Patents

Literature

38results about How to "Meet production takt requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

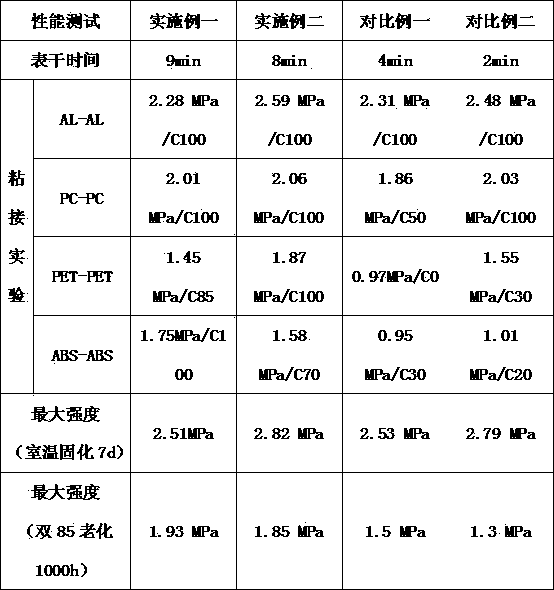

High-adhesive one-component deoximation type room-temperature vulcanized silicone rubber sealant and preparation method thereof

ActiveCN103937442ABalance activityBalance rateNon-macromolecular adhesive additivesOther chemical processesPolymer scienceVulcanization

The invention discloses a high-adhesive one-component deoximation type room-temperature vulcanized silicone rubber sealant comprising the following components from (A) to (F) in parts by weight: 100 parts of modified alpha, omega-dihydroxylpolydimethylsiloxane (A), 10-30 parts of dimethyl silicon oil (B), 7-12 parts of deketoxime crosslinking agent (C), 1-5 parts of silane coupling agent (D), 50-150 parts of reinforcing filler (E) and 0.1-1 part of catalyst (F). Compared with the traditional deoximation type sealant, the sealant has excellent adhesive property particularly for some substrates such as plastics, modified resin and the like which are difficultly adhered by using an organic silicon adhesive and can be widely applied to adhesion and sealing of industries such as electronics, automobiles, household appliances and the like. Modified polydimethylsiloxane is used as a basic polymer in deoximation type silicon rubber, so that the sealant has relatively proper surface drying time, provides more reasonable operation time and meets the production takt requirement under different working conditions; in addition, due to the adoption of the modified polydimethylsiloxane, the sealant has excellent waterproofness and is relatively high in strength retention rate under high temperature and high humidity conditions.

Owner:富乐(苏州)新材料有限公司

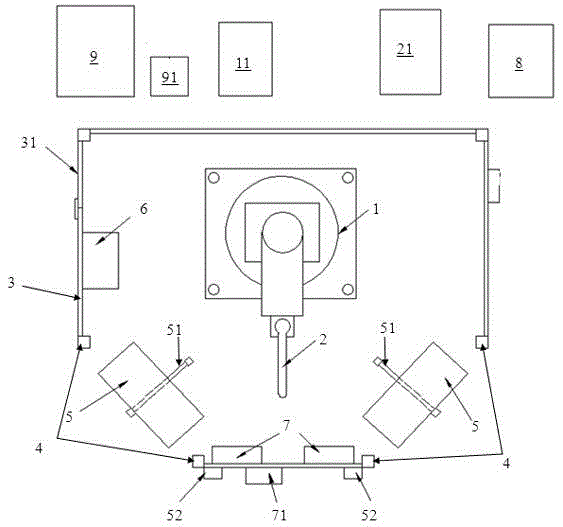

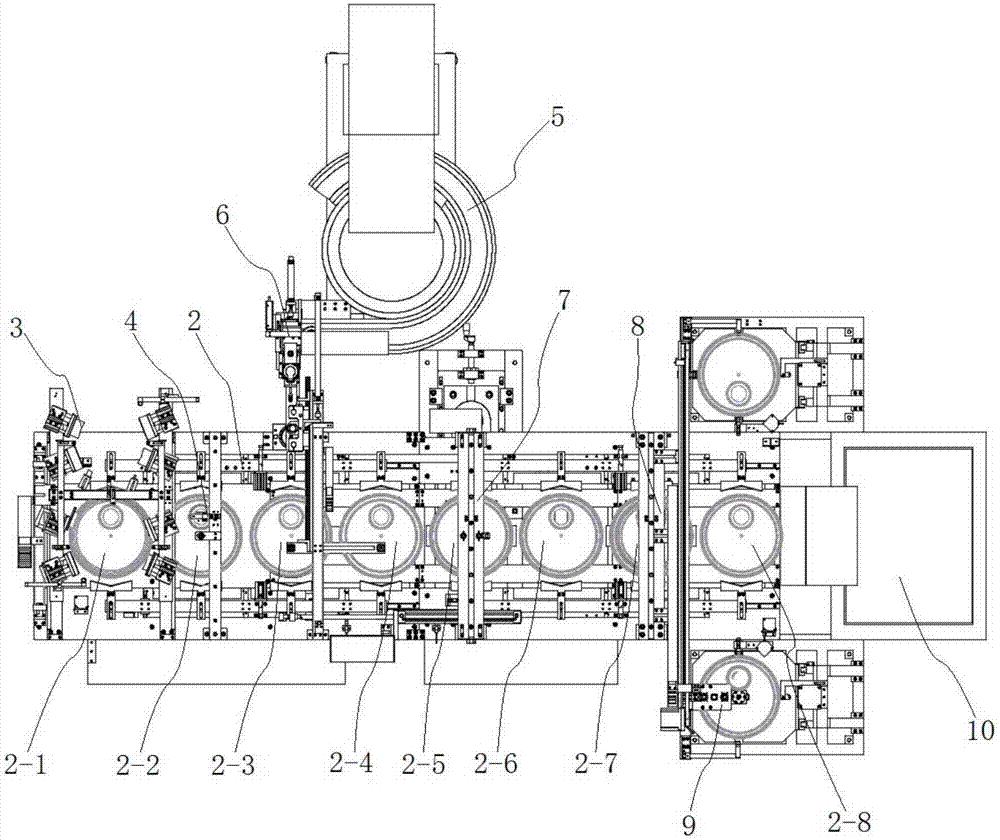

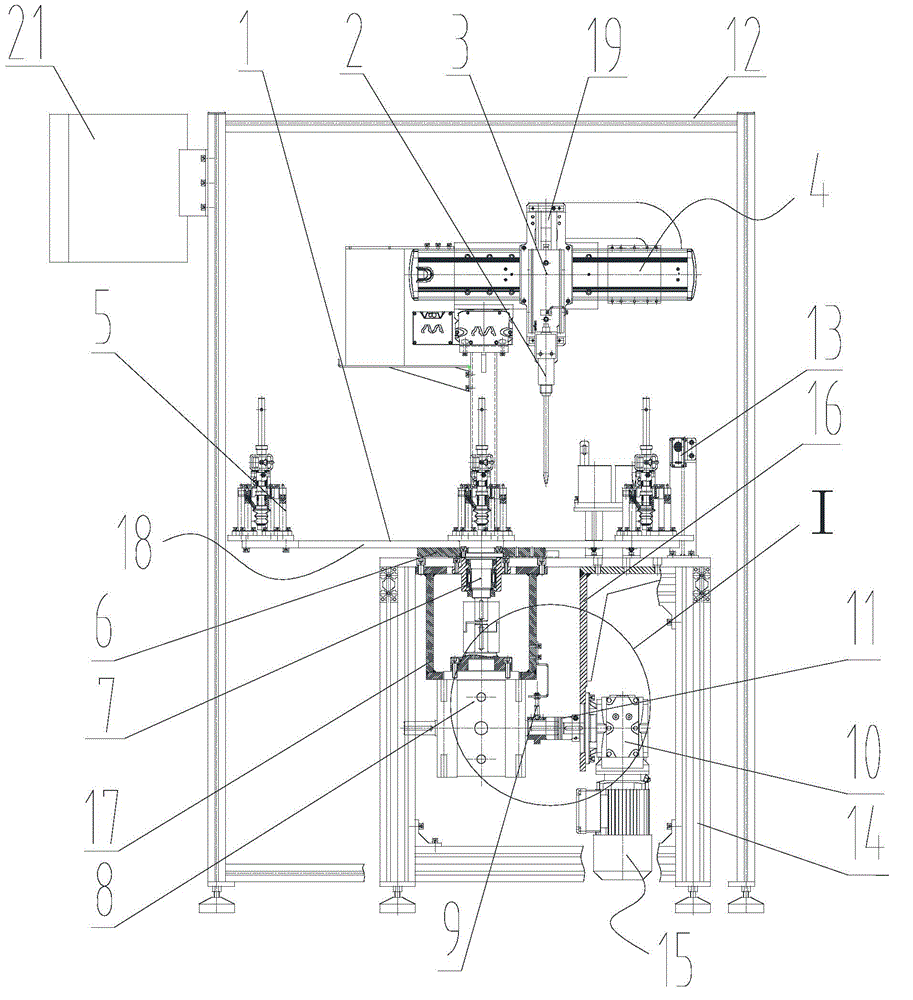

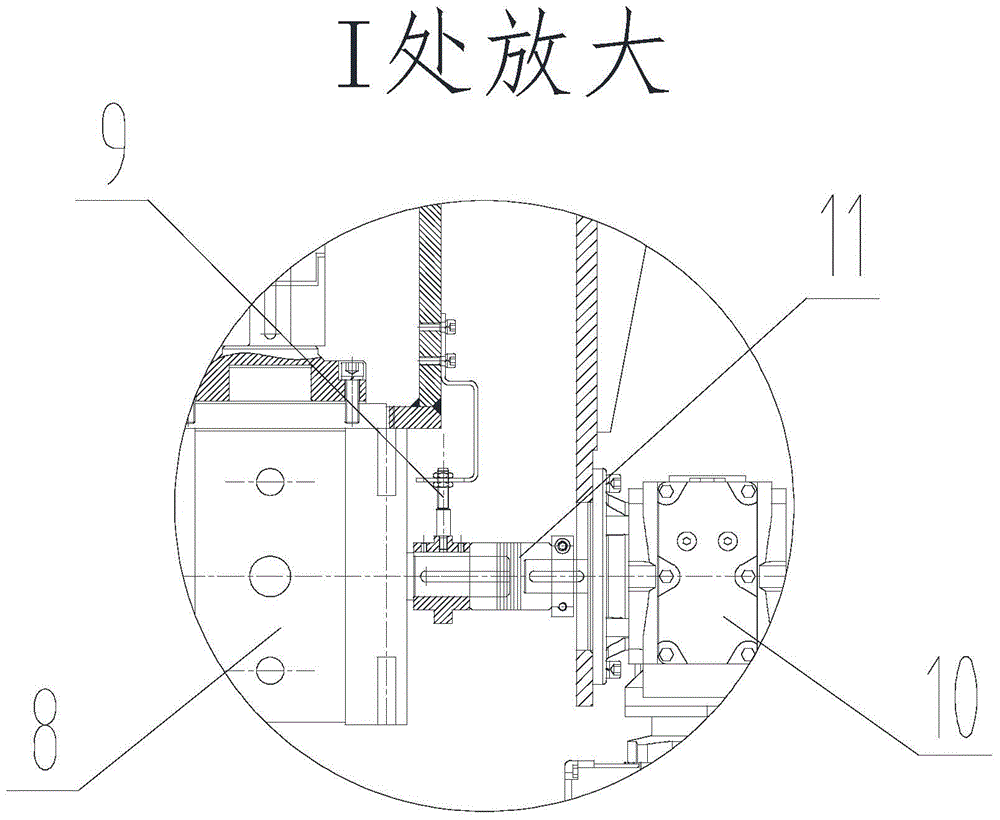

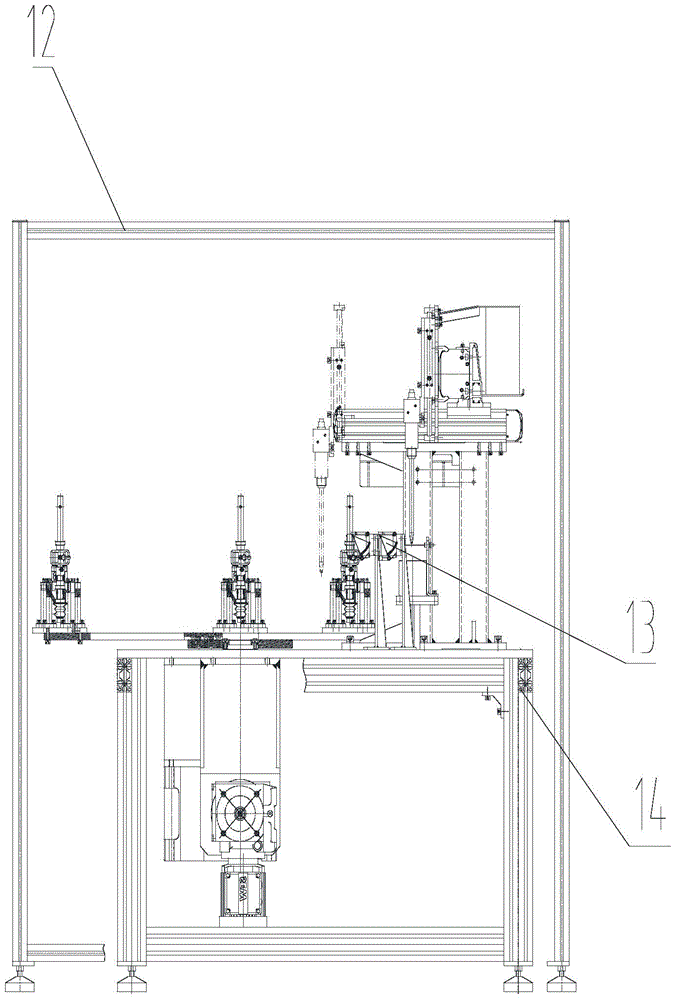

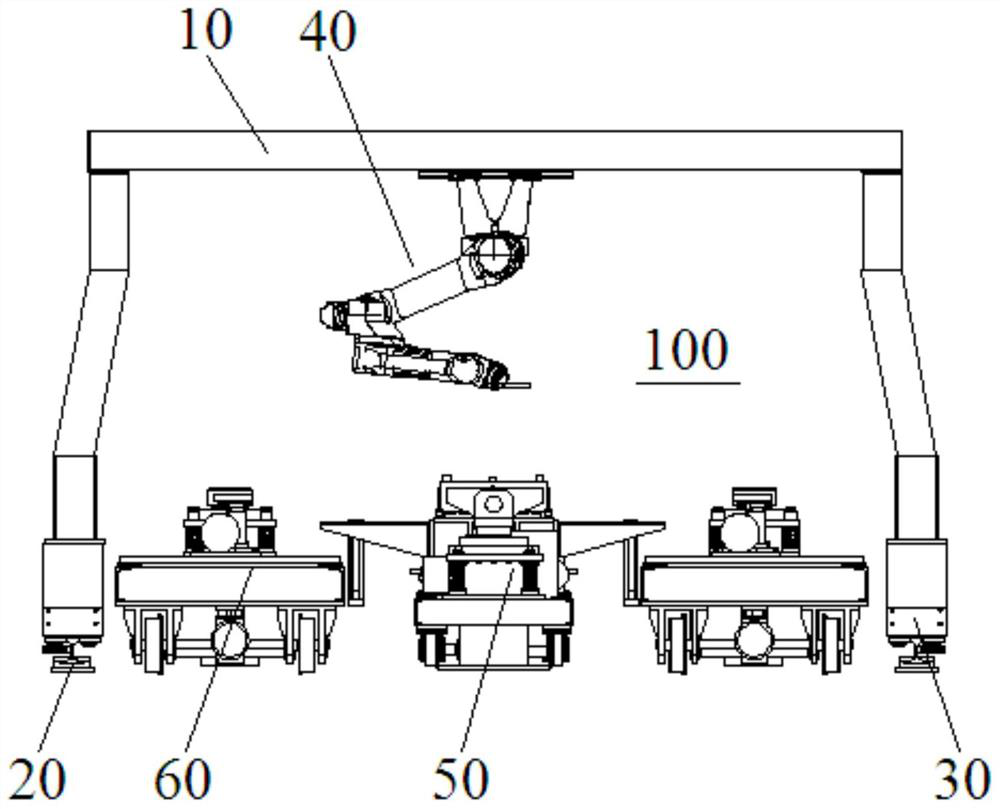

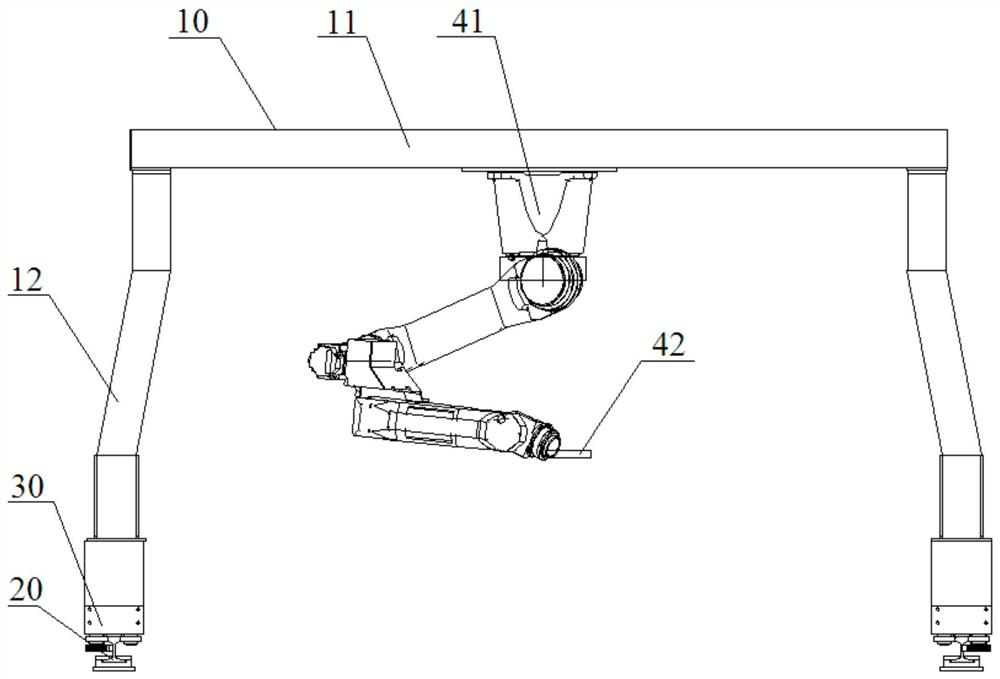

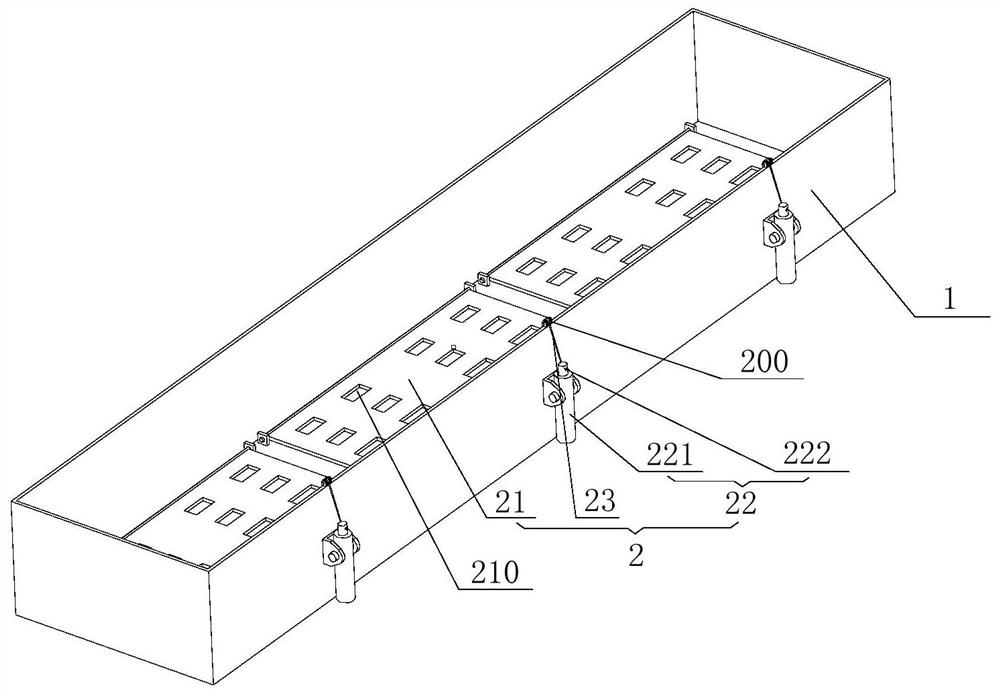

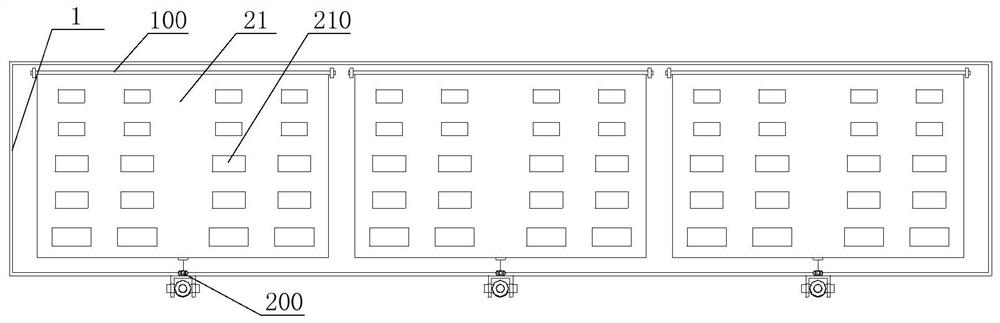

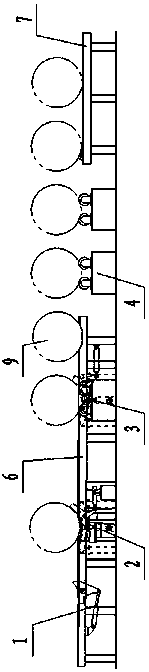

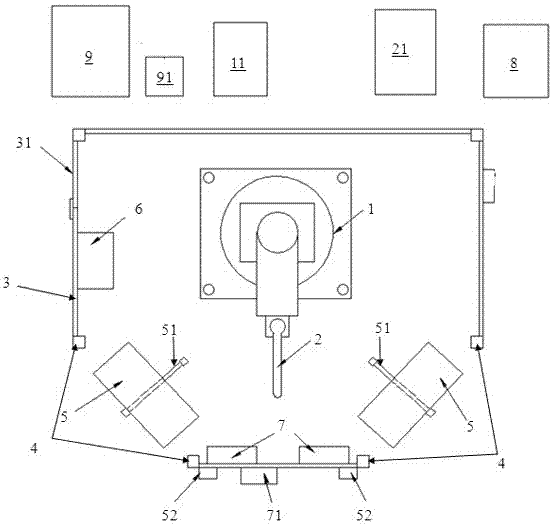

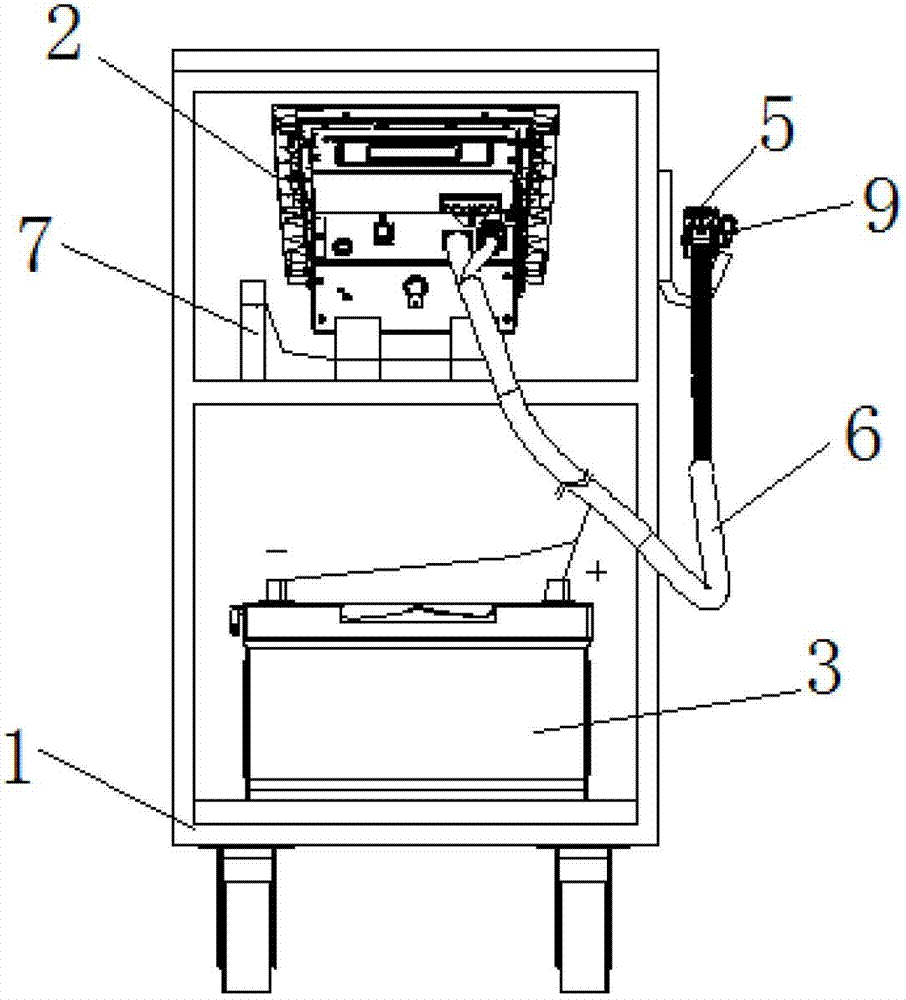

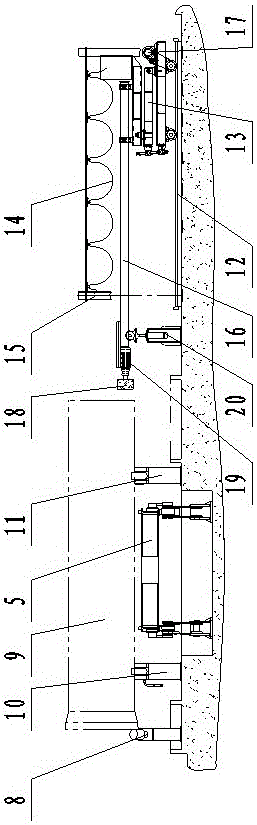

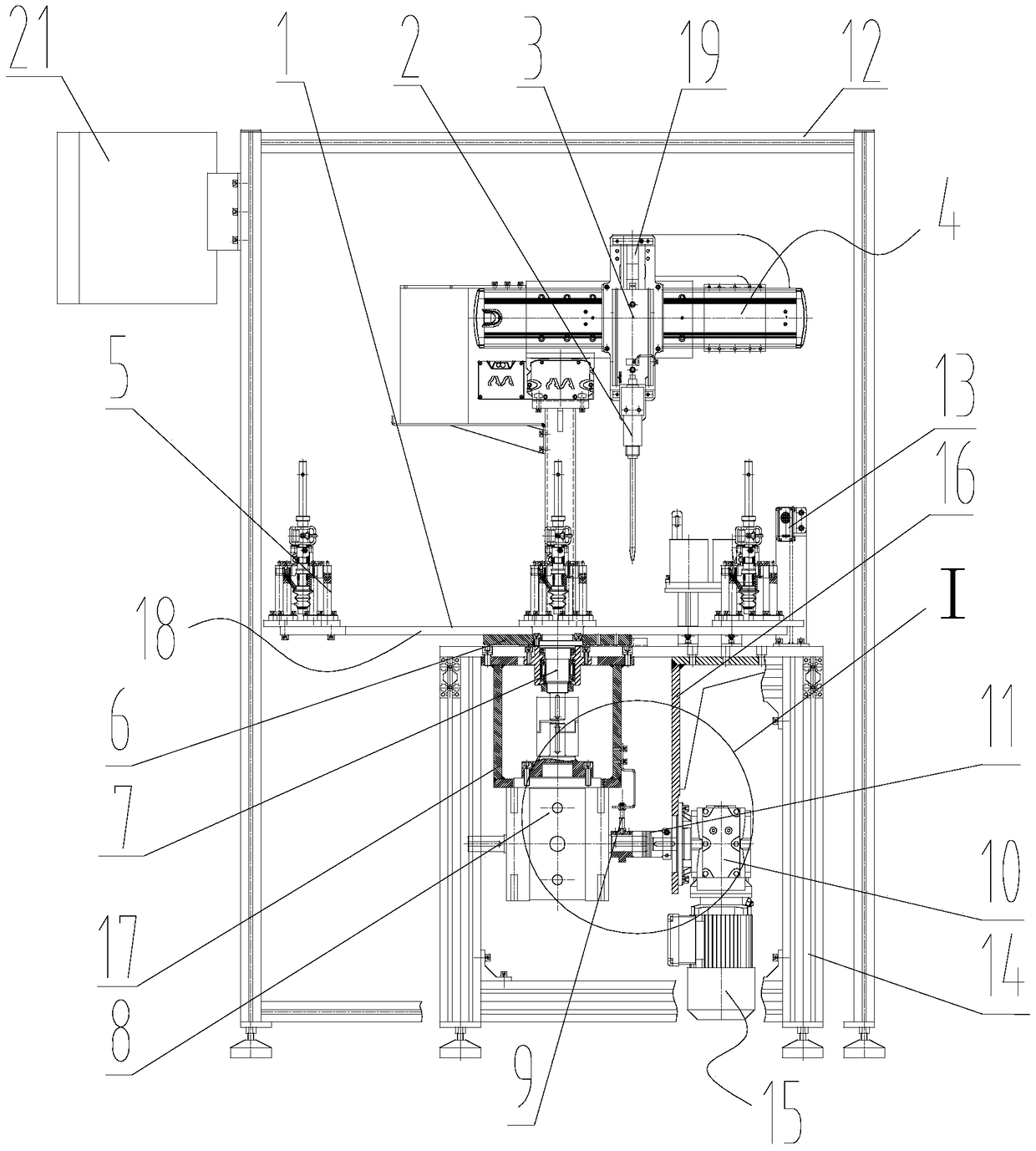

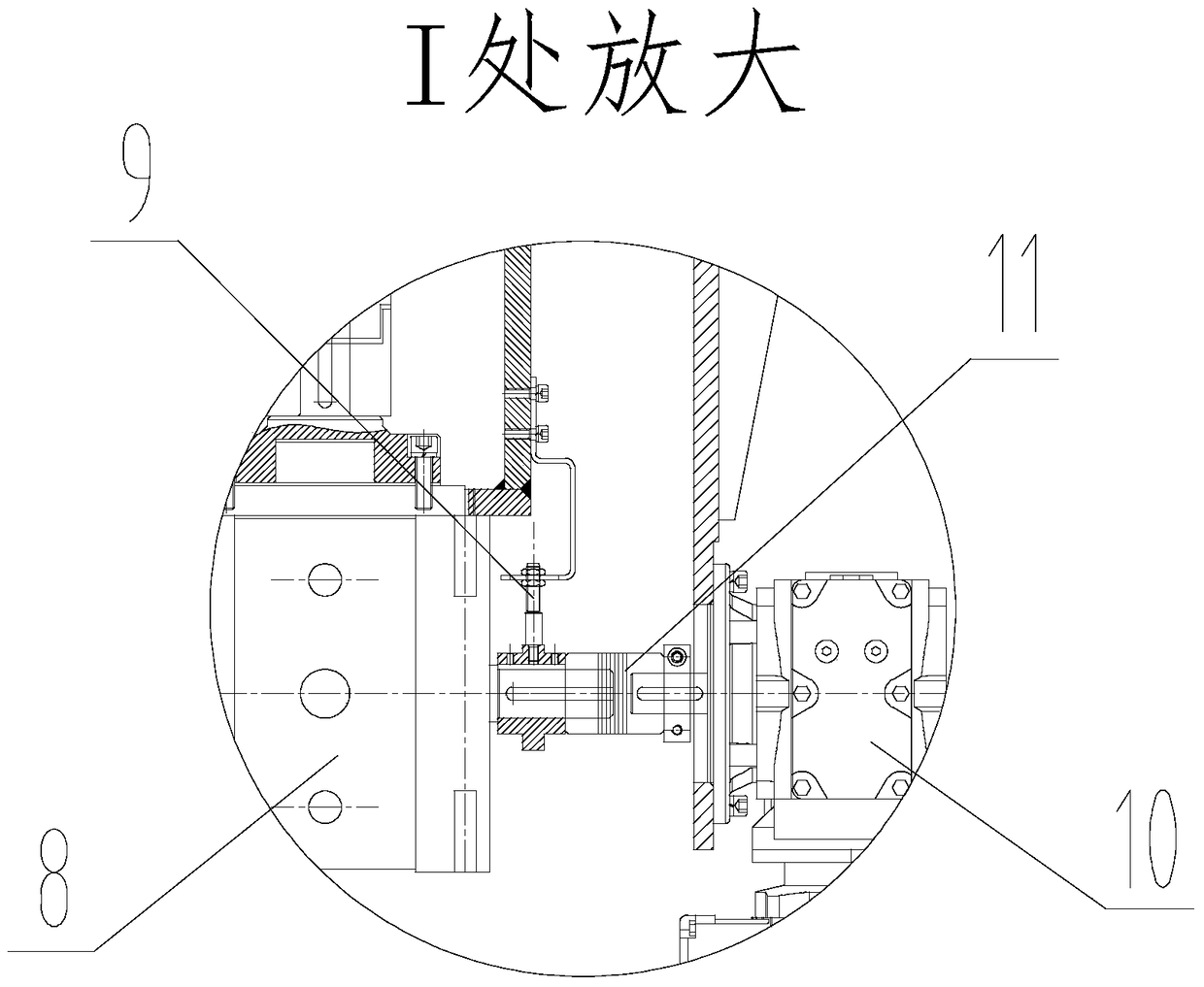

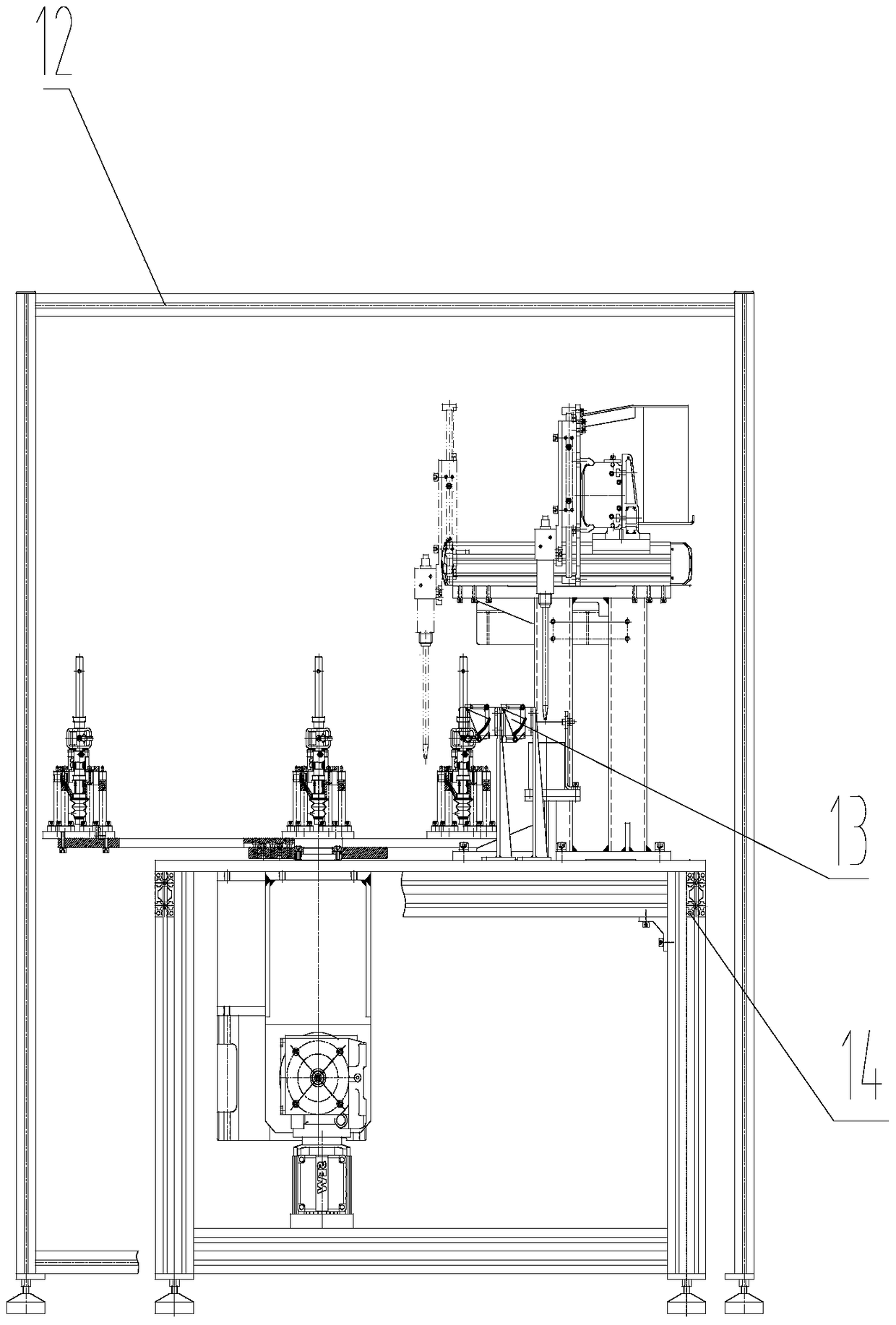

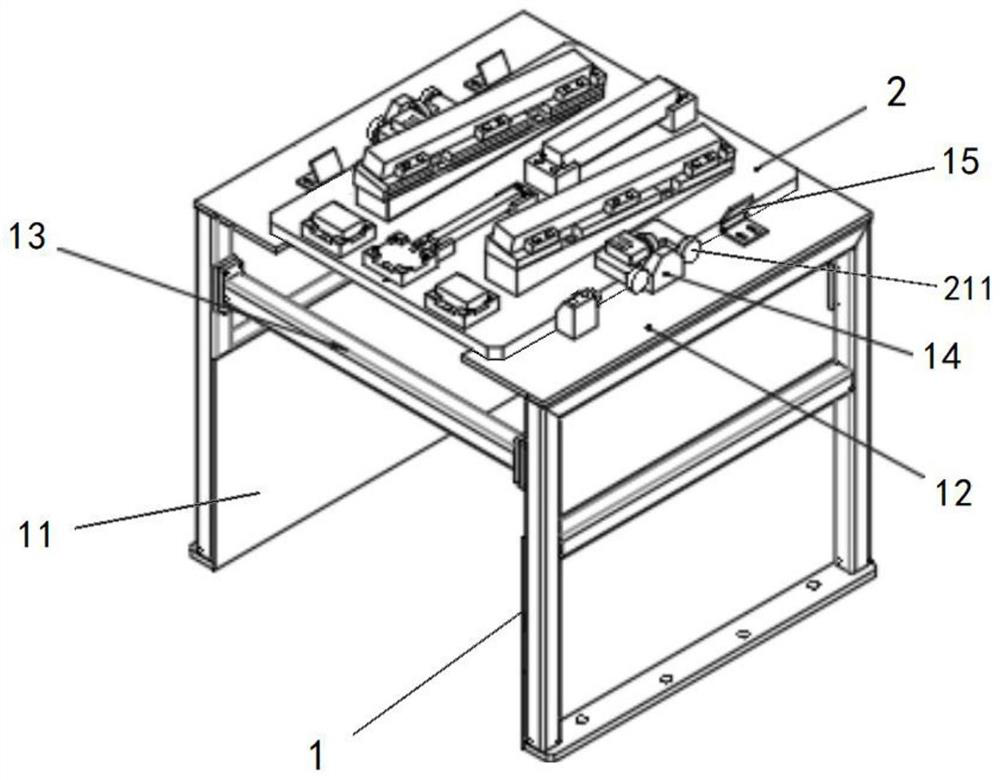

Spot welding system of air-conditioner backboard robot

ActiveCN104874907AMeet production takt requirementsReduce labor intensityWelding monitoring devicesMetal working apparatusSystem safetyRobotic systems

The invention discloses a spot welding system of an air-conditioner backboard robot. The spot welding system comprises control equipment, a welding robot system, a tooling platform and an operating area, wherein the control equipment comprises a system PLC (Programmable Logic Controller) control cabinet and a touch screen connected with the system PLC control cabinet, and the touch screen is used for monitoring a system state; the welding robot system is connected with the system PLC control cabinet and comprises a robot body and an electrode holder arranged on the robot body; the tooling platform is connected with the system PLC control cabinet, and the robot body conveys the electrode holder to the tooling platform and performs spot welding to a work-piece on the tooling platform; the operating area comprises a guard fence and a safety door, the robot body and the electrode holder are both placed in the operating area, the system PLC control cabinet monitors the state of the safety door, the system PLC control cabinet stops the operation of the welding the robot system and the tooling platform after the safety door is opened. The spot welding system provided by the invention has the advantages that the system safety can be improved by implementing monitoring, control and commissioning to the spot welding system of the air-conditioner backboard robot, under the precondition of meeting the requirements of production takts.

Owner:SHANGHAI XINSHEN METALWORK

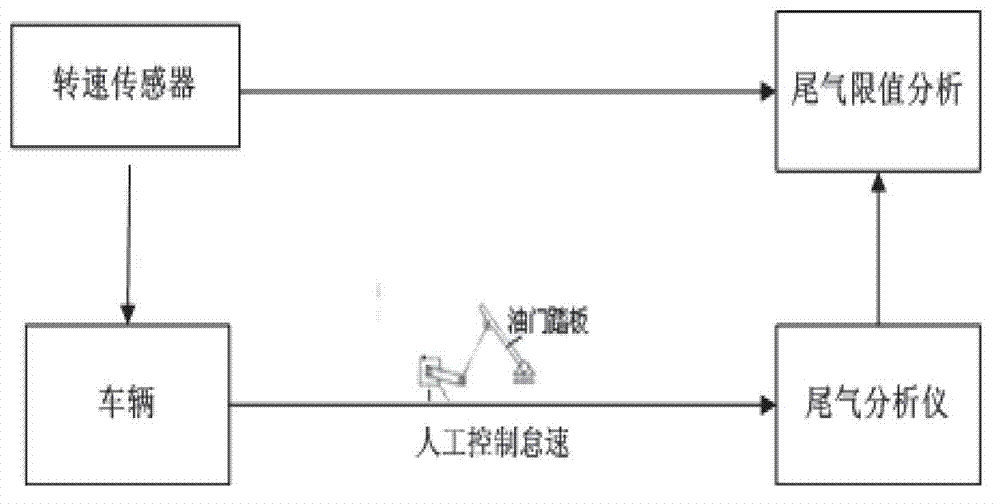

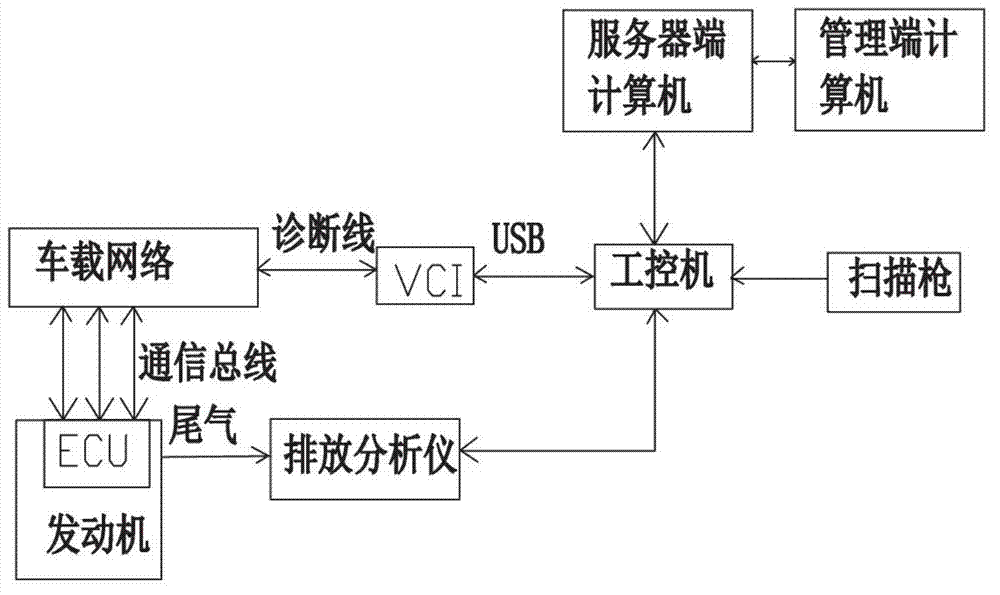

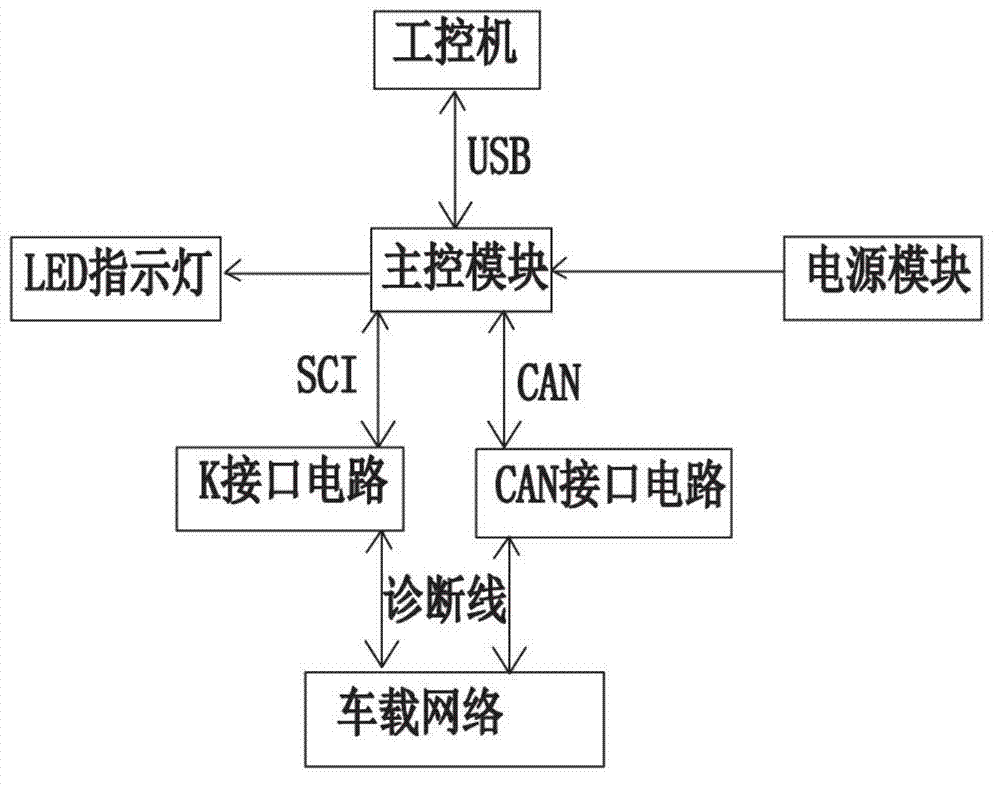

An automatic control system for vehicle off-line double-idling discharging detection

ActiveCN103034194AIncrease productivityMeet production takt requirementsTotal factory controlProgramme total factory controlAutomatic controlArea network

An automatic control system for vehicle off-line double-idling discharging detection is provided. The automatic control system improves production efficiency, meets requirements for tatk time, reduces labor strength, does not need a rotating speed sensor, and is accurate in detection. The automatic control system comprises an industrial personal computer, a scanning gun, a server end computer, a discharging analyzer and a vehicle communication transit system (VCI). The VCI comprises a main control module, a K interface circuit, a controller area network (CAN) interface circuit and a power module. The power module supplies power to the main control module connected with the industrial personal computer through a universal series bus (USB) interface, the main control module is connected with the K interface circuit and the CAN interface circuit through a serial communication interface (SCI) interface and a CAN interface, the K interface circuit and the CAN interface circuit are both connected with an in-vehicle network through diagnosis wires, the in-vehicle network is connected with an electric control module (ECU) of an engine through a communication bus, the engine is connected with the discharging analyzer connected with the industrial personal computer, the scanning gun is connected to the industrial personal computer, and the server end computer is connected with the industrial personal computer and a management end computer. The invention further provides a detecting method.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

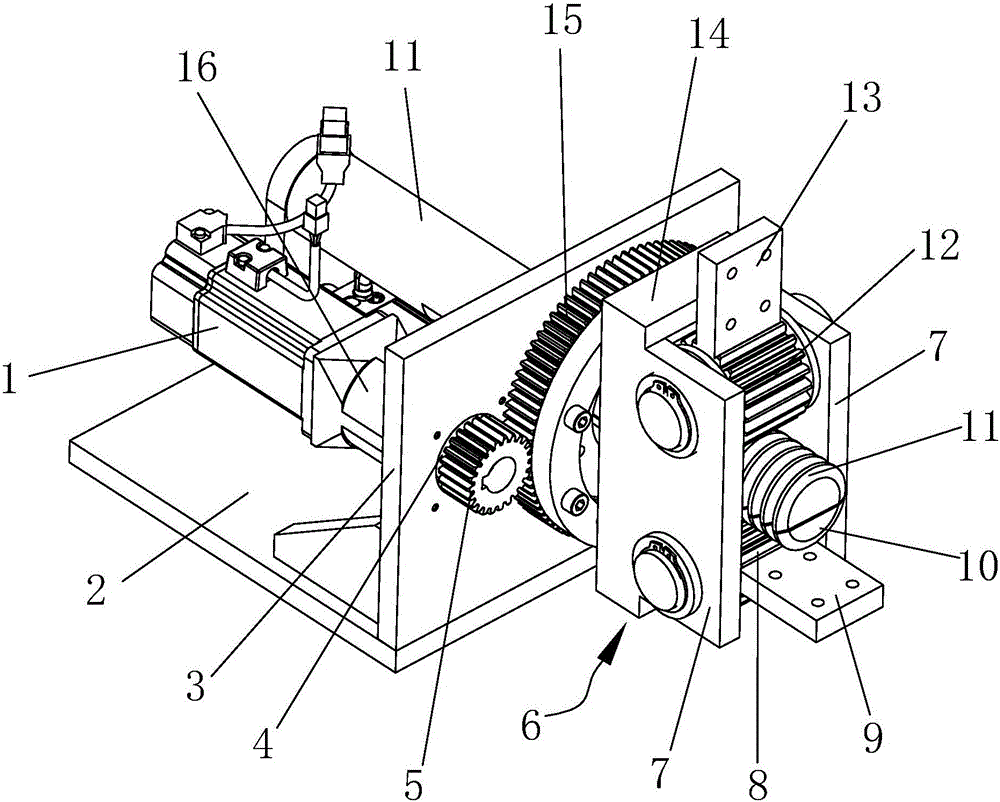

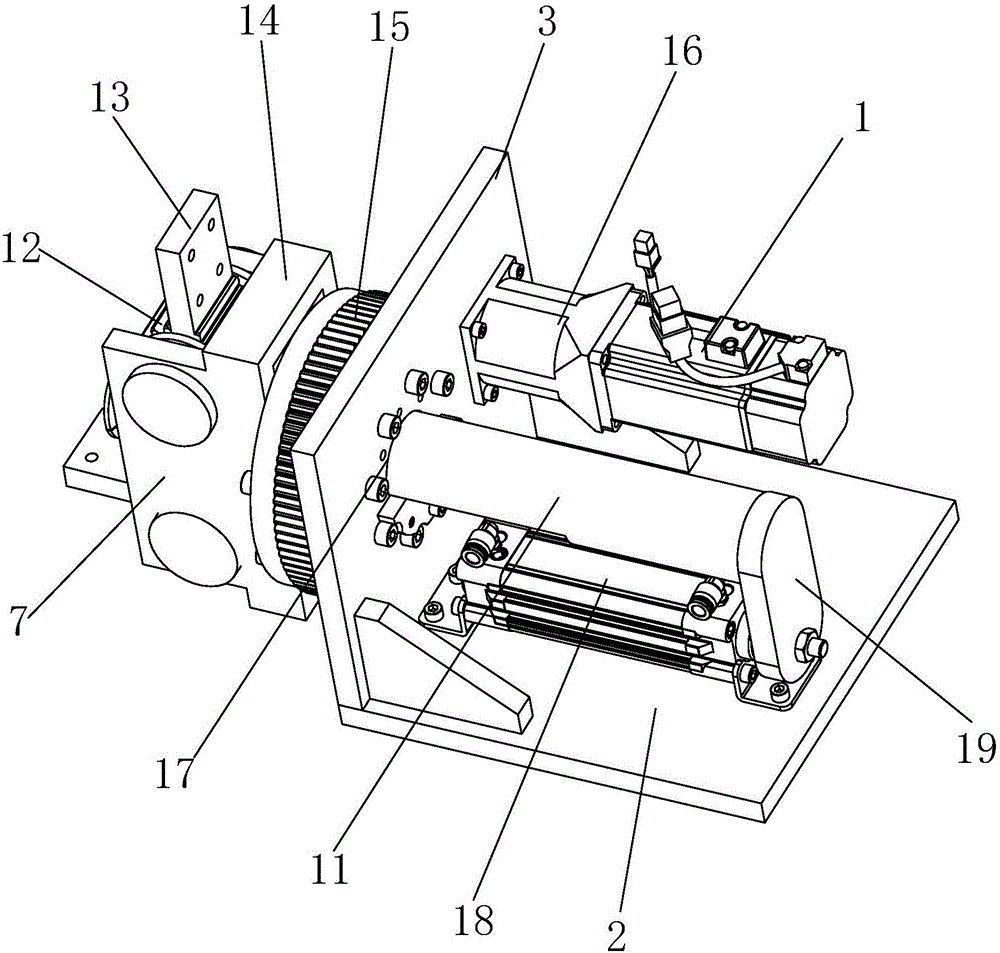

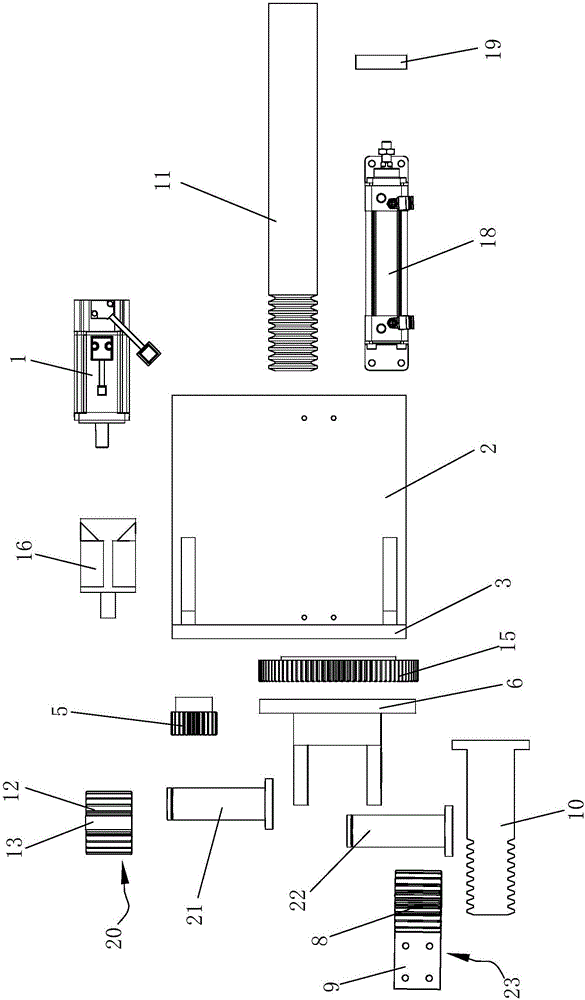

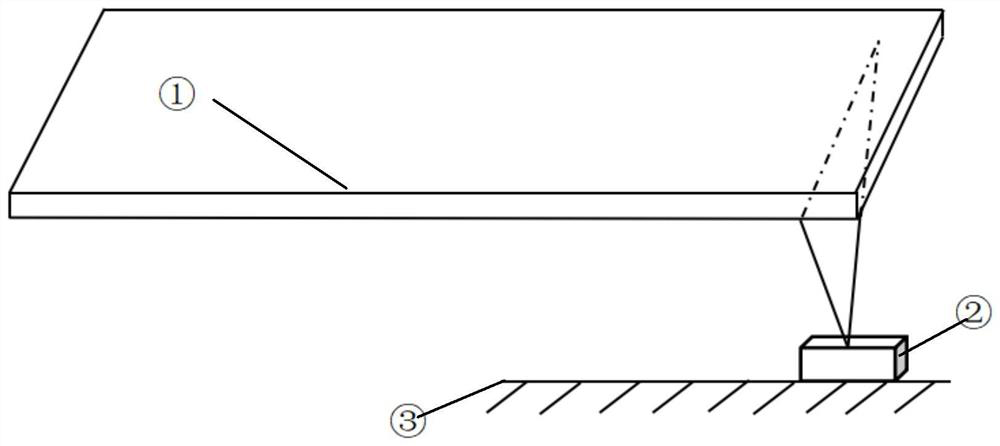

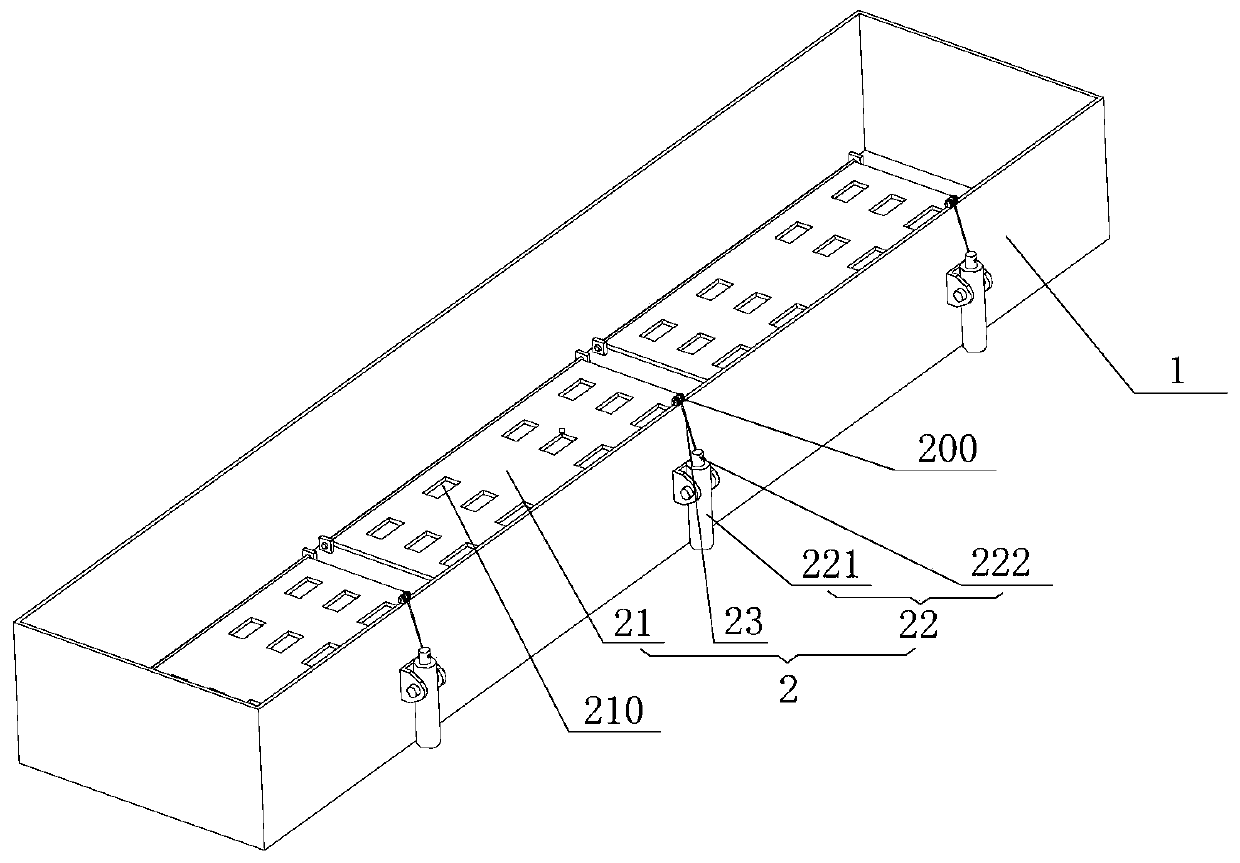

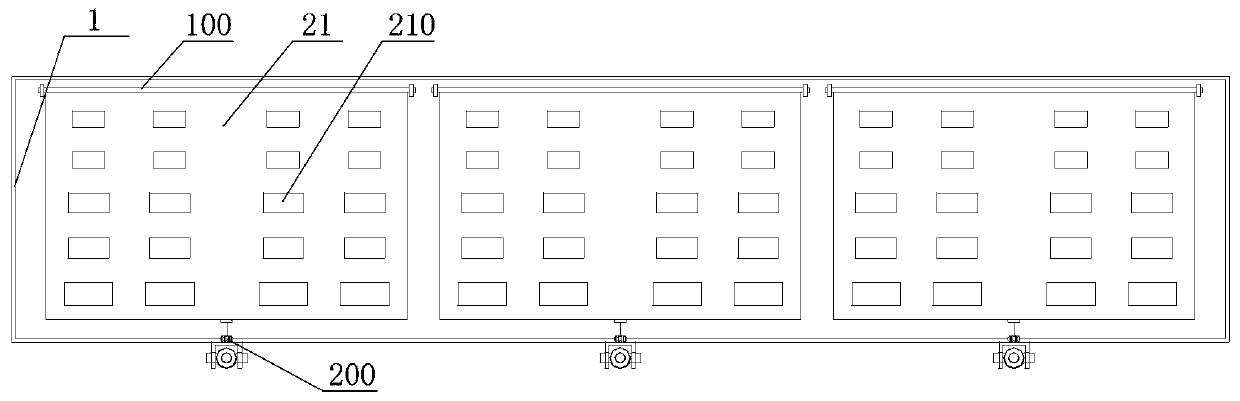

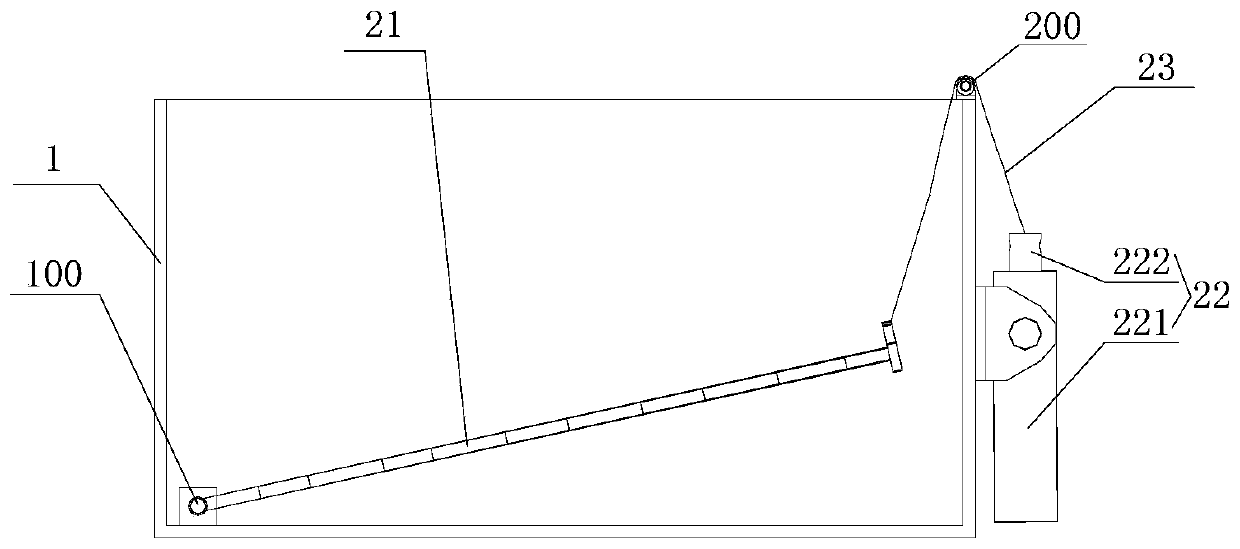

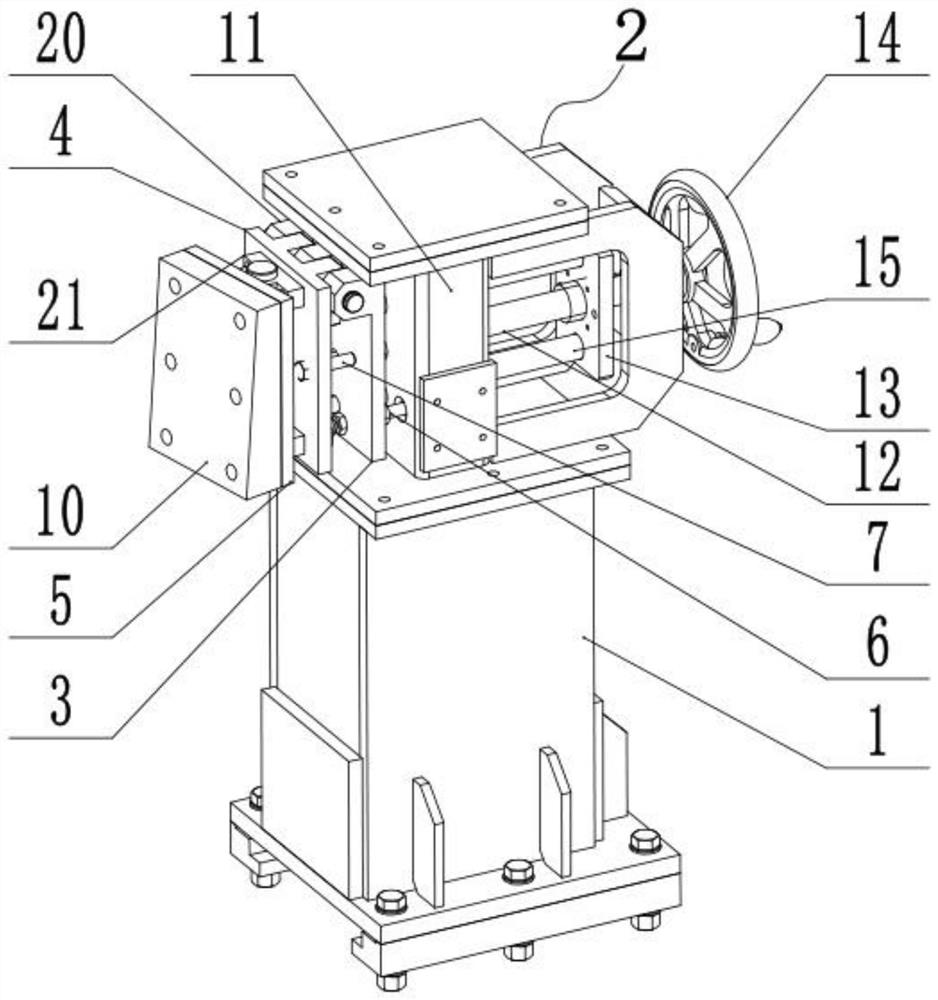

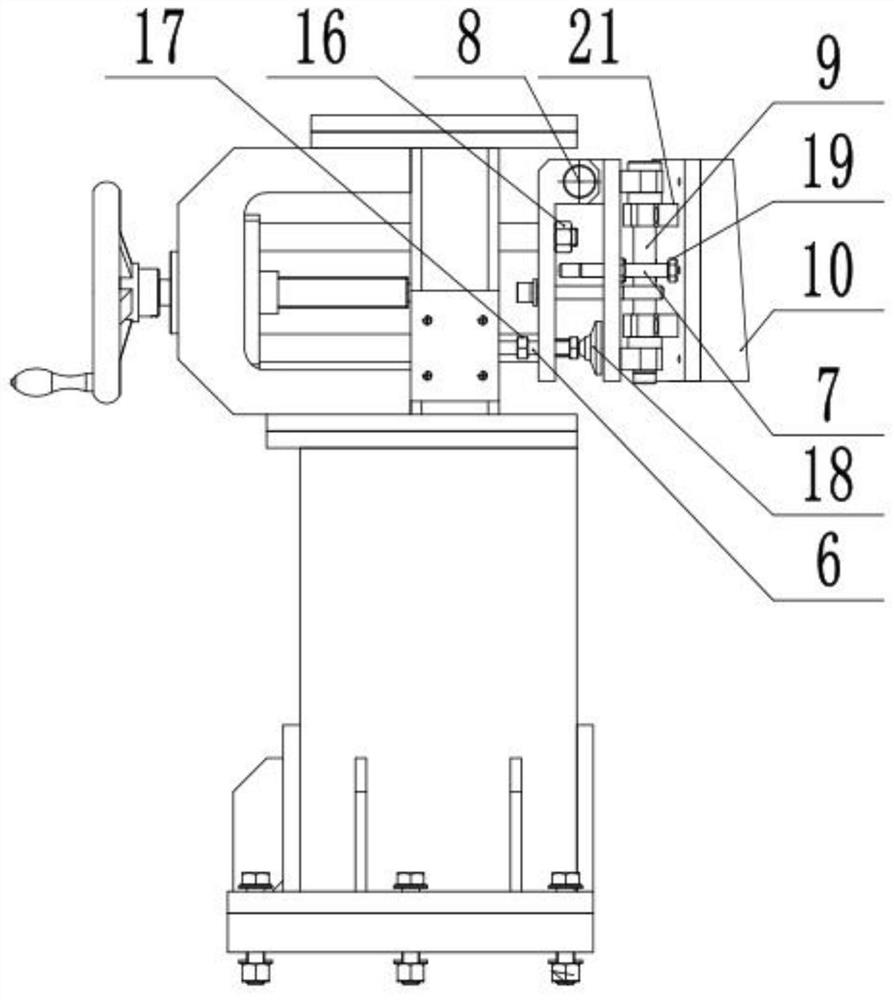

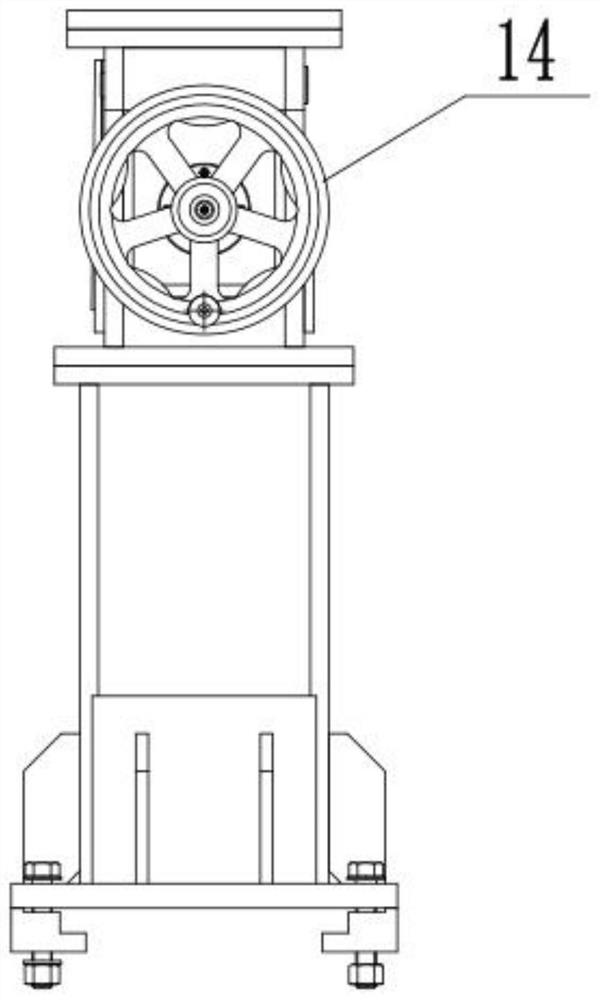

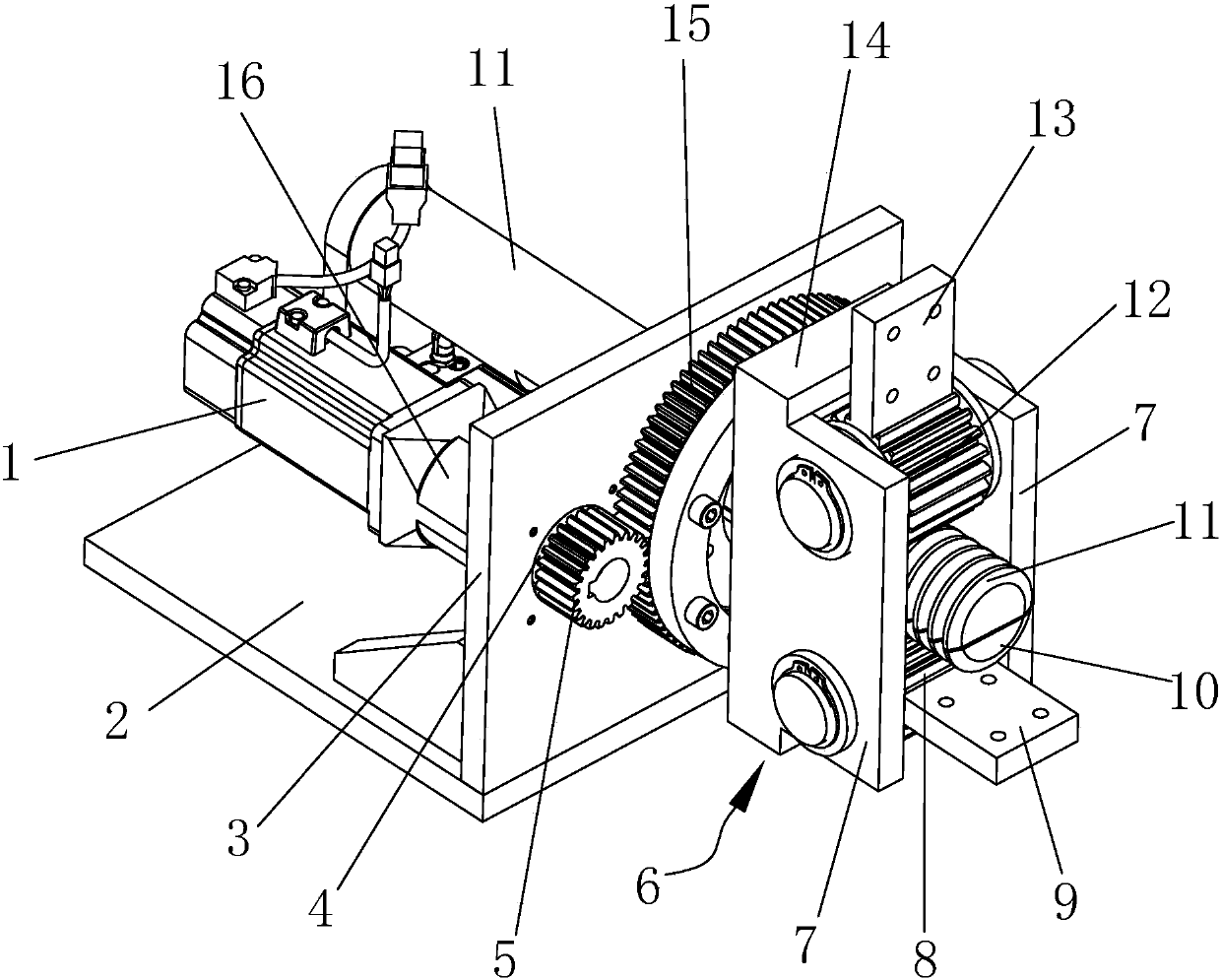

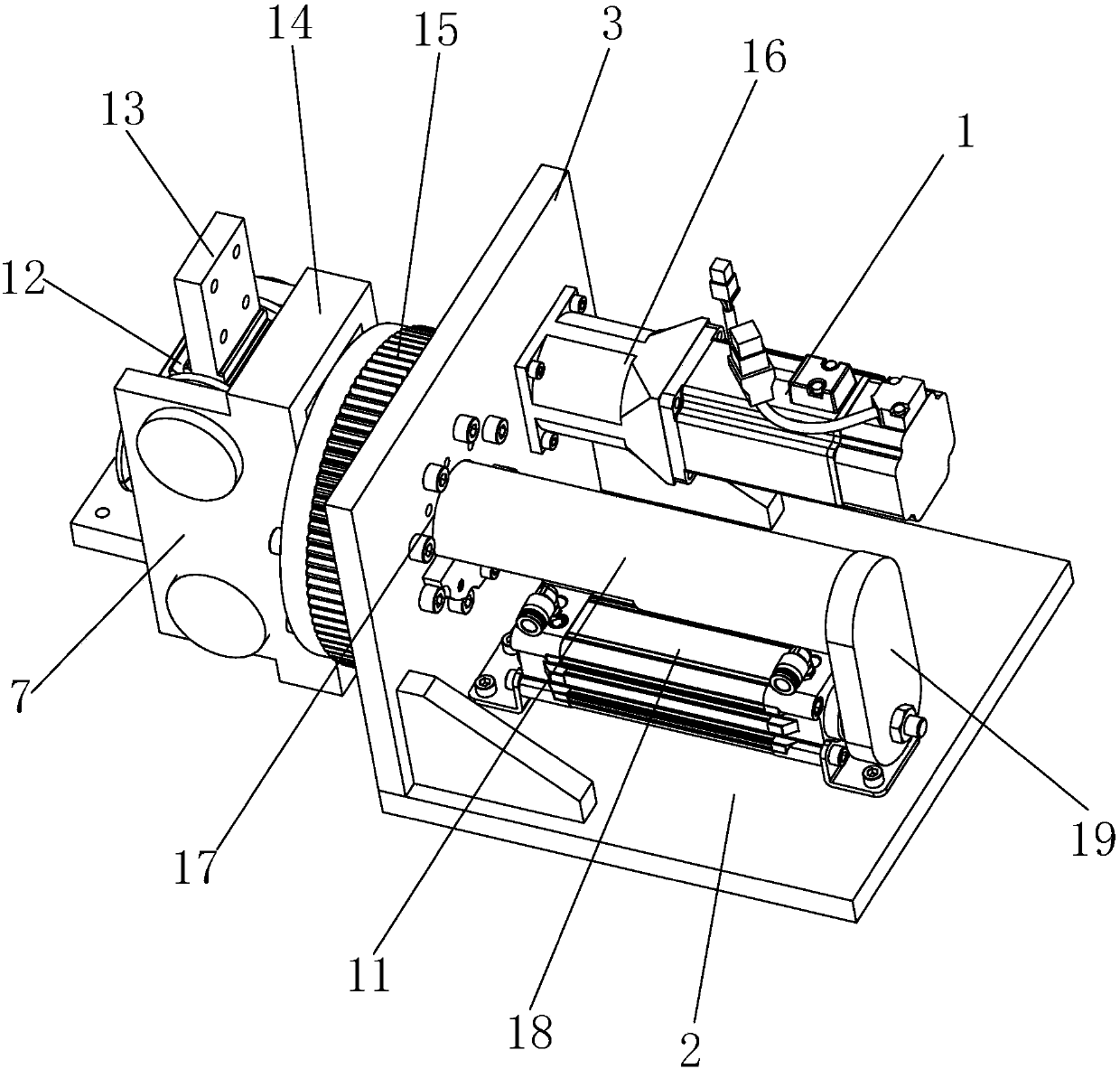

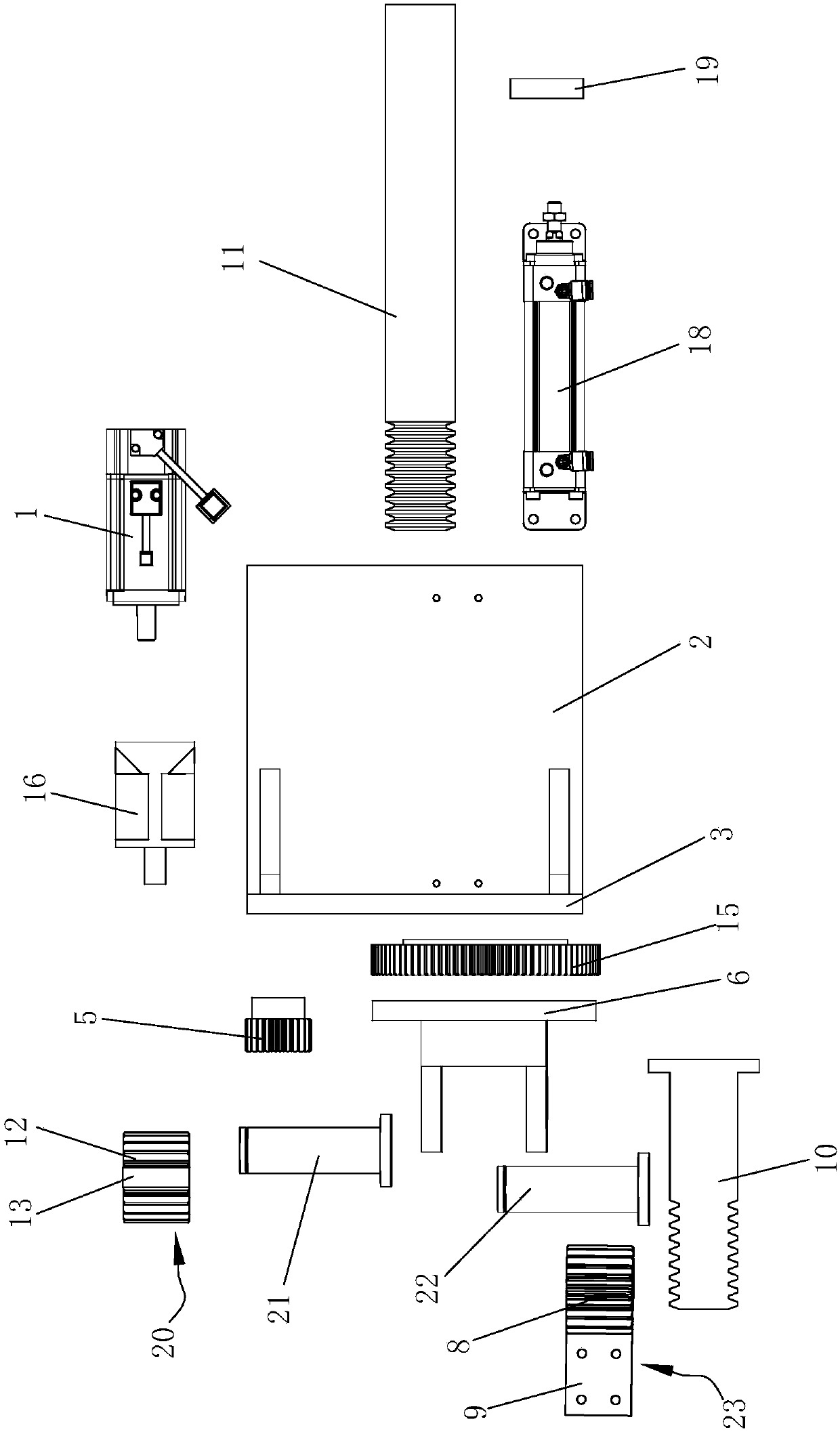

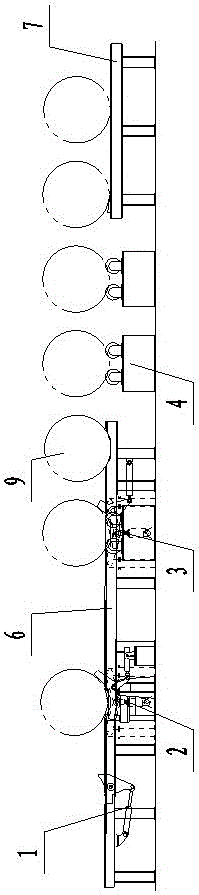

Servo turnover machine

InactiveCN105964824ASmooth motionHigh rotation accuracyMetal-working feeding devicesPositioning devicesGear wheelReducer

The invention relates to a turnover mechanism used in a production line, in particular to a servo turnover machine. The servo turnover machine comprises an installation table, a motor, a speed reducer, an air cylinder, a pinion, a big gear, a base, a pressing plate gear I, a pressing plate gear II, a half-cylinder rack I and a half-cylinder rack II. The pinion is a straight gear, the big gear is a toothed crossed roller bearing, the base fixed to the crossed roller bearing is driven through the rotating and meshing motion of the straight gear and the toothed crossed roller bearing, and therefore plates can rotate. When the plates need to be turned over, the air cylinder extends out, the half-cylinder rack I fixedly connected to a telescopic shaft of the air cylinder is pulled, the pressing plate gear I meshing with the half-cylinder rack I does rotating and clamping motion, and therefore the plates to be turned over can be clamped. When a system detects that the plates are clamped, the motor is driven to rotate to the position where the plates are to be turned over, the system then controls the air cylinder to retract, the pressing plate gear I meshing with the half-cylinder rack I does rotating and opening motion, and therefore the plates can be turned over.

Owner:LIUZHOU GAOHUA TECH CO LTD

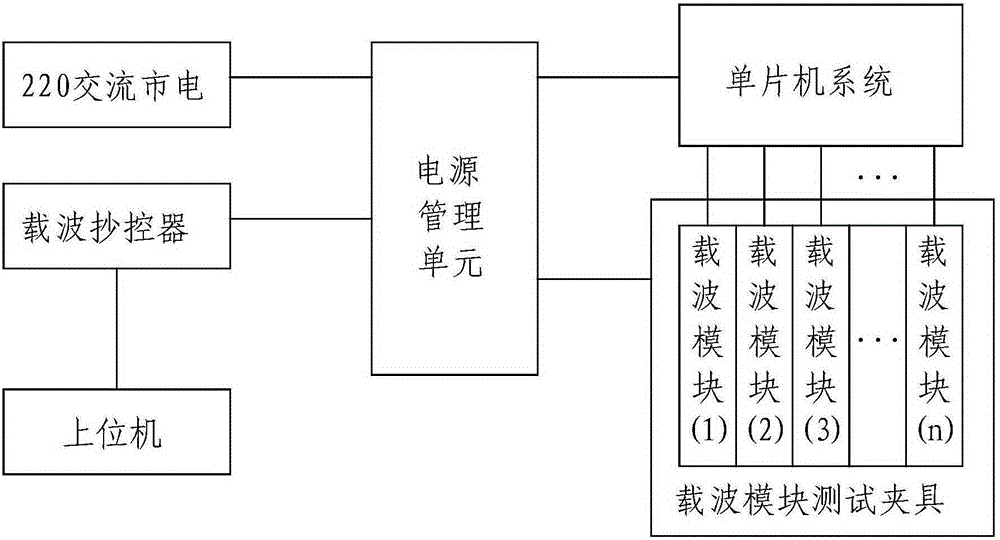

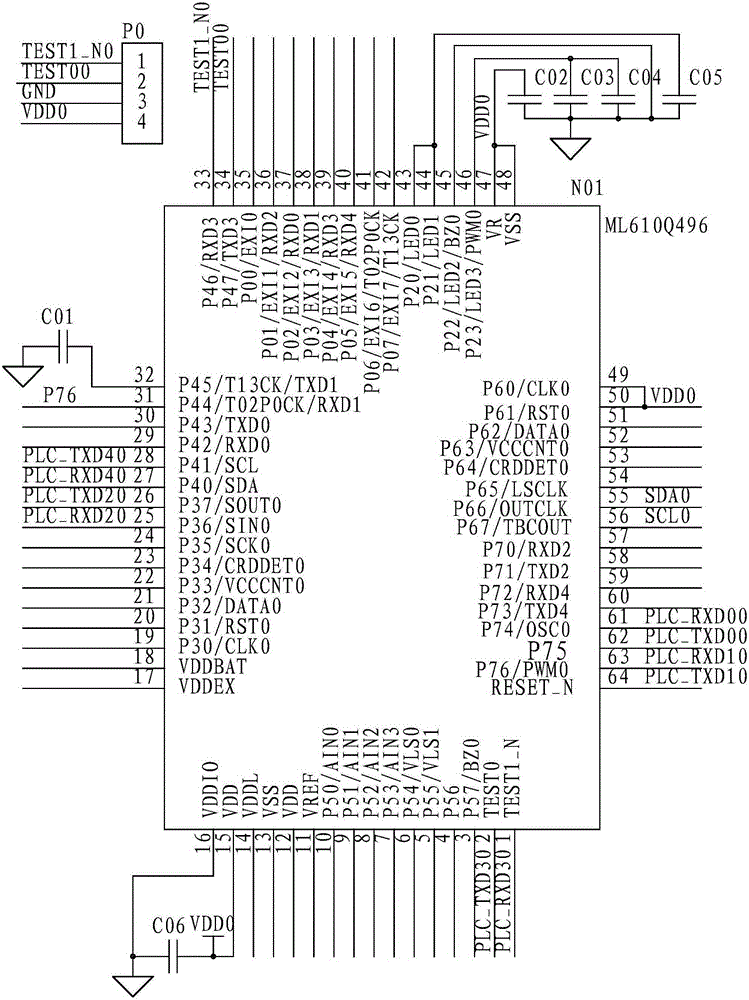

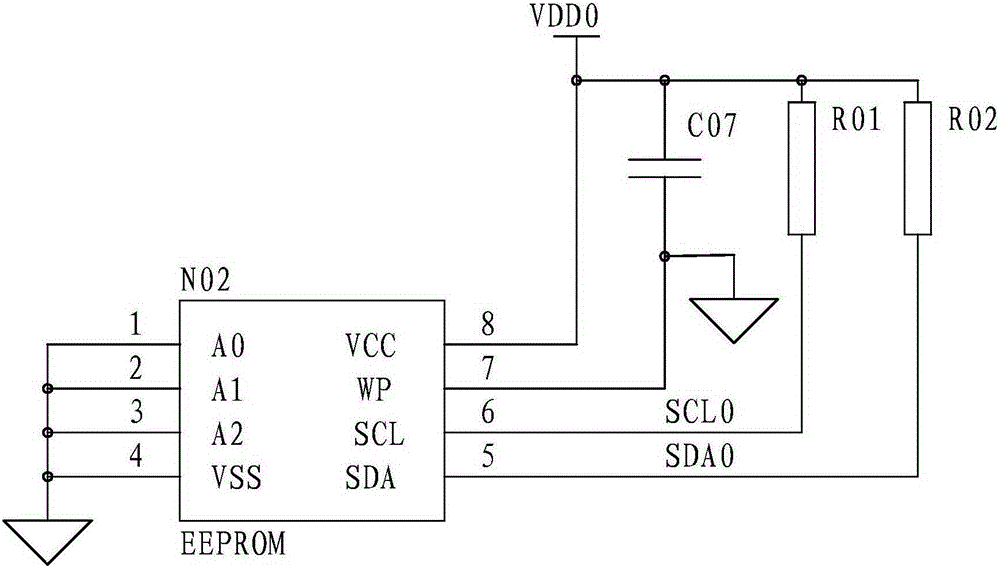

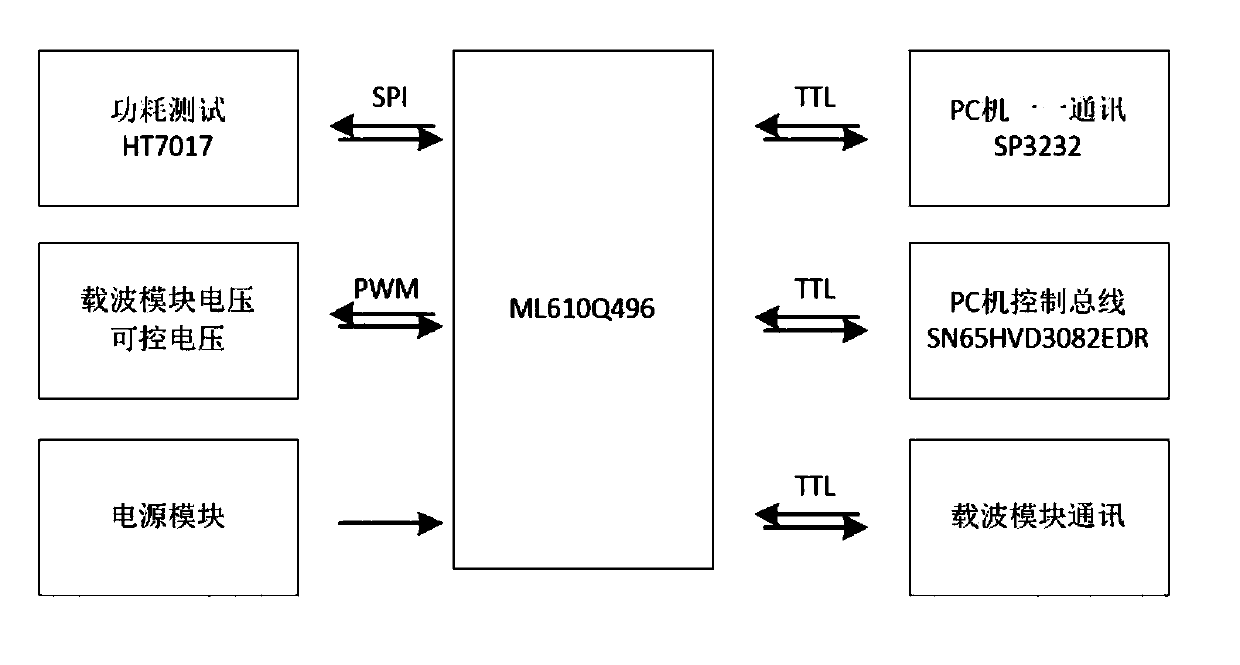

Test system for low-voltage power line carrier module

InactiveCN105356910AImprove test efficiencyFlexible configurationLine-transmission monitoring/testingMicrocontrollerLow voltage

The invention discloses a test system for a low-voltage power line carrier module. The test system comprises a 220V alternating-current mains supply, a power management unit, a singlechip system, a carrier module test clamp and a carrier reading controller; the alternating-current mains supply provides a working voltage for the power management unit, and provides a carrier channel for low-voltage power line carrier; the power management unit provides +12V working power for the carrier module and +5V / 3.3V working power for the singlechip system, and meanwhile, provides mains supply isolating output power for the carrier module; the singlechip system provides multiple paths of exchange data required for testing the carrier module; the carrier module test clamp comprises a multi-path carrier module test interface connected with the tested carrier module; and the carrier reading controller is used for reading the interactive data of the tested carrier module and sending the interactive data to an upper computer. The test system can be used for quickly and accurately testing the carrier module, meets the production requirement, reduces the fatigue strength of workers, improves the production efficiency, and improves the first pass yield of single assembly.

Owner:中电装备山东电子有限公司

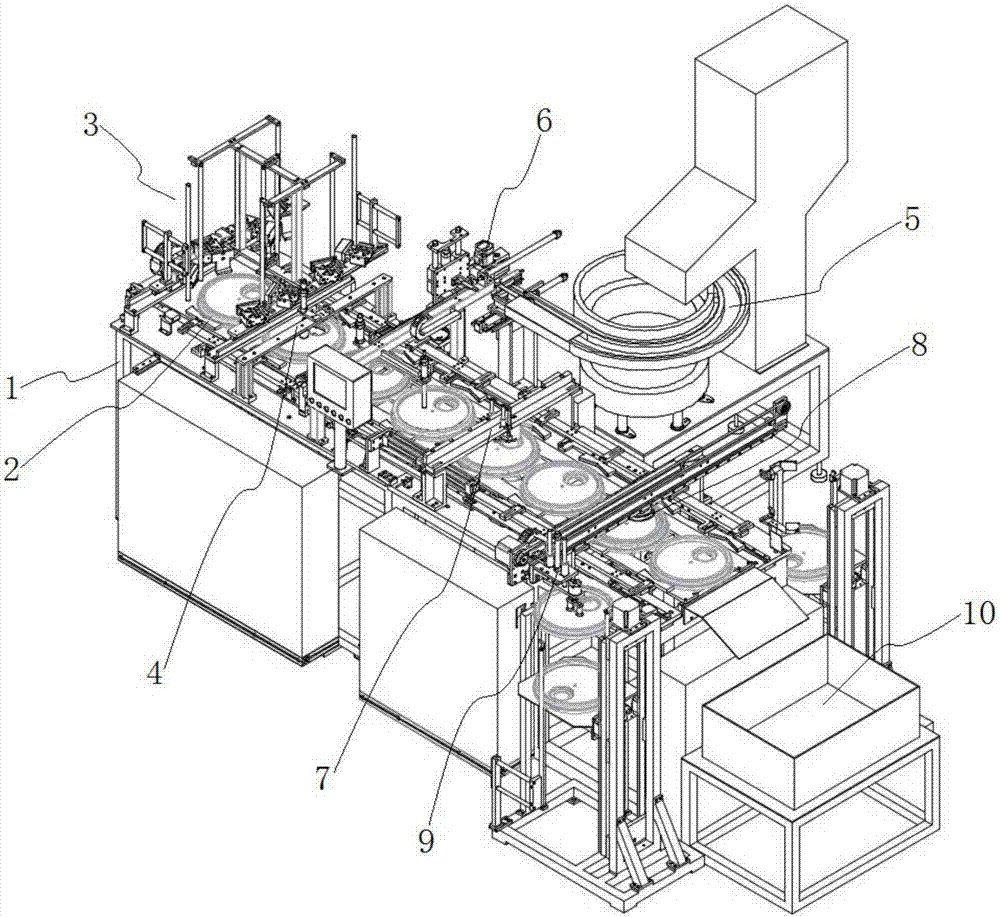

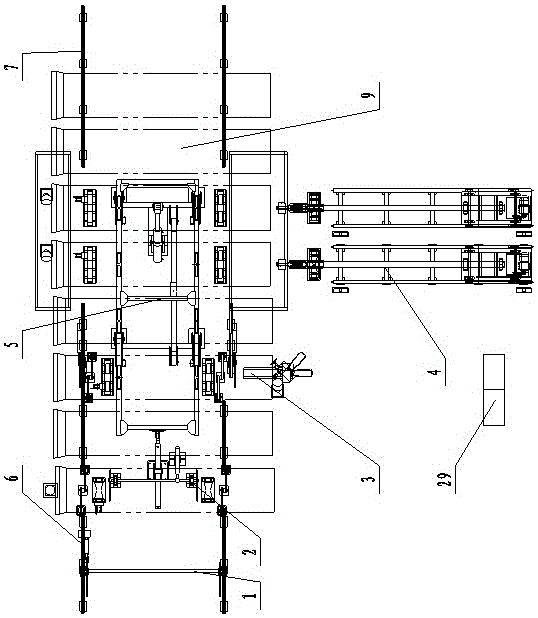

Automatic welding equipment for plastic barrel cover and oil nozzle

ActiveCN107139488ARealize continuous automatic welding productionCompact structureStacking articlesDe-stacking articlesUltrasonic weldingStructural engineering

The invention discloses automatic welding equipment for a plastic barrel cover and an oil nozzle and belongs to the field of automatic equipment. The automatic welding equipment disclosed by the invention comprises a frame and a barrel cover clamping and conveying device; a barrel cover feeding station, a barrel cover positioning station, an oil nozzle mounting station, a welding station, a detecting station and a discharging station are arranged in sequence on the barrel cover clamping and conveying device and along a rectilinear direction; a barrel cover feeding device is arranged at the barrel cover feeding station; a barrel cover rotary positioning device is arranged at the barrel cover positioning station; an oil nozzle positioning and mounting device is arranged at the oil nozzle mounting station; an ultrasonic welding device is arranged at the welding station; an air tightness detecting device is arranged at the detecting station; and a discharged material stacking device and an inferior-quality product recycling device are arranged at the discharging station. The automatic welding equipment disclosed by the invention can sequentially automatically accomplish the work of barrel cover feeding, barrel cover positioning, oil nozzle positioning and mounting, welding, air tightness detection and discharged material stacking, and is simple and compact in structure, stable and reliable in operation, flexible and convenient to control, high in production efficiency and good in welding quality.

Owner:CHANGZHOU CENTRWAY PLASTICS

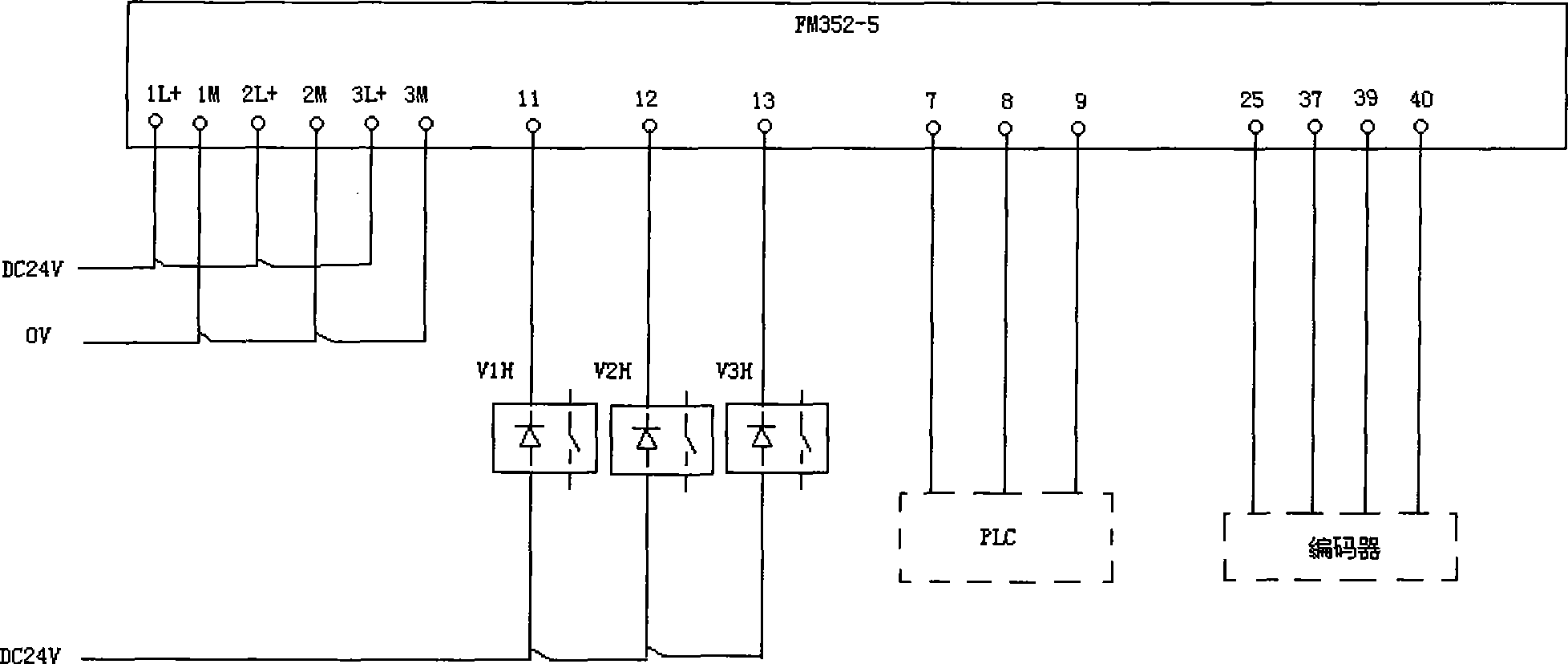

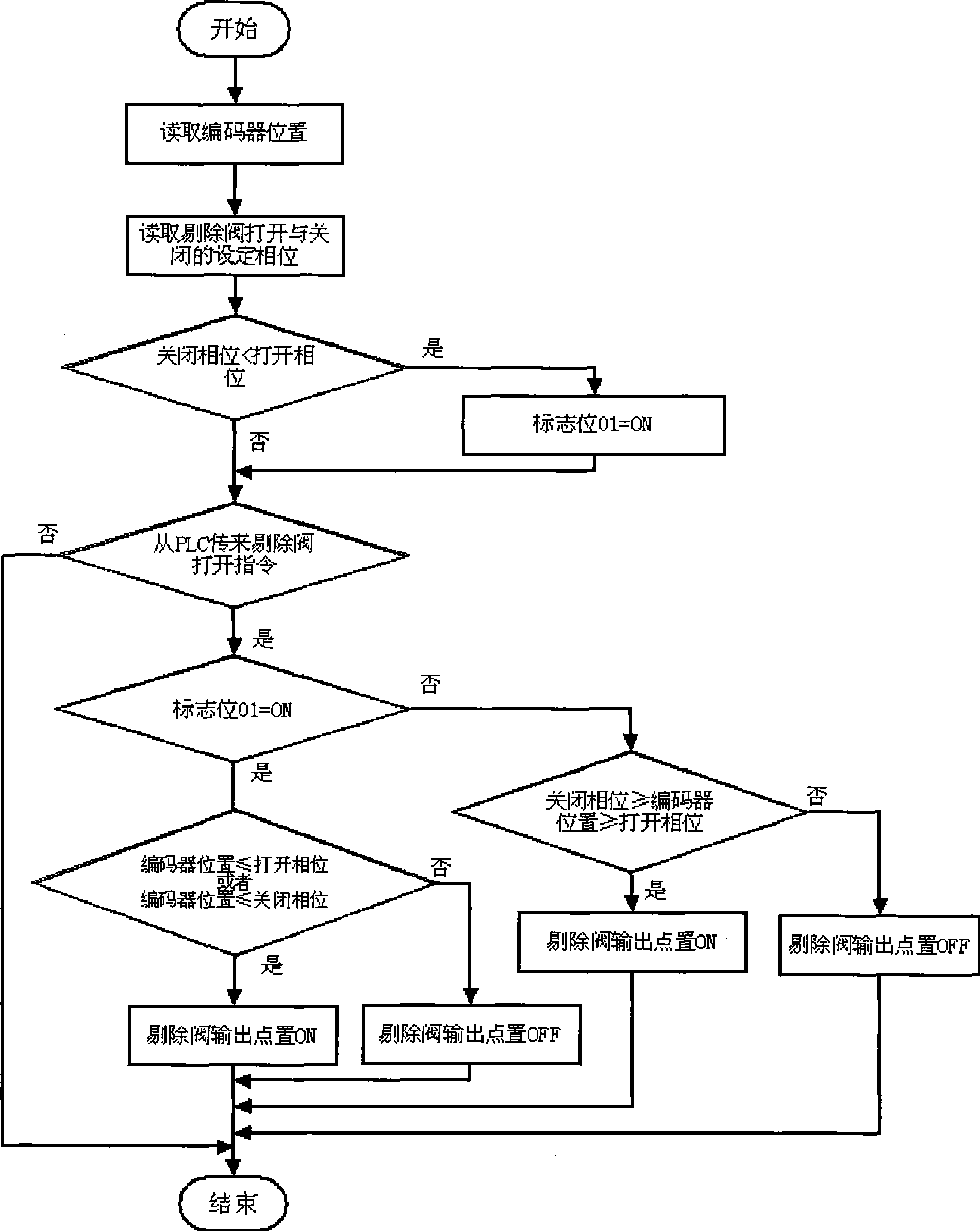

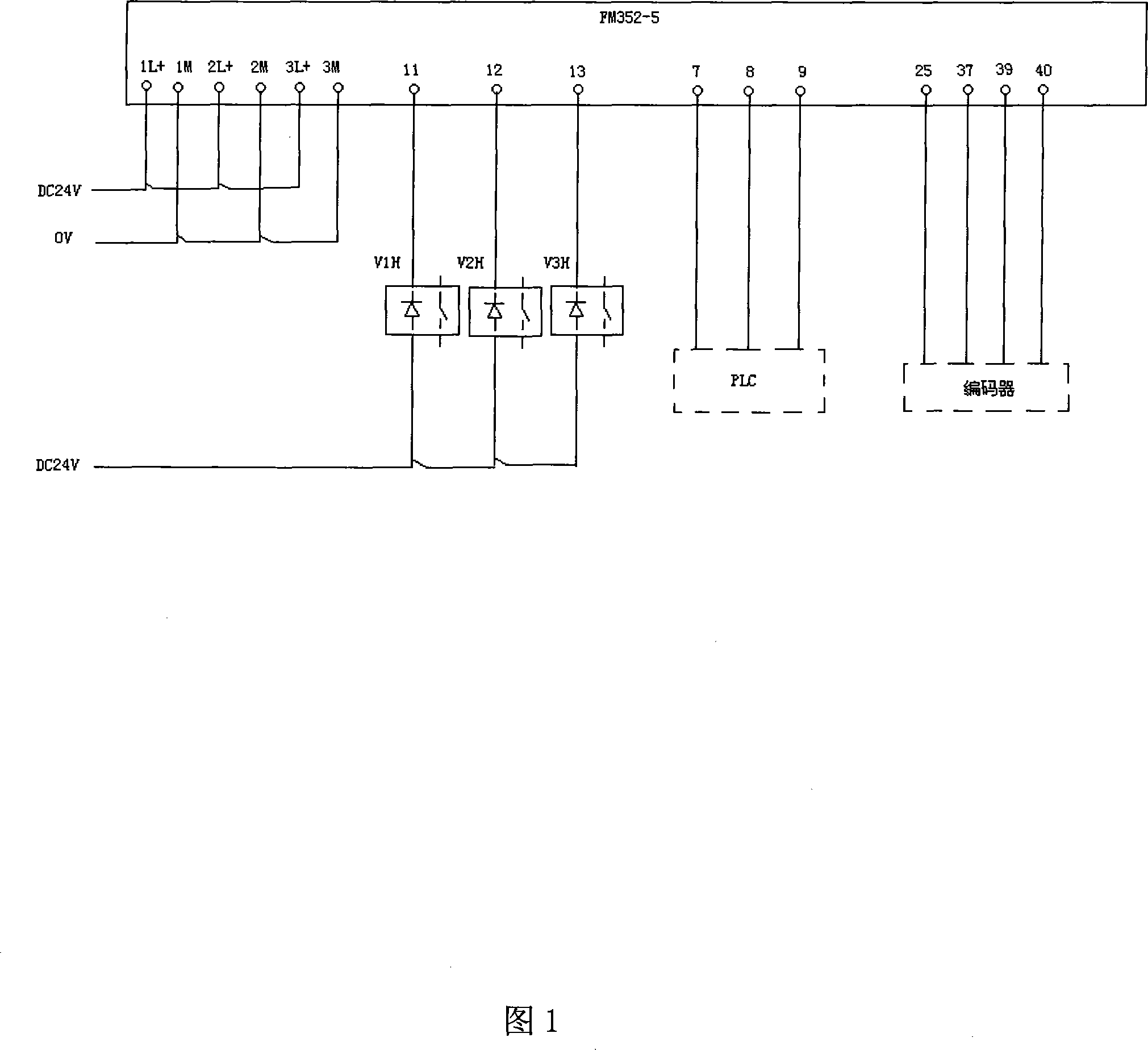

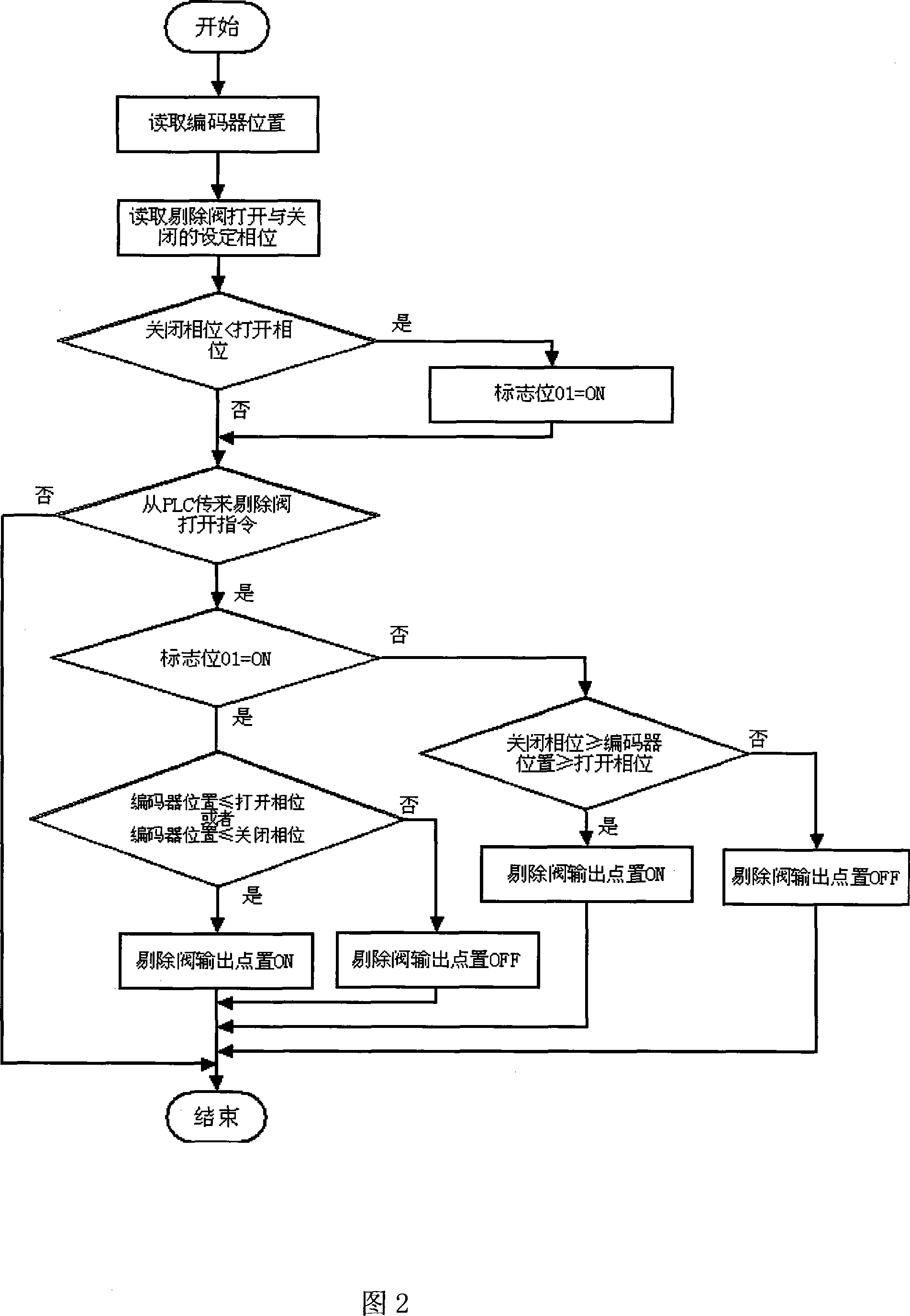

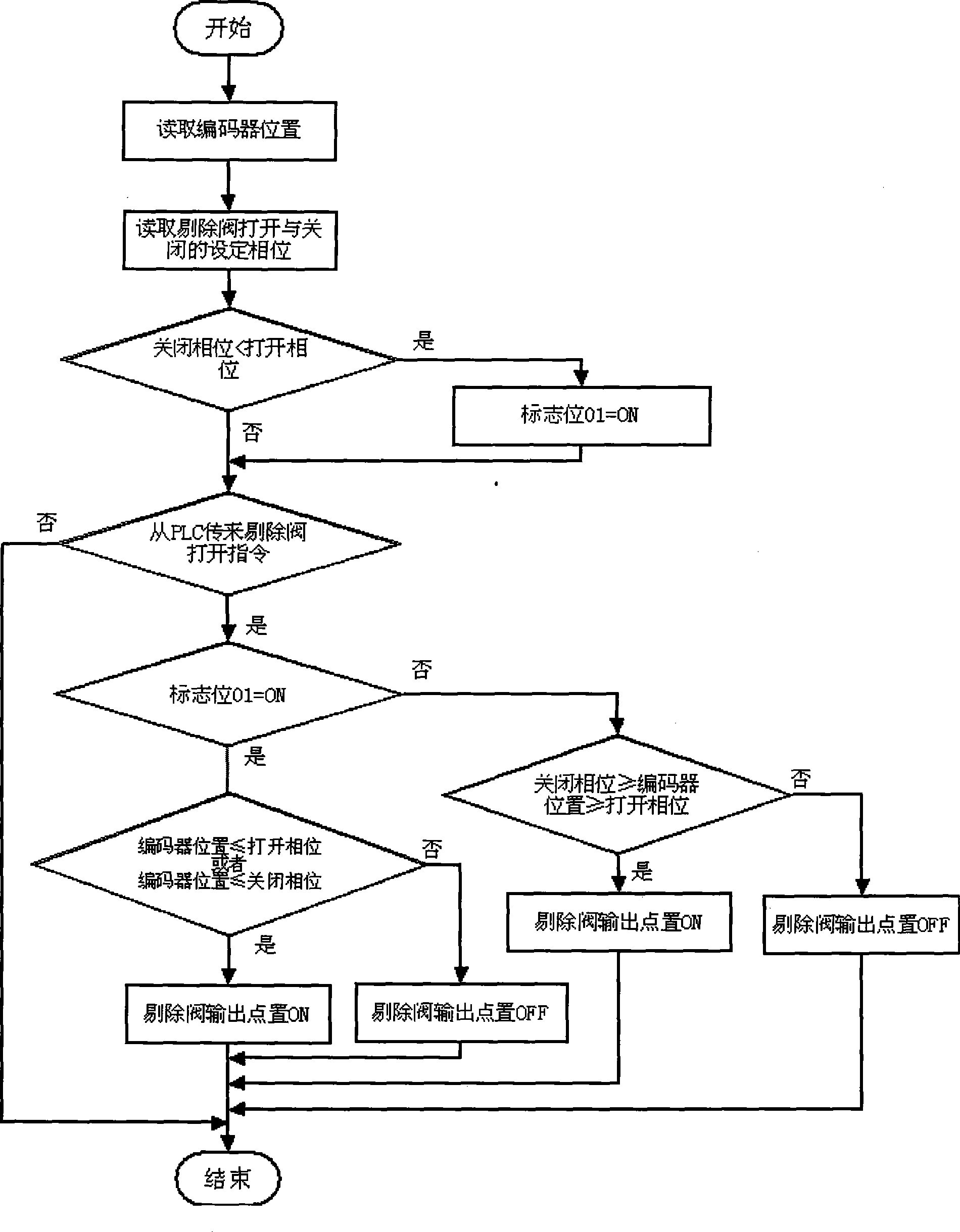

Method of accurate control for removing filter-stick of high-speed filter-stick forming device

ActiveCN101396172AMeet production takt requirementsQuickly proposeTobacco smoke filtersWaste productPulse number

The invention discloses a method for accurately controlling filter tip elimination for a high-speed filter tip forming machine. An FM352-5 high-speed Boolean processor is adopted to control the action of a ejecting valve; a PLC controls the operation of the high-speed filter tip forming machine, when needing to eliminate defective filter tips, the PLC outputs an elimination signal to the FM352-5 high-speed Boolean processor; the FM352-5 high-speed Boolean processor collects a pulse signal from a pulse coder, when an input end thereof receives the elimination signal from the PLC, the FM352-5 high-speed Boolean processor determines the position of the defective filter tips to be eliminated according to the output pulse number of the pulse coder, and opens and closes the eliminating valve at a set phase. The method can realize high speed elimination of waste products in the production course, ensures high quality of filter tips, and is applicable to high-speed filter tip forming machines in the cigarette industry.

Owner:CHINA TOBACCO MACHINERY TECH CENT

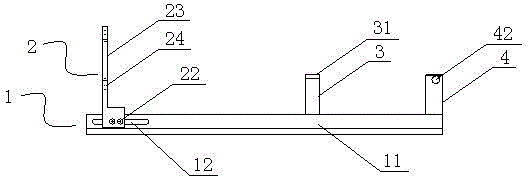

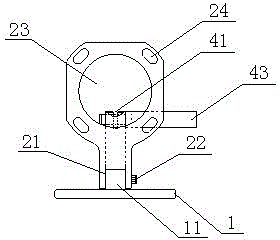

Detection tool for front shock absorber of vehicle

ActiveCN102829683ASimple structureEasy to operateMechanical measuring arrangementsUltimate tensile strengthShock absorber

The invention aims at providing a detection tool for a front shock absorber of a vehicle, which is used for detecting a front shock absorber to reduce labor intensity of staff, improving working efficiency and guaranteeing normal production. The detection tool for the front shock absorber of a vehicle comprises a base, a detection plate and a positioning column, wherein the detection plate is arranged on the base in a sliding way; the positioning column is fixed on the base; a through hole is formed in the center of the detection plate; detection holes adapted to a stud at the end part of the front shock absorber to be detected are formed at the periphery of the through hole; a positioning groove adapted to the positioning support of the front shock absorber to be detected is formed at the front end of the positioning column; the opening of the positioning groove is upward, and a through positioning hole is formed in the wall of the positioning groove; and a positioning pin is arranged in the positioning hole. The detection tool for the front shock absorber of a vehicle is simple in structure and convenient to operate, so that the labor force of staff can be reduced, the requirement for production process can be fulfilled, and normal production can be guaranteed.

Owner:CHERY AUTOMOBILE CO LTD

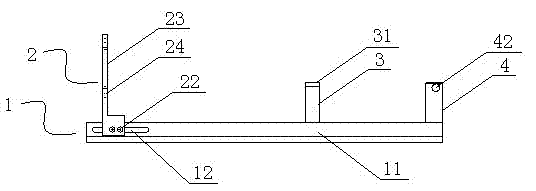

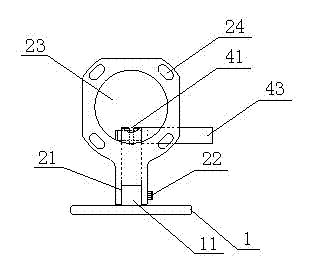

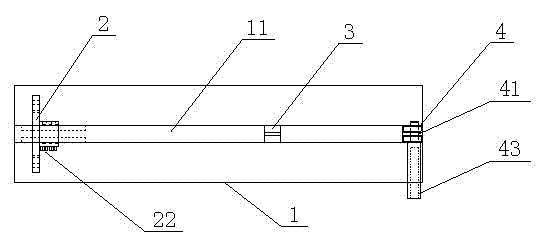

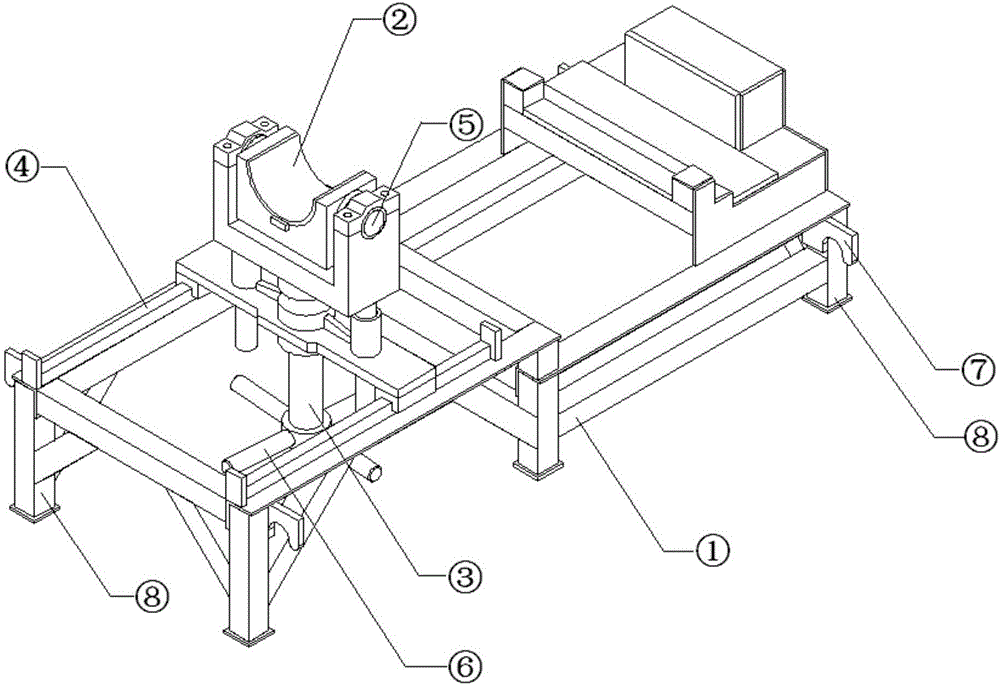

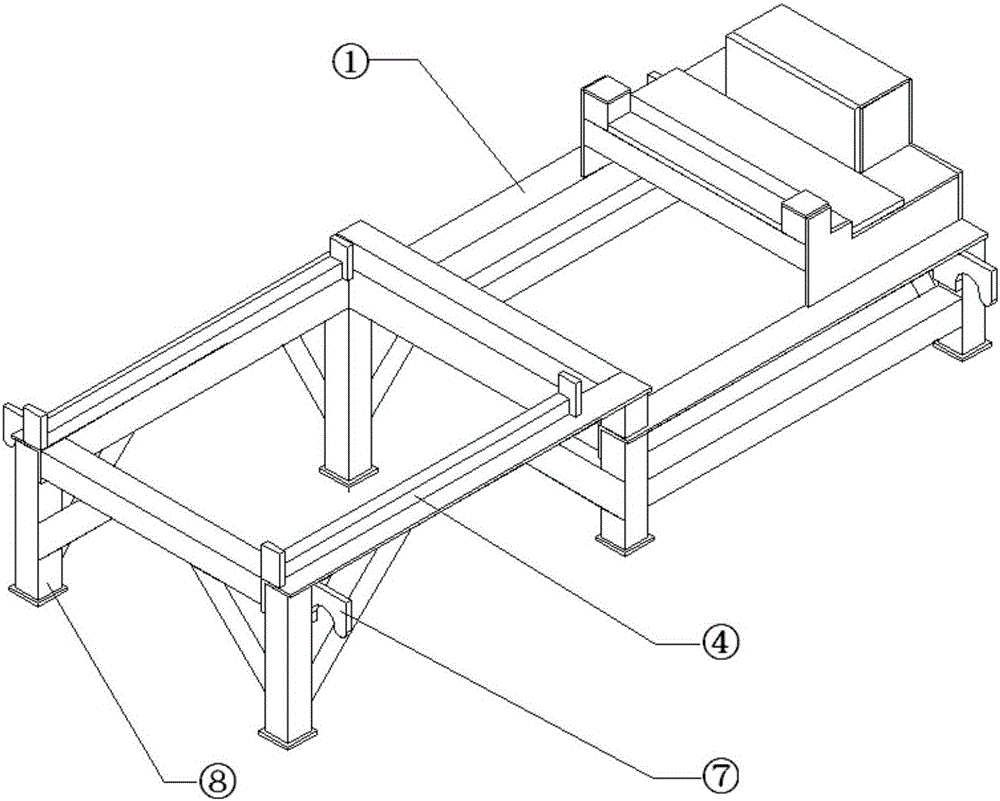

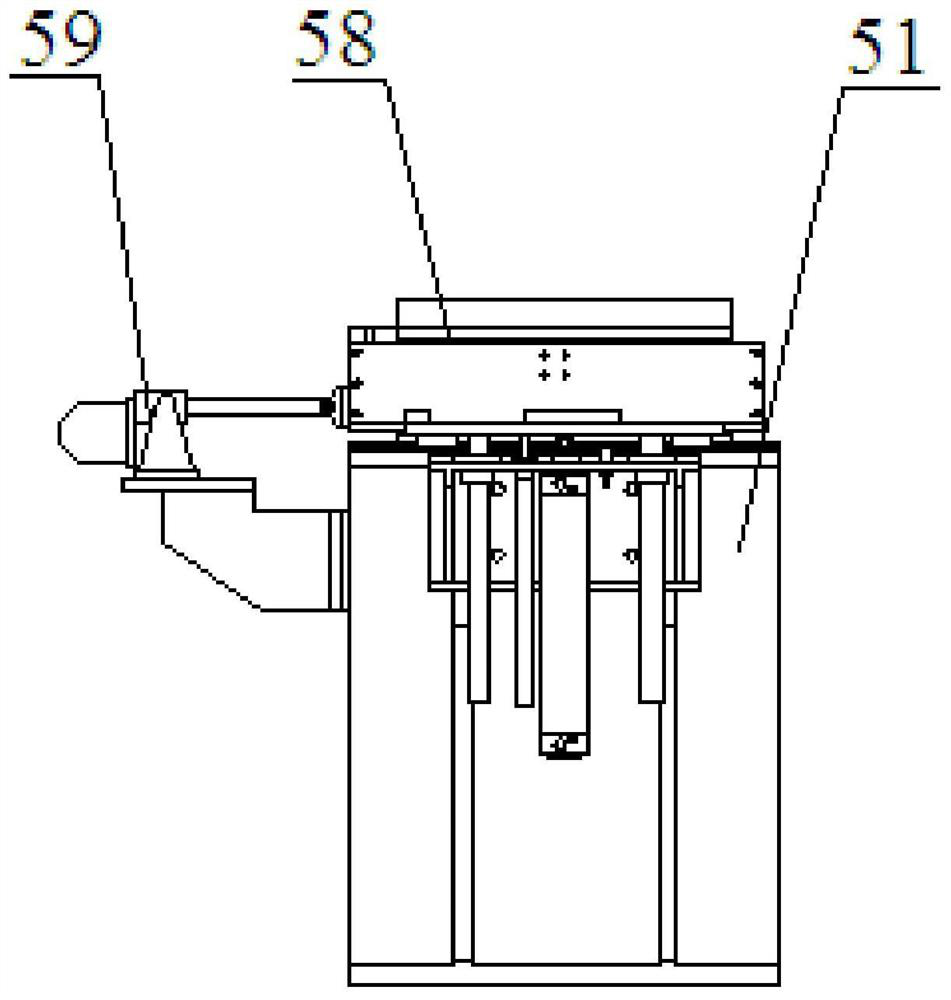

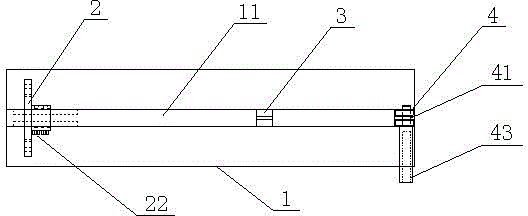

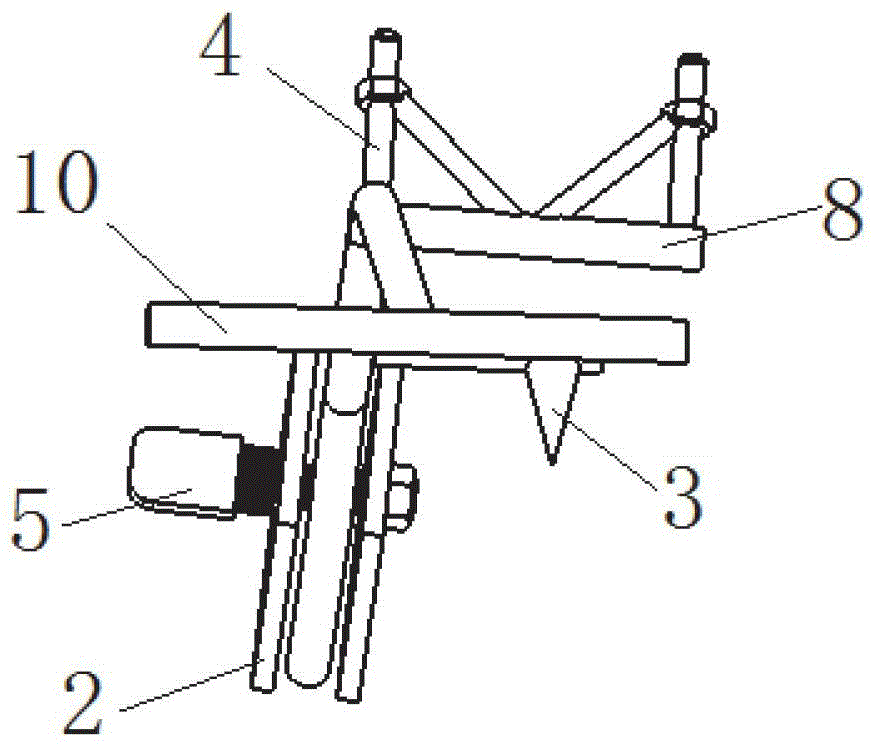

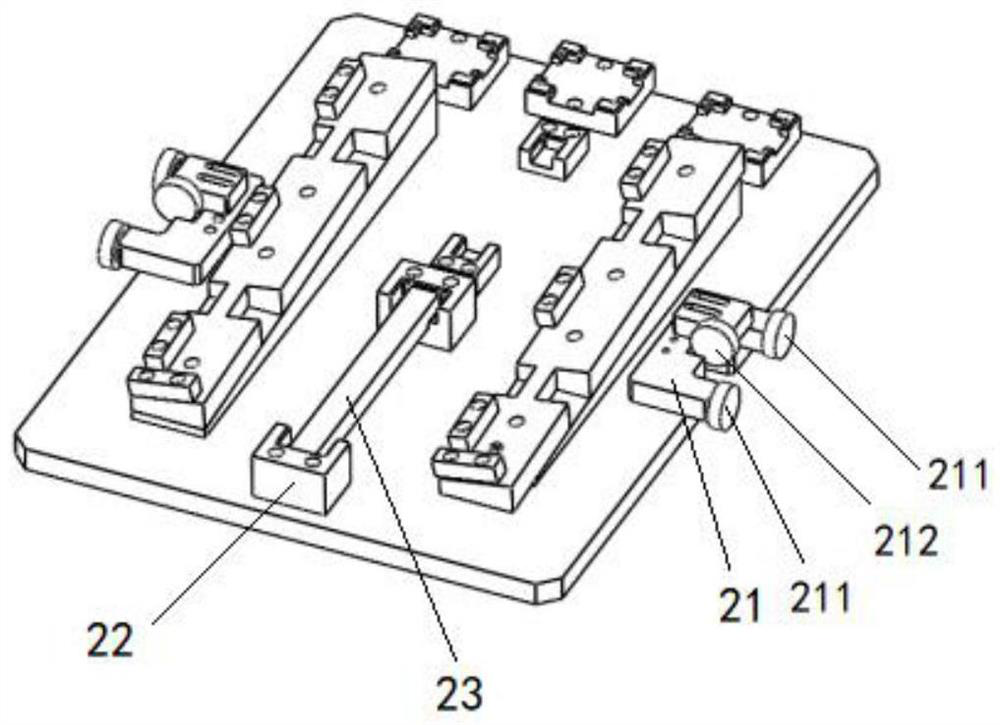

Automatic glue spreader

InactiveCN105597991AMeet production takt requirementsGuarantee the quality of gluingLiquid surface applicatorsCoatingsMechanical engineeringFixed angle

The invention relates to a glue spreader for an automobile control shaft assembly, and concretely relates to an automatic glue spreader with stations which can rotate according to a fixed angle for carrying out automatic gluing motions. The apparatus comprises a driving mechanism, a divider, a rotating mechanism, positioning tools, a planar right angle moving mechanism, a gluing gun, a safety protection frame and a working bench, wherein the driving mechanism and the divider are placed below a table top of the working bench, the driving mechanism and the divider are connected, and the divider and the rotating mechanism are connected; multiple rotating arms are arranged above the table top of the working bench, and a free end of each rotating arm is provided with a positioning tool; multiple positioning tools which are driven by the divider and the rotating mechanism rotate to a gluing station on the working bench in order according to requirements of production takt; the planar right angle moving mechanism is arranged above the table top of the working bench, and the gluing gun is driven by the planar right angle moving mechanism to move. The apparatus can satisfy working requirements of gluing accuracy and takt rate during control shaft assembly gluing work.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

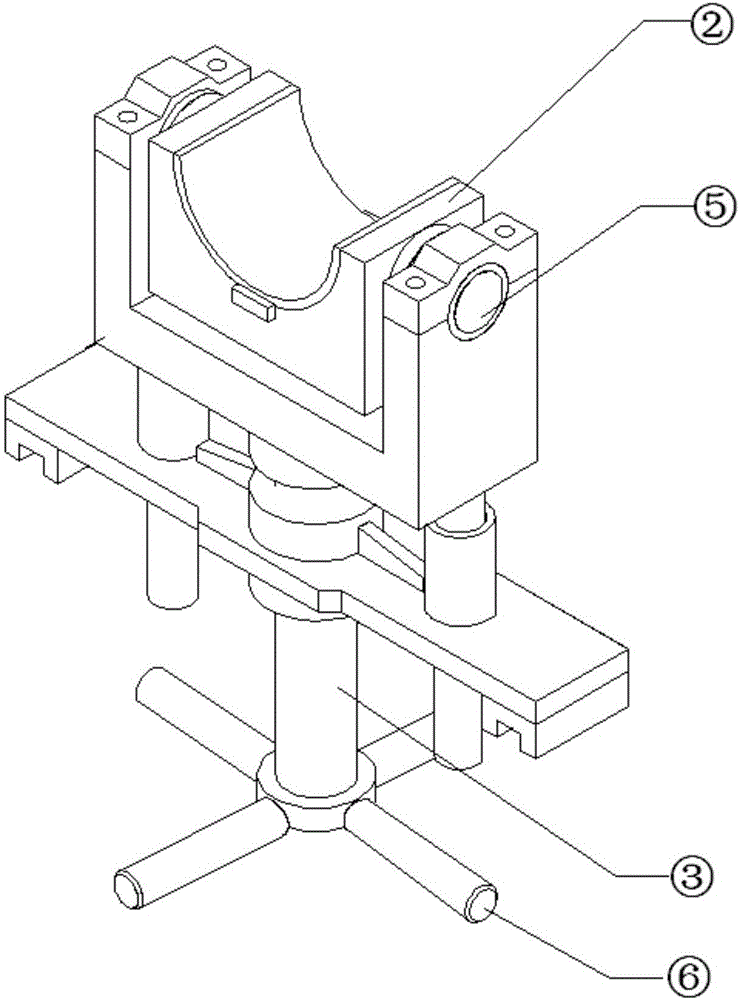

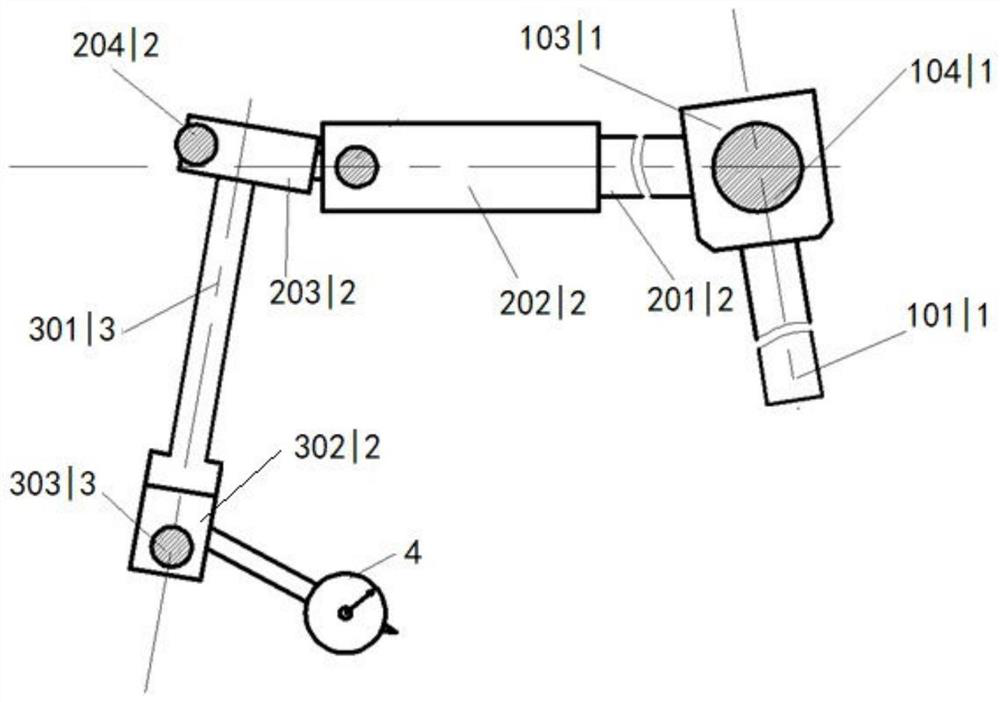

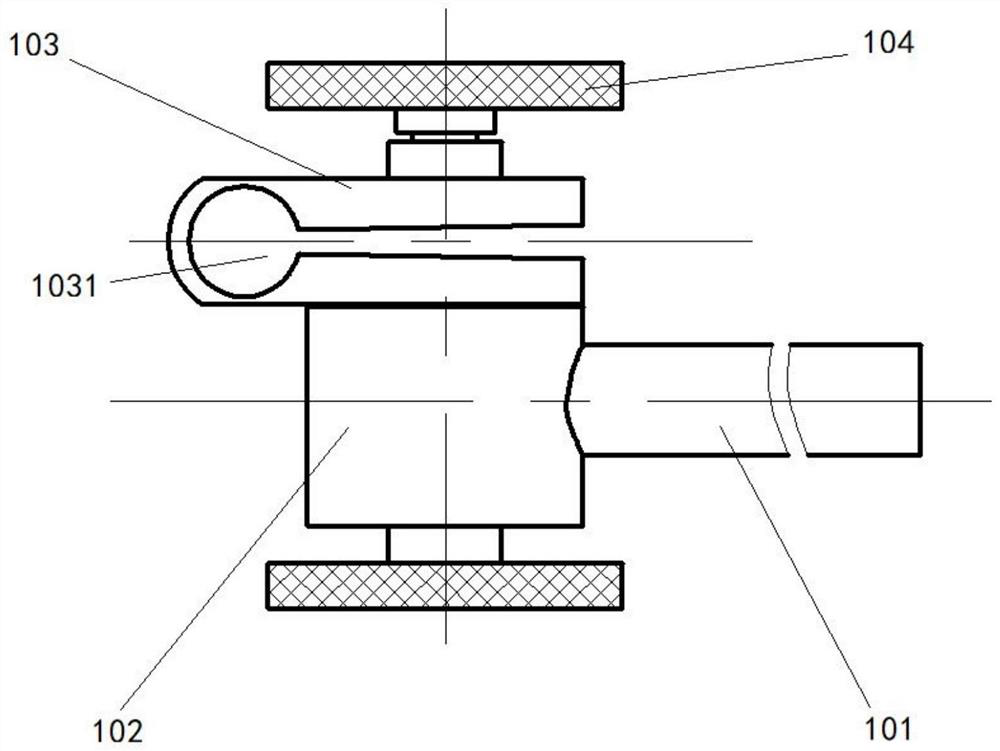

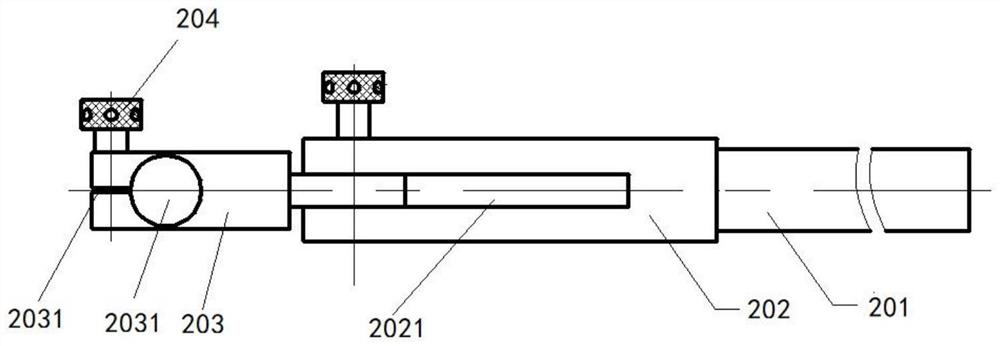

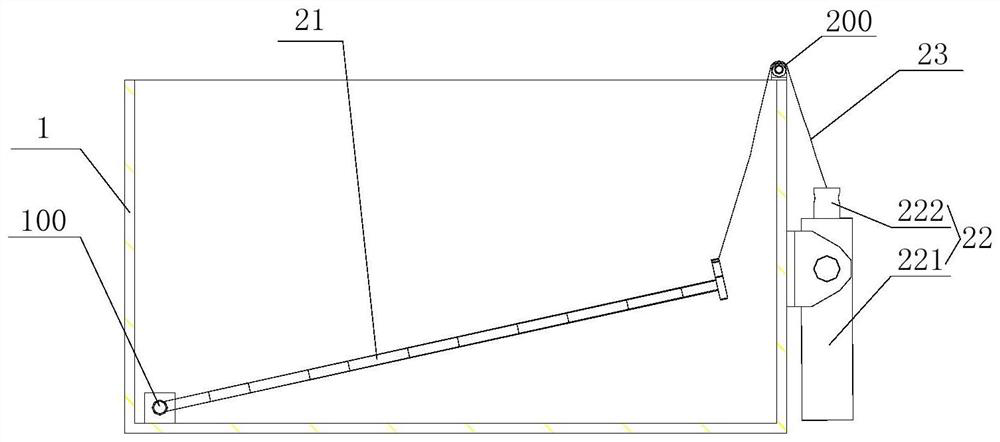

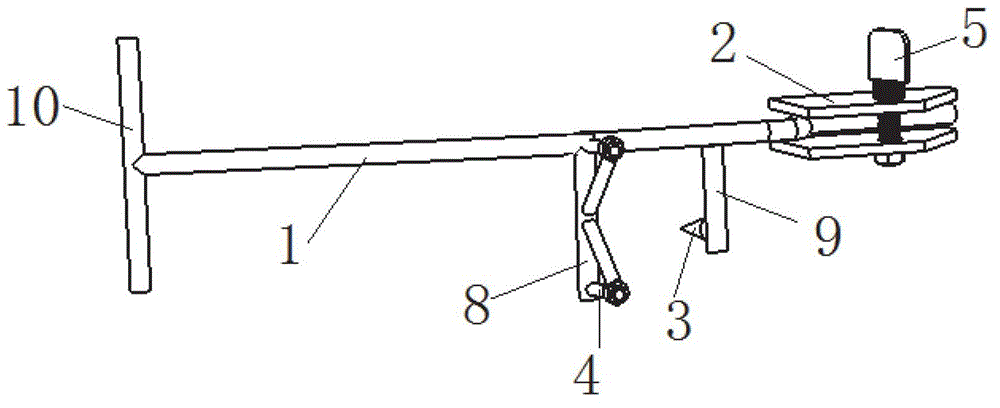

Universal auxiliary device for mounting of draw gear of rail vehicle

ActiveCN107434229AMeet production takt requirementsEasy to installLifting devicesRailway coupling accessoriesEngineeringMechanical engineering

The invention discloses a universal auxiliary device for mounting of a draw gear of a rail vehicle. The universal auxiliary device comprises a base, a draw gear traction rod supporting seat, a lead screw lifting device and a guiding rail moving device. The draw gear traction rod supporting seat can stably support a draw gear traction rod, and through a rotary shaft, the draw gear is still stably placed on a main body support while the draw gear traction rod can incline vertically. The lead screw lifting device is connected with the traction rod supporting seat, and the inclining angle of the draw gear traction rod can be adjusted by rotating a cross-shaped rod of the lower end of a lead screw. The guiding rail moving device is mounted on the base, the draw gear traction rod supporting seat is slidably connected with the guiding rail moving device, and the layout position of the draw gear traction rod supporting seat on the base can be adjusted so as to adapt to multi-structure draw gear mounting assistance and supporting. A lifting lug is used for lifting the device and placing the device to a lifting trolley for operation. Two circular holes are formed in the opposite corners of the base to be used for fixing the whole auxiliary device so as to prevent the device from toppling in the draw gear mounting process.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

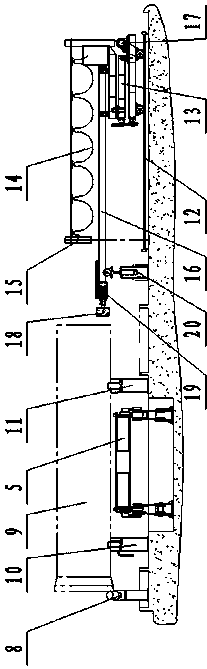

A three-dimensional detection system, online adjustment and adjustment system and method for carriage underframe

ActiveCN110793477BHigh-precision detectionCompact spaceUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansAutomotive engineeringReal-time computing

The invention discloses a three-dimensional detection system for a carriage underframe, an online adjustment system and a method. A detection gantry is provided with a three-dimensional detection and detection system in the area between the adjustment and correction system and the carriage underframe. The three-dimensional detection system includes a detection gantry and a gantry guide rail. , gantry walking device, detection device, center plate positioning device and console, the detection device is driven by the detection gantry and its accessories, so as to traverse the entire carriage chassis, and measure the external dimension characteristics of the carriage chassis by means of upper detection; The disk positioning device can not only realize the positioning of the center disk of the carriage chassis, but also detect the relevant characteristics of the center disk. The detection data is imported into the console, and the detection report is automatically generated by the console. Through the three-dimensional detection system of the carriage underframe, automatic and high-precision detection of the three-dimensional size of the carriage underframe can be carried out, and the results can be fed back to the adjustment and correction system in real time to guide the work of the adjustment and correction system.

Owner:CRRC YANGTZE CO LTD

Track plate defect online detection system and detection method based on three-dimensional laser scanning

PendingCN114384075ATakt impactMeet production takt requirementsOptically investigating flaws/contaminationUsing optical meansLaser scanningData acquisition

The invention discloses a track plate defect online detection system based on three-dimensional laser scanning, which comprises a data acquisition module, a data processing module, a man-machine interaction module and a signal input and output module, is applied to track plate defect detection after a demolding process, and overcomes the defects of low speed and low accuracy of traditional track plate defect detection. The invention further discloses a track plate defect detection method based on three-dimensional laser scanning, after the track plate is demolded, the track plate is conveyed by the trolley to enter a code spraying procedure, the trolley moves at a constant speed on a production line, and the non-contact line laser contour sensor is adopted to scan the surface of the track plate in the conveying process; each piece of collected point cloud data is accurately registered with a standard three-dimensional model of the track plate, so that the position of the defect is quickly judged and positioned; according to the method, the production takt of the track plate is not affected, the defect detection of the track plate is completed only in the two-process transmission process, and the method is accurate in detection and high in detection efficiency.

Owner:XIAN UNIV OF TECH

Stirring tank

ActiveCN111249942AAvoid failureReduce volumeTransportation and packagingRotary stirring mixersElectric machineryEngineering

The invention provides a stirring tank, and relates to the technical field of antiseptic treatment. The stirring tank comprises a tank body and a stirring assembly, and the stirring assembly comprisesa stirring bottom plate and a driving mechanism. The stirring bottom plate is rotationally connected to the inner wall of the tank body. The driving mechanism is arranged outside the tank body. The driving mechanism is in transmission connection with the stirring bottom plate, and the driving mechanism is configured to drive the stirring bottom plate to rotate. According to the invention, the technical problems as follows are at least relieved: the production takt of a whole production line can be influenced due to the fact that it takes a long time for a stirring trolley to walk from one endto the other end in a tank during preservative treatment according to an existing in-tank liquid stirring mode; a stirring motor, a walking motor and a walking chain are easily wrapped by preservative liquid to cause faults; and a stirring assembly is large in size and complex in structure.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Dial indicator switching device

PendingCN114001613ARealize Angle TransformationMeet production takt requirementsFeeler-pin gaugesEngineeringMechanical engineering

The invention discloses a dial indicator switching device which comprises a spindle connecting rod assembly, a switching rod assembly and a dial indicator connecting rod assembly. The spindle connecting rod assembly comprises a first connecting rod, a first connecting piece and a pressing piece, one end of the first connecting rod is connected with the first connecting piece, and the other end of the first connecting rod is used for being connected with an external boring machine. The pressing piece is rotatably connected to the top of the first connecting piece, and a first fixing hole is formed in the tail. The switching rod assembly comprises a second connecting rod, a second connecting piece and a switching connector, one end of the second connecting rod is clamped in the first fixing hole, and the other end of the second connecting rod is rotatably connected with the switching connector through the second connecting piece; a second fixing hole is formed in the switching connectorr close to the free end; the dial indicator connecting rod assembly comprises a third connecting rod, a third connecting piece and a dial indicator fixing piece, one end of the third connecting rod is clamped in the second fixing hole, and the other end of the third connecting rod is connected with the third connecting piece; and one surface of the third connecting piece, which is vertical to the surface connected with the third connecting rod, is rotatably connected with a dial indicator fixing piece. And the processing efficiency is improved.

Owner:SHANXI FENXI HEAVY IND

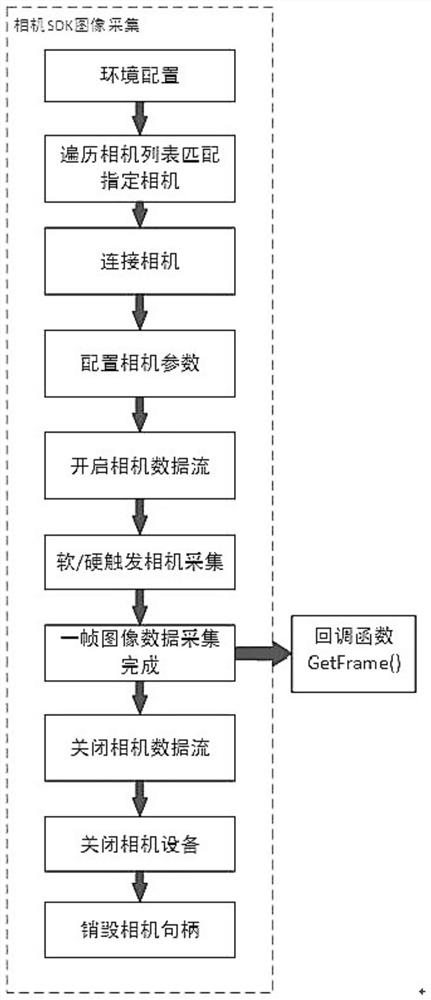

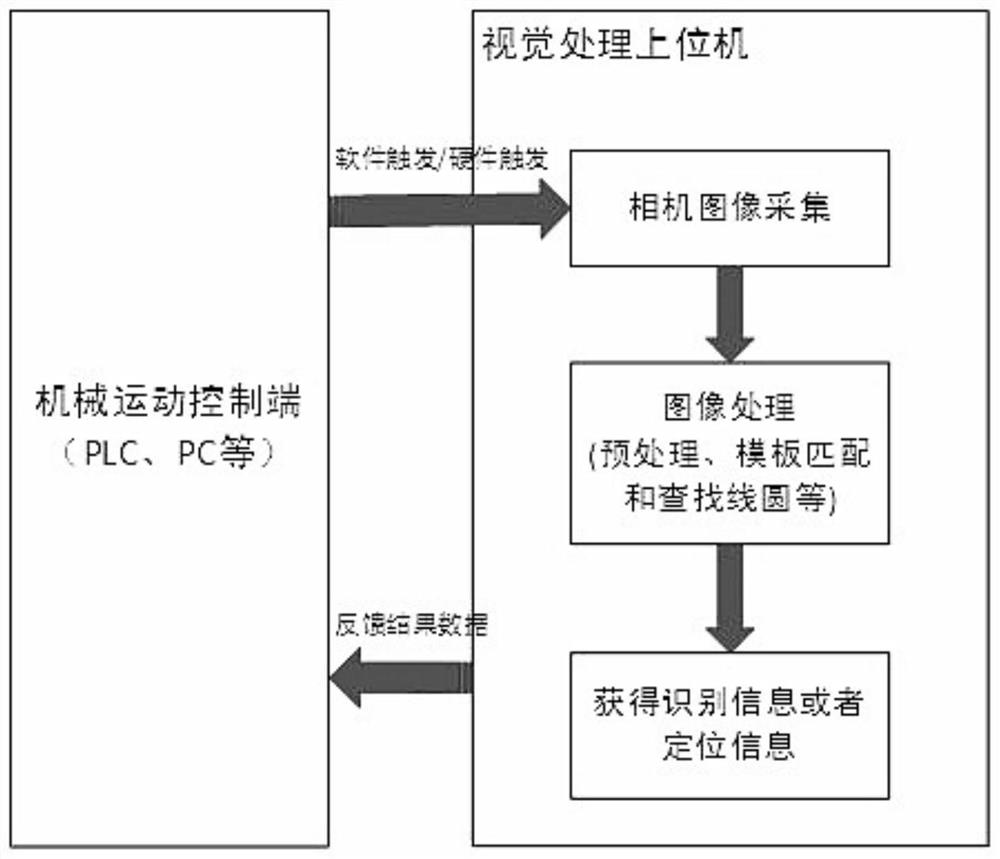

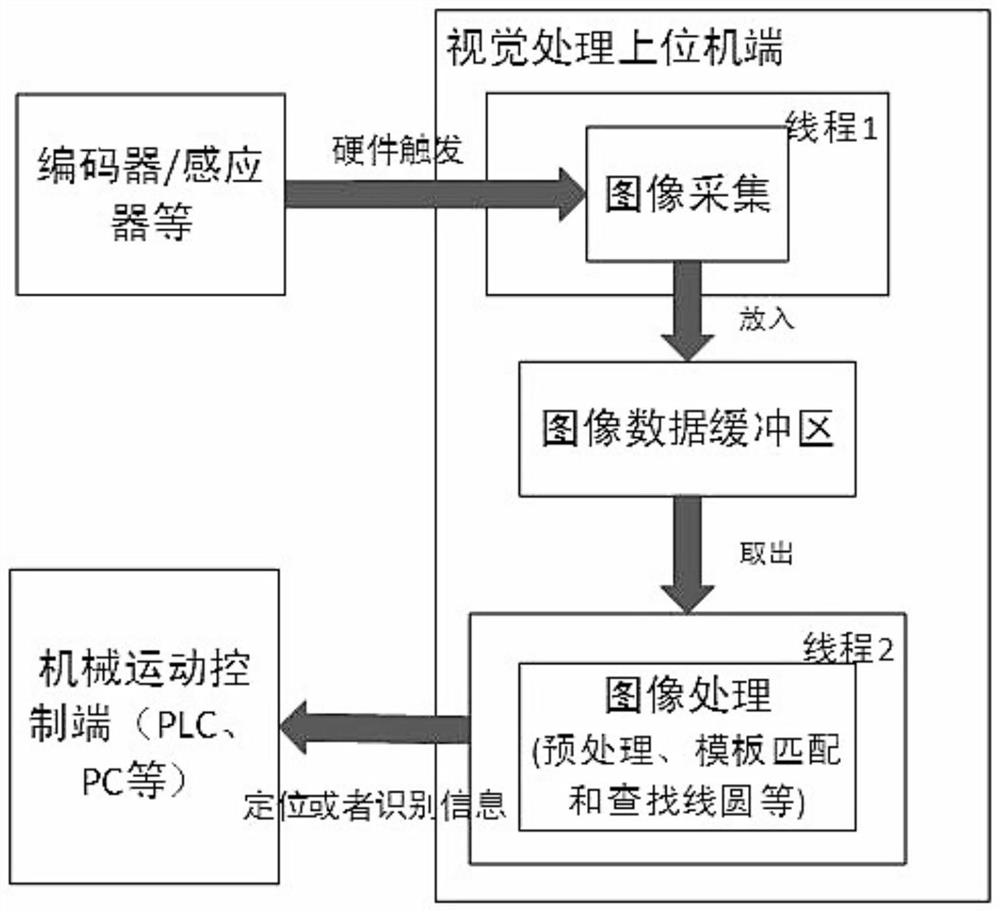

Image acquisition and processing method based on camera callback function and multi-thread technology

InactiveCN112468724AMeet Timing RequirementsMeet production takt requirementsTelevision system detailsResource allocationComputer hardwareImaging processing

The invention discloses an image acquisition and processing method based on a camera callback function and a multi-thread technology. The method comprises the following steps: (1) acquiring image data; (2) opening up a thread pool; (3) synchronizing an image processing result. According to the image acquisition and processing method based on the camera callback function and the multi-thread technology, the situation that the image processing time is far longer than the image acquisition time can be dealt with, the acquired image can be processed in time while frame loss is avoided, and therefore the time sequence requirement of equipment can be better met; the method has certain advantages in batch and continuous detection, that is, the hardware performance can be fully utilized, so that the image acquisition and processing process can better meet the requirement of production takt.

Owner:SHANGHAI SKEQI AUTOMATION ENG CO LTD

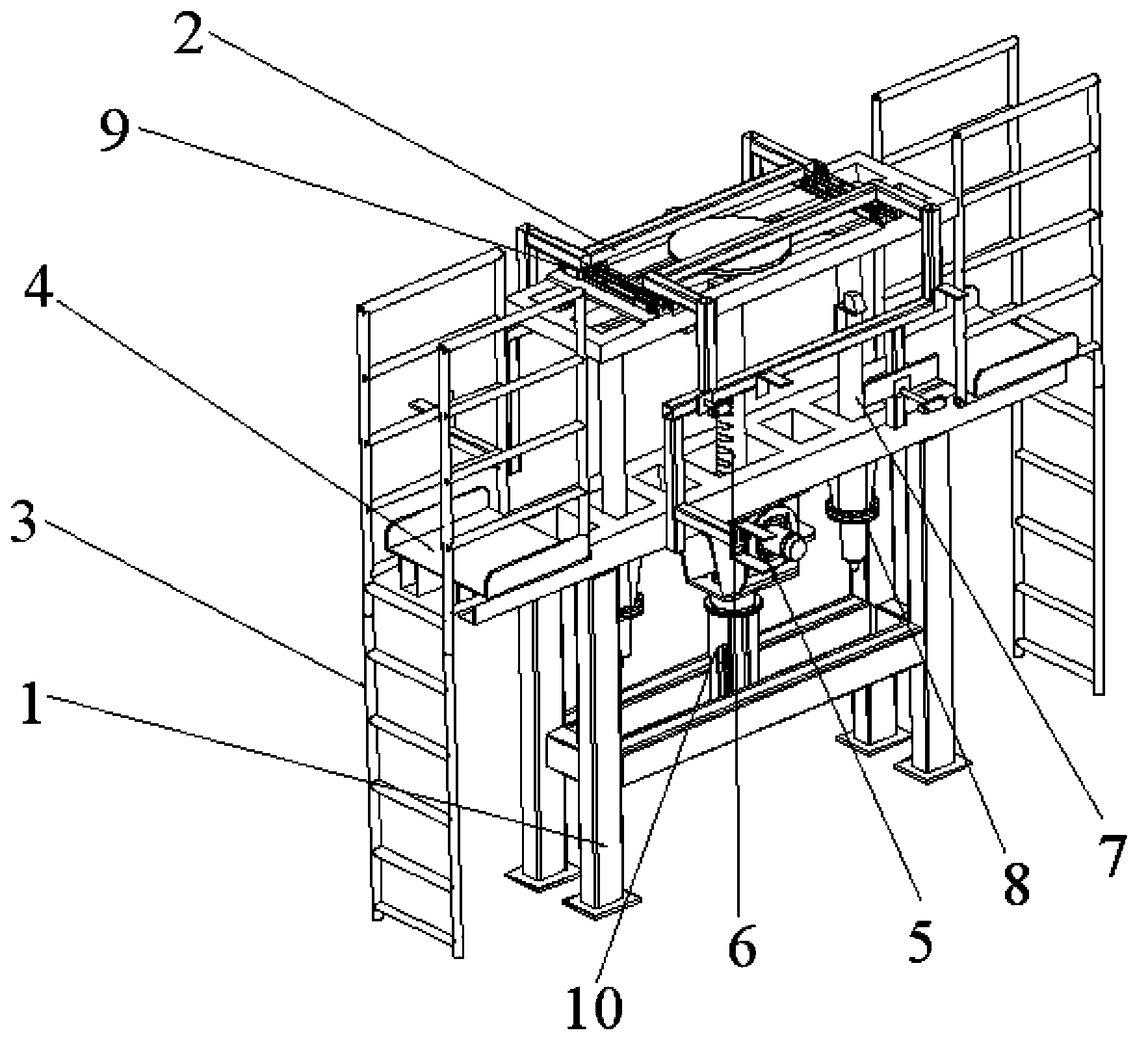

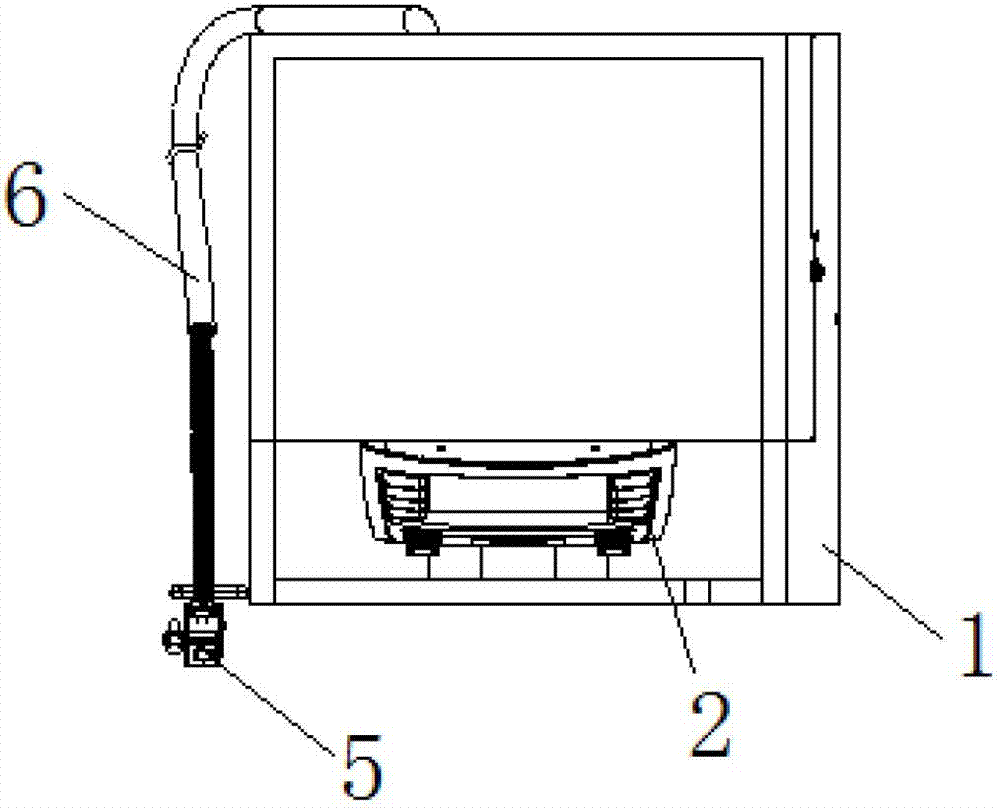

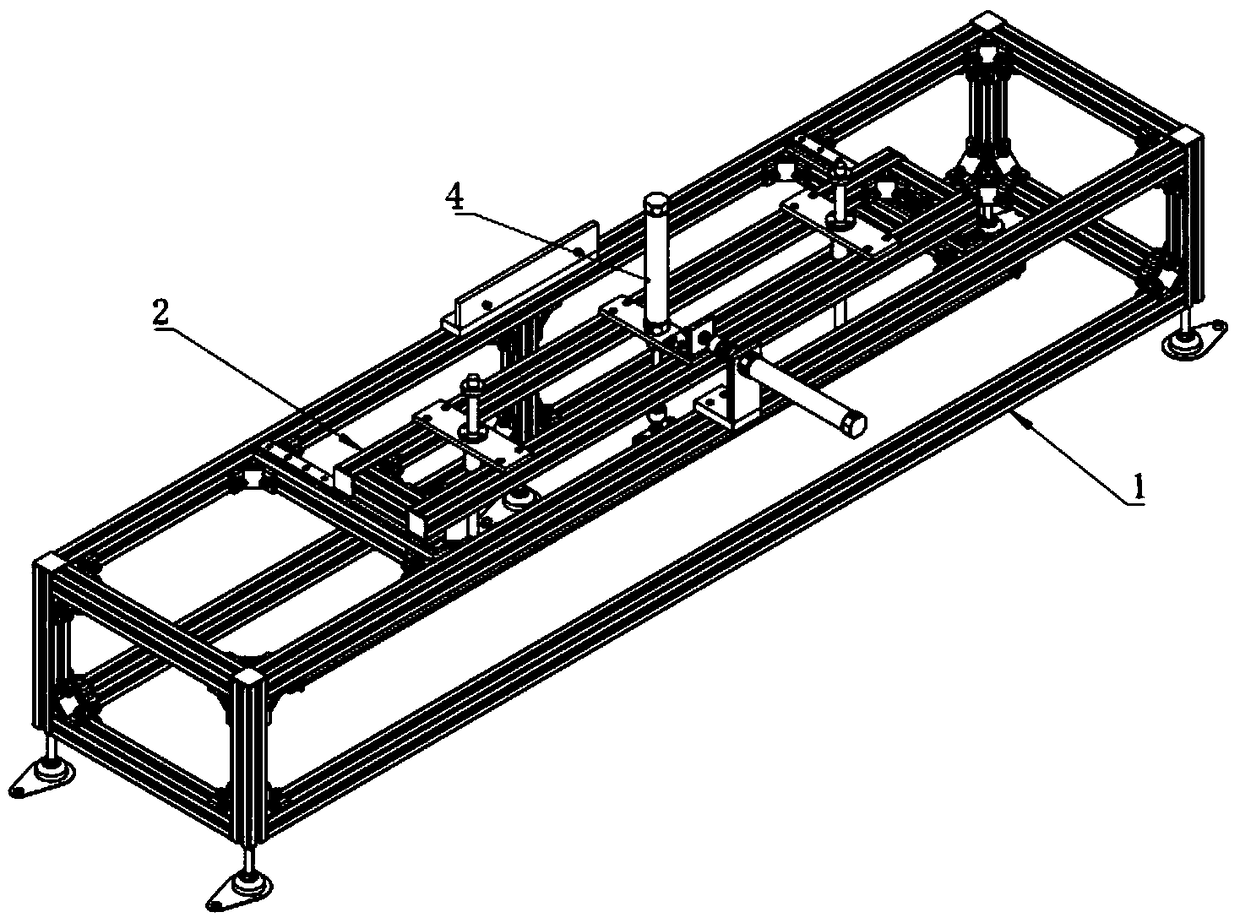

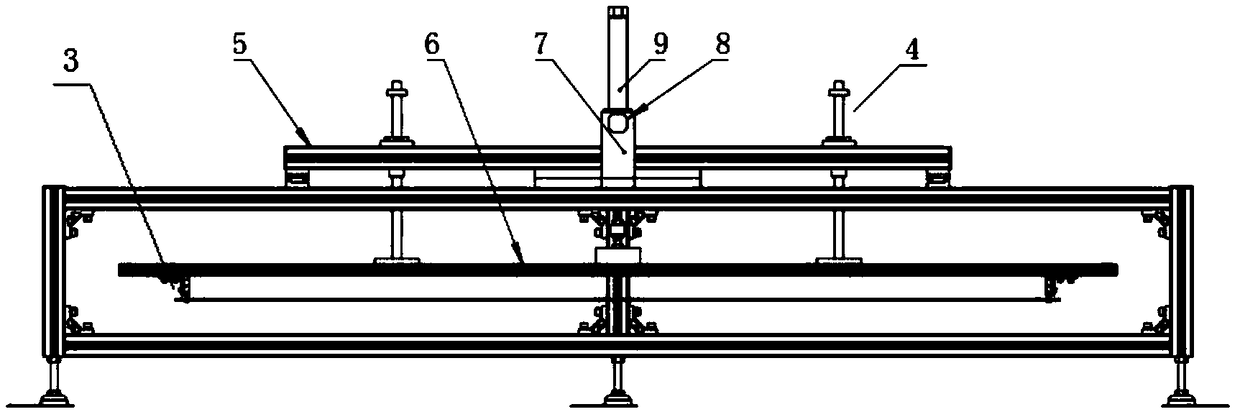

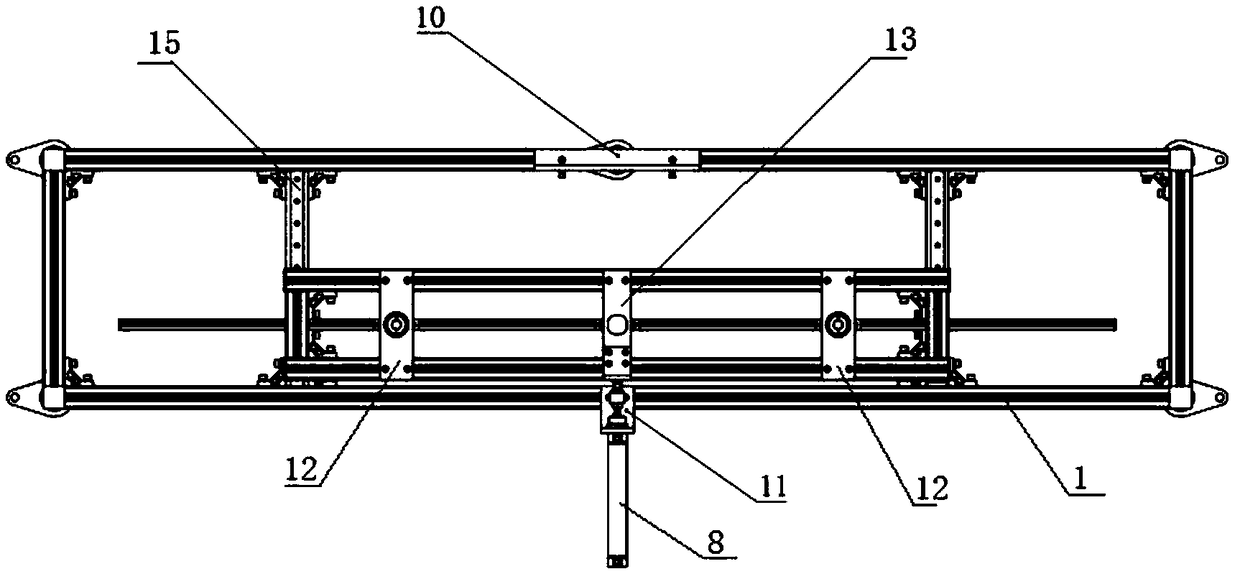

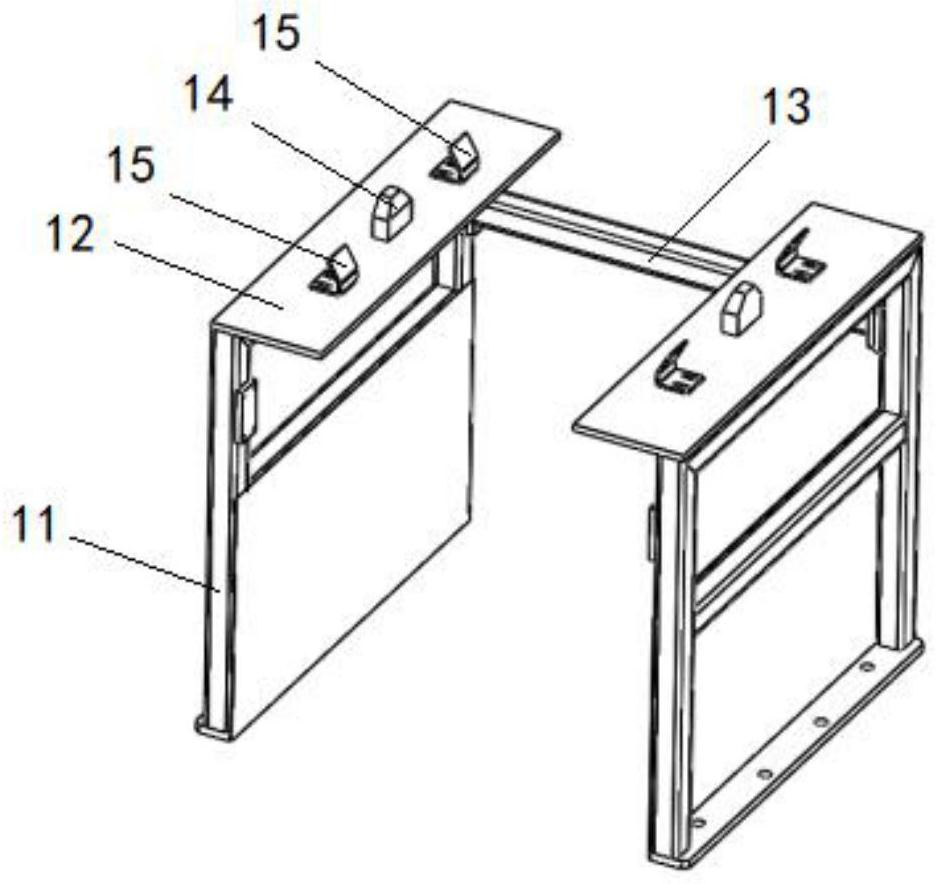

Feeding device of electric monorail transportation system for automobile factory

The invention relates to a feeding device of an electric monorail transportation system for an automobile factory. The feeding device comprises a base body, a motor, a gear, a power connection rod, a guide connection rod, a cylinder and a linear guide rail, wherein the base body is a welding framework; the bottom of the base body is connected with the ground, and the top of the base body is provided with a movable platform; a maintenance platform and a maintenance climbing ladder are arranged on two sides of the base body; the power connection rod is arranged on the middle part of the base body; the upper part of the power connection rod is connected with the movable platform; the movable platform is driven to lift due to the lifting motion; the motor and the gear are connected with the power connection rod so as to drive the power connection rod to lift; the guide connection rod is parallel to the power connection rod; the guide connection rod carries the movable platform; the cylinder and the linear guide rail are arranged on the movable platform and control the switch on and the switch off of the movable platform. Compared with the prior art, the feeding device has the advantages of wide application range, safety, reliability, high efficiency, low cost and the like.

Owner:SHANGHAI DEMEIKE AUTOMOBILE EQUIP MFG

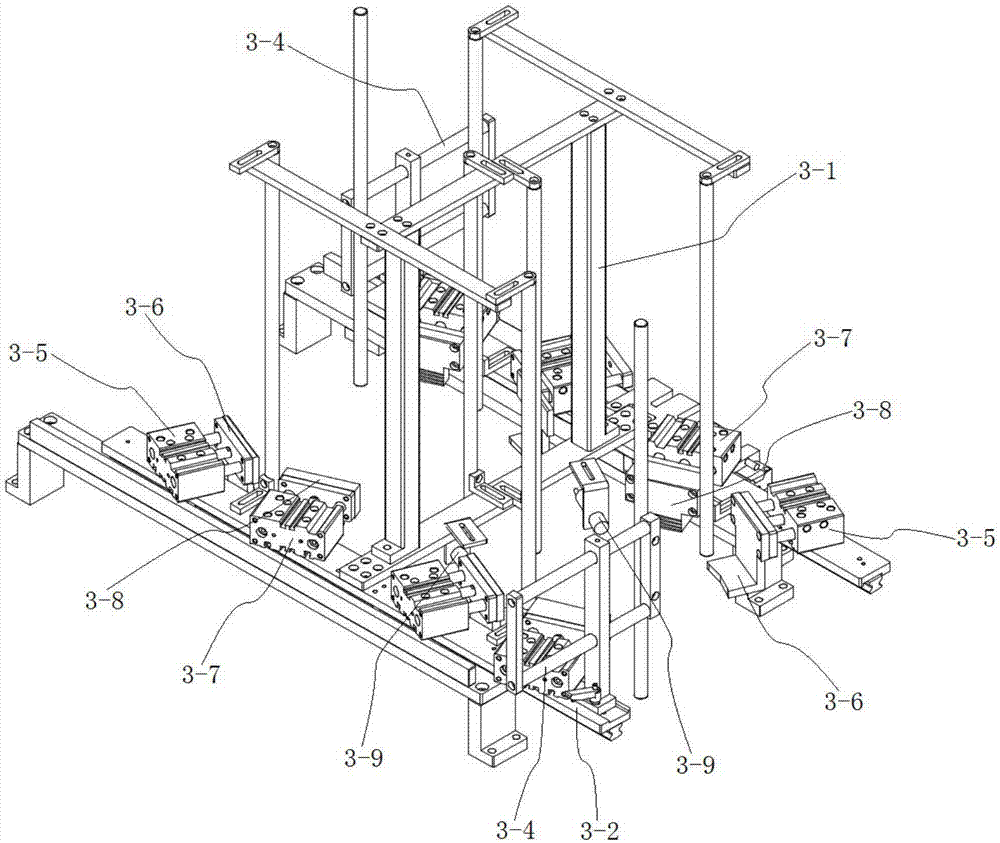

Flexible positioning tool unit for railway vehicle

PendingCN112719757AShort cycleMeet different positioning needsWelding/cutting auxillary devicesAuxillary welding devicesBraced frameMechanical engineering

Owner:河北京车轨道交通车辆装备有限公司

Stirring pool

ActiveCN111249942BAvoid failureReduce volumeRotary stirring mixersTransportation and packagingElectric machineryProcess engineering

The invention provides a stirring pool, which relates to the technical field of anti-corrosion treatment, and includes a pool body and a stirring assembly, the stirring assembly includes a stirring bottom plate and a driving mechanism; the stirring bottom plate is rotatably connected to the inner wall of the pool body; the driving mechanism is arranged outside the pool body; The driving mechanism is connected to the stirring bottom plate by transmission, and the driving mechanism is configured to be able to drive the stirring bottom plate to rotate. The present invention at least alleviates the need for a long time for the stirring trolley in the existing liquid stirring method in the pool to walk from one end of the pool to the other end during the anti-corrosion treatment. Affecting the production beat of the entire production line, stirring motors, traveling motors and walking chains are easily wrapped in anti-corrosion liquid and cause failure, and the technical problems of bulky and complex structure of stirring components.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Simulation single-phase electric energy meter for full detection compatible with narrowband module and HPLC module

InactiveCN110927445AFlexible configurationImprove test efficiencyPower distribution line transmissionElectrical measurementsLow voltageCarrier signal

The invention relates to a simulation single-phase electric energy meter for full detection compatible with a narrowband module and an HPLC module. The electric energy meter is characterized in that the electric energy meter comprises an electric energy meter body and a tool test board installed in the electric energy meter body, the tool test board is provided with a carrier module test interface, and the electric energy meter body is connected with a tested carrier module through the carrier module test interface. According to the invention, a plurality of carrier modules can be put in for testing at one time, the low-voltage power line carrier modules can be tested quickly and accurately, the requirement of production takt is met, the fatigue strength of workers is reduced, the production efficiency is improved, the one-time assembly first pass yield is improved, and the production efficiency is improved.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

A detection tool for automobile front shock absorber

ActiveCN102829683BSimple structureEasy to operateMechanical measuring arrangementsEngineeringUltimate tensile strength

The invention aims at providing a detection tool for a front shock absorber of a vehicle, which is used for detecting a front shock absorber to reduce labor intensity of staff, improving working efficiency and guaranteeing normal production. The detection tool for the front shock absorber of a vehicle comprises a base, a detection plate and a positioning column, wherein the detection plate is arranged on the base in a sliding way; the positioning column is fixed on the base; a through hole is formed in the center of the detection plate; detection holes adapted to a stud at the end part of the front shock absorber to be detected are formed at the periphery of the through hole; a positioning groove adapted to the positioning support of the front shock absorber to be detected is formed at the front end of the positioning column; the opening of the positioning groove is upward, and a through positioning hole is formed in the wall of the positioning groove; and a positioning pin is arranged in the positioning hole. The detection tool for the front shock absorber of a vehicle is simple in structure and convenient to operate, so that the labor force of staff can be reduced, the requirement for production process can be fulfilled, and normal production can be guaranteed.

Owner:CHERY AUTOMOBILE CO LTD

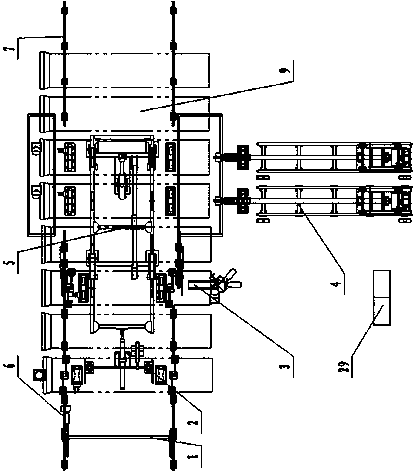

Grinding unit for cement lining of cast tube

InactiveCN107775501AEasy to useAutomated program highGrinding machinesGrinding feedersManufacturing technologyElectronic control system

The invention discloses a cast pipe cement lining grinding unit, which belongs to the technical field of ductile iron pipe production and its production equipment manufacturing, and in particular relates to the cement lining grinding of ductile iron pipes; the technical problem to be solved is to provide a cast pipe cement The liner grinding unit has high degree of automation, high production efficiency, and good product quality of processed ductile iron pipes; the technical scheme adopted is: the front rail frame and the rear rail frame are set on the same horizontal line and the front rail frame and the rear rail frame are set at the same level A cement lining grinding mechanism is installed between them, the end of the front track frame far away from the cement lining grinding mechanism is equipped with a stop mechanism, the other end of the front track frame is equipped with a chamfering mechanism, and the middle of the front track frame is installed with a centering The mechanism and the stepping conveyor are installed under the chamfering mechanism and the cement lining grinding mechanism, and the electric control system controls the operation of all mechanisms; the invention is used for chamfering of ductile iron pipes and cement lining grinding.

Owner:QINGDAO RUNCHENG VEHICLE FITTINGS CO LTD

Servo turning machine

InactiveCN105964824BSmooth motionHigh rotation accuracyMetal-working feeding devicesPositioning devicesReducerRack and pinion

The invention relates to a turnover mechanism used in a production line, in particular to a servo turnover machine. The servo turnover machine comprises an installation table, a motor, a speed reducer, an air cylinder, a pinion, a big gear, a base, a pressing plate gear I, a pressing plate gear II, a half-cylinder rack I and a half-cylinder rack II. The pinion is a straight gear, the big gear is a toothed crossed roller bearing, the base fixed to the crossed roller bearing is driven through the rotating and meshing motion of the straight gear and the toothed crossed roller bearing, and therefore plates can rotate. When the plates need to be turned over, the air cylinder extends out, the half-cylinder rack I fixedly connected to a telescopic shaft of the air cylinder is pulled, the pressing plate gear I meshing with the half-cylinder rack I does rotating and clamping motion, and therefore the plates to be turned over can be clamped. When a system detects that the plates are clamped, the motor is driven to rotate to the position where the plates are to be turned over, the system then controls the air cylinder to retract, the pressing plate gear I meshing with the half-cylinder rack I does rotating and opening motion, and therefore the plates can be turned over.

Owner:LIUZHOU GAOHUA TECH CO LTD

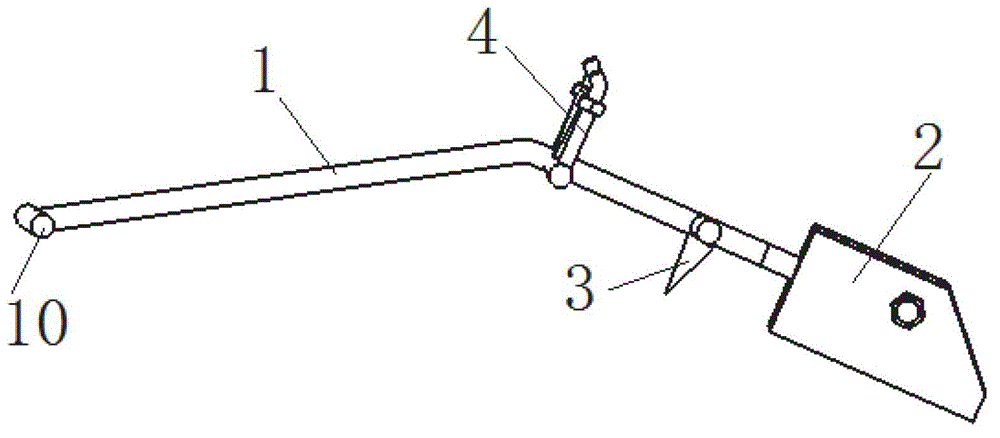

SUV (sports utility vehicle) front cover paint spraying aid and using method thereof

ActiveCN102861705BSimple structureEasy to operateLiquid surface applicatorsSpraying apparatusVertical planeEngineering

The invention discloses an SUV (sports utility vehicle) front cover paint spraying aid and a using method thereof. The paint spraying aid comprises a main strut, a positioning assembly, a clamp plate assembly and a small strut, wherein the positioning assembly is used for supporting a vehicle body front cover; the clamp plate assembly is hinged with a lock catch on the vehicle body front cover; the main strut is a rod which is bent downwards in a vertical plane; the positioning assembly, the small strut and the clamp plate assembly are sequentially fixedly connected to the main strut along the length direction of the main strut; and the small strut extends towards the lower part of the main strut and is used for being supported on a front crossbeam of a vehicle body. Compared with the prior art, the SUV front cover paint spraying aid has the advantages that the edge of the vehicle body front cover can be prevented from being damaged in a wet membrane state through the clamp plate assembly, the positioning assembly and the conical small strut, a phenomenon that lock holes of an inner plate of the vehicle body front cover are not sprayed by paint is eliminated, the appearance quality of a front cover paint membrane of the vehicle body in a finish paint coating process is guaranteed, and workers can conveniently spray paint on the inner surface of the front cover.

Owner:CHERY AUTOMOBILE CO LTD

Air conditioner back panel robot spot welding system

ActiveCN104874907BReduce labor intensityMeet production takt requirementsWelding monitoring devicesMetal working apparatusRobotic systemsProgrammable logic controller

The invention discloses a spot welding system of an air-conditioner backboard robot. The spot welding system comprises control equipment, a welding robot system, a tooling platform and an operating area, wherein the control equipment comprises a system PLC (Programmable Logic Controller) control cabinet and a touch screen connected with the system PLC control cabinet, and the touch screen is used for monitoring a system state; the welding robot system is connected with the system PLC control cabinet and comprises a robot body and an electrode holder arranged on the robot body; the tooling platform is connected with the system PLC control cabinet, and the robot body conveys the electrode holder to the tooling platform and performs spot welding to a work-piece on the tooling platform; the operating area comprises a guard fence and a safety door, the robot body and the electrode holder are both placed in the operating area, the system PLC control cabinet monitors the state of the safety door, the system PLC control cabinet stops the operation of the welding the robot system and the tooling platform after the safety door is opened. The spot welding system provided by the invention has the advantages that the system safety can be improved by implementing monitoring, control and commissioning to the spot welding system of the air-conditioner backboard robot, under the precondition of meeting the requirements of production takts.

Owner:SHANGHAI XINSHEN METALWORK

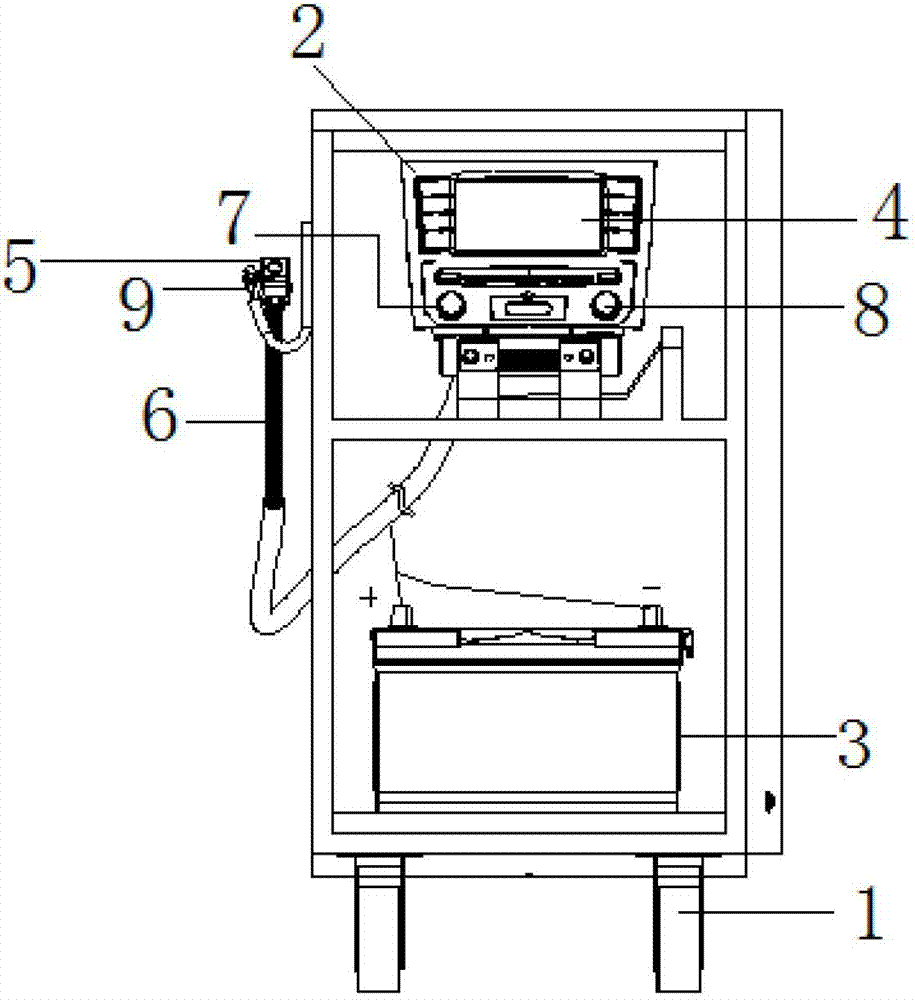

Device and method for detecting sheath of steering column of automobile

InactiveCN102730102AReduce labor intensityImprove satisfactionClosed circuit television systemsVehiclesSteering columnEngineering

The invention discloses a device and a method for detecting a sheath of a steering column of an automobile. The device comprises a bracket, wherein an image pickup system and a storage battery which is connected with the image pickup system are arranged on the bracket; the image pickup system comprises a camera for shooting the assembly condition of the sheath of the steering column of the automobile and an imaging system for displaying images shot by the camera on a display screen; the camera is connected with the imaging system by a detection handle; and a power supply switch for controlling switching-in and switching-off and an imaging switch are arranged below the display screen of the imaging system. The method for detecting the sheath of the steering column of the automobile is realized by utilizing the device for detecting the sheath of the steering column of the automobile, and comprises four steps. By the device and the method, the assembly condition of the sheath of the steering column of the automobile can be detected accurately, the assembly quality of the integral automobile is ensured, and the labor efficiency is high.

Owner:CHERY AUTOMOBILE CO LTD

Cast pipe cement lining grinding unit

ActiveCN103056734BEasy to useAutomated program highEdge grinding machinesRevolution surface grinding machinesManufacturing technologyElectronic control system

The invention provides a casting pipe cement lining grinding unit, belongs to the technical field of ductile iron pipe production and production devices of ductile iron pipes, and particularly relates to grinding of ductile iron pipe cement linings. The casting pipe cement lining grinding unit is high in automation degree and production efficiency and good in processed ductile iron pipe quality. The technical scheme is that a front track frame and a rear track frame are arranged on the same horizontal line, a cement lining grinding mechanism is installed between the front track frame and the rear track frame, a gear-stopping mechanism is installed at one end of the front track frame away from the cement lining grinding mechanism, a chamfering mechanism is installed at the other end of the front track frame, a centering mechanism is installed in the middle of the front track frame, a stepping conveyor is installed below the chamfering mechanism and the cement lining grinding mechanism, and an electronic control system controls operation of all mechanisms. The casting pipe cement lining grinding unit is applied to chamfering of the ductile iron pipes and grinding of the cement linings.

Owner:山西光华铸管有限公司

An automatic gluing machine

InactiveCN105597991BMeet production takt requirementsGuarantee the quality of gluingLiquid surface applicatorsCoatingsMechanical engineeringFixed angle

The invention relates to a glue spreader for an automobile control shaft assembly, and concretely relates to an automatic glue spreader with stations which can rotate according to a fixed angle for carrying out automatic gluing motions. The apparatus comprises a driving mechanism, a divider, a rotating mechanism, positioning tools, a planar right angle moving mechanism, a gluing gun, a safety protection frame and a working bench, wherein the driving mechanism and the divider are placed below a table top of the working bench, the driving mechanism and the divider are connected, and the divider and the rotating mechanism are connected; multiple rotating arms are arranged above the table top of the working bench, and a free end of each rotating arm is provided with a positioning tool; multiple positioning tools which are driven by the divider and the rotating mechanism rotate to a gluing station on the working bench in order according to requirements of production takt; the planar right angle moving mechanism is arranged above the table top of the working bench, and the gluing gun is driven by the planar right angle moving mechanism to move. The apparatus can satisfy working requirements of gluing accuracy and takt rate during control shaft assembly gluing work.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Automatic discharging device of venous infusion tube fitting assembly

InactiveCN109335647AAvoid secondary pollutionMeet production takt requirementsConveyor partsEngineeringMechanical engineering

The invention discloses an automatic discharging device of a venous infusion tube fitting assembly. The automatic discharging device comprises a transverse moving mechanism, a longitudinal moving mechanism, clamping jaw mechanisms and a rack; a guide rail mounting frame and guide rails are arranged on the rack, and a transverse moving air cylinder mounting seat is arranged on a front side frame ofthe rack; the transverse moving mechanism comprises a rectangular frame and an transverse moving air cylinder, and guide rail grooves are formed in the bottom faces of the left and right sides of therectangular frame; the transverse moving air cylinder is fixed to the transverse moving air cylinder mounting seat, and a jacking rod of the transverse moving air cylinder is connected with a longitudinal moving air cylinder mounting plate on the rectangular frame; a longitudinal moving air cylinder of the longitudinal moving mechanism is fixed to the longitudinal moving air cylinder mounting plate, and a jacking rod of the longitudinal moving air cylinder is connected with the middle of the upper surface of a longitudinal moving support; the lower ends of guiding columns are connected with the upper surface of the longitudinal moving support, and the guiding columns are symmetrically arranged on the two sides of the longitudinal moving air cylinder; and the clamping jaw mechanisms are arranged at the two ends of the lower surface of the longitudinal moving support, and used for grabbing assembled infusion tube workpieces. The production takt requirements are met, the working efficiency is high, manual operation is not needed, and secondary pollution to an infusion tube is avoided.

Owner:SHANGHAI UNIV

Sample transfer device for thick plate inspection and test

The invention discloses a thick plate test sample transfer device which comprises a turnover tray and a transfer frame, the transfer frame comprises two side plates and a cross beam, platforms are arranged on the side plates respectively, and each platform is provided with a limiting device; each turnover tray is provided with a set of roller positioning device; the roller positioning devices correspond to the limiting devices in position, so that when the roller positioning devices of the turnover trays are aligned with the limiting devices of the transfer frame to descend, the roller positioning devices fall into the limiting devices and are limited by the limiting devices to move horizontally, and therefore displacement of the turnover trays in the plane direction is limited. According to the device, the middle rotating disc is positioned through gravity, various tensile samples, bending samples, round tensile samples and impact samples meeting the thick plate inspection and test requirements can be met, the positioning mechanism is simple and accurate, efficient and low in cost, and the process that a grabbing robot places materials on a turnover tray and automatically takes the materials from the turnover tray is met; and high-efficiency transfer of thick plate test samples can be realized.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

Method of accurate control for removing filter-stick of high-speed filter-stick forming device

ActiveCN101396172BMeet production takt requirementsQuickly proposeTobacco smoke filtersLogic circuitsWaste productPulse number

The invention discloses a method for accurately controlling filter tip elimination for a high-speed filter tip forming machine. An FM352-5 high-speed Boolean processor is adopted to control the action of a ejecting valve; a PLC controls the operation of the high-speed filter tip forming machine, when needing to eliminate defective filter tips, the PLC outputs an elimination signal to the FM352-5 high-speed Boolean processor; the FM352-5 high-speed Boolean processor collects a pulse signal from a pulse coder, when an input end thereof receives the elimination signal from the PLC, the FM352-5 high-speed Boolean processor determines the position of the defective filter tips to be eliminated according to the output pulse number of the pulse coder, and opens and closes the eliminating valve ata set phase. The method can realize high speed elimination of waste products in the production course, ensures high quality of filter tips, and is applicable to high-speed filter tip forming machinesin the cigarette industry.

Owner:CHINA TOBACCO MACHINERY TECH CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com