Multi-point sucking disc automatic-sucking installing machine for three-dimensional flexible gasket

A three-dimensional flexible, installation machine technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as assembly that cannot be automated with three-dimensional gaskets, achieve novel structures, precise automatic assembly, and improve assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

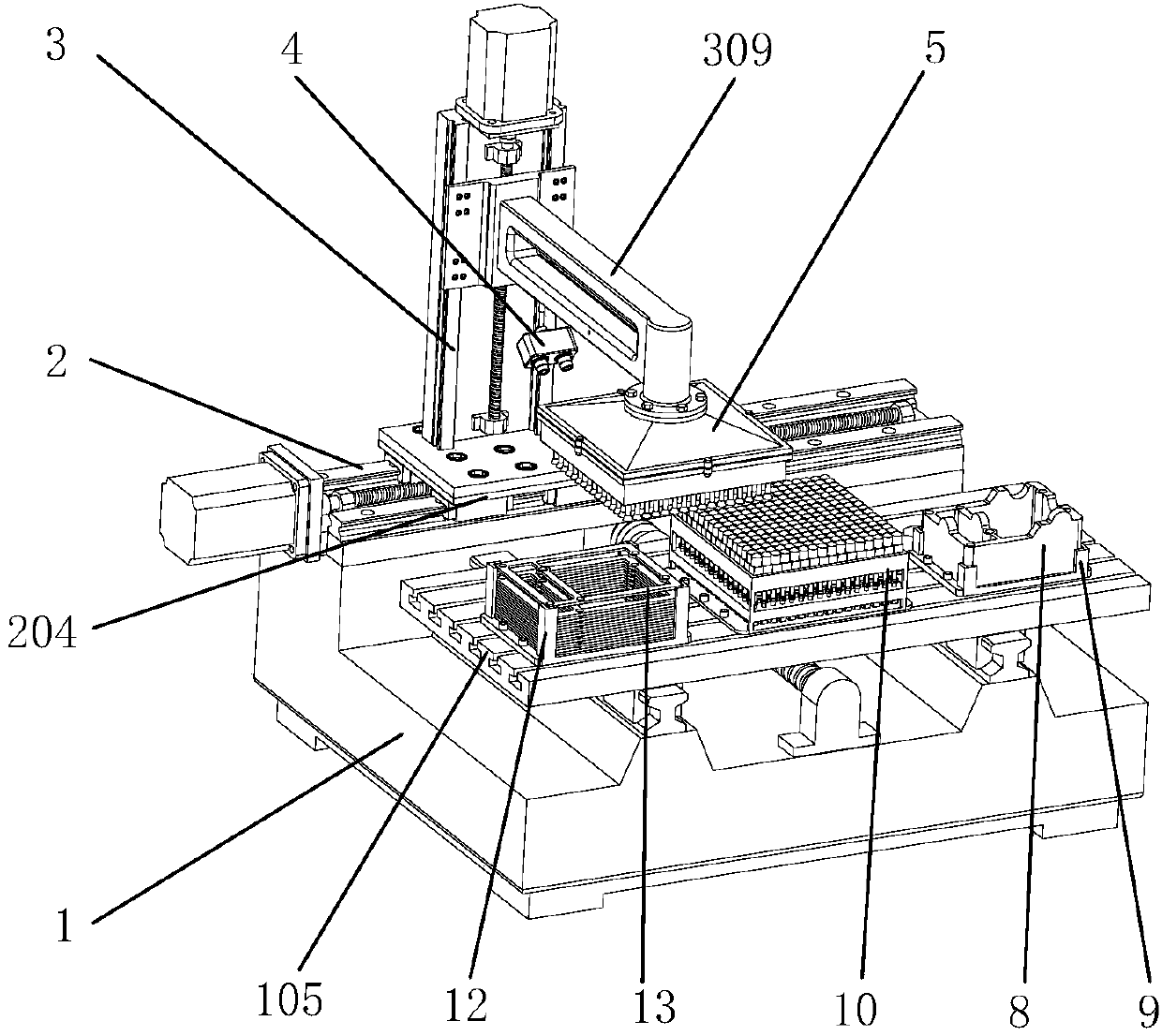

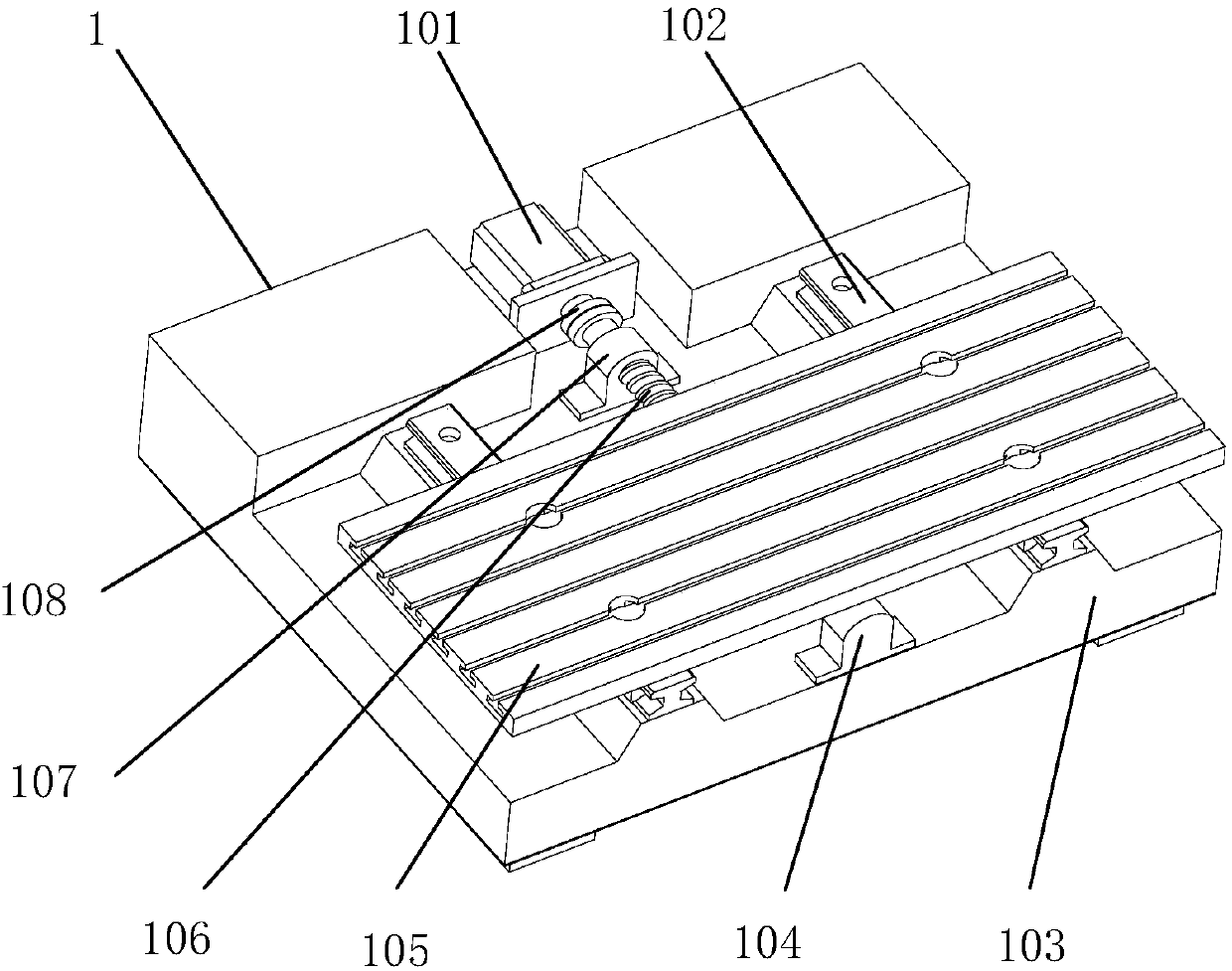

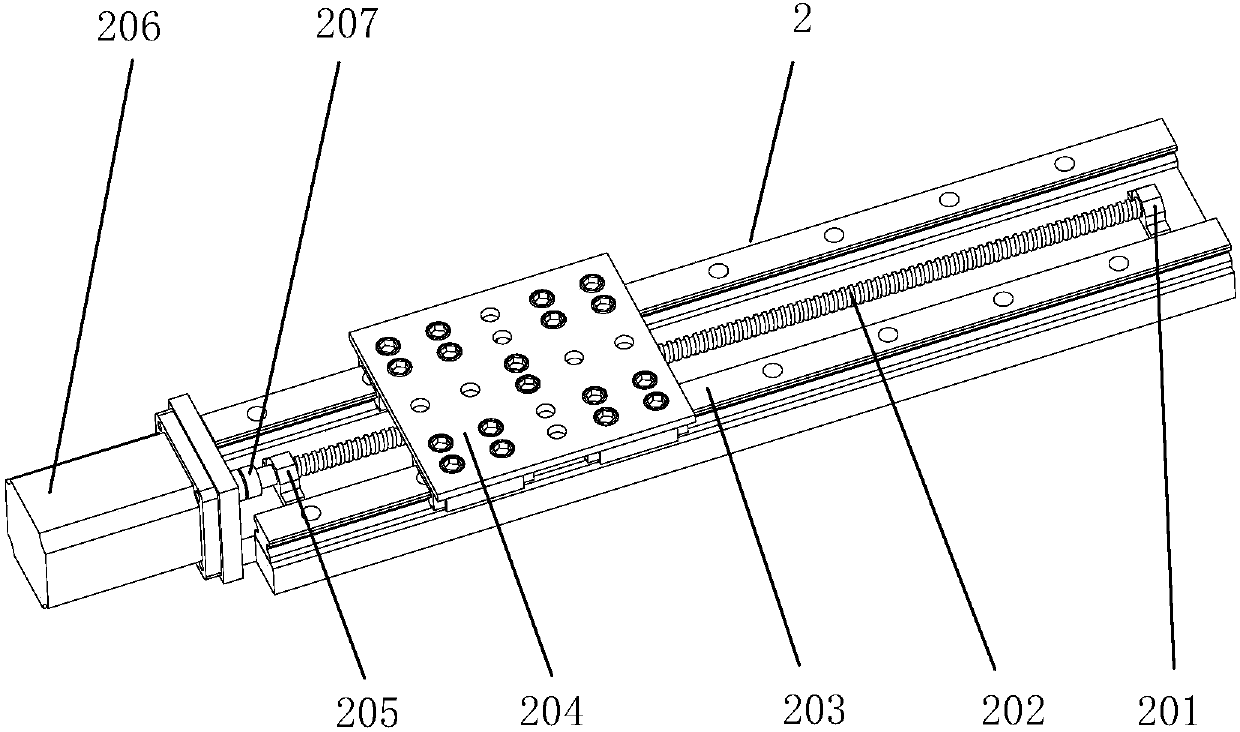

[0034] like figure 1 , including a base assembly 1, a lateral moving device 2, a vertical moving device 3, a CCD binocular camera 4, a multi-point suction cup 5, a workpiece support 9, a forming device 10, and a two-dimensional gasket support 12. The base assembly 1 includes a base 103, T-shaped slot workbench 105, laterally moving device 2 is fixedly installed on the boss behind base 103, laterally moving device 2 comprises horizontal slide plate 204, vertically moving device 3 is fixedly installed on the horizontal slide plate 204 and moves laterally The device 2 is vertical in the horizontal plane, and the vertical mobile device 3 includes a cross arm 309. The CCD binocular camera 4 is fixedly installed under the rear end of the cross arm 309. The support of the CCD binocular camera 4 includes a telescopic rod and a ball head adjustment structure. Thereby can adjust the relative height of camera and the direction angle of facing, multi-point suction cup 5 is fixedly install...

Embodiment 2

[0047] like Figure 13 As shown, the overall machine tool structure of this embodiment, the structure of the multi-point suction cup 5, the realization of the movement of the multi-point suction cup 5, the realization of the suction cup 5035 to absorb the flexible gasket, etc. are exactly the same as in the first embodiment, and different from the first embodiment The advantage is that the forming device 10 does not need to be used when assembling the three-dimensional flexible gasket that has been formed. At this time, the two-dimensional gasket support 12 in Embodiment 1 can be removed from the T-shaped slot workbench 105 Unload, the forming device 10 is fixed to the left end of the T-shaped slot workbench 105, the workpiece support 9 with the workpiece 8 to be loaded is still fixedly installed on the right-hand end of the T-shaped groove workbench 105, and the three-dimensional gasket 6 with the three-dimensional spacer 6 is housed. The sheet support 7 is placed in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com