and comprehensively utilizing the resources, enhancing the yield for hydrolysis and greatly reducing the cost.

Owner:ZHEJIANG UNIV +1

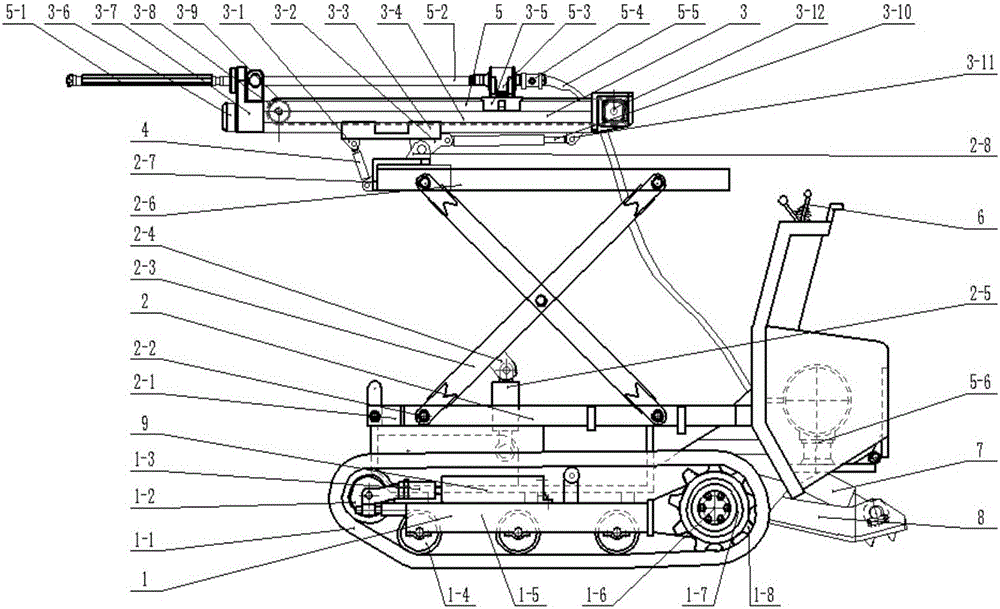

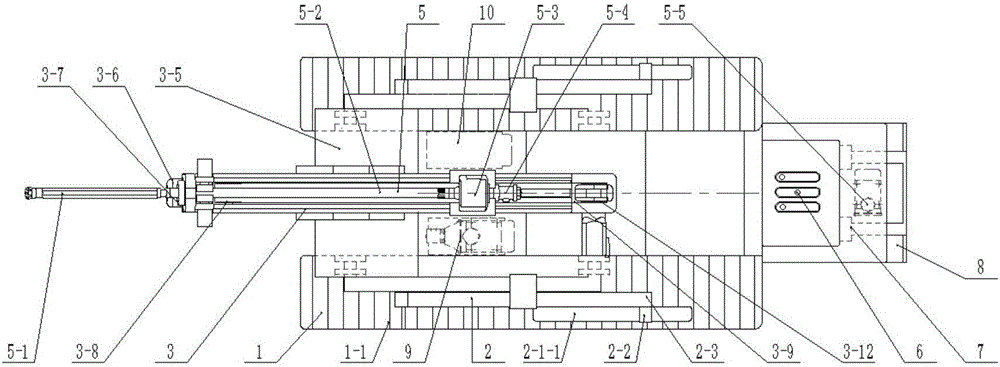

Self-moving type water jet drilling machine

The invention belongs to drilling machine equipment and particularly relates to a self-moving type water jet drilling machine. The self-moving type water jet drilling machine is composed of a walking device, a lifting device, a feeding device, an inclination adjusting oil cylinder, a stabilizing oil cylinder, a water jet drilling device, a control rod, a rear supporting oil cylinder and a rear supporting seat. The drilling machine is capable of achieving crawler belt self-walking, stable in walking, high in climbing ability, capable of turning in situ and flexible; the water jet drilling technology is adopted, and a drill bit is small in size, small in recoil and vibration and convenient to operate; dust and heat emitting are avoided, and the fireproof, anti-explosion and chemical reaction resisting capability is high; meanwhile, the dust fall effect of water can be used for remarkably reducing dust on a working surface, and the field construction condition is improved; the service life of related matching machines can be prolonged with the cooling effect of water; the drilling depth, height and perpendicularity are all adjustable, and the drilling machine is especially suitable for drilling coal mine underground gas extracting and exhausting holes, advanced detection holes, fluid injection fire-fighting holes, coal bed water injection holes, outburst prevention pressure releasing holes and geological exploring holes and other engineering hole construction.

Owner:宿州学院

Method for superfine grinding of walnut dregs by wet process by employing ball mill

The invention discloses superfine grinding technology of walnut dregs by a wet process, belonging to the technical field of agricultural products and food processing. The method comprises the process flows of coarse grinding of walnut dregs, mixture of coarsely ground powder of walnut dregs and water and superfine grinding by the wet process by a ball mill, etc. The temperature is not raised in the process of grinding; therefore, the nutrient components of the walnut dregs can not be damaged. In terms of kg / L, the ratio of coarse powder of walnut dregs to water is 1:(8-14). The parameters of the superfine grinding technology by the wet process by the ball mill are as follows: the ball-to-powder weight ratio is (1-6):10, the media are phi10mm zirconia balls, the milk grinding time is 30-120min and d50 of the walnut milk granule is 6-17mu m. The superfine grinding technology lays the foundation for subsequent preparation of walnut powder through spray drying and the application range of the superfine grinding technology in the food industry is broadened.

Owner:XINJIANG UNIVERSITY

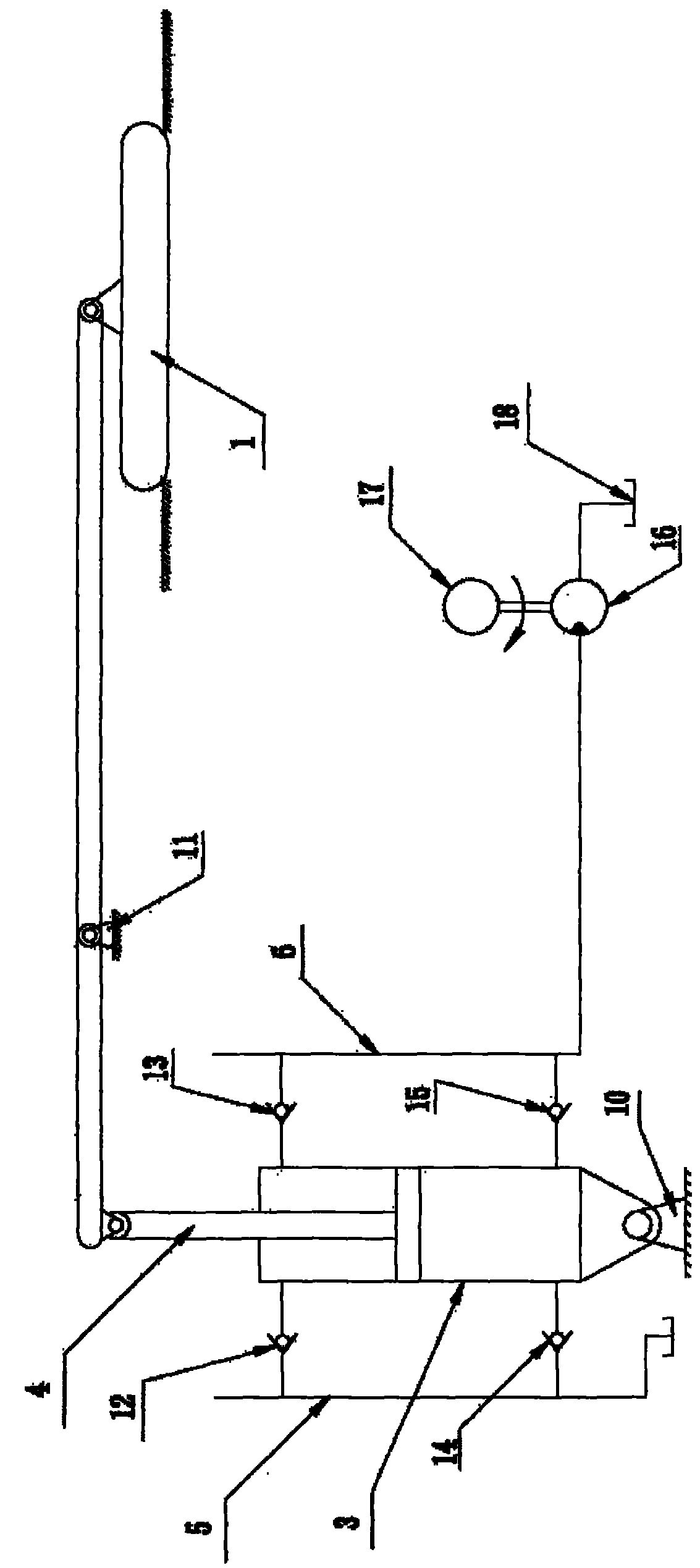

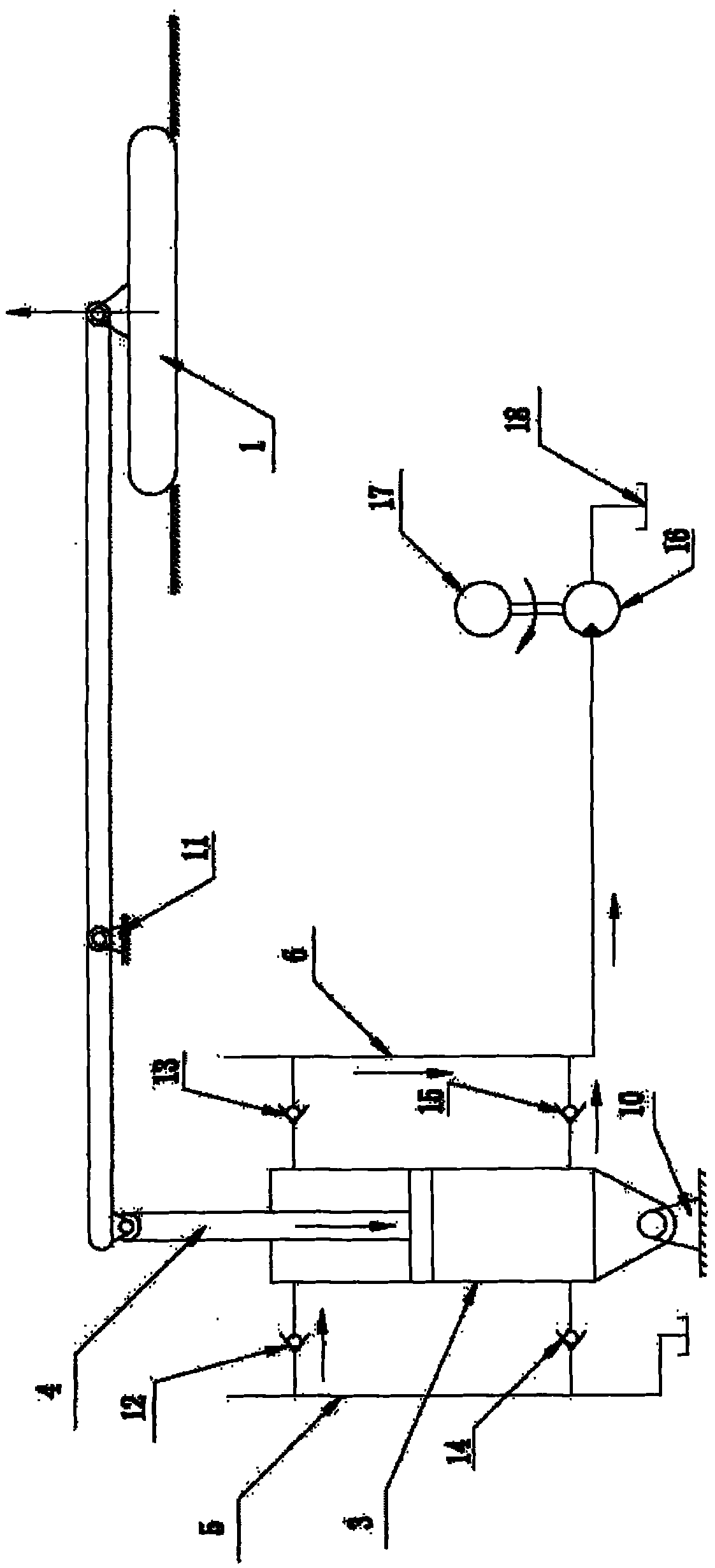

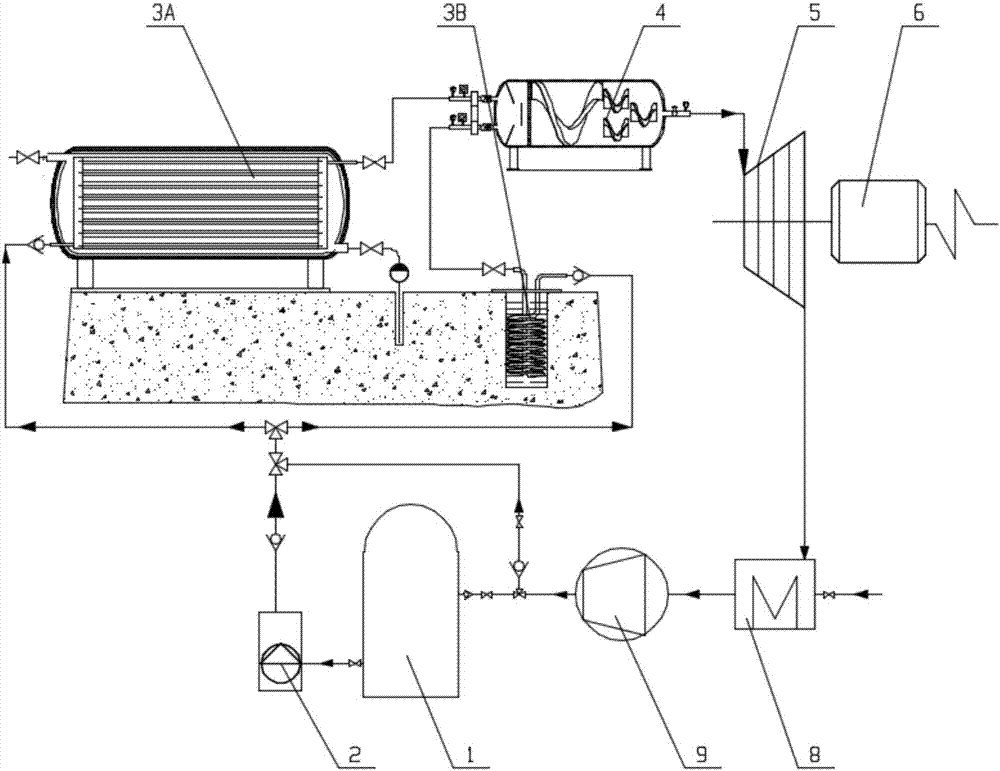

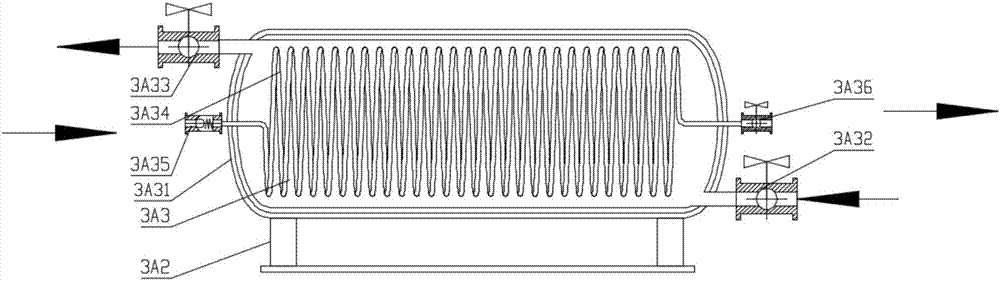

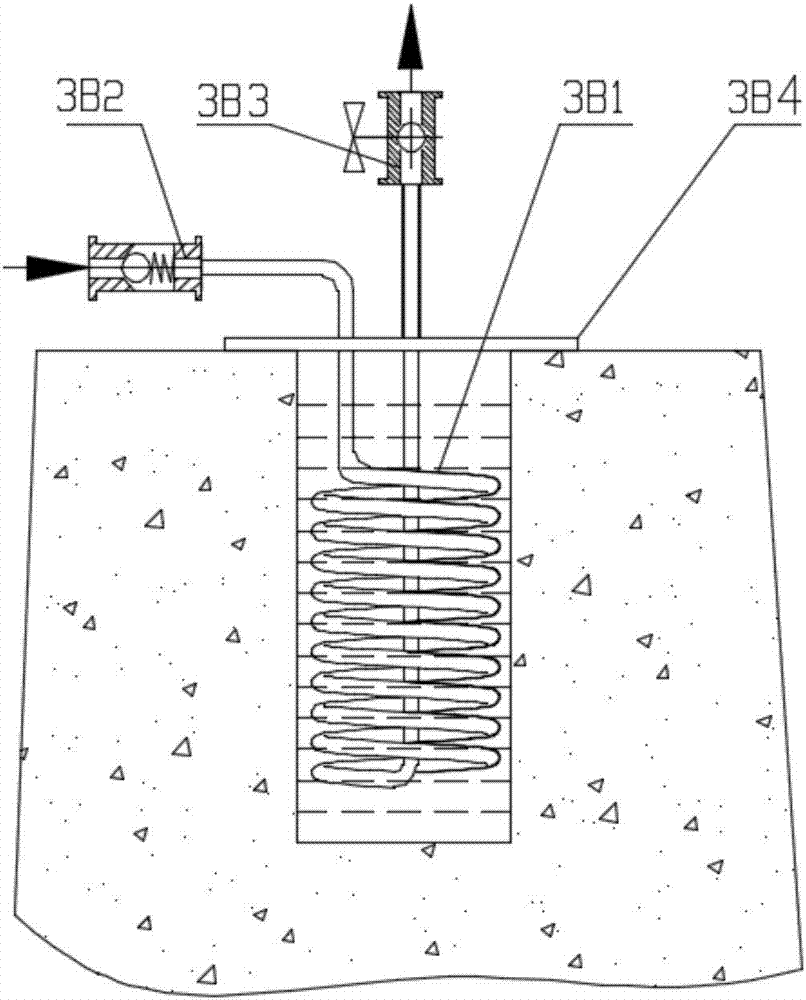

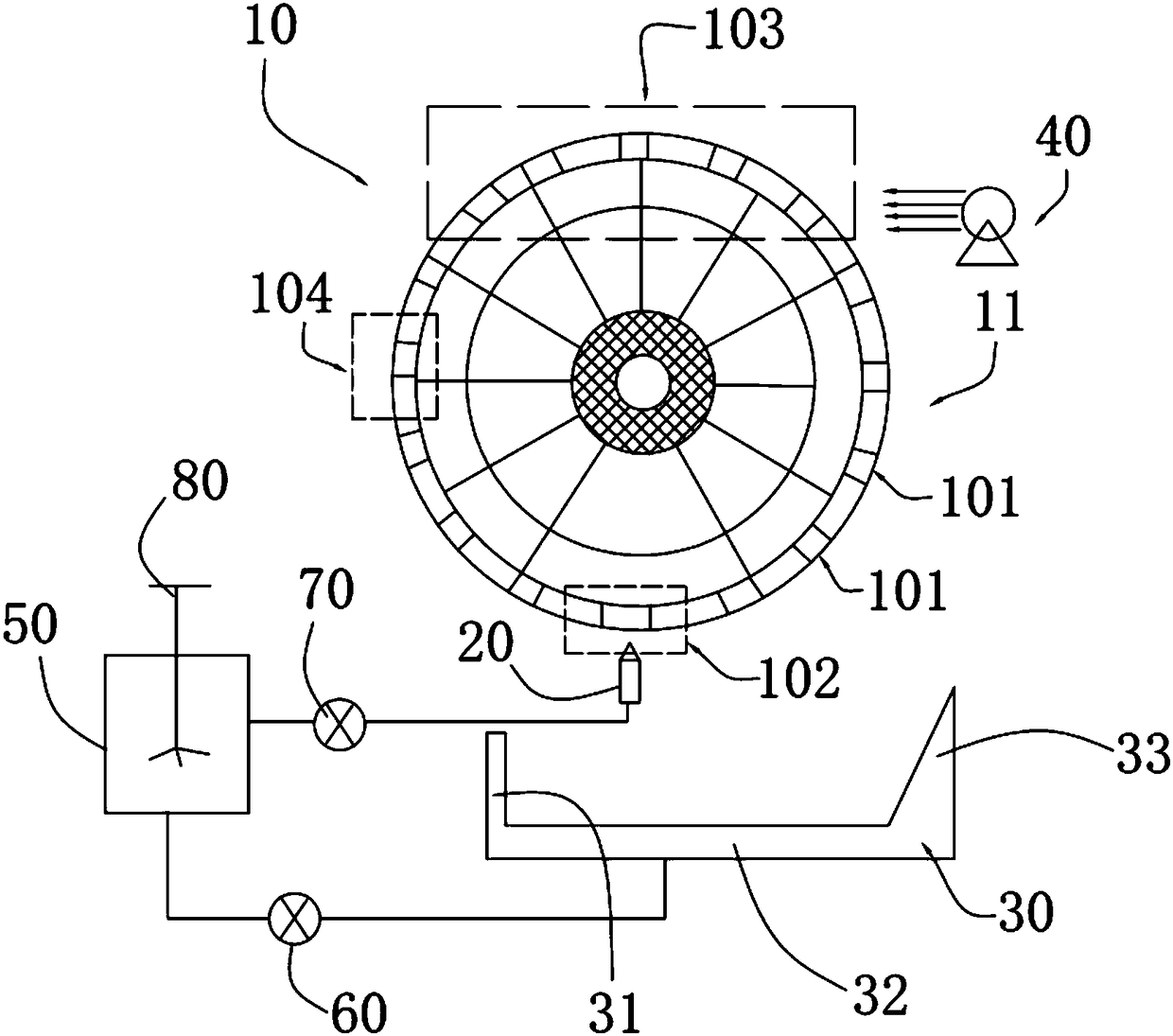

Device system and method for achieving carbon dioxide cyclic power generation through geothermal energy

ActiveCN106870043AAchieve sustainable useEfficient recyclingGeothermal energy generationGeothermal systemsThermal energyCo2 storage

The invention provides a device system and method for achieving carbon dioxide cyclic power generation through geothermal energy. The disclosed system comprises a liquid CO2 storage tank, a high-pressure pump / compressor, a geothermal energy CO2 energy storage device, a terrestrial heat production well, a steady flow adjuster, a turbine / piston expander, a power generator, a cooler and a CO2 compressor. The invention further discloses a method, in the method, low-pressure liquid CO2 fluid serves as a working medium, geothermal water and low-temperature CO2 fluid exchange heat with each other to form supercritical CO2 fluid different in temperature, pressure and energy density, then the equal-pressure supercritical CO2 fluid is achieved through adjustment of the steady flow adjuster, and then power generation is conducted. According to the device system and the method, heat energy in the geothermal water with the temperature ranging from 70 DEG C to 300 DEG C in the terrestrial heat production well is adopted for conducting energy storage on the liquid CO2, carbon dioxide cyclic power generation is achieved after tempering, the heat energy can be efficiently recycled, and high heat efficiency is improved; and energy in the terrestrial heat is effectively stored and utilized, and flexible adjustment and utilization of energy are achieved.

Owner:长沙紫宸科技开发有限公司

Ceramic slurry jetting forming device

InactiveCN108274584AReduce pinholesSimple structureAuxillary shaping apparatusClay mixing apparatusAutomatic controlMetallurgy

The invention provides a ceramic slurry jetting forming device. The ceramic slurry jetting forming device comprises a rotating component used for fixing multiple molds, and multiple nozzles used for slurry jetting; the multiple molds rotate along with the rotating component, and when slurry jetting openings of the molds right face the nozzles, the nozzles jet the slurry into the molds to form blank bodies. According to the ceramic slurry jetting forming device, the nozzles are used for jetting the slurry into the slurry jetting openings of the molds, the blank bodies are formed in the molds, the structure is simple, automatic control is easy, production efficiency can be improved, and manual cost is reduced.

Owner:许光权

Power generating method

InactiveCN1609446AImprove power generation efficiencySolve the energy crisisMachines/enginesMechanical power devicesElectric energyBoiling point

The present invention provides one kind of electricity generating method and features that liquid work medium of proper boiling point is enclosed inside circulation system and boiled in the place with relatively lower altitude to form vapor, the vapor is pipeline transferred to the place with higher altitude and condensed to obtain increased potential energy and cold energy, the liquid work medium flows in pipeline to the lower altitude place to drive the hydraulic generator to produce electricity before entering into the next circulation while co-producing great amount one cold energy. The smaller the temperature difference, the higher the electricity generating efficiency. The present invention makes it possible to utilize various low-grade energy to produce great amount of electric energy.

Owner:陈培豪

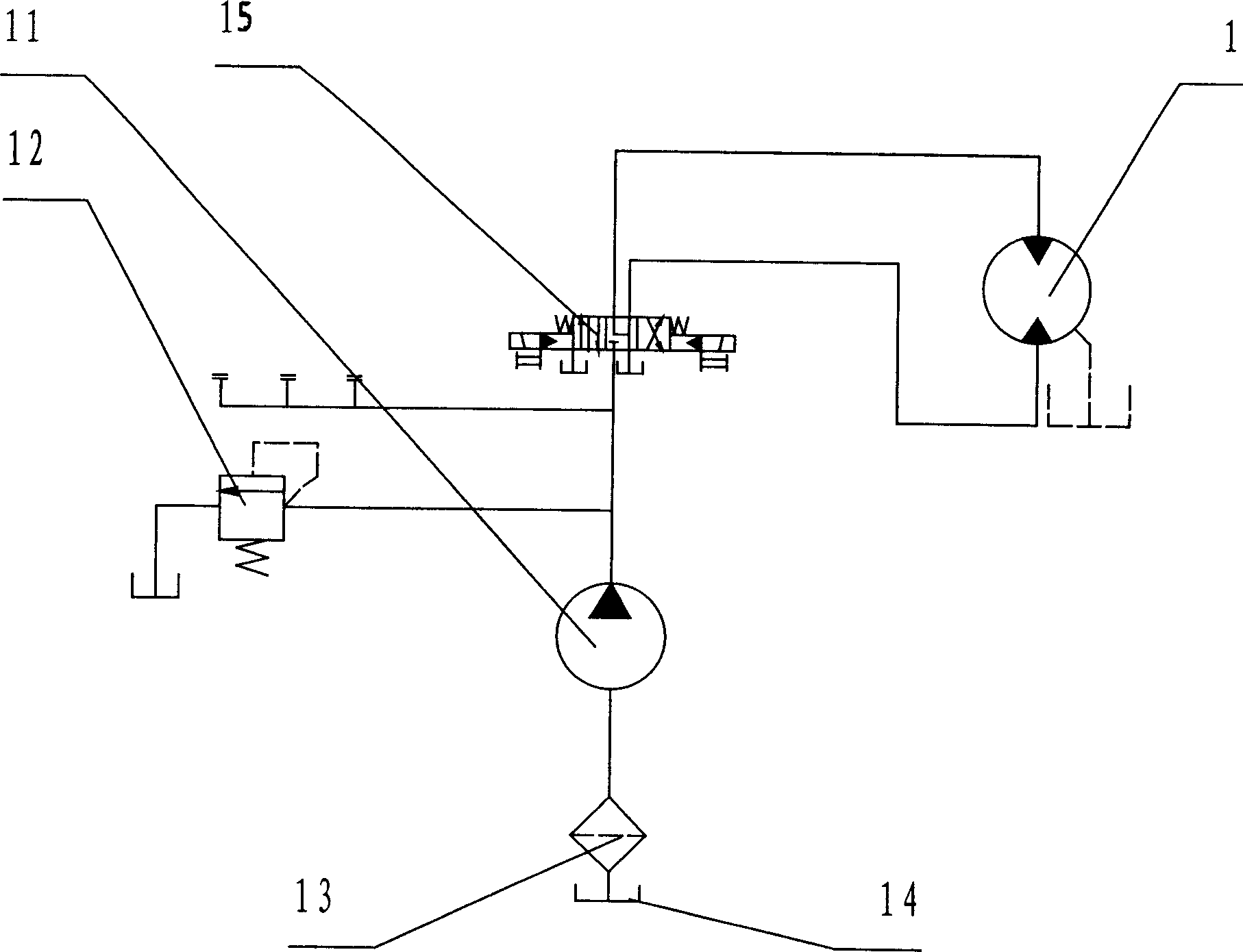

Hydraulic controllable sluice valve

InactiveCN1793707AAdjust running speedSmooth connectionOperating means/releasing devices for valvesSlide valveHydraulic motorFuel tank

The invention is a hydraulic controllable gate valve, belonging to a hydraulic driven gate valve, applied to water feeding and discharging engineering and comprising a main body and an auxiliary hydraulic pumping station; the main body comprises valve body, hydraulic motor, connection frame, drive nut, screw rod, clamp ring and copper cover; the hydraulic motor is connected with the drive nut through spline, the drive nut is axially located through the clamp ring and connection frame, and the hydraulic motor and the clamp ring are both fixed on the connection frame; the screw rod is connected with the drive nut through spiral auxiliary; the auxiliary hydraulic pump station comprises oil tank, hydraulic pump, electromagnetic directional valve and overflow valve; the inlet of the hydraulic pump is connected with the oil tank and its outlet is connected with the mouth P of the electromagnetic directional valve, the hydraulic motor is connected with mouths A and B of the electromagnetic directional valve, and the overflow valve is connected with the outlet end of the hydraulic pump.

Owner:TAIYUAN UNIV OF TECH

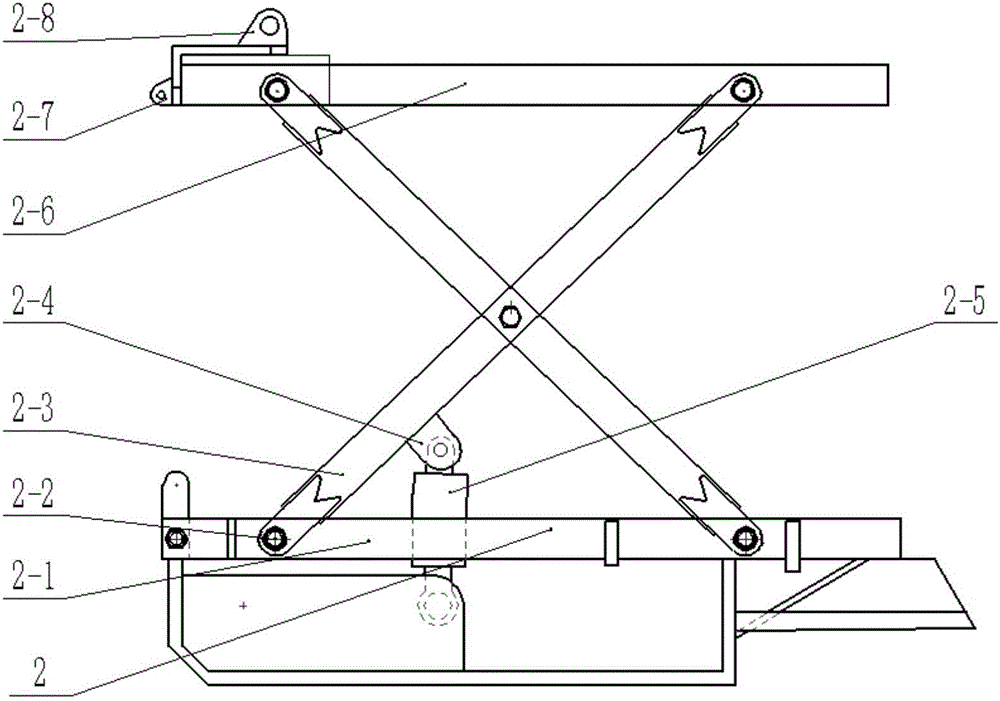

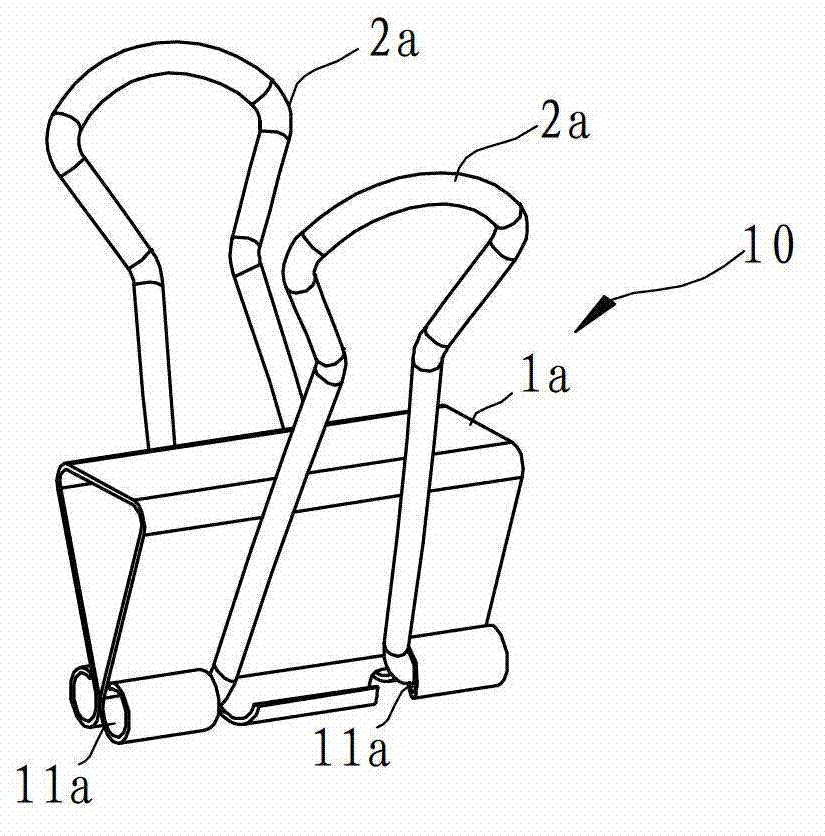

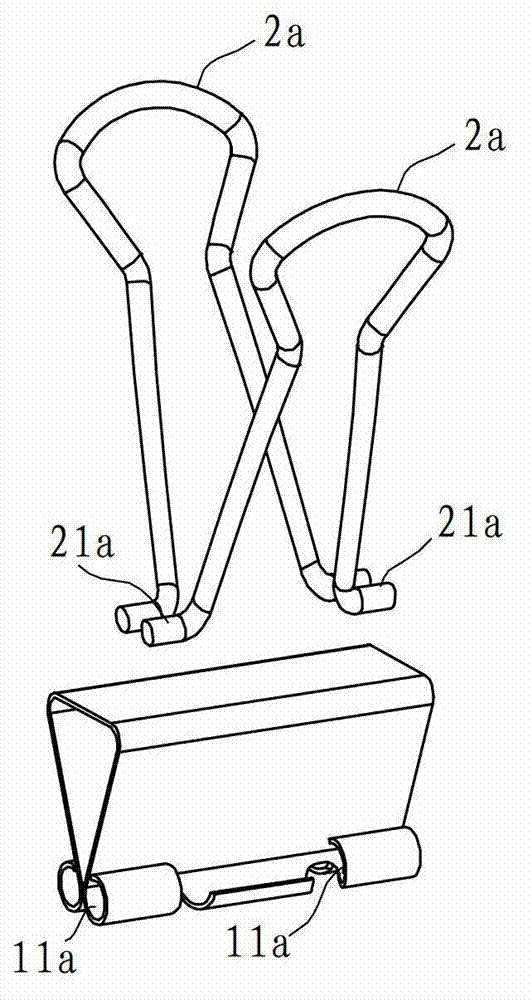

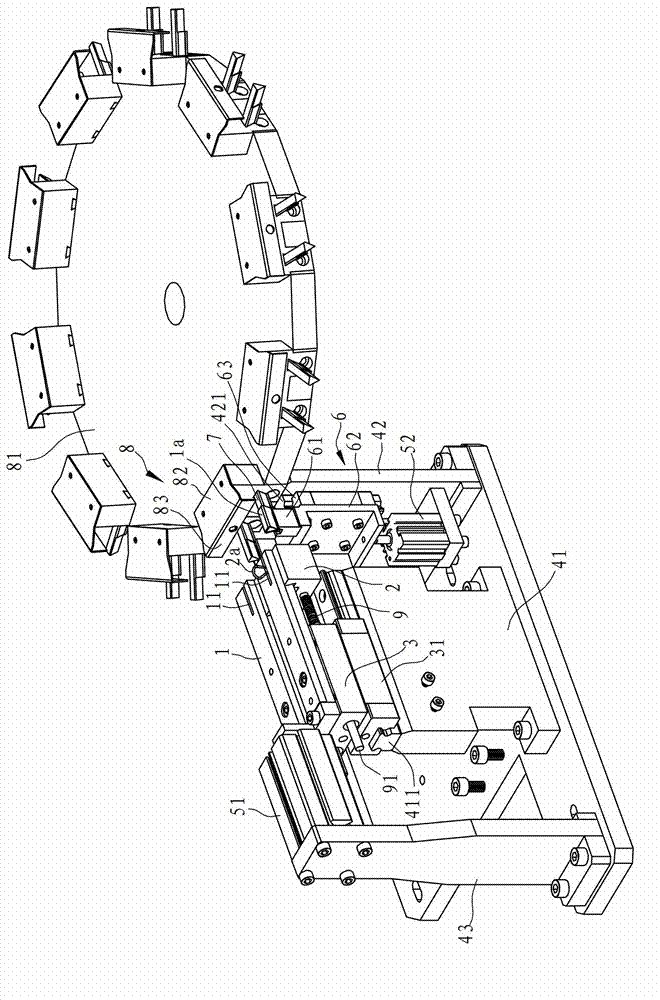

Binder chip assembling mechanism

InactiveCN102922277ALiberate human laborQuick assemblyAssembly machinesAutomatic controlVertical cylinder

A binder chip assembling mechanism is characterized by comprising a positioning block, a baffle, a pressing block, a vertical cylinder, a horizontal cylinder, a sliding block, a second push block and a spring, wherein the positioning block can be matched with a hollow inner cavity of a body, the baffle can prevent a wrench from moving forwards continuously, and the pressing block is arranged under the positioning block and can press the body on the positioning block from bottom to top; a gap and an inclined groove for arranging the wrench is arranged between a first push block and the positioning block, the front end of the inclined groove is opened, and the sliding block is arranged at the bottom of the first push block; and the first push block extends from the front end of the second push block. Compared with the prior art, the binder chip assembling mechanism has the advantages that the whole assembling process is fast and convenient, strong in maneuverability and capable of achieving automatic control easily.

Owner:宁波江北昌晟自动化科技有限公司

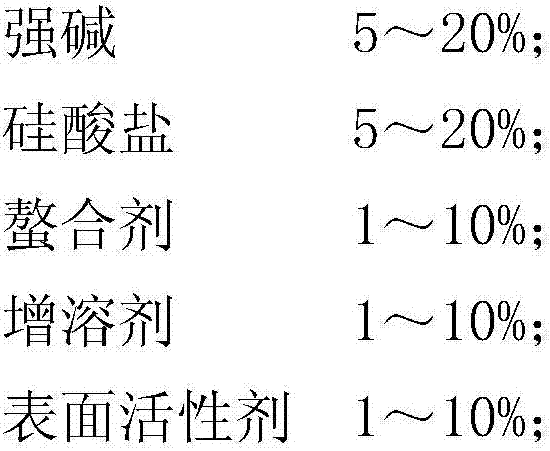

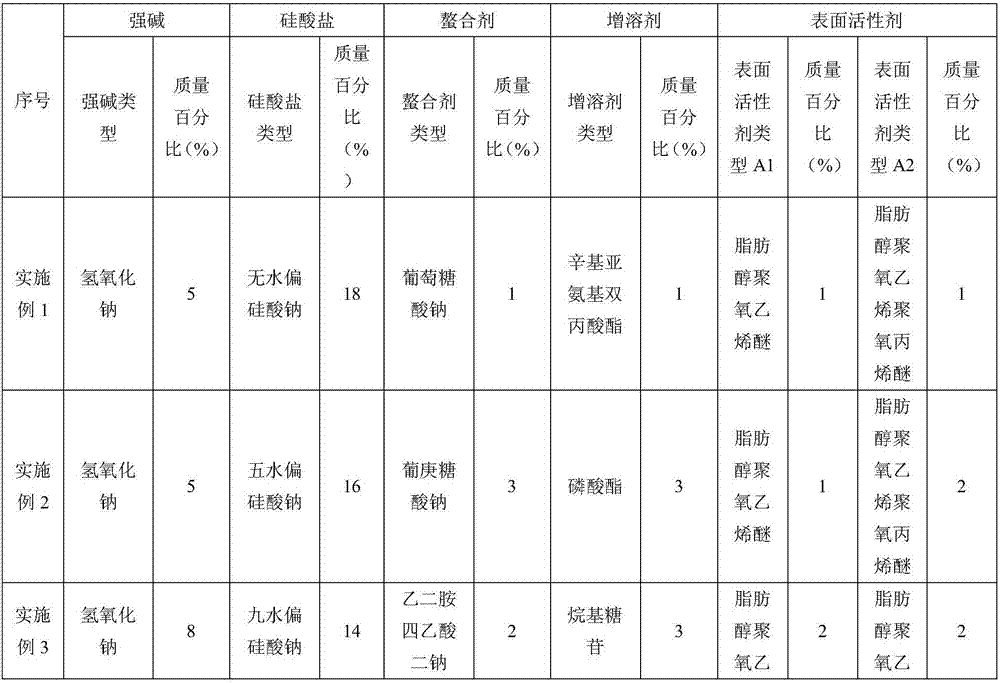

Environment-friendly type liquid degreasing agent for cleaning strip steel before annealing

The invention discloses an environment-friendly liquid degreasing agent used for cleaning steel strips before annealing. After the environment-friendly liquid degreasing agent is applied to the surface of the steel strip, a silicon dioxide layer is adsorbed on the surface of the steel strip. The environment-friendly liquid degreasing agent of the present invention is easy to add in the production process because it is a liquid type degreasing agent, thereby facilitating the realization of automatic control. In addition, the environment-friendly degreasing agent does not use phosphorus-containing additives, has low harm to the environment, and has good environmental friendliness.

Owner:SHANGHAI PARKERIZING CO LTD

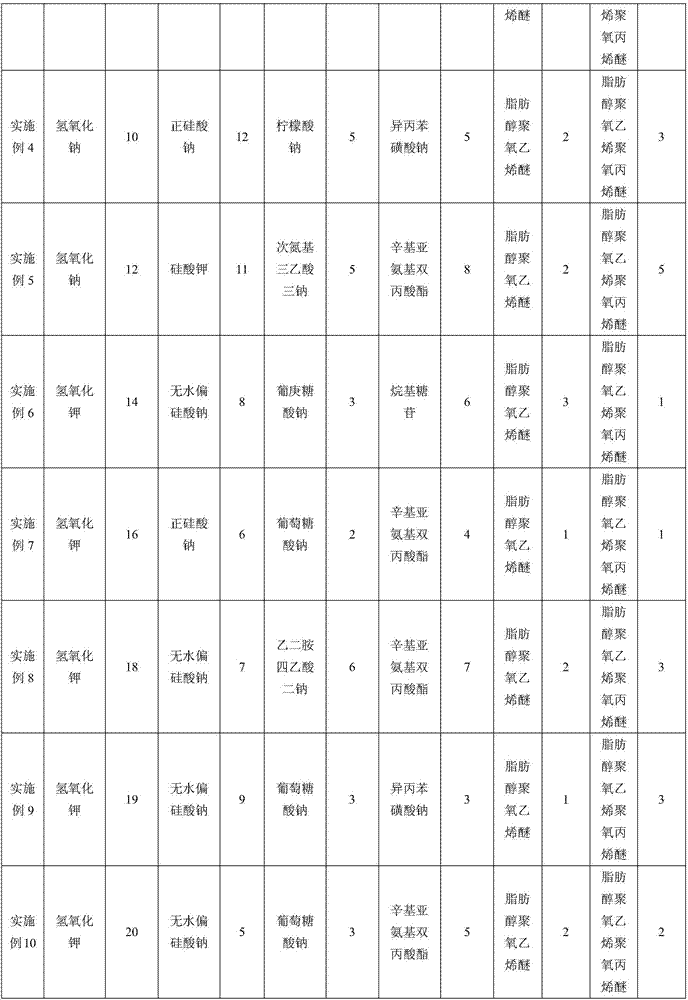

Rotary kiln for calcining refinery coke

The invention discloses a petroleum coke calcining rotary kiln, which comprises a rotary kiln(9); an insert plate valve(1) is arranged below a calcining front chamber; an adhesive tape constant feeder(2) is arranged below the insert plate valve, and an adhesive tape conveyer(3) is arranged behind the adhesive tape constant feeder (2) and connected with the rotary kiln(9) by an oblique cutting feed tipping tube of an electric insert plate valve(6); the tail part of the rotary kiln(9) is connected with a dust deposition chamber(8), and the head part of the rotary kiln(9) is connected with a cooling machine(16) and provided with a burner nozzle(13) and a burner nozzle hanger(14); the petroleum coke calcining rotary kiln is also provided with a one-time combustion fan(10) matched with the burner nozzle; and a dust-containing waste gas processing system(15) is arranged beside the cooling machine(16). The petroleum coke calcining rotary kiln has the advantages of improving the unit volume capacity, greatly enhancing comprehensive utilization of waste heat and adaptability of other calcining materials such as needle coke, anthracite and the like, reducing burning loss of charcoal, saving raw materials and energy, improving automatization level and reducing labor intensity of a worker.

Owner:GUIYANG AL-MG DESIGN & RES INST

Harbor chemical wastewater processing method

InactiveCN101508506AImprove oxygen transfer efficiencyIncrease concentrationFatty/oily/floating substances removal devicesTreatment with aerobic and anaerobic processesAutomatic controlOil separation

The invention discloses a treatment method for port chemicals wastewater. The method comprises the following steps: the oil separation-air floating treatment, the biological fluidized bed treatment, the anaerobic settling tank treatment and the ozone aeration biological filter integral device treatment. The port chemicals wastewater is retained for 1 to 3 hours in an oil separation tank; and the surface load of the oil separation tank is 0.8 to 1.5m / m.h. The hydraulic power is retained for 6 to 18 hours in a biological fluidized bed; and the gas-water ratio is 10-30:1. The hydraulic power is retained for 12 to 36 hours in an anaerobic settling tank. Then after the wastewater is retained for 1 to 2 hours in an intermediate regulation tank, 50 to 200 mg / L of ozone is added. After being oxidized by the ozone, the wastewater undergoes the biochemical treatment in the aeration biological filter; and the hydraulic power is retained for 6 to 12 hours in the aeration biological filter. The method realizes the miniaturization of equipment, reduces the floor space and energy consumption, and has stable treatment effect. The automatic control on the wastewater treatment process is easily realized and the personnel operation is simple, and the method has good industrialized application prospect.

Owner:SOUTH CHINA UNIV OF TECH

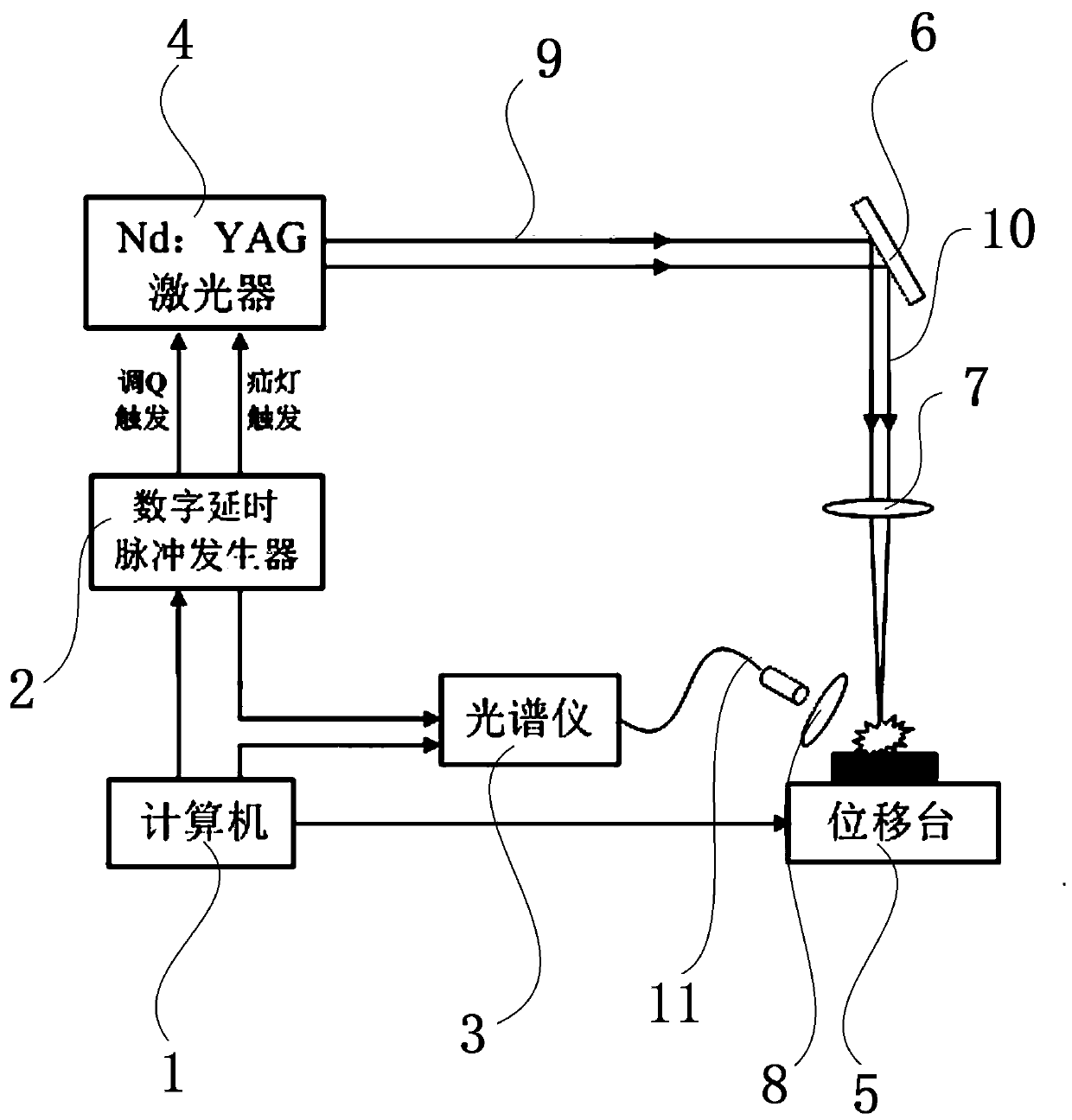

Laser induced breakdown spectroscopy (LIBS)-based dangerous waste detection system

PendingCN108195825ADetection securityQuick checkAnalysis by thermal excitationElemental compositionLaser scalpel

The invention discloses a laser induced breakdown spectroscopy (LIBS)-based dangerous waste detection system. The system comprises a computer, a digital delay pulse generator, a spectrometer, a laser,a displacement workbench, a high reflective mirror, a first focusing lens and a second focusing lens; the LIBS technology takes a laser as a plasma light source, characteristic spectrum and spectraldata transmitted in the high-temperature plasma cooling process are detected and processed, and analysis on the elemental composition and the content of the substances is realized. The system performsdeep analysis on the formation principle and the plasma spectral radiation mechanism of the laser induced plasma and builds a set of LIBS detection experimental system platform. LIBS experiment parameters are selected and optimized, a relation curve of different laser pulse energy, sample vertical displacement and C element spectral intensity is established, and optimal laser pulse energy and distance from a lens to the surface of the sample are determined.

Owner:SHANGHAI SAFBON WATER SERVICE CO LTD

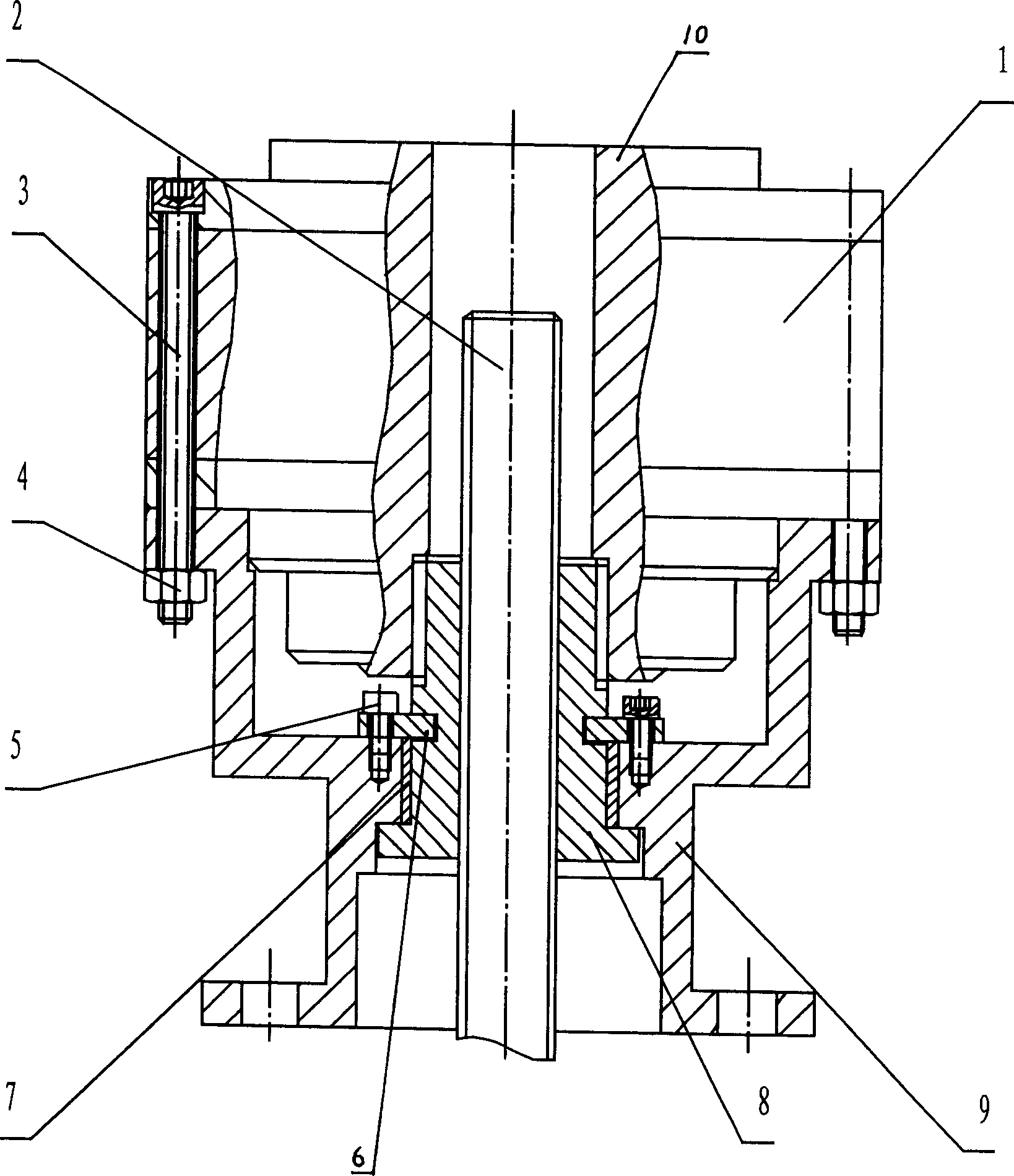

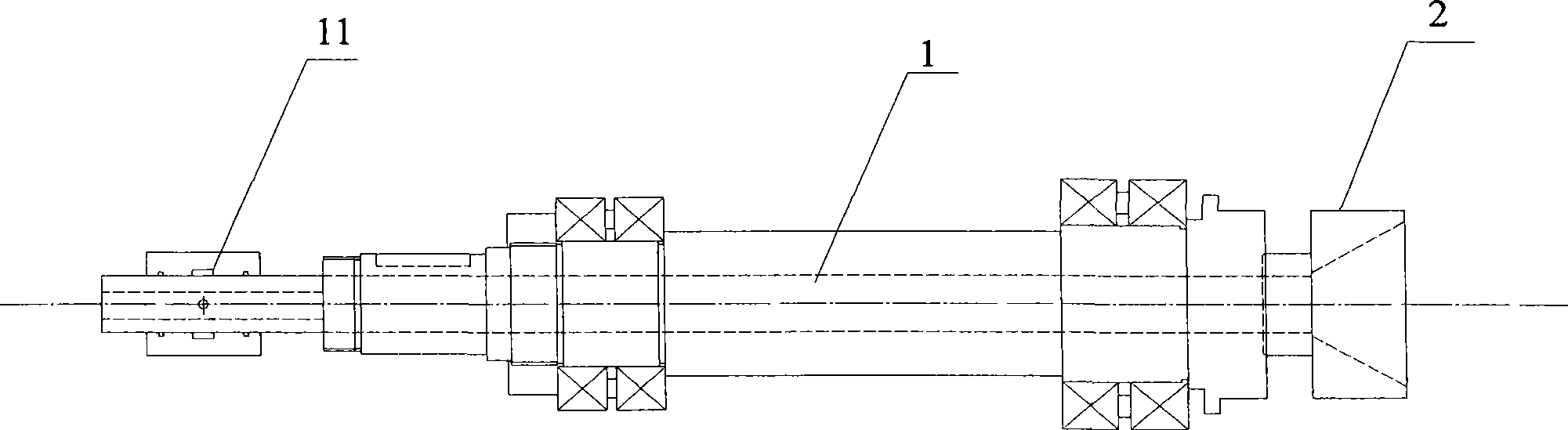

Method and device for finish-machining spherical ingot

InactiveCN101456080ACut evenlyEnsure eccentricityFeeding apparatusTurning machinesSurface finishAutomatic control

The invention relates to the technical field of ball blank processing, in particular to a method and a device for mechanically processing a high-temperature gas-cooled reactor fuel element ball blank or graphite ball blank. A main shaft holds the ball blank to rotate along an axial lead, a cutter is fed and reaches in place to move in a plane of the main shaft using a ball center of the ball blank as a circle center in an arc shape of 90 degrees, so as to finish semi-ball processing, and finishing of the whole ball blank can be finished through twice semi-ball processing. The device system can ensure even cutting of the whole ball blank, so as to ensure that a fuel-free area of fuel element produces eccentricity due to machining; in addition, when the method and the device are used for processing, surface finish can be ensured by feeding speed; the whole operating process is easy to realize automatic control, particularly when a double-shaft mechanism with the characteristics is adopted, the processing of two semi-balls can be finished continuously; and compared with the prior machine tool, precision of work pieces and working efficiency are improved greatly.

Owner:TSINGHUA UNIV +1

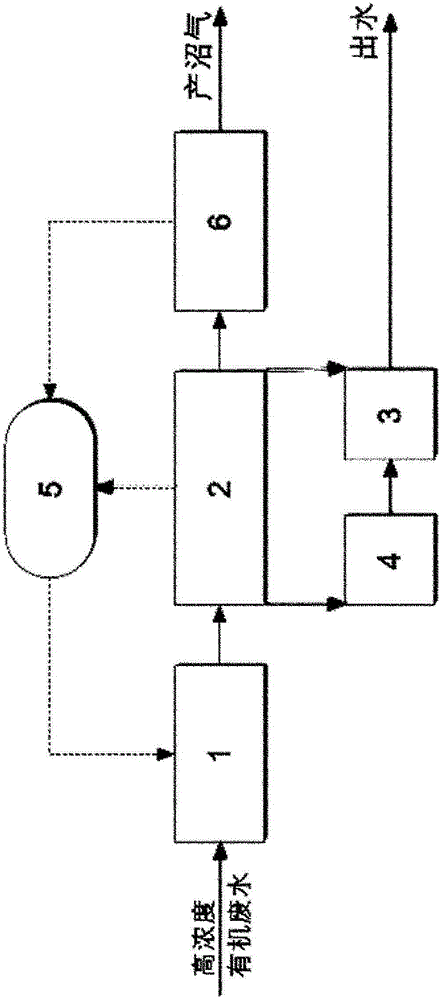

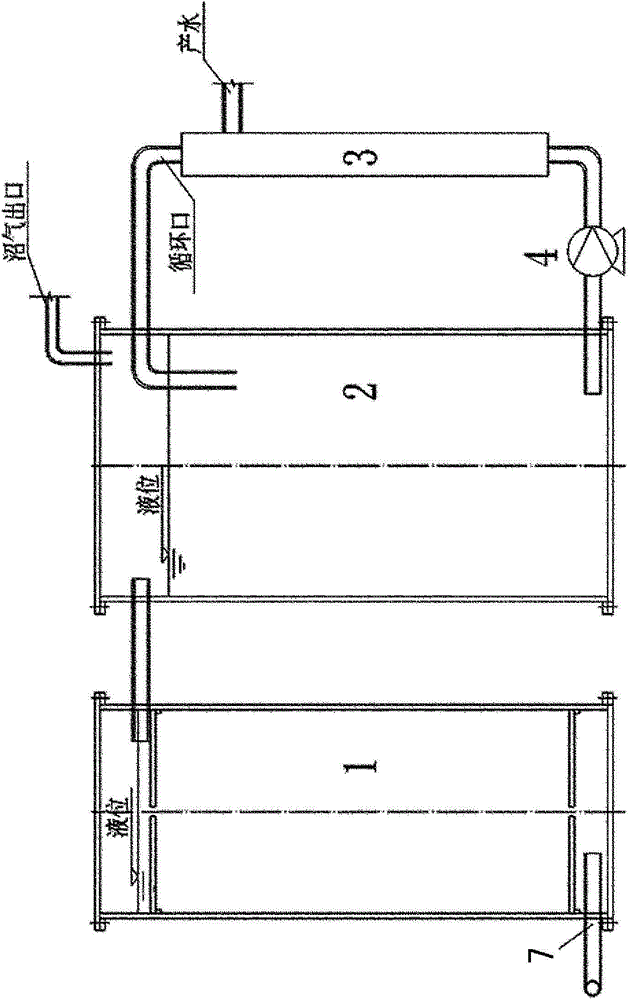

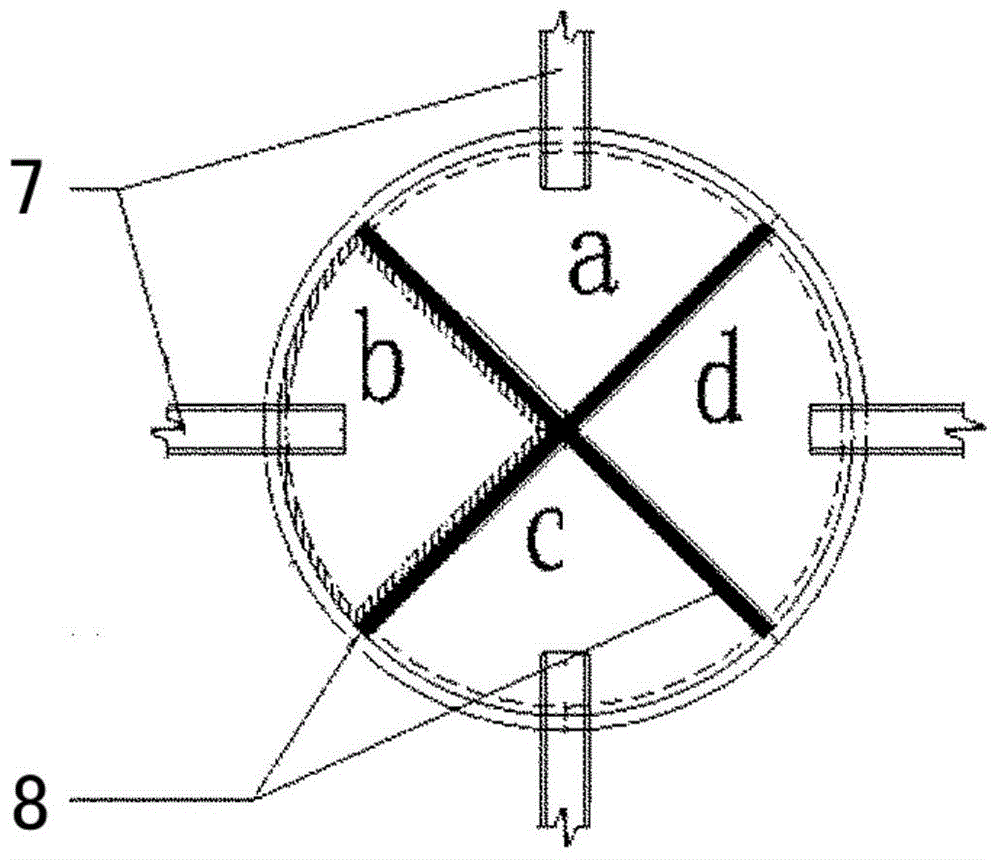

Method and device for treating organic wastewater with two-phase anaerobic tubular membrane bioreactor

ActiveCN104478172AEasy maintenanceShort processWater treatment parameter controlSpecific water treatment objectivesHigh concentrationGeneration rate

The invention discloses a method for treating organic wastewater with a two-phase anaerobic tubular membrane bioreactor. The method comprises the following steps of: adding anaerobic digested sludge into an up-flow complex acid-production reactor and a completely mixed methane-production reactor in an inoculating way; enabling organic wastewater to flow through all reaction chambers in the up-flow complex acid-production reactor in sequence and enter the completely mixed methane-production reactor, and adding wastewater into the completely mixed methane-production reactor by controlling the gas generation rate and the pH value; enabling a methane-phase mixed solution in the completely mixed methane-production reactor to scour the inner side of a tubular membrane component and flow back to the completely mixed methane-production reactor in a circulating way so as to be mixed hydraulically; separating the methane-phase mixed solution by using the membrane component to obtain effluent and methane gas; and collecting the methane gas at the methane gas outlet of the completely mixed methane-production reactor. The invention further discloses a device for implementing the method. The method and the device can be used for treating high-concentration organic wastewater so that the organic wastewater reaches the standard in a short process, and the method and the device can be also used for treating low-concentration organic wastewater so that the discharge of methane dissolved in effluent as a greenhouse gas can be reduced.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Method for desulfurization of coal by electrochemical catalytic oxidation

InactiveCN101899351AReduce material consumptionLess side effectsSolid fuelsEnvironmental chemistryStrong acids

The invention relates to a method for desulfurization of coal by electrochemical catalytic oxidation, although the exiting coal chemical desulfurization methods can almost remove all inorganic sulfur and part of organic sulfur in the coal, most of the methods need strong acid, strong base and strong oxidants and need to be operated under the conditions of high temperature and high pressure, the process conditions are harsh and the cost is high; furthermore, a plurality of chemical methods can cause series damages to the structure and the nature of the coal. The invention discloses the method for desulfurization of the coal by the electrochemical catalytic oxidation, which comprises the following steps: (A) adopting NaI with the concentration of 1.5mol / L as supporting electrolyte, weighing a certain amount of the electrolyte, adding into an anode chamber in an electrolysis bath, simultaneously adding the supporting electrolyte in the same volume and the same composition into a cathode chamber, and well connecting a gas collecting system; (B) adding a coal sample with the particle size of below minus 200 meshes into the anode chamber of the electrolysis bath, and controlling the concentration of coal slurry at 0.05g / ml; (C) connecting with circulating water of a water bath tank, and energizing for electrolysis; and (D) filtering electrolyte solution after energizing for 4 hours, washing the coal sample, drying, weighing and carrying out sulfur, calorific value, ash content and infrared spectrum analysis. The technology is used for the coal desulfurization.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com