Swinging detector of automobile shock absorption ring

A technology of automobile shock absorber and shock absorber ring, which is applied in the direction of measuring device, application of repeated force/pulsation force to test material strength, instrument, etc., can solve problems such as undetermined cause, uncontrollable angle, uncontrollable speed, etc., to achieve promotion Rubber molding process, elimination of artificial factors, and the effect of liberating human labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below in conjunction with the accompanying drawings.

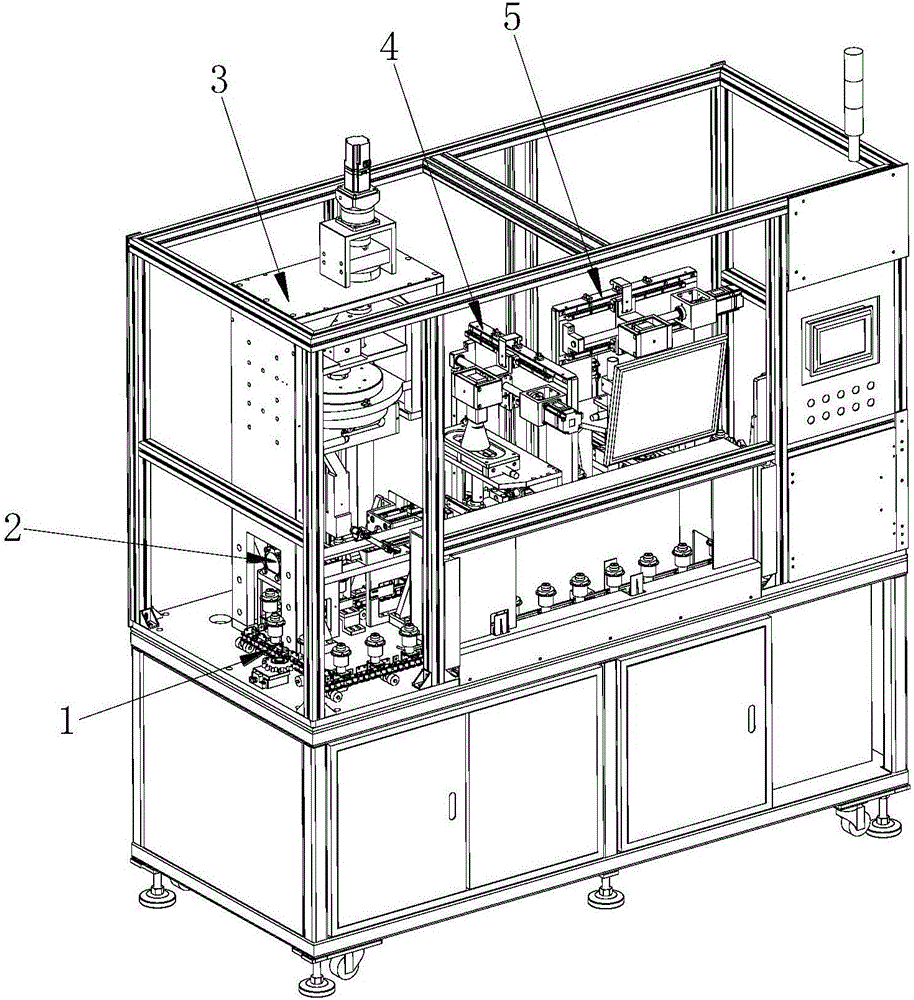

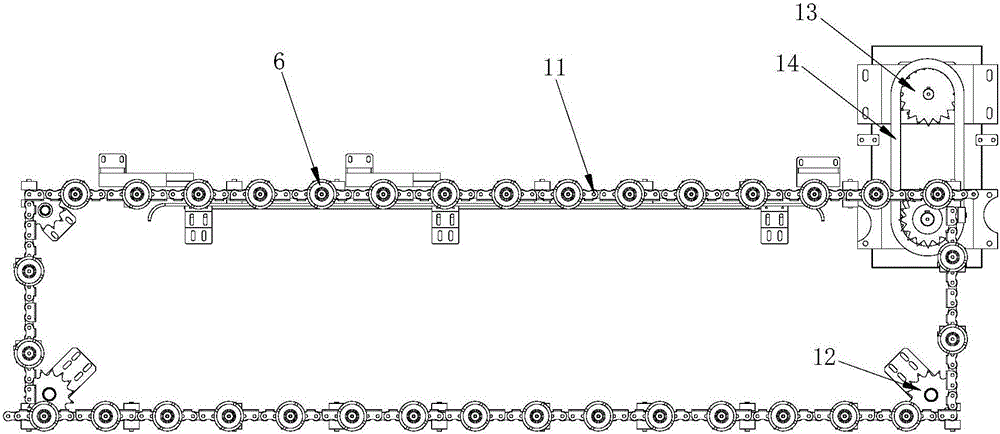

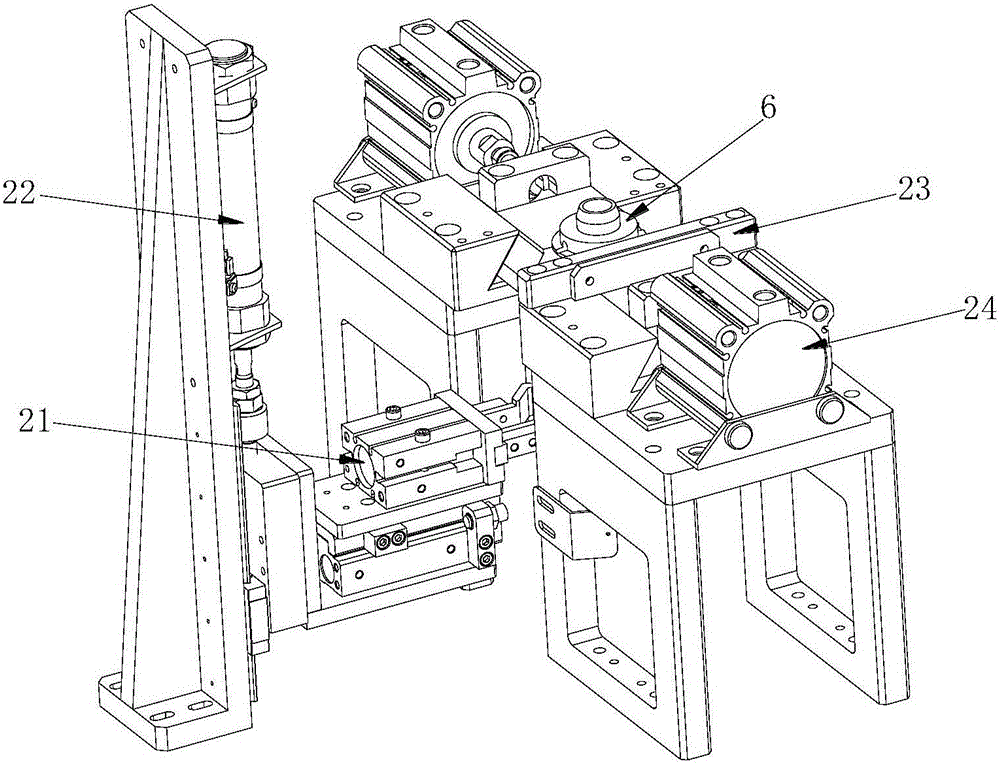

[0020] Such as Figure 1-6 Shown is a preferred embodiment of the present invention: an automobile shock absorber swing detection machine, including a shock absorber transport mechanism 1 and a shock absorber transport and clamping mechanism 2 arranged above the shock absorber transport mechanism 1, 360 degrees Rotation mechanism 3, front and rear swing mechanism 4, left and right swing mechanism 5, marking of qualified products and blanking mechanism (not shown in the figure), shock absorbing ring transport mechanism 1 includes transport chain 11 and transport chain support rod (not shown in the figure) Out), used to send the shock absorbing ring 6 to each detection mechanism position, the transport chain 11 realizes bidirectional circular motion through the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com