Pneumatic press-fitting terminal device

A terminal device, pneumatic press-fitting technology, applied in the assembly/disassembly of contacts, can solve the problems of unguaranteed product quality, low operation efficiency, labor consumption, etc., to improve product quality, easy operation, and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

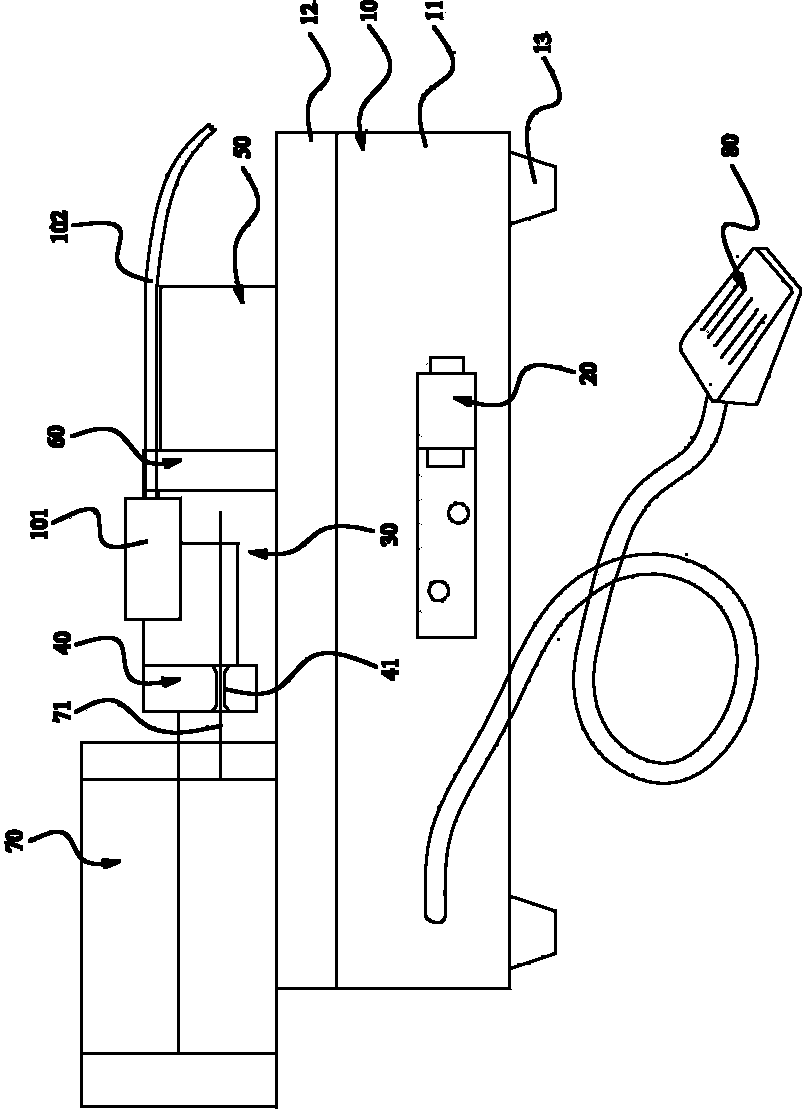

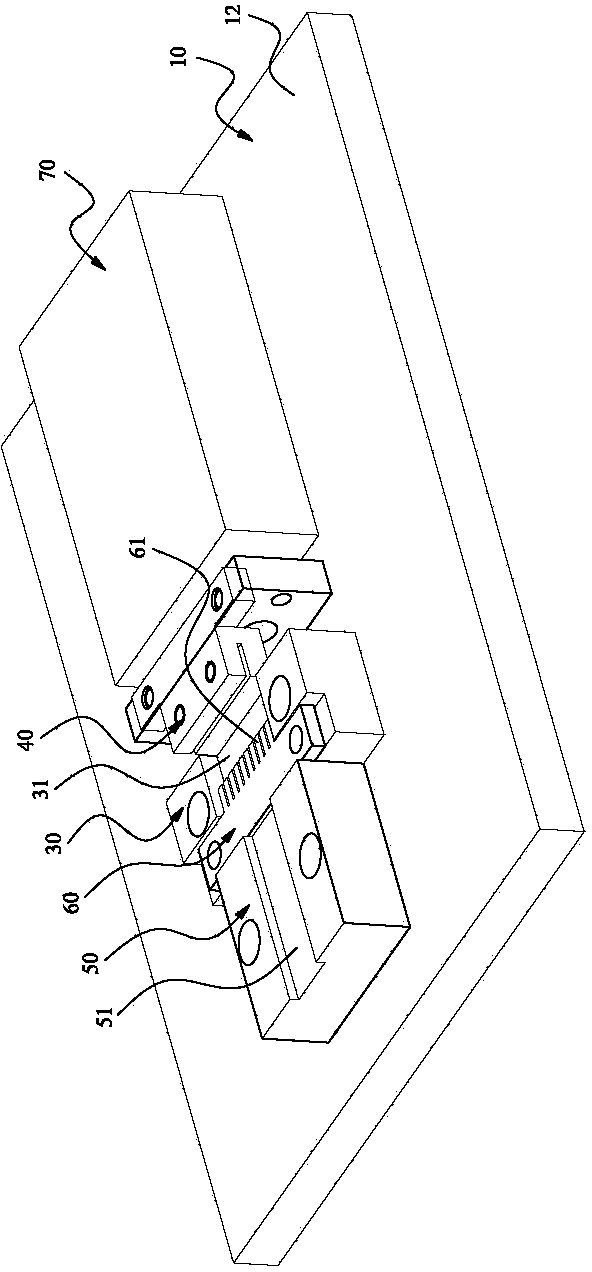

[0026] Please refer to figure 1 and figure 2 As shown, it shows the specific structure of the preferred embodiment of the present invention, including organic base 10, solenoid valve 20, glue positioning mold 30, punch 40, wire support mold 50, push block 60 and driving punch 40 Cylinder 70 that moves back and forth.

[0027] Wherein, the electromagnetic valve 20 is arranged in the machine base 10, the electromagnetic valve 20 is connected with the cylinder 70, the electromagnetic valve 20 controls the operation of the cylinder 70, the plastic parts positioning die 30, the punch 40, the wire support die 50, the pushing block 60 and the cylinder 70 are all arranged on the surface of the base 10; specifically, the base 10 includes an electrical box 11 and a panel 12 fixed on the electrical box 11, and the electromagnetic valve 20 is arranged on the surface surrounded by the panel 12 and the electrical box 11. In the formed space, the glue positioning die 30 , the punch 40 , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com