Automatic cutter grinding device of silage maize harvester and silage maize harvester automatically grinding cutters

An automatic knife sharpening and silage machine technology, applied in agricultural machinery and implements, other manufacturing equipment/tools, cutting equipment, etc., can solve the problems of complex structure and control system, difficult manufacturing and processing, and high cost, and achieve difficult manufacturing and processing. Small size, simple structure, and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific structure, working principle and working process content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

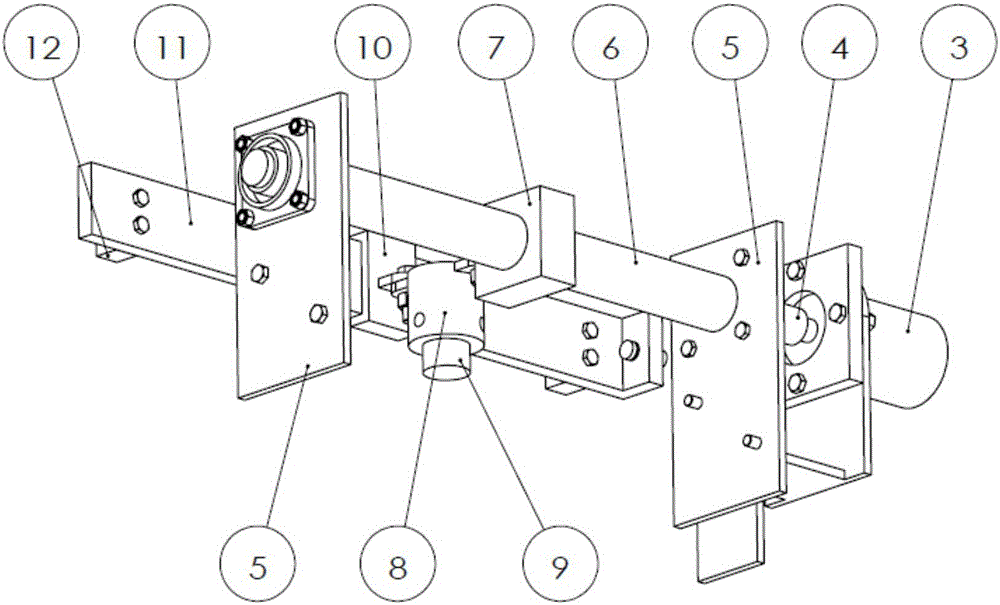

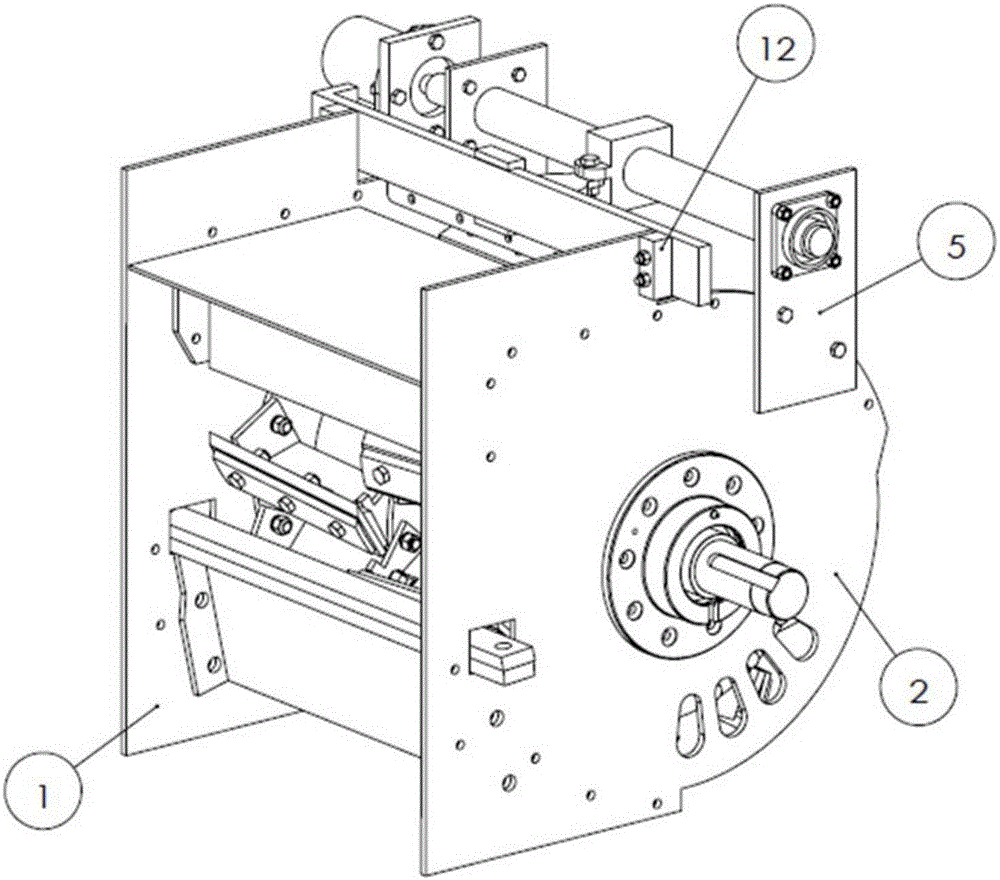

[0022] Such as figure 1 and 2 As shown, an automatic knife sharpening device for a silage machine, the silage machine includes a left side plate 1 and a right side plate 2, the knife sharpening device includes a horizontal transmission device, a whetstone sleeve 8, a whetstone 9. Slider 10, guide rail 11, guide rail fixing block 12;

[0023] The two ends of the horizontal transmission device are respectively fixed on the left side plate 1 and the right side plate 2, and the two ends of the guide rail 11 are fixed on the left side plate 1 and the right side plate 2 through the guide rail fixing block 12. Block 10 is installed on the guide rail 11, and whetstone sleeve 8 top links to each other with slide block 10 and horizontal transmission device by bolt, and whetstone 9 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com