Method and device for finish-machining spherical ingot

A technology for spherical blanks and processing steps, which is applied in the field of spherical blank processing, can solve the problems that have not been reported, the accuracy and efficiency are difficult to meet the requirements, etc., and achieve the effects of improving workpiece accuracy and work efficiency, easy automatic control, and ensuring surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

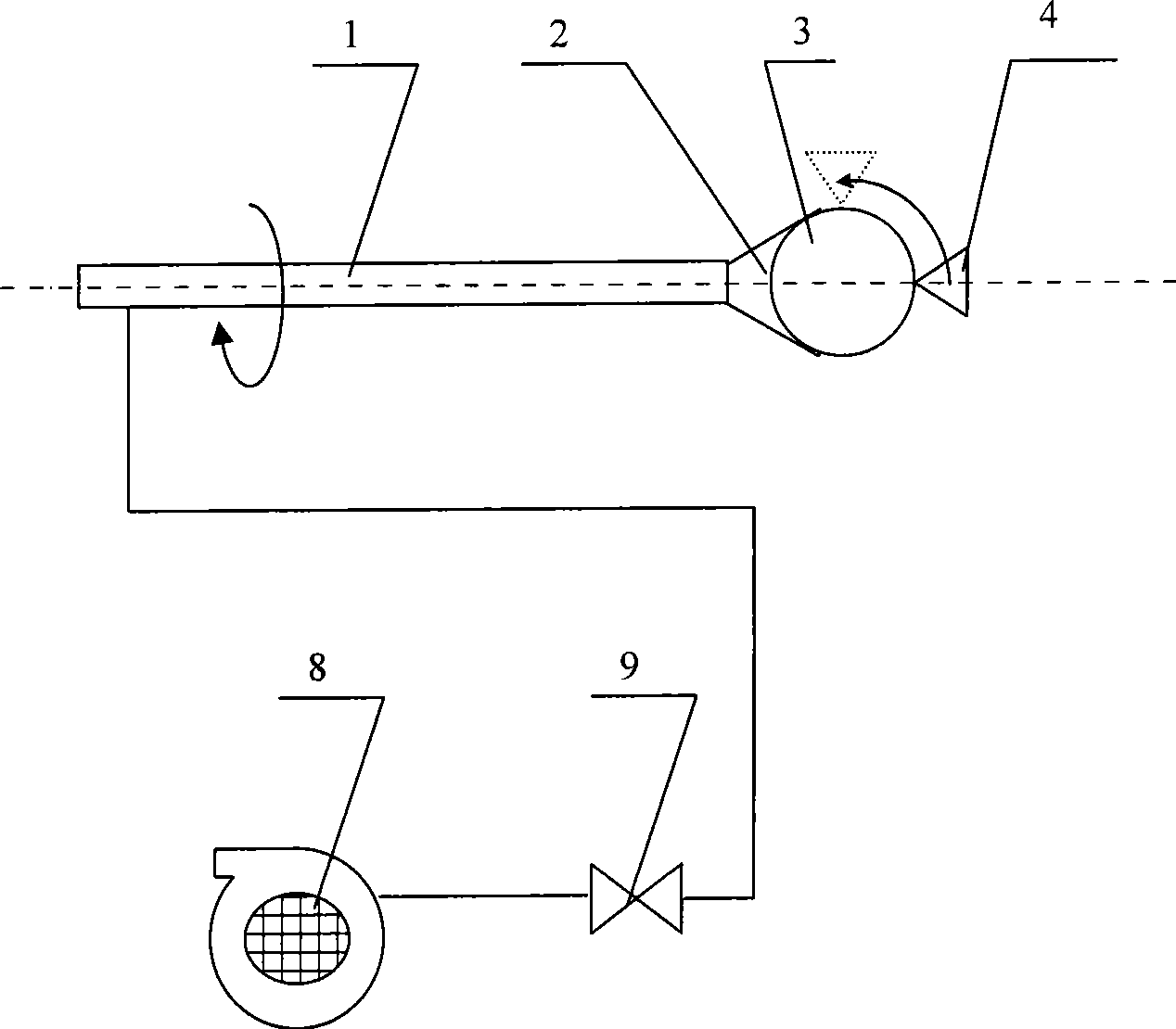

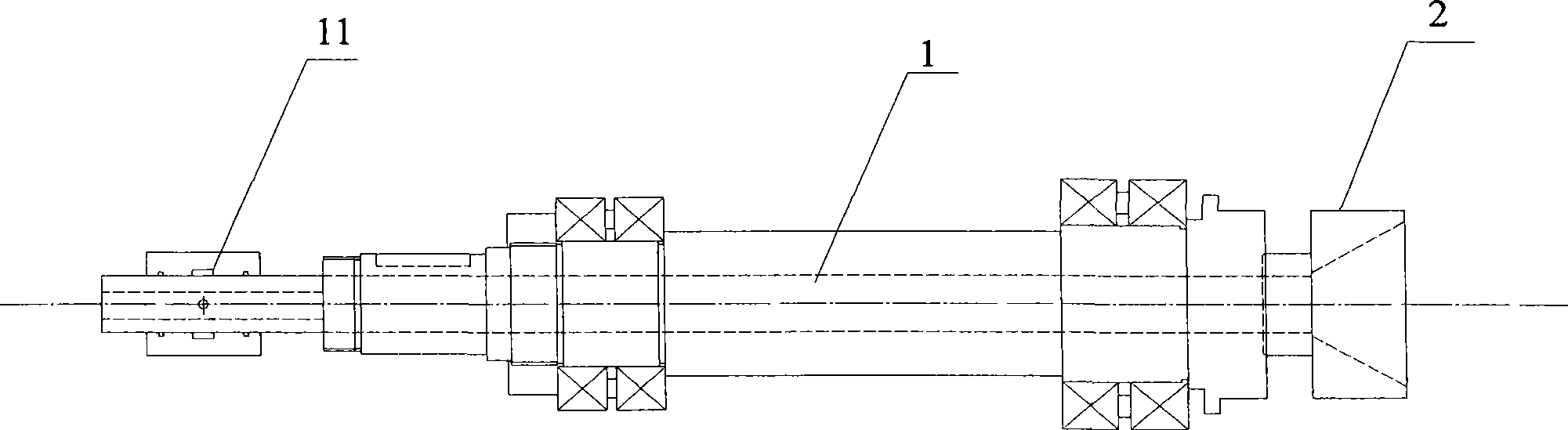

[0025] figure 1 It is a schematic structural view of the device in the form of a single spindle in the present invention. One end of the hollow main shaft 1 is installed with a trumpet-shaped vacuum suction cup clamping tool 2, and the main shaft tool 4 performs a lateral feed movement in the direction of the center line of the main shaft 1 or a 90° arc-shaped movement in the plane of the main shaft 1; the main shaft The other end of the valve is connected with the electromagnetic valve 9 and the vacuum pump 8 in turn through the moving fit joint 11 and the vacuum pipeline.

[0026] When processing the billet, first start the vacuum pump 8, open the solenoid valve 9 to conduct the vacuum pipeline, and then place the billet 3 on the clamping tool 2; after the billet 3 is fixed, the spindle 1 starts to rotate around the axis, and at the same time The tool holder drives the spindle tool 4 to feed the ball blank 3 along the axis; after the feed is in place, the tool 4 takes the c...

Embodiment 2

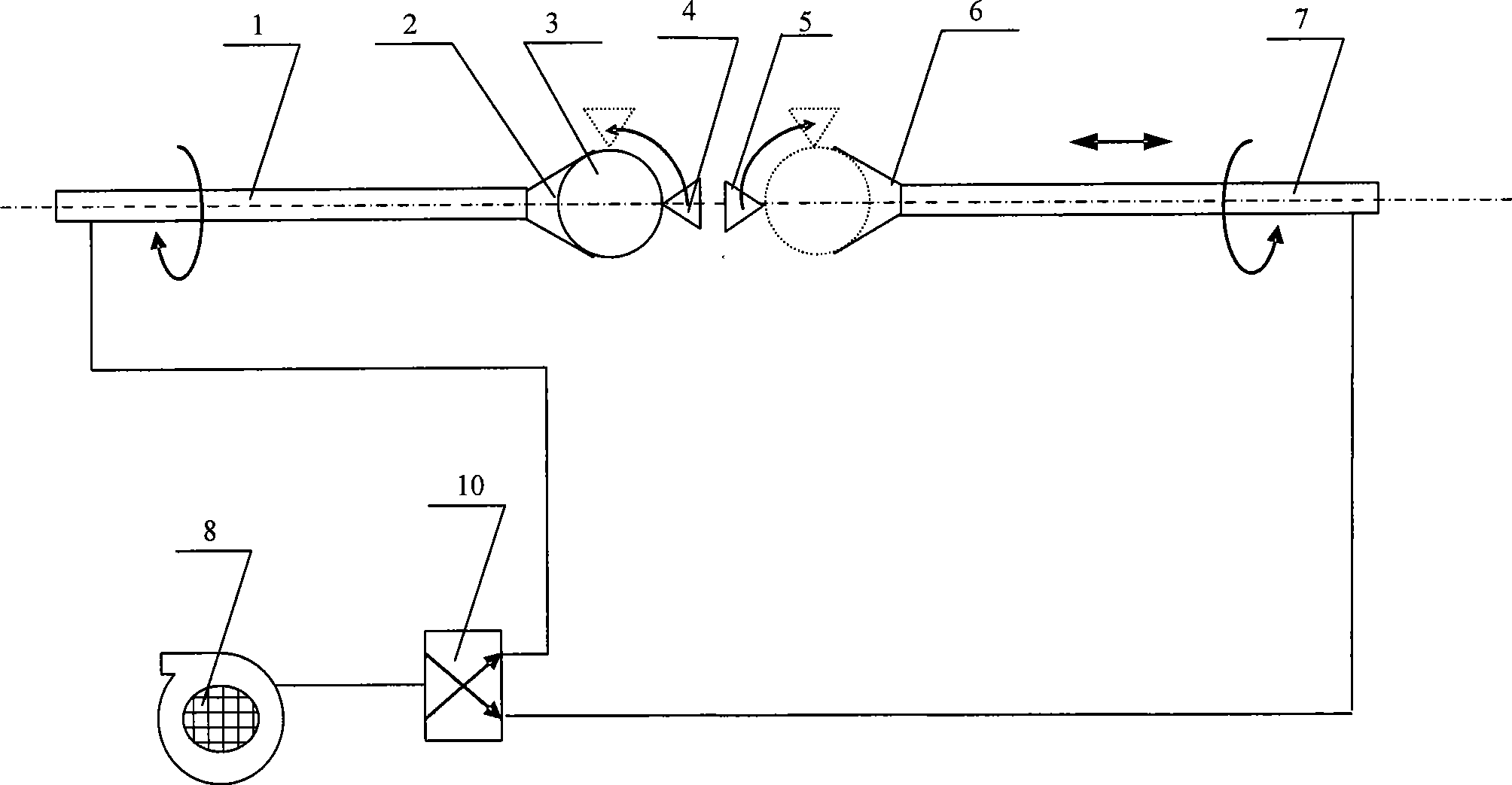

[0028] figure 2 It is a schematic diagram of the structure of the device in the form of dual spindles in the present invention. One end of the hollow main shaft 1 is installed with a trumpet-shaped vacuum suction cup clamping tool 2, and the main shaft tool 4 performs a lateral feed movement in the direction of the center line of the main shaft 1 or a 90° arc-shaped movement in the plane of the main shaft 1; the main shaft 1 is fixed in the direction of its axis and only rotates around its axis.

[0029] The sub-spindle 7 with the same structure as the main shaft 1 is on the same axis as the main shaft 1, and the end of the sub-spindle 7 close to the ball blank 3 is provided with a vacuum suction cup type sub-spindle clamping tool 6, and the sub-spindle tool 5 is formed along the center line of the sub-spindle 7. Lateral feed movement or 90° arc-shaped movement in the plane where the sub-spindle 7 is located; both the main shaft 1 and the sub-spindle 7 are connected to the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com