Patents

Literature

42results about How to "Make sure it fits in place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

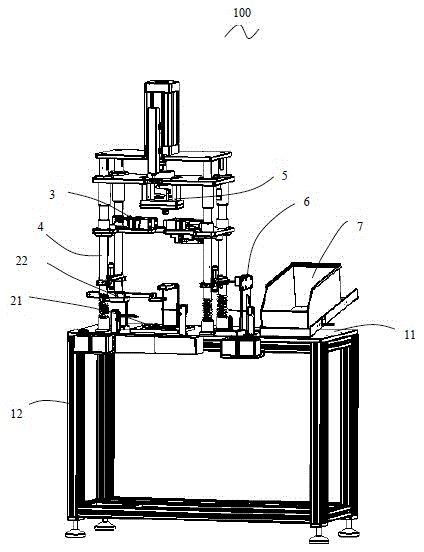

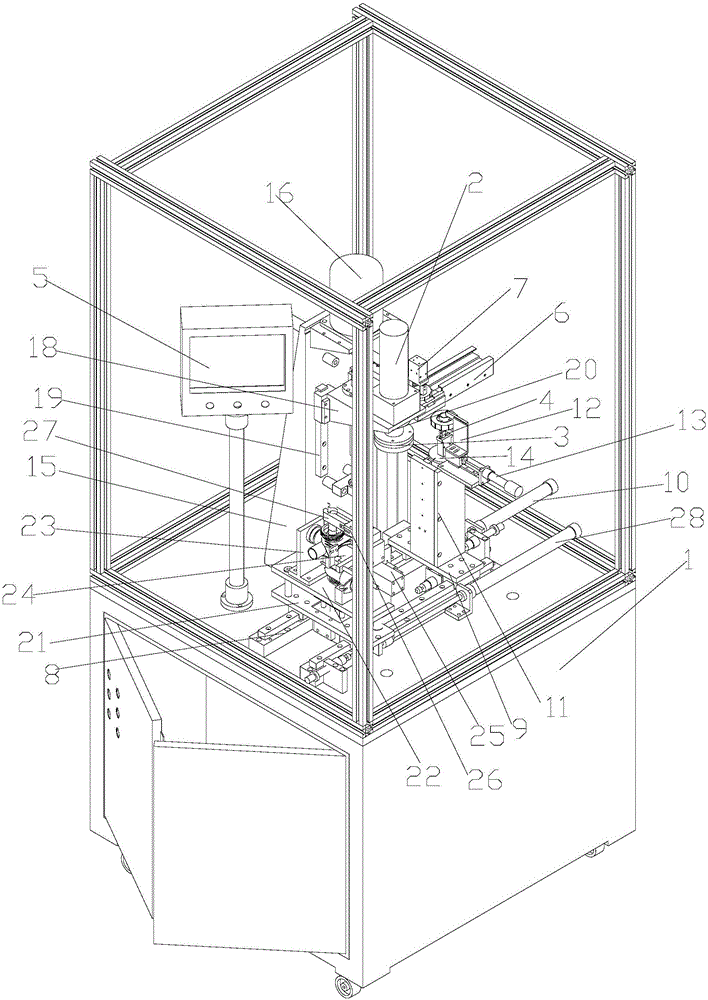

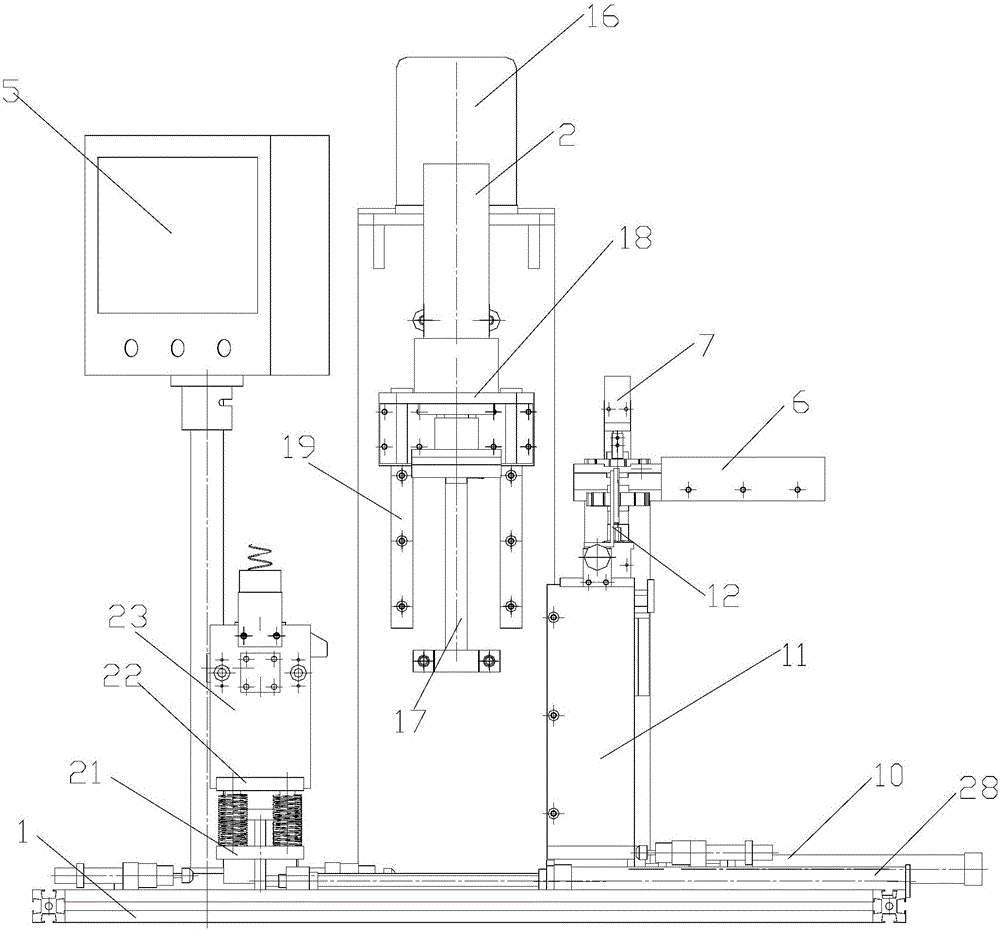

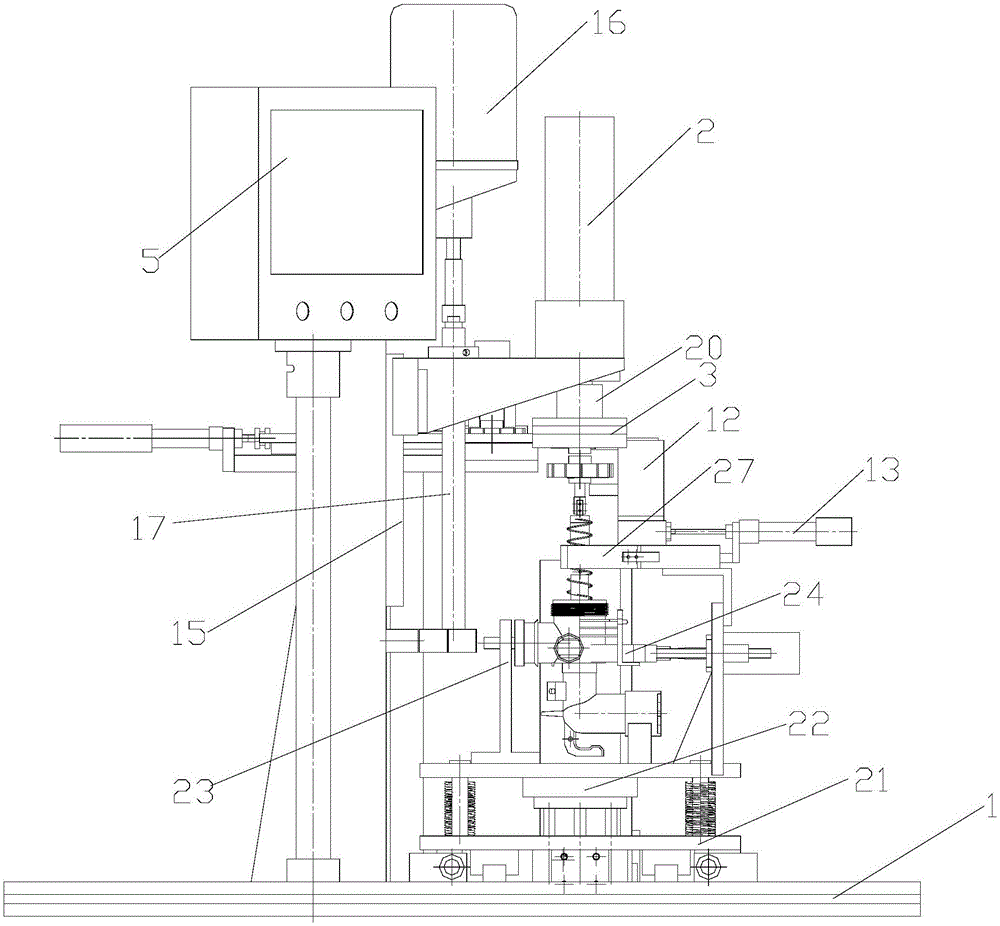

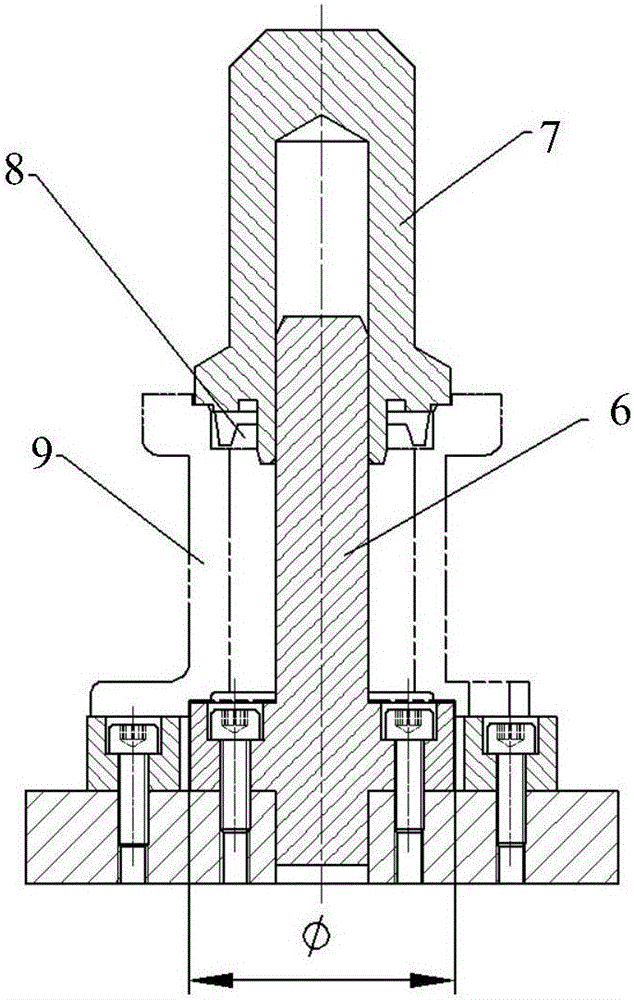

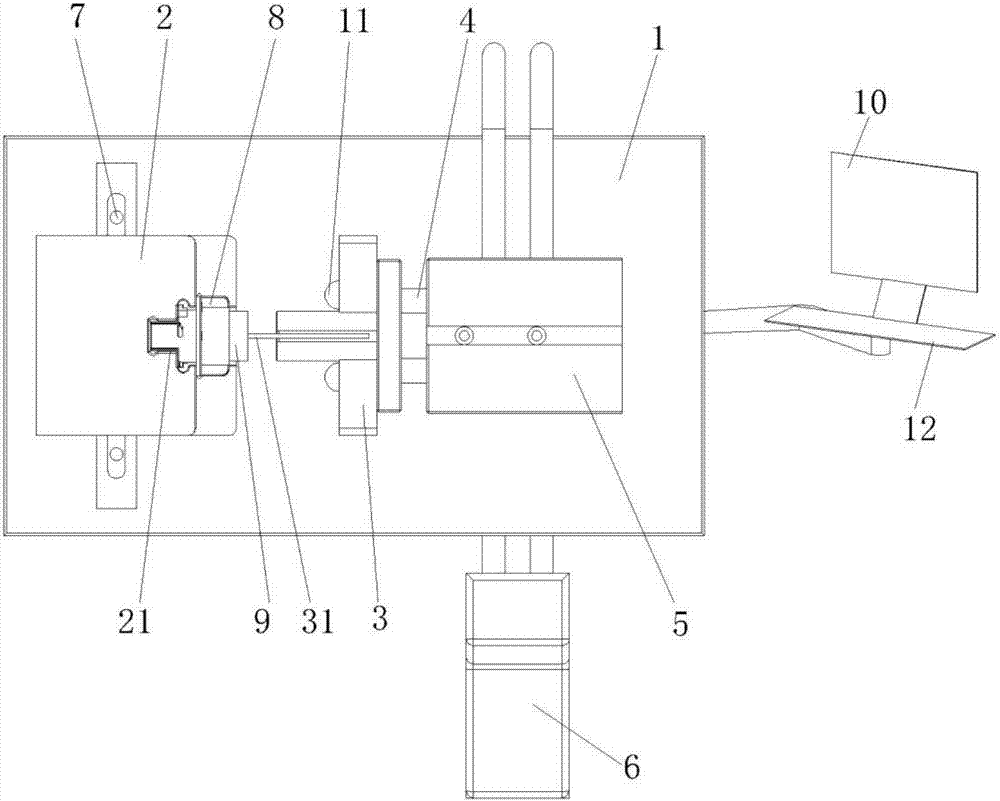

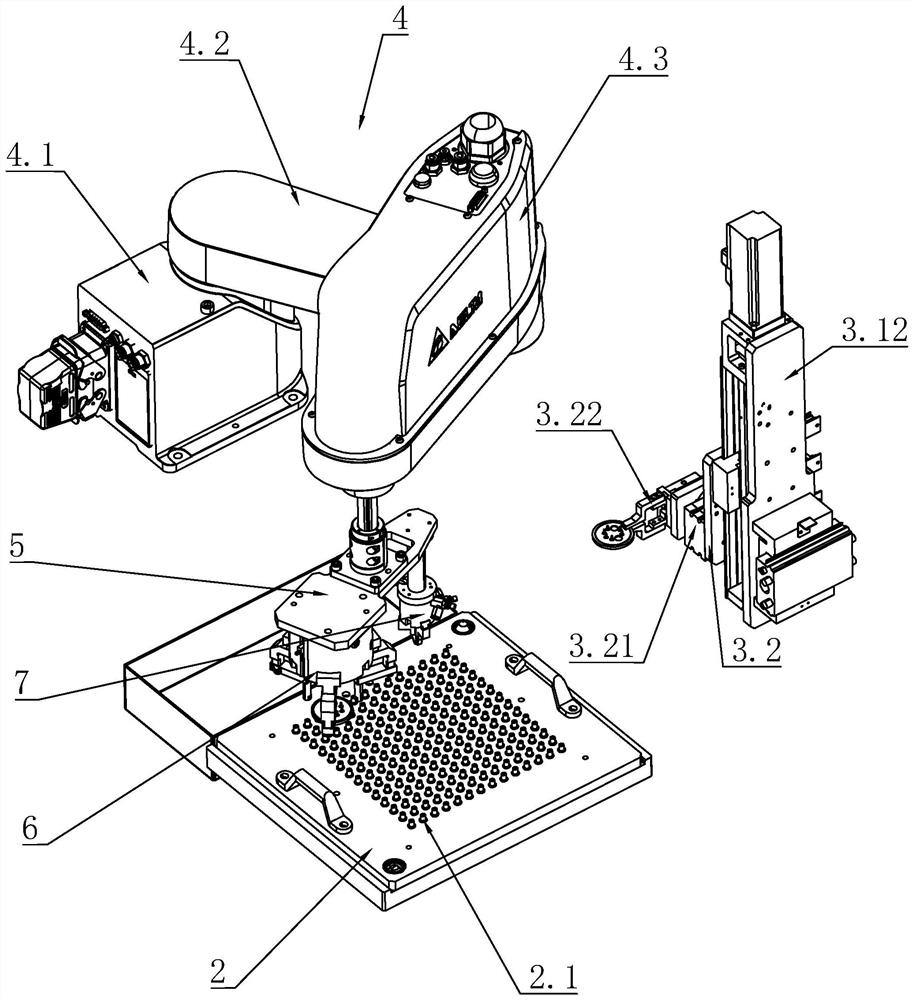

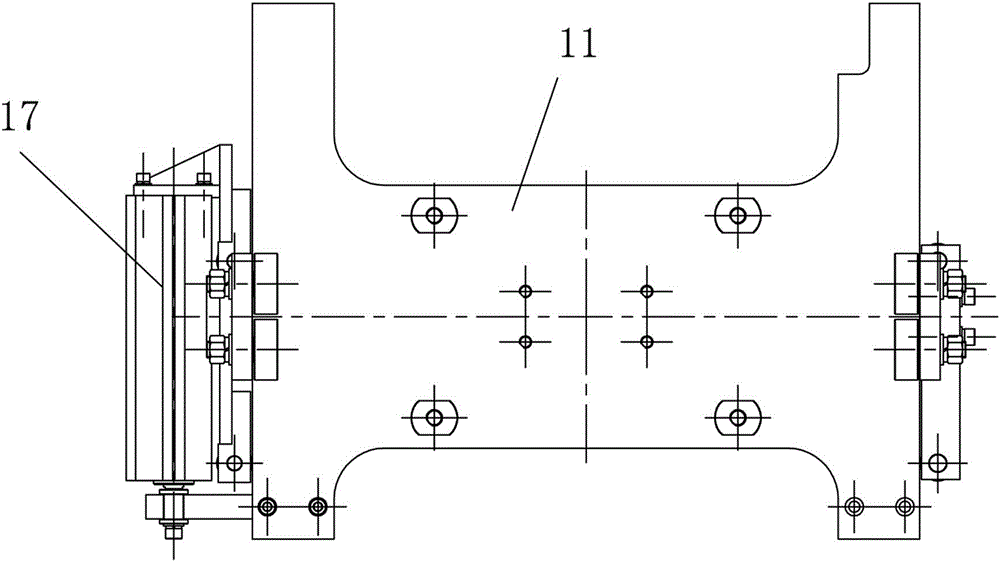

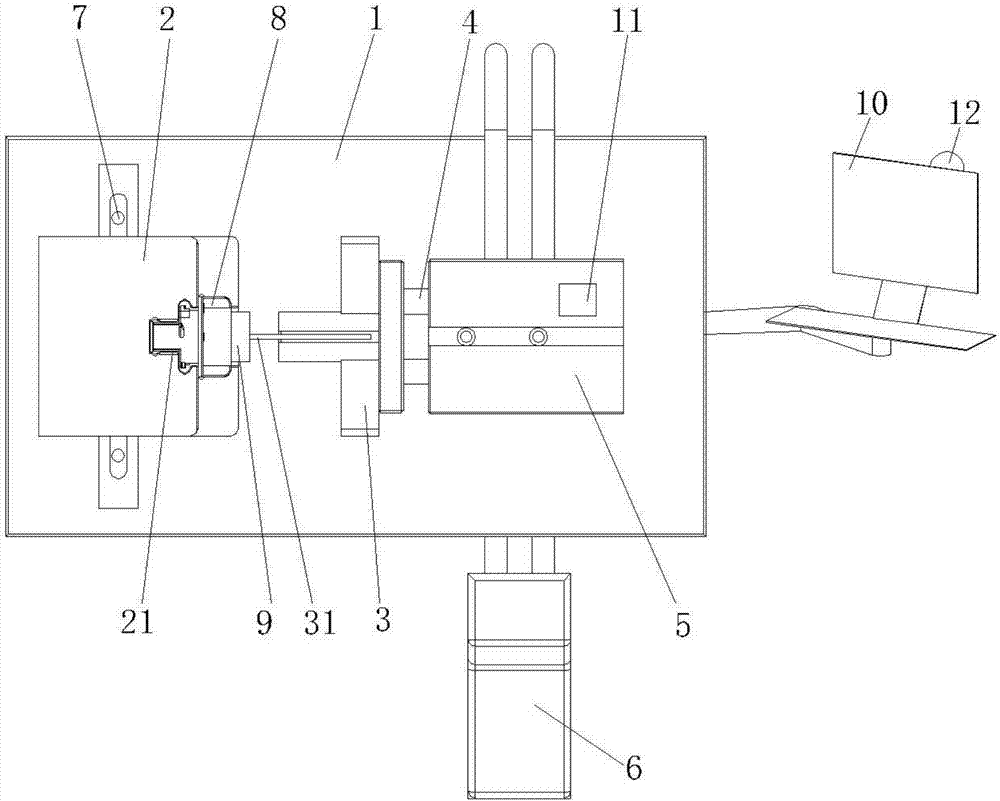

Ball head pressing equipment

InactiveCN104015031AFully automatedMake sure it fits in placeMetal working apparatusHead pressingForce sensor

The invention relates to ball head pressing equipment used for mounting a ball head on an operating rod of a workpiece. The ball head pressing equipment comprises a working table, a workpiece holder fixed on the working table and used for fixing the workpiece, a travel frame arranged on the working table, and a pressing device arranged on the travel frame and capable of vertically moving along the travel frame, wherein the pressing device comprises a pressing plate used for pressing the ball head on the operating rod, a cylinder used for driving the pressing plate to move, a force sensor fixed on the pressing plate and used for detecting the thrust of the cylinder to the pressing plate, and a displacement detecting piece arranged at one side of the cylinder and used for detecting the displacement of the pressing plate. The ball head pressing equipment realizes the ball head pressing automation, guarantees the pressing in place and reduces the erroneous judgment through being provided with the pressing device which comprises the pressing plate, the cylinder, the force sensor and the displacement detecting piece.

Owner:SIP GOLDWAY TECH

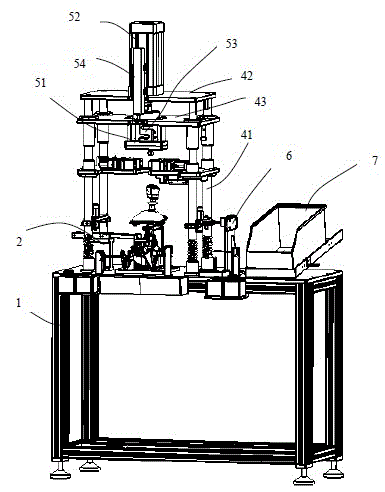

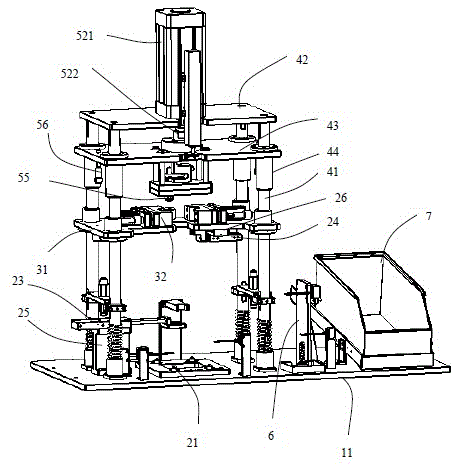

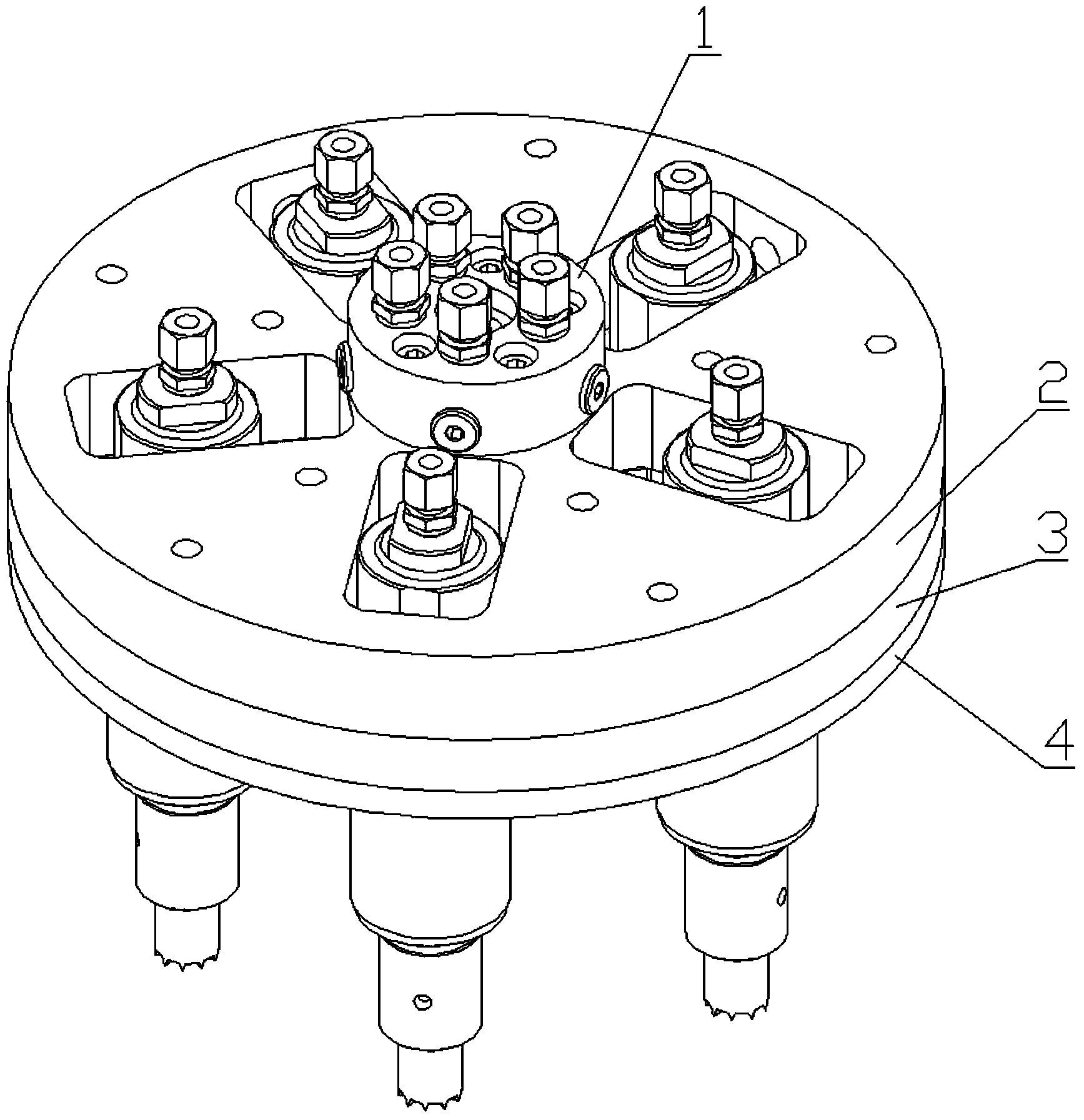

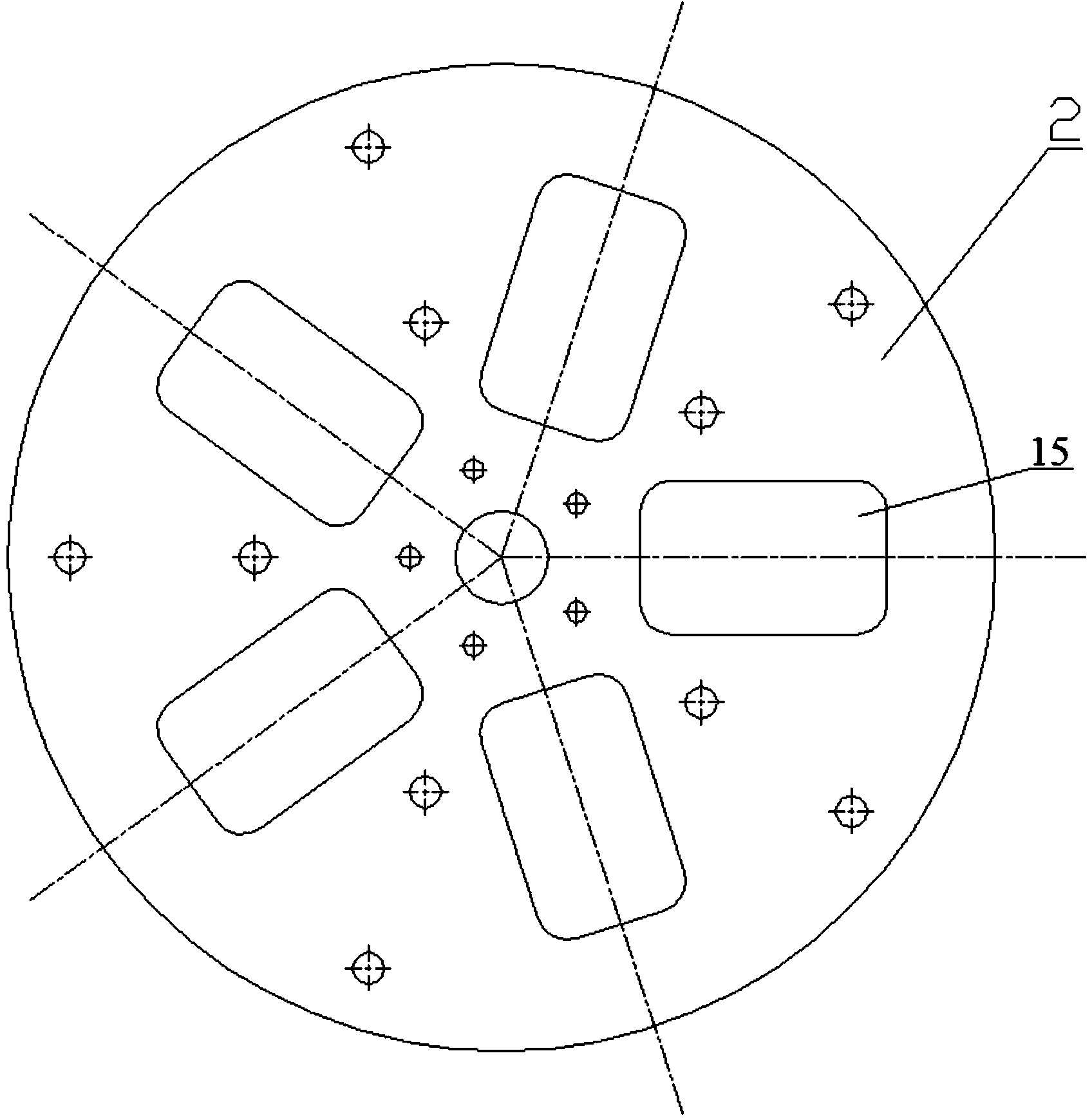

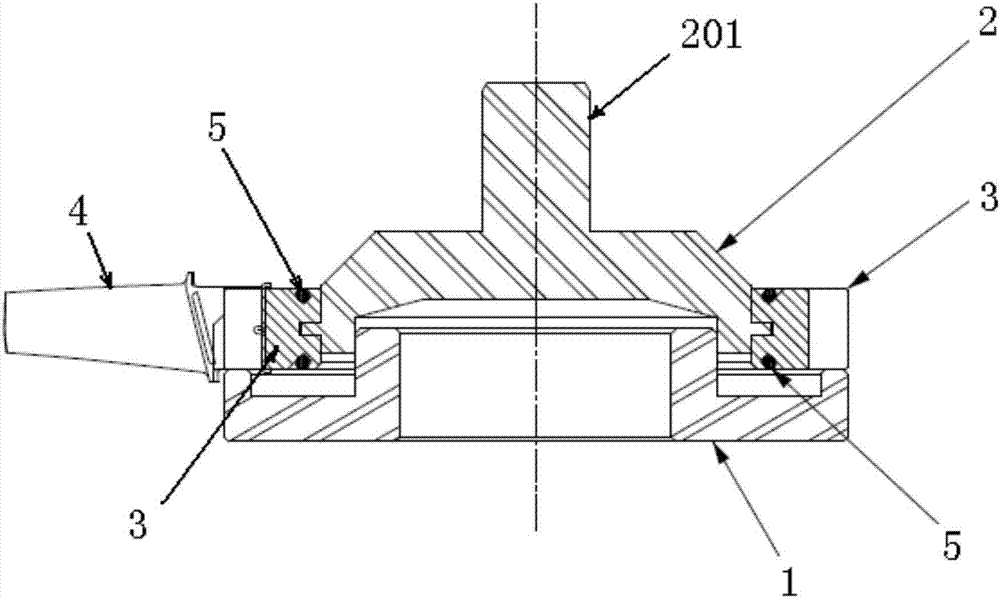

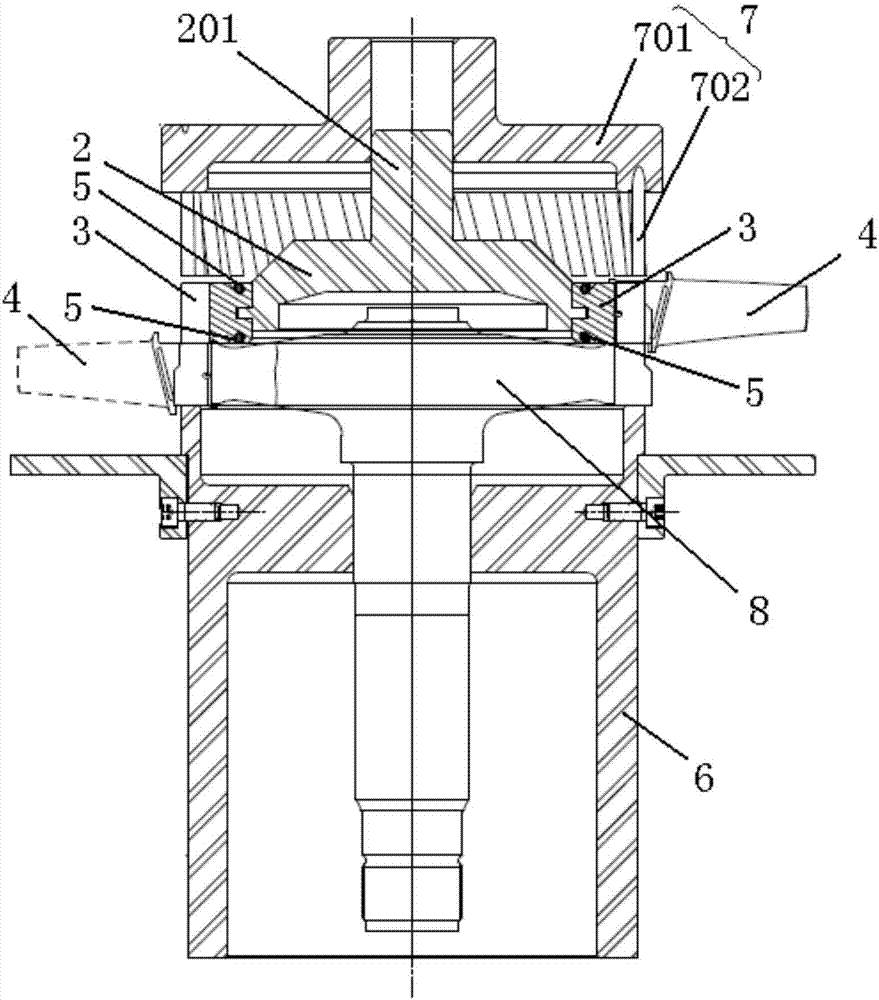

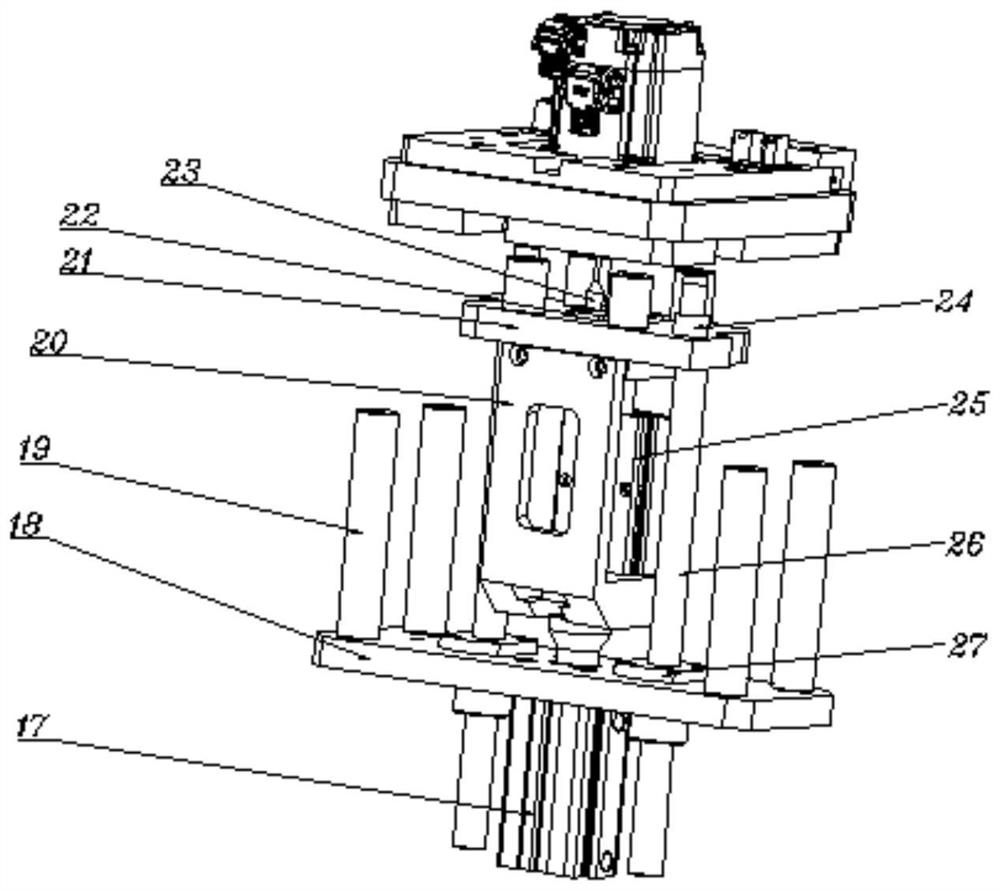

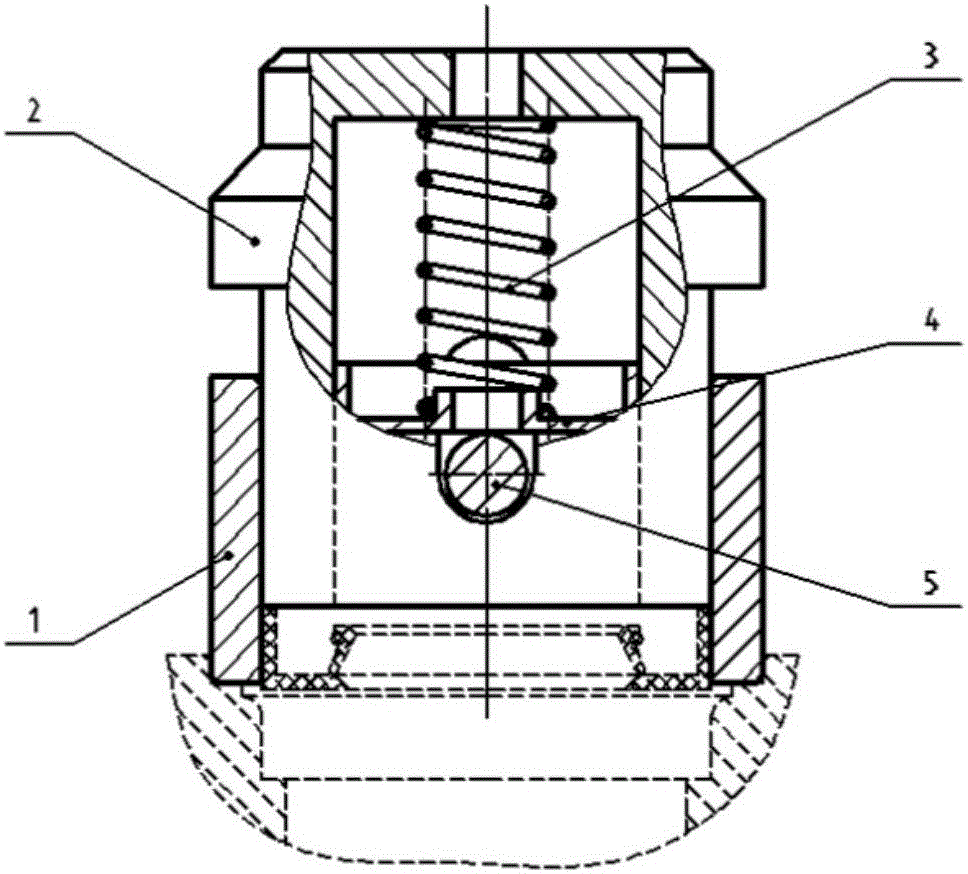

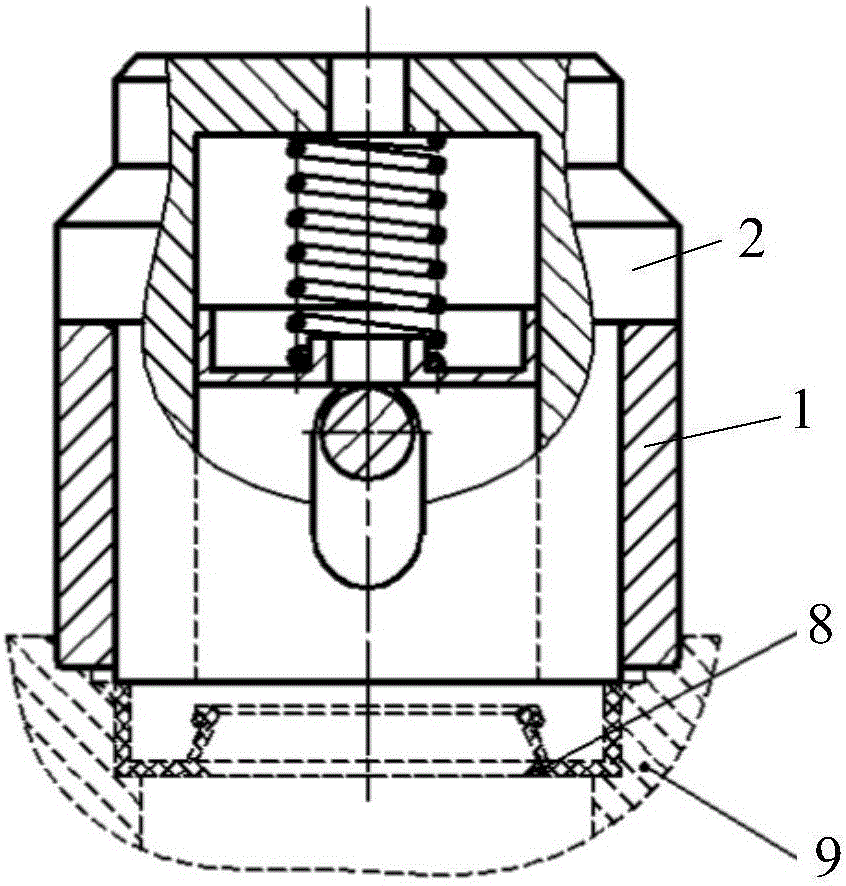

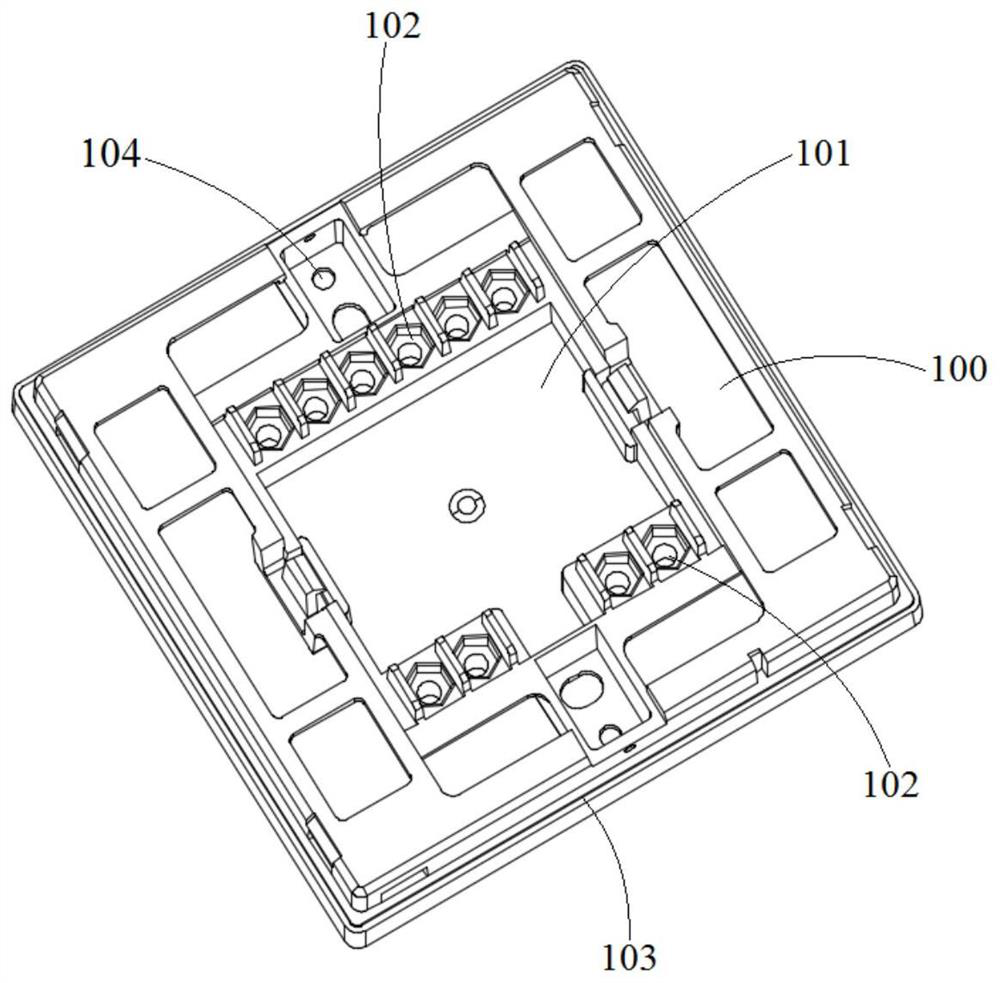

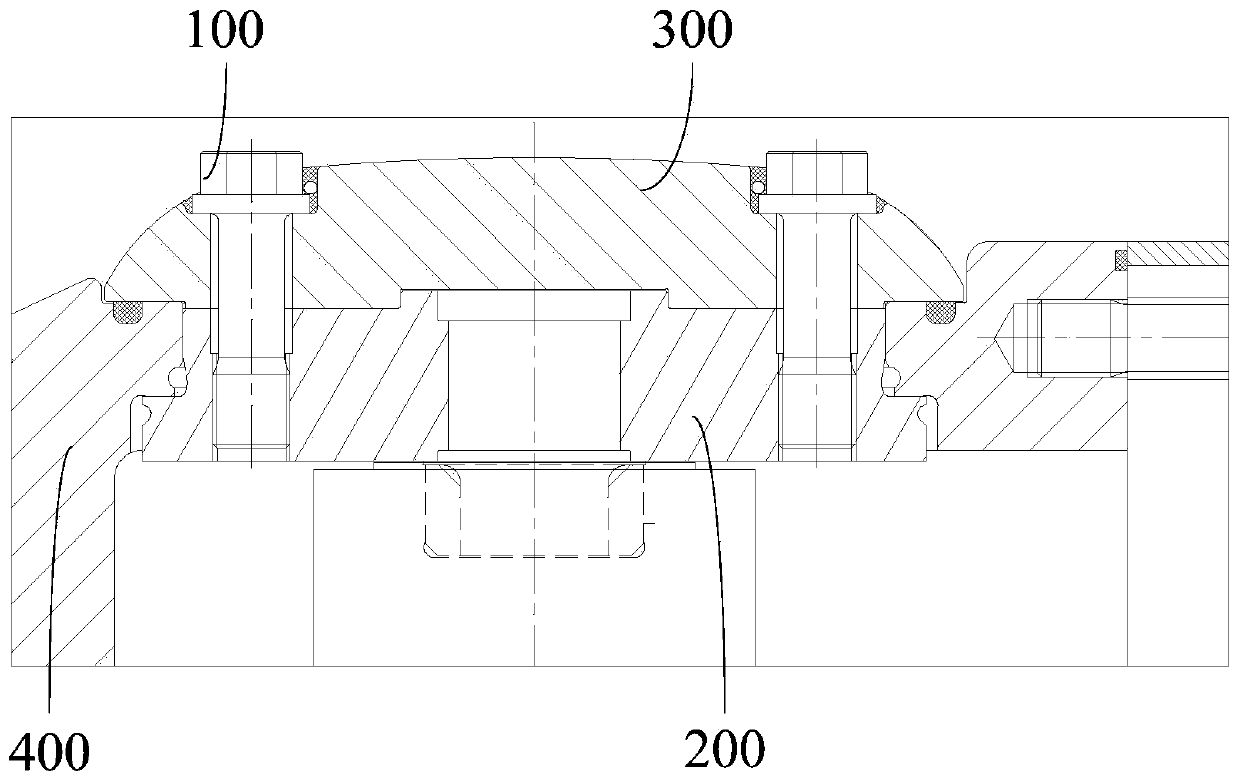

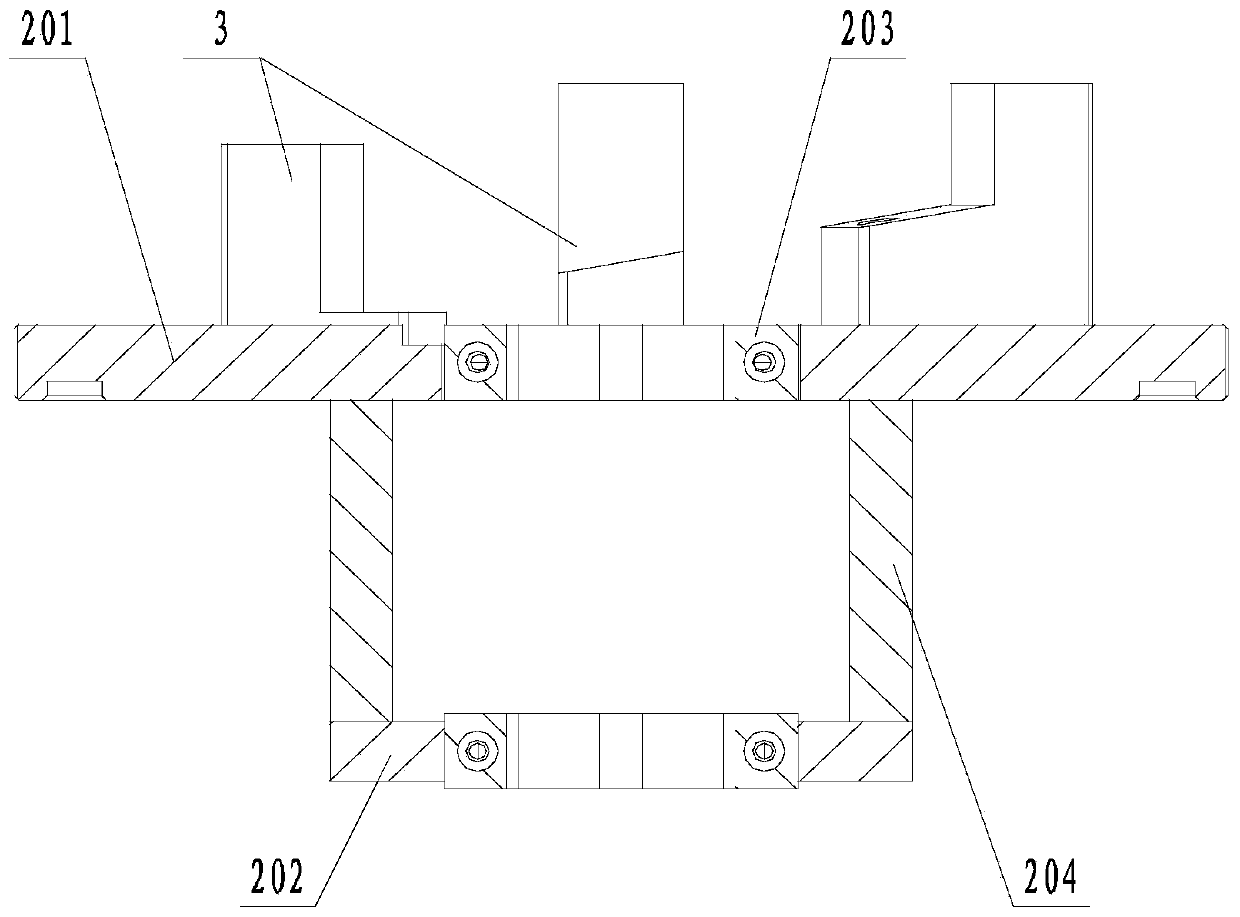

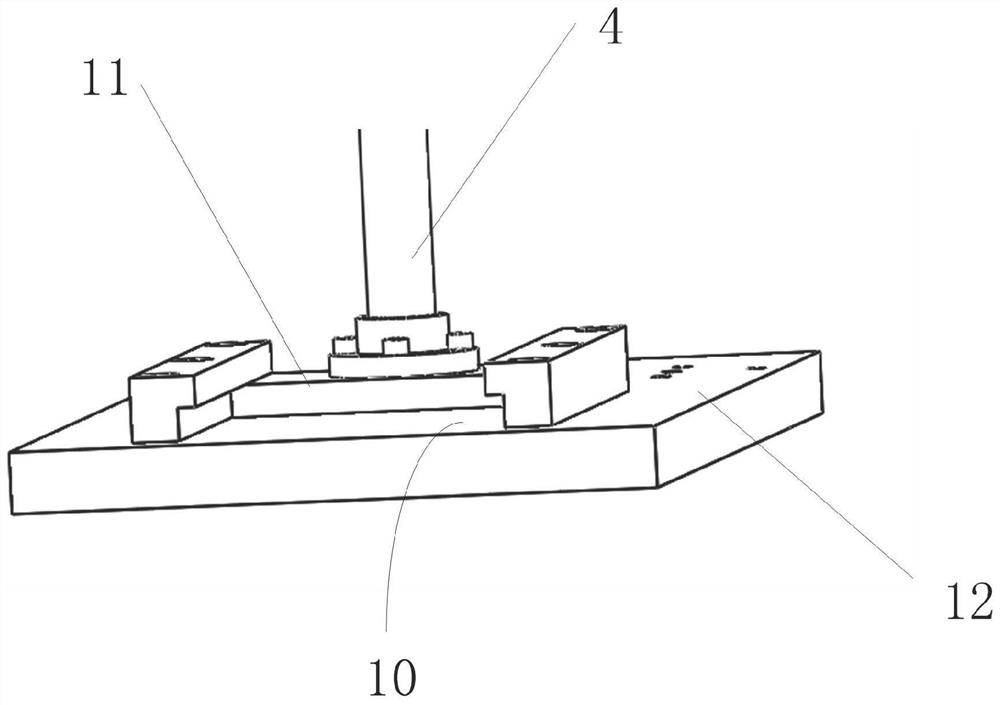

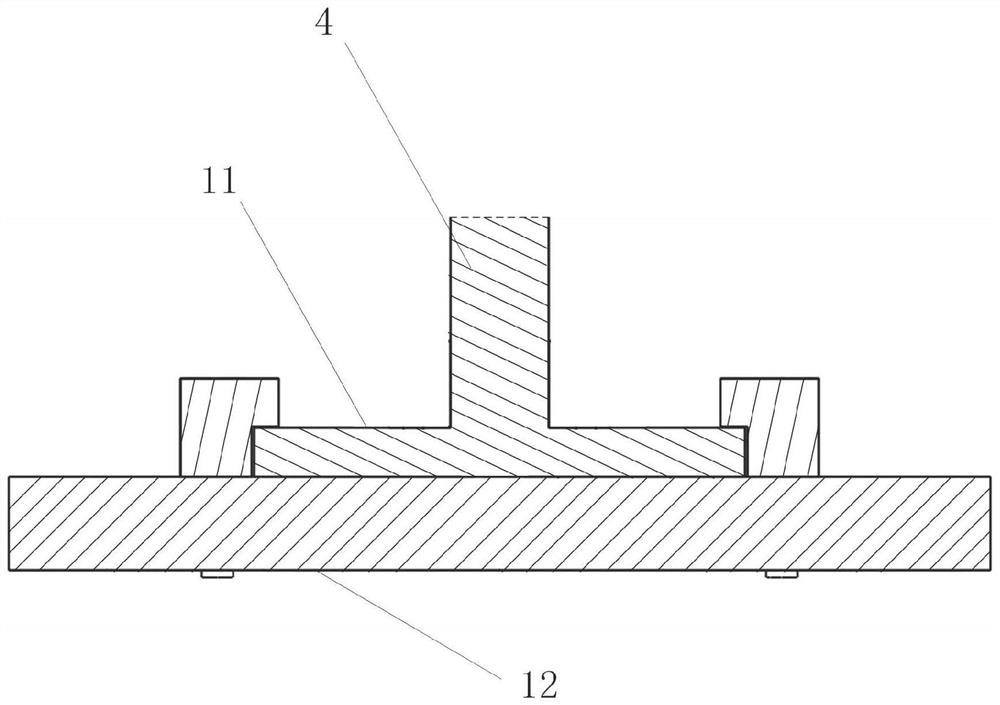

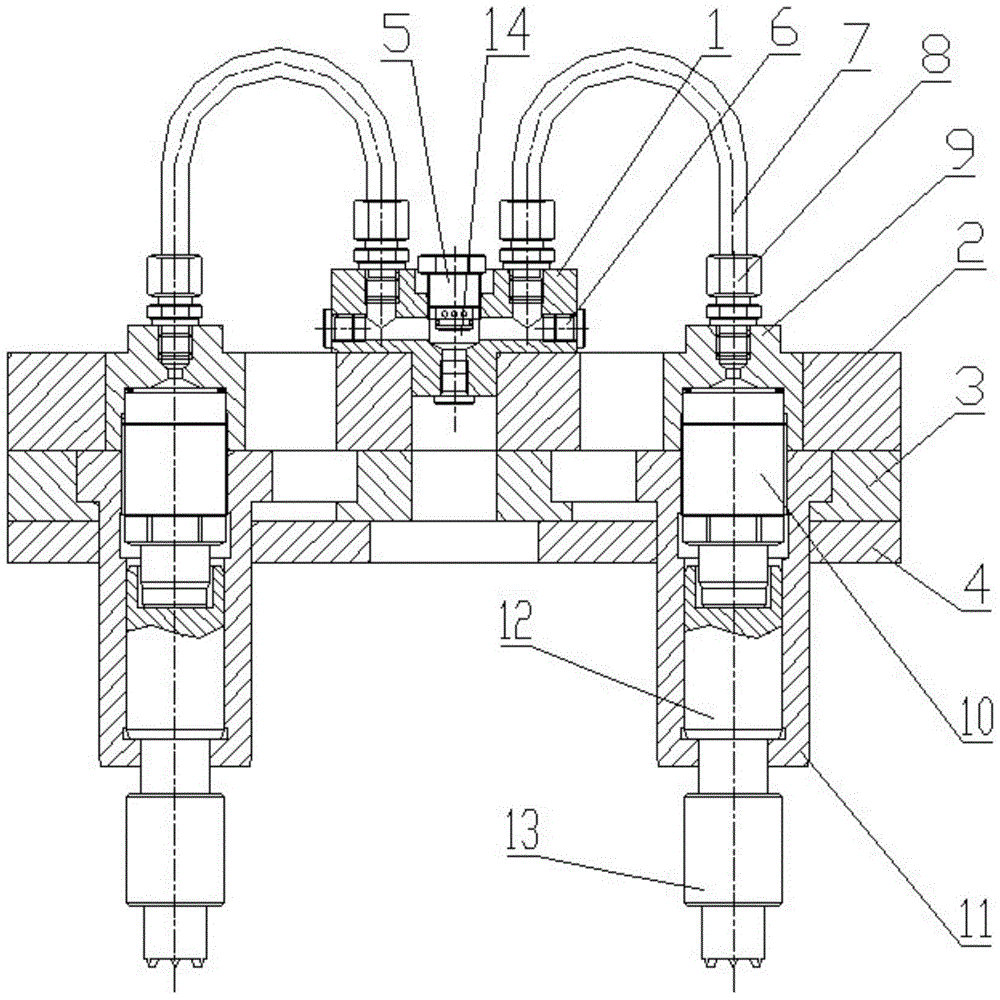

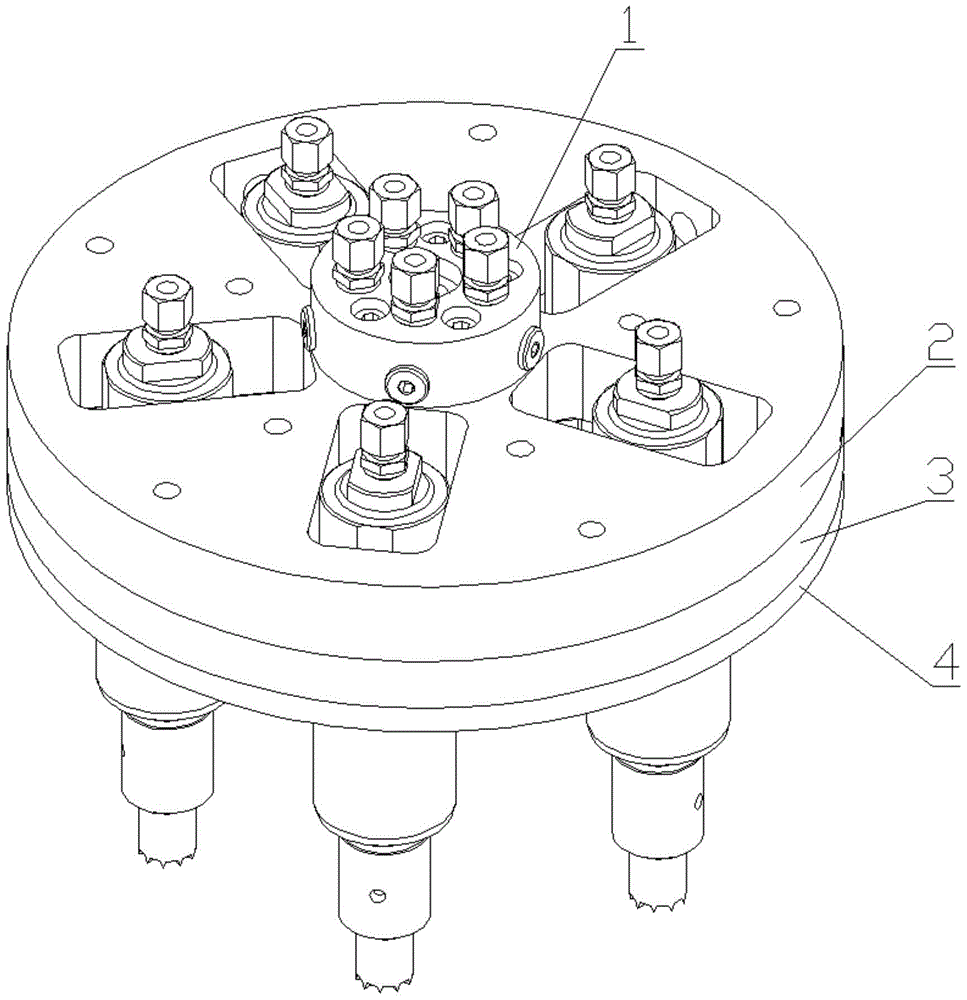

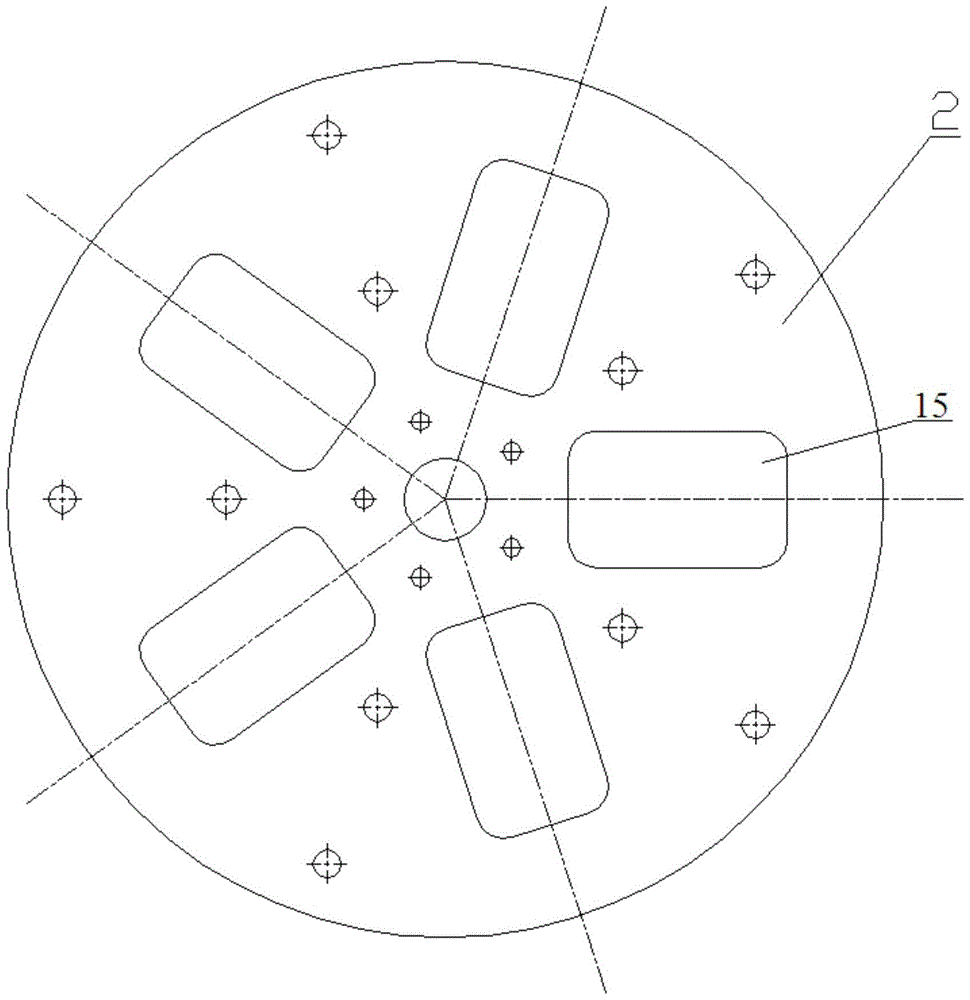

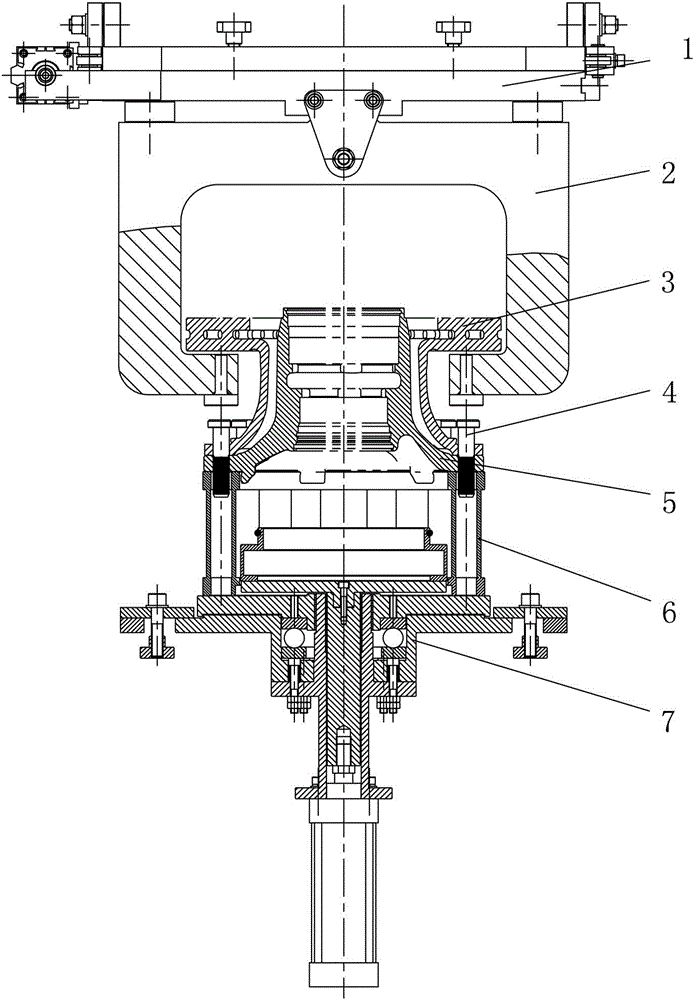

Floating pressure head device

InactiveCN103962828AUniform pressing force of the indenterImprove connectivityMetal working apparatusMechanical engineering

The invention discloses a floating pressure head device. The floating pressure head device comprises an oil distributing base, a base, an index plate, a positioning plate and multiple pressure head assemblies in a sequential overlaying mode. Multiple through installation grooves are formed in the base and the index plate. The pressure head assemblies are correspondingly arranged in the installation grooves. Each pressure head assembly can horizontally move in the corresponding installation groove. A cavity is formed in the oil distributing base, and the oil distributing base is provided with an oil filling port which leads to the cavity. A one-way valve is installed on the oil distributing base, and multiple oil outlets are respectively formed in the oil distributing base and lead to the cavity. Hydraulic hoses are correspondingly connected between the oil outlets and the pressure head assemblies. Hydraulic oil in all the pressure head assemblies is communicated, so that press fitting force of pressure heads of all the pressure head assemblies is even, press fitting is performed on each part in place, and press fitting precision is improved. Multiple parts can be pressed into the device in a one-off mode, so that time is saved, efficiency is improved, operation is convenient and cost is reduced, and the number of the pressure heads of all the pressure head assemblies can be designed according to workpieces.

Owner:HEFEI UNIV OF TECH

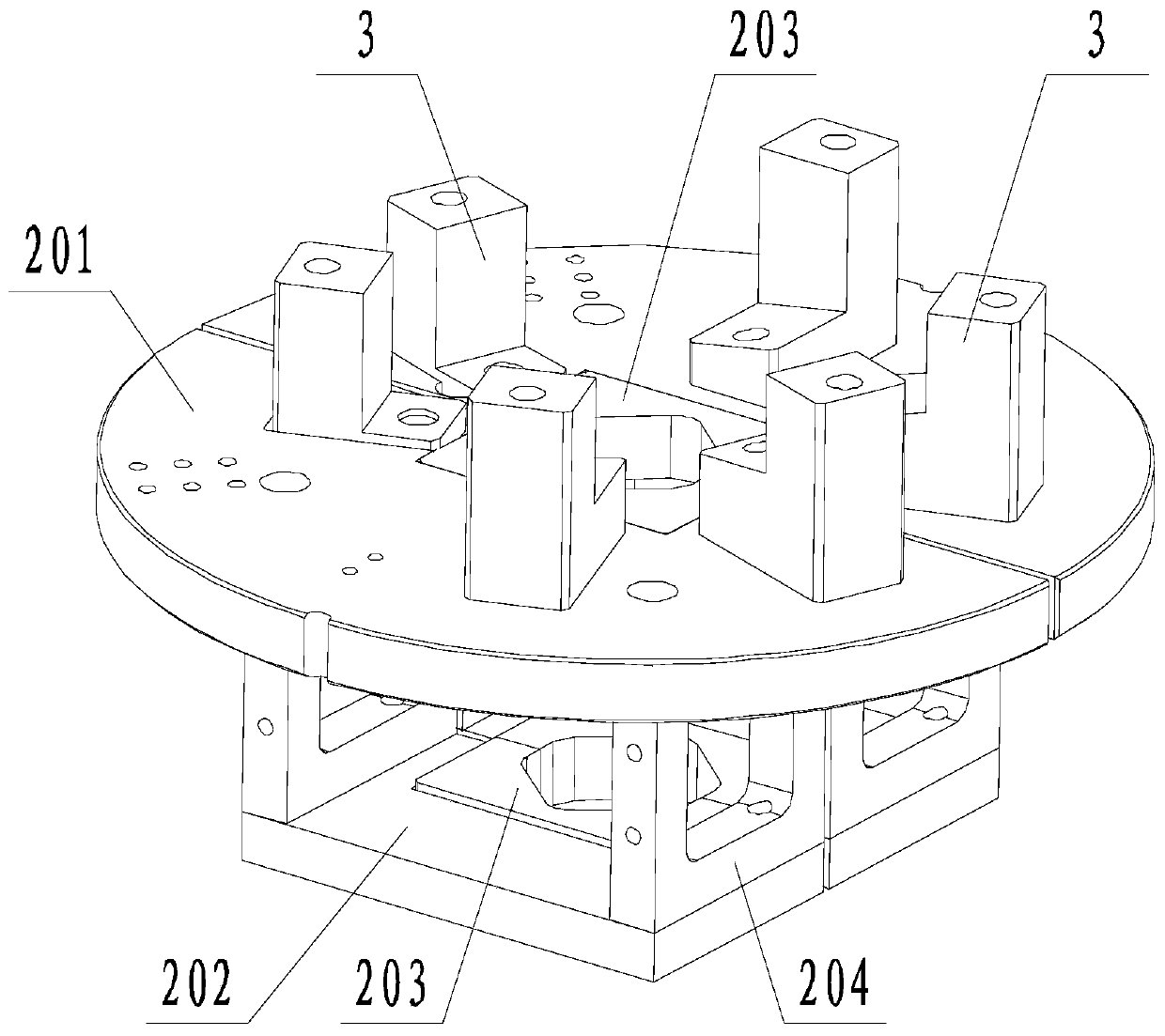

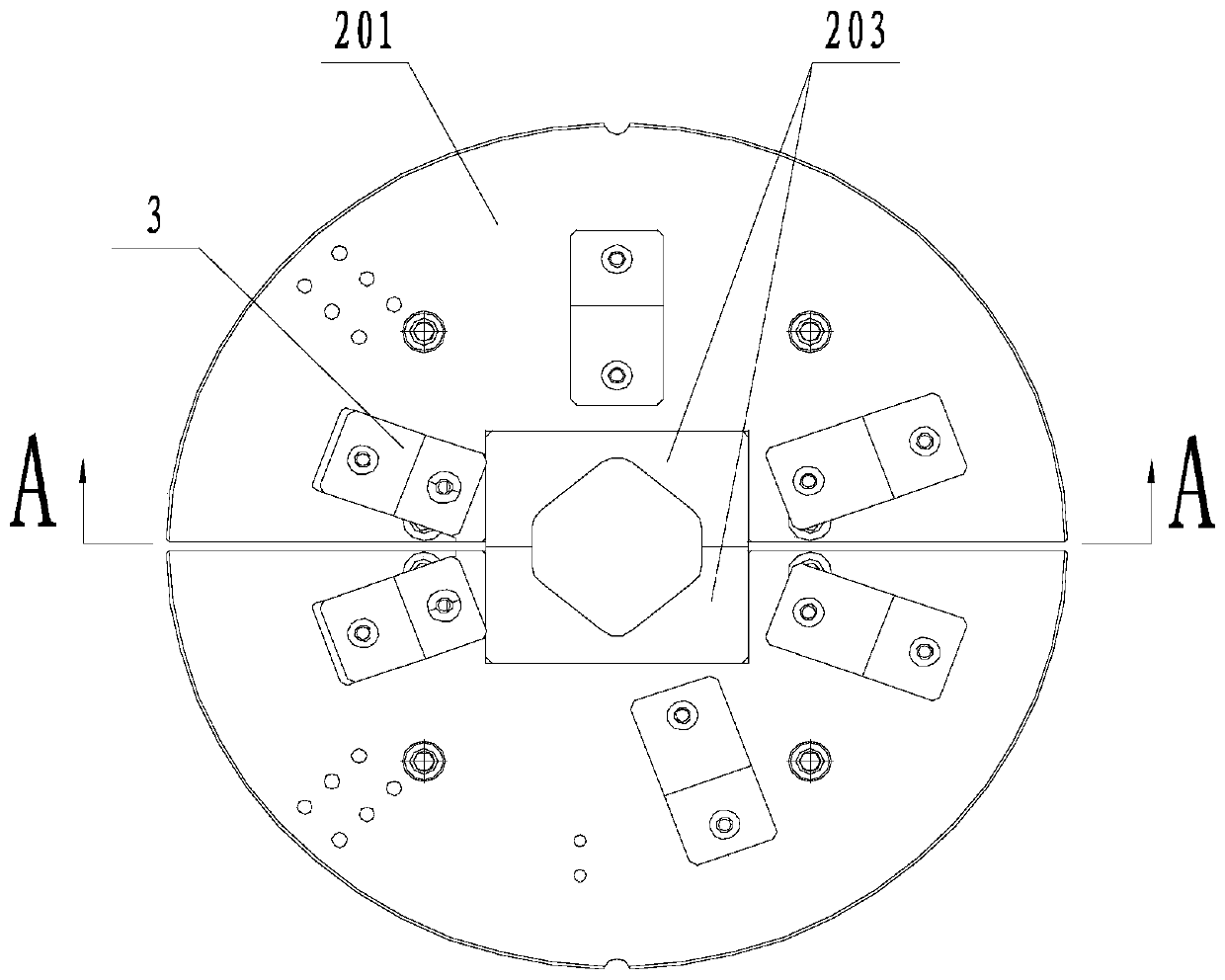

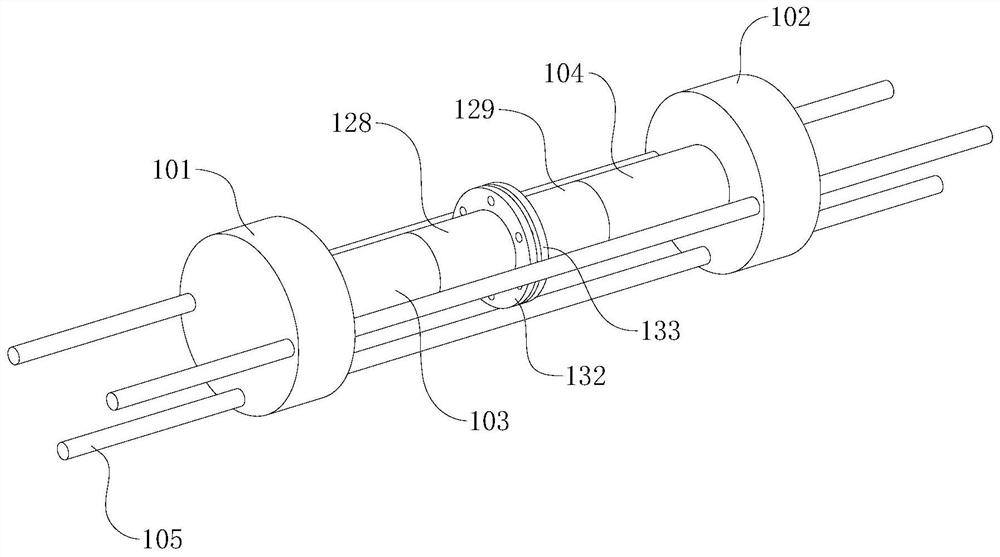

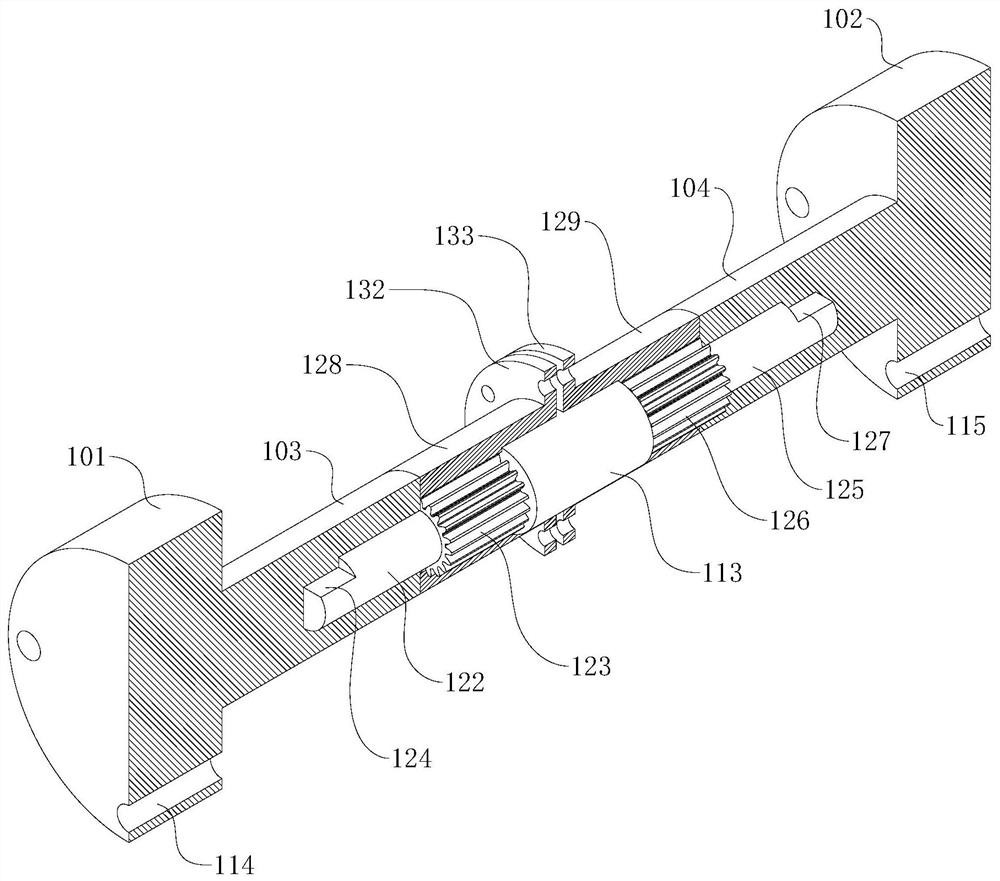

Die assembling mechanism for turbine rotor with vibration attenuation plate, assembling mechanism and method

ActiveCN107131008AEasy to installImprove assembly efficiencyBlade accessoriesMachines/enginesVibration attenuationEngineering

The invention discloses a die assembling mechanism for a turbine rotor with a vibration attenuation plate, an assembling mechanism and a method. The die assembling mechanism for the turbine rotor with the vibration attenuation plate comprises a bottom die support for forming bottom support and an inner core support for forming radial support. The bottom die support and the inner core support are fixed and positioned in an embedded manner. A plurality of movable process mortise units which are used for enabling turbine rotor vane tenon teeth to be vertically inserted and assembled and move within a constraint range to assemble the vibration attenuation plate to the part between adjacent turbine rotor vanes. The multiple movable process mortise units are distributed in an adjoining manner in the circumferential direction of the inner core support, and the movable process mortise units and the turbine rotor vanes are distributed in a one-to-one corresponding manner. The circumferential dimensions of the movable process mortise units are matched with those of the turbine rotor vanes, and thus the assembled turbine rotor vanes are distributed in an adjoining manner in the circumferential direction of the inner core support. The overall transferring of a preassembled structure is facilitated, and the assembling efficiency of the turbine rotor is improved.

Owner:CHINA HANGFA SOUTH IND CO LTD

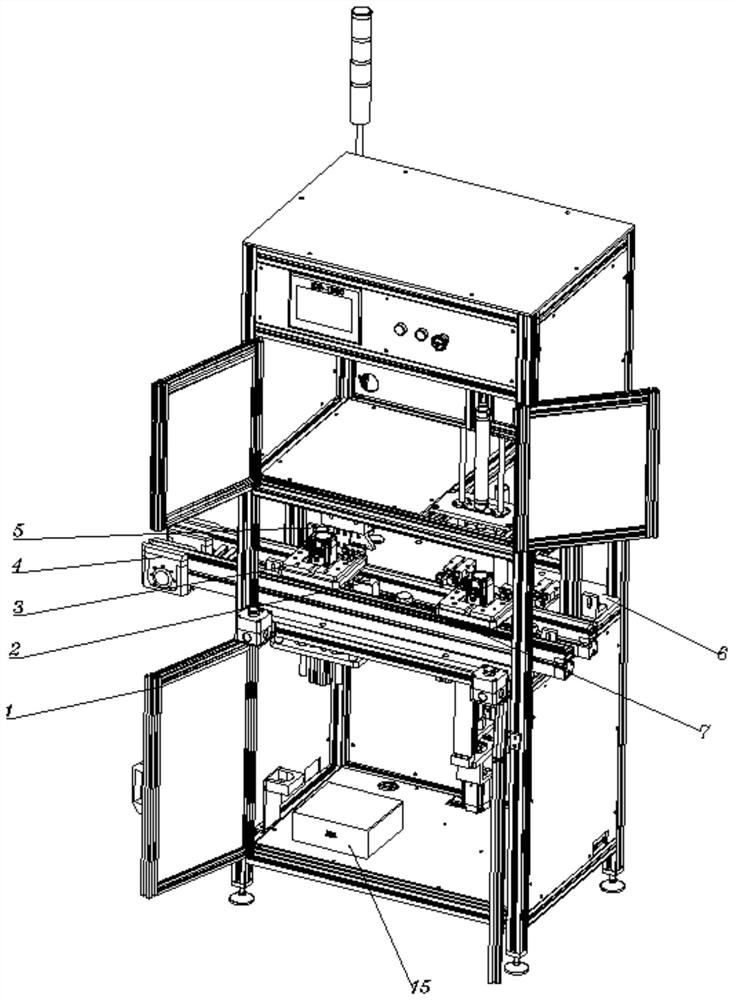

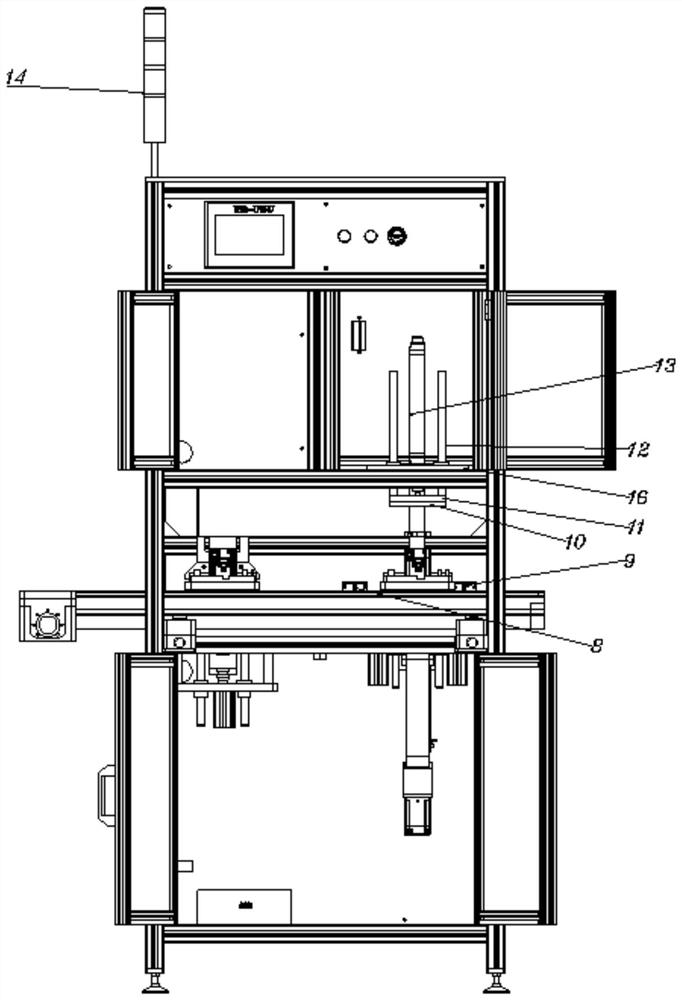

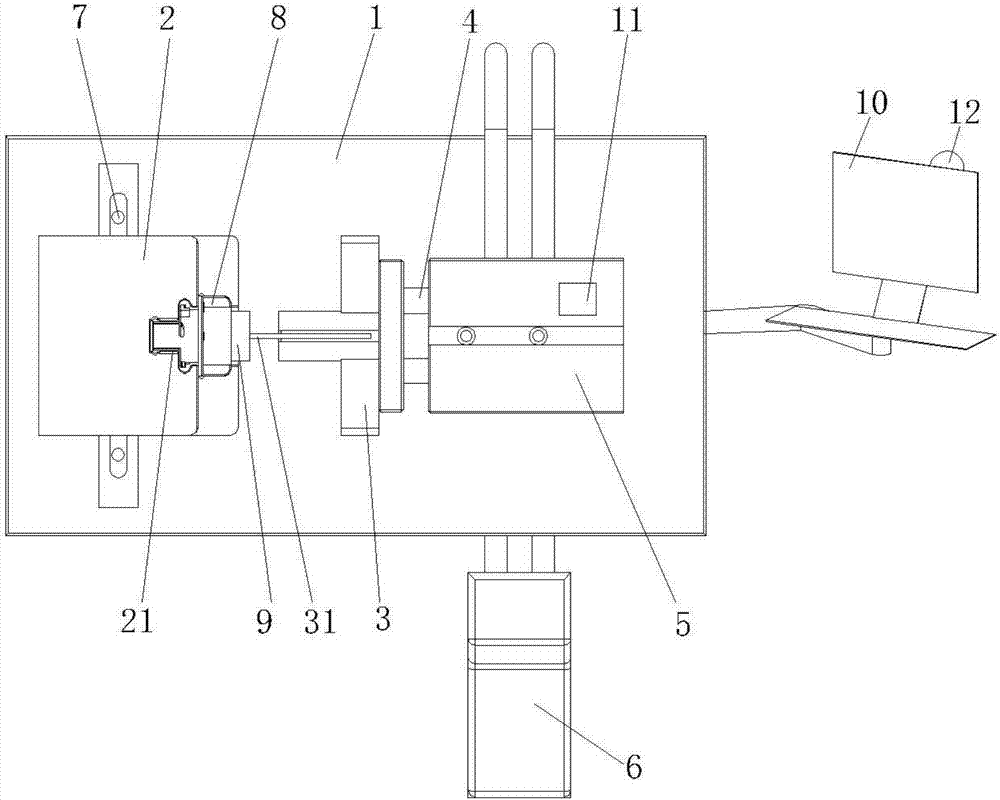

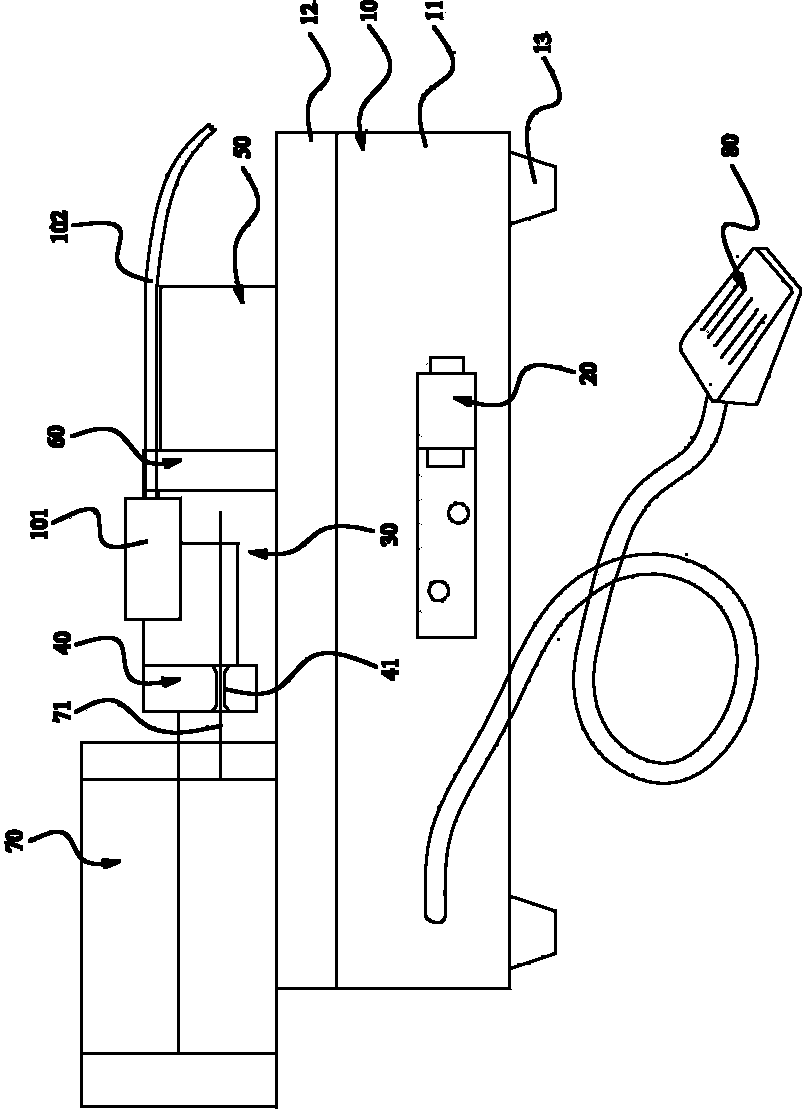

Automatic drain valve deck screwing device and assembling method of valve deck

ActiveCN106392592AImplement automatic installationConsistent tightening forceMetal working apparatusMechanical engineering

The invention discloses an automatic drain valve deck screwing device which comprises a rack, a lifting mechanism arranged on the rack, an automatic deck feeding mechanism and a fixed valve body horizontal-moving mechanism. A deck screwing mechanism capable of moving up and down is arranged on the lifting mechanism and comprises a deck screwing motor and a valve deck sleeve connected with the deck screwing motor. The automatic deck feeding mechanism comprises a valve deck holding shaft and an ejecting cylinder used for ejecting out the valve deck holding shaft. A valve deck is fed into the valve deck sleeve through the ejecting cylinder, and driven by the deck screwing motor to rotate so as to be assembled with a valve body. The automatic drain valve deck screwing device further comprises a controller used for controlling operation of all cylinders and the motor. According to the automatic drain valve deck screwing device, since the valve deck and the valve body are automatically transported and installed, the assembling efficiency is greatly improved, the assembling precision and the product percent of pass are high, and the automatic drain valve deck screwing device can be widely used in the field of assembling of valve decks and valve bodies.

Owner:黄山市屯溪工程塑料厂

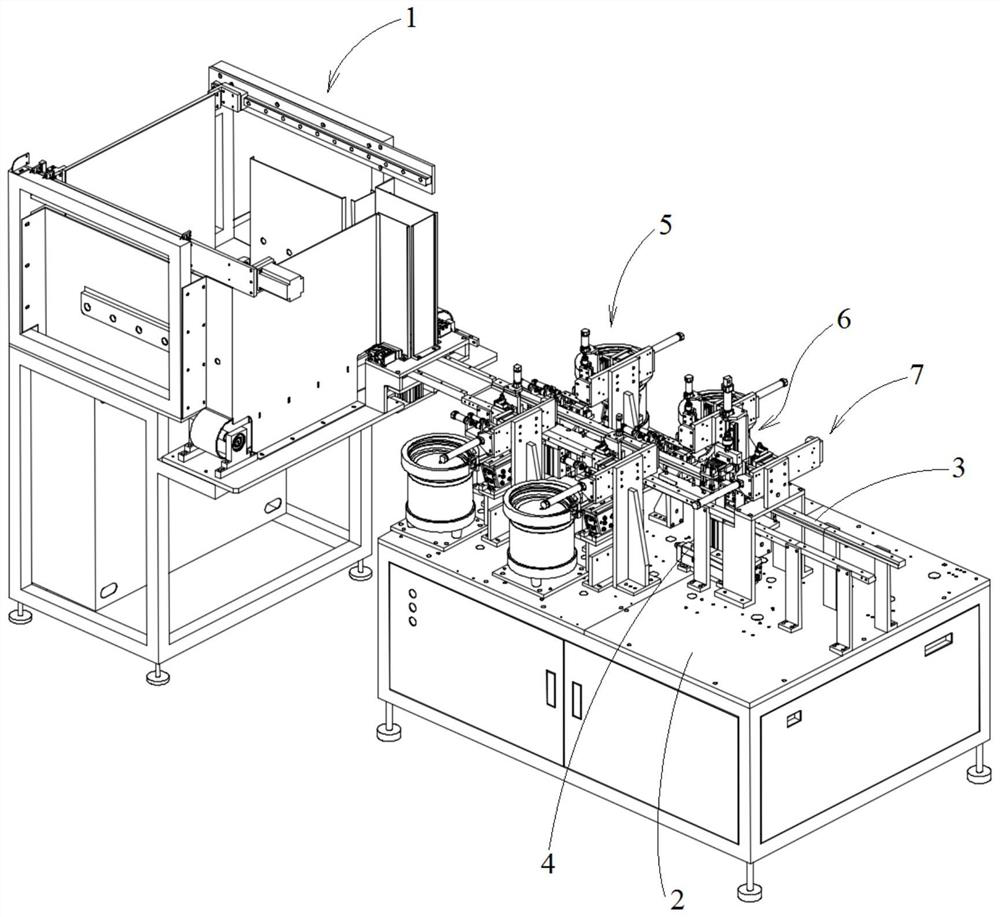

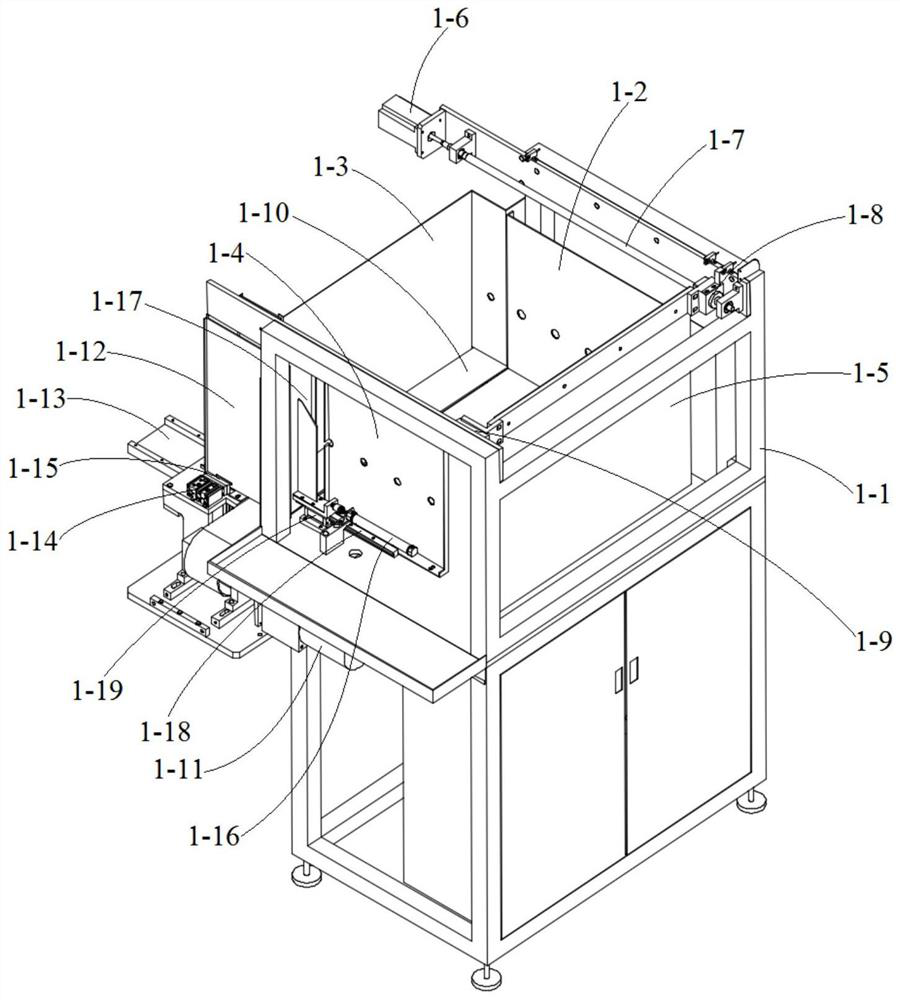

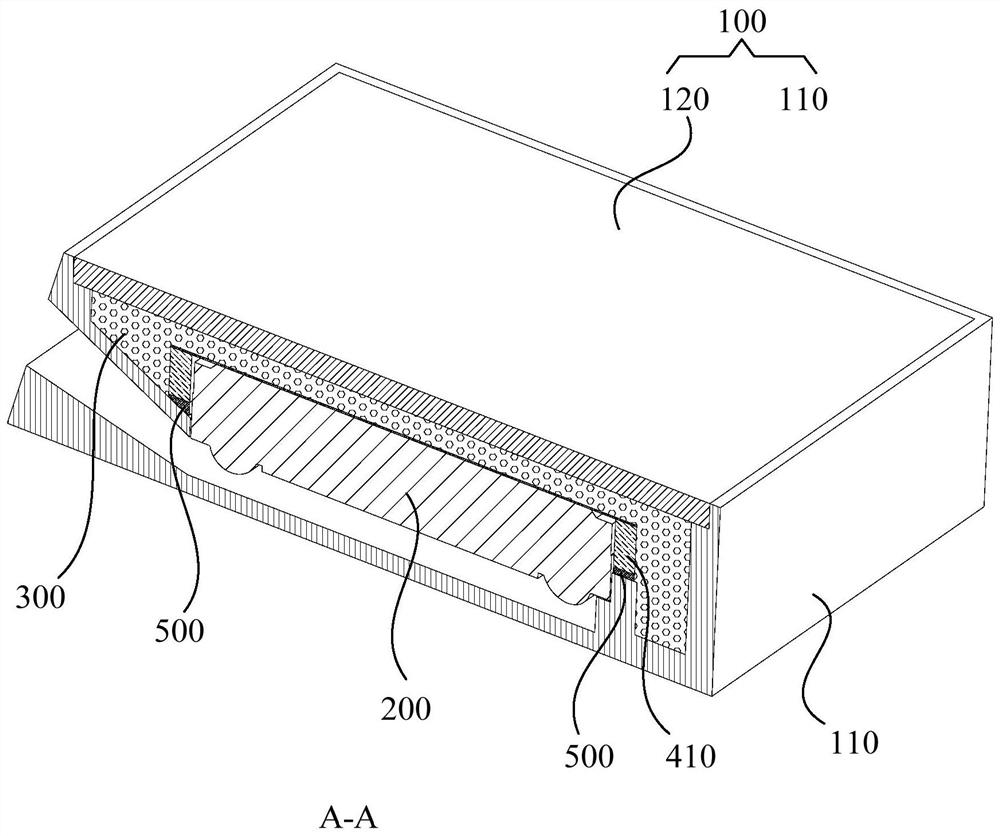

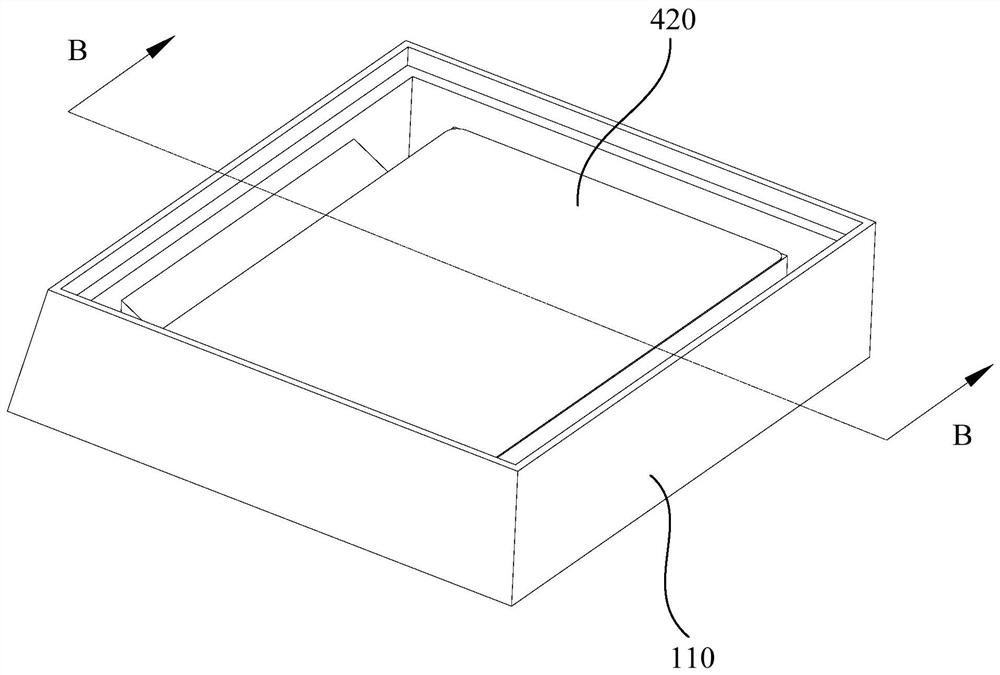

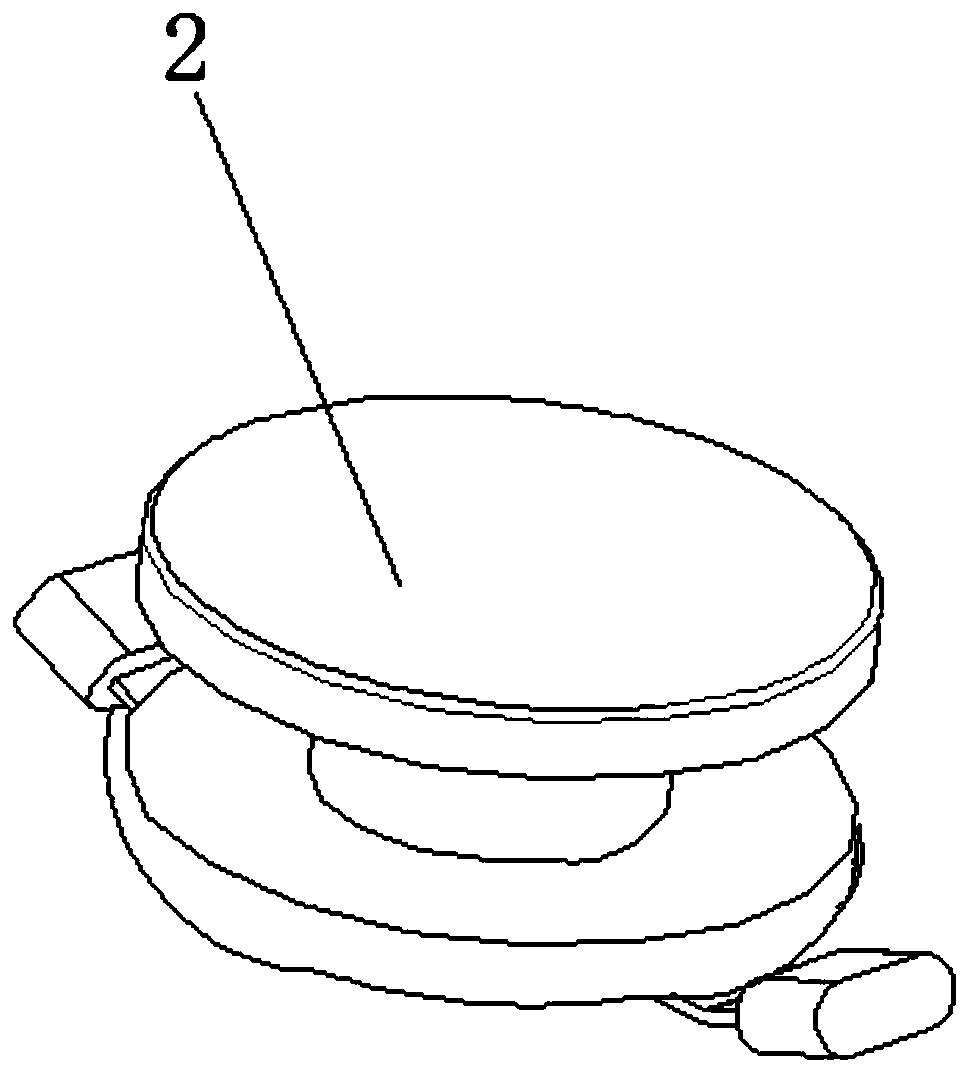

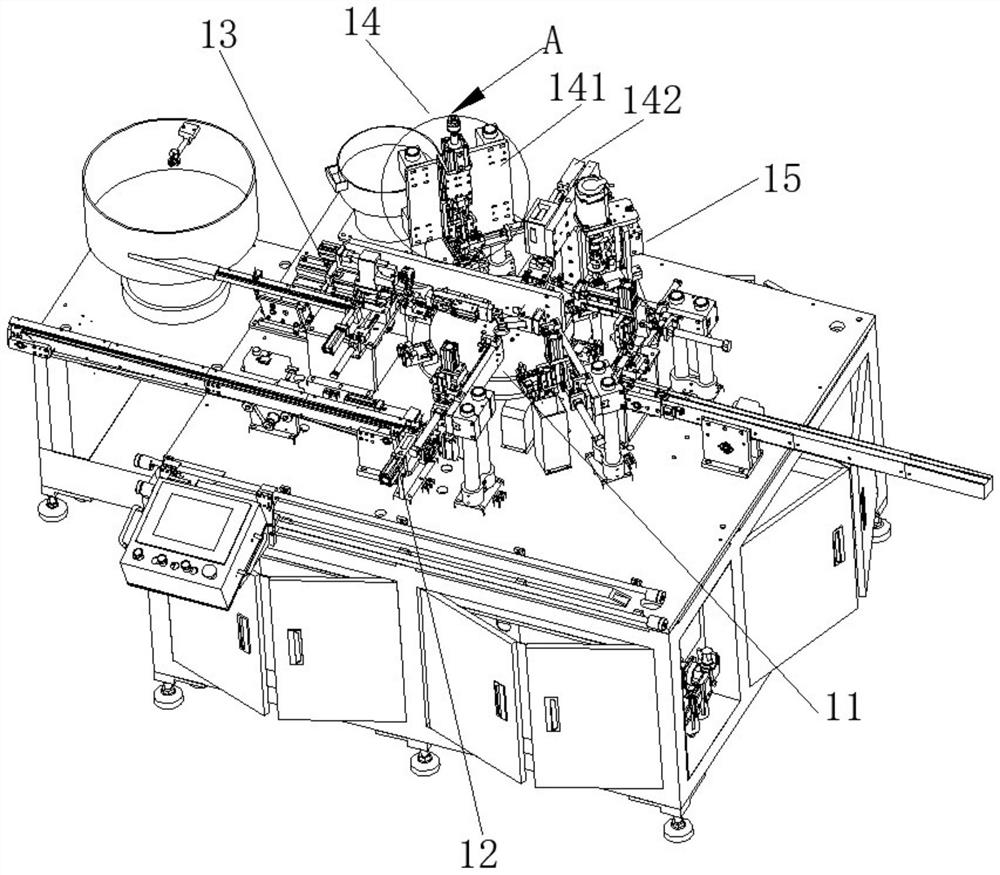

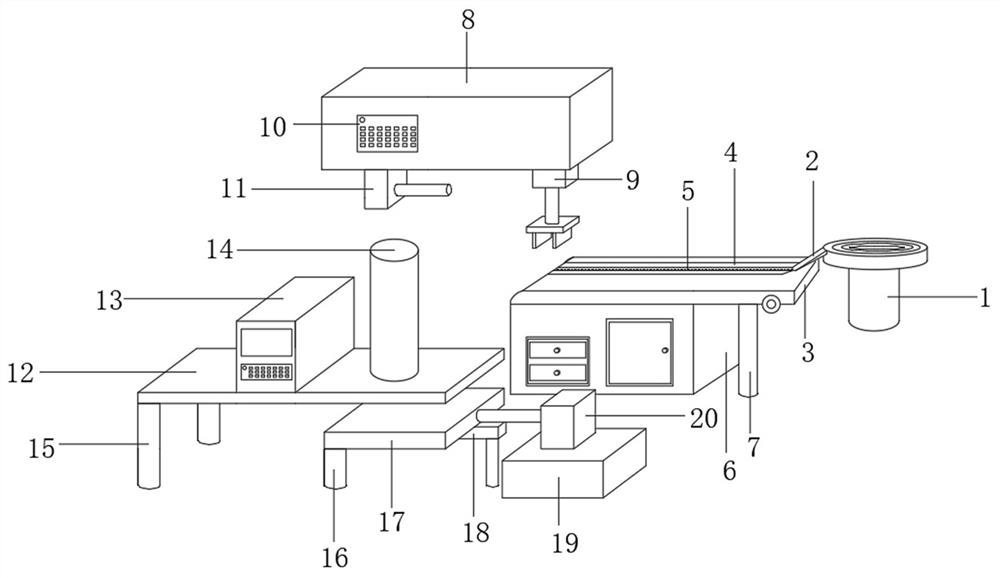

Automatic oil seal mounting equipment

PendingCN112894315AMake sure it fits in placeImprove assembly efficiencyMetal working apparatusElectric machineryEngineering

The invention discloses automatic oil seal mounting equipment. The automatic oil seal mounting equipment comprises a conveying mechanism, a gluing mechanism and a press-fitting mechanism. A tray is arranged on the conveying mechanism, and the motor is placed on the tray and moves along with the conveying mechanism. The gluing mechanism comprises a gluing needle head and a second pushing part. When the motor moves to a gluing station, the second pushing part pushes the gluing needle head to move towards the motor to the gluing position, the gluing needle head can conduct gluing on the motor, after gluing is completed, the second pushing part controls the gluing needle head to be withdrawn, and the tray continues to move along with the conveying mechanism. The press-fitting mechanism comprises a material pipe, a material guiding assembly and a press-fitting assembly. When the tray moves to a press-fitting station, an oil seal moves to the material guiding assembly along the material pipe, the material guiding assembly pushes the oil seal to the press-fitting station, then the press-fitting assembly applies pressure to the oil seal, the oil seal is fixed to the motor, and mounting of the oil seal is completed. The automatic oil seal mounting equipment can be automatically controlled to complete assembly of the motor and the oil seal, the assembly efficiency can be improved in the assembly process, and stable product quality is guaranteed.

Owner:ZHEJIANG HECHUAN TECH

Oil-seal press-mounting clamp and using method thereof

InactiveCN105856153AGuaranteed vertical press fitImprove unityMetal-working hand toolsMechanical engineeringEngineering

Owner:SHAANXI FAST GEAR CO

Safe assembling device for assembling automobile lamp holder sealing ring

InactiveCN107150308AImprove lighting effectsEasy to operateMetal-working hand toolsTime efficientDisplay device

The invention discloses a safety assembly device for assembling sealing rings of automobile lamp holders, and relates to the technical field of automobile manufacturing; one side of the lamp holder positioning jig is provided with a card slot, and the lamp holder is embedded in the card slot The front end of the movable push seat is inlaid with a push rod, the movable push seat is driven by the cylinder and linearly slid to the base through two telescopic rods, the front end of the movable push seat corresponds to the position of the sealing ring; the cylinder and The foot switches are connected with each other; the surface of the base is provided with a protective cover, and the protective cover is fixedly connected with the base through an inlay; the top of the cylinder is provided with a detection mechanism connected to an external display; the top of the display is provided with an acoustic Optical alarm; the assembly device of the present invention greatly improves the production efficiency of products, improves the quality of products, reduces the output of defective products, reduces the work intensity of employees, and has good safety, ensuring long-term and efficient assembly work proceed steadily.

Owner:SUZHOU CONYET AUTOMATION TECH

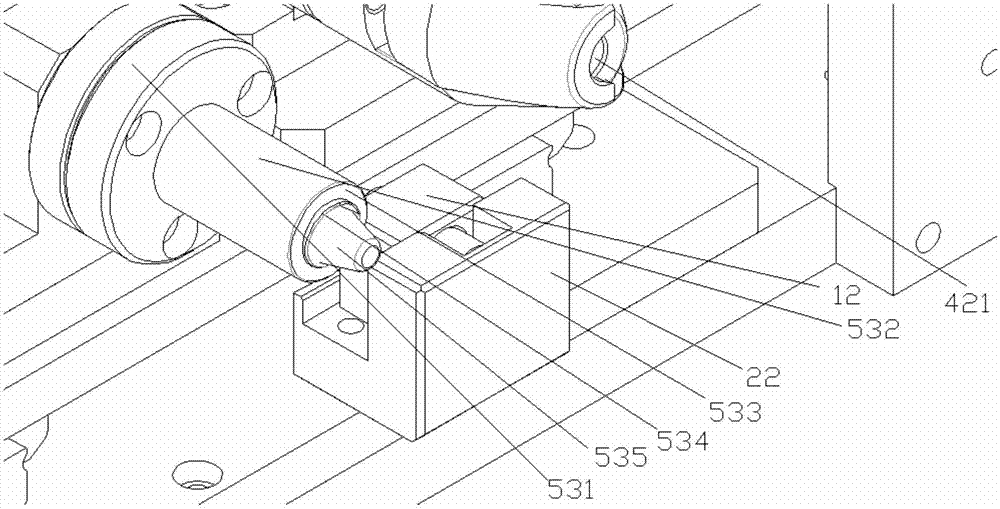

Spring spinning mechanism

ActiveCN107309634AGuaranteed stabilityMake sure it fits in placeMetal working apparatusGratingEngineering

The invention discloses a spring spinning mechanism. The spring spinning mechanism comprises a supporting plate, a bearing plate, a spring guide-in assembly, a spring spinning assembly and a visual detection device, wherein the supporting plate is arranged on a base plate in a front-back sliding mode, the bearing plate is arranged on the supporting plate in a left-right sliding mode, the spring guide-in assembly and the spring spinning assembly are arranged on the bearing plate in a corresponding mode, and the visual detection device is arranged on the base plate through a detection mounting frame and is coordinated with the spring guide-in assembly and the spring spinning assembly for use; a sensing device composed of a groove-shaped grating is arranged on the base plate; a sensor chip which is coordinated with the sensing device for use is arranged on the supporting plate; and the sensing device is coordinated with the sensor chip for use so as to form physical induction detection which is coordinated with a visual detection sensor for use. According to the spring spinning mechanism, the manual installation operation is simulated, springs can be automatically installed, labor cost can be saved, visual detection and physical detection are combined so that the stability for pinning the springs can be guaranteed, the springs can be ensured to be assembled in place, and therefore the product quality can be guaranteed.

Owner:BOZHON PRECISION IND TECH CO LTD

Pneumatic press-fitting terminal device

ActiveCN103515832AMake sure it fits in placeAvoid troubleContact member assembly/disassemblySolenoid valveTerminal equipment

The invention discloses a pneumatic press-fitting terminal device which comprises a machine base, a solenoid valve, a plastic piece locating die, a punch, a wire supporting die, a pushing block and an air cylinder. The solenoid valve is connected with the air cylinder. A concave position is arranged on the plastic piece locating die in a concave mode. The punch is placed in front of the plastic piece locating die and right faces an opening of the concave position. The wire supporting die is placed behind the plastic piece locating die. A groove is formed in the wire supporting die in a concave mode. The pushing block is fixedly arranged between the plastic piece locating die and the wire supporting die. The pushing block is provided with a plurality of pushing columns which extend into the concave position. Accordingly, the wire supporting die is used for supporting product wires, the plastic piece locating die is used for locating plastic pieces, the pushing columns of the pushing block are used for abutting against a terminal, the air cylinder and the punch are matched to push the plastic pieces to move, and therefore the terminal is fixed in the plastic parts in a press-fitting mode, the pneumatic press-fitting terminal device is simple in structure, convenient to operate and capable of effectively saving manpower and greatly improving working efficiency, the fact that the terminal is in position by press fitting can be well guaranteed, product quality is improved, and enterprise problems are solved.

Owner:LEOCO DONGGUAN

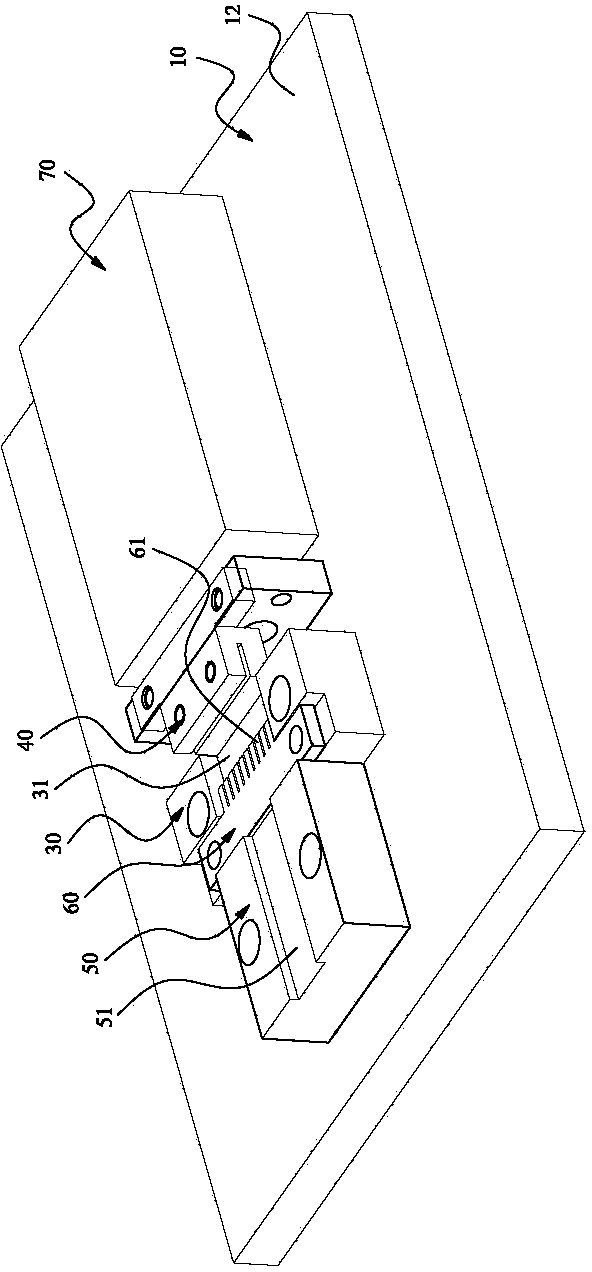

Automatic press-fitting device for product embedded nuts

ActiveCN113649788AStable press fitImprove installation efficiencySortingMetal working apparatusProcess engineeringWorkbench

The invention discloses an automatic press-fitting device for product embedded nuts, and belongs to the field of automatic assembly equipment. The automatic press-fitting device comprises a product feeding mechanism, a workbench, a product conveying rail, a product moving mechanism and a nut feeding press-fitting mechanism, wherein the product conveying rail is horizontally erected on the workbench, one end of the product conveying rail is connected with a discharging port of the product feeding mechanism, the product moving mechanism is arranged below the product conveying rail, and the nut feeding press-fitting mechanism is arranged on the workbench and is located on the side of the product conveying rail. According to the automatic press-fitting device, automatic feeding and discharging of the nuts are realized by utilizing a nut staggered arrangement mechanism, automatic grabbing and press-fitting of the nuts are realized by utilizing a nut grabbing press-fitting mechanism, so that rapid and stable press-fitting of the plurality of nuts on a product is realized, the nut installation efficiency is high, the installation quality is good, the assembly efficiency of the product is greatly improved, the labor intensity of manual assembly is reduced, and the automatic press-fitting device has the advantages of being compact and ingenious in structural design, stable and reliable in press-fitting action, high in working efficiency and the like.

Owner:江苏墨新电子科技有限公司

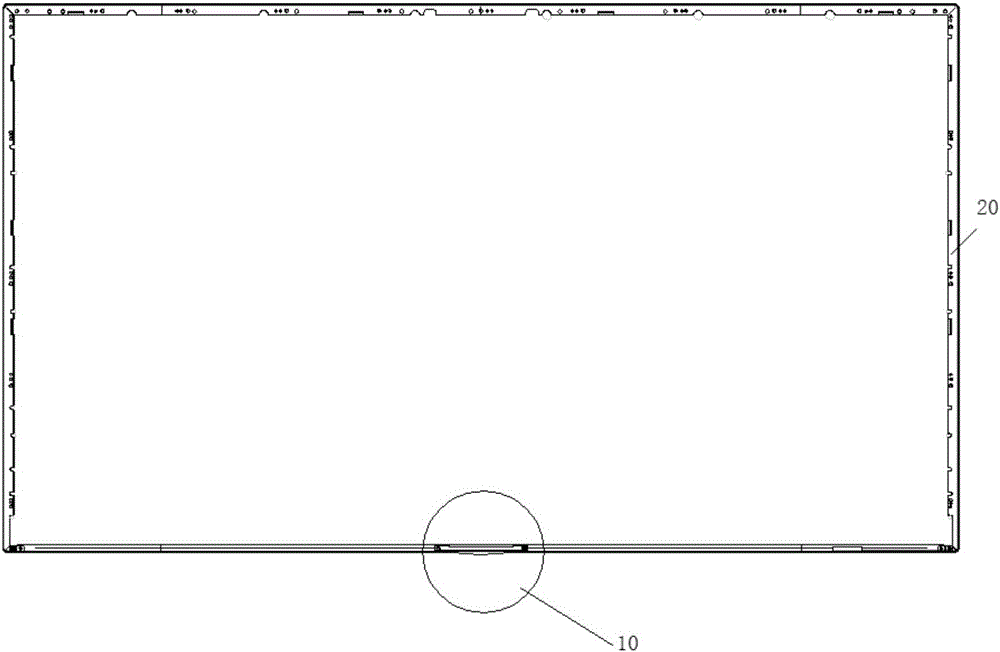

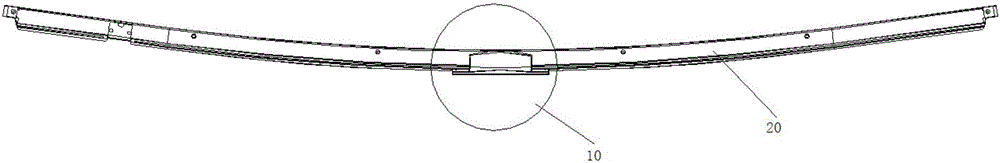

Display device

ActiveCN105042425AEasy to installSnap firmlyLight fasteningsFixed installationLight guideDisplay device

The embodiment of the invention provides a display device and relates to the field of display equipment. By the adoption of the display device, a lighting component can be easily installed and stably clamped. The display device comprises a front shell, a rear shell and the lighting component. The lighting component comprises a light bar and a light guide plate, wherein one end of the light guide plate is provided with a concave light groove, the light bar is arranged in the light groove, and the extending direction of the light groove is perpendicular to the extending direction of the light guide plate; two mounting holes are formed in the two ends of the light groove in the two extending directions of the light groove, and each mounting hole is open in the extending direction of the light guide plate. Two riveting pillars are arranged on the frame of the front shell, and the riveting pillars are inserted into the mounting holes. The edge of the rear shell is abutted against the outer wall of the light groove of the light guide plate. The display device is used for display device assembly.

Owner:HISENSE VISUAL TECH CO LTD

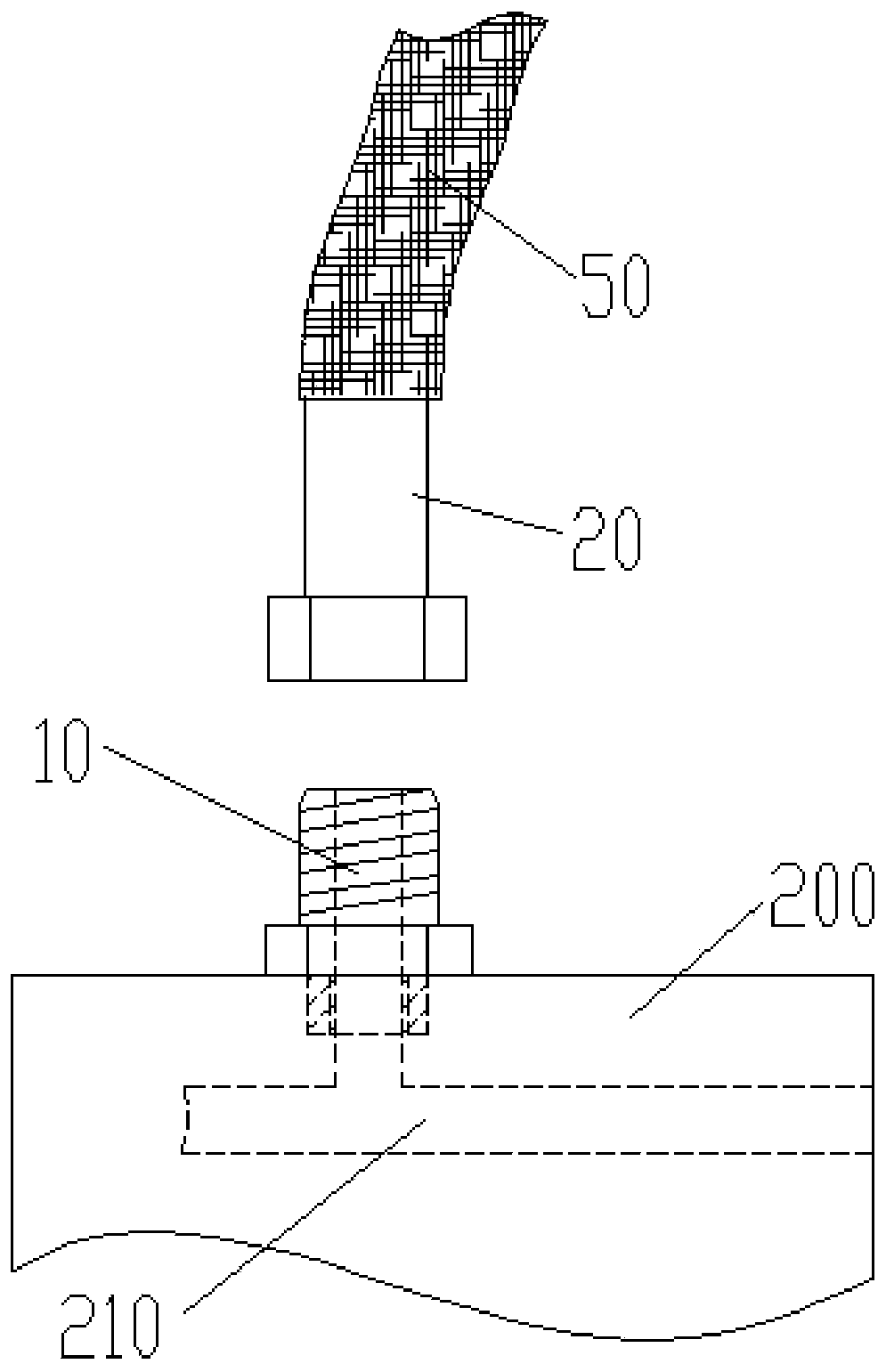

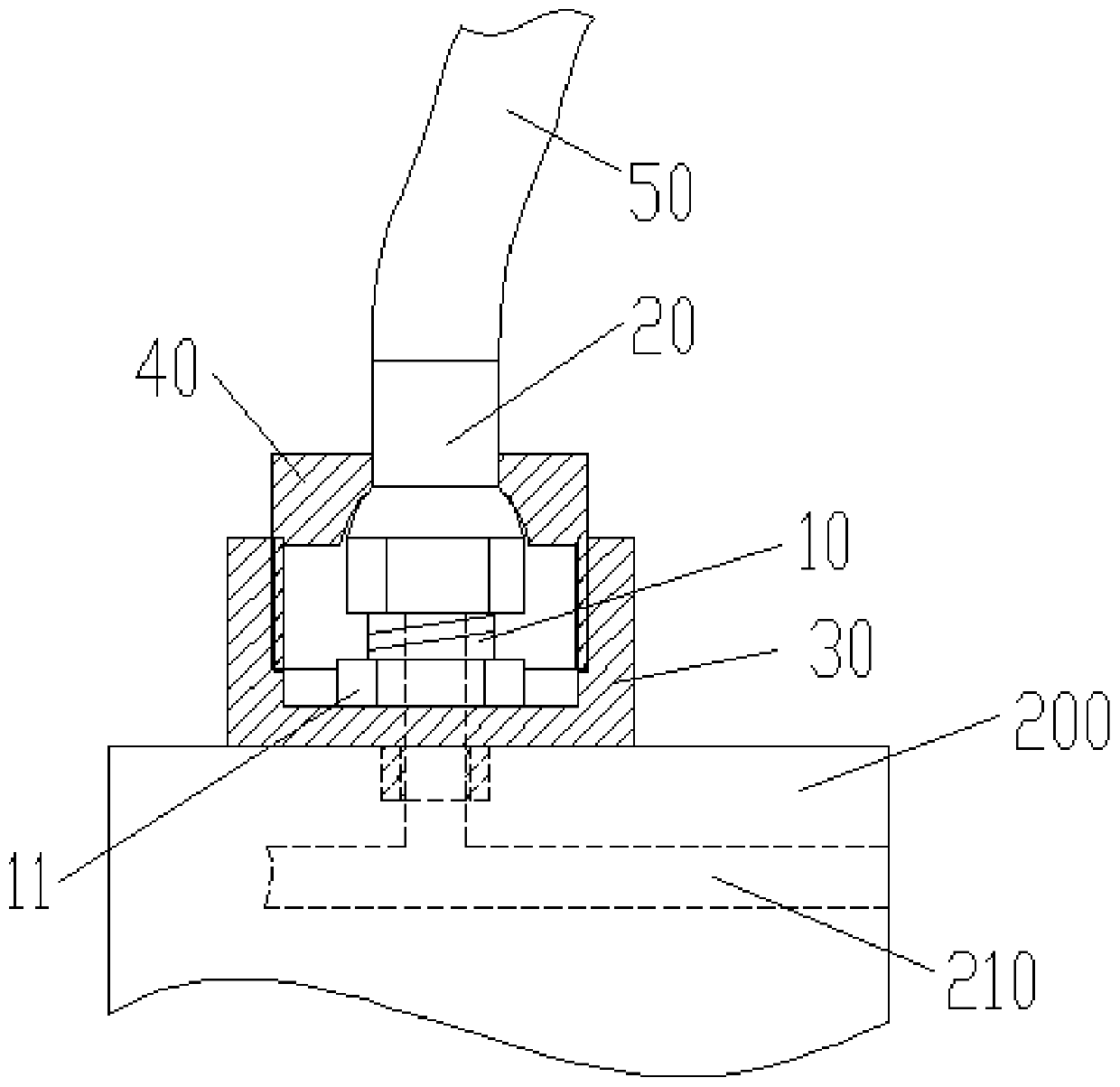

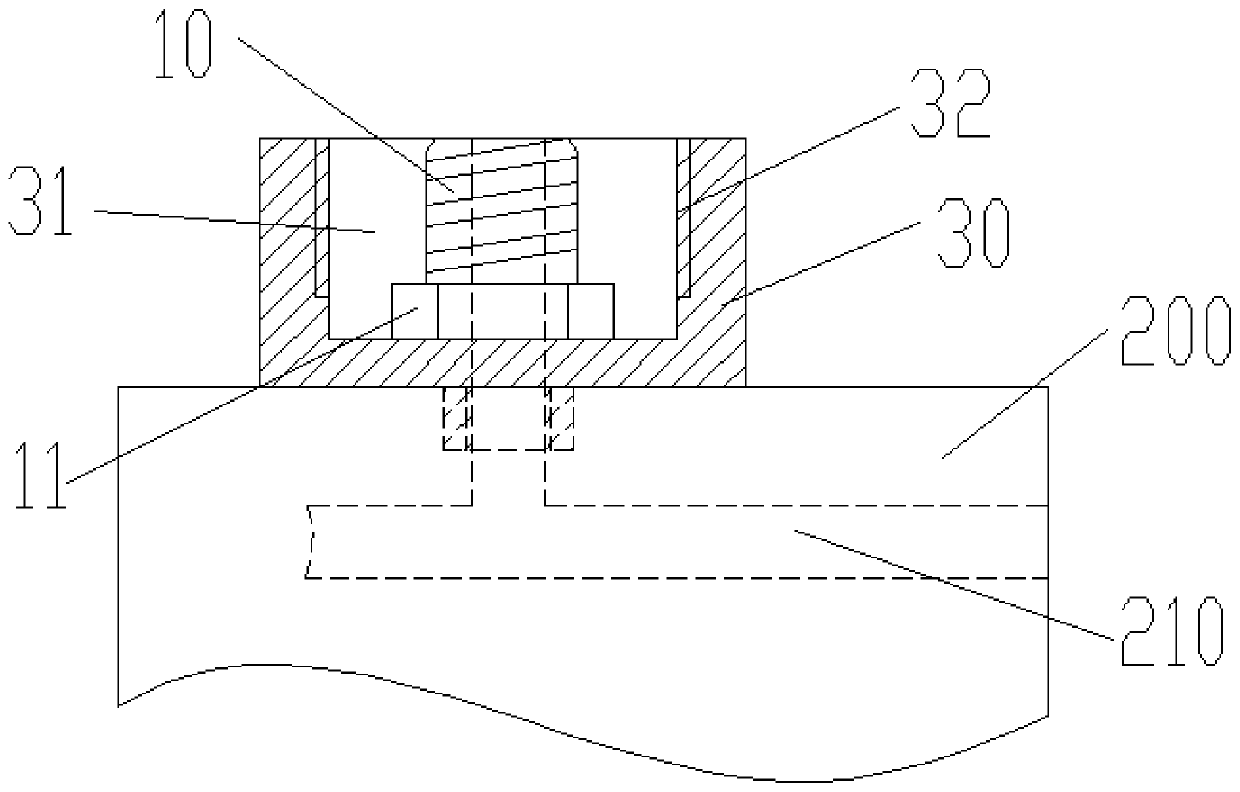

Blade bolt for controllable-pitch propeller

The invention discloses a blade bolt for a controllable-pitch propeller, and belongs to the field of ships. Wherein the paddle bolt comprises a main bolt and a plurality of pushing pieces, the main bolt comprises a screw rod and a screw cap, a plurality of screw holes are formed in the screw cap, and one pushing piece is inserted into each screw hole. According to the invention, the plurality of pushing pieces abut against the blades, and under the action of the pushing pieces, the blades can be tightly attached to the crankpin disc, so that the friction force between the blades and the crankpin disc is increased, the looseness prevention is realized, and the connection and fixation of the blades and the crankpin disc are realized in a labor-saving manner.

Owner:WUHAN MARINE MACHINERY PLANT

Intelligent assembling device for assembling automobile lamp holder sealing ring

InactiveCN107186457AReduce manual operation fatigueIncrease productivityMetal working apparatusDisplay deviceCcd camera

The invention discloses an intelligent assembly device for assembling sealing rings of automobile lamp holders, and relates to the technical field of automobile manufacturing; a lamp holder positioning jig and a cylinder are fixedly connected to a base through bolts; one side of the lamp holder positioning jig There is a card slot, and the lamp holder is inlaid in the card slot; the front end of the movable push seat is inlaid with a push rod, the movable push seat is driven by the cylinder and linearly slid on the base through two telescopic rods, and the front end of the movable push seat is correspondingly sealed The location of the ring; the cylinder and the foot switch are connected to each other; the cylinder is connected to the external controller, and the front end of the movable push seat is equipped with a CCD camera connected to the external display; the surface of the base and the foot switch are coated with a self-luminous layer; this The invention of the assembly device greatly improves the production efficiency of the product, and at the same time improves the quality of the product, reduces the output of defective products, and reduces the work intensity of the employees. It is safe and environmentally friendly, and the operation of the personnel is simple, ensuring that the assembly work can be carried out efficiently and stably for a long time conduct.

Owner:太仓市华天冲压五金制品厂

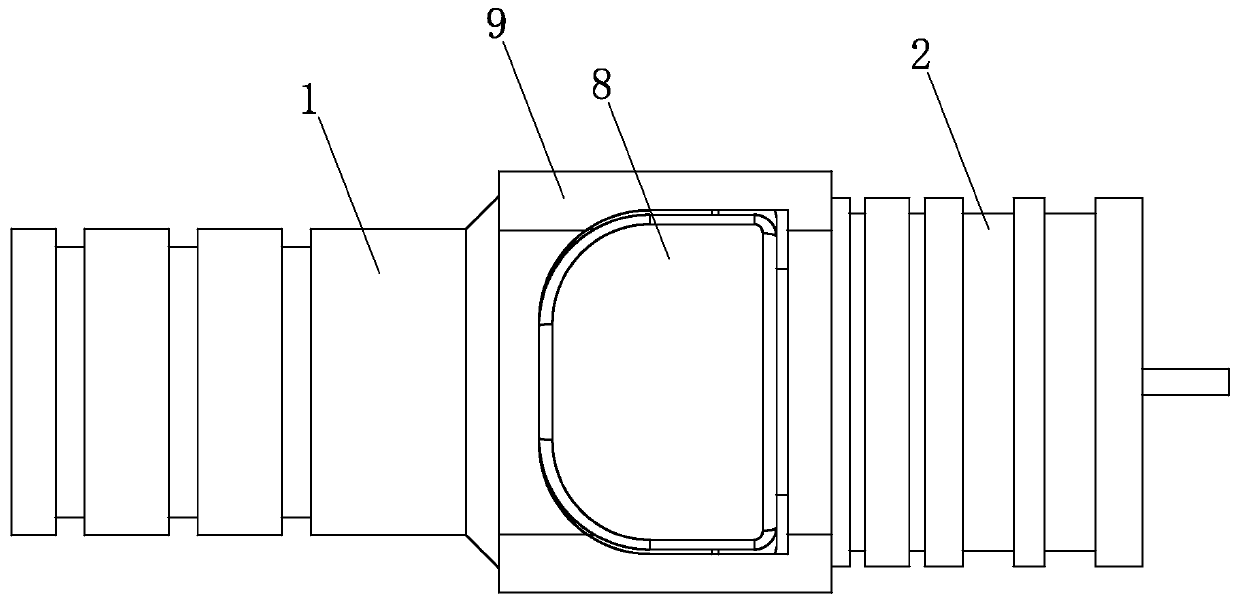

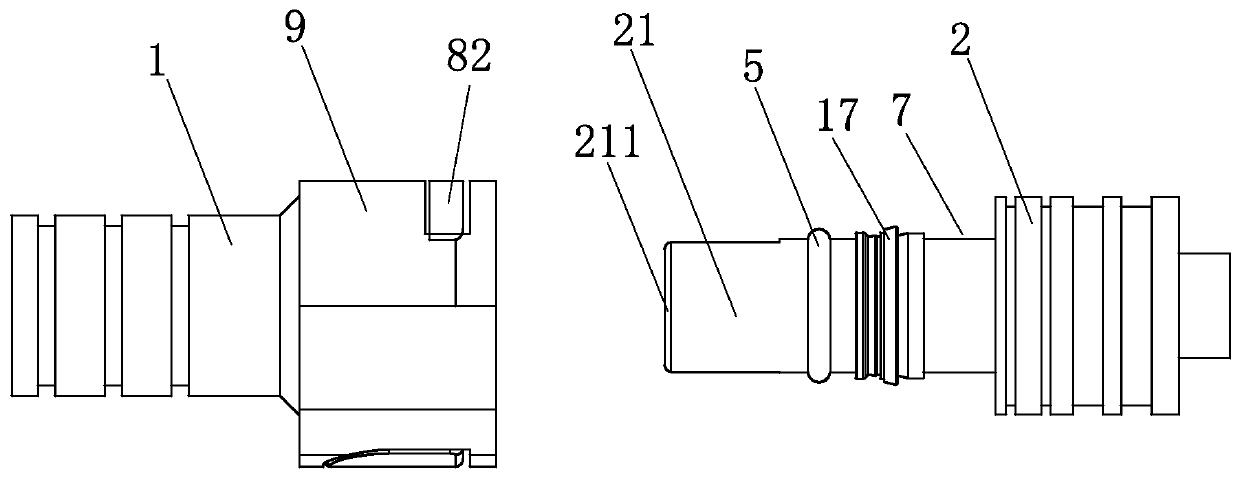

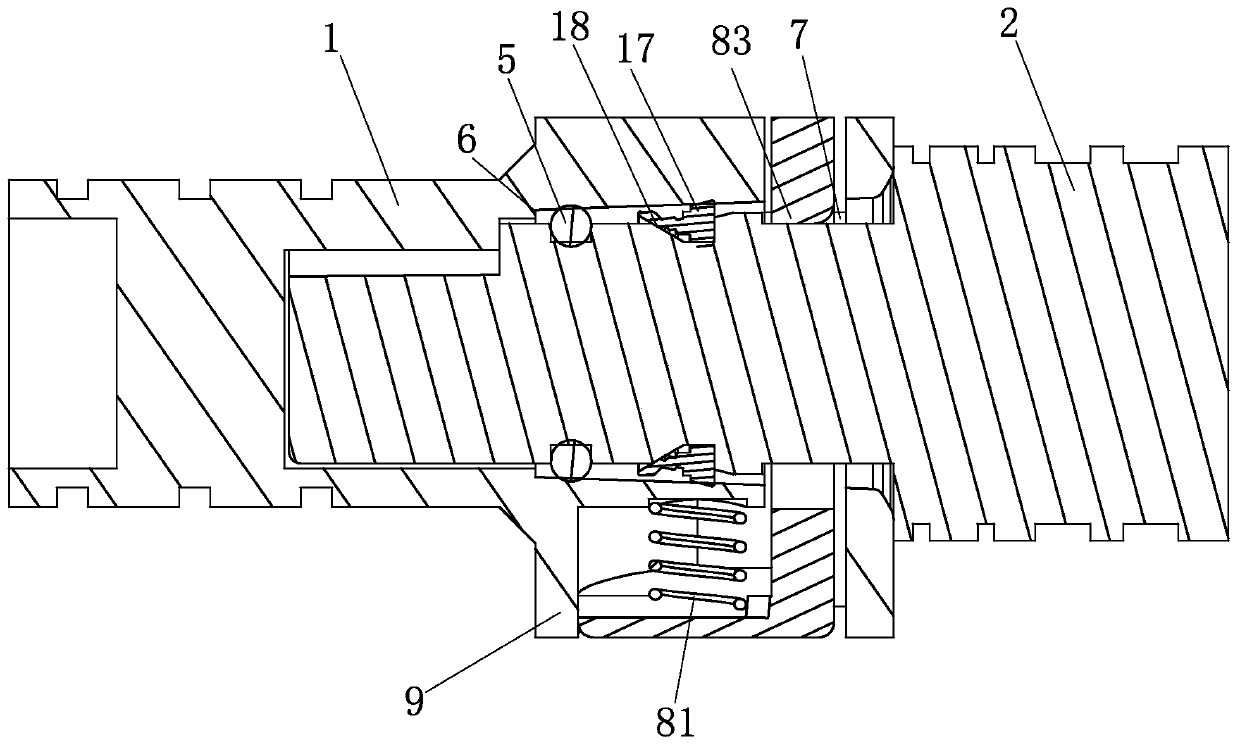

Pressing-type self-locking waterproof connection mechanism

PendingCN110661135AGuaranteed fixed effectEasy to fixCouplings bases/casesTwo-part coupling devicesEngineeringStructural engineering

The invention discloses a pressing-type self-locking waterproof connection mechanism, which comprises a female joint and a male joint, wherein the male joint comprises an inserting part, the peripheral surface of the inserting part is provided with a sealing ring and a clamping and locking part for clamping, and sealing is formed between the sealing ring and the inner cavity wall of the female joint when the inserting part enters an extending cavity of the female joint. Meanwhile, an elastic self-locking plugging mechanism is matched with the clamping and locking part on the inserting part, sothat the male joint can be clamped in the female joint, the elastic self-locking plugging mechanism can be moved in a pressing mode so as to be separated from the clamping and locking part, the malejoint can be disassembled from the female joint conveniently, and quick and effective assembly and disassembly can be realized. Therefore, the connection mechanism can simultaneously have the functions of water resistance and convenient disassembly, can be used for outdoor wiring work for a long time, has better tensile performance after assembly due to the fact that the movable elastic self-locking plugging mechanism can be inserted into the clamping and locking part after self-locking, and is improved in performance and simpler and more convenient in assembly process compared with the existing connector.

Owner:广东迪艾生光电技术有限公司

Loudspeaker module and manufacturing method thereof

PendingCN111901711AEffectively fixedMake sure it fits in placeTransducer casings/cabinets/supportsAdhesiveEngineering

The invention provides a loudspeaker module. The loudspeaker module comprises a module shell, a sound production single body and a breathable isolation assembly. An accommodating cavity, a first mounting position and a second mounting position are arranged in the module shell; the sound production single body is mounted ata first mounting position to divide the accommodating cavity into a front sound cavity and a rear sound cavity, and the rear sound cavity is filled with sound absorption particles; the breathable isolation assembly comprises an isolation frame and a breathable isolation piecemounted on the isolation frame, the isolation frame sleeves one end, located in the rear sound cavity, of the sound production unit and is mounted to the second mounting position, and the breathableisolation piece covers one side, deviating from the front sound cavity, of the sound production unit so as to separate the sound production unit from the sound absorption particles; the sound production single body is bonded with the first installation position through a photosensitive adhesive, and the isolation frame is a light-transmitting isolation frame through which light for curing the photosensitive adhesive can pass. The invention further provides a manufacturing method of the loudspeaker module. According to the invention, the sound production monomer can be ensured to be effectivelyfixed, the isolation frame can be ensured to be assembled in place, and the situation that the isolation frame is jacked up due to over-high photosensitive adhesive coating is avoided.

Owner:GOERTEK INC

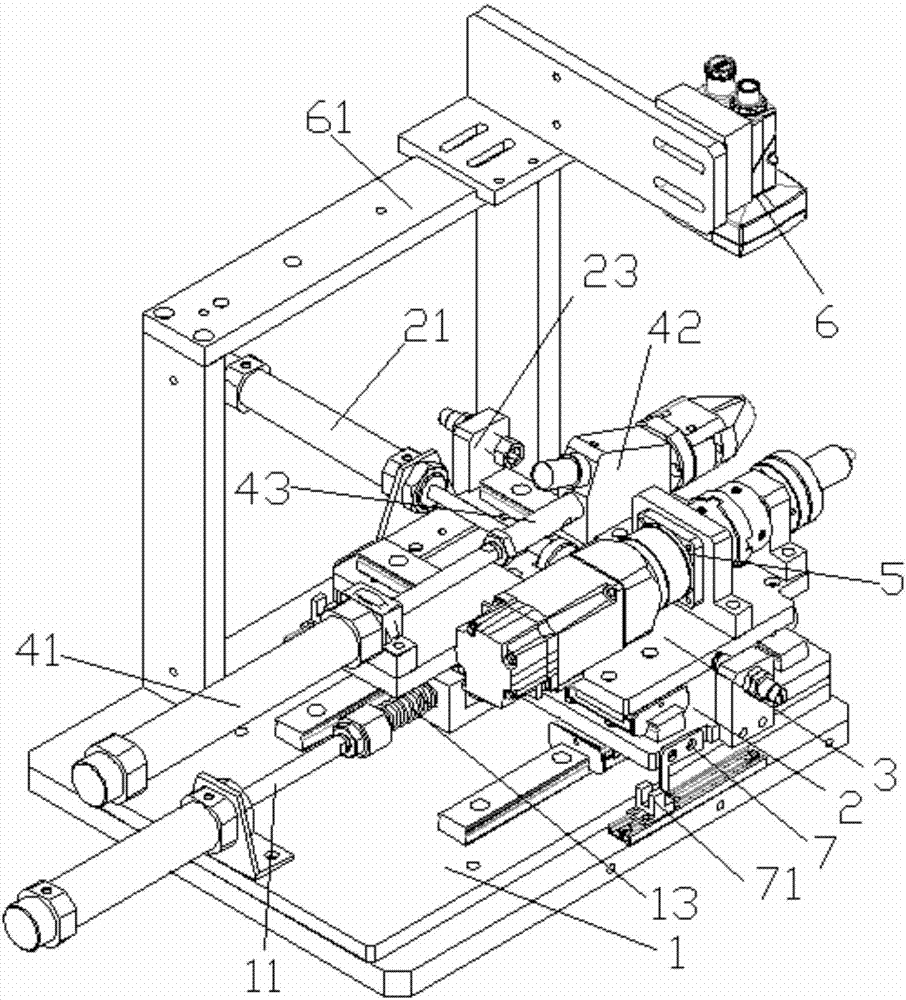

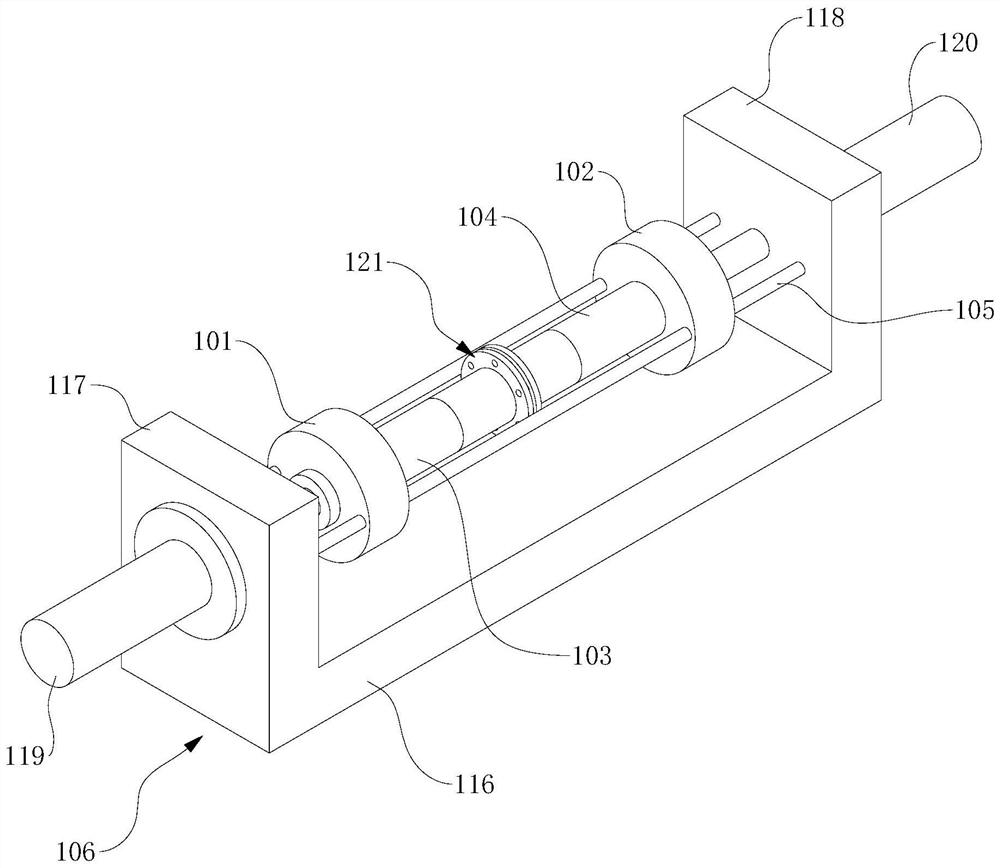

Spring mounting tooling of semi-automatic spring mounting machine for shock absorber and spring mounting method of spring mounting tooling

PendingCN111113005AShorten the timeIncreased press strokeMetal working apparatusSemi automaticEngineering

The invention discloses a spring mounting tooling of a semi-automatic spring mounting machine for a shock absorber and a spring mounting method of the spring mounting tooling. The spring mounting tooling comprises an upper spring compressing tooling, and further comprises a lower spring compressing tooling positioned below the upper spring compressing tooling, wherein the lower spring compressingtooling is used for limiting a spring and compressing the spring to a working part; and a spring disc positioning tooling is arranged on the upper surface of the lower spring compressing tooling and used for positioning a spring disc. In order to solve the problem that in the prior art, the spring head in-place rate is low, the spring mounting and compressing stroke is limited, the spring mountingefficiency is low, the spring mounting tooling of the semi-automatic spring mounting machine for the shock absorber and the spring mounting method of the spring mounting tooling are provided; and thepurposes of ensuring the one-time in-place of a spring head, enlarging the spring mounting and compressing stroke, and improving the spring mounting efficiency can be fulfilled.

Owner:SICHUAN NINGJIANG SHANCHUAN MACHINERY

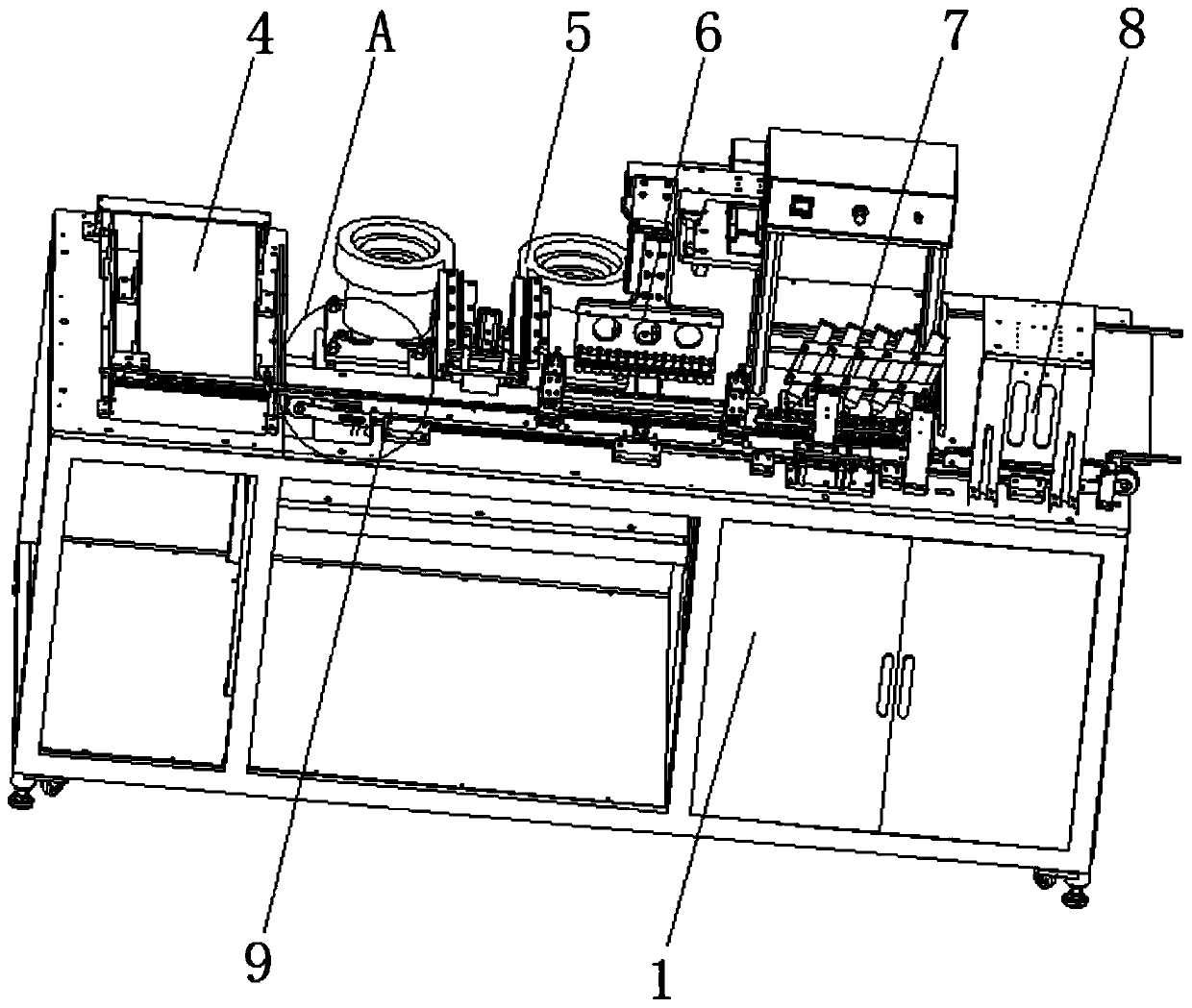

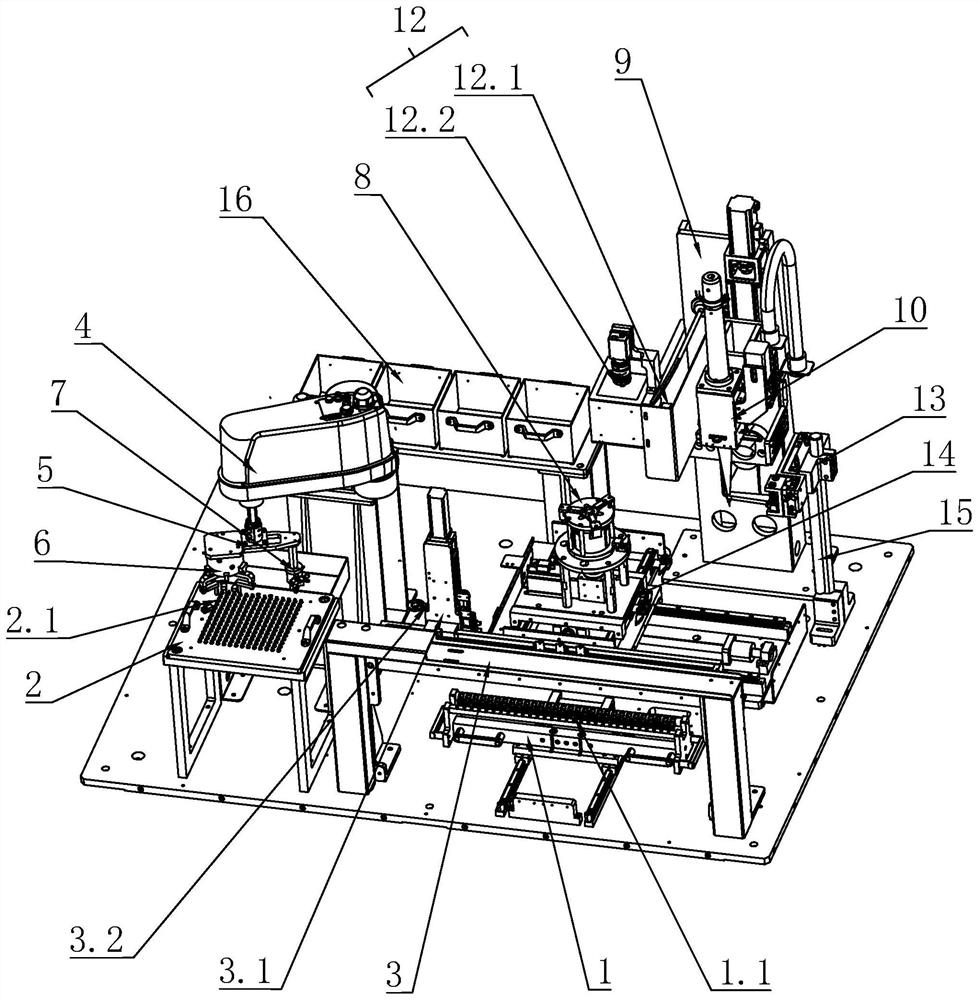

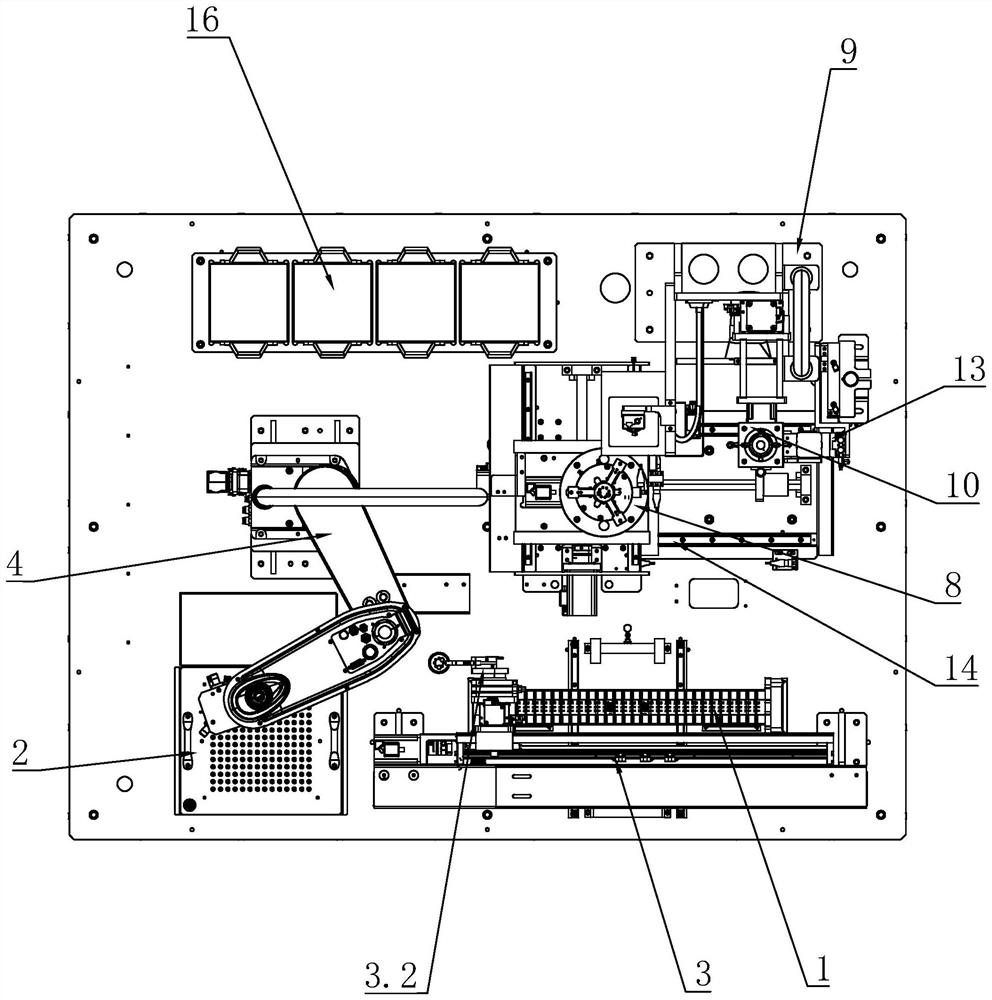

A magnetic box assembly glue coating machine

ActiveCN108766749BCompact structureEasy to useLiquid surface applicatorsInductances/transformers/magnets manufactureAssembly machineManufacturing engineering

The invention discloses a magnetic box assembling gummer, comprising a rack, a printing rod for positioning and installing a semi-finished product workpiece, and a semi-finished product feeding mechanism, a magnetic box feeding mechanism, an assembling mechanism, a gumming mechanism and a finished product discharge mechanism which are respectively arranged on the rack; wherein the rack is providedwith a conveying mechanism which enables the semi-finished product feeding mechanism, the assembling mechanism, the gumming mechanism and the finished product discharge mechanism to be successively connected and is used for conveying the printing rod, the assembling mechanism comprises a positioning assembly used for positioning the printing rod and a mounting assembly which is capable of adsorbing a magnetic box from the magnetic box feeding mechanism and mounting the magnetic box onto the semi-finished product workpiece. The magnetic box assembling gummer provided by the invention has the beneficial effects of compact structure, convenient use, high automation degree, capacity for integrating the processes of magnetic box assembling and gumming, capacity for greatly improving productionefficiency and product quality, and capacity for reducing production cost.

Owner:广西昭信平洲电子有限公司

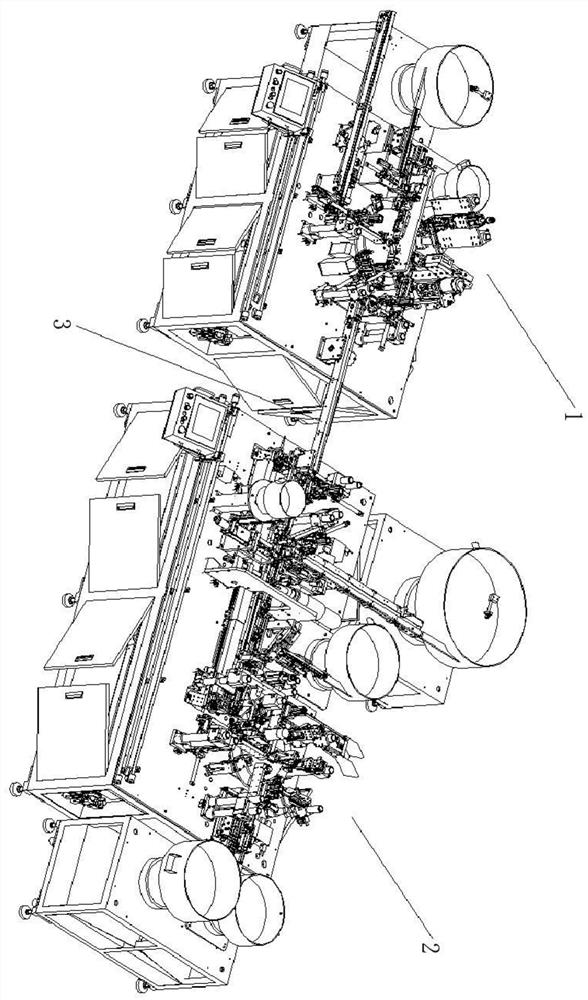

Automatic hinge production equipment

PendingCN112388307AGuarantee product qualityGuaranteed assemblyAssembly machinesCircular discManufacturing cost reduction

The invention relates to the technical field of hinge production, in particular to automatic hinge production equipment. First module equipment comprises a first rotating disc, and an adjusting seat feeding mechanism, a crank mounting mechanism, an eccentric rivet mounting mechanism and a riveting detection mechanism are sequentially arranged in the clockwise direction of the first rotating disc;second module equipment comprises a jig conveyer belt circulating mechanism and a second rotating disc, an external fixing part mounting mechanism, a flat head rivet mounting mechanism and a torsionalspring mounting and pressing mechanism are sequentially arranged along the jig conveyer belt circulating mechanism, and the second rotating disc is arranged beside the torsional spring mounting and pressing mechanism; and a buffer part mounting mechanism, a function testing mechanism and a product discharging mechanism are sequentially arranged in the anticlockwise direction of the second rotating disc. Assembly of all components of a hinge can be completed fully automatically, and an existing manual assembly mode is replaced; not only can the production efficiency be greatly improved, and the manufacturing cost is reduced, but also it can be guaranteed that all the components are assembled in place; and the hinge production quality is guaranteed.

Owner:东莞市鼎力自动化科技有限公司

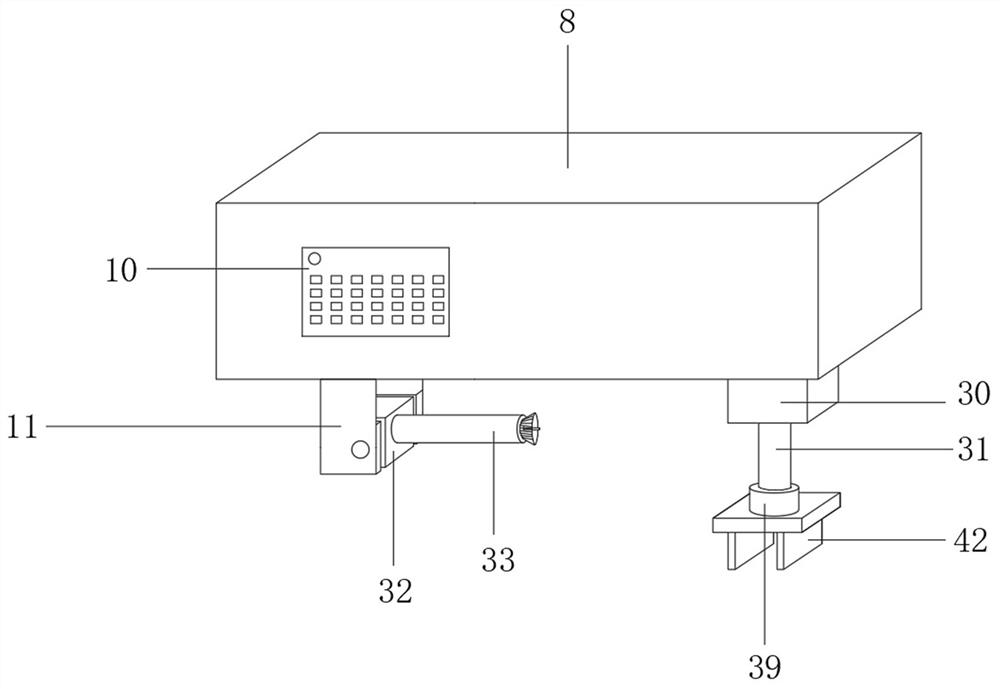

Installing device for air spring buffer block

PendingCN111958214AMake sure it fits in placeIncrease productivityMetal working apparatusAuto regulationAir spring

The invention relates to an installing device for an air spring buffer block. The installing device comprises a lower fixed plate. A slide groove, a slider, a lower cylinder and two first connecting rods are disposed on the lower fixed plate. The slider is slidably disposed in the slide groove. A second connecting rod is disposed on the slider. A buffer block groove is formed in the top end of thesecond connecting rod. The slider is connected with the lower cylinder. The slider can slide along the slide groove under the push-pull action of the lower cylinder. The top ends of the two first connecting rods are jointly connected with an upper fixed plate. An upper cylinder is fixed to the upper fixed plate. A control box and a start button unit which are electrically connected with the uppercylinder and the lower cylinder are disposed on the first connecting rods. The installing device can set feeding pressure and time in accordance with different assembly sizes of the buffer block by its automatic regulating function, and meanwhile makes sure that no size deviation occurs when the buffer block is assembled and makes sure that the buffer block is assembled in place with the aid of acentring unit, thereby synchronously improving production efficiency and reducing labor intensity in the whole assembly process only by starting button control.

Owner:广东溢康通空气弹簧有限公司

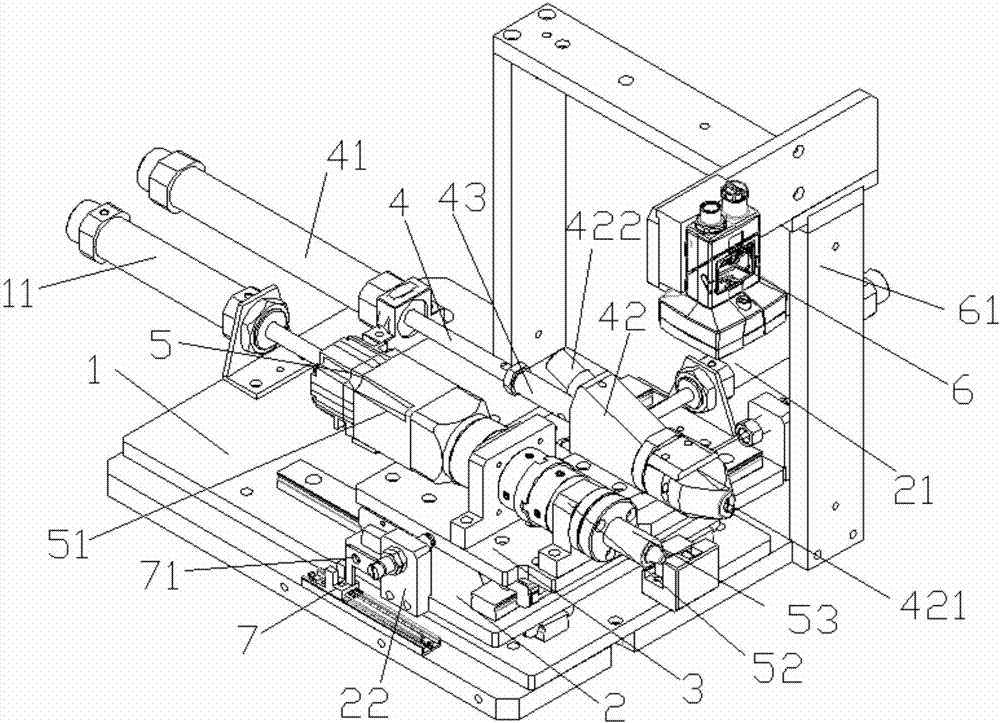

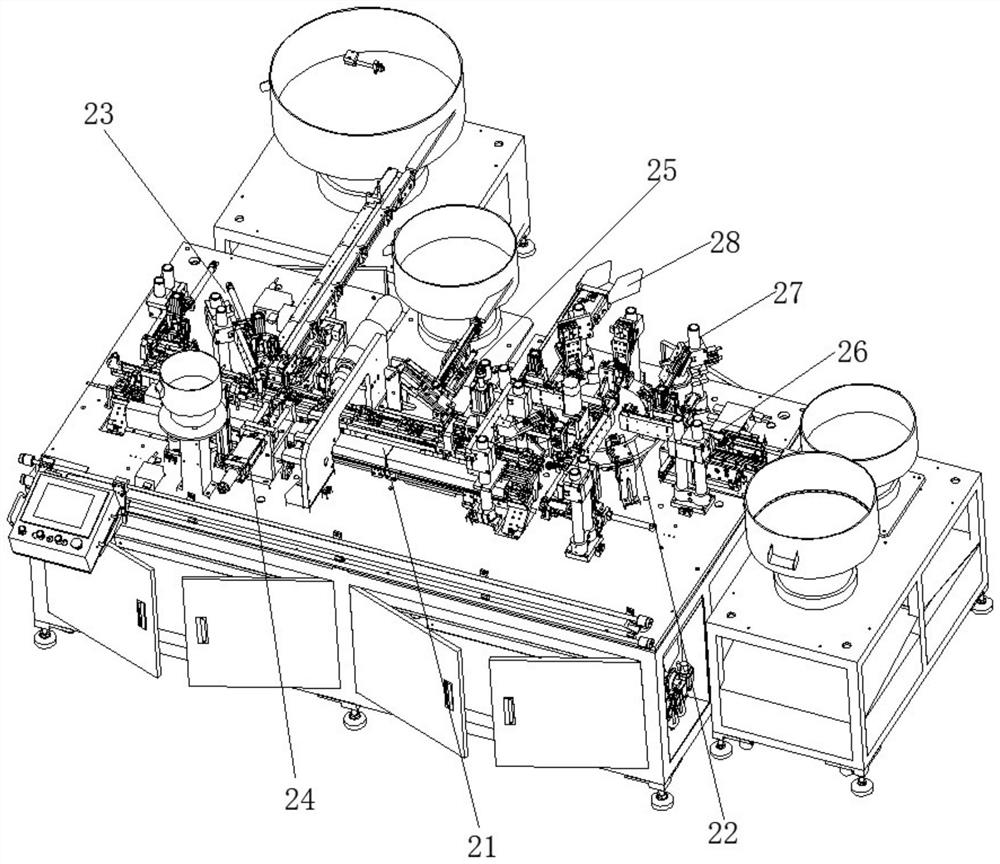

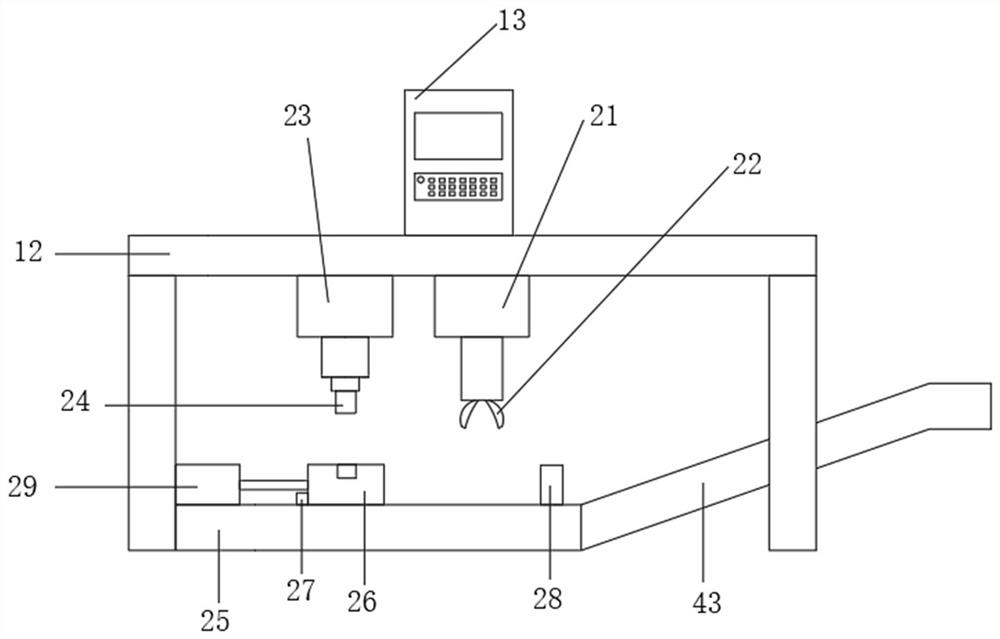

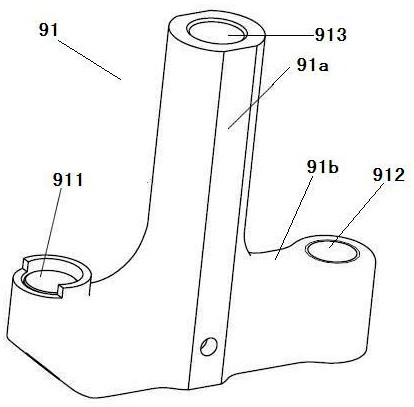

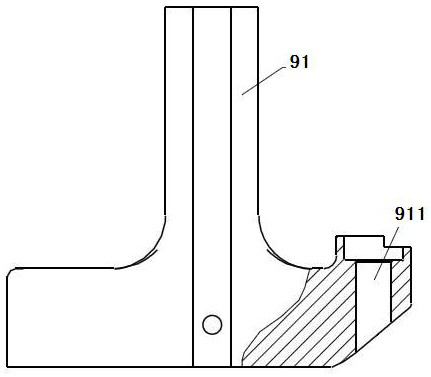

A stamping system of electronic fuel injection pump

ActiveCN112692789BGuaranteed stabilityMake sure it fits in placeMetal-working hand toolsPunchingEngineering

The invention relates to a stamping system of an electric fuel injection fuel pump, which includes a feeding vibration plate, a first conveying mechanism, a second conveying mechanism, a detection mechanism, and a stamping mechanism. The detection mechanism is composed of a guiding test cylinder, a bottom movable plate, and a controller The stamping mechanism is composed of a stamping machine and a guiding stamping mechanism arranged at the bottom of the stamping machine. The guiding stamping mechanism is composed of a movable sleeve, a connecting column, and a guiding column. Guide grooves are evenly opened on the side of the connecting column. The inner side of the movable sleeve is provided with a guide protrusion matching the guide groove, and a threaded strip is fixedly connected to the guide column. The threaded strip provided on the guide column can effectively ensure the stability of the guide stamping mechanism when it is pressed, and can effectively To ensure that the spring to be pressed is in place, the overall system realizes the automatic operation of spring pressing of the EFI fuel pump from feeding, detection to pressing and forming, which improves the pressing efficiency and facilitates the control of the pressing force of the spring, ensuring The spring is pressed into place.

Owner:安徽宝隽机车部件有限公司

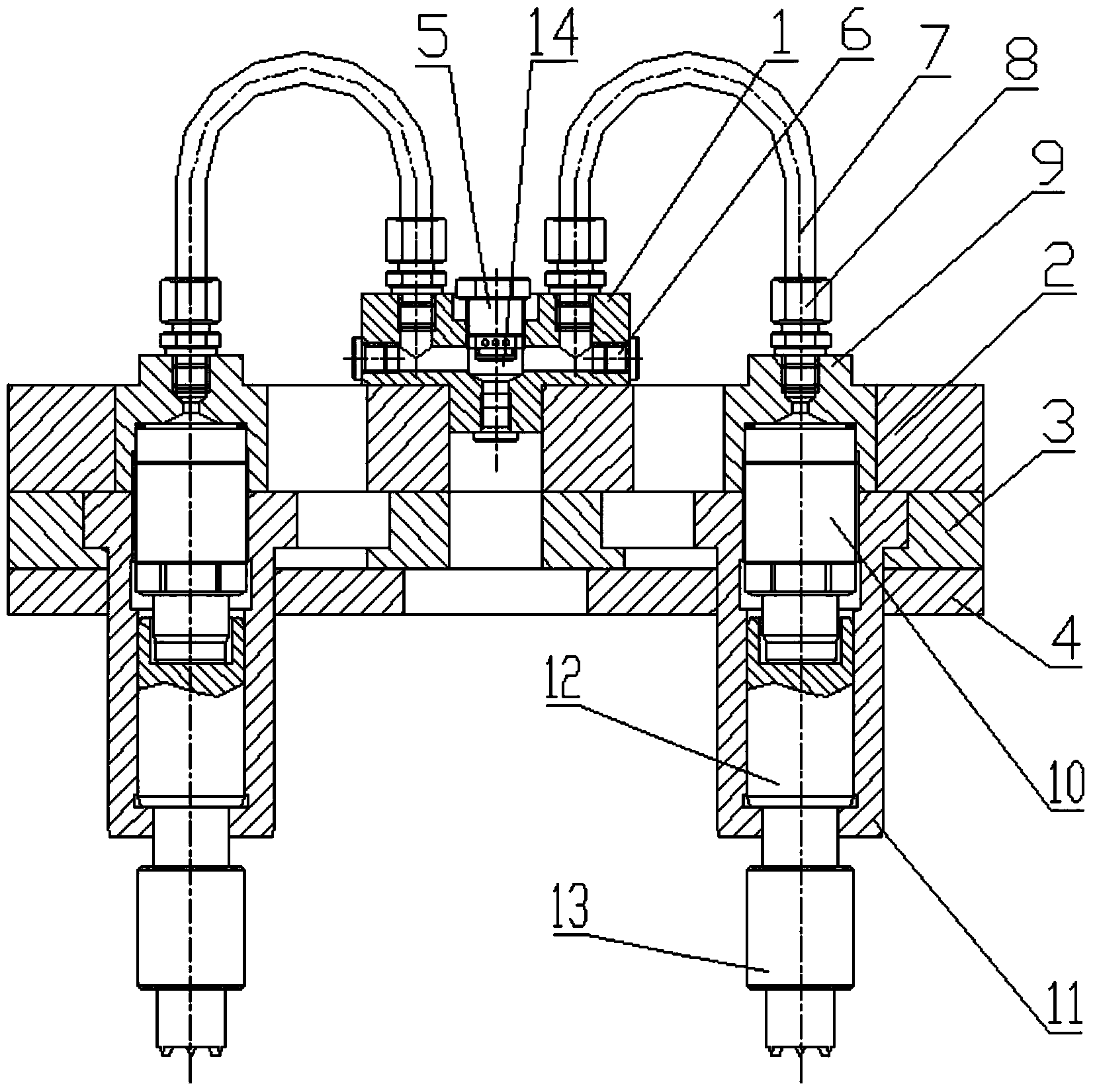

Floating head device

InactiveCN103962828BUniform pressing force of the indenterImprove connectivityMetal working apparatusMechanical engineering

The invention discloses a floating pressure head device. The floating pressure head device comprises an oil distributing base, a base, an index plate, a positioning plate and multiple pressure head assemblies in a sequential overlaying mode. Multiple through installation grooves are formed in the base and the index plate. The pressure head assemblies are correspondingly arranged in the installation grooves. Each pressure head assembly can horizontally move in the corresponding installation groove. A cavity is formed in the oil distributing base, and the oil distributing base is provided with an oil filling port which leads to the cavity. A one-way valve is installed on the oil distributing base, and multiple oil outlets are respectively formed in the oil distributing base and lead to the cavity. Hydraulic hoses are correspondingly connected between the oil outlets and the pressure head assemblies. Hydraulic oil in all the pressure head assemblies is communicated, so that press fitting force of pressure heads of all the pressure head assemblies is even, press fitting is performed on each part in place, and press fitting precision is improved. Multiple parts can be pressed into the device in a one-off mode, so that time is saved, efficiency is improved, operation is convenient and cost is reduced, and the number of the pressure heads of all the pressure head assemblies can be designed according to workpieces.

Owner:HEFEI UNIV OF TECH

Pipe connection mechanism

ActiveCN108223933BGuaranteed tightnessMake sure it fits in placeScrew threaded jointsEngineeringScrew thread

The invention provides a pipeline connecting mechanism, which comprises an outer joint, a pipe joint, an inner joint and a pressing sleeve. The pressing sleeve is interworked with the inner joint so as to jointly form a sealed chamber; the outer joint is arranged in the inner joint, partially downwards stretches out relative to the inner joint, and is connected with a pipeline on an equipment body; the pipe joint is arranged in the pressing sleeve, and upwards partially stretches out relative to the pressing sleeve; a rubber pipe is connected onto a part, stretching out of the pressing sleeve,of the pipe joint; and the outer joint and the pipe joint are connected and fixed in a screw thread way. According to the pipeline connecting mechanism provided by the invention, through the reasonable structure arrangement, a sealing effect is ensured when the equipment body outwards conveys a medium through the rubber pipe, so that the occurrence of equipment field safety accidents caused by medium leakage and seepage is avoided.

Owner:SHANGHAI ZHONGLIN FEEDWATER MATERIAL CO LTD

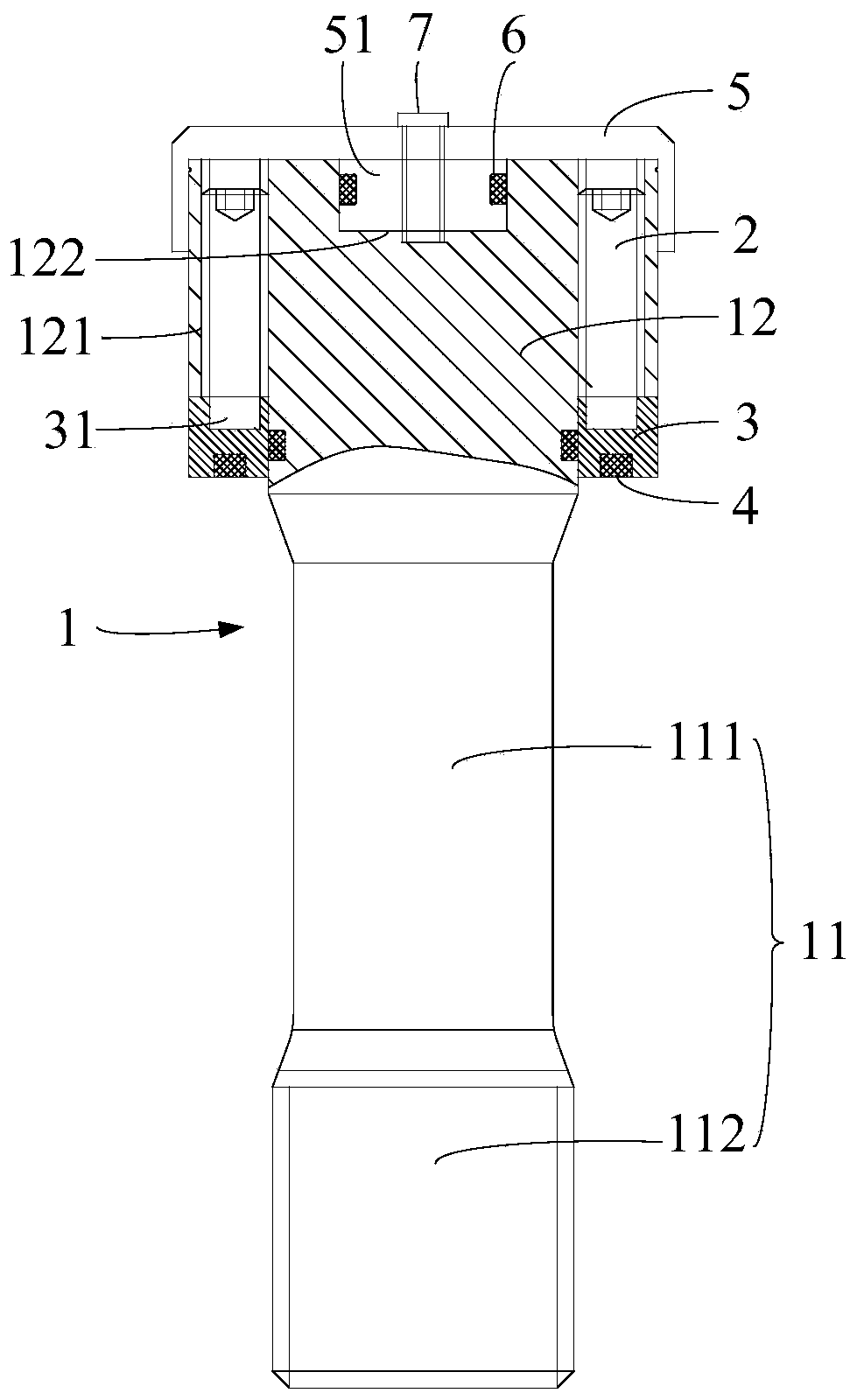

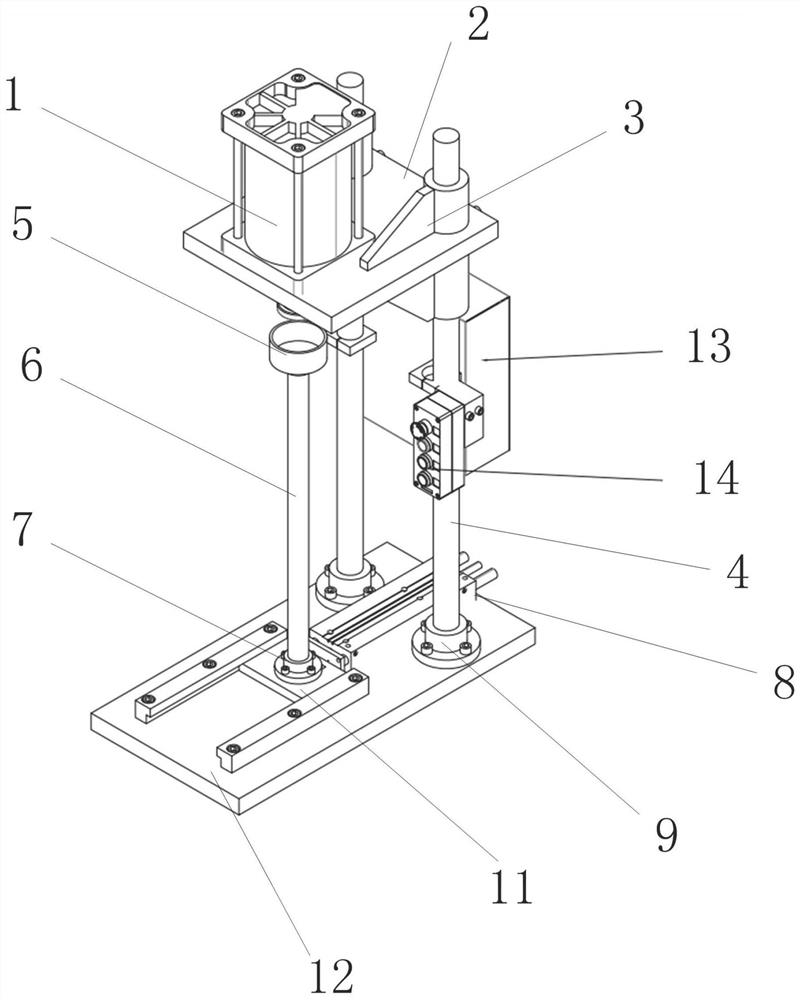

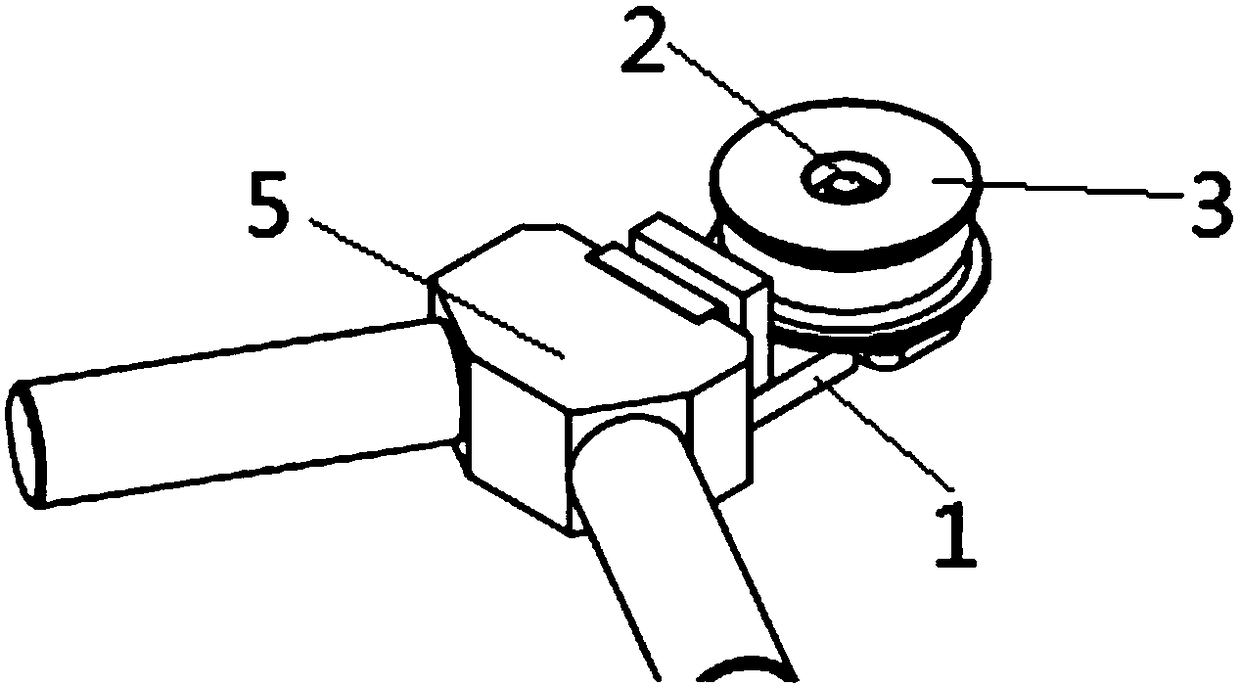

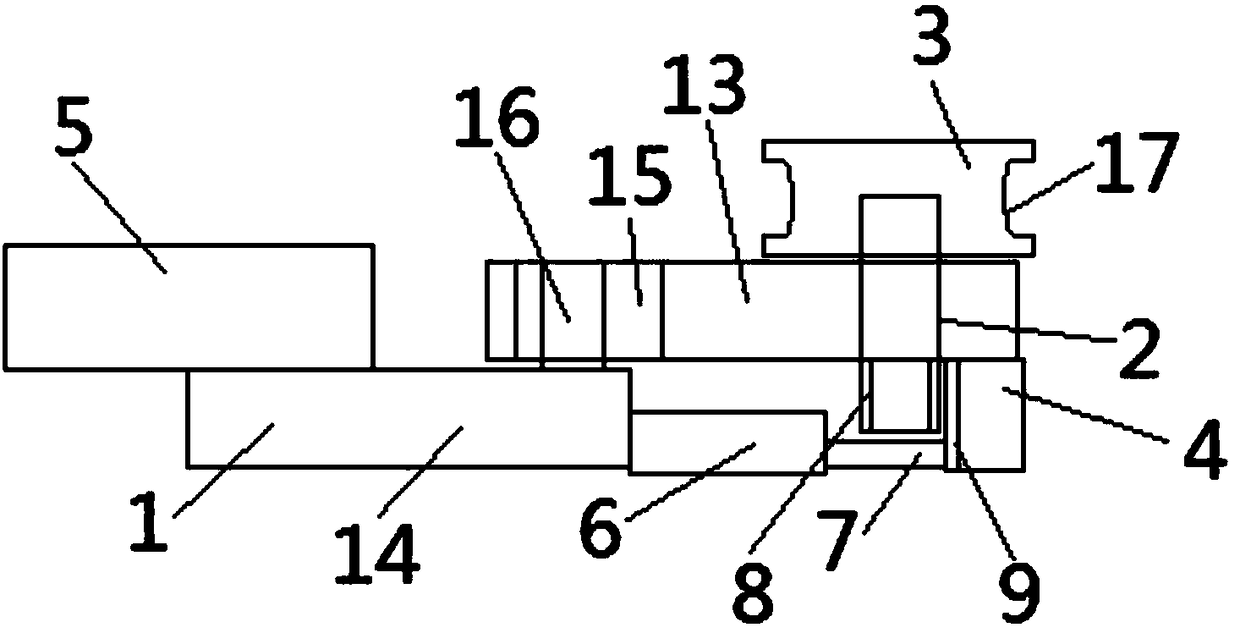

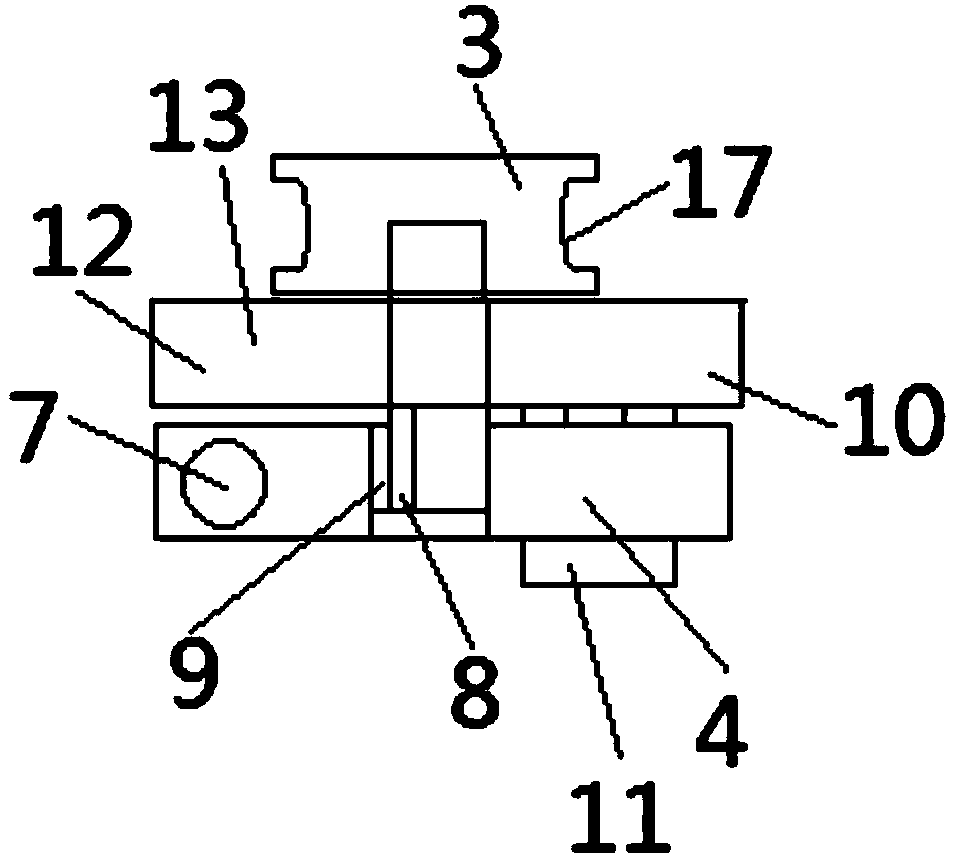

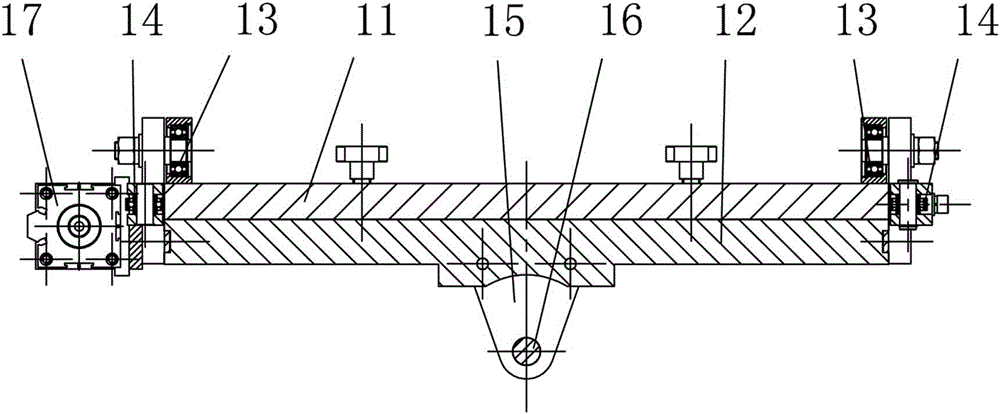

A sunroof sealing strip assembly tooling

InactiveCN106826664BMake sure it fits in placeGuaranteed assembly qualityMetal-working hand toolsWater leakageAssistive device/technology

The invention provides a skylight sealing strip assembly tool applied to the technical field of auxiliary equipment for automobile part mounting. A tool main support (1) of the skylight sealing strip assembly tool is connected with a telescoping spring (6), one end of a block pin (7) is connected with the telescoping spring (6), and the other end of the block pin (7) abuts against a spindle press block (4); a spindle (2) is mounted at one end of a fixing part (13), a pin groove (15) is arranged at the other end of the fixing part (13), a sliding block (16) is arranged at a movable part (14) and movably clamped in the pin groove (15), an operating handle (5) is fixedly connected with the movable part (14), and one end, connected with the tool main support (1), of the telescoping spring (6) is connected with the movable part (14). The skylight sealing strip assembly tool is simple in structure and convenient to operate, the work efficiency is improved, the skylight sealing strip assembly consistency is improved, and the water leakage problem is solved.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

Round battery cover transferring and welding device

PendingCN114192984AEasy to transportEasy to grabWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringSpot welding

The invention discloses a circular battery cover transferring and welding device which comprises a feeding station and a welding station, the feeding station comprises a cover body material frame used for allowing a plurality of battery covers to be vertically placed at intervals, a weldment disc used for allowing a plurality of weldments to be contained, and a feeding frame comprising a first moving module and a transferring material claw; the feeding manipulator is movably arranged between the cover body rack and the weldment disc; the welding station comprises a welding seat and a vertical frame, a positioning groove for horizontally placing the battery cover is formed in the welding seat, the vertical frame comprises a vertical module and a laser head which are arranged above the welding seat, a visual pickup assembly is arranged on the laser head, and the vertical module drives the laser head to be focused with the welding position of the battery cover through the visual pickup assembly; the laser head carries out spot welding through the positioning protruding part and the through hole of the weldment, it is guaranteed that the weldment and the battery cover are fixed, then the laser head carries out full welding on the weldment and the groove base, and the welding quality is effectively improved.

Owner:宁波航工智能装备有限公司

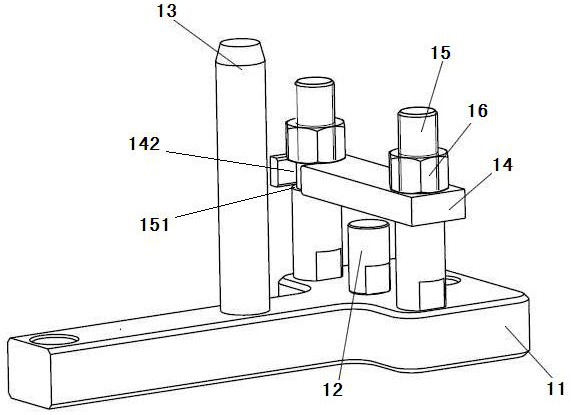

Assembly tool for valve bridge assembly and assembly method thereof

ActiveCN110549297BPrevent rotationAvoid leaningWork holdersMetal working apparatusStructural engineeringMechanical engineering

Owner:中国船舶集团有限公司第七一一研究所

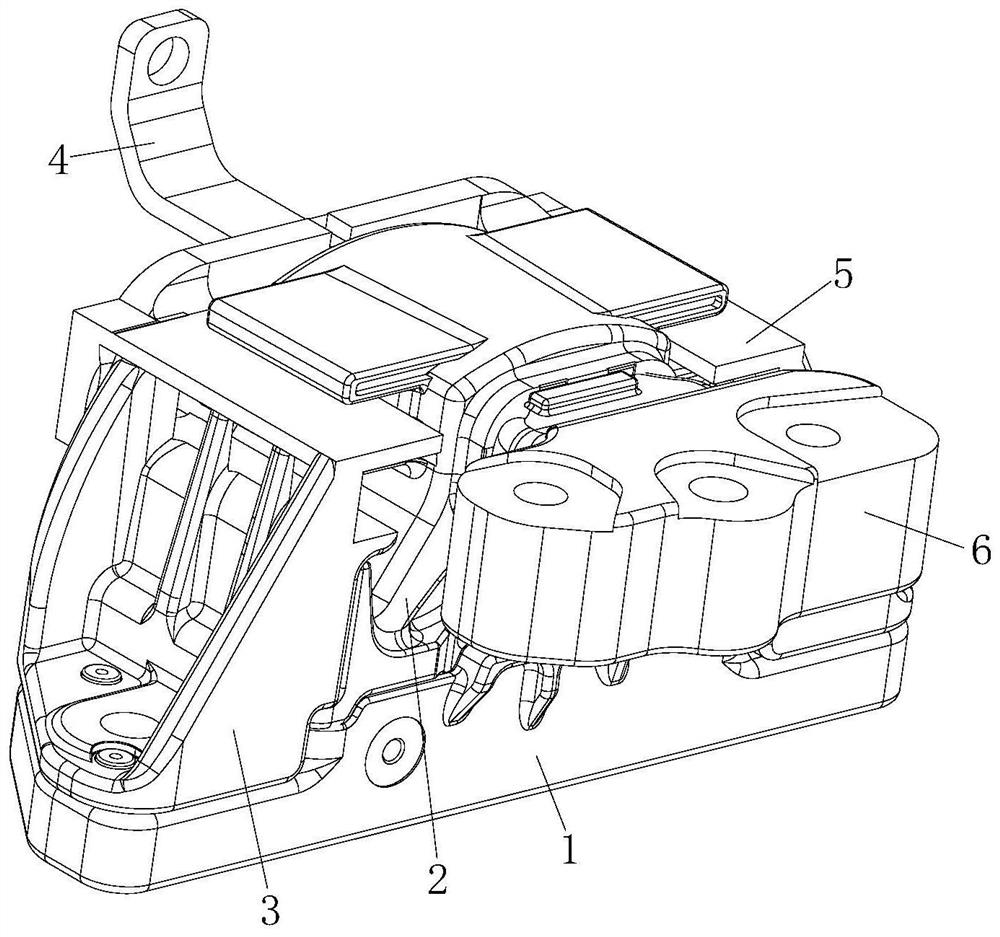

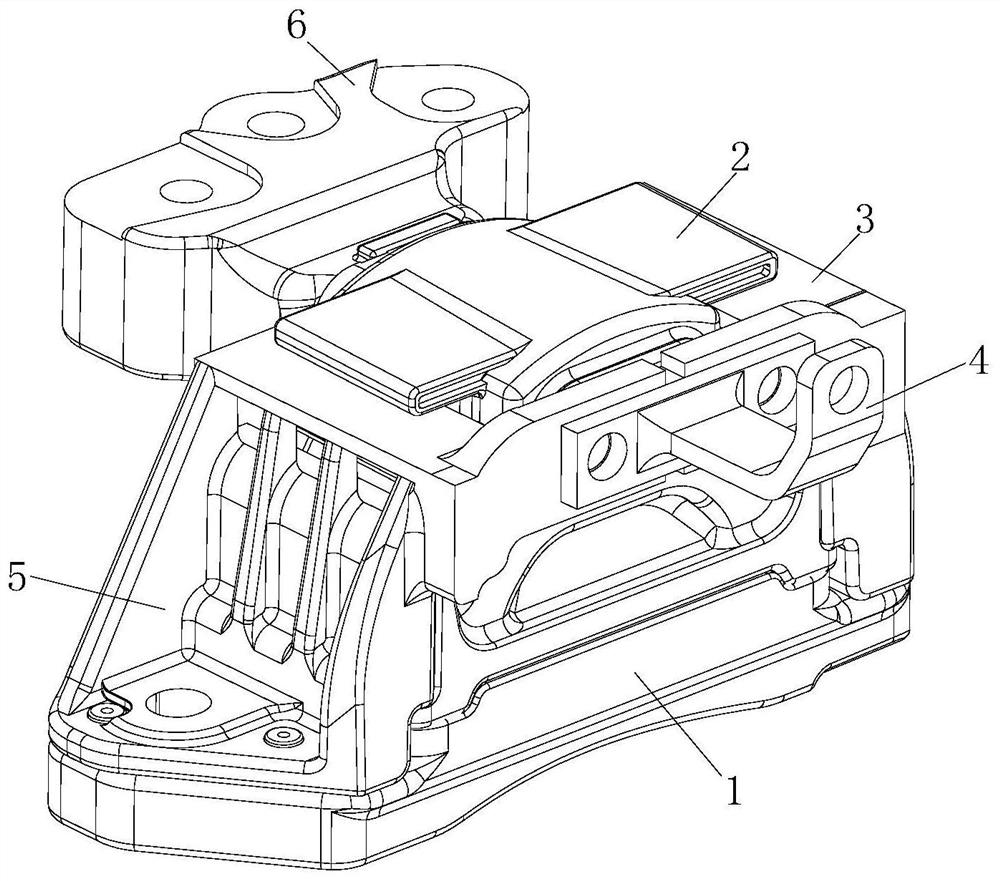

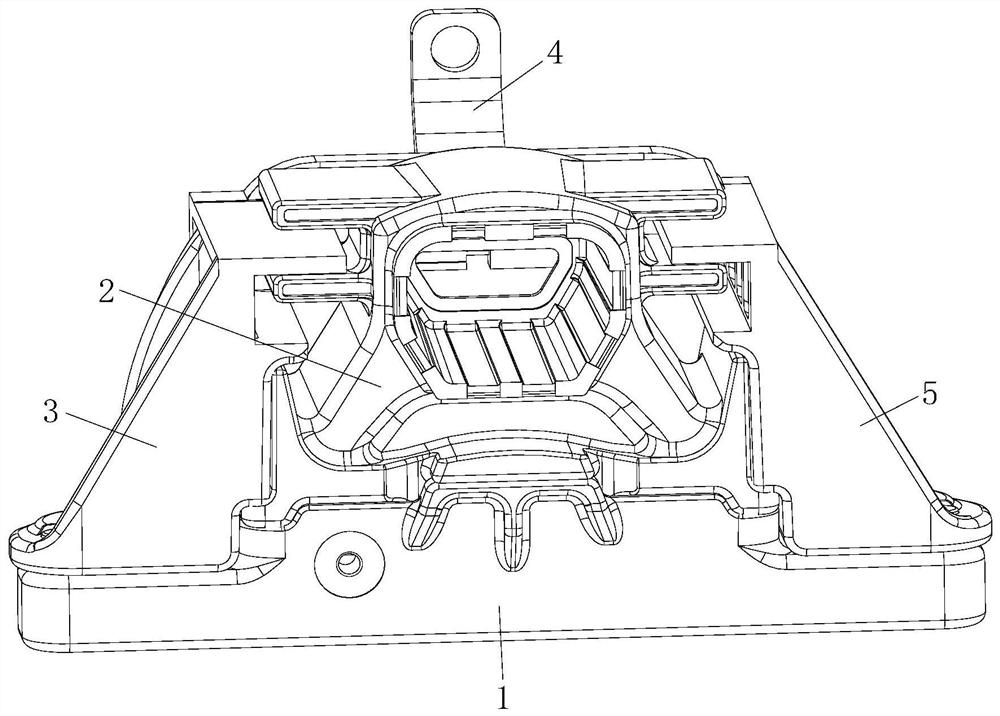

Suspension structure

ActiveCN114274755AEasy to assembleEasy to useJet propulsion mountingInternal combustion mountingClassical mechanicsStructural engineering

The invention relates to a suspension structure which comprises a base, a rubber damping assembly, a left support, a right support and a supporting arm, the rubber damping assembly is arranged on the base, a core tube mounting hole is formed in the rubber damping assembly, and a core tube is embedded in the core tube mounting hole; the left support and the right support are located on the two sides of the rubber damping assembly respectively, the left support and the right support are fixedly connected with the base, an installation space is formed between the left support and the base and between the right support and the base, the rubber damping assembly is fixed in the installation space, and the corbel is fixedly connected with the core tube. According to the suspension structure, a split structure of the left support and the right support is adopted, and the left support and the right support are fixedly connected with the base, so that the rubber damping assembly is fixed, and the suspension structure can be conveniently assembled.

Owner:GREAT WALL MOTOR CO LTD

Assembling mold

ActiveCN114193367AStay parallelMake sure it fits in placeFinal product manufactureWork holdersEngineeringMechanical engineering

Owner:YANGZHOU HENGDE IND TECH CO LTD

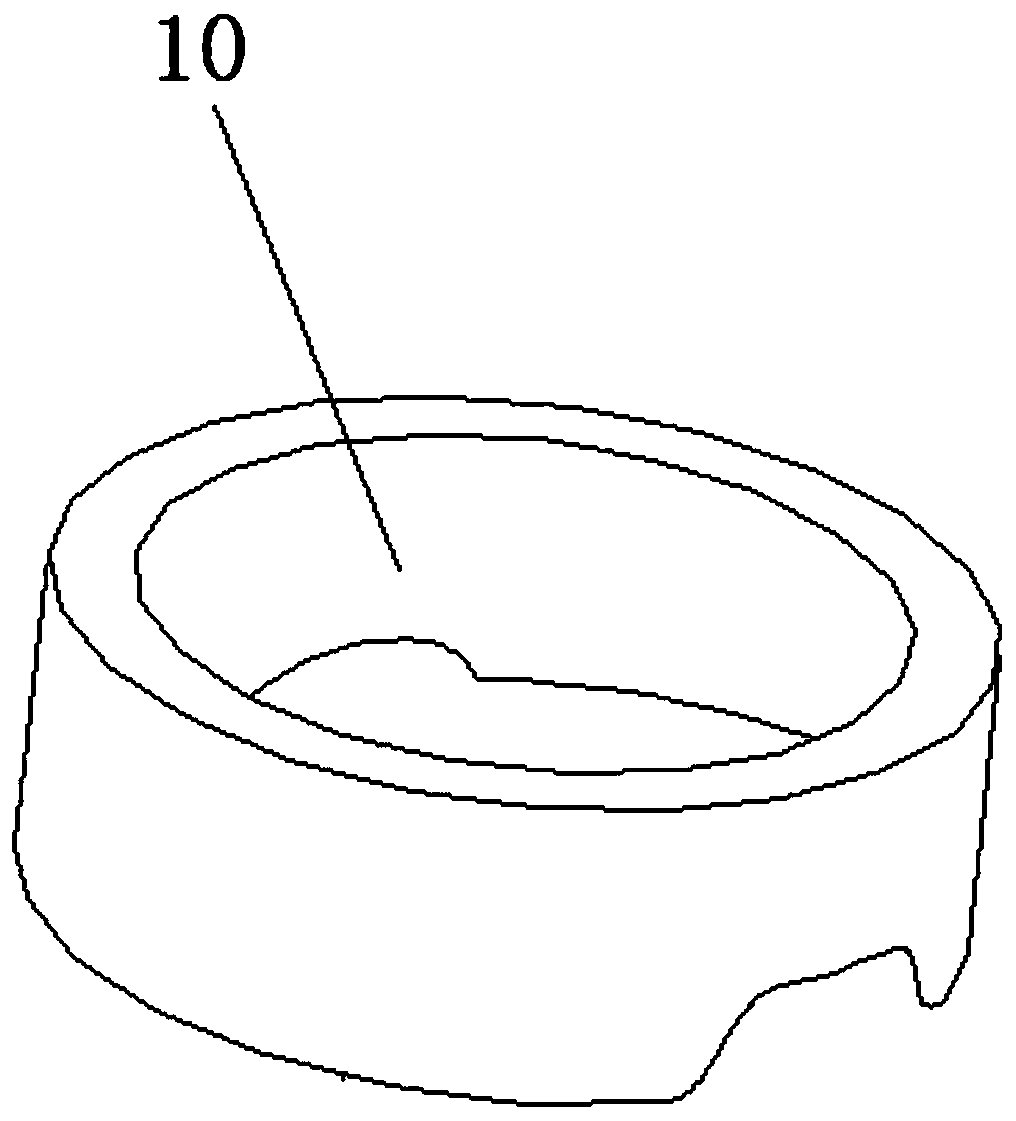

Multi-purpose hub bolt quick press installation device

ActiveCN103659237BMake sure it fits in placeMeet production takt requirementsVehicle componentsMetal working apparatusEngineeringMachine press

The invention discloses a multipurpose hub bolt rapid press-fitting device. The multipurpose hub bolt rapid press-fitting device comprises a press and a workbench, and further comprises a pressing rod, a pressing rod slide rail mechanism, a locating rotary disc, a supporting board and a supporting board lifting mechanism. The locating rotary disc is arranged on the workbench. The supporting board is arranged in the locating rotary disc. The locating rotary disc is provided with a bolt press-fitting hole being in fit with a bolt hole in a hub. The pressing rod comprises a pressing frame and a working end. When the bolt is pressed, the working end moves to the position above a bolt pre-plugged in the bolt hole of the hub through the pressing rod slide rail mechanism, and the working end of the pressing rod is pressed to the bolt on the hub through the press. The lever-type double-pressing-rod structure is adopted, two bolts are pressed at a time in every stroke of the press, the efficiency is doubled than that of the mode that single bolts are pressed one by one, the requirement of the product rhythm is met, action force of one bolt and action force of the other bolt interact and balance with each other when press fitting is carried out due to the lever-type structure, and therefore the bolts can be effectively pressed in place.

Owner:GUANGDONG FUWA HEAVY IND

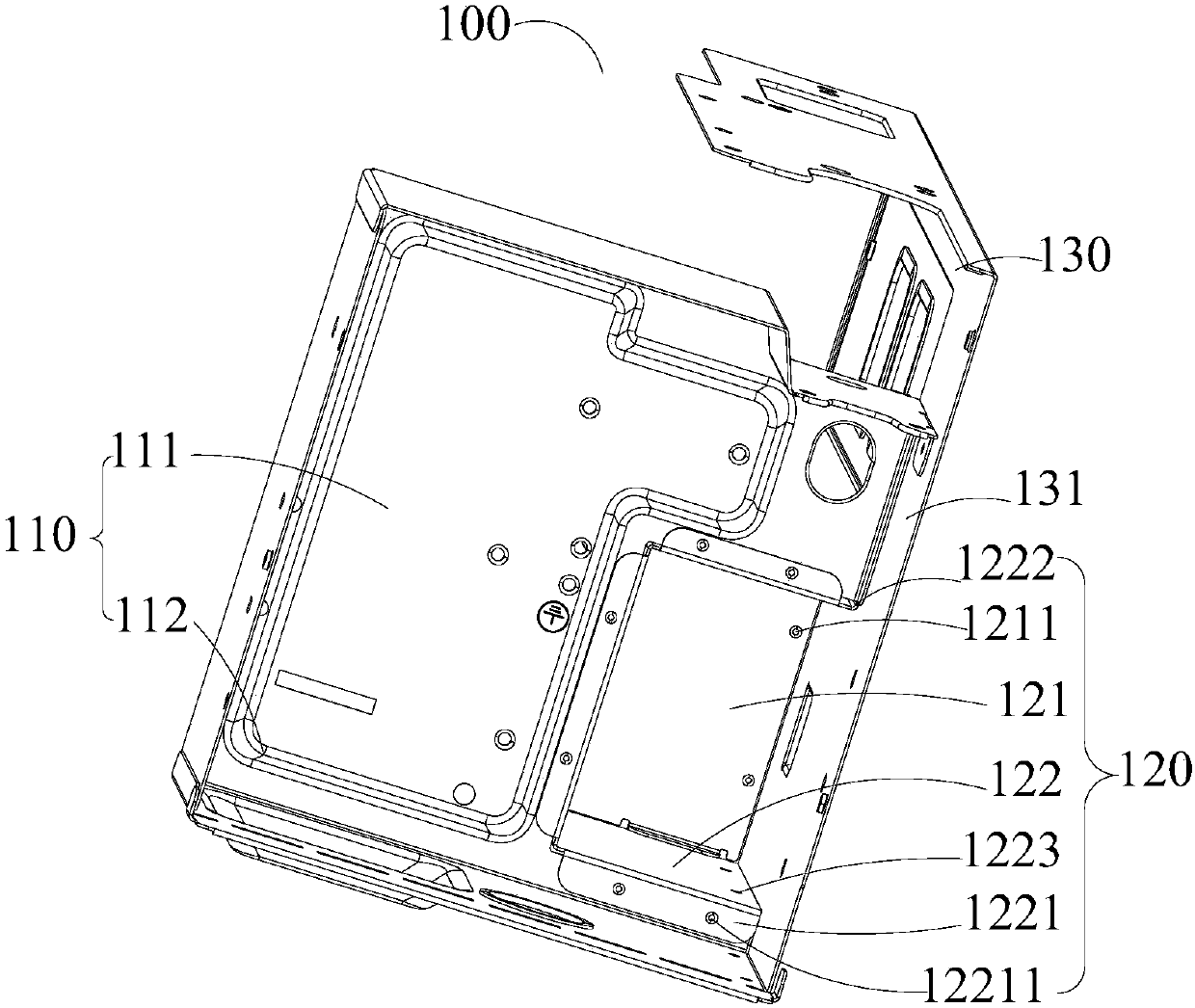

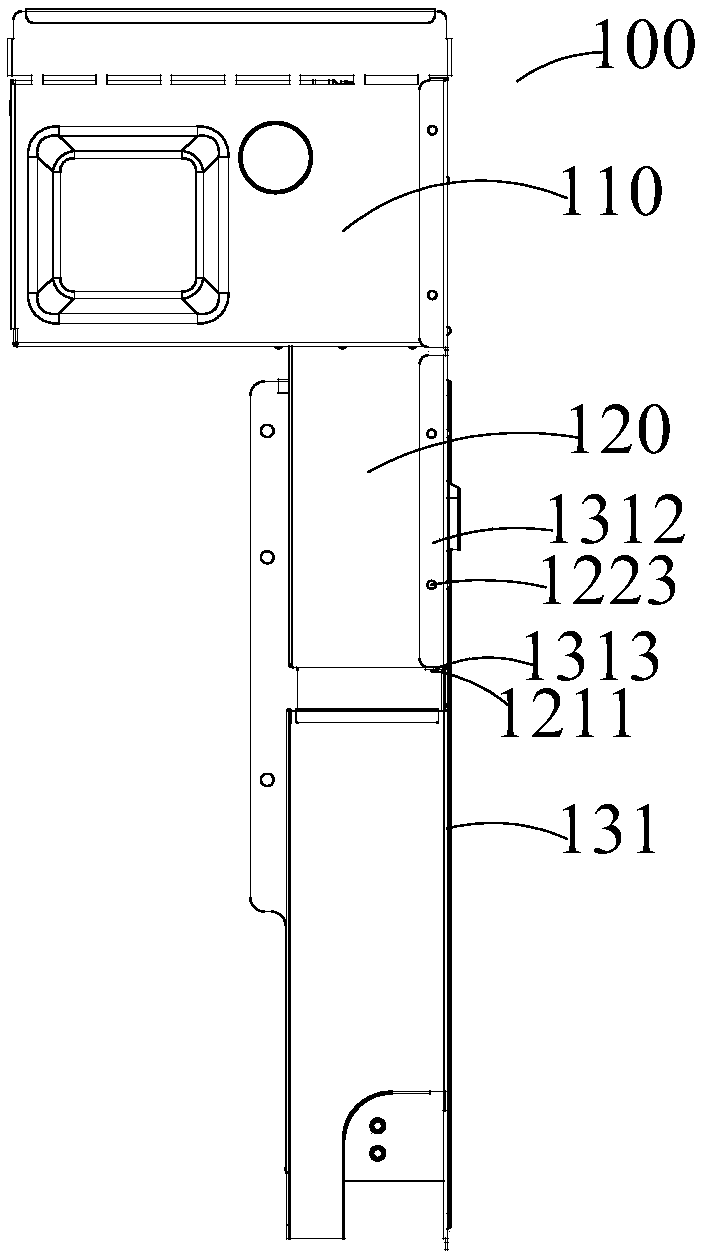

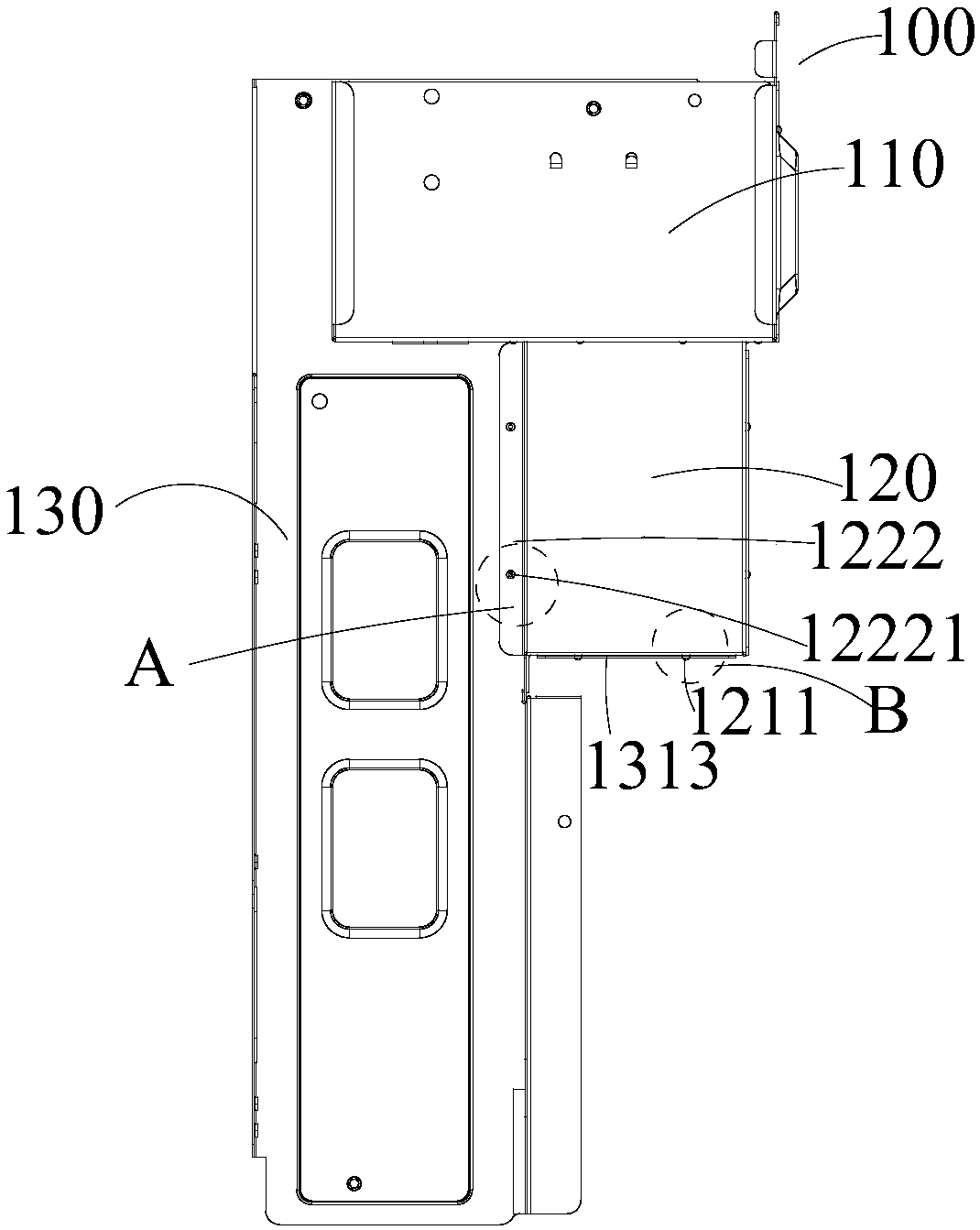

Air conditioner and its electrical box structure

ActiveCN106304705BSimple structural designRealize self-locking fixationClosed casingsCasings/cabinets/drawers detailsEngineeringMechanical engineering

The invention provides an electrical box structure. The electrical box structure comprises a mounting box, an expansion box and a front baffle plate, wherein the mounting box comprises a mounting bottom plate and three mounting side plates, and a first limiting part is arranged on the mounting bottom plate; the expansion box comprises an expansion bottom plate and three expansion side plates, expansion folding sides are arranged on the expansion side plates, and first matching parts are arranged on the expansion folding sides, and matched with the first limiting part; expansion turning sides are arranged on the expansion side plates, and second matching parts are arranged on the expansion turning sides; the front baffle plate comprises a plate body; a second limiting part is arranged on the plate body, and the second limiting part is matched with the second matching parts. According to the electrical box structure disclosed by the invention, the expansion folding sides and the expansion turning sides of the expansion box are used for limiting the positions of the front baffle plate and an electrical box, so that the expansion box, the mounting box and the front baffle plate are fixedly connected to facilitate convenient and reliable assembly and ensure in-place assembly of an electrical box so as to improve the assembling efficiency. The invention further provides an air conditioner.

Owner:GREE ELECTRIC APPLIANCES INC

Working method for automobile lamp holder sealing ring assembling device with detection function

InactiveCN107378855AFixed firmlyImprove assembly efficiencyMetal-working hand toolsEngineeringMechanical engineering

The invention discloses a working method of an assembly device for a sealing ring of an automobile lamp holder with a detection function, and relates to the technical field of automobile manufacturing; The position of the movable push seat; the staff step on the foot switch with their feet, and under the expansion and contraction of the cylinder, the telescopic rod drives the movable push seat to move forward; finally, the sealing ring is pushed into the lamp holder through the ejector rod on the movable push seat. Predetermine the inside of the hole until the sealing ring is assembled in place; the working method of the present invention greatly improves the production efficiency of the product, improves the quality of the product at the same time, reduces the output of defective products, reduces the work intensity of employees, and has good safety. It ensures that the assembly work can be carried out safely and stably for a long time.

Owner:太仓市华天冲压五金制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com