Grinding unit for cement lining of cast tube

A technology of cement lining and cast pipe, applied in the direction of grinding machine parts, grinding machine, grinding feed movement, etc., can solve the problems of production efficiency and treatment effect, peeling and foaming, low degree of automation, etc. problems, to achieve the effect of meeting the production cycle requirements, improving the performance and working reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

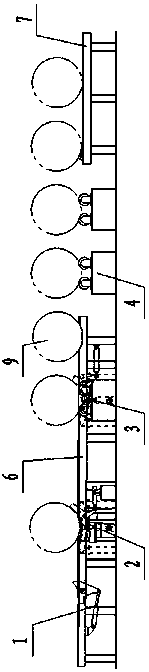

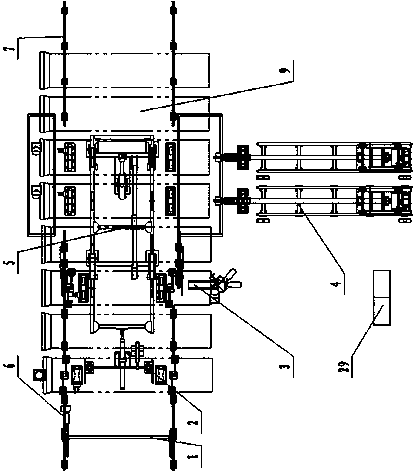

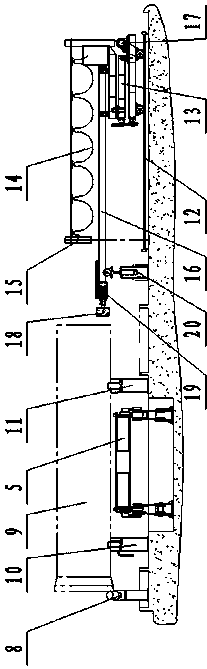

[0040] Such as figure 1 As shown in -9, a cast pipe cement lining grinding unit of the present invention includes a stop mechanism 1, a centering mechanism 2, a chamfering mechanism 3, a cement lining grinding mechanism 4, a stepping conveyor 5, and a front track Frame 6, rear rail frame 7 and electric control system 29, front rail frame 6 and rear rail frame 7 are arranged on the same horizontal line and cement lining grinding mechanism 4 is installed between front rail frame 6 and rear rail frame 7, front rail One end of the frame 6 away from the cement lining grinding mechanism 4 is equipped with a stop mechanism 1, the other end of the front track frame 6 is equipped with a chamfering mechanism 3, and the middle of the front track frame 6 is equipped with a centering mechanism 2, and the stepping conveyor 5 is installed below the chamfering mechanism 3 and the cement lining grinding mechanism 4, and the electric control system 29 controls the operation of all mechanisms. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com