High-adhesive one-component deoximation type room-temperature vulcanized silicone rubber sealant and preparation method thereof

A room temperature vulcanization, high-adhesion technology, applied in chemical instruments and methods, non-polymer adhesive additives, adhesives, etc. Adhesion and other problems, to meet the production cycle requirements, delay the surface curing speed, increase the effect of the bonding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

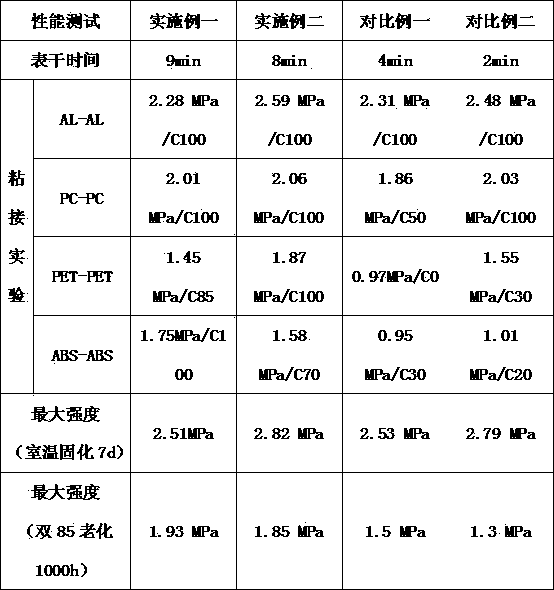

Examples

Embodiment 1

[0028] Example 1: Preparation of modified α, ω-dihydroxy polydimethylsiloxane

[0029] The method as described in CN 103044920A: 100 parts of 20000 mPa.s viscosity of α, ω-dihydroxypolydimethylsiloxane, 2 parts of vinyltrimethoxysilane are added to the planetary stirring tank, and the 2 In the atmosphere, add the reactant of dibutylamine and acetic acid as a catalyst for the capping reaction, stir the reaction at a certain temperature for 10-60min, and then remove the low boilers at 100°C and vacuum >-0.09MPa to obtain a modified α,ω-Dihydroxypolydimethylsiloxane.

Embodiment 2

[0031] According to implementation 1, 100 parts of modified α, ω-dihydroxy polydimethylsiloxane, 15 parts of dimethyl silicone oil with a viscosity of 500mpa.s, 80 parts of calcium carbonate, and 10 parts of fumed white carbon black were added to the kneading In the machine, start stirring and dispersing, dehydrate at 130°C~140°C, -0.09~-0.1MPa vacuum for 2~4 hours, then cool down to below 40°C. The above slurry is transferred to the planetary stirring tank, under N 2 Under protection, add 10 parts of vinyl tributylketoxime silane, 2 parts of γ-aminopropyltrimethylsilane, and 0.3 part of dibutyltin dilaurate, and stir under vacuum condition of -0.09~-0.1MPa until uniform and free of bubbles.

[0032] Example 2:

[0033] 100 parts of modified α, ω-dihydroxy polydimethylsiloxane prepared according to implementation 1, 15 parts of simethicone oil with a viscosity of 1000pa.s, 100 parts of calcium carbonate, and 8 parts of white carbon black were added to the kneader In the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com