Patents

Literature

45results about How to "Liberate human labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

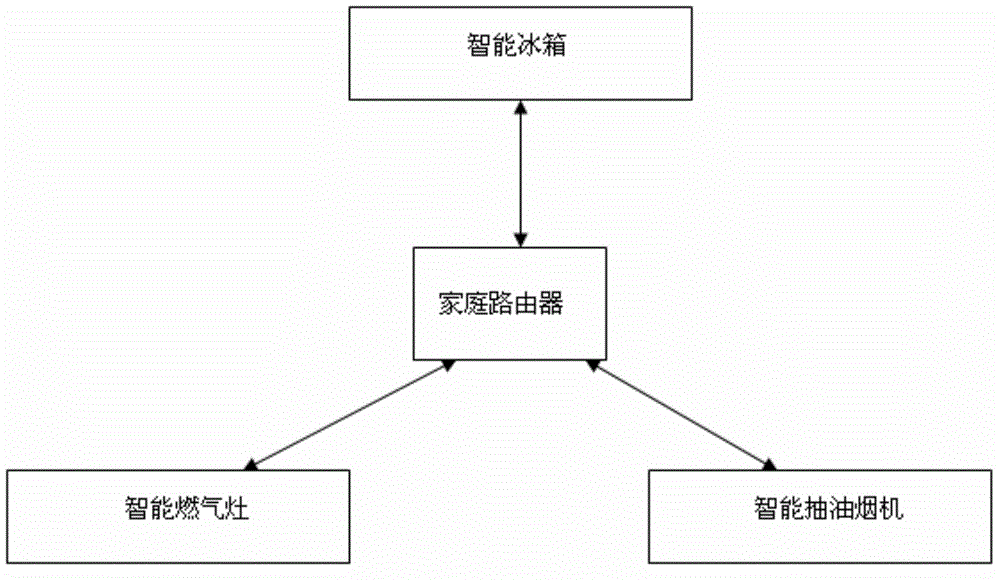

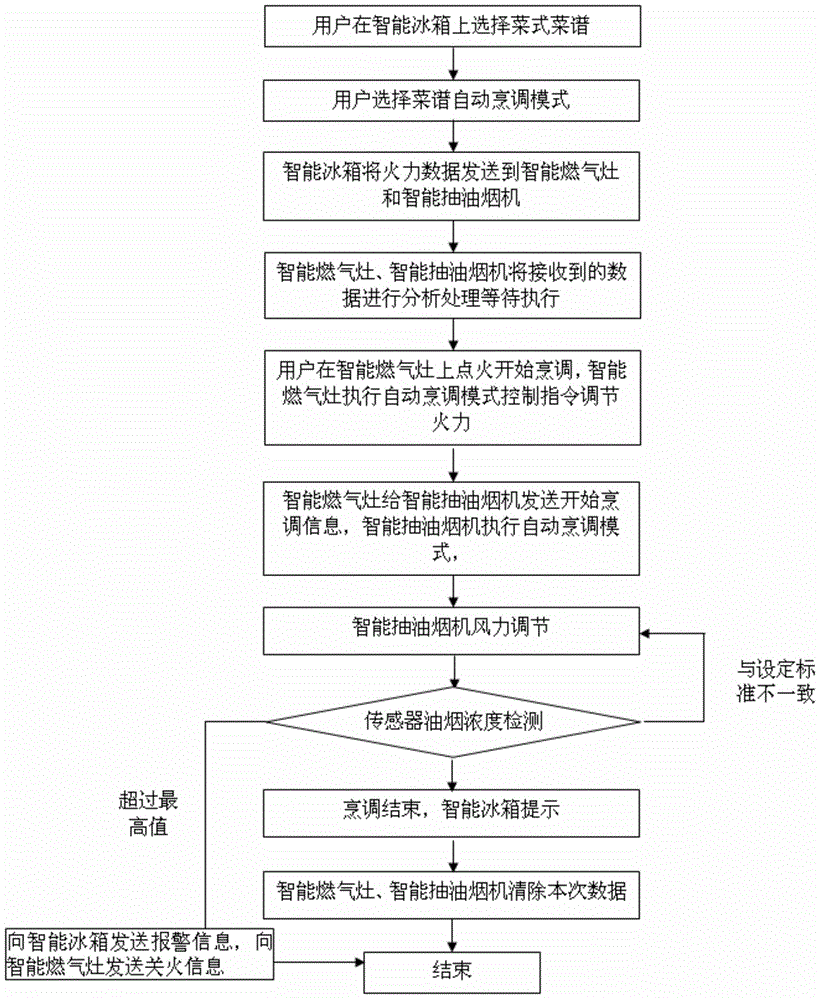

A kitchen device intelligent interaction system and an interaction method

ActiveCN103605296AReduce participationImprove experienceProgramme control in sequence/logic controllersInteraction systemsHuman–computer interaction

The invention relates to an interaction control technique applied between intelligent devices. The invention discloses a kitchen device intelligent interaction system and an interaction method, so that problems that information interaction and cooperative working between kitchen devices can not be carried out in the prior art are solved. According to the invention, an intelligent refrigerator, an intelligent gas-cooker and an intelligent smoke ventilator are connected through a household router. A user can select dish types and menus on the intelligent refrigerator. The intelligent refrigerator sends fire power control data according to the menus selected by a user. The intelligent gas-cooker executes an automatic cooking mode to automatically adjust the fire power. The intelligent smoke ventilator executes the automatic cooking mode to automatically adjust a wind force, and carries out self-adaptive wind power adjusting according to a present oil smoke concentration detected by an oil smoke concentration sensor. The kitchen device intelligent interaction system and the interaction method of the invention are applicable to household kitchens.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

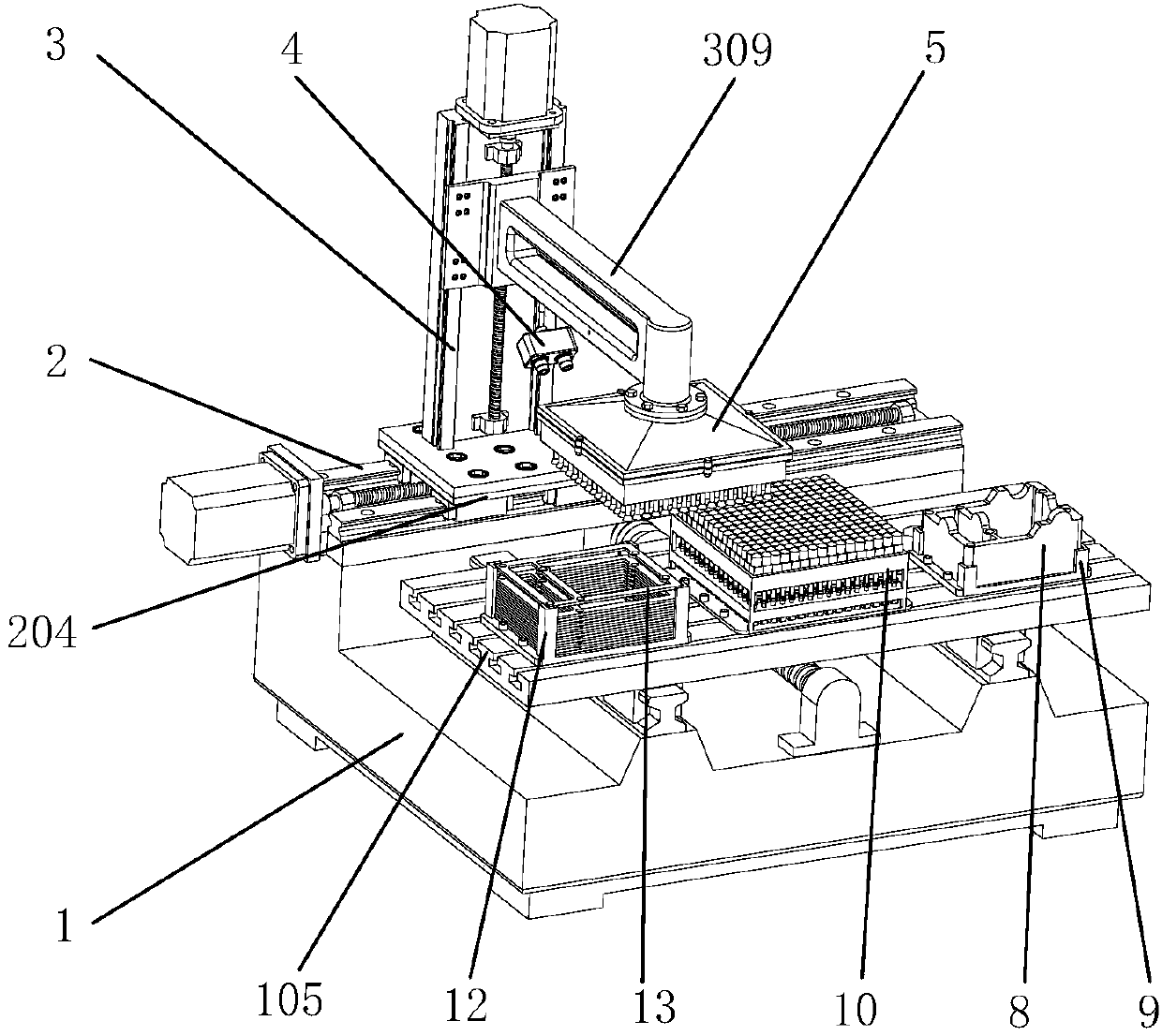

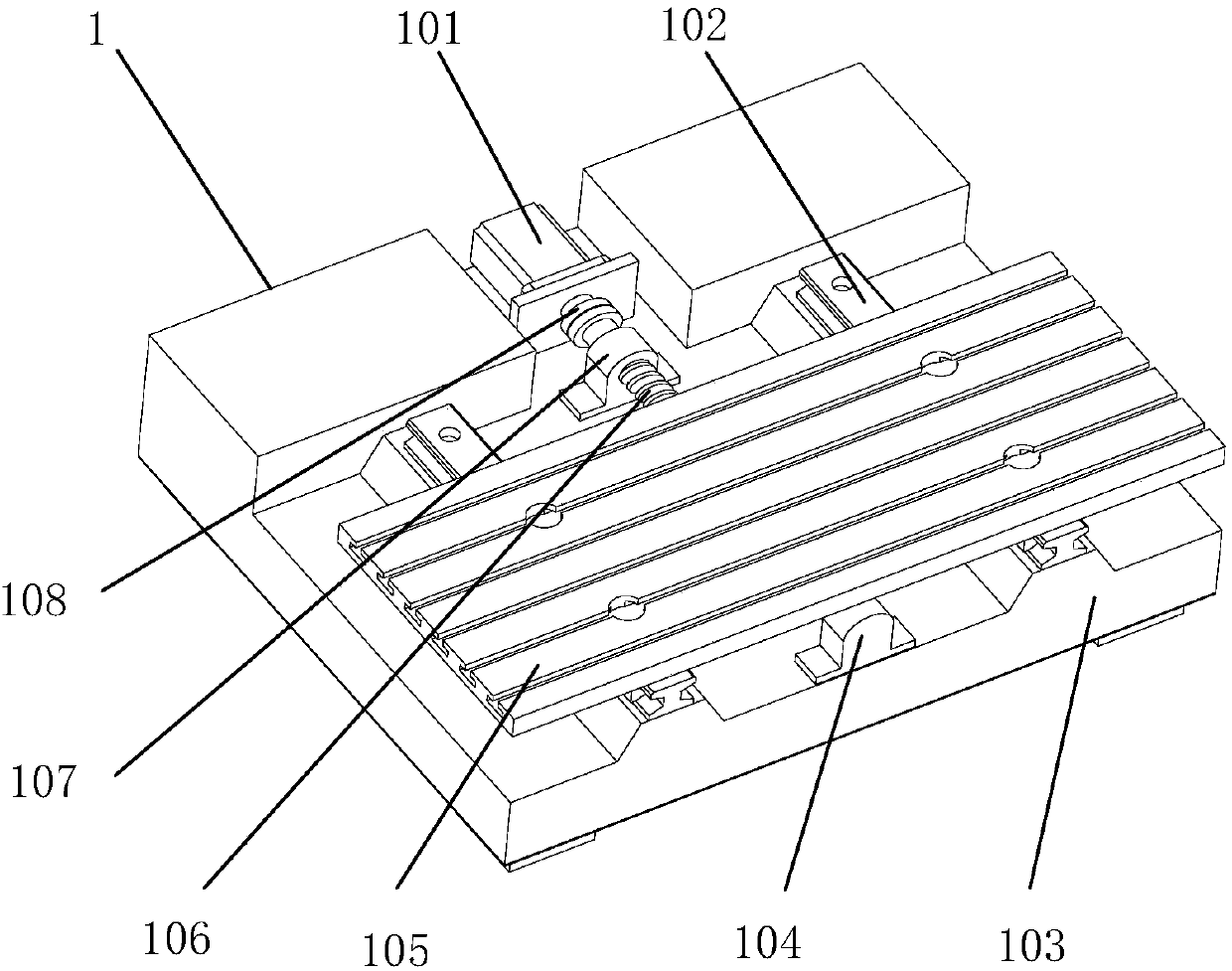

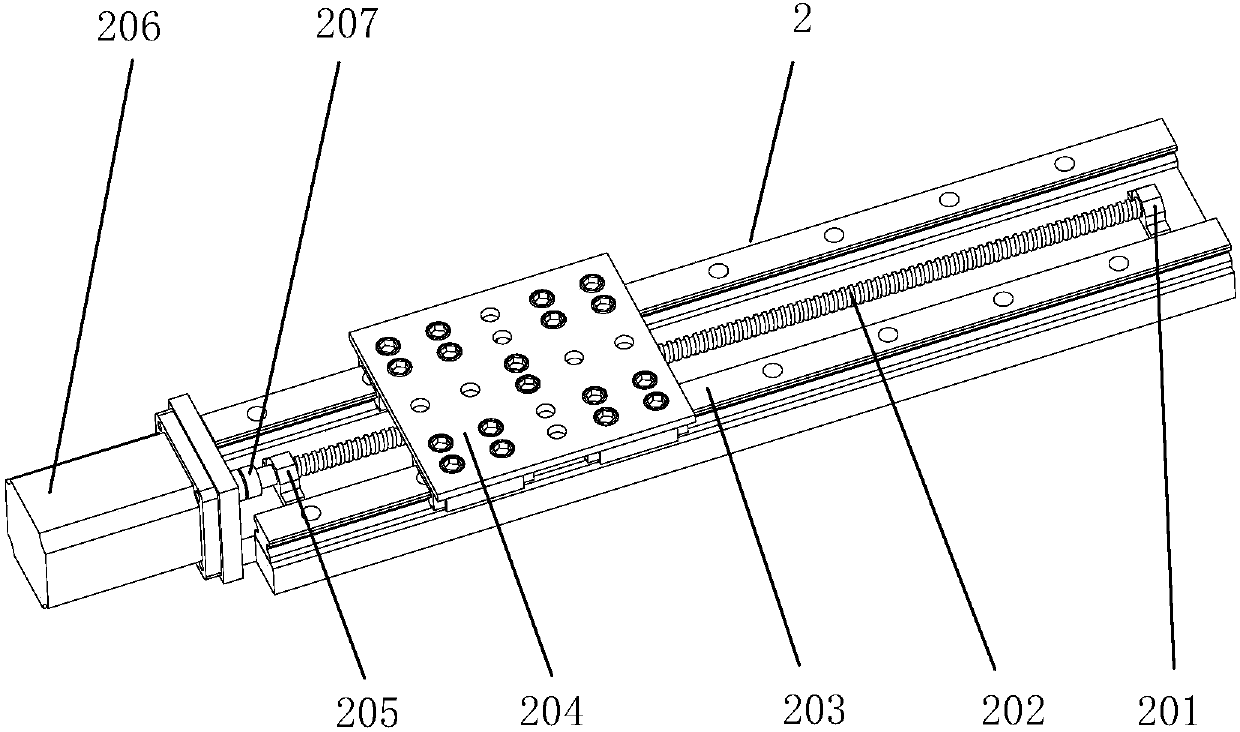

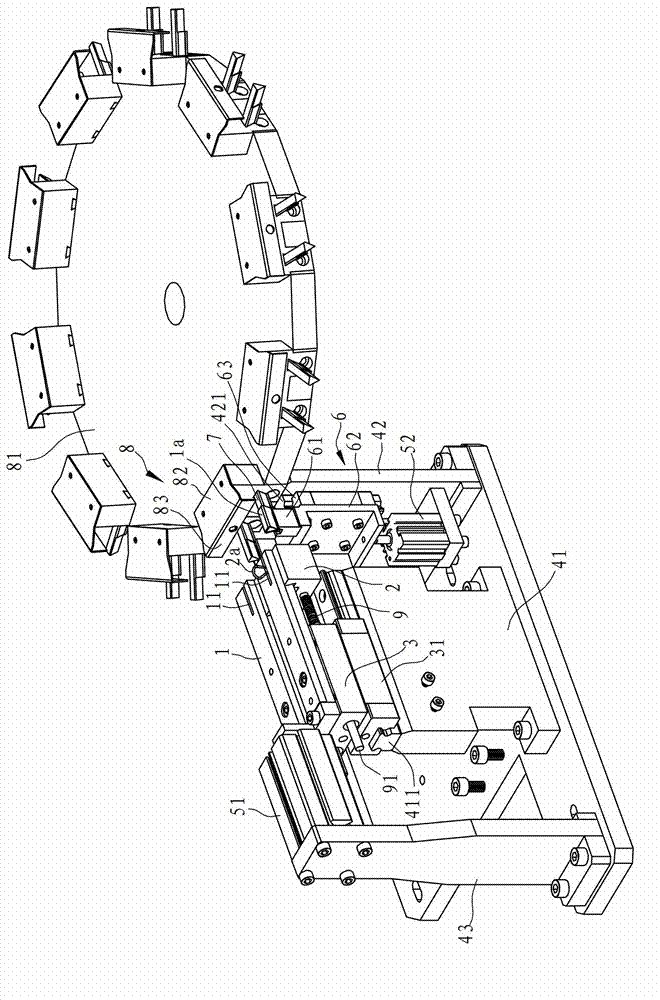

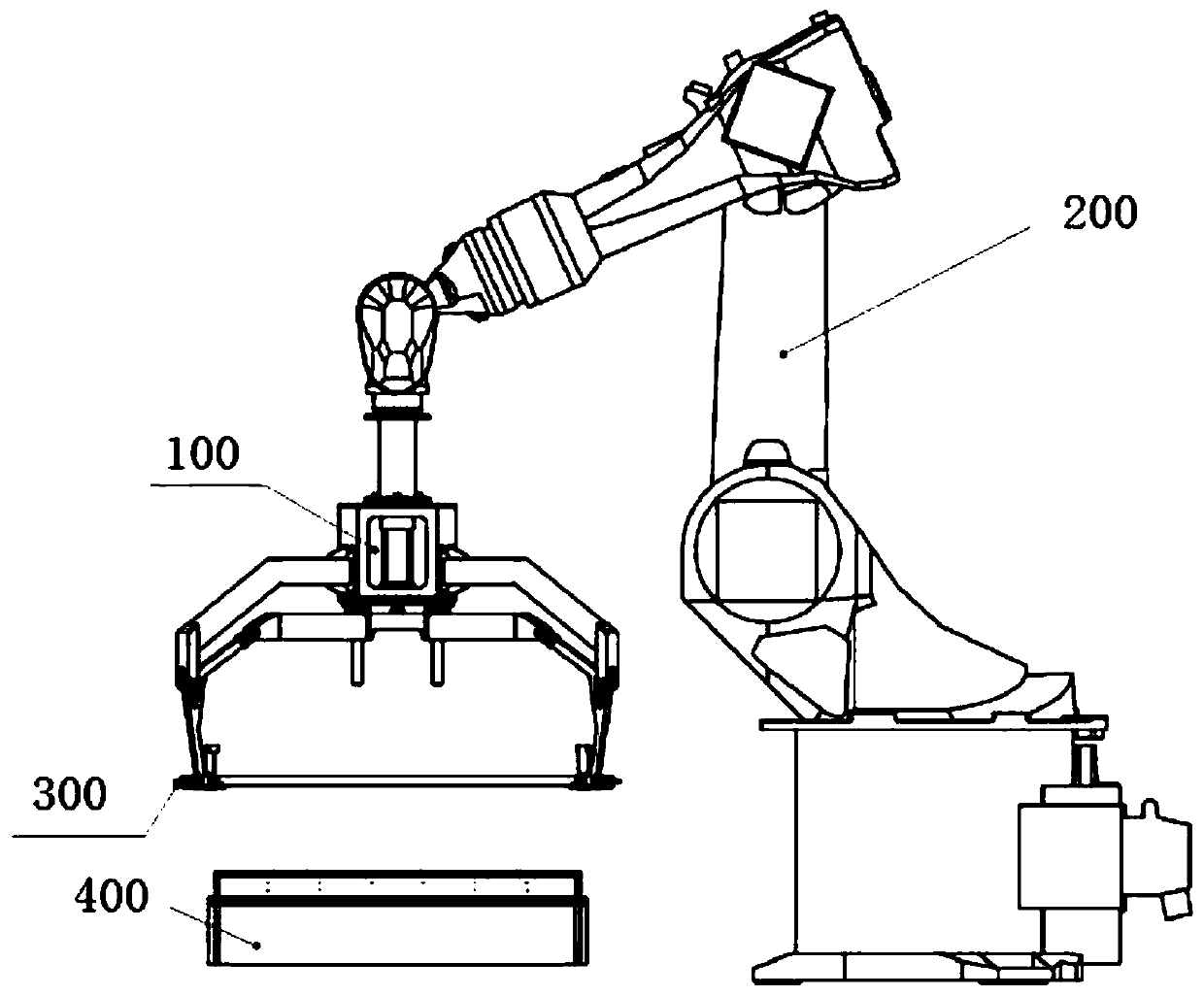

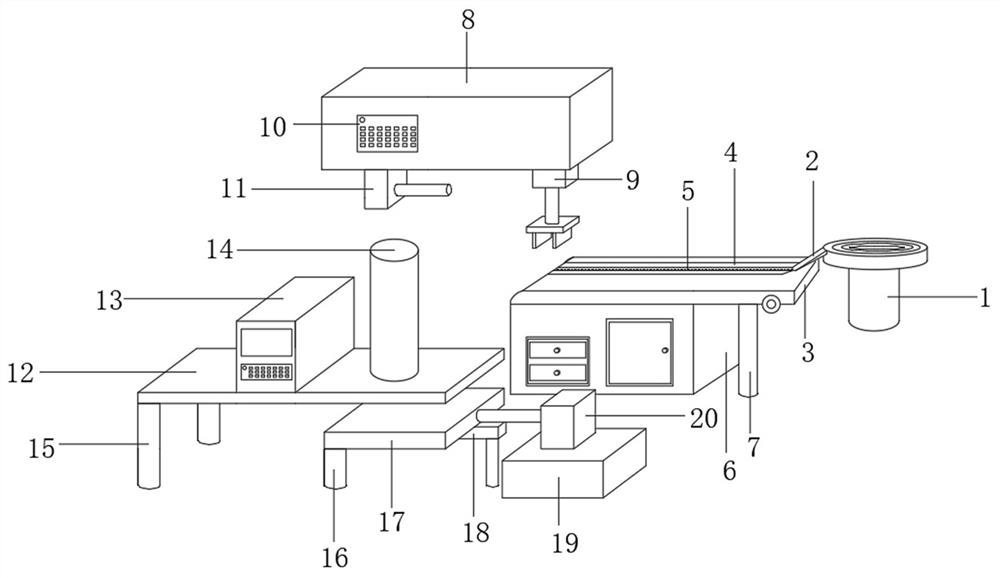

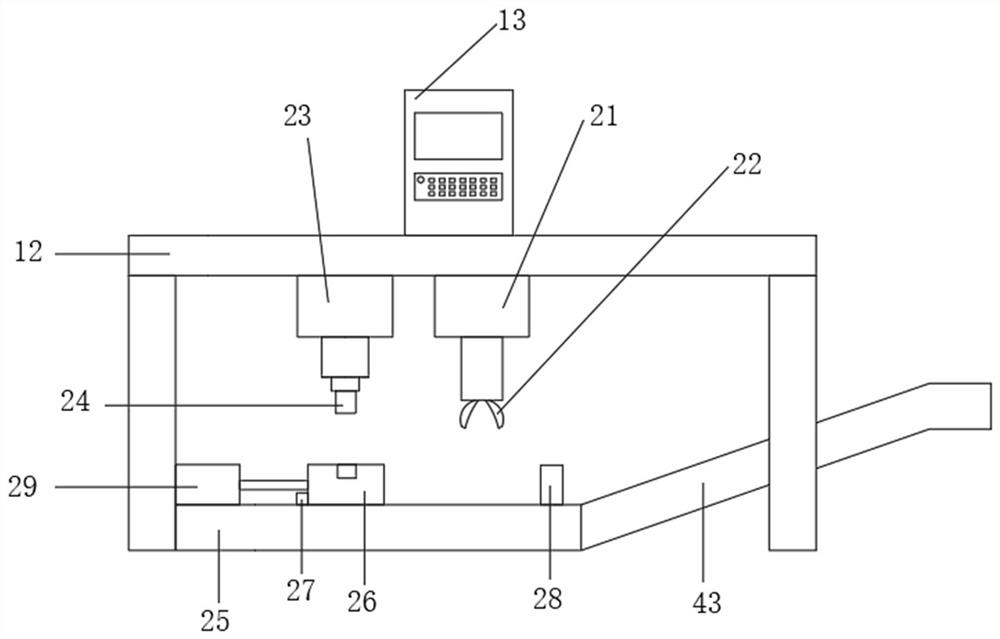

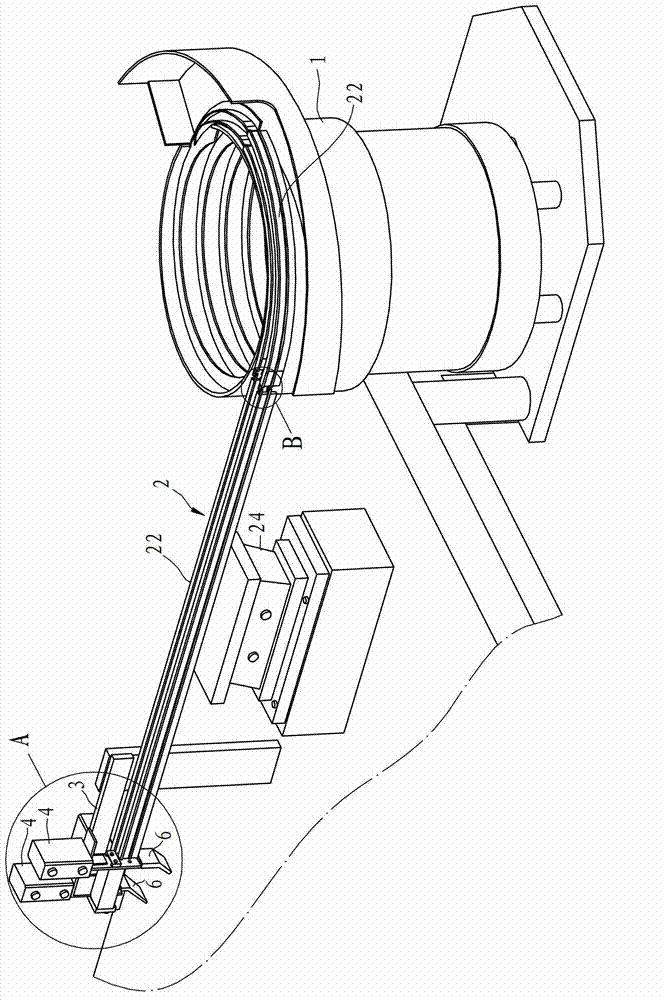

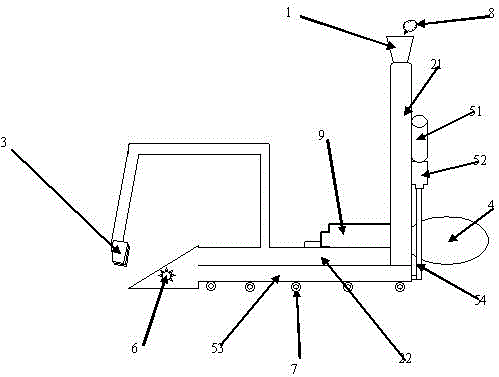

Multi-point sucking disc automatic-sucking installing machine for three-dimensional flexible gasket

PendingCN107825407ASolve the problem of forming a three-dimensional gasket and assembling it preciselyNovel structureProgramme-controlled manipulatorGripping headsBall screwEngineering

The invention relates to a multi-point sucking disc automatic-sucking installing machine for a three-dimensional flexible gasket, and belongs to the field of mechanical manufacturing. A transverse moving device, a longitudinal ball screw used for completing longitudinal movement of T-shaped grooves, longitudinal sliding rails and the like are fixedly installed on a base; a transverse moving mechanism is vertically distributed with the longitudinal ball screw and the longitudinal sliding rails; a T-shaped groove workbench is fixed on the longitudinal sliding rails, and the T-shaped groove workbench can longitudinally move along the longitudinal sliding rails; a vertical moving device is fixed on a transverse sliding plate of the transverse moving device, and the vertical moving device can transversely move along with the transverse sliding plate; and a sucking disc is fixed on a cross arm of the vertical moving device, and can move up and down along with the cross arm, and the sucking disc is located above the T-shaped groove workbench. According to the installing machine, the gasket is converted from two-dimensional to three-dimensional, meanwhile, accurate and automatic assembly is carried out, so that labor is liberated, and assembly efficiency of a system is improved.

Owner:JILIN UNIV

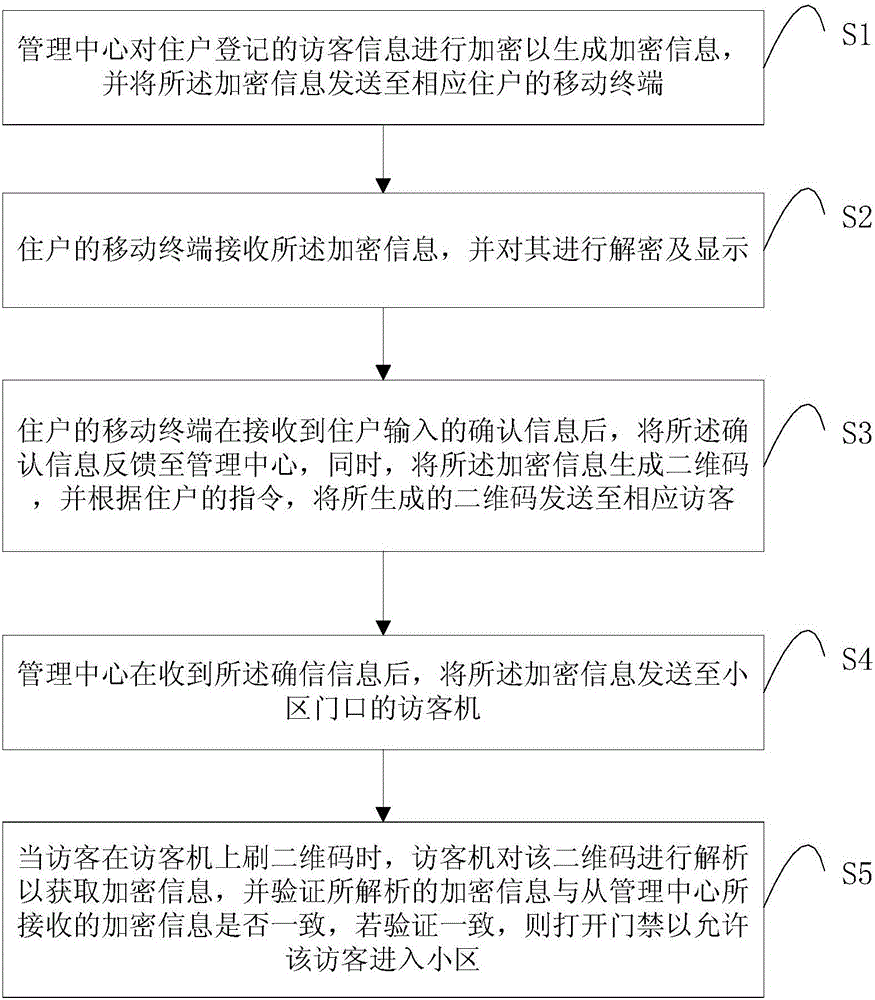

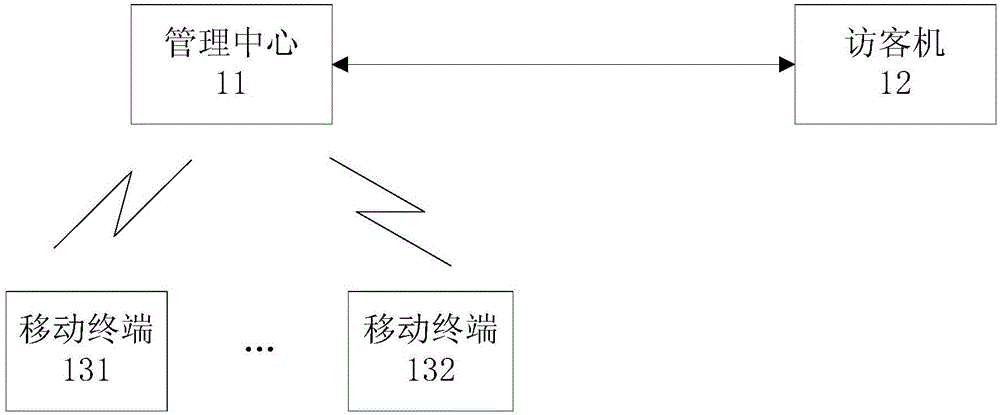

Visitor reservation management method and visitor reservation management system

InactiveCN106408689AImprove securityImprove convenienceData processing applicationsIndividual entry/exit registersManagement systemInformation feedback

The present invention discloses a visitor reservation management method and a visitor reservation management system. The visitor reservation management method comprises that a management center encrypts the visitor information registered by a resident to generate encrypted information and transmits the encrypted information to the mobile terminal of the corresponding resident; the mobile terminal of the resident decrypts and displays the encrypted information; after the mobile terminal of the resident receives the confirmation information input by the resident, the confirmation information is fed back to the management center while a two-dimensional code is generated from the encrypted information and is transmitted to the corresponding visitor; after the management center receives the confirmation information, the encrypted information is transmitted to the visitor machine at the entrance of a residential district; and when the visitor inputs the two-dimensional code on the visitor machine, the visitor machine parses the two-dimensional code to obtain the encrypted information and verifies whether the parsed encrypted information is consistent with the encrypted information received from the management center, and opens the entrance to allow the visitor to enter the residential district if the two encrypted information are consistent with each other. With the application of the technical scheme of the present invention, the safety of the residential district and the convenience of the residents can be improved, the human labor is liberated, and the artificial error is reduced.

Owner:BEIJING QDING INTERCONNECTION TECHNOLOGY CO LTD

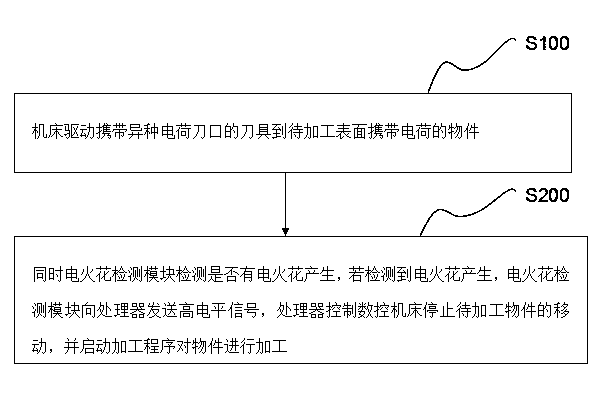

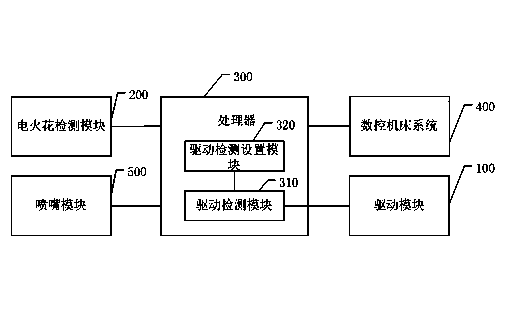

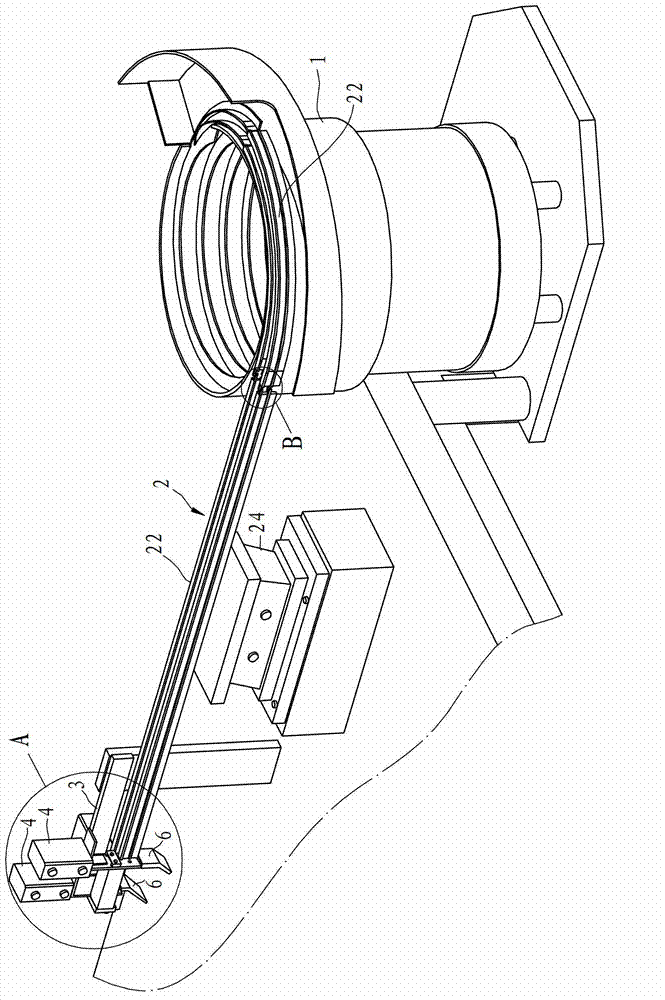

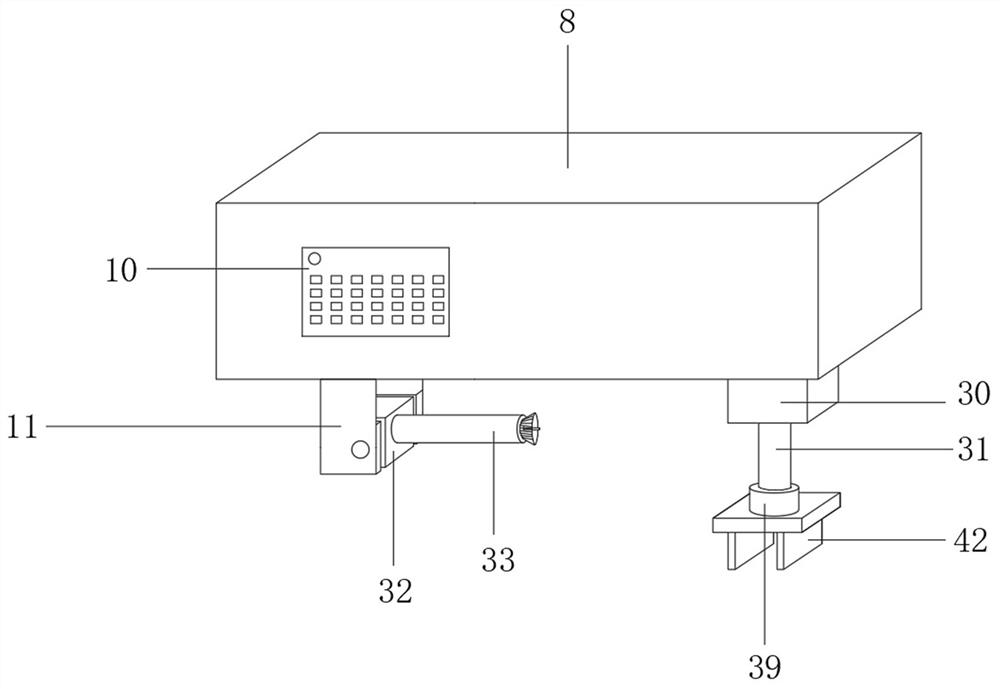

Accurate tool-setting method of numerical control machine tool and numerical control machine tool

InactiveCN103737423ALiberate human laborPrevent eye strainAutomatic control devicesMeasurement/indication equipmentsEngineeringMachine tool

The invention discloses an accurate tool-setting method of a numerical control machine tool and the numerical control machine tool. The accurate tool-setting method of the numerical control machine tool comprises the steps that A, the machine tool drives a tool provided with an opposite charge tool edge to a workpiece to be machined, wherein the surface of the workpiece carries a charge; B, an electric spark detection module detects whether an electric spark is generated at the same time, wherein if an generated electric spark is detected, the electric spark detection module sends a high level signal to a processor, and the processor controls the numerical control machine tool to stop the movement of the workpiece to be machined and starts a machining program to machine the workpiece. According to the numerical control machine tool, whether the workpiece and the tool edge are aligned is judged according to whether an electric spark is generated between mutually exclusive charges carried by the workpiece to be machined and the tool edge, and then the workpiece machining method is implemented; since the numerical control machine tool can conduct tool setting automatically and accurately, more labor is liberated, and full automation is realized; the problem that fatigue of human eyes causes unqualified machining of the workpiece can also be effectively prevented, and the intelligent demand for numerical control is met.

Owner:TIANSHUI SPARK MACHINE TOOL

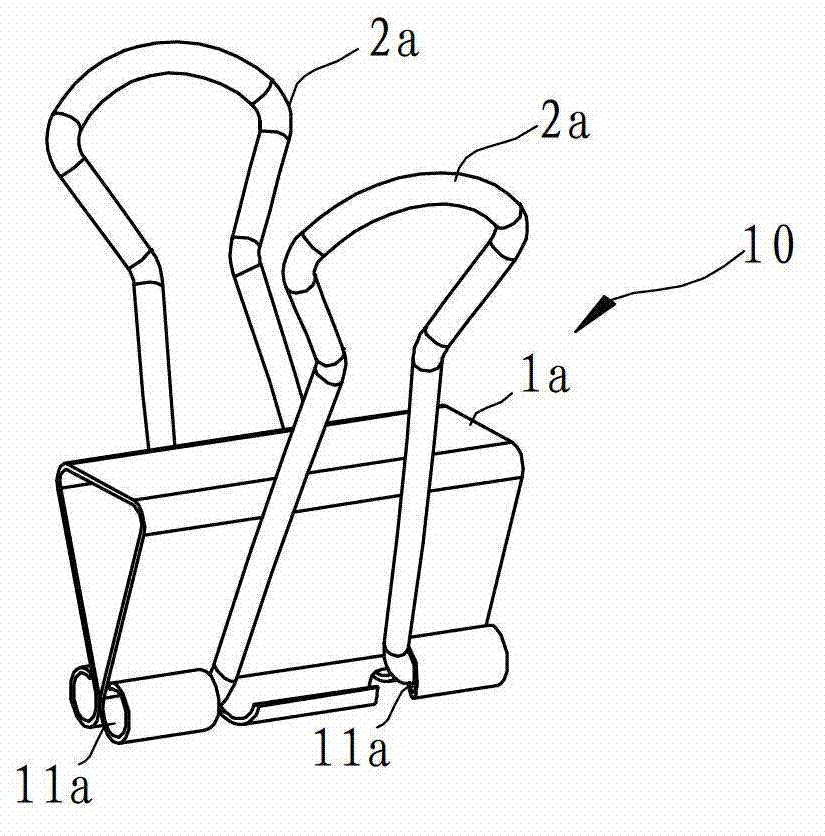

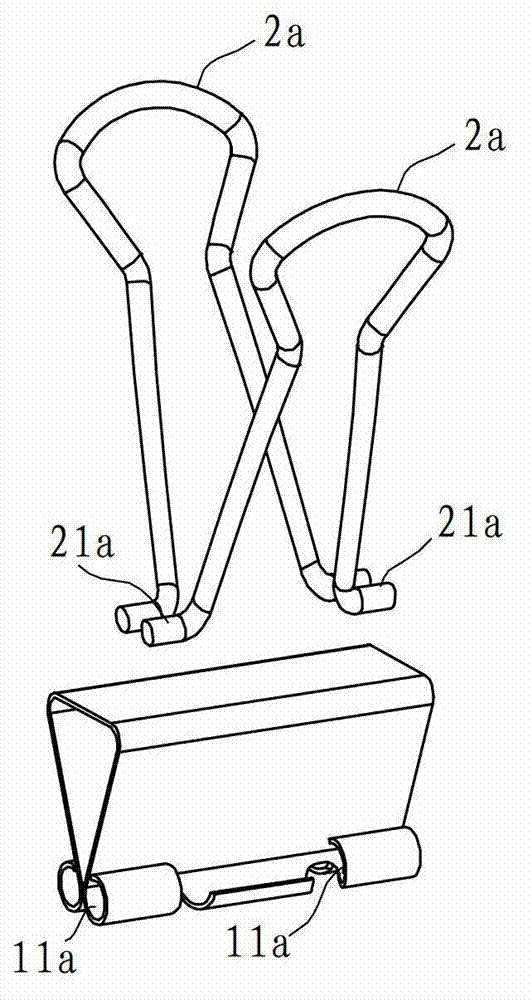

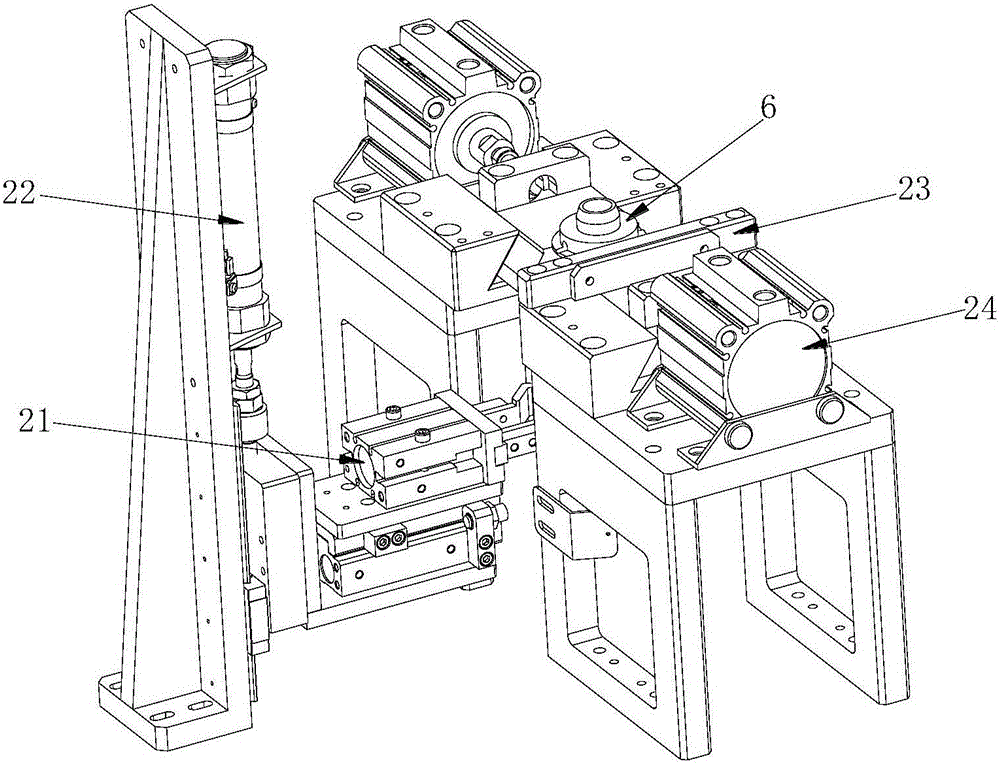

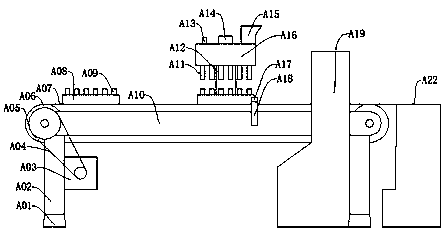

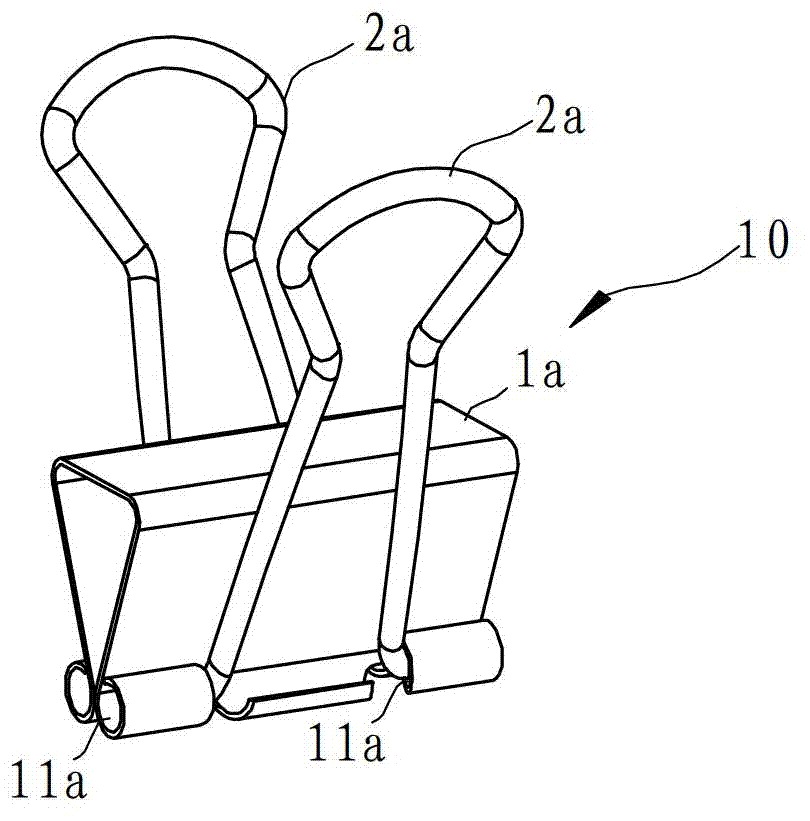

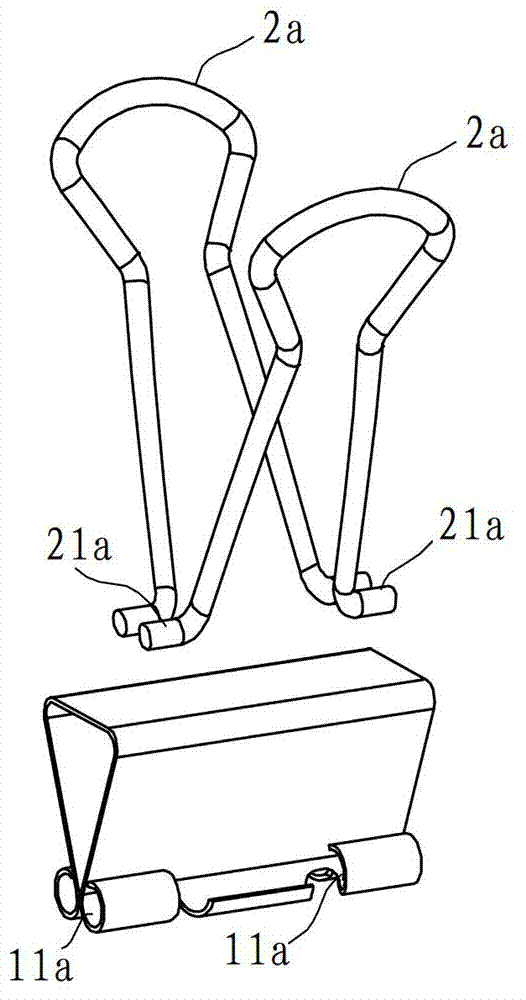

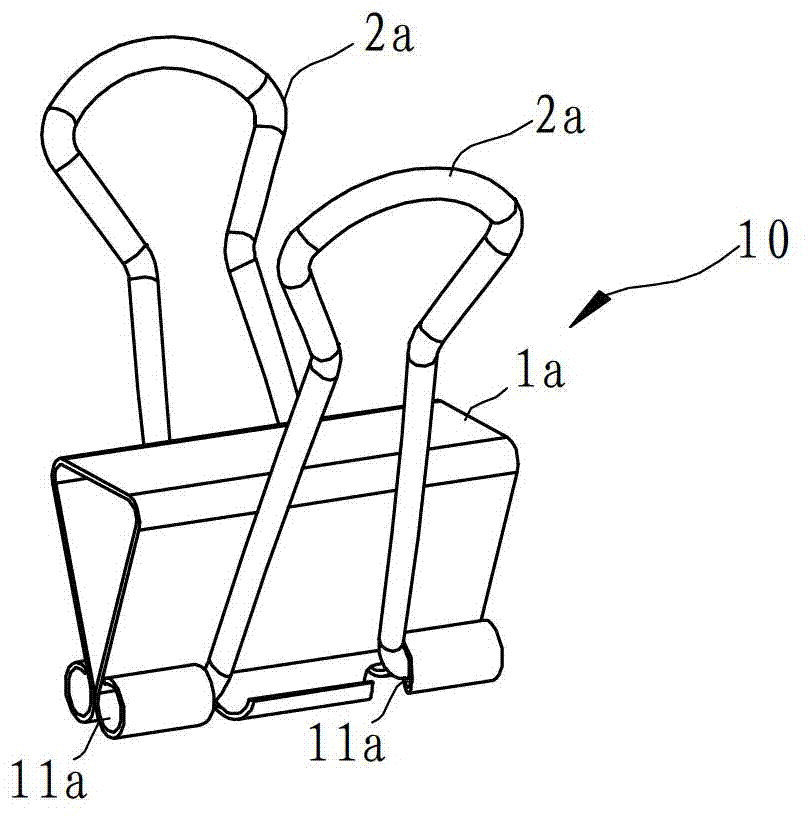

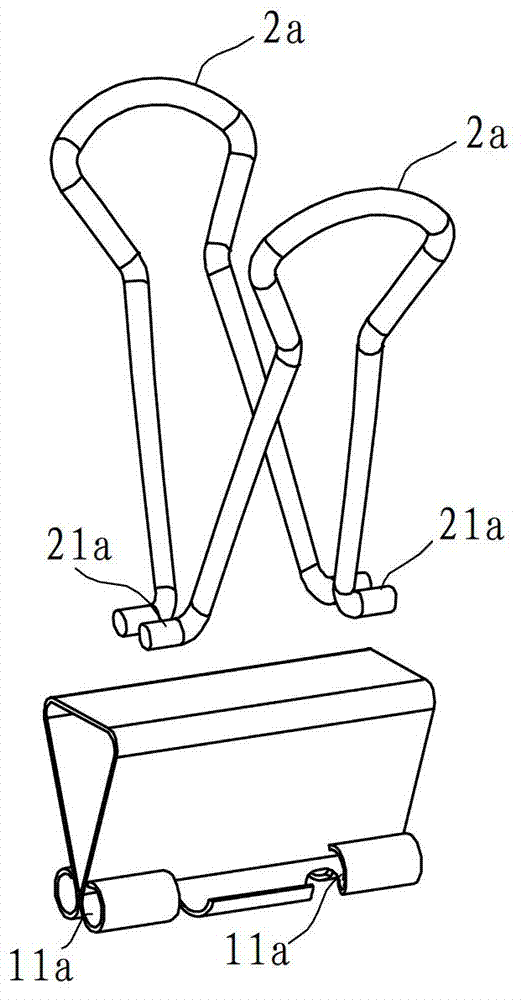

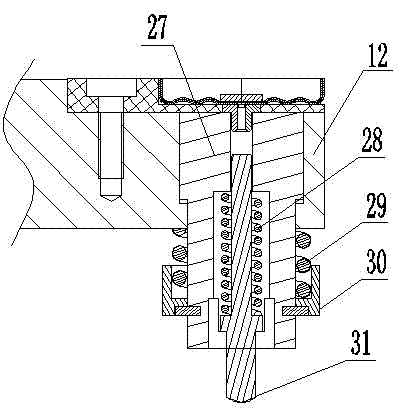

Binder chip assembling mechanism

InactiveCN102922277ALiberate human laborQuick assemblyAssembly machinesAutomatic controlVertical cylinder

A binder chip assembling mechanism is characterized by comprising a positioning block, a baffle, a pressing block, a vertical cylinder, a horizontal cylinder, a sliding block, a second push block and a spring, wherein the positioning block can be matched with a hollow inner cavity of a body, the baffle can prevent a wrench from moving forwards continuously, and the pressing block is arranged under the positioning block and can press the body on the positioning block from bottom to top; a gap and an inclined groove for arranging the wrench is arranged between a first push block and the positioning block, the front end of the inclined groove is opened, and the sliding block is arranged at the bottom of the first push block; and the first push block extends from the front end of the second push block. Compared with the prior art, the binder chip assembling mechanism has the advantages that the whole assembling process is fast and convenient, strong in maneuverability and capable of achieving automatic control easily.

Owner:宁波江北昌晟自动化科技有限公司

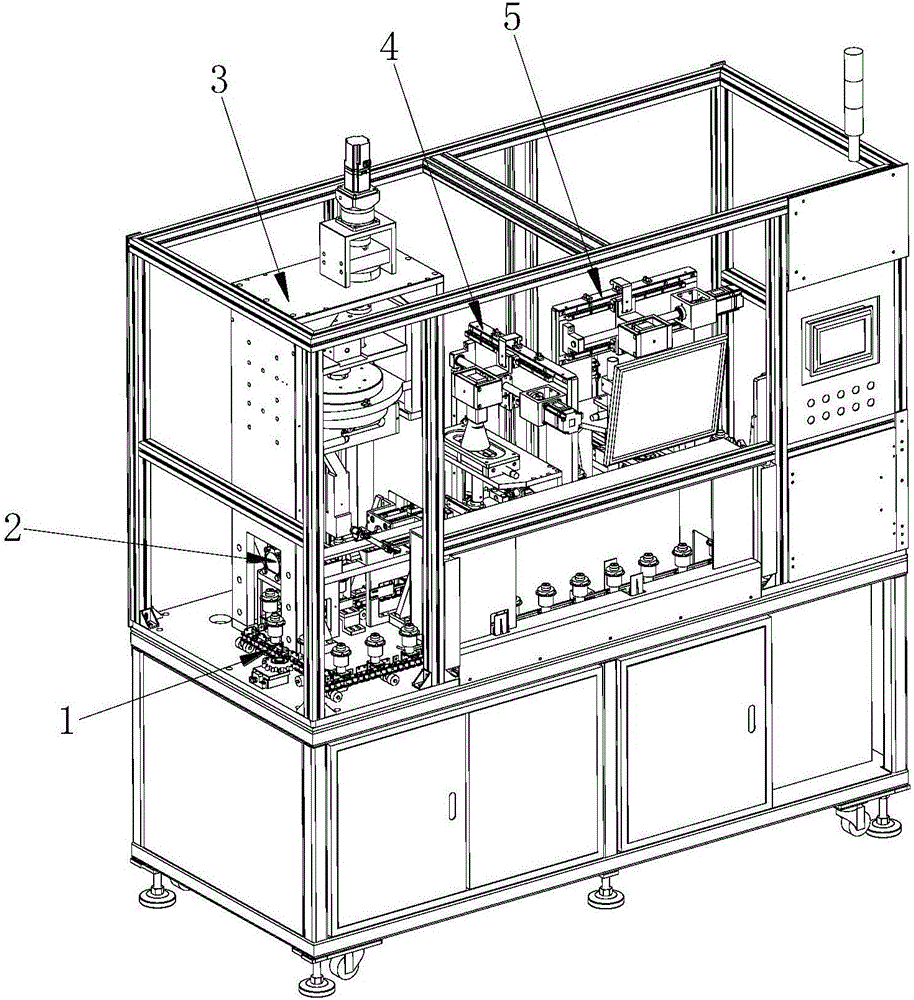

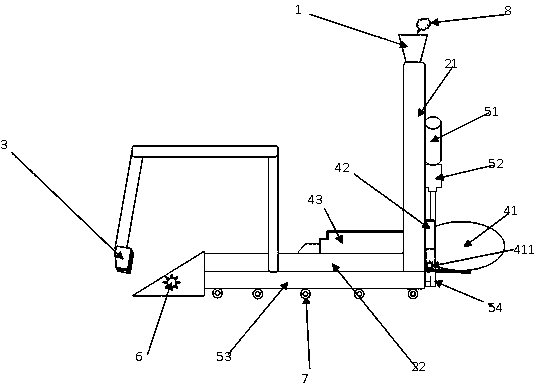

Swinging detector of automobile shock absorption ring

ActiveCN105865958ASimple molding processLiberate human laborMaterial strength using repeated/pulsating forcesEngineeringUltimate tensile strength

The invention provides a swinging detector of an automobile shock absorption ring. The swinging detector comprises a shock absorption ring conveying mechanism, a shock absorption ring transporting and clamping mechanism, a 360-degree rotation mechanism, a front-back swinging mechanism, a left-right swinging mechanism, a qualified product dotting marking and discharging mechanism, wherein the shock absorption ring transporting and clamping mechanism is used for conveying the product to all detection mechanism positions, so that the shock absorption ring is detected at all the detection mechanism positions; when the product is qualified, the product is conveyed out of the detector through the qualified product dotting marking and discharging mechanism. The swinging detector can simulate a manual operation process, manpower labor is released and industrial standards are established. Furthermore, the labor intensity of swinging workers is great so that the swinging workers cannot work contentedly and the post loss is serious; and the swinging detector completely replaces the manual operation and completely eliminates artificial factors; the product is detected according to a certain process and can be traced and can be produced and used according to the standards. Reversely, the swinging detector has great significance of facilitating a rubber molding process, a series of production reformation including raw material detection and the like.

Owner:GUANGDONG MINGHAO AUTOMATION EQUIP CO LTD

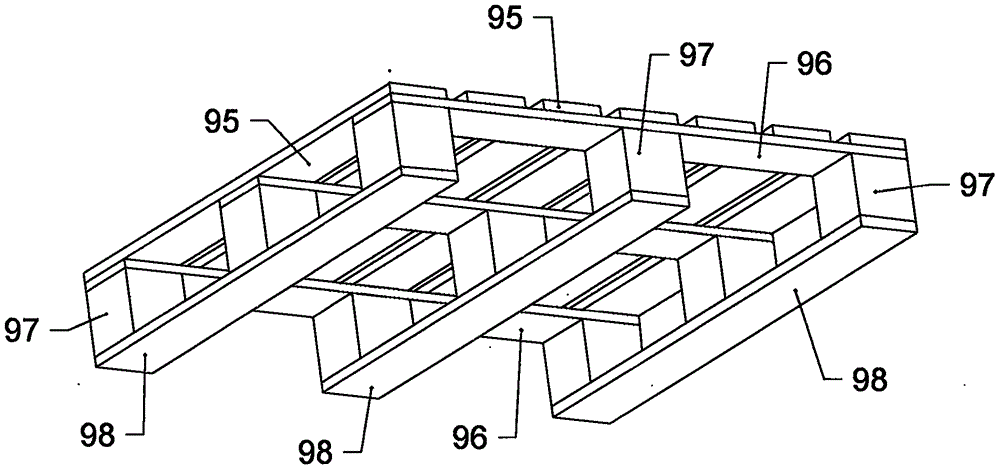

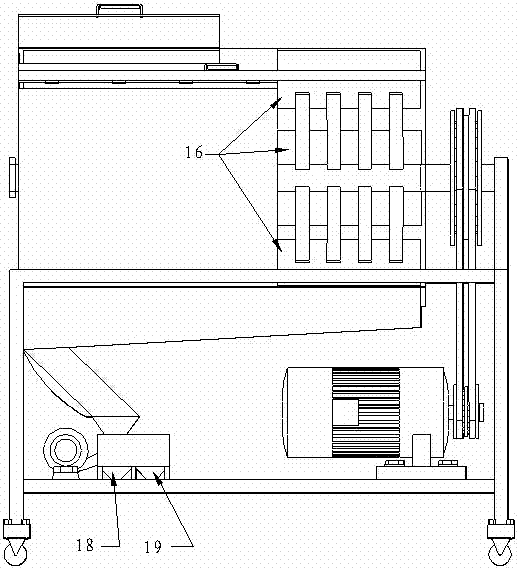

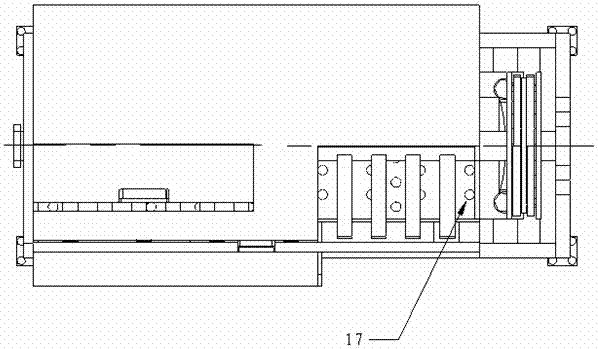

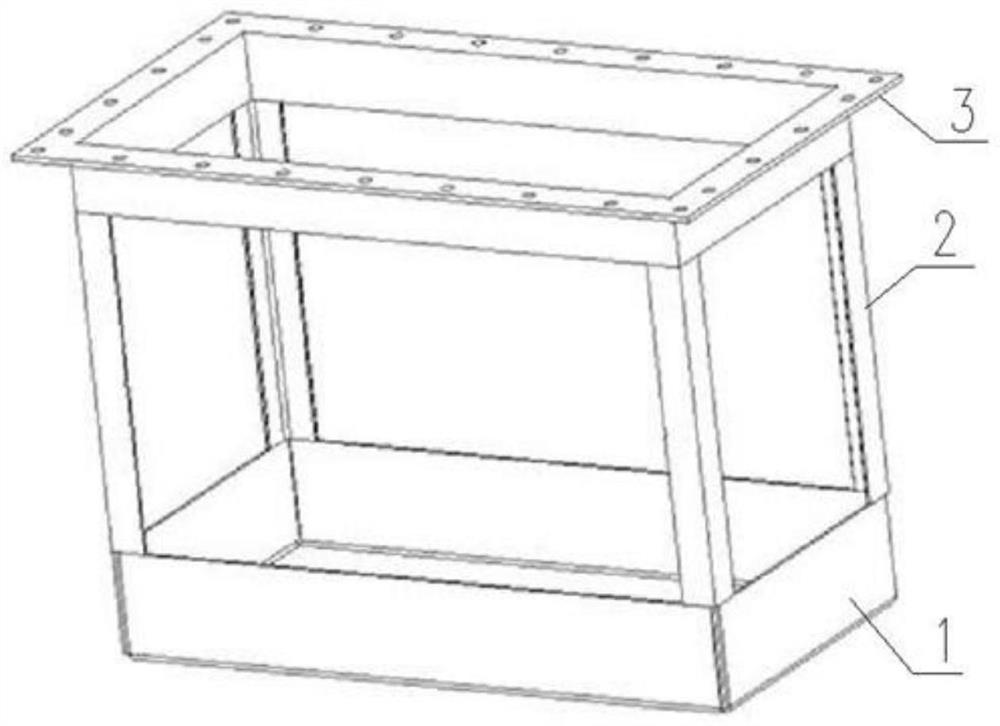

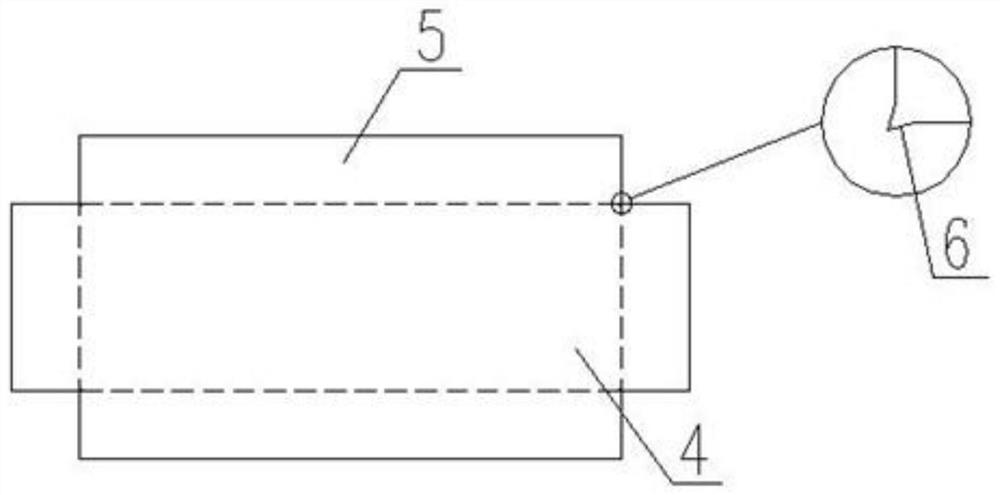

Full-automatic wooden tray production machine

InactiveCN105729607ALiberate human laborReduce labor costsWood working apparatusReciprocating motionEngineering

The invention disclose a full-automatic wooden tray production machine which comprises a rack, a wooden tray stacking bracket, nailing devices, wood plate cutting machines and a plancon cutting machine. The rack is provide with a wooden tray conveying rail, the wooden tray stacking bracket can do reciprocating motion on the wooden tray conveying rail, and the nailing devices are used for nailing wooden trays. According to the full-automatic wooden tray production machine, the aims of effectively improving the production efficiency and product quality of the wooden trays and reducing manpower cost are achieved.

Owner:WENZHOU JIANJING WOOD IND CO LTD

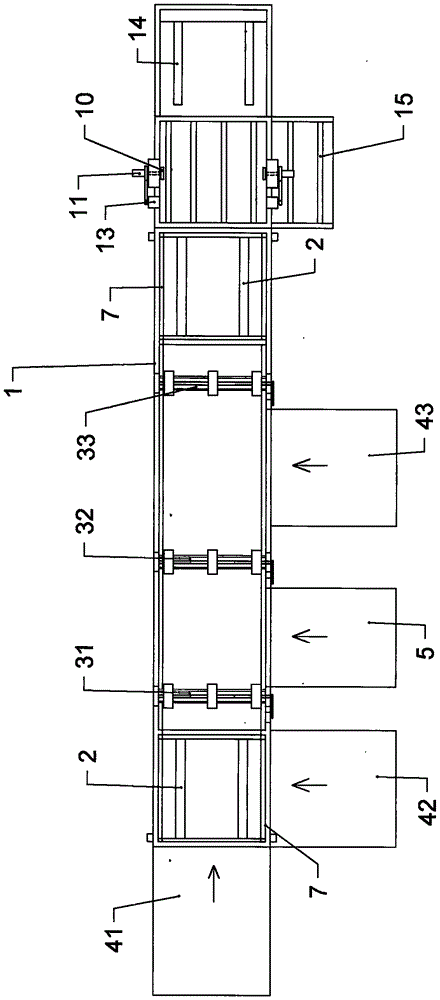

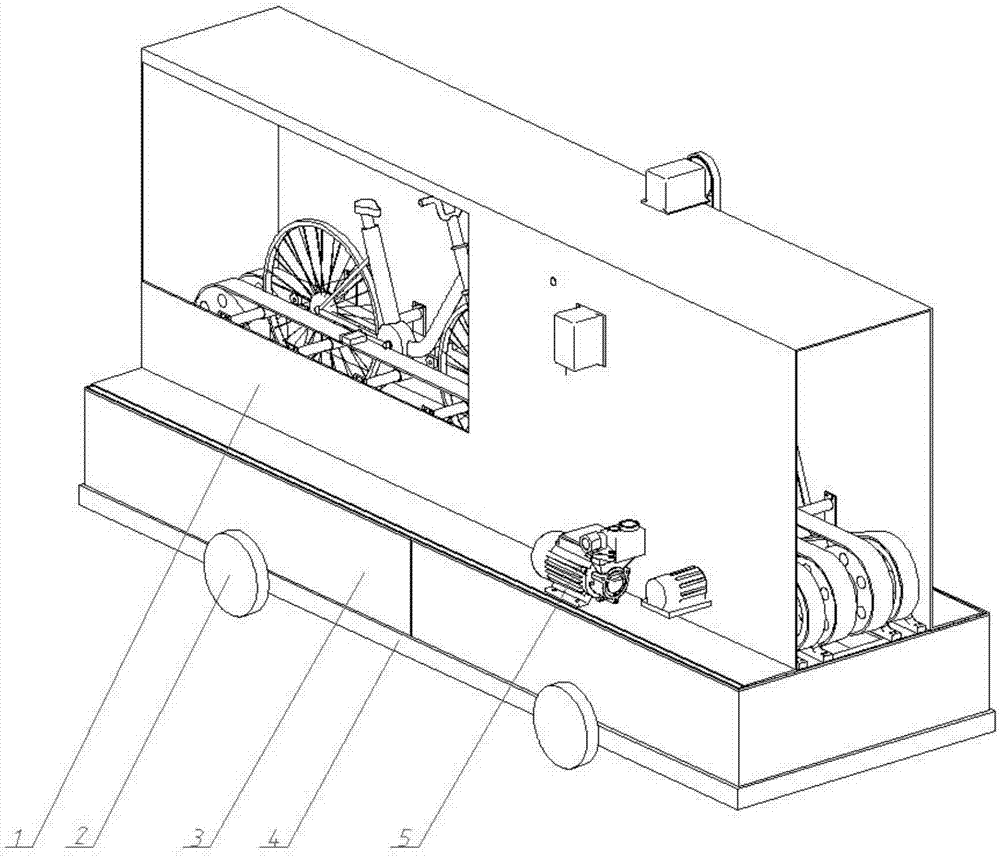

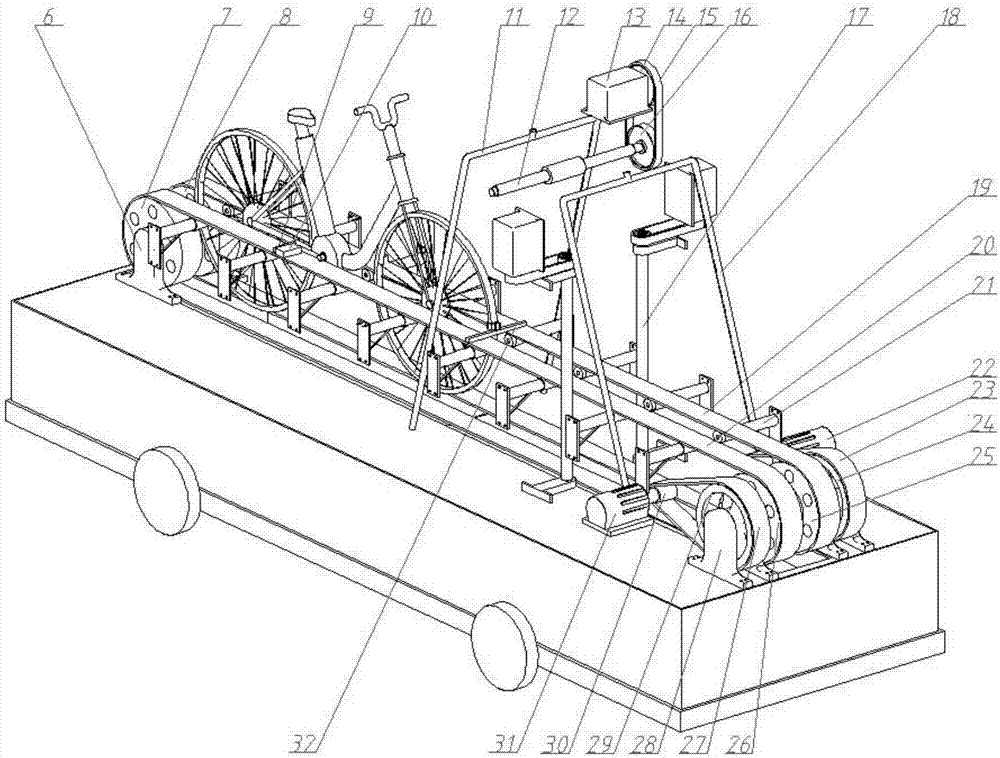

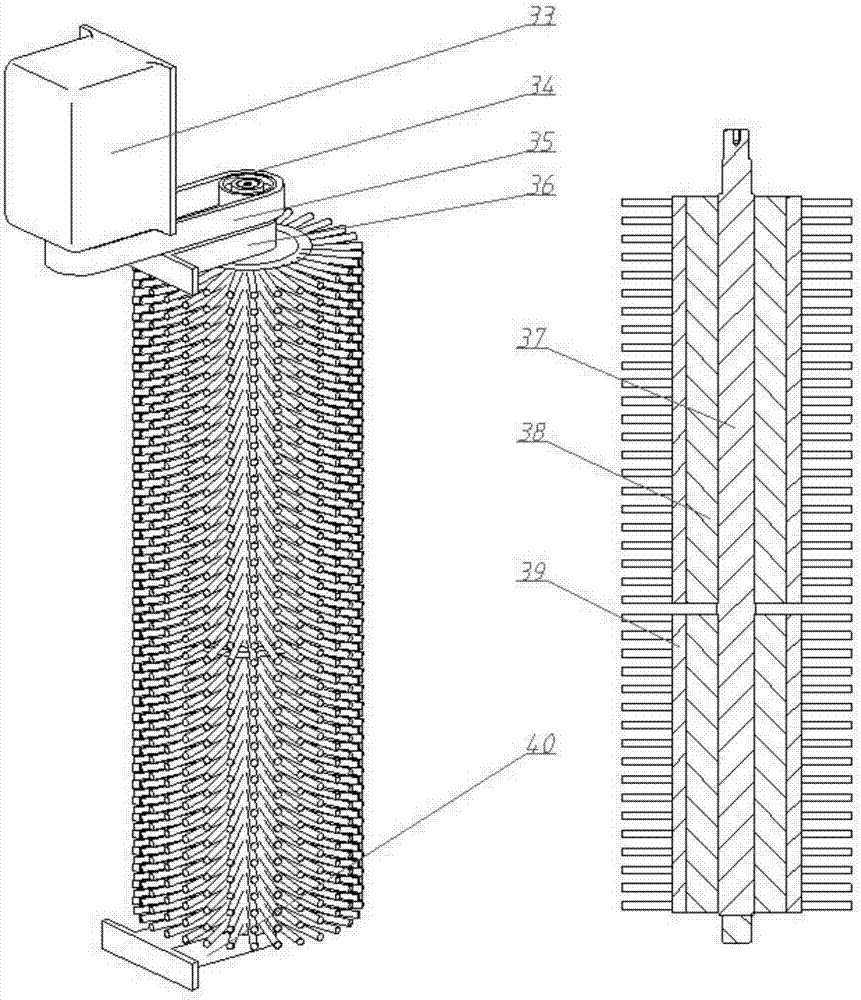

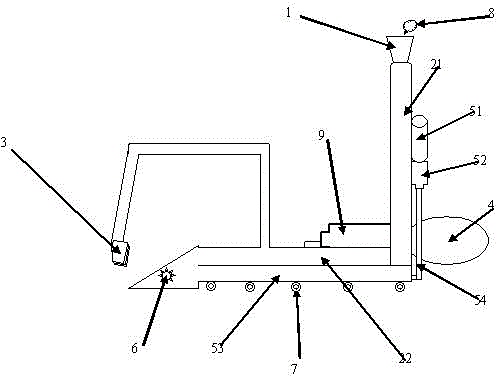

Automatic cleaning device of public bicycles on city road

PendingCN106915335AAchieve fixationPrevent rotationCleaning apparatus for vehicle exteriorsEngineeringElectrical and Electronics engineering

The invention discloses an automatic cleaning device of public bicycles on a city road. According to the automatic cleaning device of the public bicycles on the city road, the problems that in the prior art, bicycles are low in operation efficiency and poor in cleaning effect are solved, and the effects that cleaning efficiency is high, water for a machine is recycled, and manual labor is relieved are achieved. According to the scheme of the automatic cleaning device of the public bicycles on the city road, the automatic cleaning device of the public bicycles on the city road comprises a base and a side hairbrush; a spray mechanism is arranged on the base, one side of the spray mechanism is provided with a bicycle scrubbing mechanism which comprises a support, and the bicycle is arranged on one side of the support; and the top of the support is provided with a horizontally or obliquely arranged top hair brush which can rotate to clean the upper half portion of a bicycle body of the bicycle, and the side hairbrush is vertically arranged or obliquely arranged and can rotate to clean the lower half portion of the bicycle body of the bicycle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Intelligent small animal waste cleaning device

InactiveCN105594620AImprove cooling effectEasy to cleanBird housingsSmall animalAgricultural science

The invention relates to an intelligent small animal waste cleaning device which comprises an induction device, a freezing device, a cleaning and collecting device, an advancing device and a control device. Through reasonable setting of the devices and particularly the freezing device, the animal waste is frozen instantly and separated from the ground; and due to the induction device, automation of the device is realized so that the animal waste in a non-fertilizer storage area can be effectively and efficiently cleaned. Meanwhile, by improving the material of a freezing injection pipe, the low-temperature strength is guaranteed in the case of light weight so as to guarantee the service life of the equipment.

Owner:李彦忠 +6

Small animal waste cleaning device

The invention relates to a small animal waste cleaning device which comprises an induction device, a freezing device, a cleaning and collecting device, an advancing device and a control device. Through reasonable setting of the devices and particularly the freezing device, the animal waste is frozen instantly and separated from the ground; and due to the induction device, automation of the device is realized so that the animal waste in a non-fertilizer storage area can be effectively and efficiently cleaned.

Owner:史耀东 +6

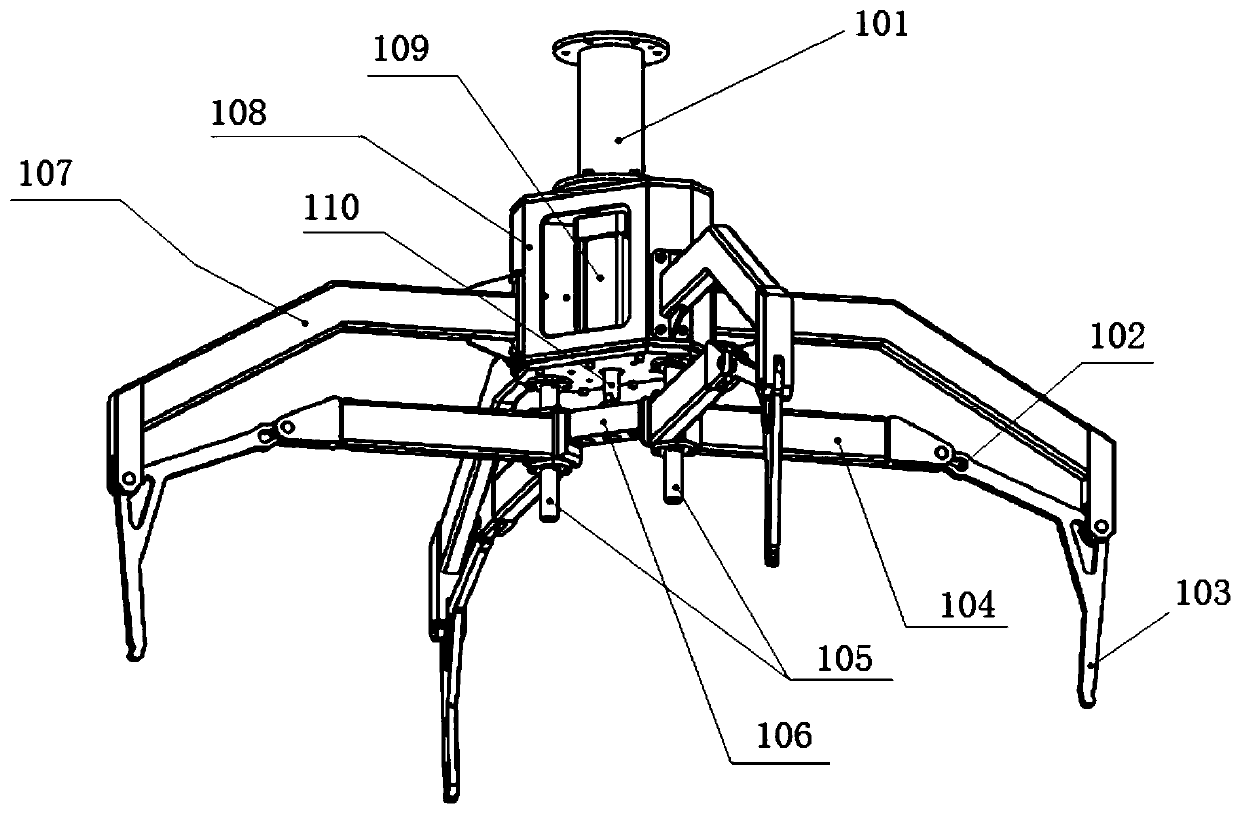

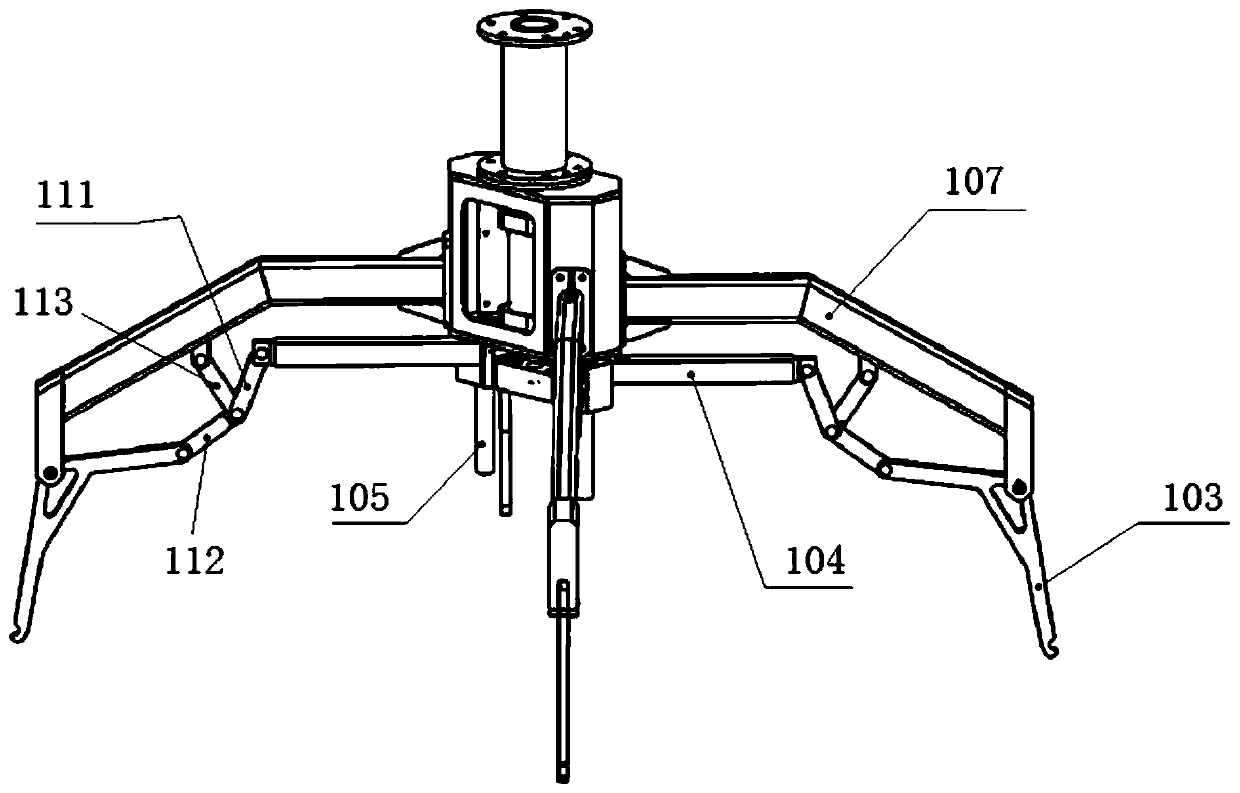

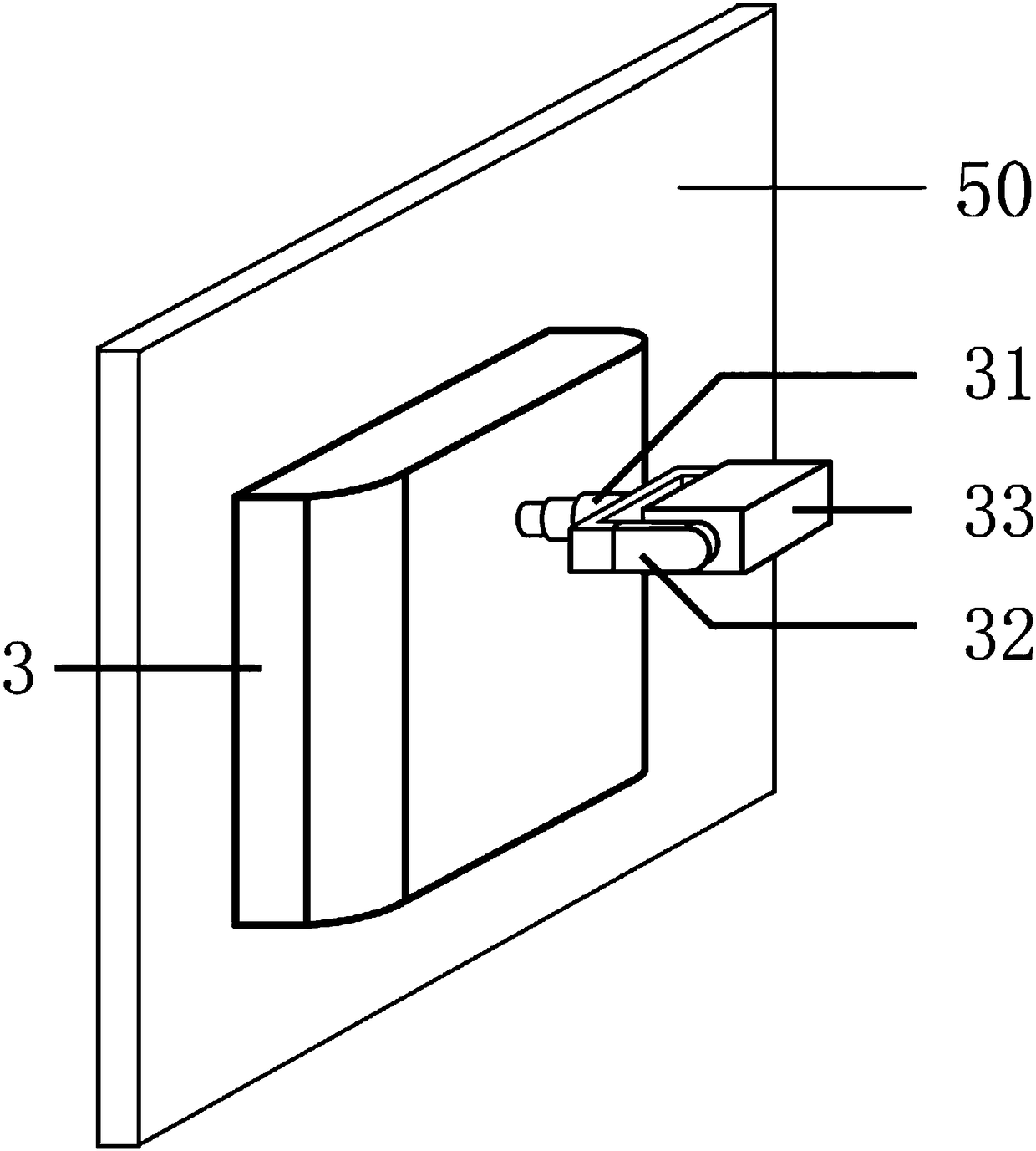

Disassembling and assembling device of corner clamping plate positioning and tensioning device

ActiveCN109940652AImprove bonding qualityLiberate human laborGripping headsProduction rateEngineering

The invention relates to a disassembling and assembling device of a corner clamping plate positioning and tensioning device. The disassembling and assembling device comprises a fixed base, a movable base, a driving part, a fixed arm, a movable arm and a handle, wherein the movable base is arranged below the fixed base, the driving part is installed on the fixed base and is used for connecting anddriving the movable base to move up and down, the fixed arm is arranged on the side surface of the fixed base and is unfolded outwards, and the movable arm is arranged on the movable base and is unfolded outwards; and the handle is L-shaped, the middle bent position of the handle is hinged to the end, which is outwards unfolded, of the fixed arm, one end of the handle is movably connected to the end part, which is outwards unfolded, of the movable arm, and the other end of the handle is bent downwards. Compared with the prior art, the disassembling and assembling device can replace manual assembling and disassembling of the positioning and tensioning device, the labor is liberated, the production rate is improved, and the bonding quality of a corner clamping plate is improved.

Owner:SHANGHAI JIAO TONG UNIV +1

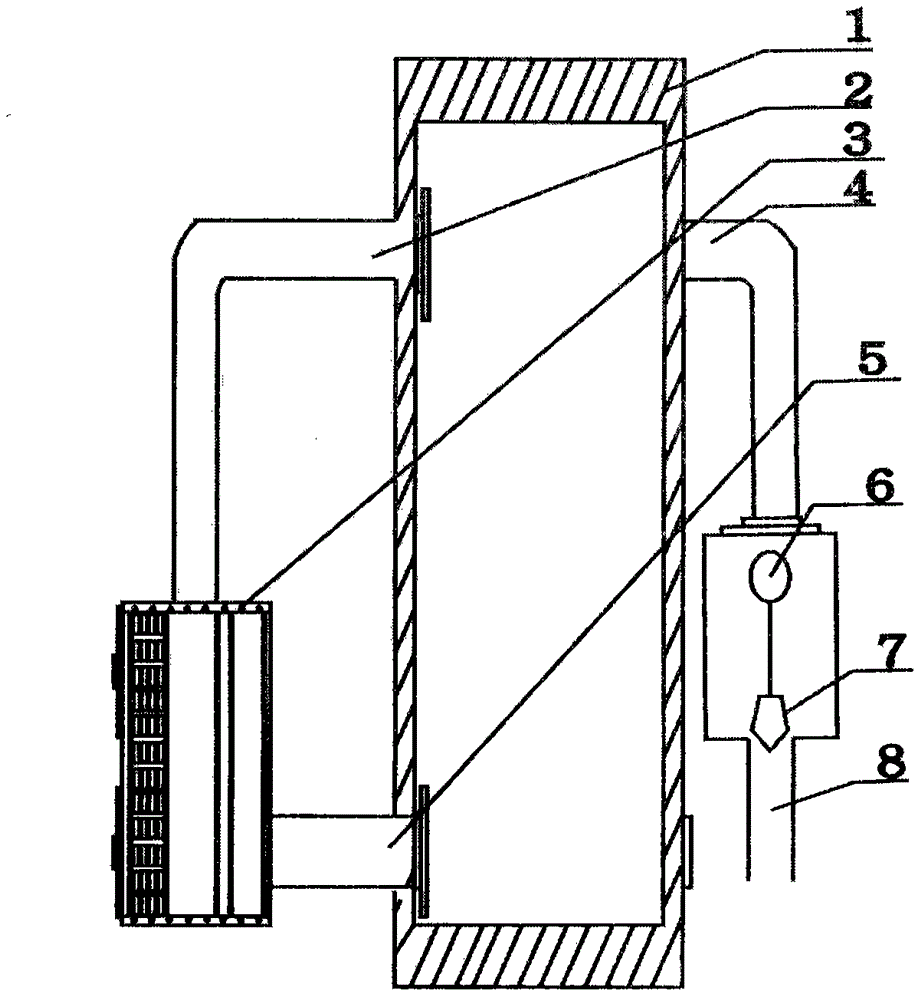

Automatic drainage device for moistureproof power distribution cabinet

InactiveCN105720490AHigh degree of automationLiberate human laborSubstation/switching arrangement casingsAgricultural engineeringWater storage tank

The invention discloses an automatic drainage device for a moistureproof power distribution cabinet, comprising a power distribution cabinet, a drying host, a blast tube connected to the drying host, a return duct, water exhaust port after the air is filtered, and a water storage tank connected to the water exhaust port; the moist air goes through the return duct and is dehumidified by the drying host and then sends the wind into the power distribution cabinet; and the water after the air is filtered is drained through the exhaust port. The automatic drainage device for moistureproof power distribution cabinet is high in automation, librates the workforce and improves the working efficiency.

Owner:洛阳双兴电气科技有限公司

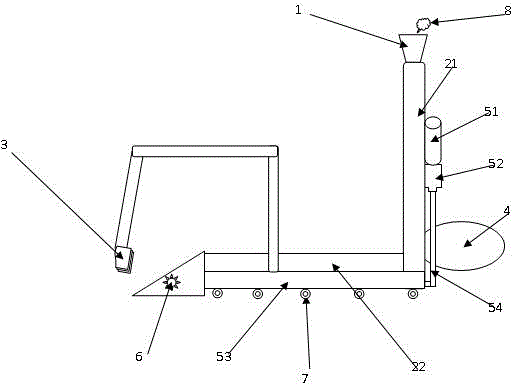

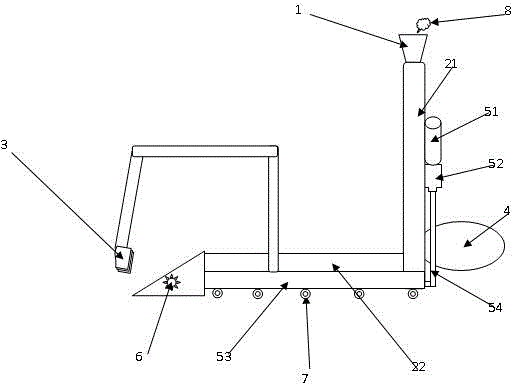

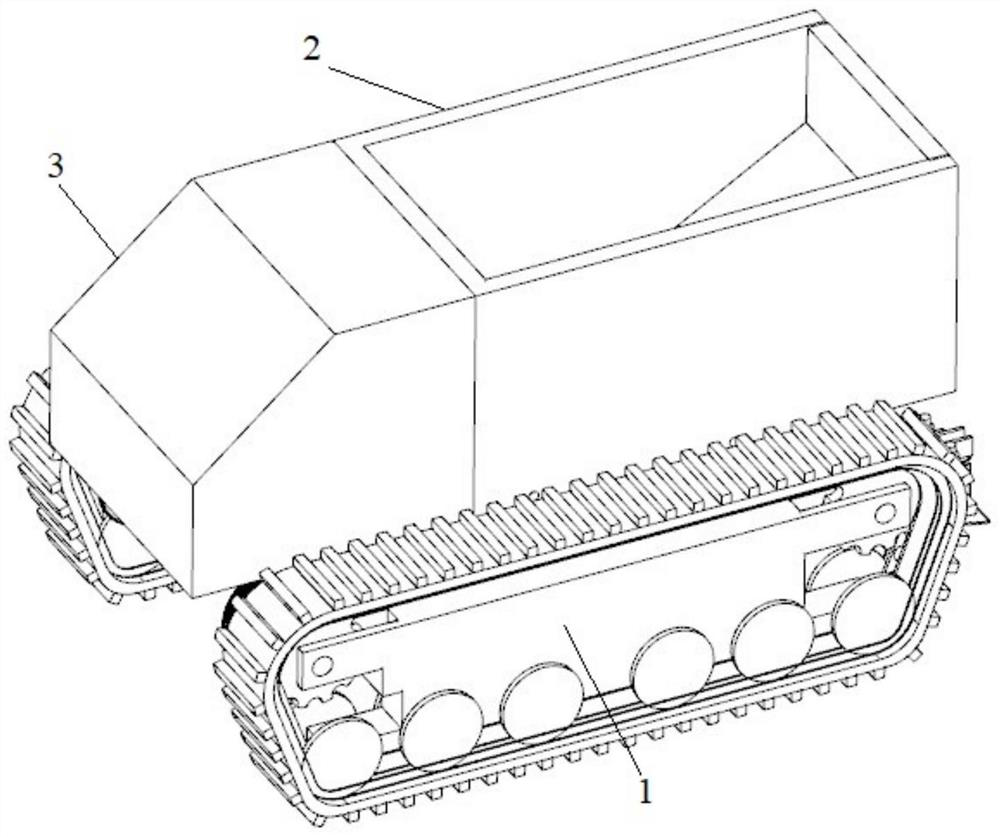

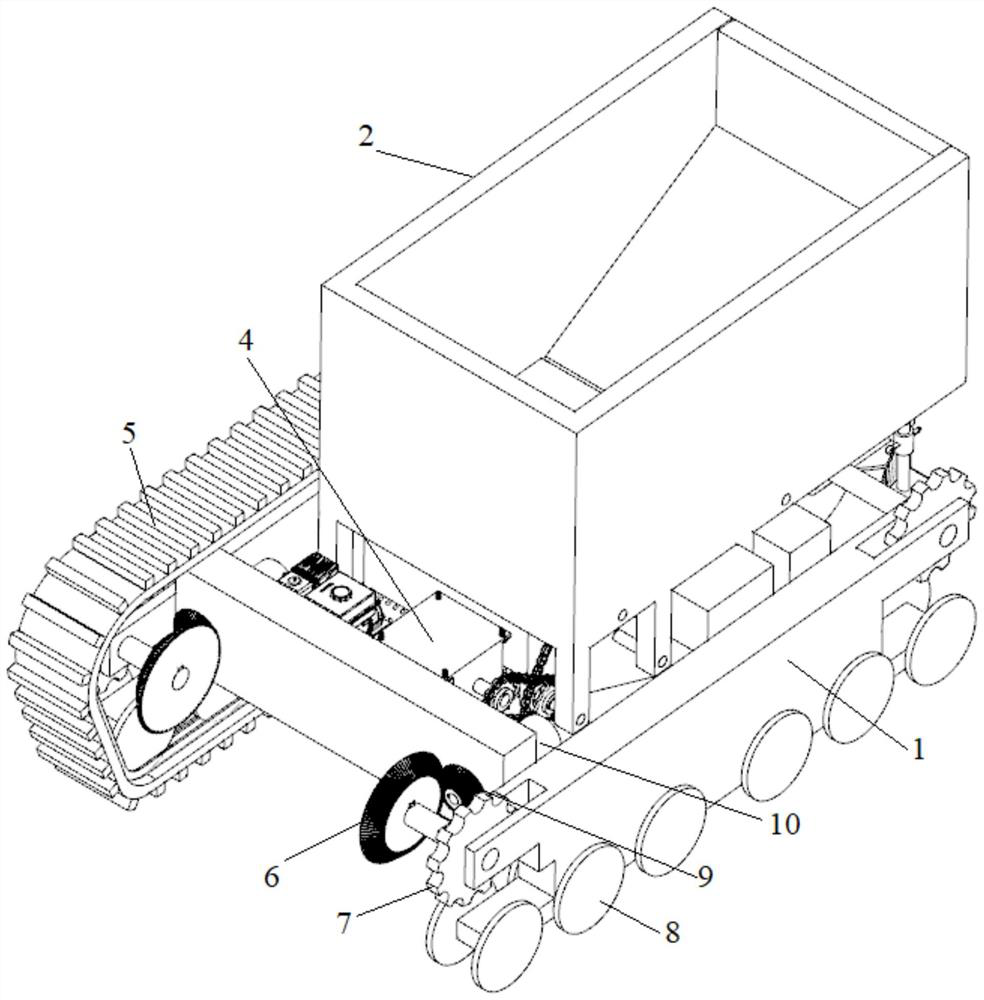

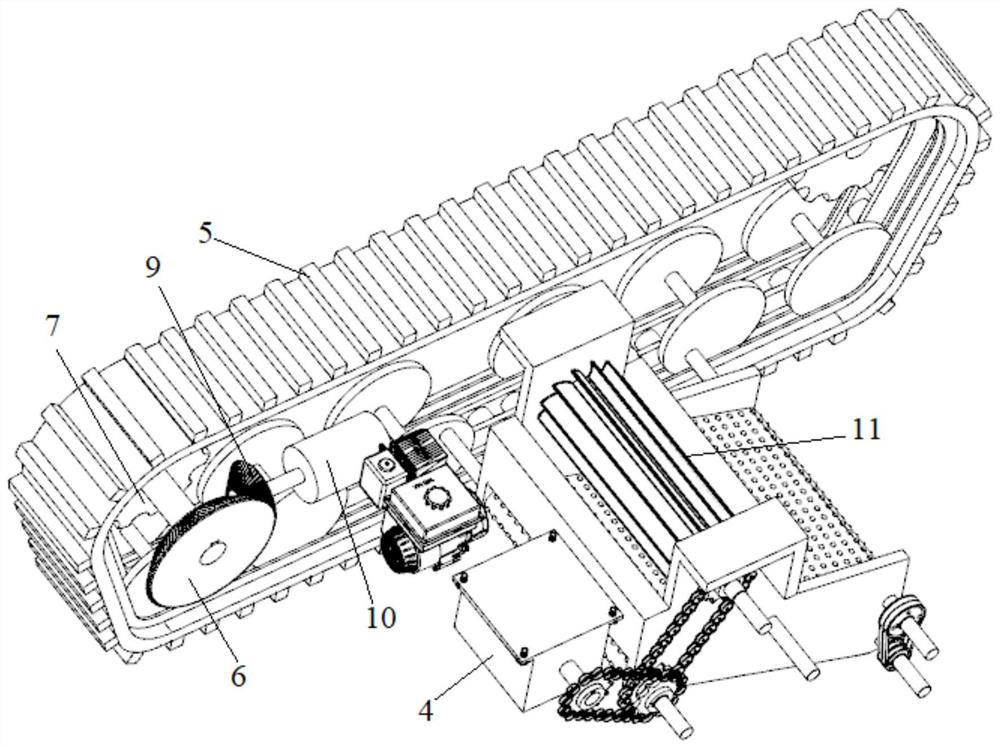

Auxiliary equipment for grass grid desertification control

InactiveCN113756275AIncrease productivitySimple structureSoil preservationVehicle frameAgricultural engineering

The invention discloses auxiliary equipment for grass grid desertification control. The auxiliary equipment comprises a vehicle frame, moving mechanisms are arranged on the two sides of the vehicle frame, a stock bin, a vehicle head and a conveying mechanism are arranged on the upper side of the vehicle frame, the vehicle head is located on the rear side of the stock bin, the conveying mechanism is located below the discharging port of the stock bin, grass poking wheels are arranged in the stock bin. A pressing wheel is arranged on the lower side of the vehicle head. According to the auxiliary equipment for grass grid desertification control, the problems that traditional manual desertification control is large in labor intensity, low in working efficiency, slow in progress and high in cost are solved.

Owner:SHAANXI UNIV OF SCI & TECH

High-strength lightweight intelligent animal dung cleaning device

The invention relates to a high-strength lightweight intelligent animal dung cleaning device, comprising a sensing device, a freezing device, a cleaning and collecting device, an advancing device and a control device. Dung is instantaneously frozen and separated from the ground through the reasonable arrangement of the devices, especially the freezing device, and the automation of the device is realized through the arrangement of the sensing device, so that animal dung can be effectively and efficiently cleaned in the non-manure storage area. Meanwhile, the material of a freezing injection pipe is improved, and the strength at the low temperature is guaranteed under the condition of being lightweight, so that the service life of the equipment is guaranteed.

Owner:广州荷德曼农业科技有限公司

Preparing device and use method of bee product soft capsules

The invention provides a preparing device and use method of bee product soft capsules. The preparing device comprises a machine base, a machine frame and capsule plates. A supporting leg is arranged at the upper end of the machine base and provided with a motor. A belt is arranged on the motor. The other end of the motor is provided with a rolling wheel. A transmission wheel is arranged outside the rolling wheel. A conveying belt is arranged outside the transmission wheel. The capsule plates are arranged on the conveying belt. A support is arranged at the upper portion of the machine frame. Amixing box is arranged on the support and provided with a filling pipe. A flow meter is arranged on the filling pipe. An electromagnetic valve is arranged at the lower end of the flow meter. Accordingto the capsule preparing device, automatic control and mechanical conveying are adopted, the flow meter is arranged to precisely control the amounts of raw materials in the capsules, all the preparedcapsules are the same in bee product content, the high-quality products are prepared and the plates are put away at a time, and efficiency is greatly improved.

Owner:MINGGUANG HAOHAO BEES

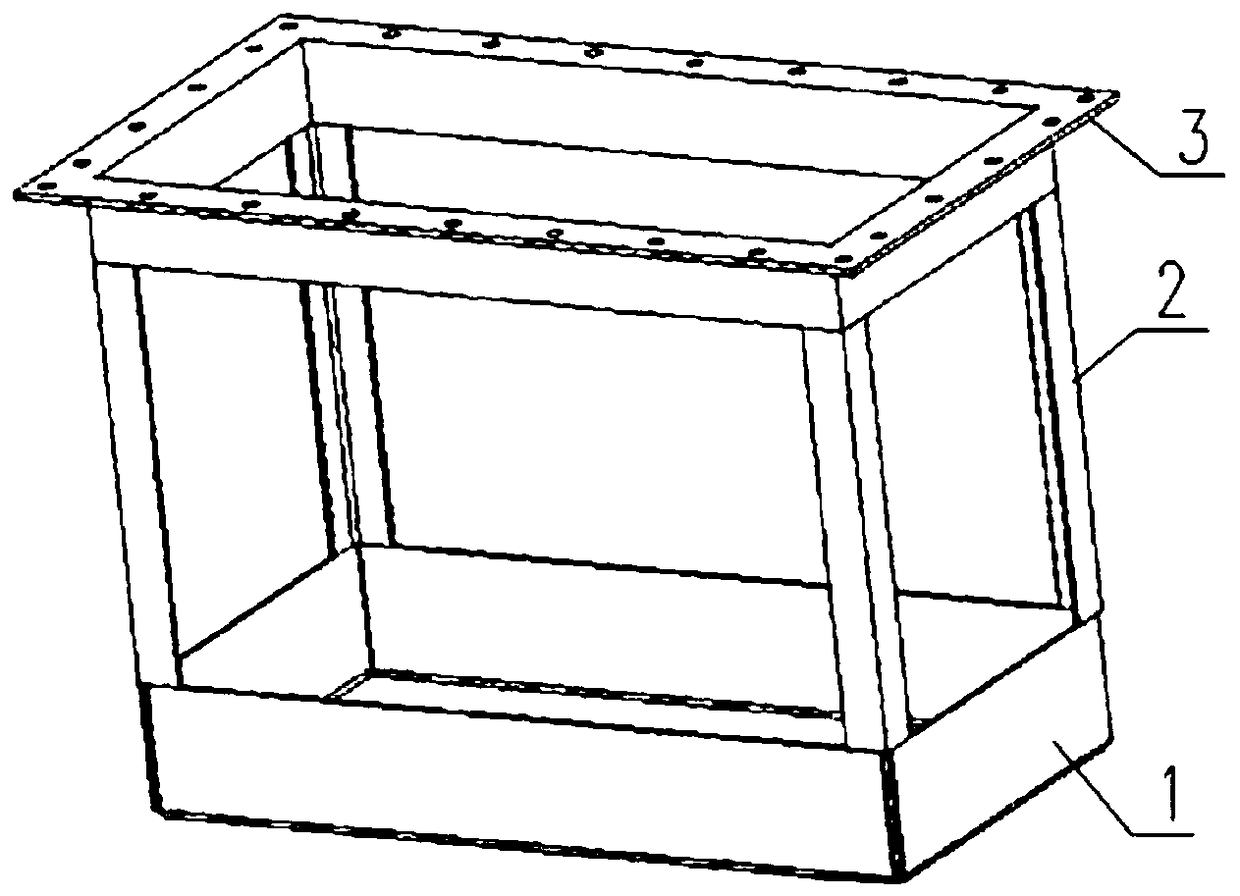

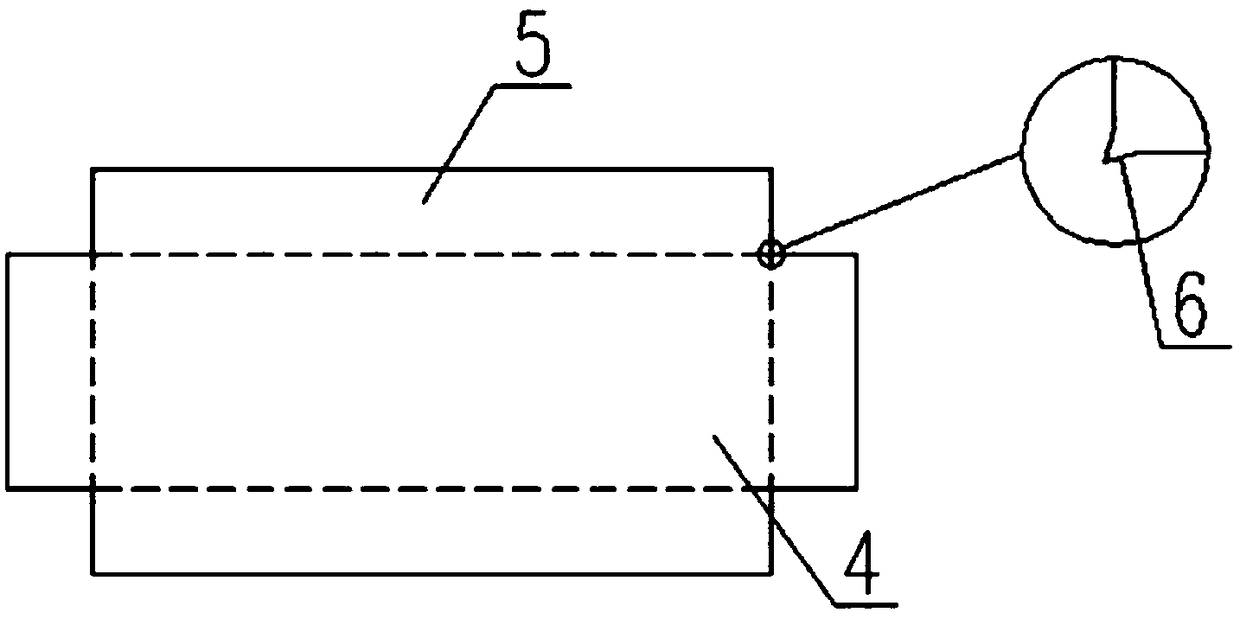

A transformer tank adapted to the operation of a welding robot and a design and processing method thereof

ActiveCN109216003AIncrease productivityLiberate human laborInductances/transformers/magnets manufactureWork in processEngineering

The invention provides a transformer oil tank adapted to welding robot and a design and processing method thereof. The three-layer skeleton with distinct hierarchy comprises a bottom part connected from bottom to top in turn, a main body skeleton part and a box edge part. The semi-finished product of the oil tank is welded on the outside, so that the welding gun of the manipulator is convenient towork. The panel at the bottom of the transformer is designed by integrative molding, the right angle of the bottom of the transformer is slotted by triangle method, and the main body skeleton is positioned by groove method. Through the design method and the structural design of the oil tank skeleton, a standard process flow is provided to the transformer manufacturer, and the production efficiency of the transformer manufacturer is improved. It solves the problem that welding torch is difficult to enter when welding robot on traditional oil tank is working, and solves the problem that weldingtorch is difficult to enter when welding robot is working. Convenient for welding robot manufacturers to uniformly plan the standardization of various types of supporting tooling; Reduce production costs, reasonable control of the production accuracy and aesthetics of products.

Owner:山东泰开箱变有限公司

Simple back patter

The invention provides a simple back patter comprising a base, a moving block, an output rod, a power rod, a link rod, a motor I, and a patting member. The moving block is movably disposed on the base. One end of the power rod is connected with the moving block through a hinge I; the other end of the moving rod is connected with one end of the link rod through a hinge II; the other end of the link rod is connected with the output rod through a hinge III; the output rod is connected with the moving block through a hinge IV; the output rod is connected with the patting member; the motor I is disposed on the base, and an output shaft of the motor I is connected with the hinge I. Compared with the prior art, the simple back patter is driven by a crank-rocker mechanism and allows patting frequency and patting force to be adjusted by controlling the motor I, labor of others is freed, conveniences are brought to users, and cost and time can also be saved.

Owner:SUZHOU INST OF TRADE & COMMERCE

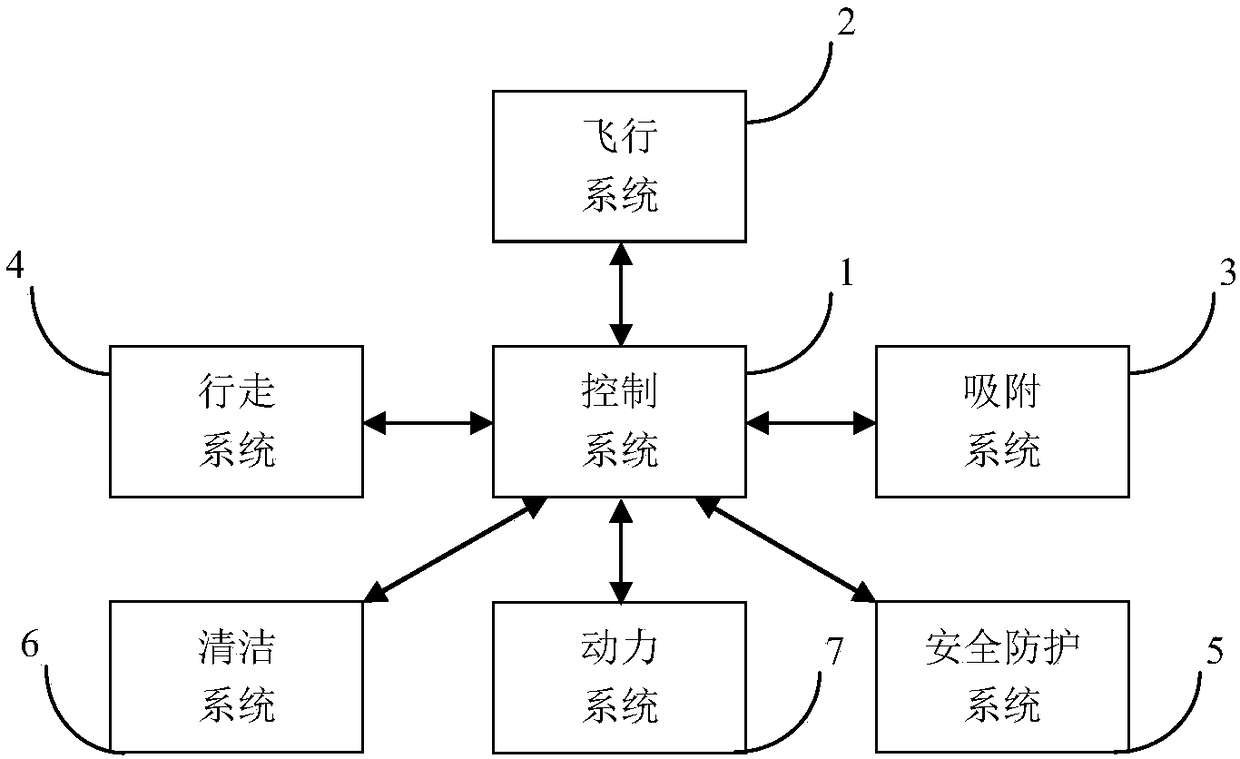

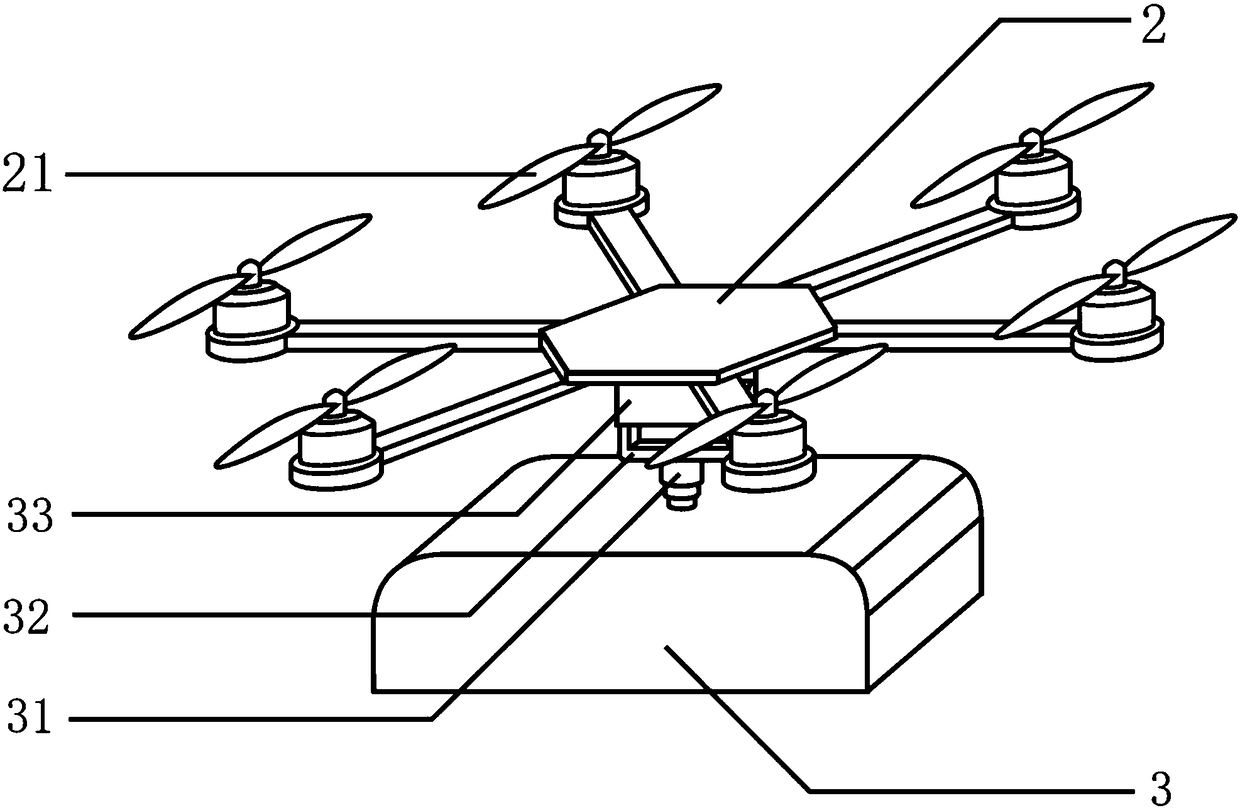

Robot device for cleaning vertical planes of buildings and adsorption method thereof

InactiveCN108316665AImprove securityLiberate human laborBuilding repairsAircraft convertible vehiclesVertical planeControl system

The invention relates to a robot technology and discloses a robot device for cleaning vertical planes of buildings and an adsorption method thereof. The robot device disclosed by the invention mainlycomprises a power system, a control system, a flight system, an adsorption system, a running system, a cleaning system and a safety protection system, wherein the control system comprises a remote control system and a self-control system and is used for controlling a robot to perform flight, adsorption, running and cleaning processes; the adsorption system comprises a sucker, a telescopic rotatingmechanism and a vacuum pump; the sucker is connected with the vacuum pump and is connected with the robot flight system through the telescopic rotating mechanism; the sucker can extend out of a vertical plane of a contact building to perform adsorption and then can be rotated to the direction parallel to the vertical plane of the building; and when the safety protection system detects the condition that the robot falls off, the flight system is started to prevent the robot from falling off. The robot device disclosed by the invention has the beneficial effects of improving the cleaning efficiency and the safety performance of the robot during working, and is very suitable for cleaning and maintaining the vertical planes of buildings such as glass curtain walls.

Owner:SICHUAN UNIV

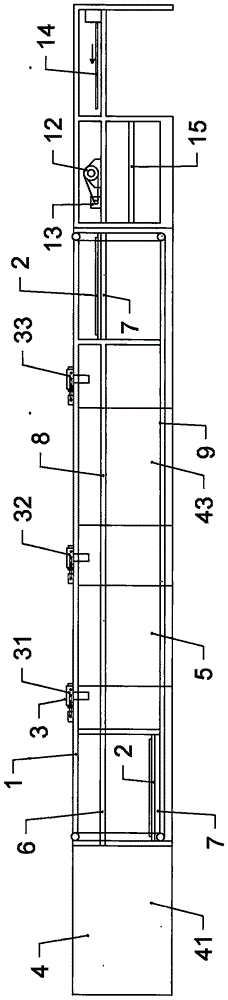

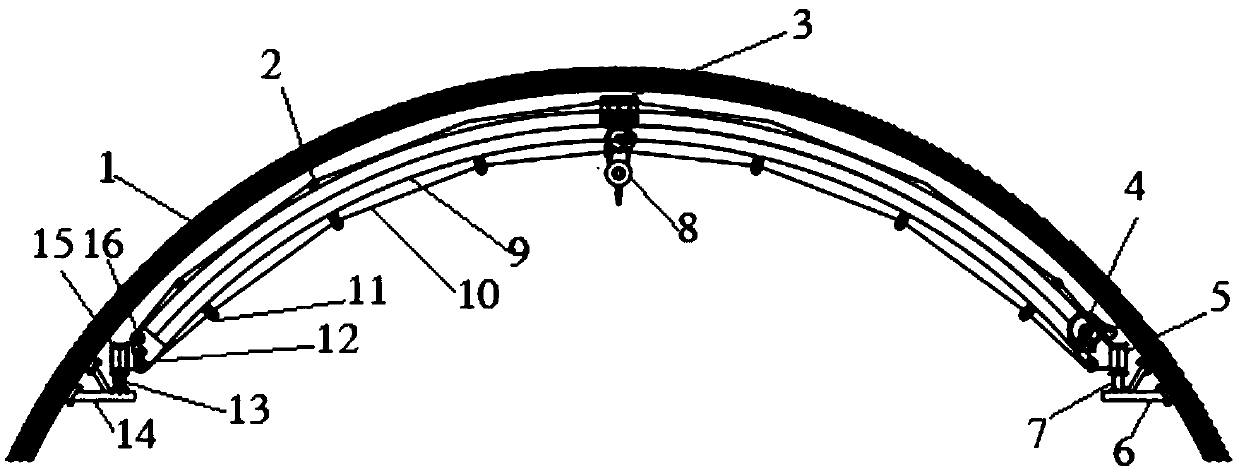

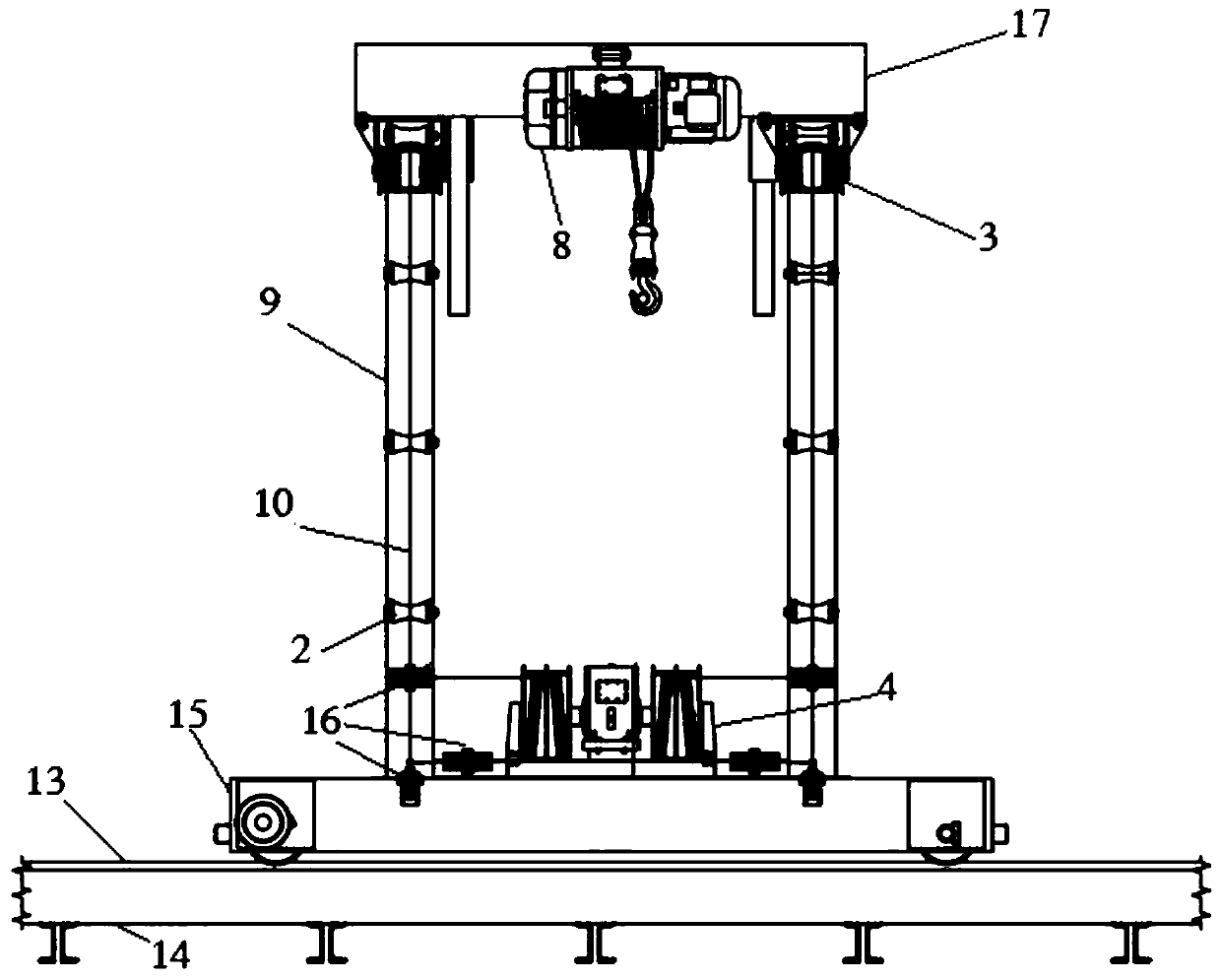

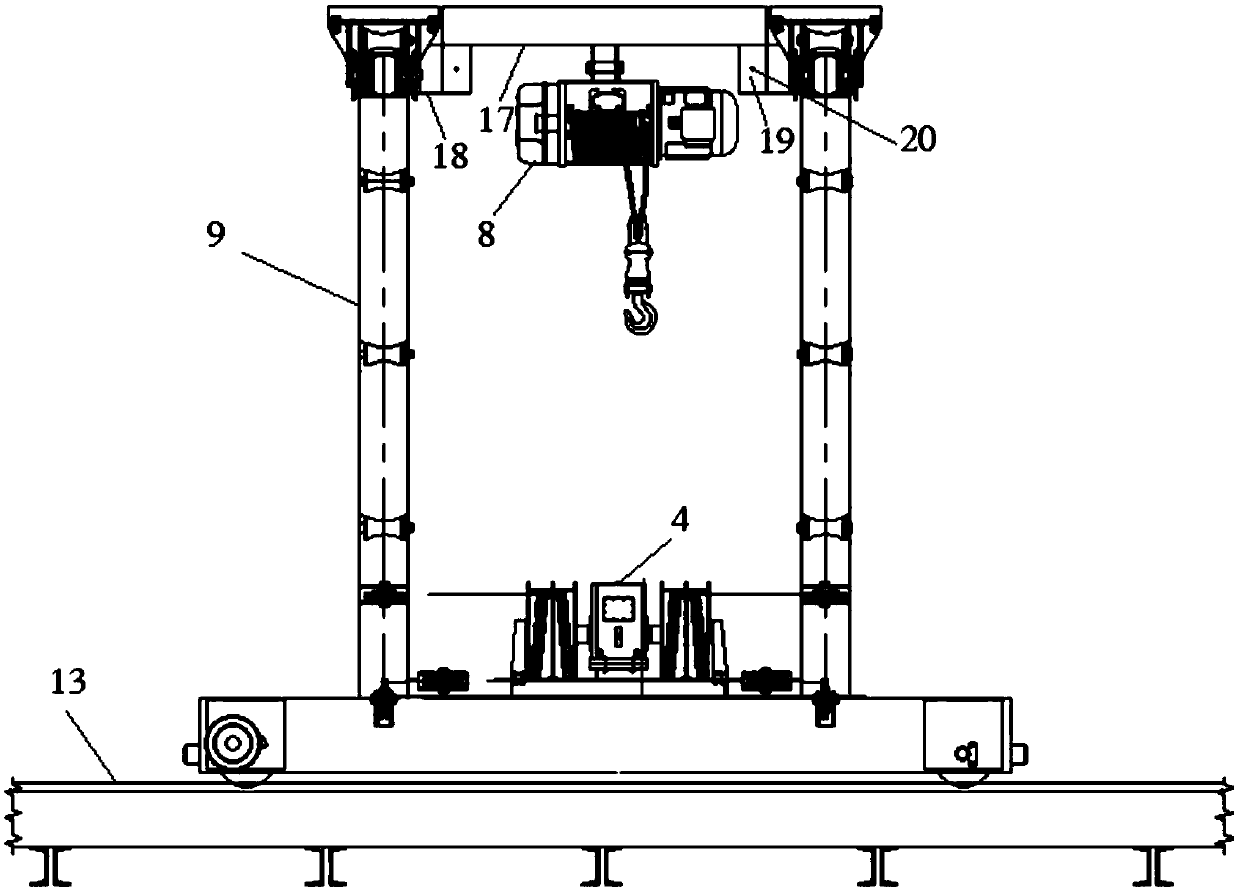

Double-arch-bridge type installation machine for railway tunnel formwork trolley

ActiveCN109650260ASimple and ingenious structureSmall footprintTravelling cranesTravelling gearRailway tunnelTraveling block

The invention discloses a double-arch-bridge type installation machine for a railway tunnel formwork trolley. A first track support and a second track support are arranged on the two sides of the interior of a tunnel primary support section. A first travelling beam is arranged on the first track support in a sliding mode, and a second travelling beam is arranged on the second track support in a sliding mode. A pair of arched beams are arranged between the first travelling beam and the second travelling beam, and a plurality of guide pulleys are arranged on the arched beams. Sliding trolleys are arranged on the arched beams, and pulling ropes are arranged at the two ends of each sliding trolley. After the ends of the two pulling ropes of each sliding trolley move in the opposite directions,the pulling ropes are connected with one driving end of a pulling mechanism. The two sliding trolleys are connected through a transverse beam, and a lifting crane is arranged on the side of the transverse beam. The double-arch-bridge type installation machine for the railway tunnel formwork trolley is simple and exquisite in integral structure and small in occupied space, installation of the double-arch-bridge type installation machine can be achieved under the condition that over-excavation of a tunnel is not required, the manpower labor is greatly relieved, and the efficiency of tunnel operation is improved.

Owner:SHAANXI RAILWAY INST

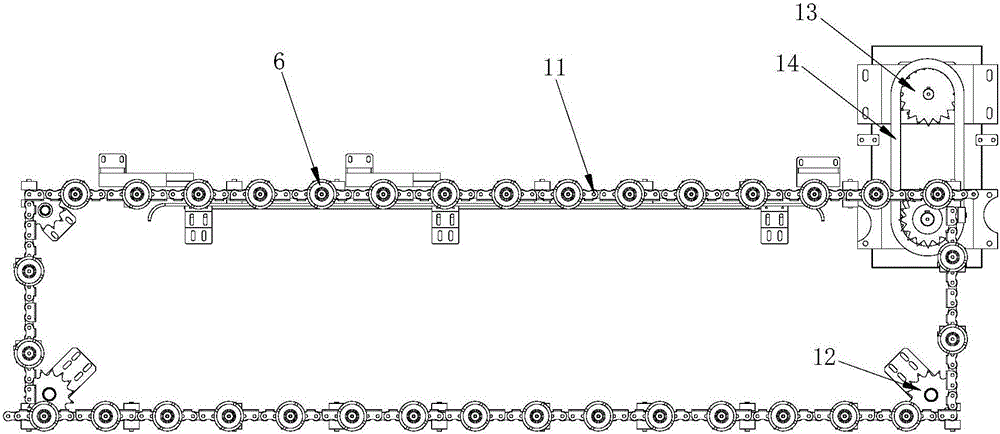

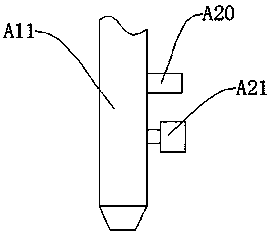

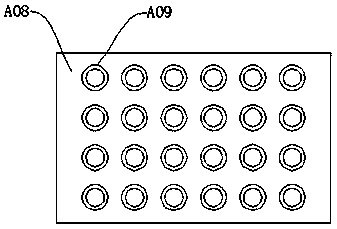

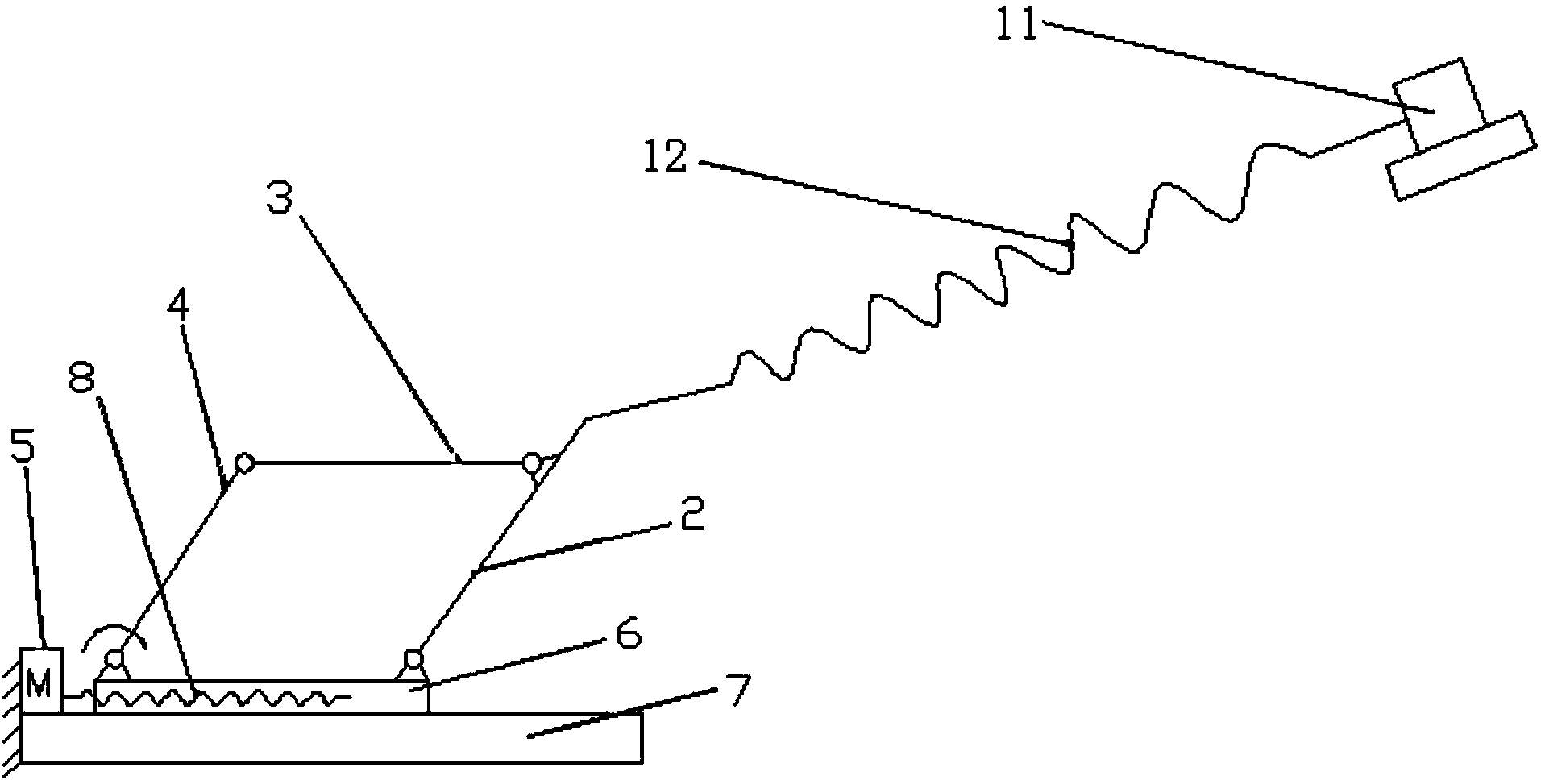

Conveying and positioning mechanism for long tail clip wrench

The invention relates to a conveying and positioning mechanism for a long tail clip wrench, which is characterized by comprising a vibration disc, a conveying rail, a support, a baffle, a magnet, an output slot and a vertical air cylinder, wherein the baffle is arranged on the support and is provided with a first side surface and a second side surface; a gap for the wrench to pass through is formed between the first side surface of the baffle and the tail end of the conveying rail; the magnet is arranged on the first side surface of the baffle; the output slot is formed in the bottom end of the baffle; and the vertical air cylinder is arranged on the support, and a push plate capable of vertically moving downwards to push the wrench into the output slot is arranged at the power output end of the vertical air cylinder. The conveying and positioning mechanism has the advantages that firstly, labors can be saved; and secondly, the wrench can be orderly arranged and accurately positioned to provide a good assembly foundation for subsequent assembly with a main body.

Owner:宁波江北昌晟自动化科技有限公司

Intelligent poultry manure cleaning device

The invention relates to an intelligent livestock manure cleaning facility. A sensor device, a freezing device, a cleaning and collecting device, a running gear and a control device are arranged reasonably, and materials thereof are improved; livestock manure is frozen immediately by the freezing device and then is separated from the earth surface, automation is achieved by means of the sensor device; accordingly, livestock manure in a region without manure storage can be cleaned effectively. Since the material for making freeze jet pipes are improved, the whole device is lightened, low-temperature strength is guaranteed, and service life of the device is guaranteed.

Owner:雷英 +1

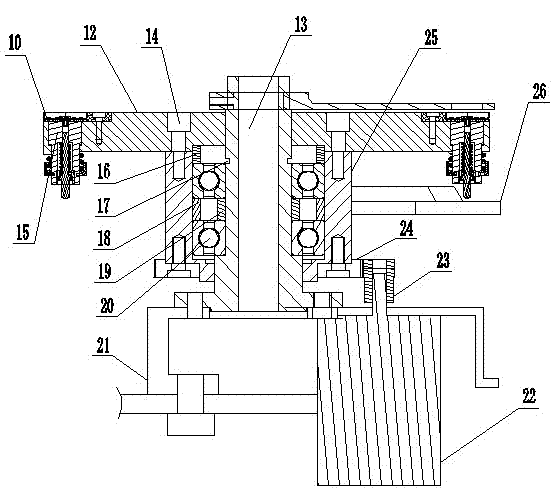

A stamping system of electronic fuel injection pump

ActiveCN112692789BGuaranteed stabilityMake sure it fits in placeMetal-working hand toolsPunchingEngineering

The invention relates to a stamping system of an electric fuel injection fuel pump, which includes a feeding vibration plate, a first conveying mechanism, a second conveying mechanism, a detection mechanism, and a stamping mechanism. The detection mechanism is composed of a guiding test cylinder, a bottom movable plate, and a controller The stamping mechanism is composed of a stamping machine and a guiding stamping mechanism arranged at the bottom of the stamping machine. The guiding stamping mechanism is composed of a movable sleeve, a connecting column, and a guiding column. Guide grooves are evenly opened on the side of the connecting column. The inner side of the movable sleeve is provided with a guide protrusion matching the guide groove, and a threaded strip is fixedly connected to the guide column. The threaded strip provided on the guide column can effectively ensure the stability of the guide stamping mechanism when it is pressed, and can effectively To ensure that the spring to be pressed is in place, the overall system realizes the automatic operation of spring pressing of the EFI fuel pump from feeding, detection to pressing and forming, which improves the pressing efficiency and facilitates the control of the pressing force of the spring, ensuring The spring is pressed into place.

Owner:安徽宝隽机车部件有限公司

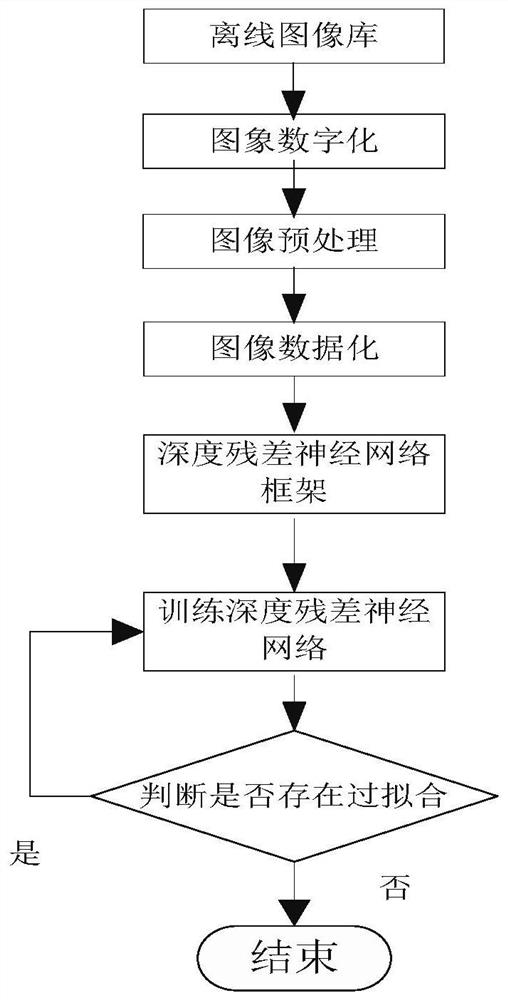

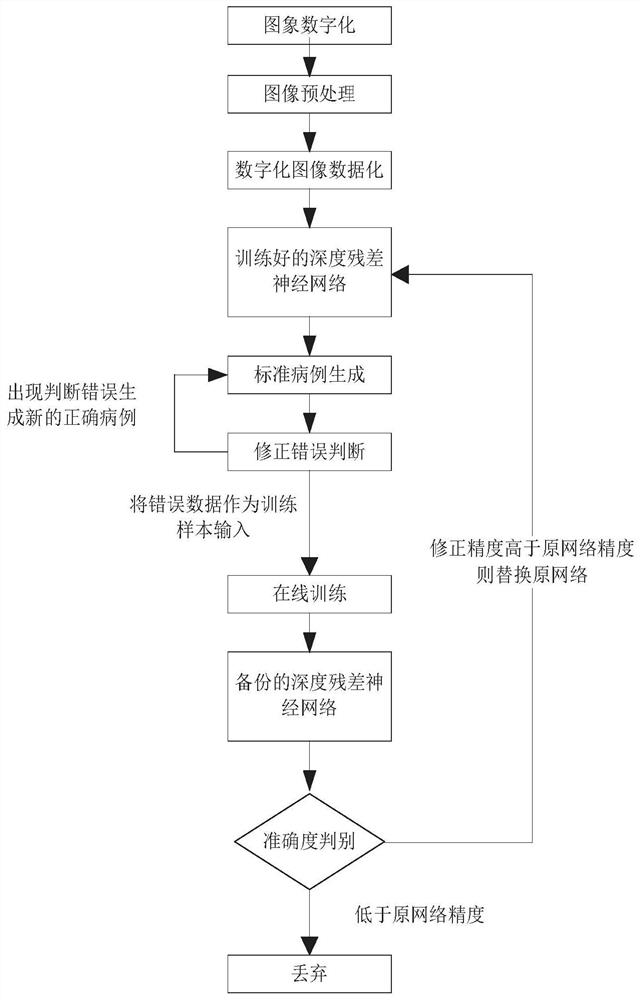

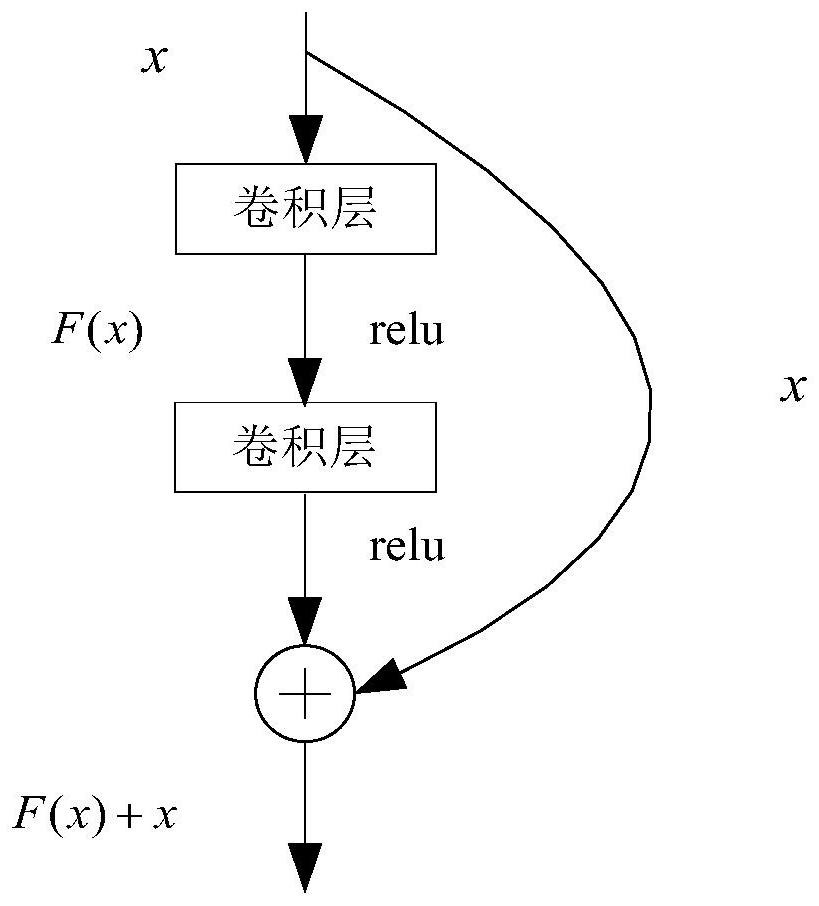

Classification and grading of orthopedic disease lesions based on deep residual network

The invention discloses a method for classifying and grading orthopedic disease lesions based on a deep residual network, which is specifically implemented according to the following steps: Step 1, offline learning, preprocessing professionally classified and marked orthopedic disease lesion images, and then performing Deep residual neural network training; step 2, online learning, back up the deep residual neural network trained in step 1 and deploy it to daily diagnosis and treatment, and use the training method of online learning to make the deep residual neural network pass daily The diagnosis and treatment data are constantly self-correcting. The method for classifying and grading orthopedic disease lesions based on the deep residual network of the present invention solves the problem that the accuracy of the existing convolutional neural network increases with the increase of the depth of the neural network structure, and then the accuracy decreases, and the offline learning method cannot be used for every day. There is a problem that self-correction cannot be performed as the number of consultations increases due to the use of medical treatment data.

Owner:XIAN UNIV OF TECH

Conveying and positioning mechanism for long tail clip wrench

The invention relates to a conveying and positioning mechanism for a long tail clip wrench, which is characterized by comprising a vibration disc, a conveying rail, a support, a baffle, a magnet, an output slot and a vertical air cylinder, wherein the baffle is arranged on the support and is provided with a first side surface and a second side surface; a gap for the wrench to pass through is formed between the first side surface of the baffle and the tail end of the conveying rail; the magnet is arranged on the first side surface of the baffle; the output slot is formed in the bottom end of the baffle; and the vertical air cylinder is arranged on the support, and a push plate capable of vertically moving downwards to push the wrench into the output slot is arranged at the power output end of the vertical air cylinder. The conveying and positioning mechanism has the advantages that firstly, labors can be saved; and secondly, the wrench can be orderly arranged and accurately positioned to provide a good assembly foundation for subsequent assembly with a main body.

Owner:宁波江北昌晟自动化科技有限公司

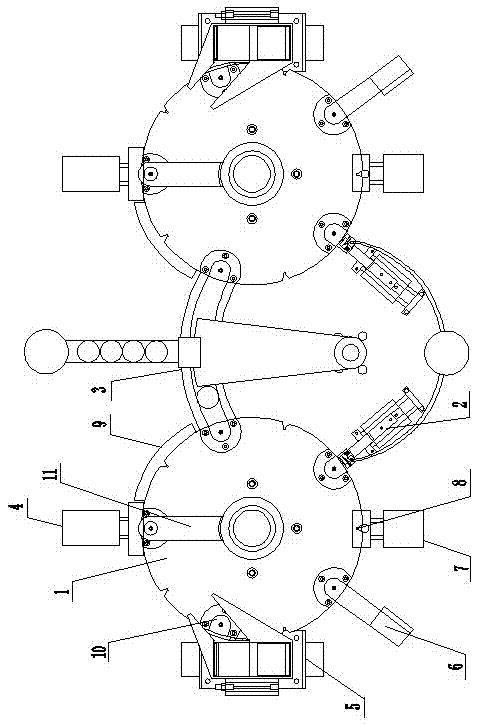

An automatic spot welding machine for welding membrane boxes

InactiveCN103252592BQuality improvementLiberate human laborWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingMechanical engineering

The invention provides an automatic spot welding machine for welding a capsule and relates to the field of spot welding equipment. The automatic spot welding machine comprises two turntable devices, handle feeding devices, a sheet feeding device, welding devices, unloading devices, mold cleaning devices and turntable positioning devices, wherein the two turntable devices are distributed on the two sides of the sheet feeding device; a sheet feeding guide groove capable of conveying capsule sheets to the turntable devices on the two sides respectively is formed in the sheet feeding device; each handle feeding device, each welding device, each unloading device, each mold cleaning device and each turntable positioning device are distributed around each turntable device; each turntable device comprises a turntable; clamp grooves matched with each turntable positioning device is distributed at the circumferential edge of each turntable at intervals; capsule positioning grooves with center through holes are distributed on the upper surface of the turntable around the periphery of the turntable at intervals; and a welding ejection mechanism is arranged below each capsule positioning groove. With the adoption of the automatic spot welding machine, spot welding is conducted automatically, the labor is liberated, the potential safety hazards of manual operation are avoided, and the spot welding efficiency and the quality of a spot welding product are improved.

Owner:平顶山市联立机电有限公司

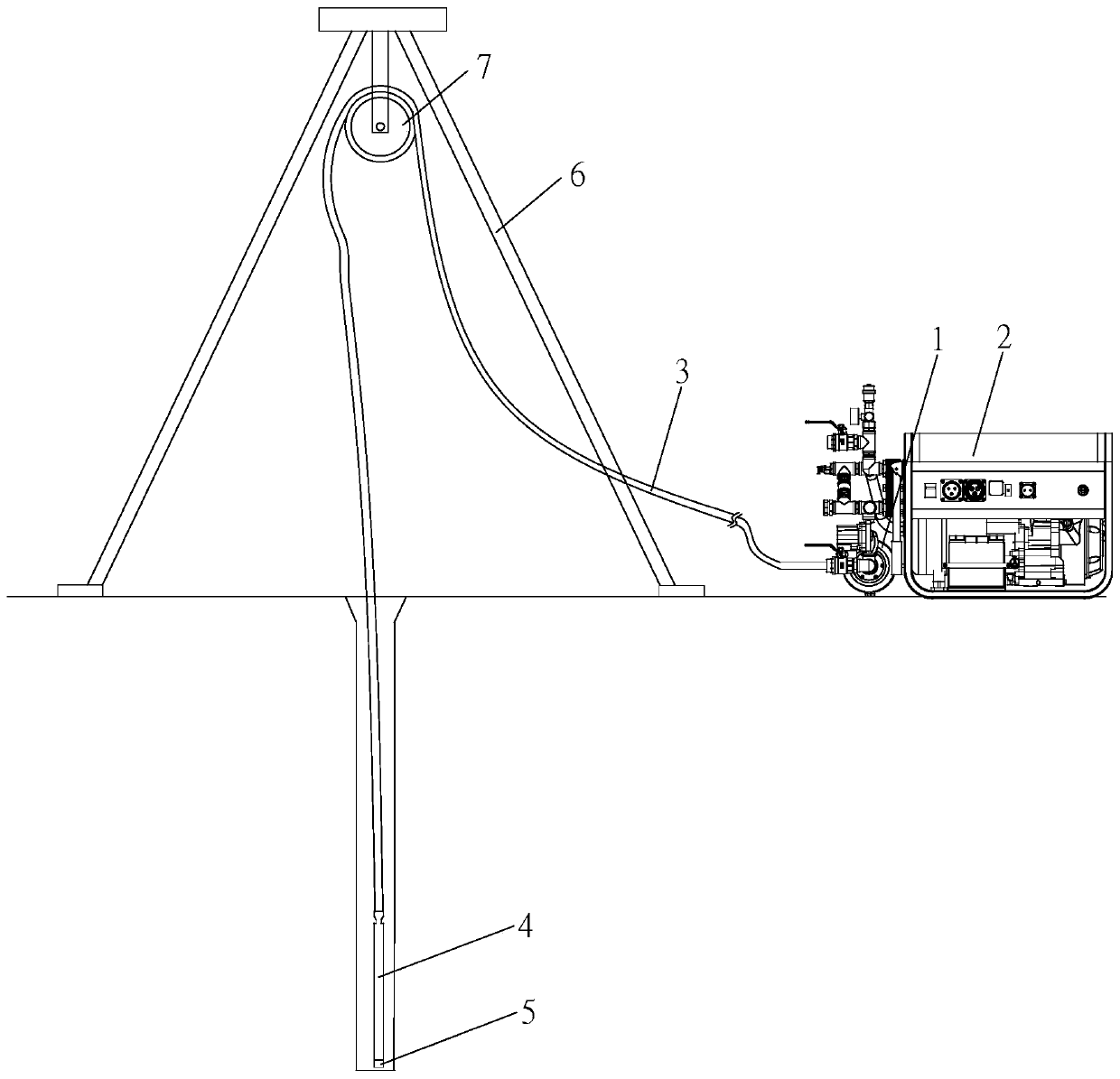

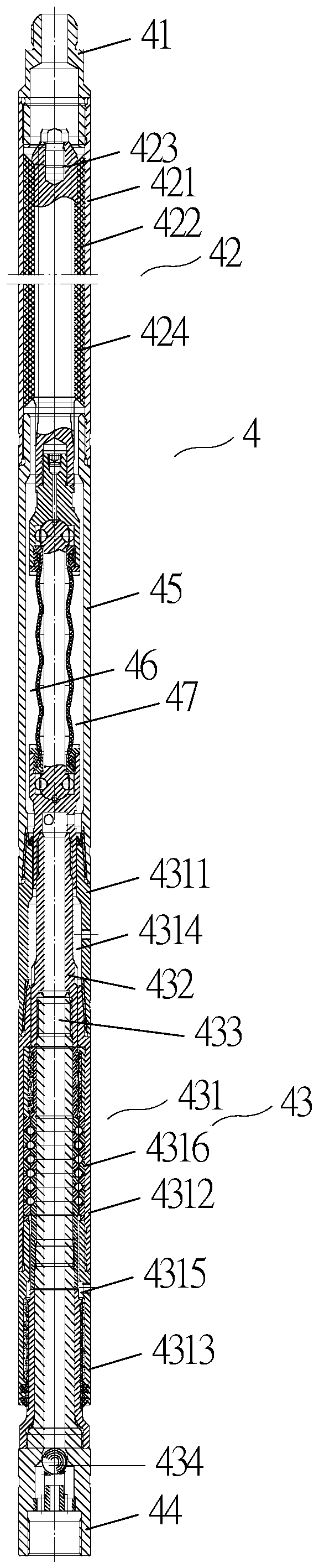

Gas-liquid hose drilling machine and exploration method

PendingCN110847810ALower center of gravityUniform pore sizeBorehole drivesDrilling machines and methodsWell drillingAir pump

The invention belongs to the technical field of petroleum exploration and provides a gas-liquid hose drilling machine comprising a pump. A power source drives the pump. One end of a hose is connectedwith the pump and used for conveying pumped gas or liquid. A drilling rig is connected with the other end of the hose, and the drilling rig is driven by the gas or liquid conveyed by the hose. A drillbit is arranged on the drilling jig and driven by the drilling jig. The pump is a slurry pump or a gas pump. The power source is an engine. The gas-liquid hose drilling machine further comprises a tripod. A fixed pulley is arranged on the tripod and used for guiding the hose. By the adoption of the technical scheme, the problems that in the prior art, during petroleum exploration, a lot of wellsneed to be dug and are located on the mountainous areas, most of the wells need to be manually dug for 10-30 meters, the actually common tools are Luoyang shovels, efficiency is low, even if a drilling platform is adopted, operation of drill stem connection is complicated, and no appropriate device can solve the problem that operation of drill stem connection is complicated are solved.

Owner:HEBEI ZHONGRONG PETROLEUM MACHINERY CO LTD

High-strength and light-weight intelligent animal waste cleaning device

ActiveCN105780693BImprove cooling effectEasy to cleanRoad cleaningEngineeringUltimate tensile strength

The invention relates to a high-strength lightweight intelligent animal dung cleaning device, comprising a sensing device, a freezing device, a cleaning and collecting device, an advancing device and a control device. Dung is instantaneously frozen and separated from the ground through the reasonable arrangement of the devices, especially the freezing device, and the automation of the device is realized through the arrangement of the sensing device, so that animal dung can be effectively and efficiently cleaned in the non-manure storage area. Meanwhile, the material of a freezing injection pipe is improved, and the strength at the low temperature is guaranteed under the condition of being lightweight, so that the service life of the equipment is guaranteed.

Owner:广州荷德曼农业科技有限公司

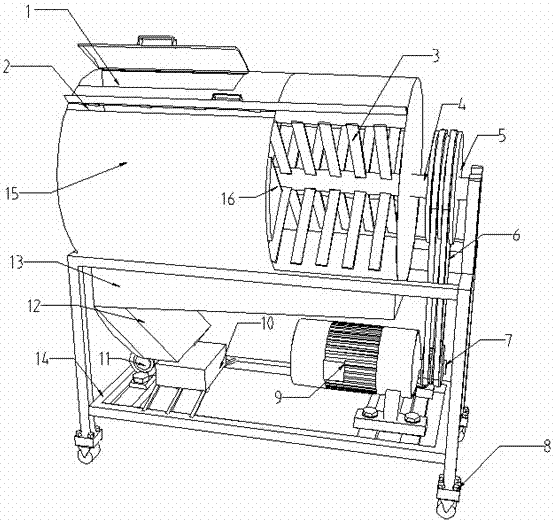

A poplar seed thresher and poplar seed thresher method

The invention relates to the field of forest product processing machine and processing method, in particular to a poplar seed threshing machine. The poplar seed threshing machine comprises a power device, a threshing device and a screening device. The threshing device comprises an outer drum and a rotating shaft. The rotating shaft is arranged in an outer drum cavity. Shaft racks are fixedly arranged on the rotating shaft in the axial direction. A steel plate is fixed in the outer drum. The shaft racks can make contact with the steel plate. The power device drives the rotating shaft to rotate. The screening device is arranged under the outer drum. At the same time, the invention further discloses a poplar seed threshing method utilizing the poplar seed threshing device. The poplar seed threshing machine and the poplar seed threshing method have the advantages that the operation is simple, the structure is reasonable, manpower labor is emancipated, and threshing can be conducted on the poplar seed quickly; at the same time, the quality of the poplar seed is guaranteed, thereby the production cost is saved, and the seedling and sowing area of poplar sexual propagation can be enlarged quickly in a short time.

Owner:NANJING UNIV OF INFORMATION SCI & TECH +1

A distribution transformer fuel tank suitable for welding robot operation and its design and processing method

ActiveCN109216003BIncrease productivityLiberate human laborInductances/transformers/magnets manufactureDistribution transformerRobot hand

The invention provides a transformer oil tank adapted to welding robot and a design and processing method thereof. The three-layer skeleton with distinct hierarchy comprises a bottom part connected from bottom to top in turn, a main body skeleton part and a box edge part. The semi-finished product of the oil tank is welded on the outside, so that the welding gun of the manipulator is convenient towork. The panel at the bottom of the transformer is designed by integrative molding, the right angle of the bottom of the transformer is slotted by triangle method, and the main body skeleton is positioned by groove method. Through the design method and the structural design of the oil tank skeleton, a standard process flow is provided to the transformer manufacturer, and the production efficiency of the transformer manufacturer is improved. It solves the problem that welding torch is difficult to enter when welding robot on traditional oil tank is working, and solves the problem that weldingtorch is difficult to enter when welding robot is working. Convenient for welding robot manufacturers to uniformly plan the standardization of various types of supporting tooling; Reduce production costs, reasonable control of the production accuracy and aesthetics of products.

Owner:山东泰开箱变有限公司

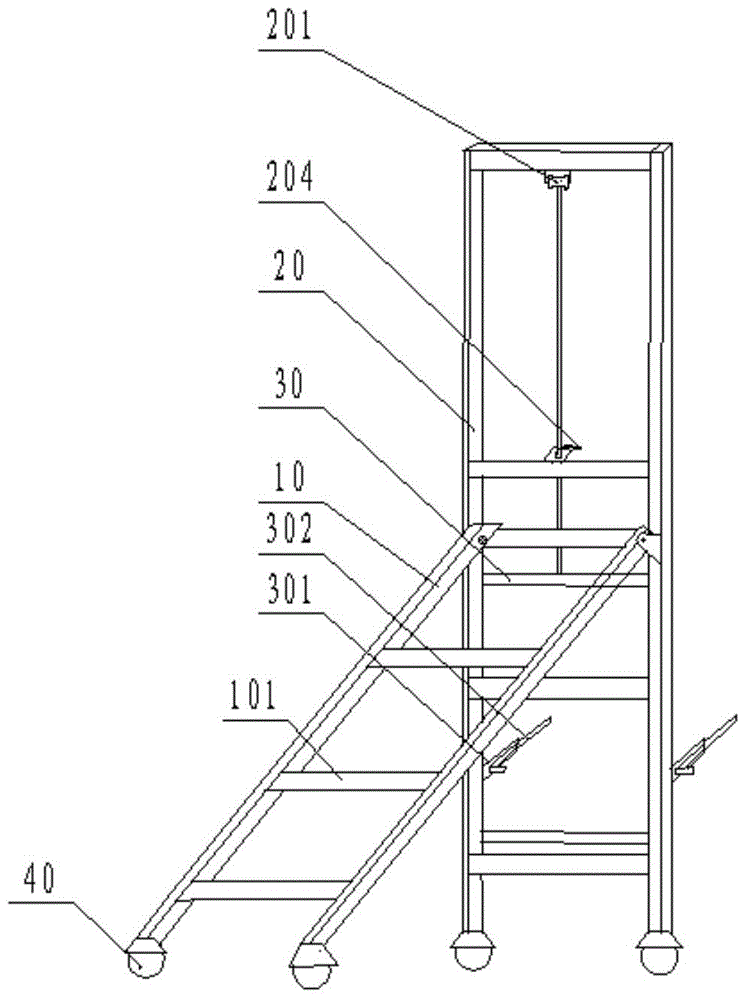

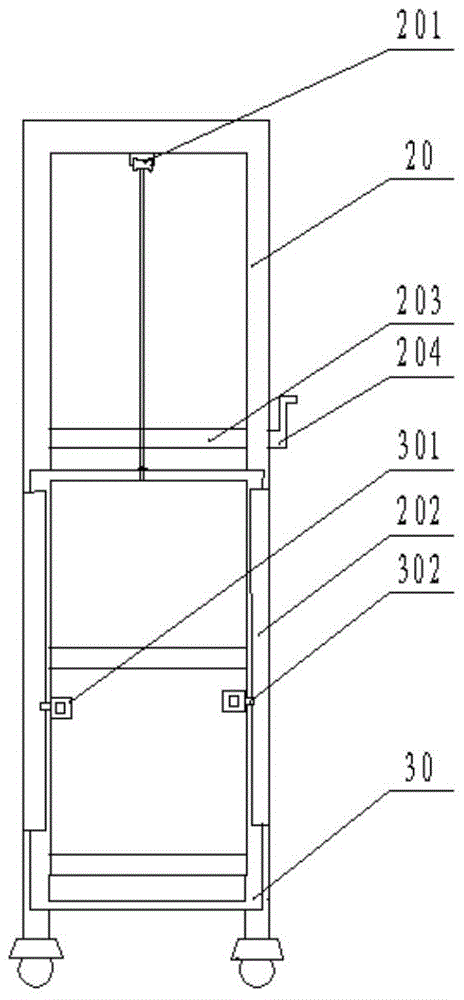

Electric meter box installation auxiliary tool and its installation method

InactiveCN104924270BImprove work efficiencyReduce workloadMetal-working hand toolsEngineeringSymmetric structure

The invention discloses an auxiliary installation tool and an installing method of an electricity meter box, belongs to the field of assembly devices special for switchboards for power supply or power distribution and methods and aims at solving the problem that time and effort are wasted for installation of a metal box in the prior art. The auxiliary installation tool comprises a vertical frame, a support and a carriage which are of axis-symmetric structures, wherein the support is hinged to the middle position of the vertical frame, and a horizontal pedal is arranged on the support. A longitudinal slide groove I is formed in the back side of the vertical frame, the carriage is arranged in the slide groove I, and a supporting frame is arranged on the carriage. A fixed pulley is fixed to the top of the vertical frame, a crank is arranged in the middle of the vertical frame, one end of a rope is fixed to the top of the carriage, and the other end of the rope is wound around the fixed pulley and then is fixed to a rotary shaft of the crank. The auxiliary tool is convenient to carry, labors are liberated, and the working efficiency can be improved by means of the installing method.

Owner:国网山东莒南县供电公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com