Binder chip assembling mechanism

A technology of assembly mechanism and long tail clamp, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of finger injury, low work efficiency, and labor-intensive workers, and achieve the liberation of human labor, the assembly process is fast, Manipulative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

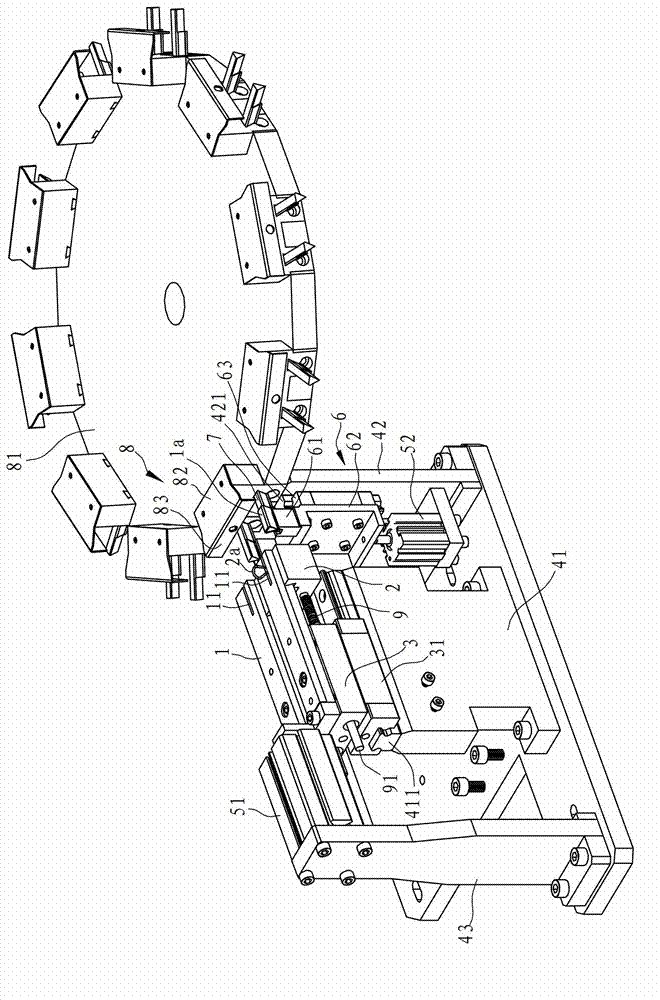

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

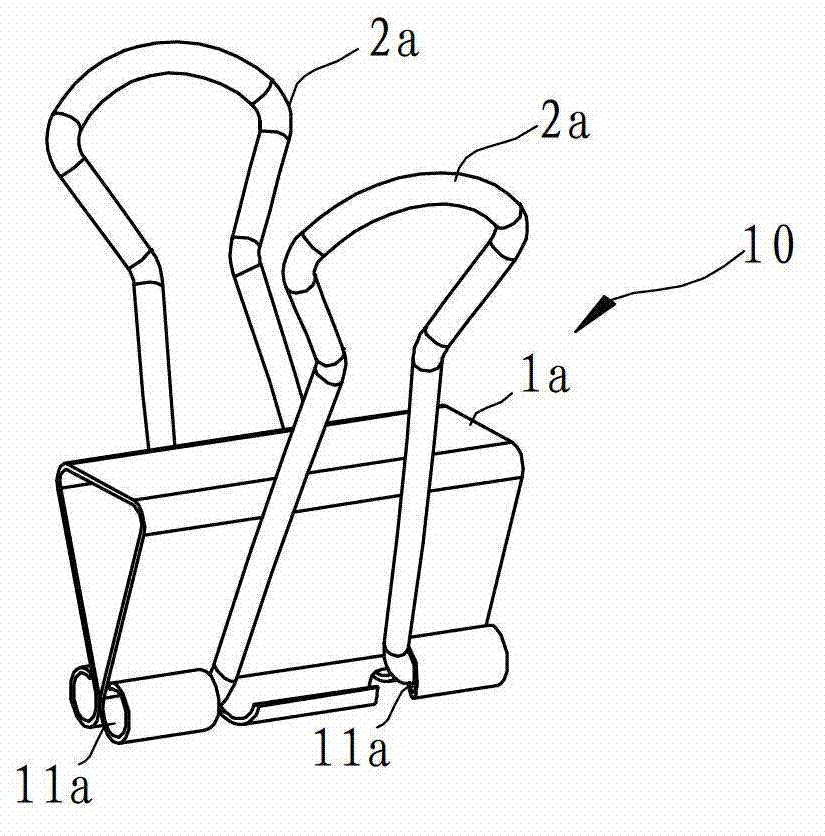

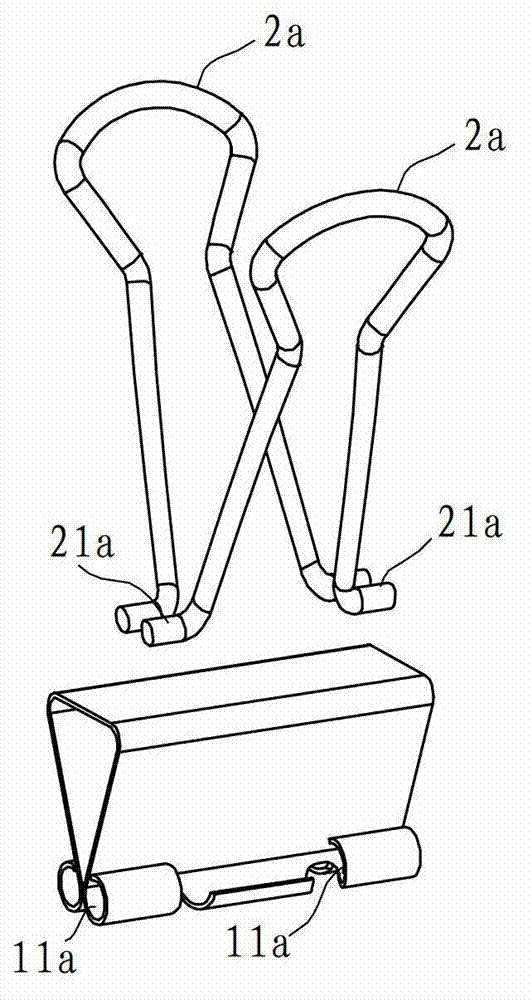

[0034] Such as image 3 , Figure 4 , Figure 5 with Image 6 As shown, the long tail clip assembly mechanism in this embodiment includes a positioning block 7, a baffle plate 81, a pressing block 6, a vertical cylinder 52, a first push block 1, a horizontal cylinder 51, a slider 3, a spring 9, and a guide rod 91. The first support 41 , the second support 42 and the third support 43 .

[0035] The positioning block 7 can be adapted to the hollow inner cavity of the main body 1a, for the main body 1a to hang upside down, and the cross section is an inverted triangle; the baffle plate 8 is arranged on the turntable 81, and the baffle plate cross section is L-shaped, including a horizontal part 82 and a vertical part 83, the horizontal part 82 is fixed on the upper surface of the turntable 81, and the vertical part 83 can limit the wrench 2a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com