Patents

Literature

122results about How to "High strength retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for pressure hydrothermal synthesis of MCM-41 mesoporous molecular sieve

InactiveCN1401568AThe synthesis method is simpleEasy to operateCrystalline aluminosilicate zeolitesHydrothermal synthesisNitrogen gas

A process for synthesizing the mesoporous molecular sieve MCM-41 includes mixing template agent with water and alkali catalyst, adding Si source, stirring to obtain mother liquid, feeding it in high-pressure reactor with teflon liner, filling nitrogen gas, heating, crystallizing, cooling, filtering, water washing, drying, heating, and calcining to remove template agent. The product has high stability.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Polyamide material and its preparing process

The invention discloses a polyamide material and making method, which comprises the following parts: 45-65% PA, 10-40% glass fiber, 2-10% compatible flexibilizer, 5-25% mineral fill, 0.2-2% antioxidant and 0.1-2% heat stabilizer. The making method comprises the following steps: weighing raw material; disposing the surface of glass fiber through gamma-amphotaethoxy silane; blending polyamide, compatible flexibilizer, heat stabilizer, anti-oxidant and mineral fill in the high-speed blender for 1-4min; placing glass fiber and mixed raw material in the double-screw squeezer to mix; fusing; squeezing; graining.

Owner:SHENZHEN KEJU NEW MATERIAL

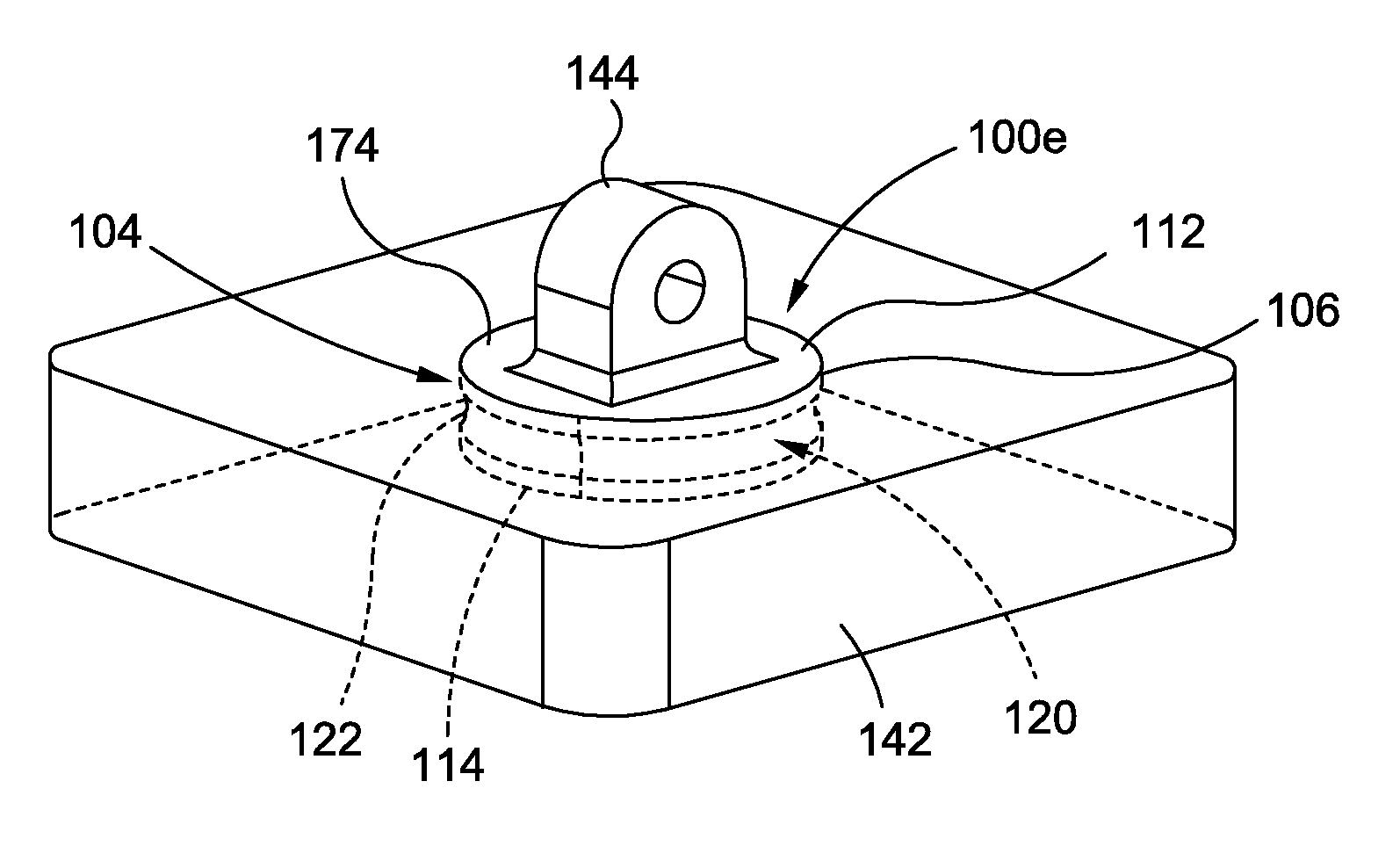

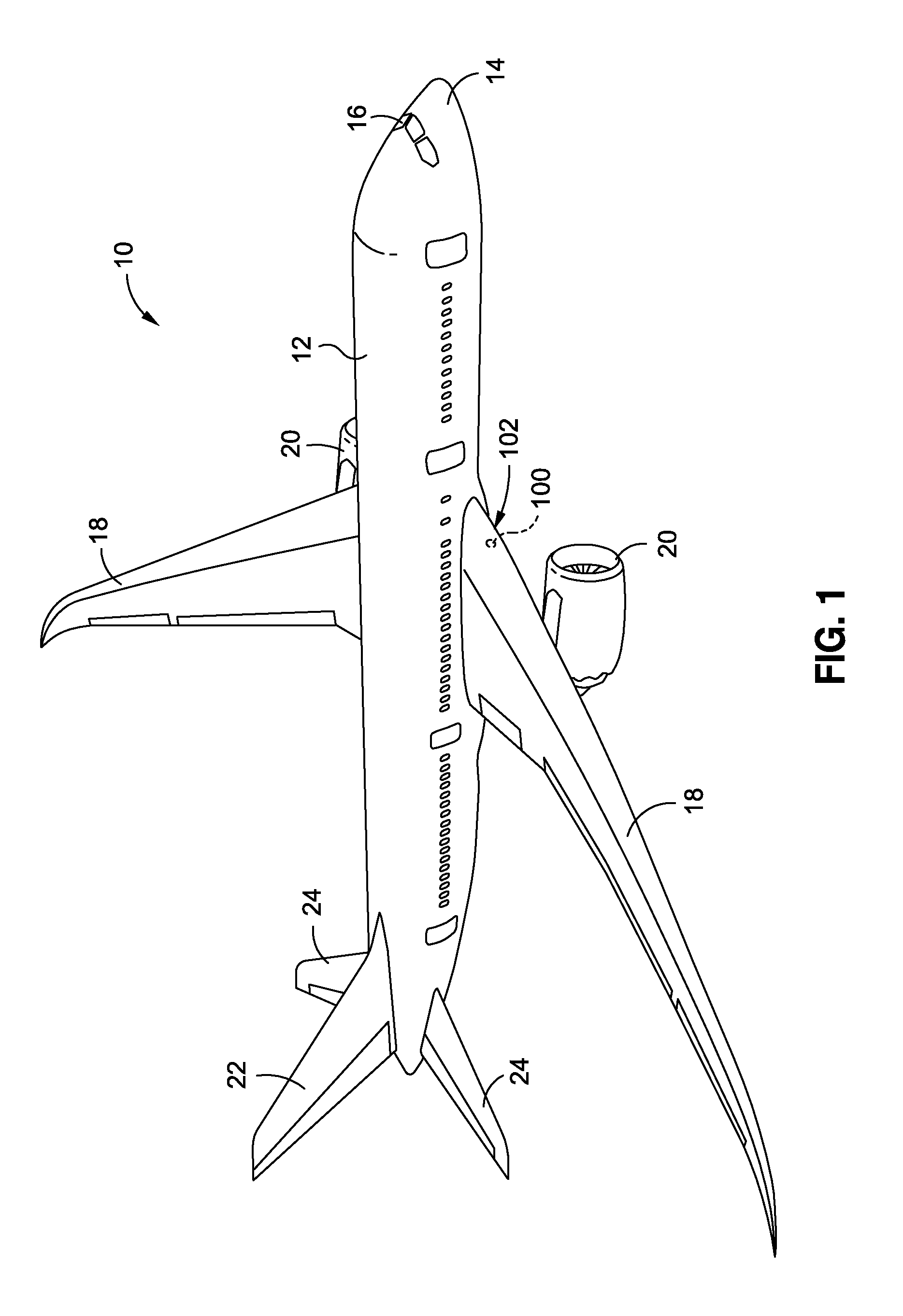

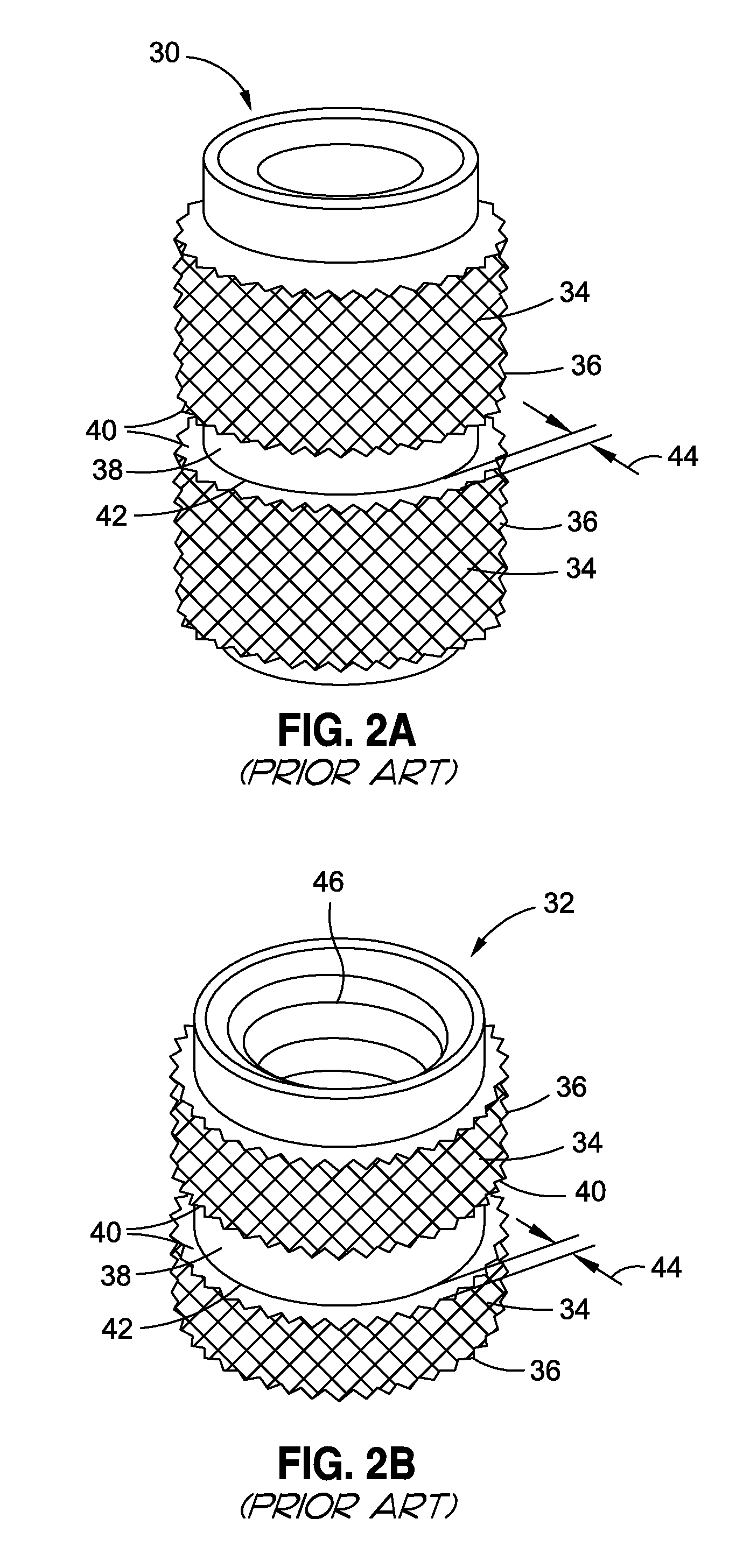

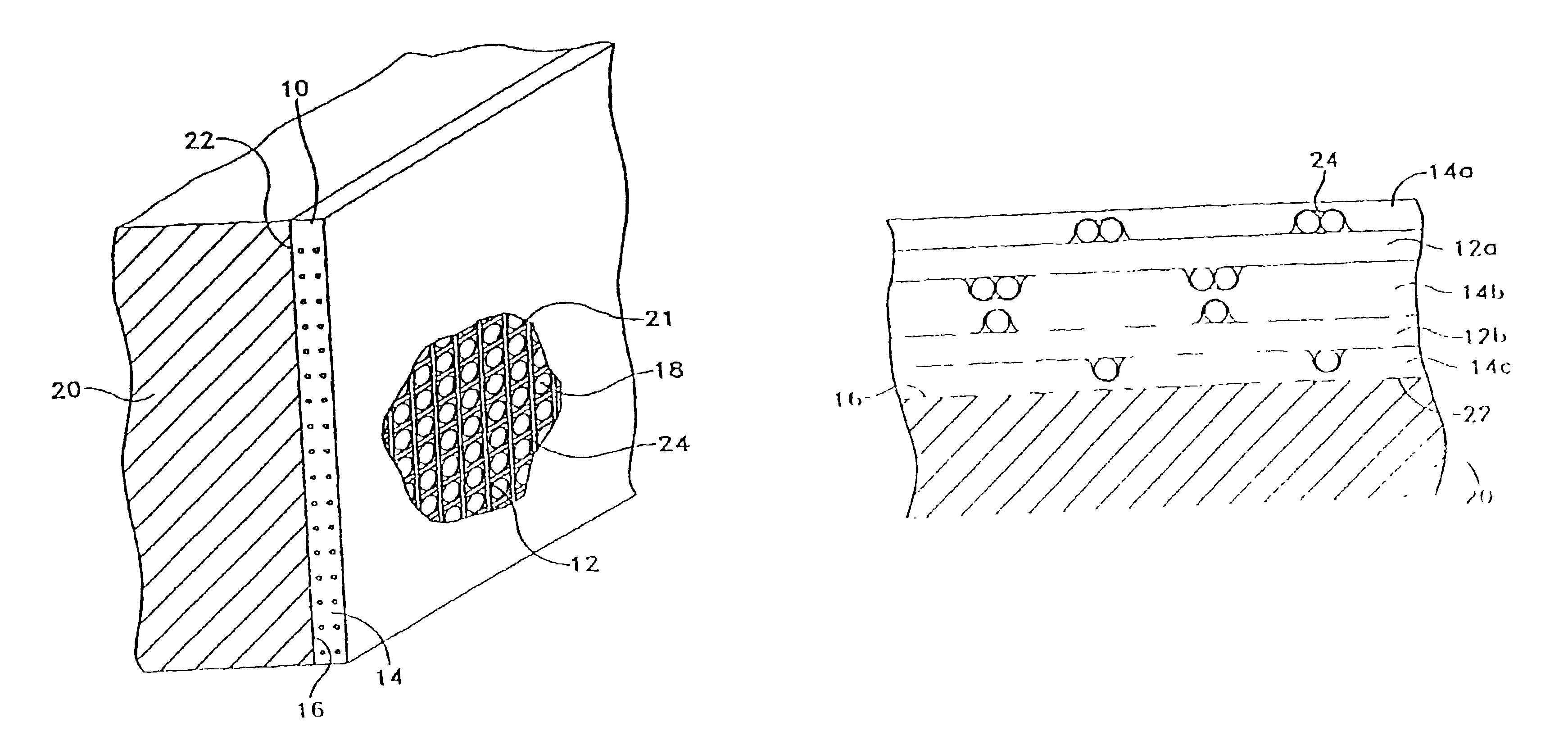

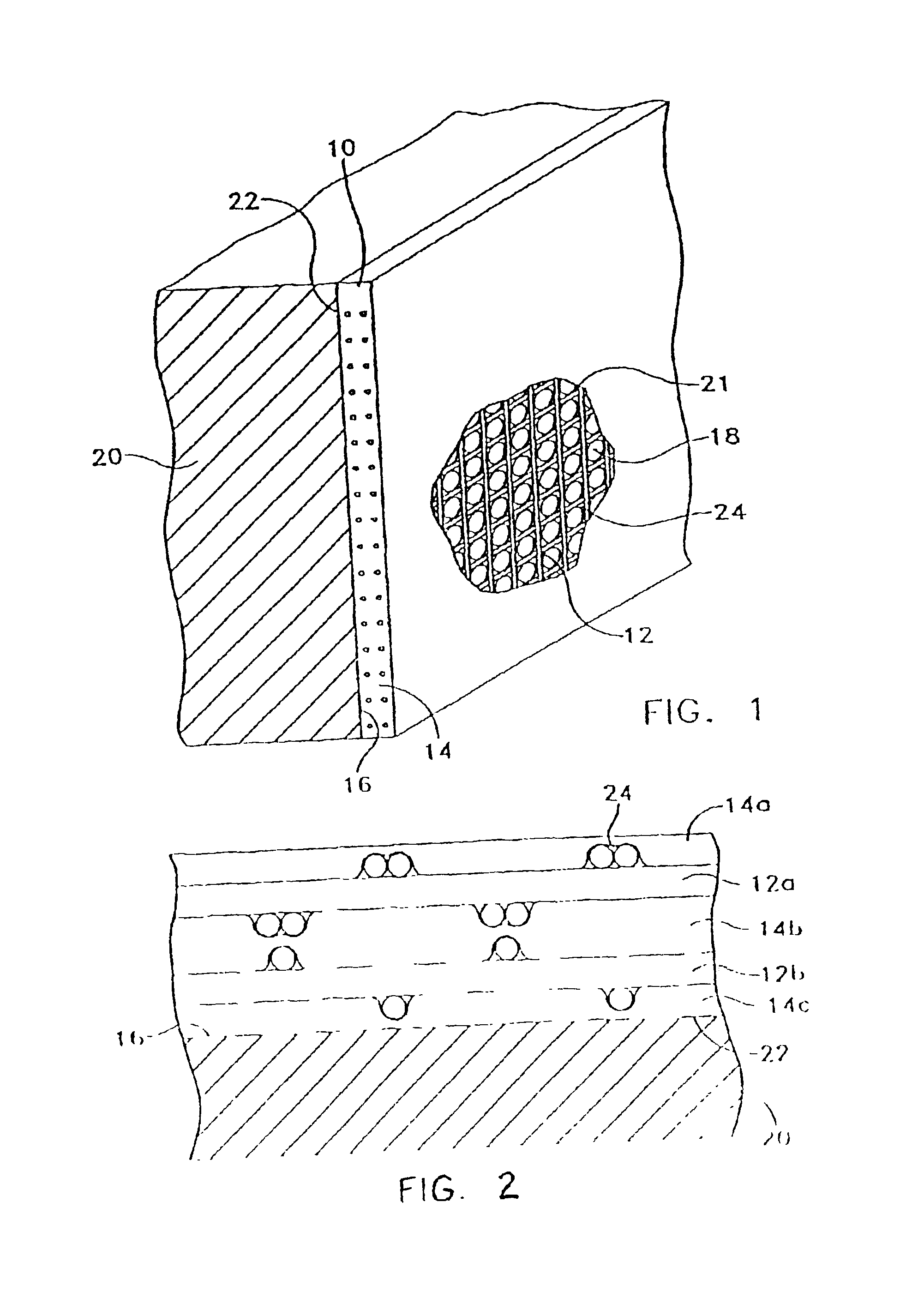

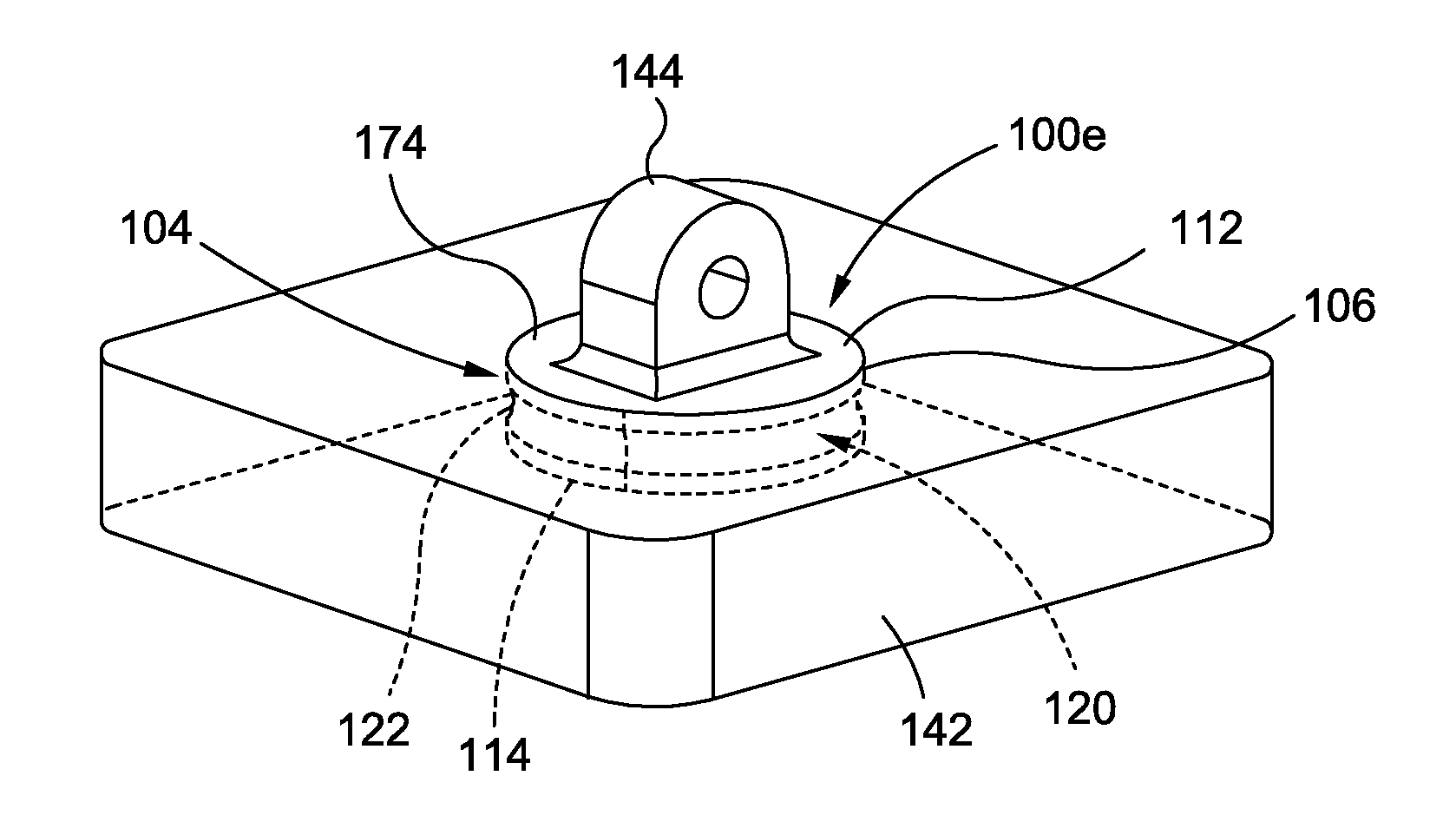

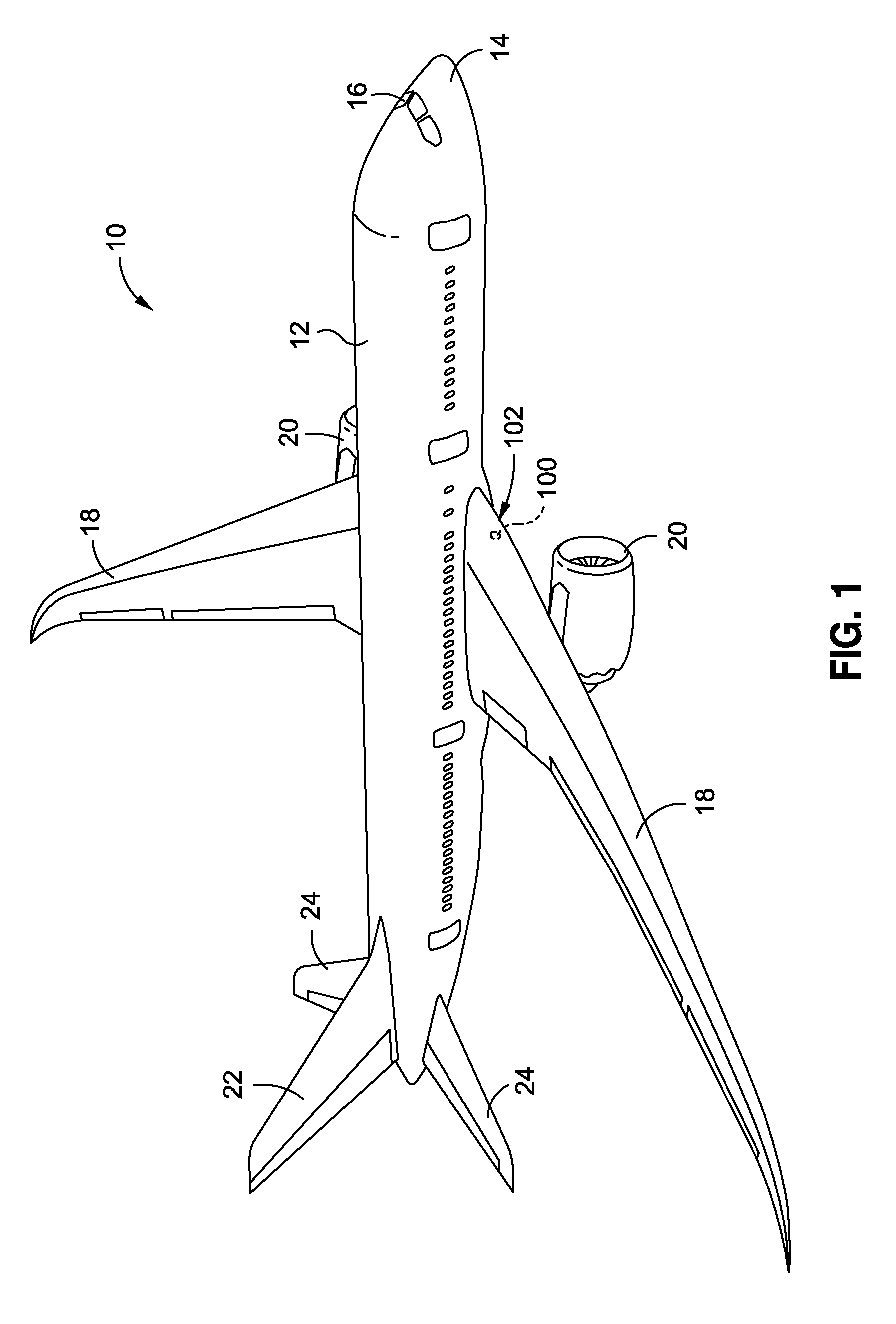

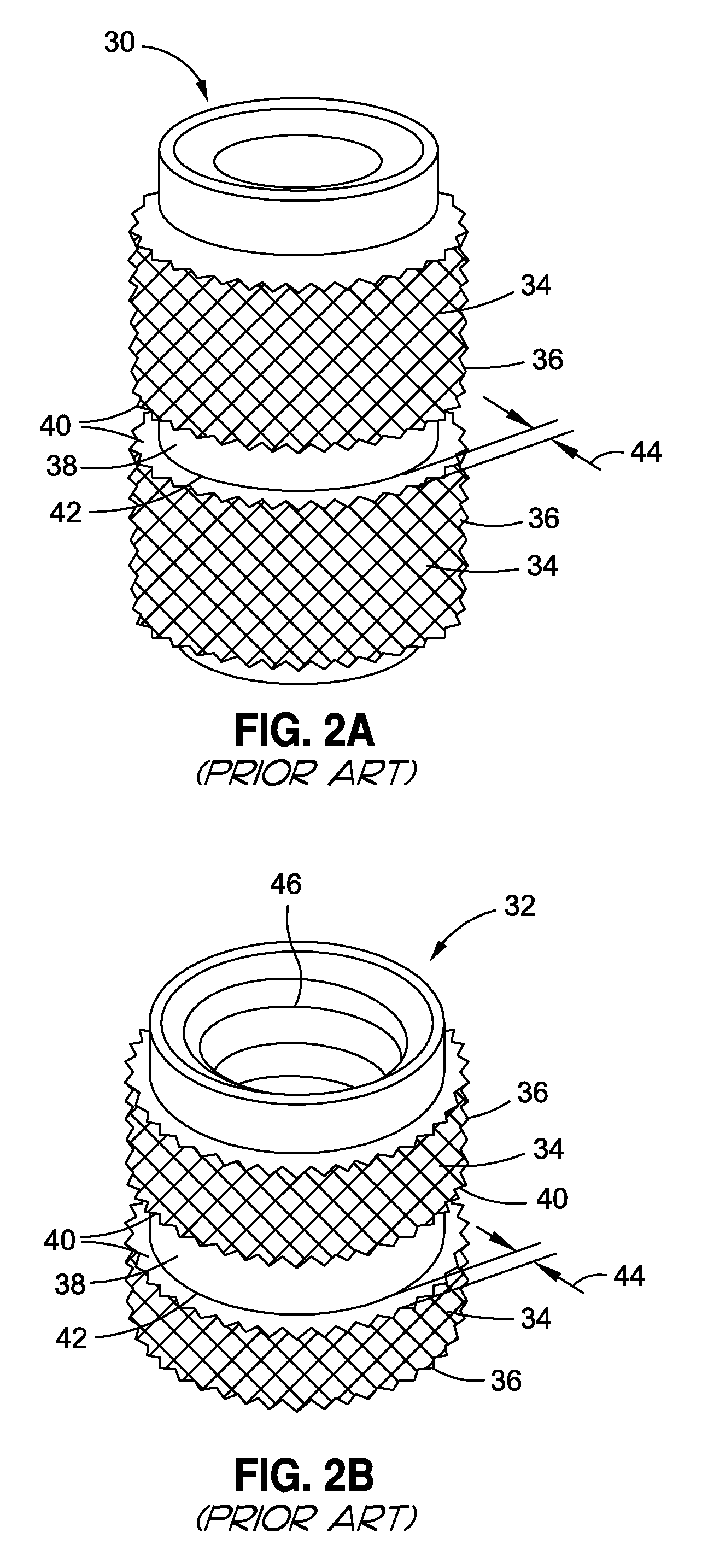

Molded-In Insert and Method for Fiber Reinforced Thermoplastic Composite Structure

ActiveUS20130022391A1High strength retentionMeet actual needsNutsSecuring devicesEngineeringThermoplastic composites

In an embodiment of the disclosure, there is provided a molded-in insert for high strength retention in a fiber reinforced thermoplastic composite structure. The insert has a cylindrical body and at least one circumferential groove formed in the cylindrical body, the groove having a substantially concave configuration, having a groove radius of 0.025 inch or greater, and having the groove radius greater than or equal to a groove depth.

Owner:THE BOEING CO

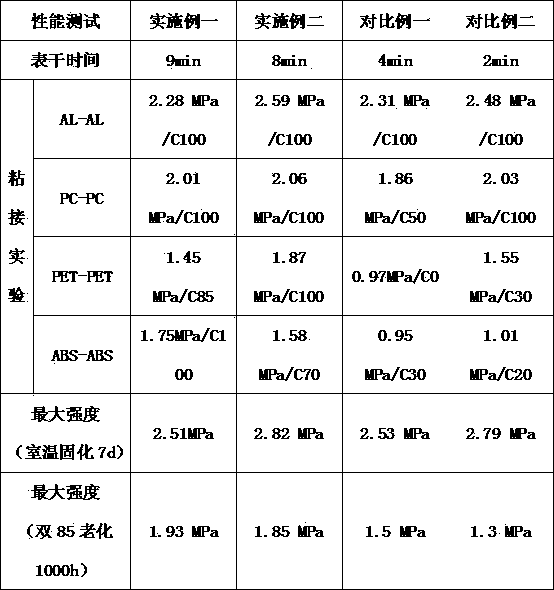

High-adhesive one-component deoximation type room-temperature vulcanized silicone rubber sealant and preparation method thereof

ActiveCN103937442ABalance activityBalance rateNon-macromolecular adhesive additivesOther chemical processesPolymer scienceVulcanization

The invention discloses a high-adhesive one-component deoximation type room-temperature vulcanized silicone rubber sealant comprising the following components from (A) to (F) in parts by weight: 100 parts of modified alpha, omega-dihydroxylpolydimethylsiloxane (A), 10-30 parts of dimethyl silicon oil (B), 7-12 parts of deketoxime crosslinking agent (C), 1-5 parts of silane coupling agent (D), 50-150 parts of reinforcing filler (E) and 0.1-1 part of catalyst (F). Compared with the traditional deoximation type sealant, the sealant has excellent adhesive property particularly for some substrates such as plastics, modified resin and the like which are difficultly adhered by using an organic silicon adhesive and can be widely applied to adhesion and sealing of industries such as electronics, automobiles, household appliances and the like. Modified polydimethylsiloxane is used as a basic polymer in deoximation type silicon rubber, so that the sealant has relatively proper surface drying time, provides more reasonable operation time and meets the production takt requirement under different working conditions; in addition, due to the adoption of the modified polydimethylsiloxane, the sealant has excellent waterproofness and is relatively high in strength retention rate under high temperature and high humidity conditions.

Owner:富乐(苏州)新材料有限公司

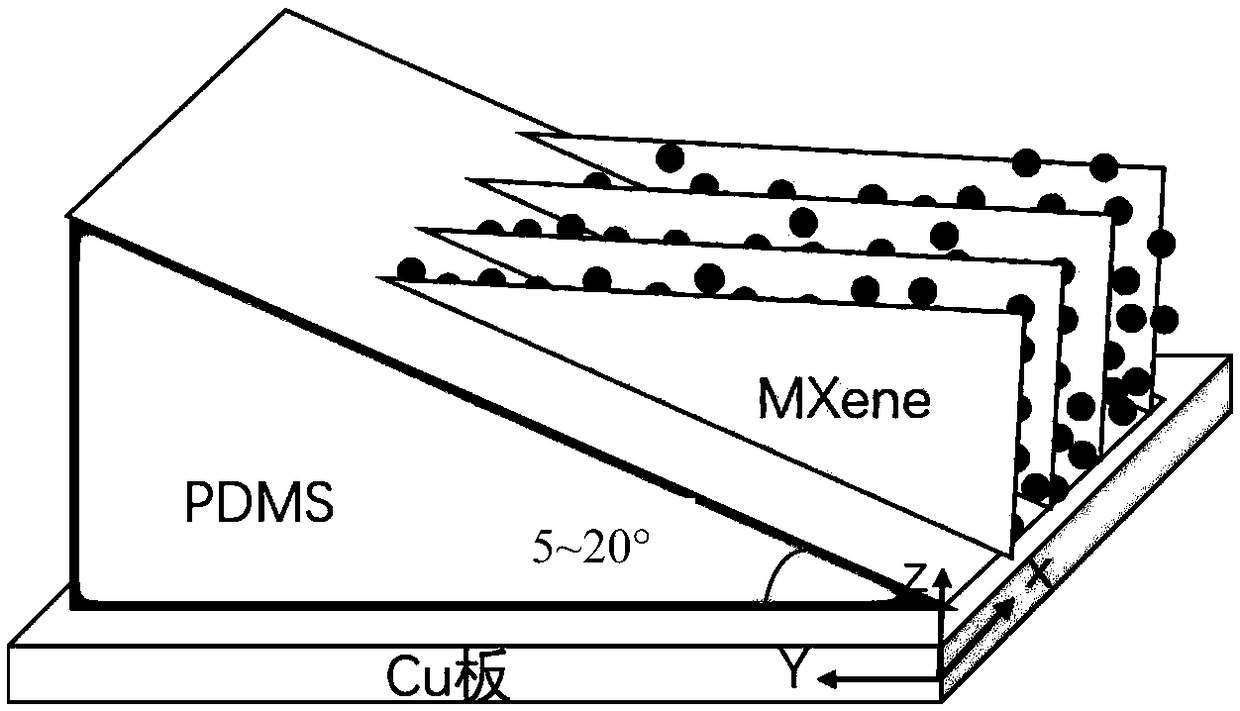

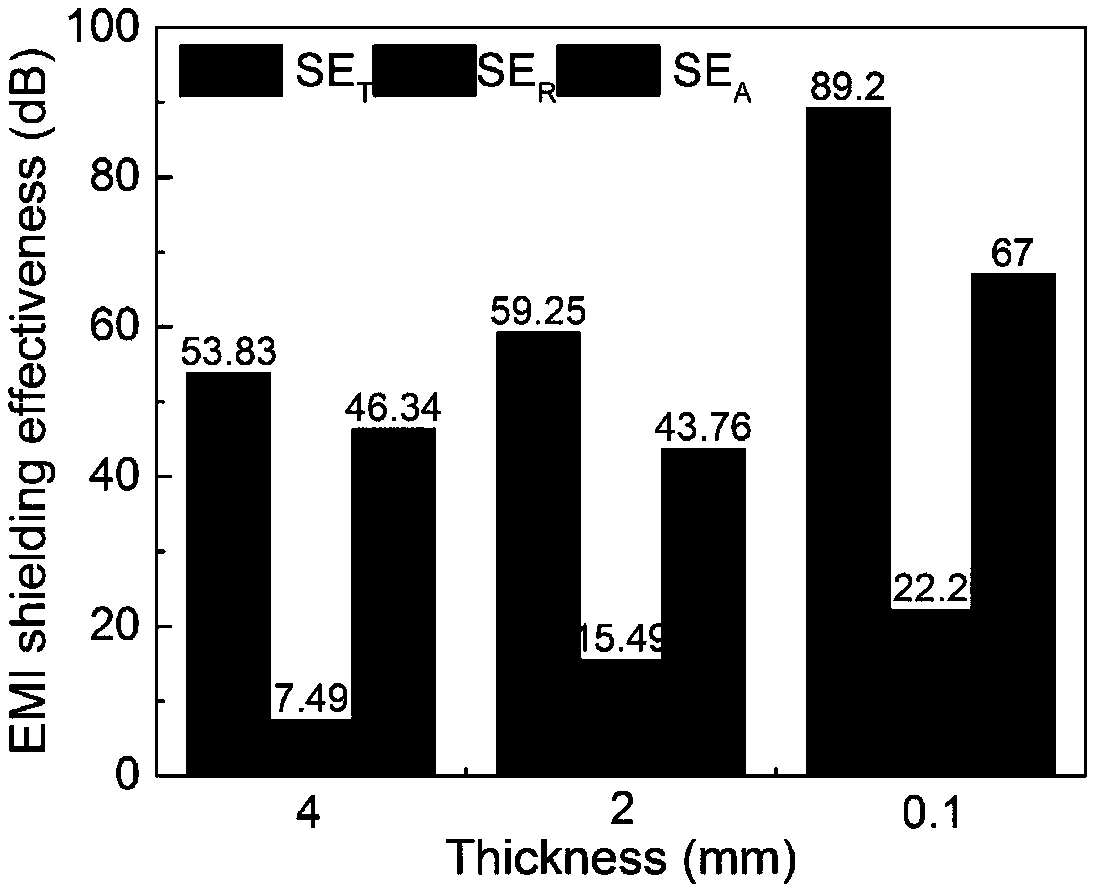

Three-dimensional layered MXene electromagnetic shielding foam and preparation method thereof

InactiveCN108811478AHigh mechanical strengthHigh electromagnetic shieldingMagnetic/electric field screeningEtchingElectromagnetic shielding

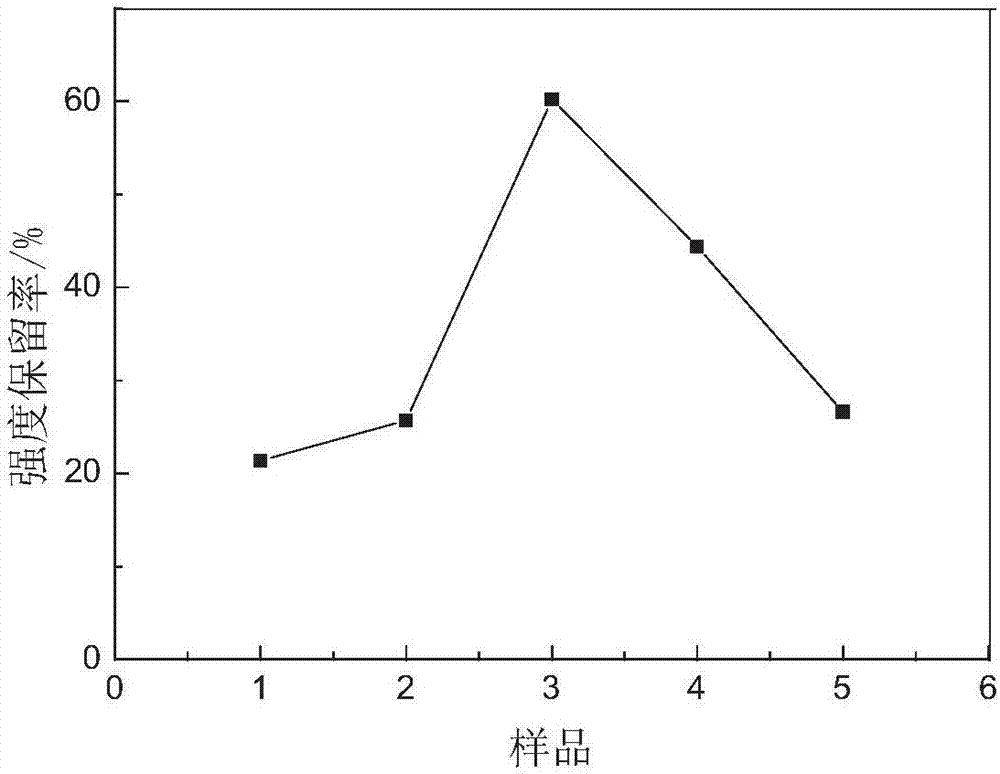

The invention relates to three-dimensional layered MXene electromagnetic shielding foam and a preparation method thereof and aims at solving the problems that an existing porous electromagnetic shielding material is low in absorbing and shielding effectiveness, poor in mechanical property and complicated in preparation process. According to the technical scheme, few-layer MXene dispersion liquid is prepared through wet chemical etching of an MAX phase; the dispersion liquid is directionally frozen through a bidirectional freezing process; and MXene aerogel is prepared through vacuum drying. The prepared MXene aerogel is of a layered structure, is long in range and ordered and has a good compression cycle characteristic, and the strength retention can reach over 60%. The total electromagnetic shielding effectiveness can reach 60-100dB; and the absorbing and shielding effectiveness can be adjusted through compressing the foam, so that the absorption-dominated electromagnetic shielding characteristic is achieved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

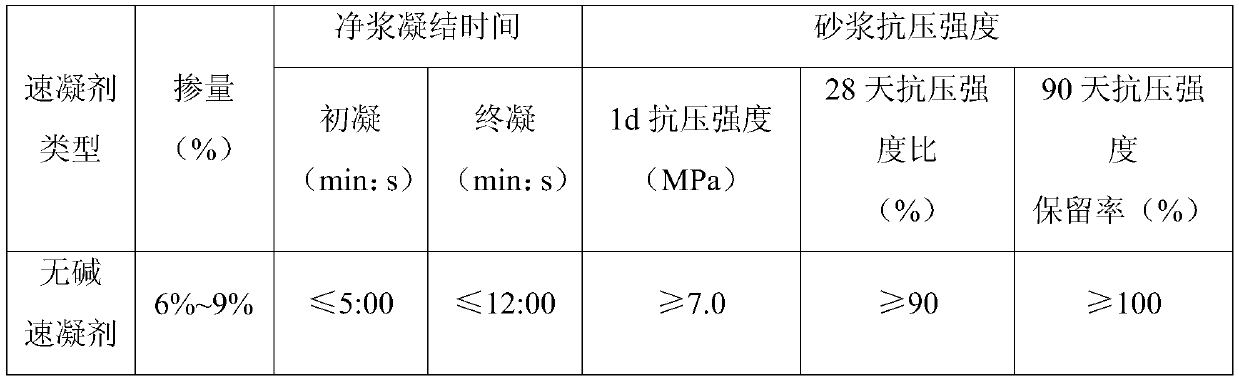

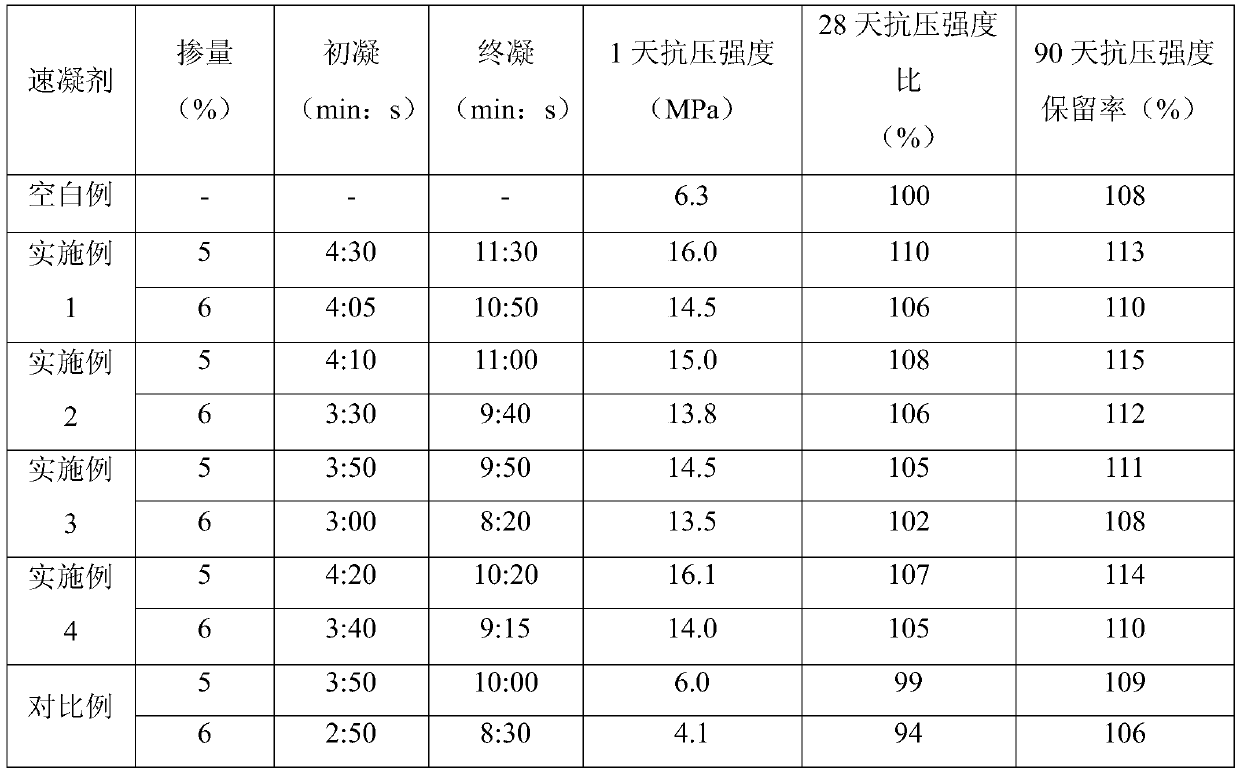

Low-dosage high-early-strength alkali-free liquid accelerator and preparation method thereof

The invention discloses a low-dosage high-early-strength alkali-free liquid accelerator and a preparation method thereof. The alkali-free liquid accelerator is prepared from the following raw materials: 1, an alkali-free liquid accelerator; 50%-60% of modified aluminum sulfate, 2%-4% of a fluorine-aluminum complex solution, 3%-6% of an organic cosolvent, 1%-2% of a pH regulator, 0.5%-1.5% of an inorganic stabilizer, 0.3%-0.5% of a viscosity regulator, 4%-6% of a composite early strength agent and the balance of water, wherein the sum of the mass percentages of the components is 100%. The invention also provides a preparation method of the alkali-free liquid accelerator. The preparation process of the alkali-free liquid accelerator is simple; hydrofluoric acid-free process, alkali-free, chlorine-free, rust-free steel bar, non-polluting environment. Meanwhile, when the mixing amount of the alkali-free liquid accelerator is 5%-6%, the technical requirements of GB / T35159-2017 on the alkali-free accelerator can be met, the one-day compressive strength is larger than or equal to 13.0 MPa, and the alkali-free liquid accelerator has the advantages of being low in mixing amount, good in stability, high in early strength and large in later strength retention rate.

Owner:刘翠芬

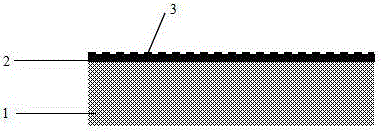

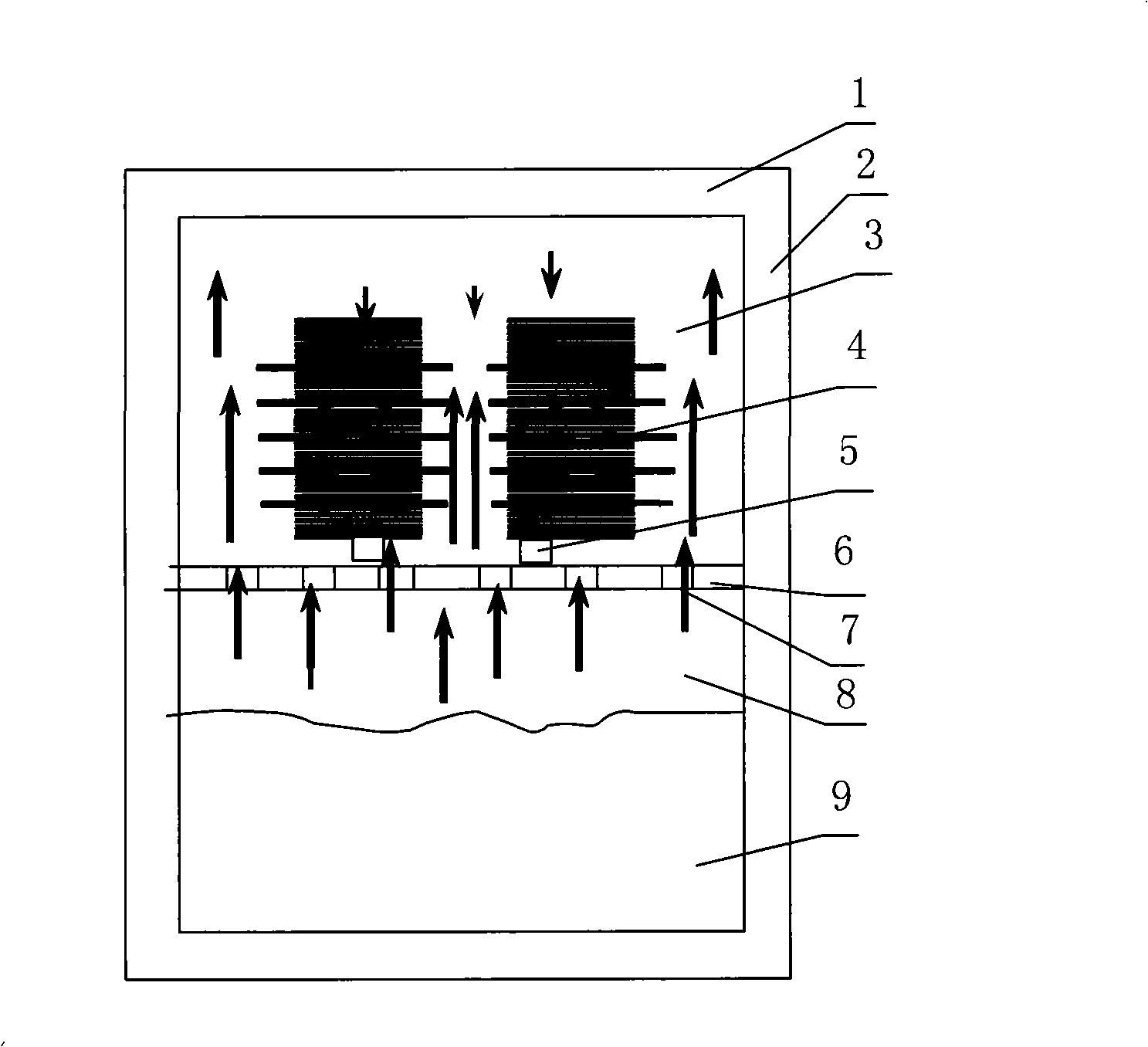

High-temperature-tolerance frequency selection wave-transmitting structure and preparation method thereof

ActiveCN106630979AImprove mechanical propertiesImprove electrical performanceLaser beam welding apparatusFiberElectrical conductor

The invention discloses a high-temperature-tolerance frequency selection wave-transmitting structure. The high-temperature-tolerance frequency selection wave-transmitting structure successively comprises a wave-transmitting layer, a modification bonding layer and a frequency selection layer from inside to outside, wherein the wave-transmitting layer is made of a continuous fiber reinforced ceramic-based wave-transmitting composite material; the modification bonding layer is made of a low-dielectric-constant material; the frequency selection layer is a noble metal physical plating layer or a noble metal glass conductor coating with periodic structure patterns. The high-temperature-tolerance frequency selection wave-transmitting structure can tolerate high temperature of 700 DEG C or more, and has excellent high temperature tolerance. The invention also provides a production method of the high-temperature-tolerance frequency selection wave-transmitting structure; the modification bonding layer is produced by using a plasma spraying process; the thermal damage to the substrate can be avoided, so that the substrate has high strength retention rate; the size accuracy of the frequency selection layer produced by a laser processing process can be higher than 20 microns; the frequency selection layer has high size accuracy.

Owner:NAT UNIV OF DEFENSE TECH +1

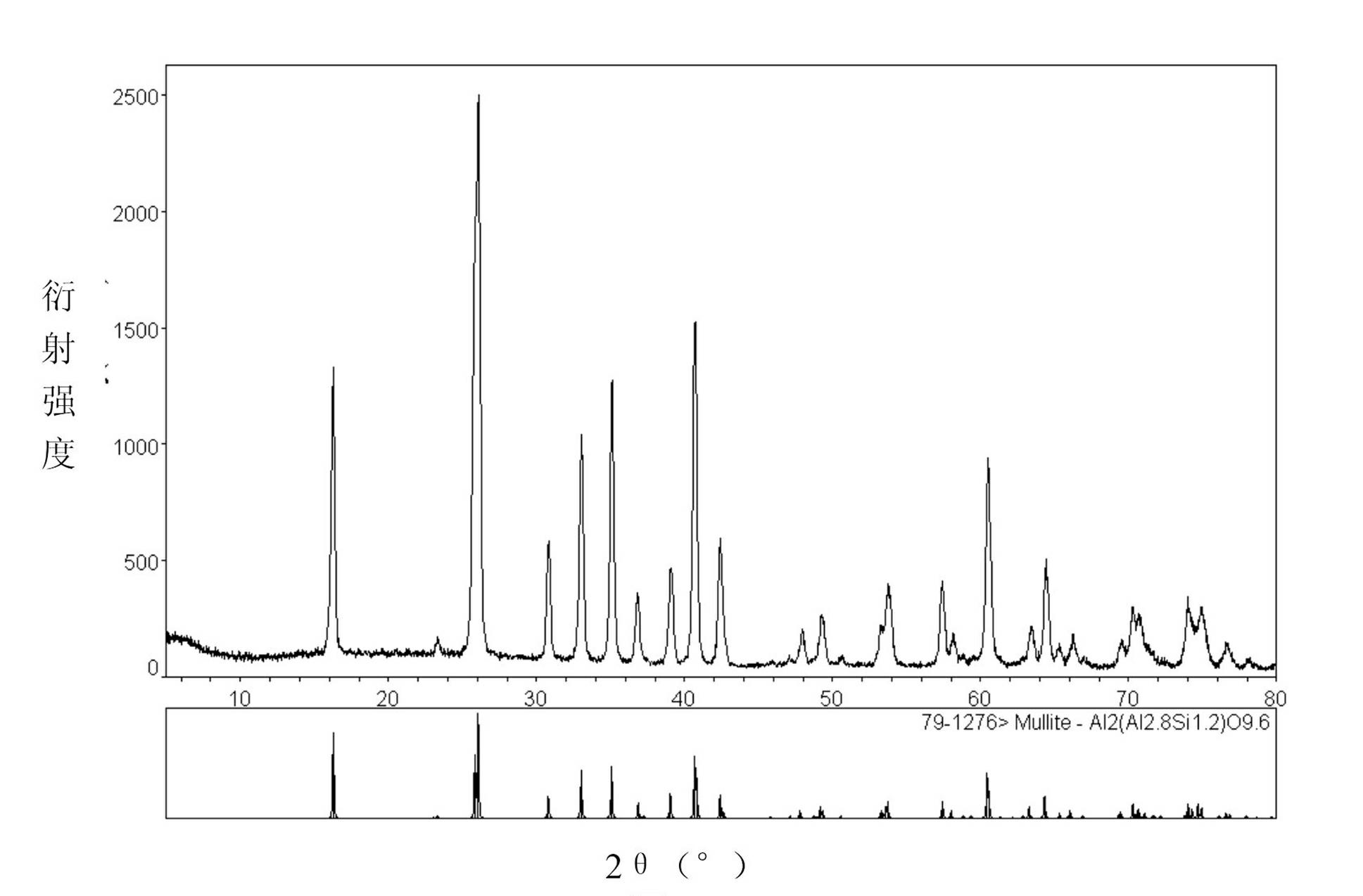

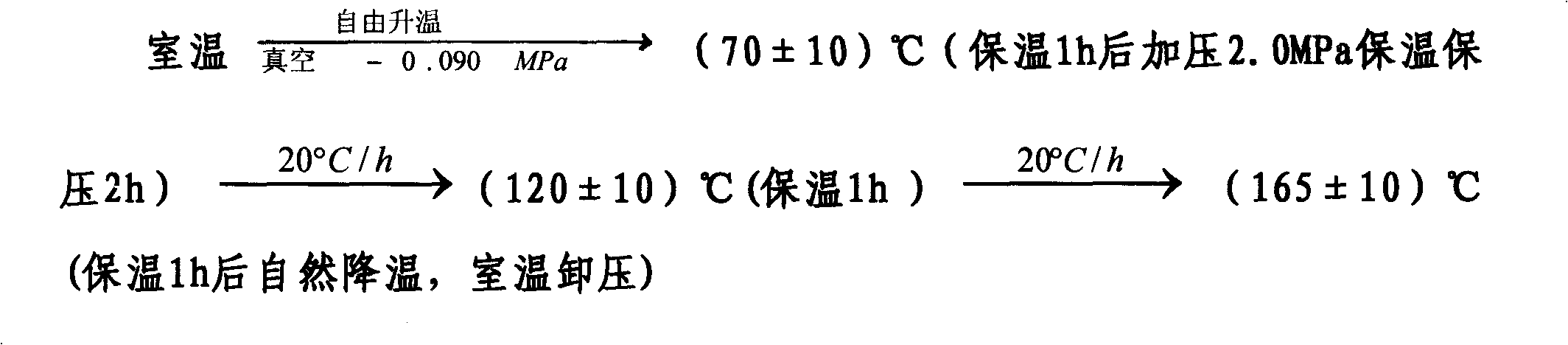

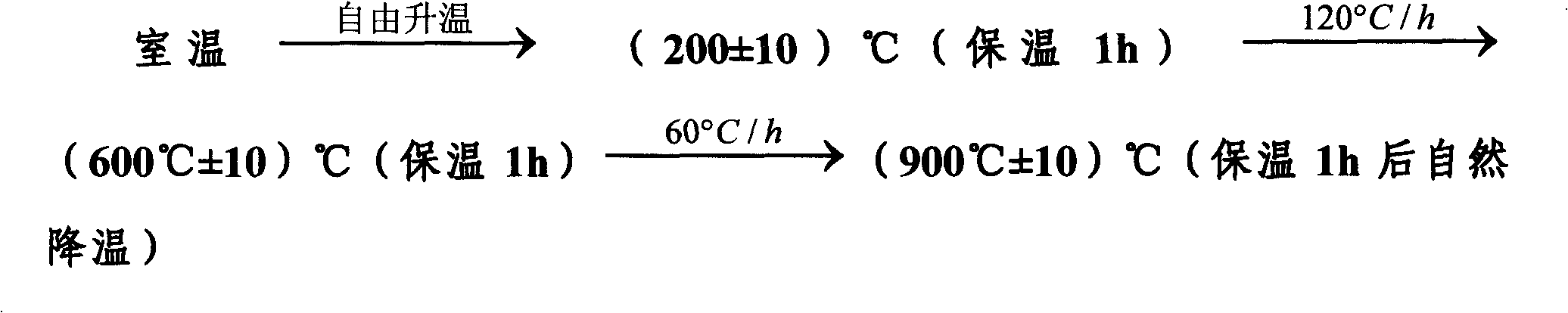

Three-dimensional carbon fiber fabric reinforced mullite ceramic and preparation method thereof

The invention discloses a three-dimensional carbon fiber fabric reinforced mullite ceramic. In the ceramic, mullite is used as a matrix, a three-dimensional carbon fiber fabric is used as a reinforcement body, and a silicon carbide boundary phase is form between the mullite matrix and the three-dimensional carbon fiber fabric reinforcement body by preparing a silicon carbide coating on the surface of the three-dimensional carbon fiber fabric. The invention also discloses a preparation method of the ceramic. The preparation method comprises the following process steps of: preparing the siliconcarbide coating; preparing mullite sol with high solid content; densifying one time; densifying repeatedly, and the like. The mullite ceramic has the advantages of high mechanical property such as high toughness and high intensity; and the preparation method of the mullite ceramic has the advantages of short cycle, low cost and capability of effectively improving the densification of a material.

Owner:NAT UNIV OF DEFENSE TECH

Method for preparing carbon/carbon/silicon carbide composite material

The invention relates to a preparation method of a carbon / carbon / silicon carbide composite material. The preparation method is characterized in that: chemical gas phase permeation technology is adopted to prepare reactive carbon atom and provide protection for carbon fiber, and is combined with the resin liquid phase dipping carbonizing technology to prepare carbon / carbon composite material through adopting a pore adjusting method of a composite material blank; moreover, the density of the obtained carbon / carbon composite material is between 1.0g / cm<3> and 1.90g / cm<3>; a method according to which the gaseous atom generated through the evaporation of solid silicon and the carbon atom in the carbon / carbon composite material are formed into SiC through chemical reaction under high temperature ranging from 1,650 DEG C to 2,200 DEG C is adopted to carry out the rapid preparation of the carbon / carbon / silicon carbide composite material. Compared with body carbon / carbon composite material, the mechanical property of the carbon / carbon / silicon carbide composite material is substantially increased to an equivalent degree and has outstanding antioxidation. Moreover, the preparation method is an engineered method which can realize the efficient preparation of a small-scale thin-wall special-shaped high-performance carbon / carbon / silicon carbide composite material.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material

InactiveCN101550634AHigh strengthHigh strength retentionFiltration separationNon-woven fabricsFiberSulfide

The invention relates to a process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material, belongs to the fibrous raw material textile production technology field. The process uses polyphenylene sulfide fiber as raw material, has the following steps: processing raw material by checking, weighing, feeding, feeding into long certain, mixing cotton and fine loosing; layering and carding respectively by a first carding machine and a second carding machine; putting respectively into mesh placing machine for placing mesh; debatching, congruent, superposing and prewetting; spunlacing by a plurality of spunlacing machine, dewatering, drying and reeling. The advantages of the invention is that: the invention adopts polyphenylene sulfide high-performance fiber as raw material, the raw material is adapted to high efficient high speed carding production for its self physical and chemical properties, structure and adaptability to meshing and reinforcing process; improves spunlacing entanglement effect to fiber; improves the mechanical strength of spunlaced composite filtering material significantly, and ensures the end product to achieve excellent mechanical properties, filtering quality and chemical resistance property.

Owner:SHAOXING RONGLIDA TEXTILE TECH

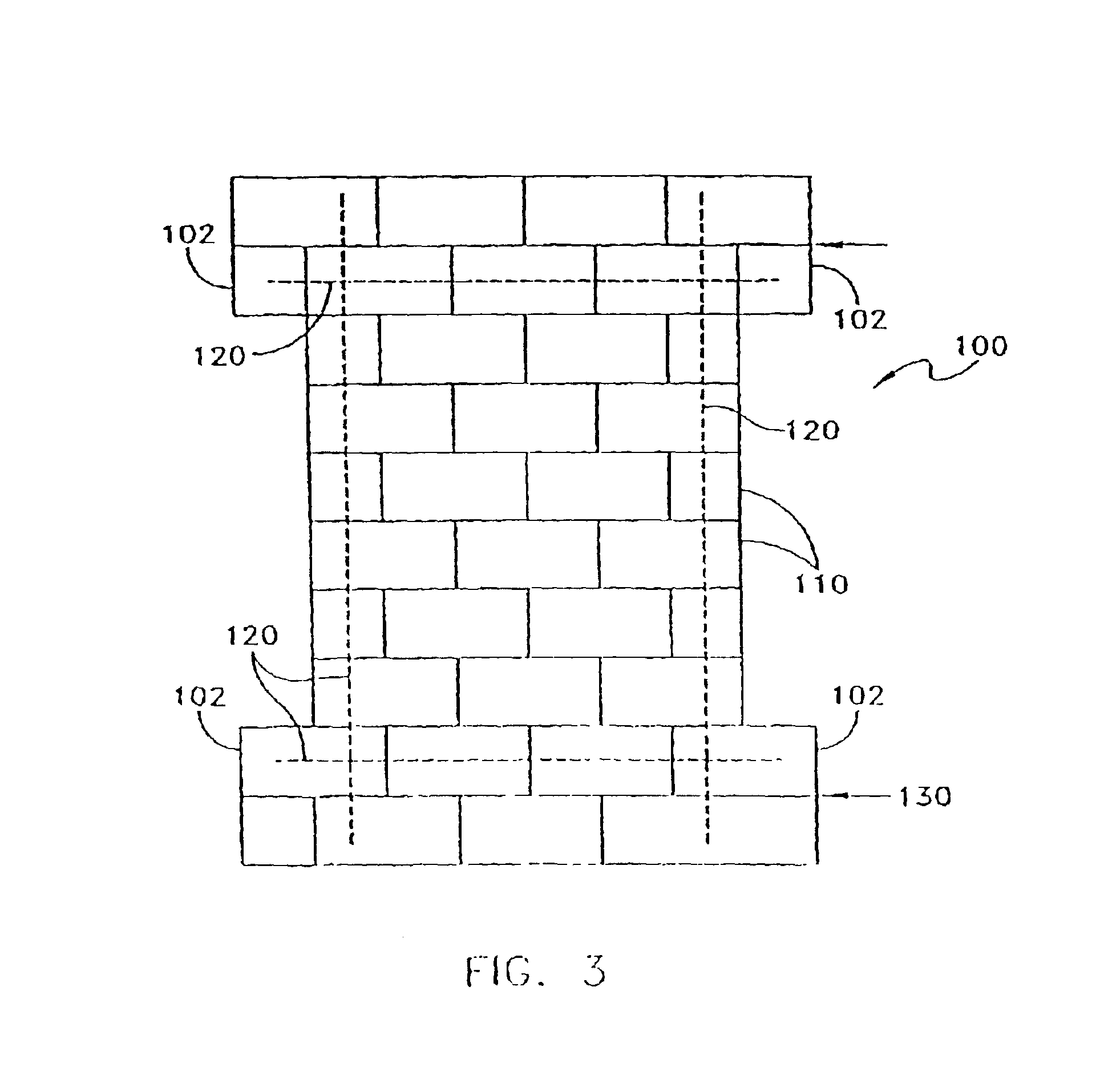

Inorganic matrix-fabric system and method

A method of reinforcing a structural support, includes applying a reinforcement system comprising an AR-glass fibrous layer embedded in an inorganic matrix to the structural support. The AR-glass fibrous layer has a sizing applied thereon, and a resinous coating applied is applied over the sizing. The inorganic matrix is adherent to the resinous coating and the resinous coating is adherent to the sizing.

Owner:SAINT GOBAIN ADFORS CANADA LTD

Electrolytic Copper Foil, and Negative Electrode Current Collector for Secondary Battery

InactiveUS20140346048A1High tensile strengthLow tensile strengthDuplicating/marking methodsElectrode carriers/collectorsElectrolysisCopper foil

Present invention provides an electrolytic copper foil having a high normal tensile strength and a resistance to the lowering of the tensile strength after thermal treatment. An electrolytic copper foil having a normal tensile strength of 500-750 MPa and a tensile strength after heating at 400° C. for one hour of at least 350 MPa.

Owner:JX NIPPON MINING& METALS CORP

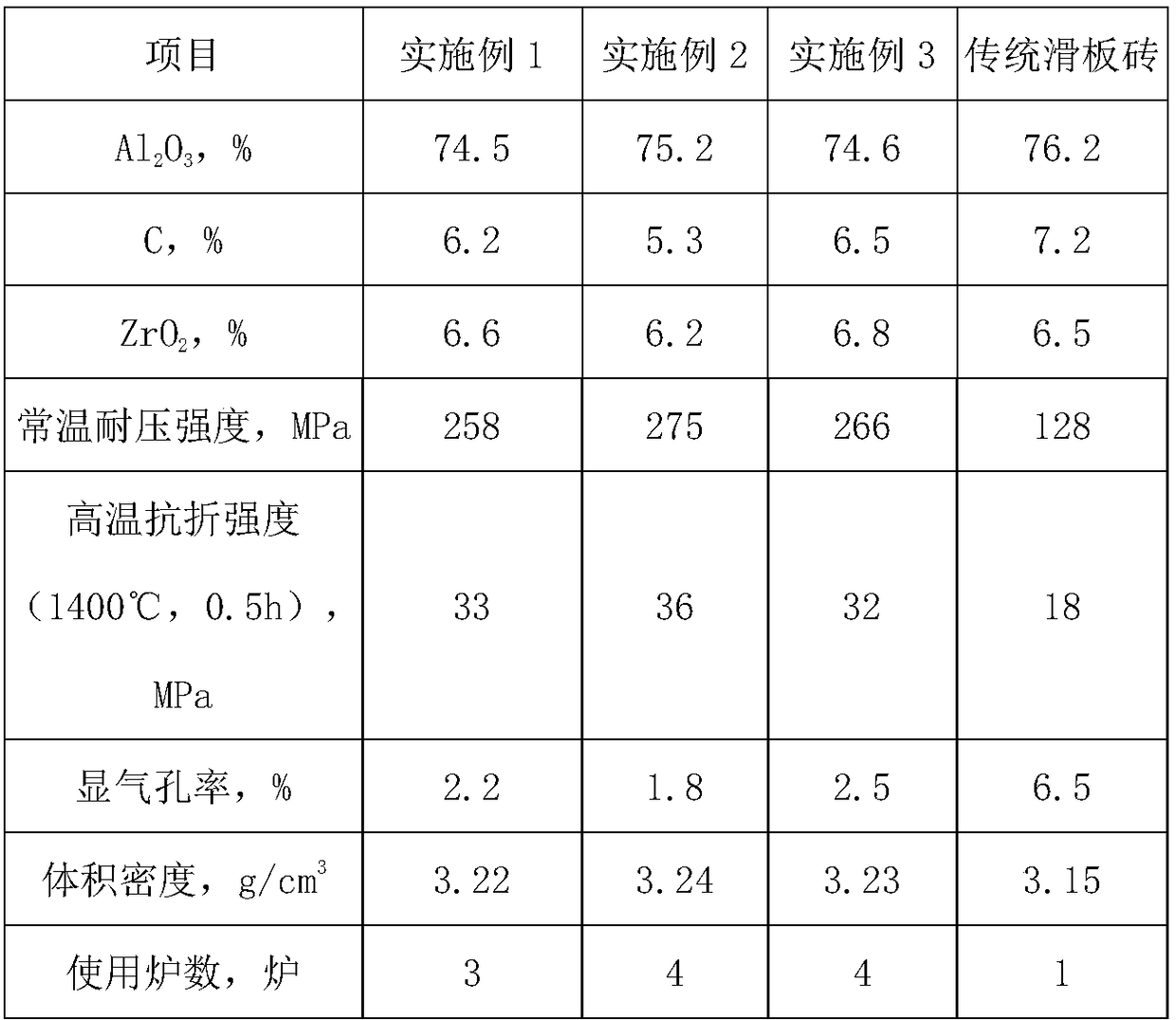

Sliding plate brick added with compound aluminium oxide micropowder and carbon source and preparation method thereof

The invention discloses a sliding plate brick added with compound aluminium oxide micropowder and a carbon source and a preparation method thereof and relates to the technical field of refractory materials. The sliding plate brick is prepared from the following raw materials and components in percentage by weight: 40-50% of platy corundum granule, 10-20% of fused zirconia corundum granule, 5-10% of platy corundum fine powder, 5-10% of fused zirconia corundum fine powder, 10-15% of compound aluminium oxide micropowder, 0.5-3% of flake graphite, 0.5-3% of carbon black, 0.5-5% of metal aluminiumpowder, 0.5-5% of metal silicon powder and 1-4% of special additive, and the sum of the percents is 100%; in addition, 4-6% of phenolic resin is added. The finished sliding plate brick is obtained bythe processes of crushing and mixing of raw materials, mixing and rolling, forming, heat treatment, firing, digestion and carbonization, finish processing, inspection and packaging and the like. The sliding plate brick added with the compound aluminium oxide micropowder and the carbon source has the beneficial effects that by changing for the adjustment of the aluminium oxide micropowder, the heatshock resistance, washout resistance and erosion resistance of the sliding plate brick are improved and the service life is prolonged.

Owner:瑞泰马钢新材料科技有限公司

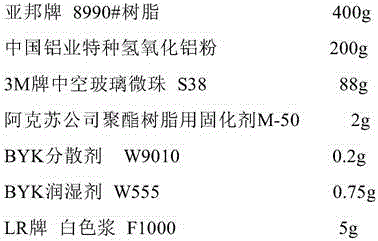

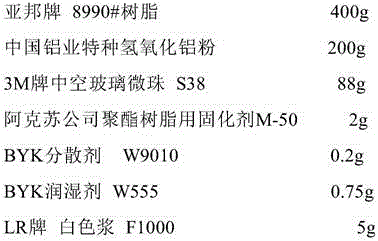

Artificial stone material and preparation method and use thereof

The present invention relates to the field of materials, and discloses an artificial stone material and a preparation method and use thereof, and the artificial stone material comprises the following components by weight: 20 to 60 parts of resin, 10 to 30 parts of a filling material and 6 to 10 parts of hollow glass beads. The hollow glass beads as a lightweight filler are added into the artificial stone formula, on the one hand, the density of the artificial stone formula is reduced, so that the artificial stone material is lighter in weight, on the other hand, due to good interface compatibility of the hollow glass beads and the resin and other filler relative to other lightweight materials, the artificial stone material is higher in strength retention rate, the artificial stone material is easier to polish, a product prepared from the artificial stone material has contamination-resistant surface appearance with good chemical resistance, a surface coating or gel coat is not needed, and artificial stone products are easy to design.

Owner:KOHLER CHINA INVESTMENT

Polyester multifilament yarn for rubber reinforcement and method of producing the same

ActiveUS6967058B2High modulusLow shrinkageSynthetic resin layered productsPneumatic tyre reinforcementsYarnPolyester

Owner:HYOSUNG ADVANCED MATERIALS CORP

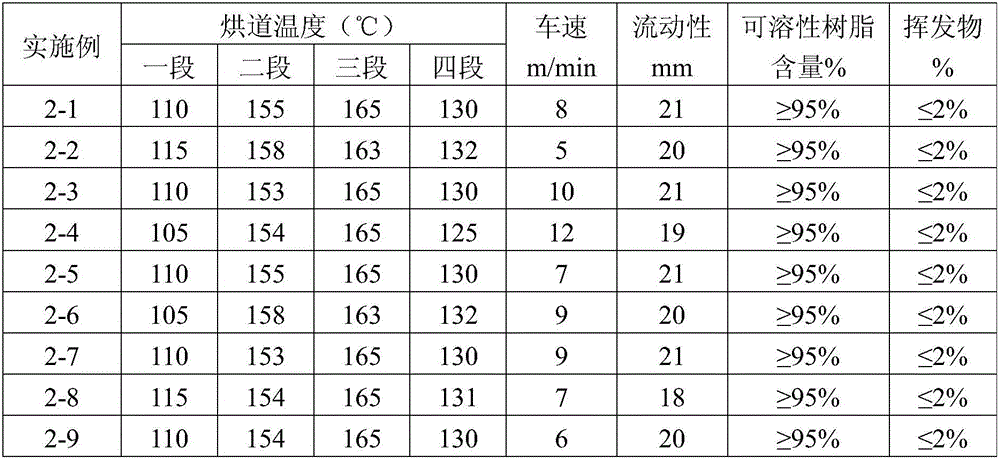

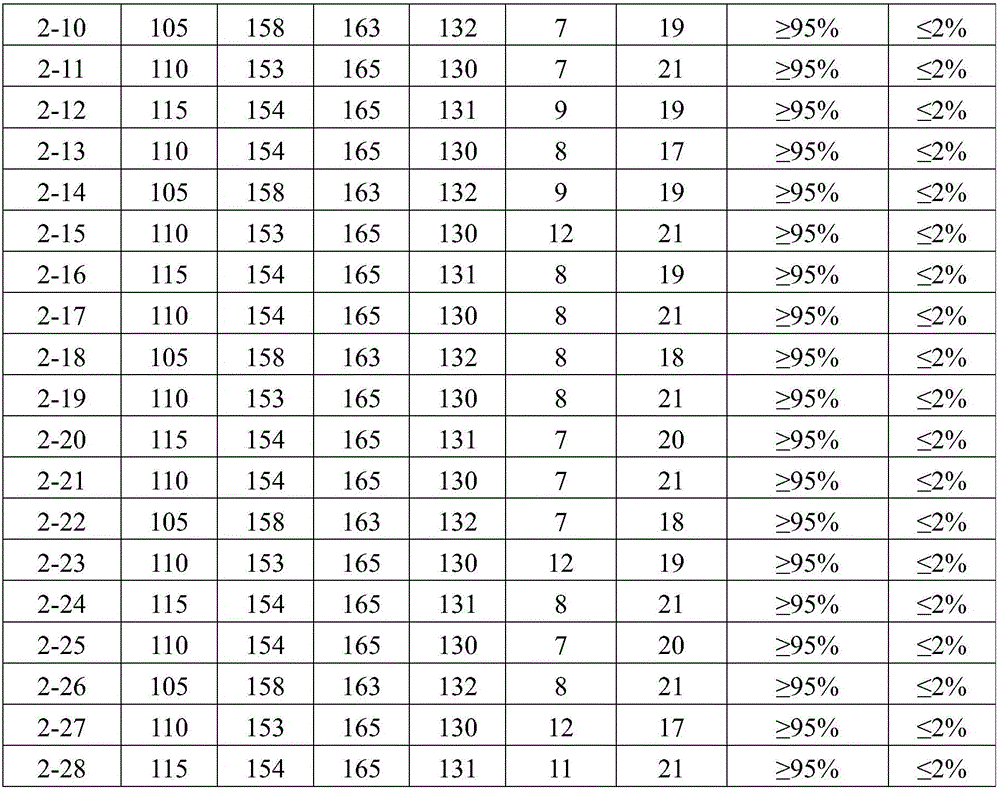

Glass fibrofelt laminated plate and preparation method thereof

ActiveCN106626617AImprove tracking resistance performanceHigh strength retentionLaminationLamination apparatusEpoxyFiber

The invention discloses a glass fibrofelt laminated plate and a preparation method thereof. The glass fibrofelt laminated plate and the preparation method thereof are characterized in that the glass fibrofelt laminated plate is a composite material prepared by performing hot-press molding on one layer or more than one layer overlapped high-strength tracking-resistant resin glass fibrofelt prepreg, and the tracking-resistant index is more than or equal to 600 V; the prepreg is a material formed by dipping or spray-coating a high-strength tracking-resistant resin adhesive on alkali-free glass fibrofelt and then roasting; and the high-strength tracking-resistant resin adhesive consists of 20 to 55 parts by weight of high-temperature-resistant epoxy resin, 15 to 60 parts by weight of modified phenolic resin, 10 to 35 parts by weight of a curing agent, 5 to 35 parts by weight of inorganic powder, 0.01 to 1 part by weight of an accelerant and 100 to 130 parts by weight of a solvent. The glass fibrofelt laminated plate provided by the invention is suitable for manufacturing of insulation structural components of large generator sets and nuclear power generators as well as manufacturing of high-temperature-resistant high-strength insulating composite materials for motors, transformers, military products and the like under the high-temperature working environment.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

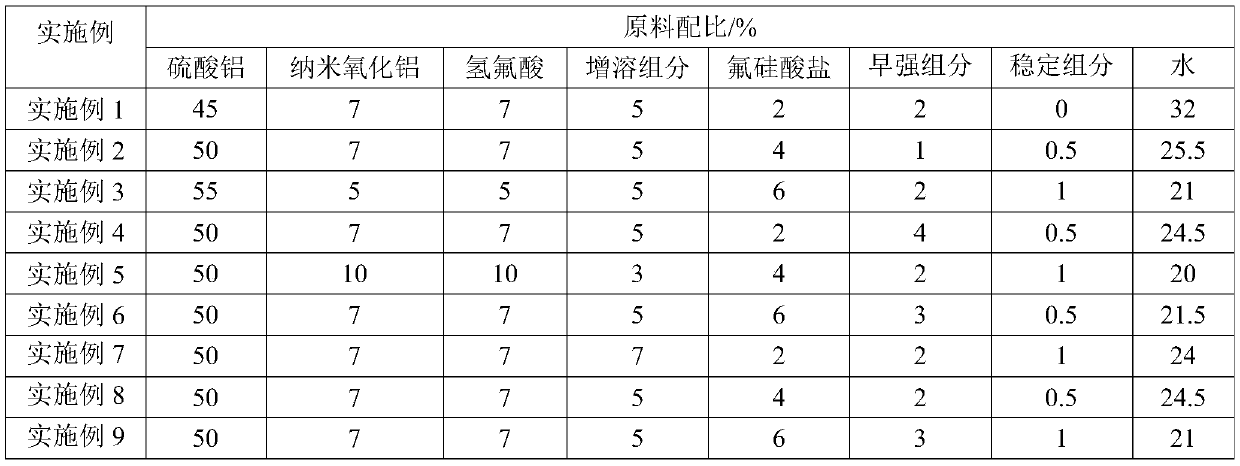

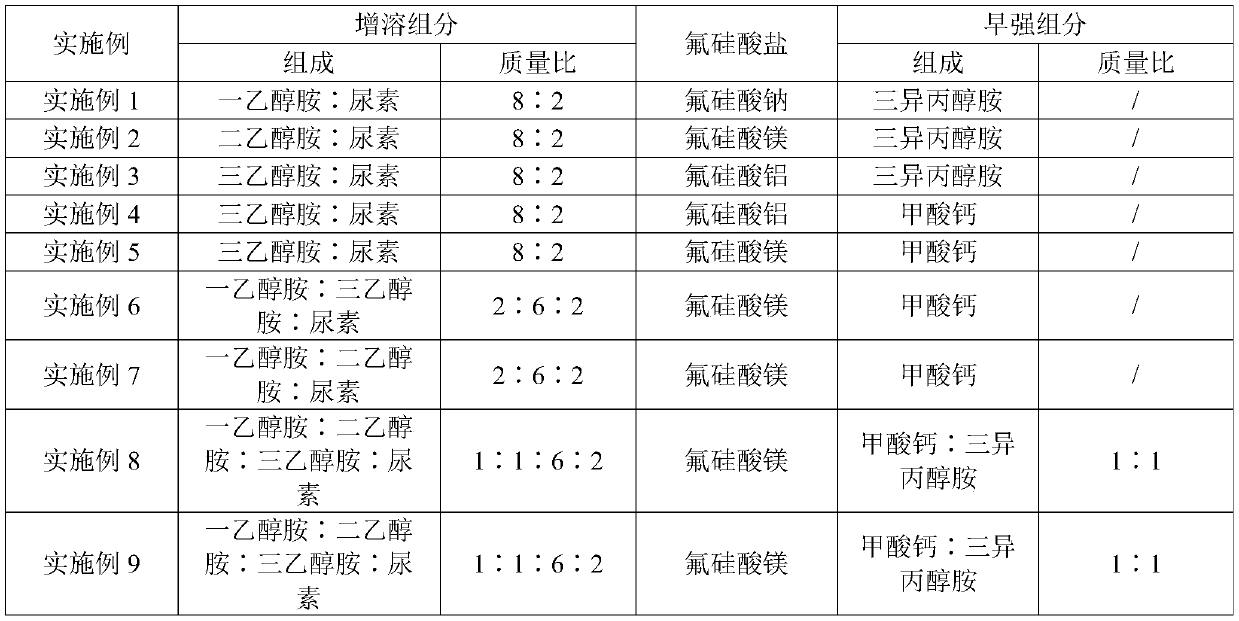

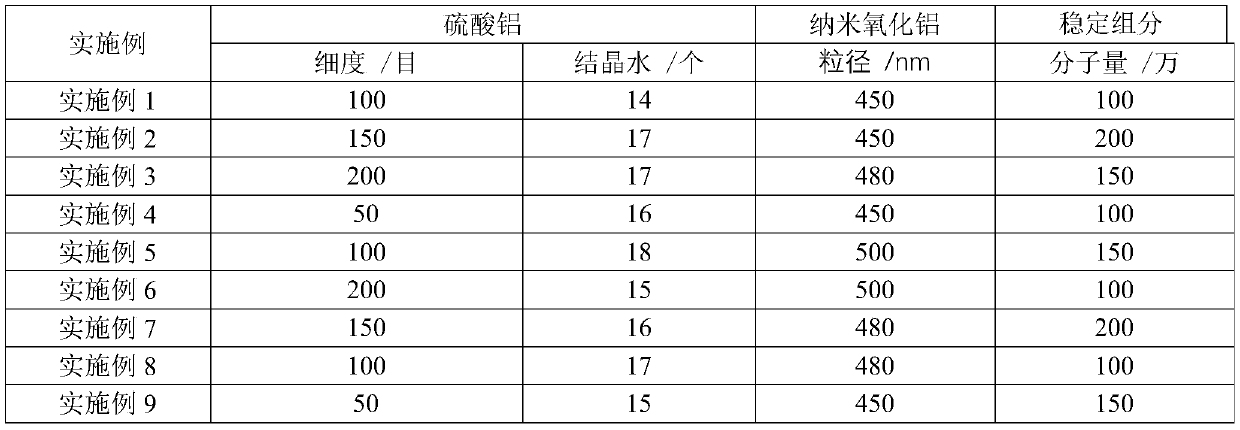

Alkali-free liquid quick-setting agent, preparation method and applications thereof

ActiveCN110255955AImprove the coagulation effectImprove long-term stabilityHydrofluoric acidAluminium sulfate

The invention provides an alkali-free liquid quick-setting agent, a preparation method and applications thereof, wherein the raw materials comprise, by mass, 45-55% of aluminum sulfate, 5-10% of nanometer alumina, 5-10% of hydrofluoric acid, 3-7% of a solubilizing component, 2-6% of fluorosilicate, 1-4% of an early strength component, 0.5-1% of a stabilizer, and 20-32% of water. According to the present invention, the aluminum sulfate is used as the main raw material, and is matched with the nanometer alumina, the hydrofluoric acid, the solubilizing component, the fluorosilicate, the early strong component and the stabilizer, such that the obtained alkali-free liquid quick-setting agent has characteristics of good setting acceleration effect, long-term stability and low rebound rate, can substantially improve the earth strength of concrete, and can have high strength retention rate in late strength, wherein various performance indexes can meet the requirements on the first-class quick-setting agent in standard JC477-2005 Flash setting admixtures for shotcrete at a dosage of 7%.

Owner:WUHAN UNIV OF TECH

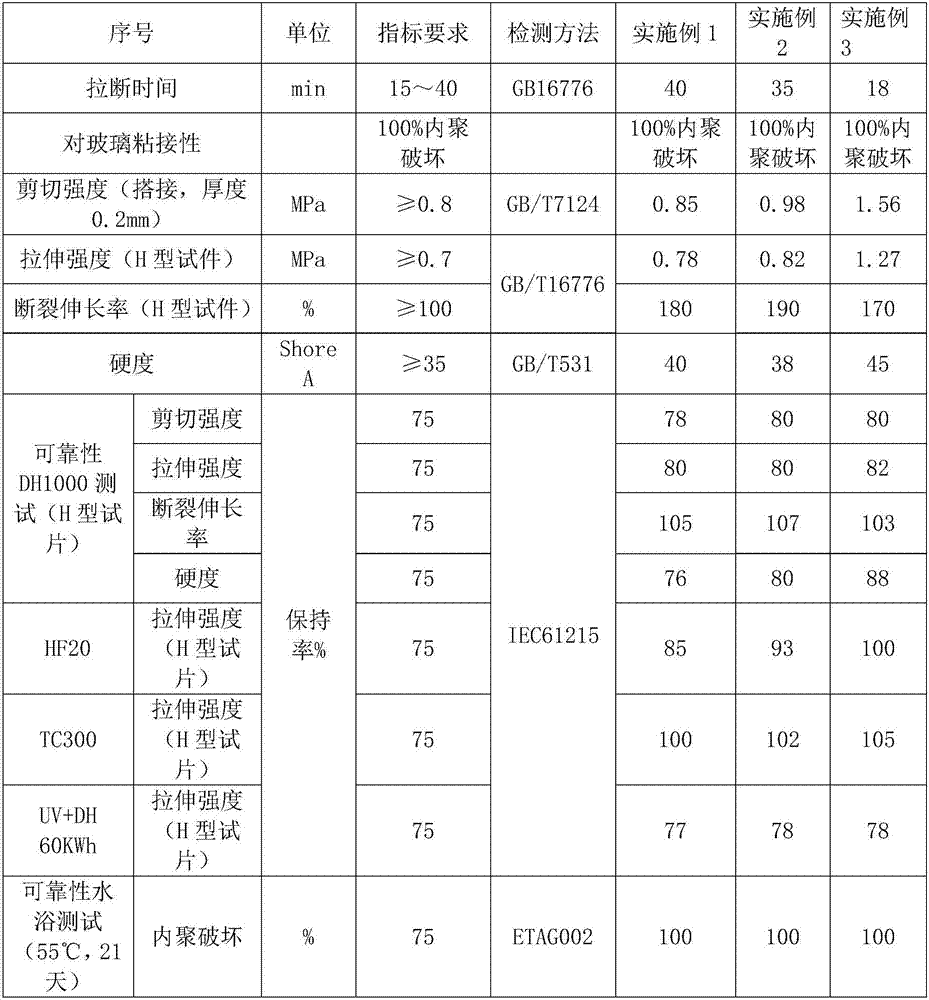

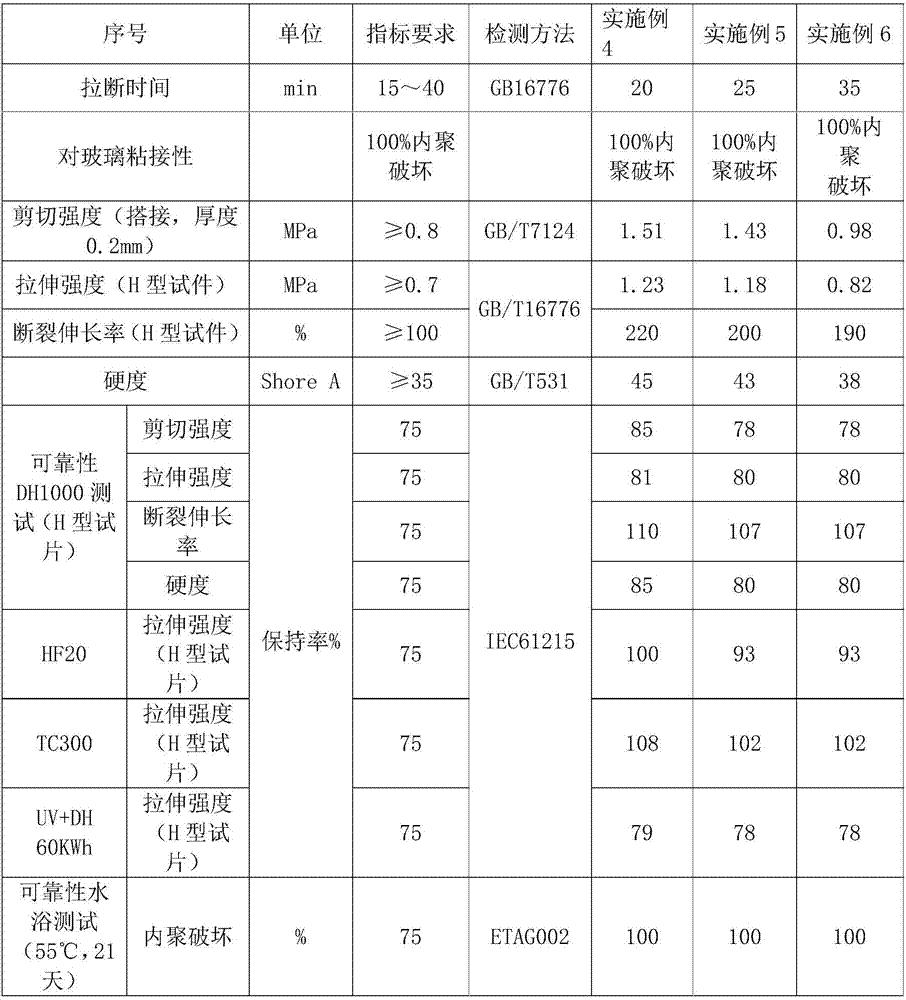

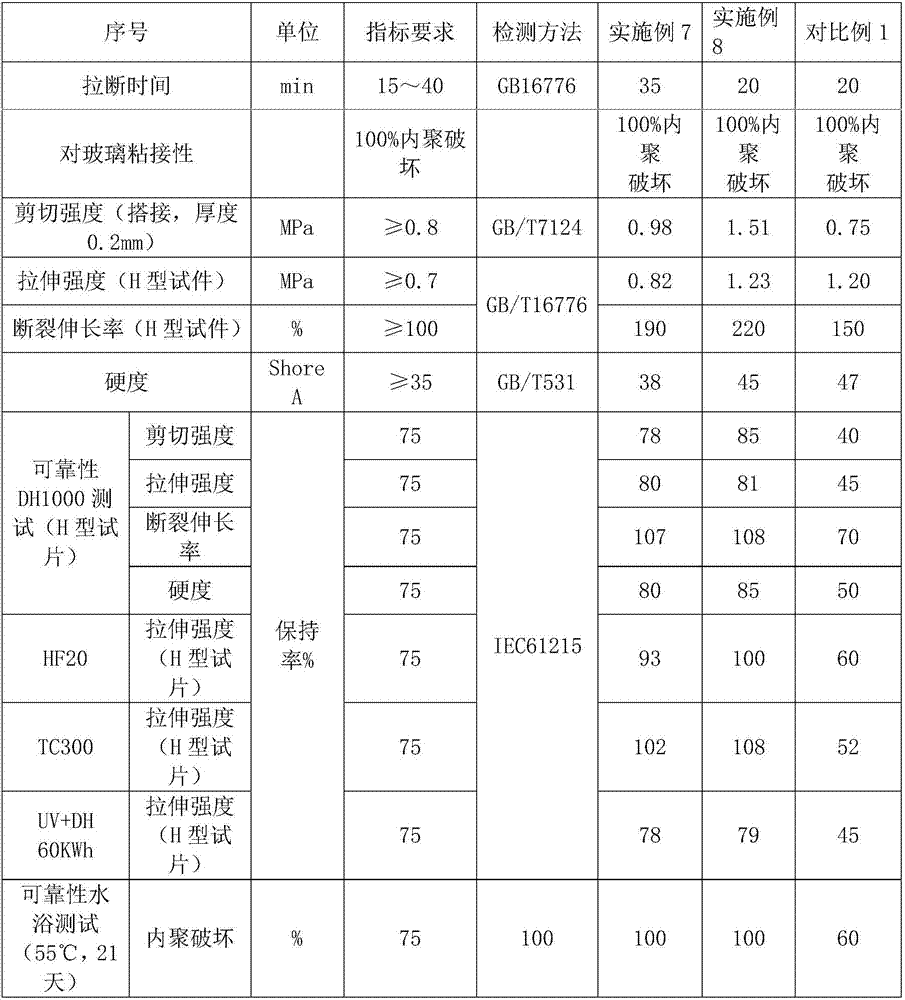

Moisture-resistant and heat-resistant high-strength silicone structural adhesive special for photovoltaic assemblies

ActiveCN107880797AExcellent heat and humidity resistanceHumidity has little effectNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveAntioxidant

The invention discloses a moisture-resistant and heat-resistant high-strength silicone structural adhesive special for photovoltaic assemblies. The moisture-resistant and heat-resistant high-strengthsilicone structural adhesive special for the photovoltaic assemblies consists of an A component and a B component according to a volume ratio of 10:1, wherein the A component consists of hydroxyl-terminated polydimethylsiloxane, a thixotropic agent, a reinforcing filler, a heat-resistant filler and a plasticizer; and the B component consists of methyl-terminated polydimethylsiloxane, pigment carbon black, a silane coupling agent, an active hydrogen blocking agent, a crosslinker , a catalyst, an antioxidant, a light stabilizer, and a deep curing agent. According to the moisture-resistant and heat-resistant high-strength silicone structural adhesive special for the photovoltaic assemblies, the problem that currently strength of a silicone structural adhesive decreases after damp-heat aging is solved; and the moisture-resistant and heat-resistant high-strength silicone structural adhesive special for the photovoltaic assemblies is applicable to the fields of structural bonding of double glass assembly back tracks, and between hanging buckles and glass, and bonding and sealing of photovoltaic assembly frames, and junction boxes, etc.; and the structural adhesive has high strength, excellent heat and humidity resistance and adhesion, and can play a structural adhesive role.

Owner:ZHEJIANG FORST NEW MATERIAL RES INST CO LTD

High-temperature brazing filler metal for soldering C/C and C/SiC composite materials and preparation methods thereof

ActiveCN103240544AImprove wettabilityHigh strength retentionWelding/cutting media/materialsSoldering mediaIngotUltimate tensile strength

A high-temperature brazing filler metal for soldering C / C and C / SiC composite materials and preparation methods thereof relate to high-temperature soldering materials and preparation methods of the high-temperature soldering materials and mainly solve the problems of low high-temperature strength retention rate and poor performance of soldering joints in existing high-temperature solders for soldering the C / C and C / SiC composite materials. The high-temperature brazing filler metal for soldering the C / C and C / SiC composite materials is made from Ni and Zr or ZrH2. A method I comprises 1) weighing Ni and Zr or ZrH2, 2) performing smelting to obtain an alloy ingot and 3) performing foil fabrication. A method II comprises 1) weighing Ni and Zr or ZrH2, 2) performing ball milling to obtain a mixed powder and 3) pressing the mixed power to obtain foils and washing and drying the foils. The high-temperature brazing filler metal for soldering the C / C and C / SiC composite materials can provide a good wettability for the C / C and C / SiC composite materials and can mainly be formed into two structures during a soldering process, thereby guaranteeing the mechanical performance of the soldering joints. The components of the high-temperature brazing filler metal for soldering C / C and C / Sic composite materials do not contain precious metals, so that the cost is low; and the melting point of the component Zr is 1852 DEG C, so that the soldering joints can be guaranteed to have a high strength retention rate at 600 DEG C.

Owner:HARBIN INST OF TECH

Method for degradation of composite material by directional bond breaking and recovery of fiber from composite material

ActiveCN110527137ASimple componentsEasy to separate, purify and reusePlastic recyclingSolvent effectsFiber strength

The invention provides a method for degradation of a composite material by directional bond breaking and recovery of fibers from the composite material. The method comprises the following steps that (1) the composite material is cut into composite material blocks with the target size for standby application; (2) the composite material blocks, solvents, metal salts, ligands, pH regulators and oxidants are mixed evenly, and then heated, the composite material blocks are naturally cooled to the room temperature after being completely degraded, and then high-speed centrifugal separation is conducted to obtain crude fiber products; and (3) the crude fiber products are washed and dried, and finally fiber fine products are obtained. According to the method, through the hot solvent effect, unsaturated complexation and weak complexation, the solvents, the metal salts, the ligands, the pH regulators, the oxidants and the composite material are mixed, and then heated, directional bond breaking degradation of resin is achieved, finally the fibers with little surface resin residue, basically no defect and the fiber strength retention rate up to 97.1% are obtained, and the degradation rate of the resin is as high as 100%.

Owner:WUHAN UNIV OF TECH

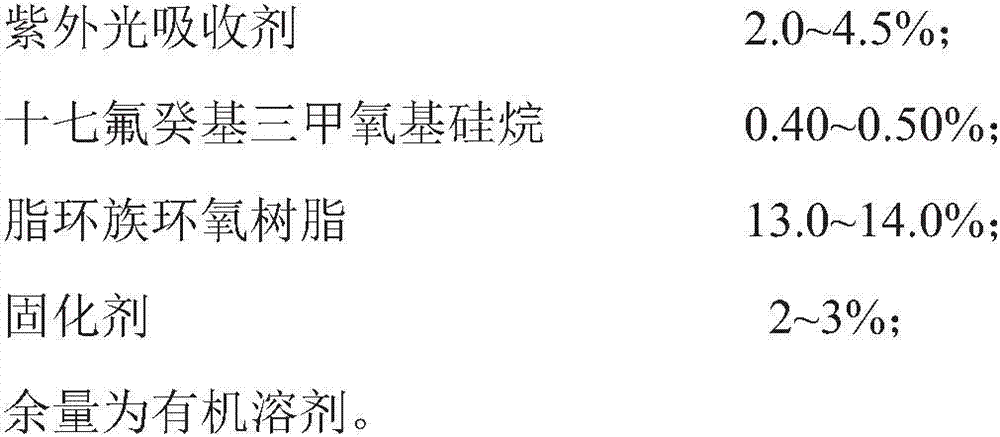

Coating material for surface modification of PBO (Poly-p-phenylene Benzobisoxazole) fibers, surface modified PBO fibers and preparation and application thereof

ActiveCN107385919AGood UV resistanceHigh hydrophobic performance and weather resistanceLight resistant fibresSurface modificationPolymer chemistry

The invention discloses a coating material for surface modification of PBO (Poly-p-phenylene Benzobisoxazole) fibers. The coating material is prepared from an ultraviolet absorbent, heptadecafluorodecyl trimethoxysilane, cycloaliphatic epoxy resin, a curing agent and an organic solvent. The invention further provides a method for carrying out surface modification on the PBO fibers and surface modified PBO fibers prepared through the method. Furthermore, the invention further provides an extra-high voltage live working tool soft material which is prepared by braiding and twisting the surface modified PBO fibers. The treated PBO fibers overcome the disadvantage of no ageing resistance, have very good insulating performance and can be widely applied to insulating ropes for extra-high voltage live working.

Owner:LIVE WORKING CENT OF STATE GRID HUNAN ELECTRIC POWER +3

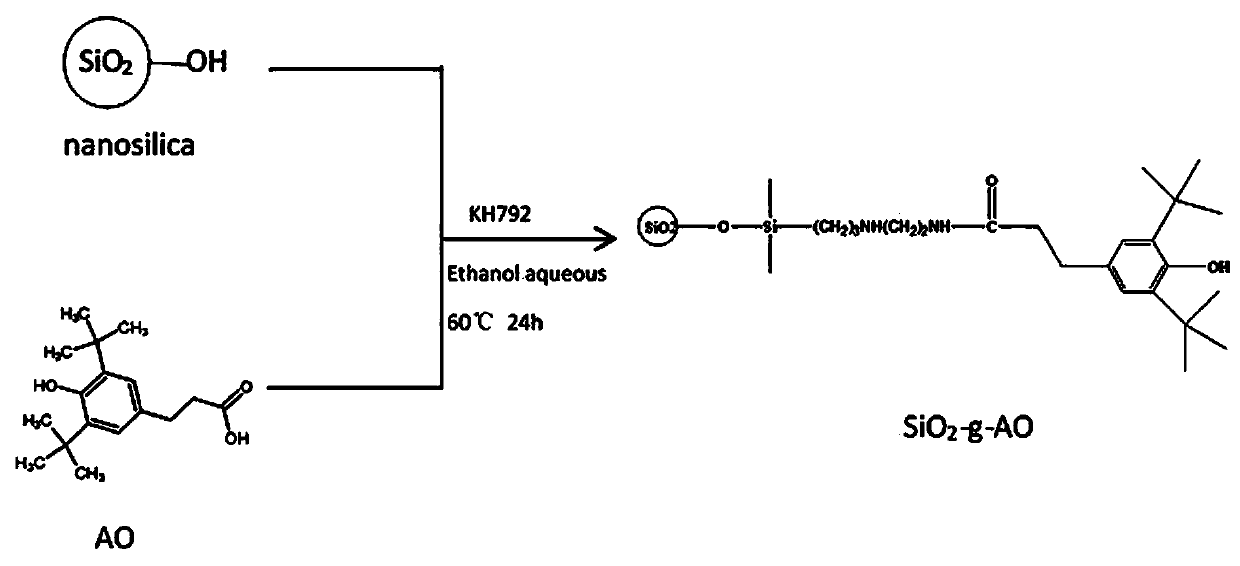

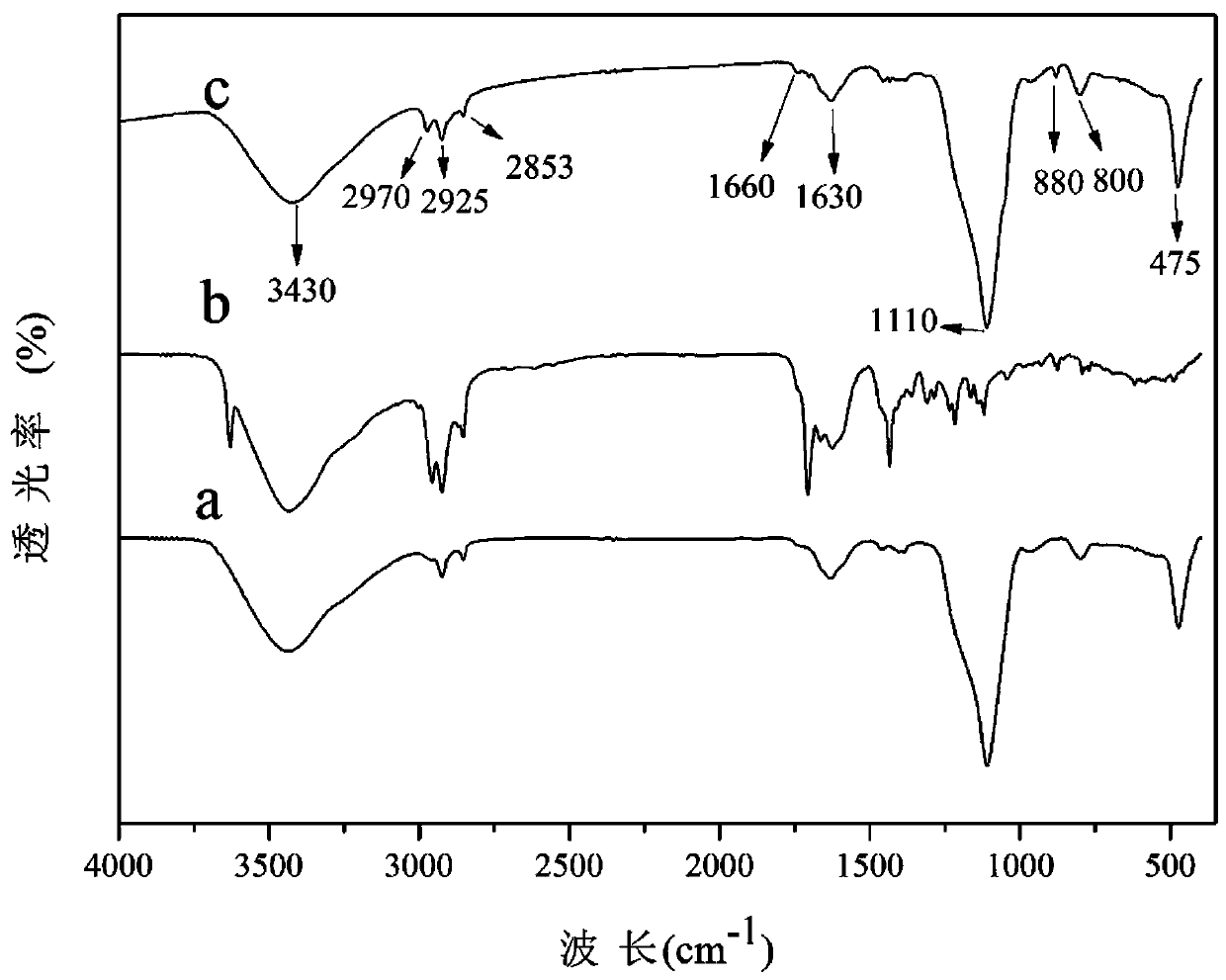

Antioxidation polyphenylene sulfide/modified nano silicon dioxide composite fiber and preparation method thereof

ActiveCN110205703AHigh breaking strengthHigh strength retentionMonocomponent synthetic polymer artificial filamentArtifical filament manufactureFiberBreaking strength

The invention belongs to the technical field of chemical fiber and provides antioxidation polyphenylene sulfide / modified nano silicon dioxide composite fiber and a preparation method thereof. The composite fiber is prepared from polyphenylene sulfide and modified nano silicon dioxide proportionally, and modified nano silicon dioxide is formed by using a silane coupling agent to load an antioxidantonto the surface of modified nano silicon dioxide through chemical grafting reaction. Fiber number of the composite fiber prepared by the method is 1.0-5.0dtex, breaking strength is 2.0-3.0cN / dtex, elongation rate at break is 45-48%, and oxidative induction temperature is 470-480 DEG C; breaking strength retention rate of the composite fiber after being treated at temperature of 220 DEG C for 360h is 85-90%; compared with pure PPS fiber, oxidative induction temperature of the composite fiber is increased by about 20 DEG C, strength retention rate is increased by 20-25% after the composite fiber is treated at temperature of 220 DEG C for 360h, and antioxidation performance of the composite fiber is improved obviously.

Owner:TAIYUAN UNIV OF TECH

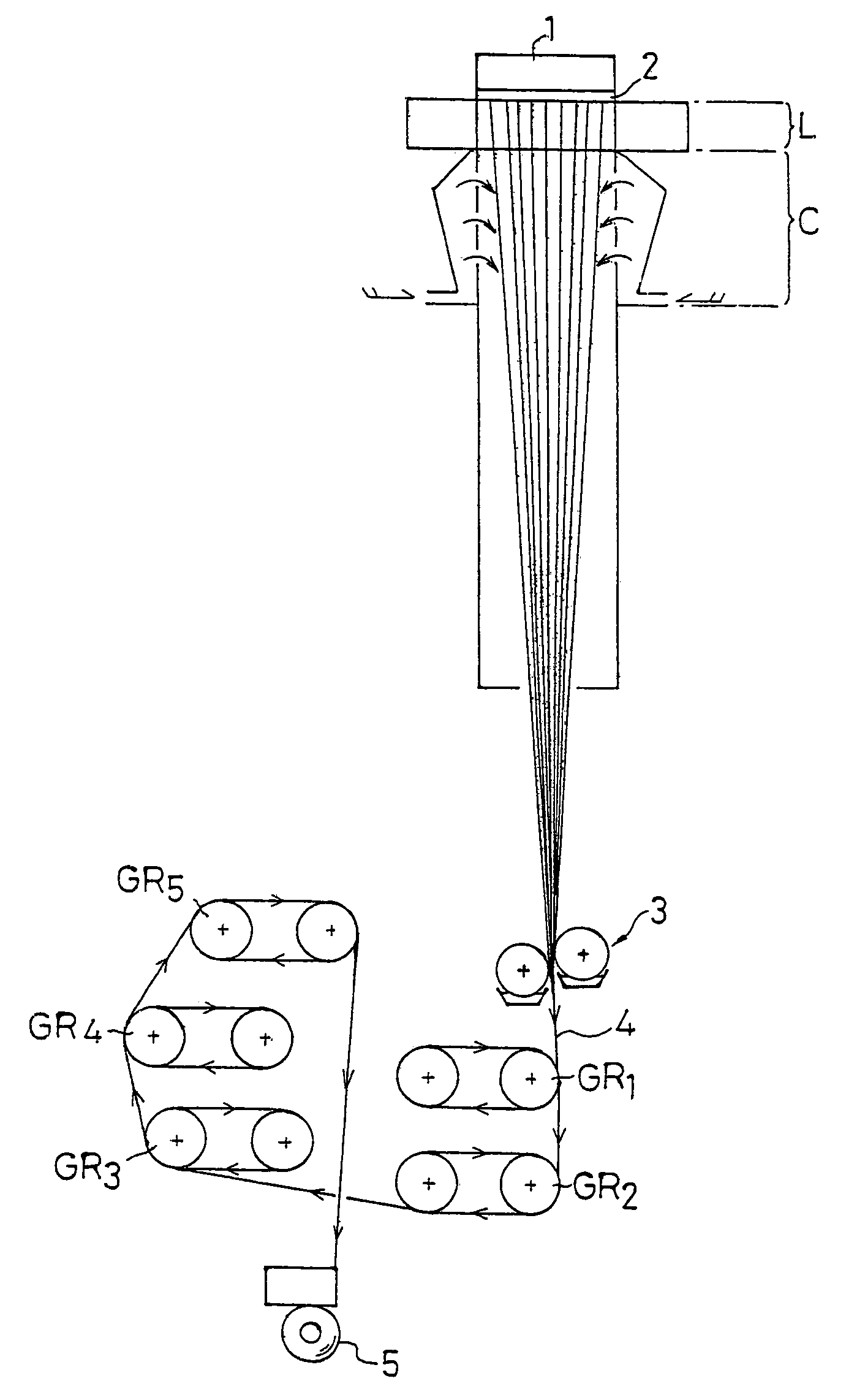

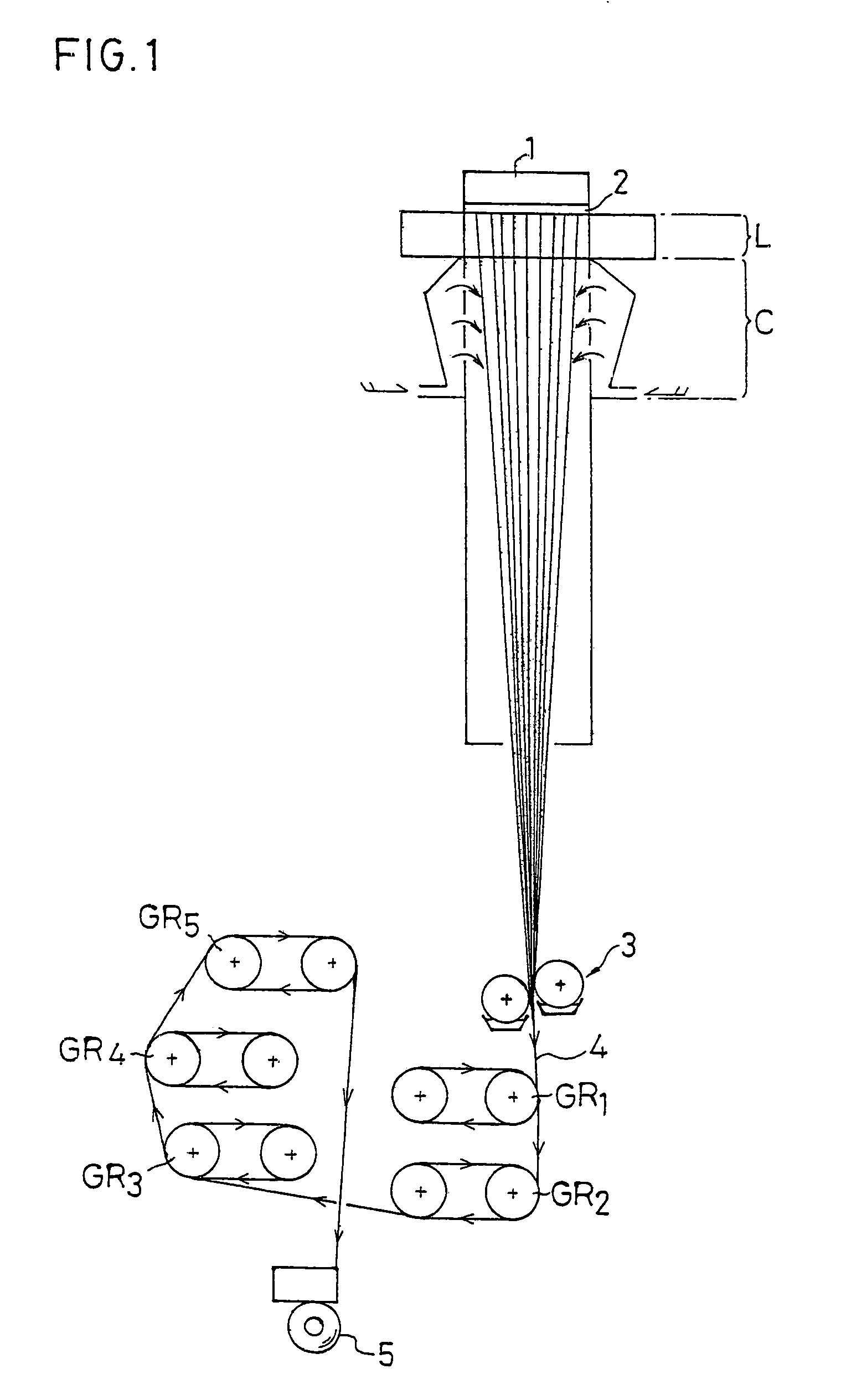

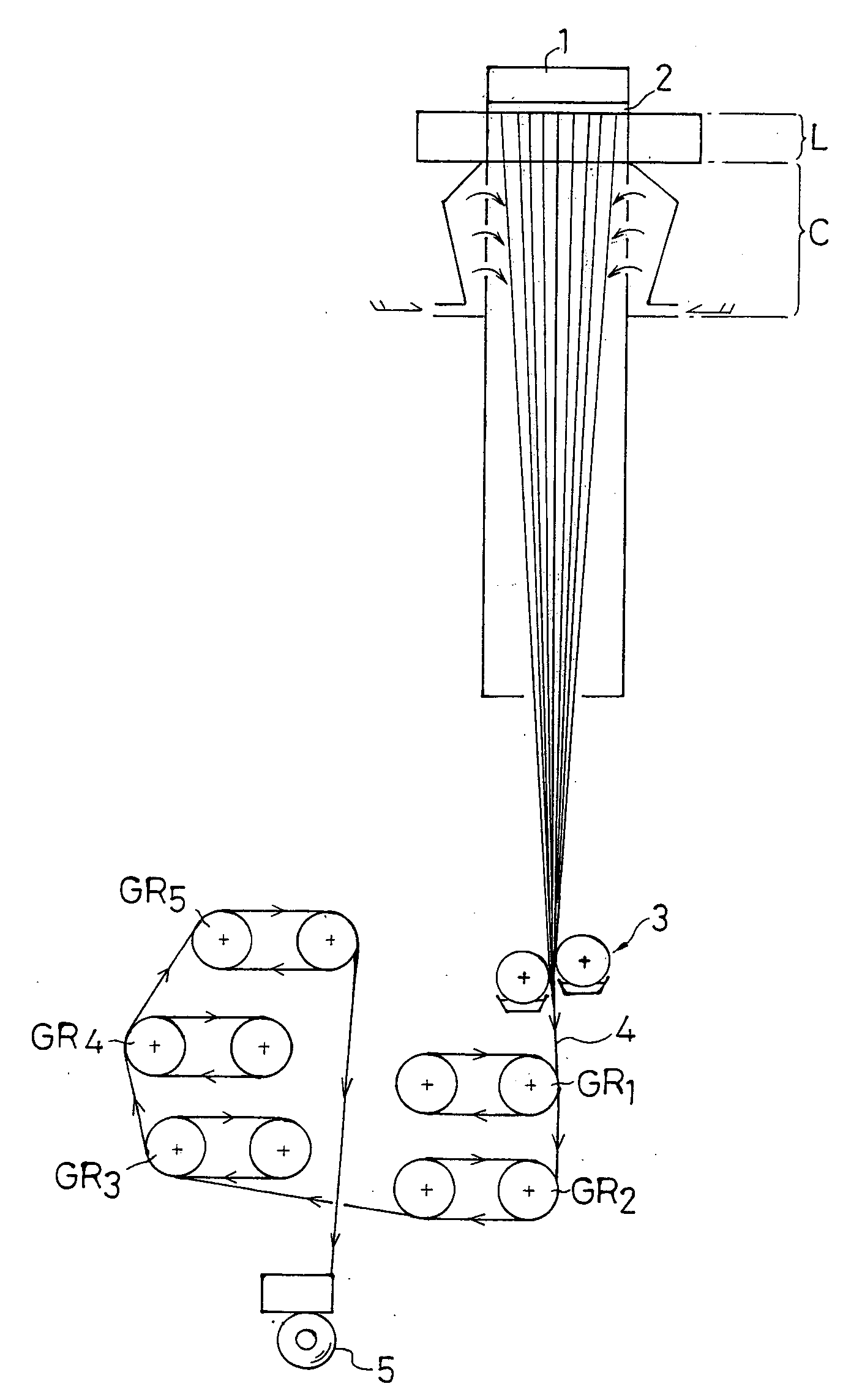

Production process for polytetrafluoroethylene (PTFE) aqua tex composite high-temperature tail gas filter material

InactiveCN102527156AGood chemical resistanceImprove performanceSynthetic resin layered productsGlass/slag layered productsGlass fiberFiber

The invention relates to a production process for a polytetrafluoroethylene (PTFE) aqua tex composite high-temperature tail gas filter material, which belongs to the technical field of spinning filter materials. Polytetrafluoroethylene fibers and glass fiber base fabrics are adopted as raw materials. Firstly, the polytetrafluoroethylene fibers are detected and weighted, then sequentially fed into a long curtain, a horizontal opener, a large-cabinet and a fine opener, combed by a combing machine 1 and a combing machine 2 in layering mode, and respectively fed into a cross lapping machine 1 and a cross lapping machine 2 to be lapped. The glass fiber base fabrics are laminated between the raw materials sent out of the cross lapping machine 1 and the cross lapping machine 2 to be coincided and then sequentially is processed by a prewetting process, an aqua tex process, a dewatering process, a drying process and a coiling process. The PTFE aqua tex composite high-temperature tail gas filter material is strong in mechanical performance, filter performance, high temperature resistance and chemical corrosion resistance and stable in size.

Owner:ZHEJIANG HEZHONG NONWOVEN

Polyester multifilament yarn for rubber reinforcement and method of producing the same

InactiveUS20050196610A1High modulusLow shrinkageSynthetic resin layered productsPneumatic tyre reinforcementsPolyesterYarn

Disclosed is a method of producing a polyethylene terephthalate-based polyester fiber, including spinning polyethylene terephthalate based polyester to produce an undrawn yarn with an intrinsic viscosity of 0.83 or more and a density of 1.338 g / cm3 or more, multi-stage drawing the undrawn yarn, heat-setting the drawn yarn, relaxing the heat-set yarn, and winding the relaxed yarn to produce the resulting drawn yarn with an intrinsic viscosity of 0.83 or more and a density of 1.38 to 1.3865 g / cm3. Compared to a prior polyester yarn with high modulus and low shrinkage, produced according to conventional melt-spinning and drawing processes, an industrial polyester yarn with high modulus and low shrinkage according to the present invention contributes to significantly improving strength retention (tenacity of a dip cord / tenacity of a grey yarn) of the dip cord, produced by treating the polyester yarn of the present invention with an adhesive (RFL) and subsequently heat-treating the RFL-treated polyester yarn. Therefore, the polyester multifilament yarn according to the present invention is useful as a tire cord.

Owner:HYOSUNG ADVANCED MATERIALS CORP

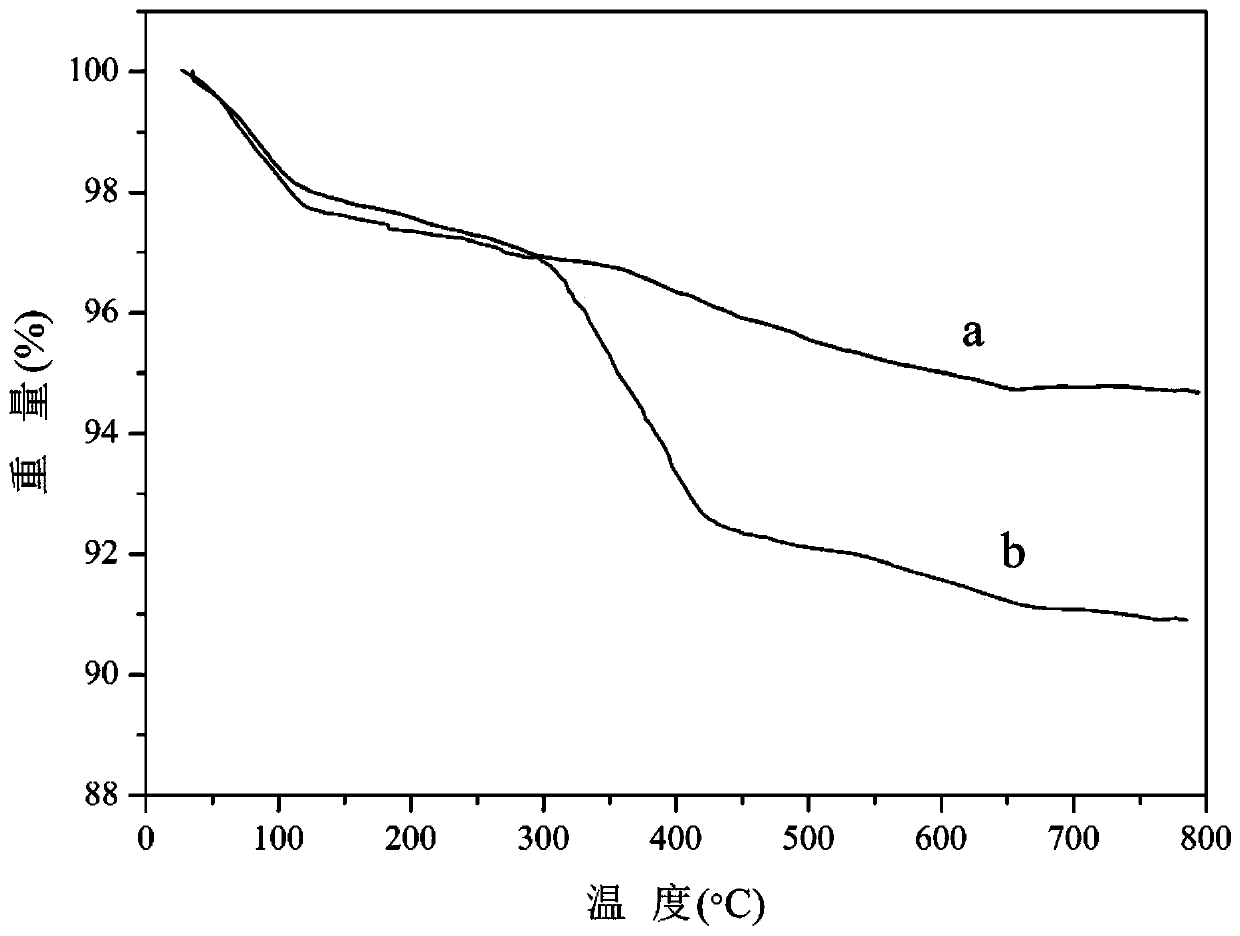

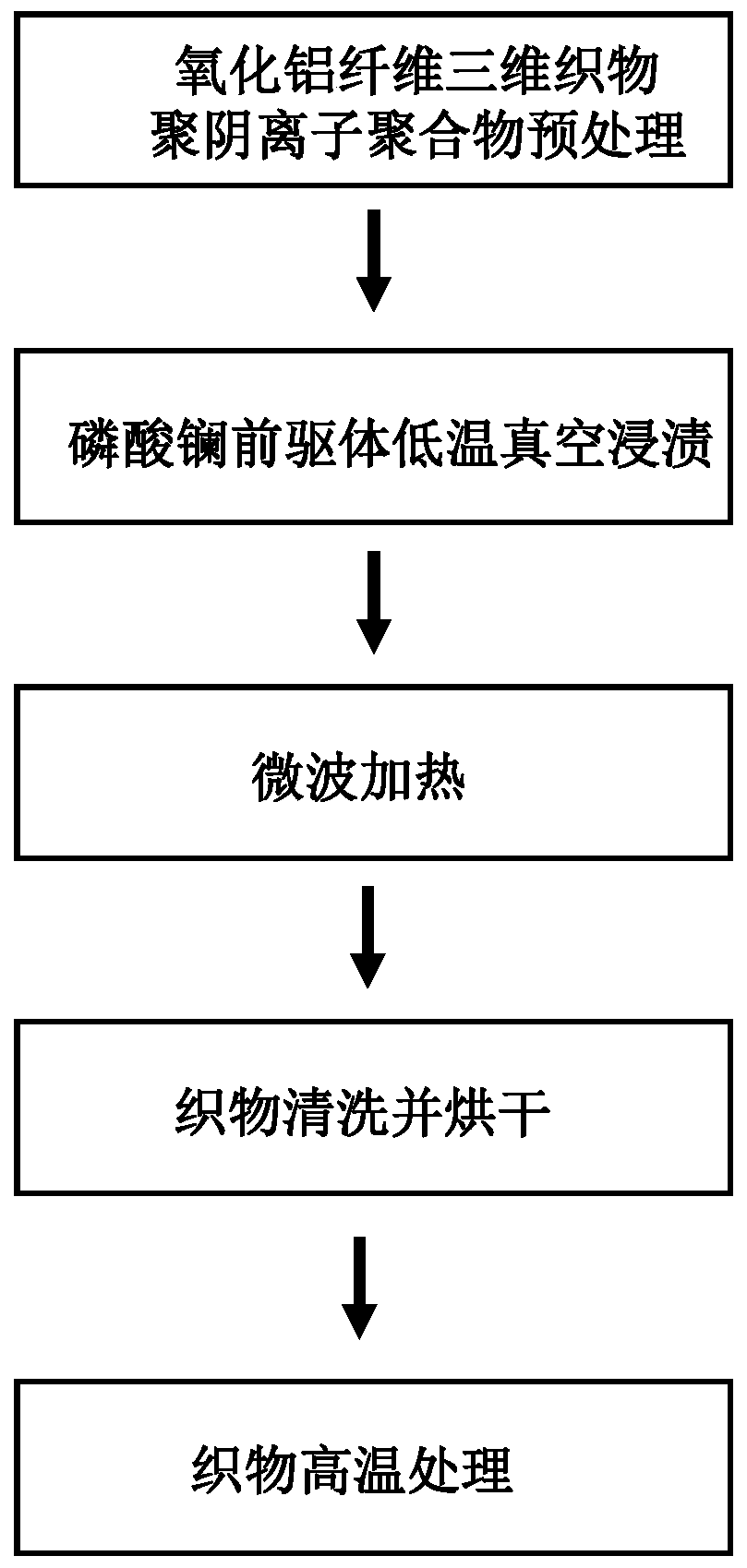

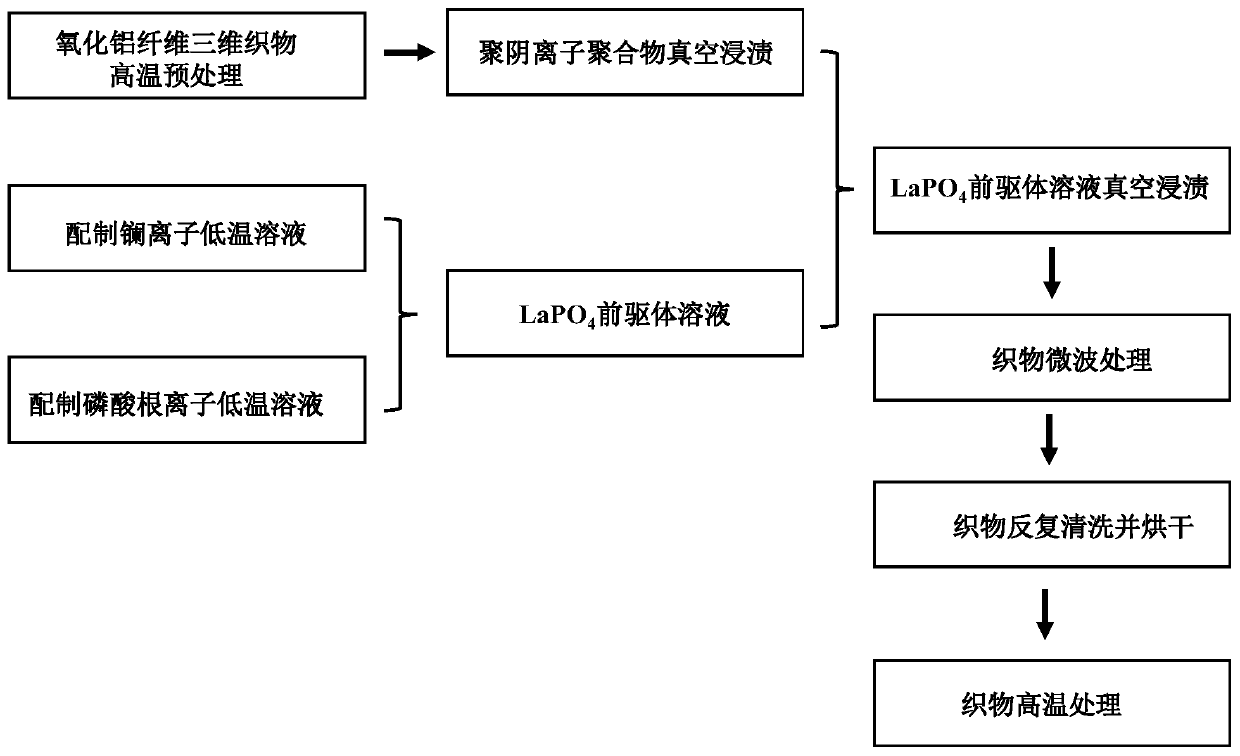

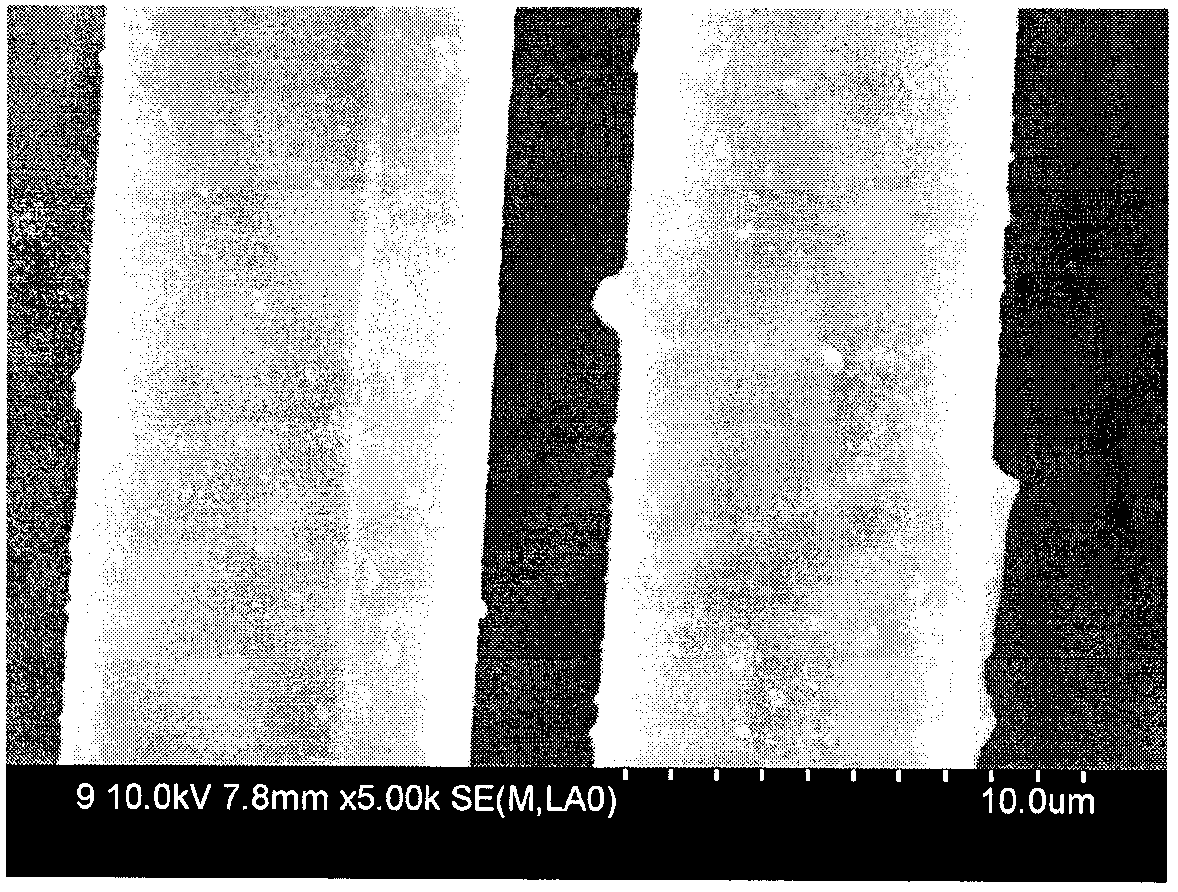

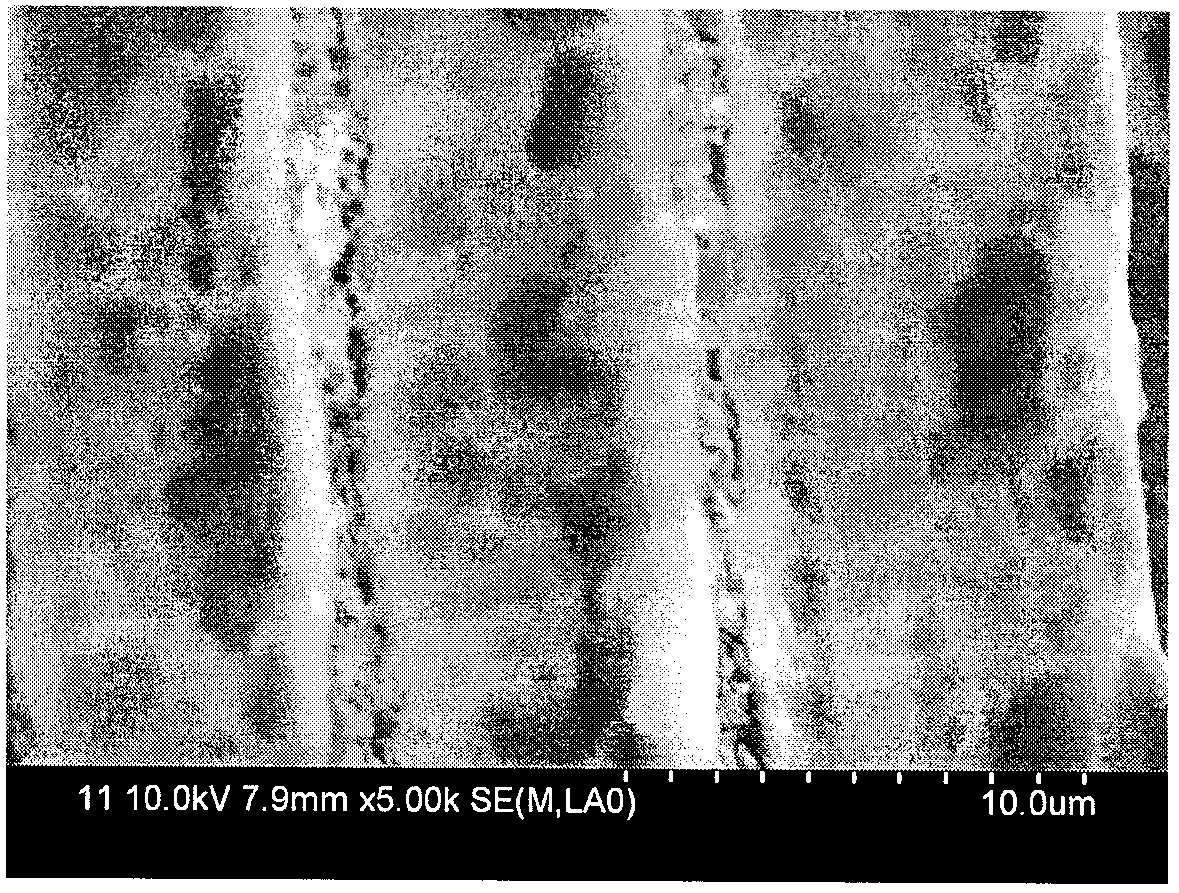

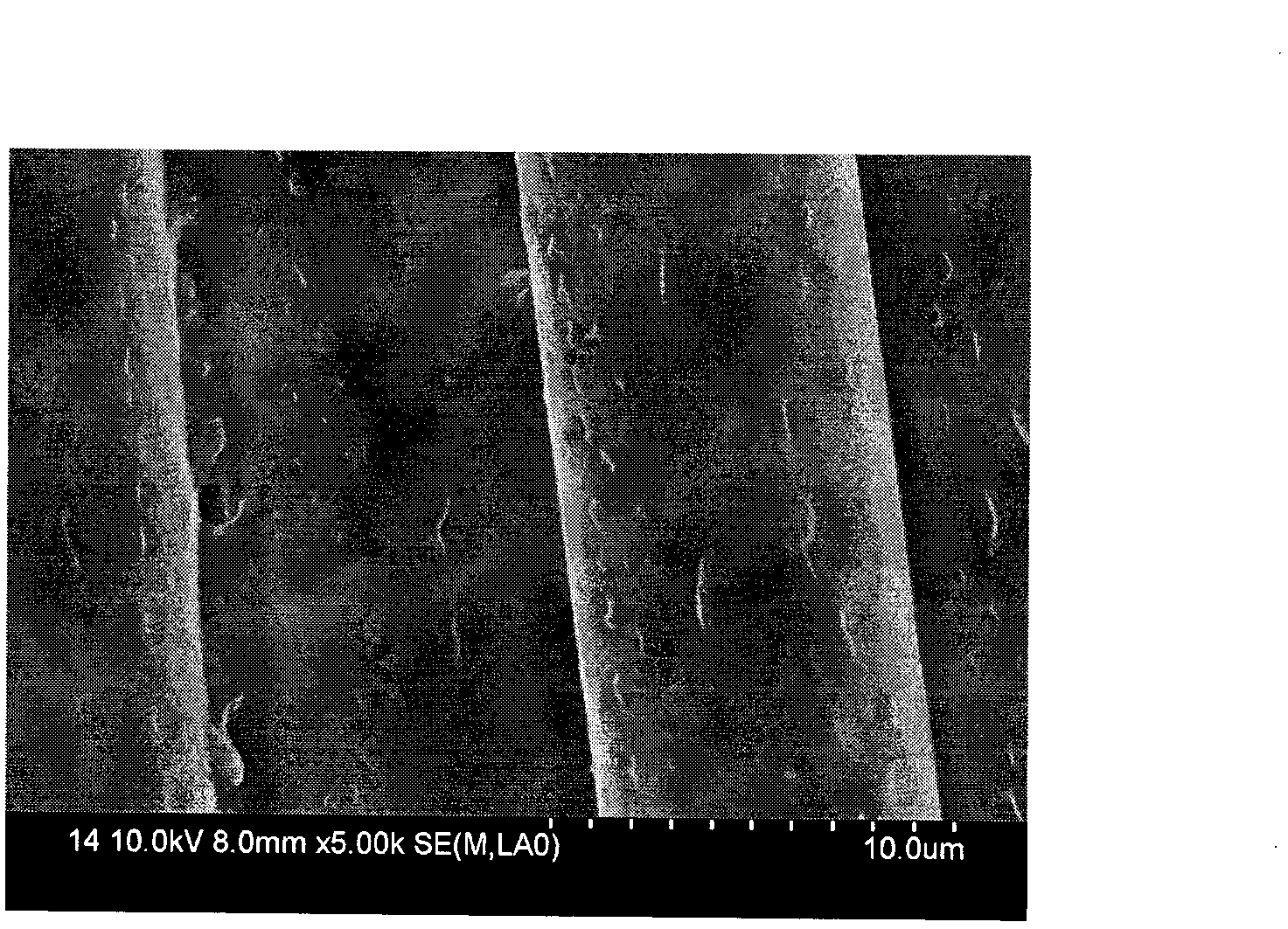

Method for carrying out interface modification on alumina fiber three-dimensional fabric and modified alumina fiber three-dimensional fabric prepared by same

ActiveCN111005226AMild reaction conditionsIncrease profitPhysical treatmentLiquid/gas/vapor removalFiberAlumina composite

The invention relates to a method for carrying out interface modification on an alumina fiber three-dimensional fabric and a modified alumina fiber three-dimensional fabric prepared by the same. The method comprises the steps of: carrying out preprocessing on the alumina fiber three-dimensional fabric by adopting polyanion polymer solution to obtain a preprocessed alumina fiber three-dimensional fabric; preparing lanthanum phosphate precursor solution of which a temperature is not higher than 5 DEG C; under the conditions of vacuum and a temperature which is not higher than 10 DEG C, carryingout vacuum impregnation on the preprocessed alumina fiber three-dimensional fabric by adopting the lanthanum phosphate precursor solution; and carrying out microwave heating processing on the aluminafiber three-dimensional fabric subjected to vacuum impregnation, and then sequentially carrying out steps of cleaning, drying and high-temperature processing so as to complete interface modification on the alumina fiber three-dimensional fabric. The method is simple in process, does not require complex equipment and regents, and is high in utilization rate of a raw material and low in cost; and analumina fiber reinforced aluminum oxide composite material prepared by adopting the fiber three-dimensional fabric modified by the process disclosed by the invention still has high strength after long-time high-temperature processing.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method for alumina/quartz glass composite fiber

The invention discloses a preparation method for alumina / quartz glass composite fiber and belongs to the field of inorganic fiber. The preparation method comprises the steps as follows: 1, pretreating quartz fiber with a dilute sulfuric acid solution; 2, preparing boehmite sol through a sol-gel method by taking AlCl3.6H2O, metal Al powder, lactic acid and H2O as raw materials; and 3, impregnating the pretreated quartz fiber in the boehmite sol, drying and conducting heat treatment to obtain the alumina / quartz glass composite fiber. The preparation method has the advantages of simple process, convenience in operation and low energy consumption, and the tensile strength and the alkaline resistance of the prepared composition fiber are greatly improved in comparison with those of the quartz fiber.

Owner:TIANJIN POLYTECHNIC UNIV

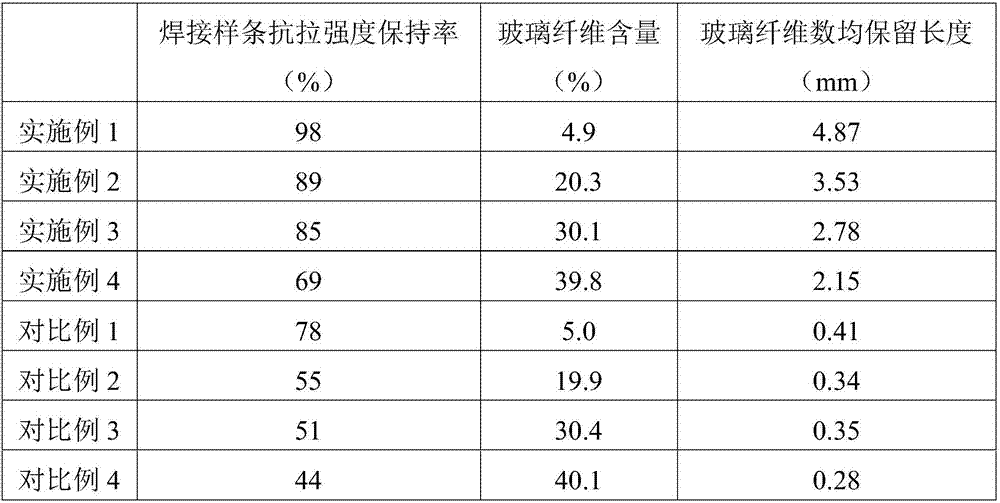

Light or colorless polyamide composite material for laser welding

The invention discloses a light or colorless polyamide composite material for laser welding. The light or colorless polyamide composite material for laser welding comprises a laser absorption part and a laser transmission part, wherein the laser absorption part comprises polyamide, a phosphate compound, a copper halide metal compound, a halogenated metal salt compound and glass fibers; the laser transmission part comprises polyamide, the copper halide metal compound, the halogenated metal salt compound and the glass fibers; halide ions in the copper halide metal compound are chloride ions, bromide ions or iodide ions; copper ions in the copper halide metal compound are Cu<+> or Cu<2+>; metal elements in the halogenated metal salt compound are alkali or alkaline-earth metal elements; the diameters of the glass fibers are 5-20mu m; and the number average lengths of the glass fibers are 0.05-30mm; and compared with a body material without a welded conjunction surface, the composite material disclosed by the invention is relatively high in strength retention rate or even exceeds that of the body material, the property retention rate of the composite material is even up to 95% or above, and the properties of the composite material are remarkably prior to those of welding materials of common short cut glass fibers.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +1

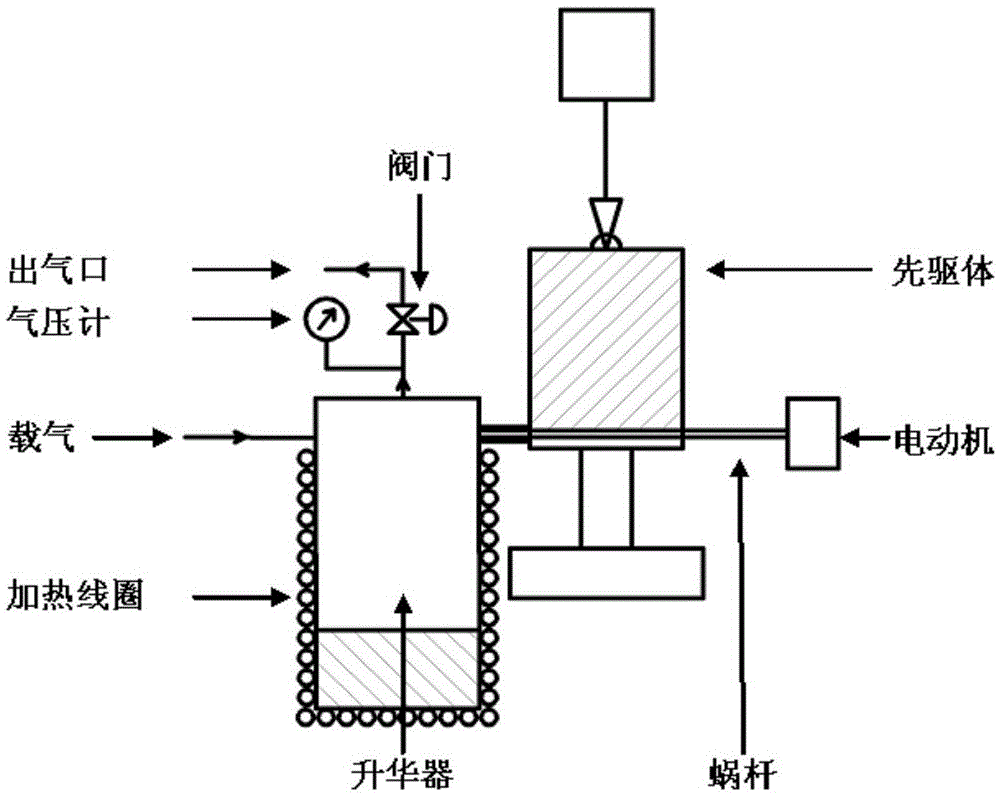

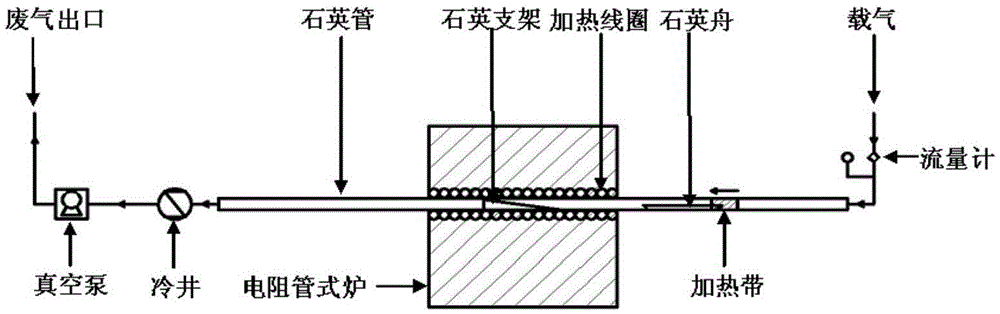

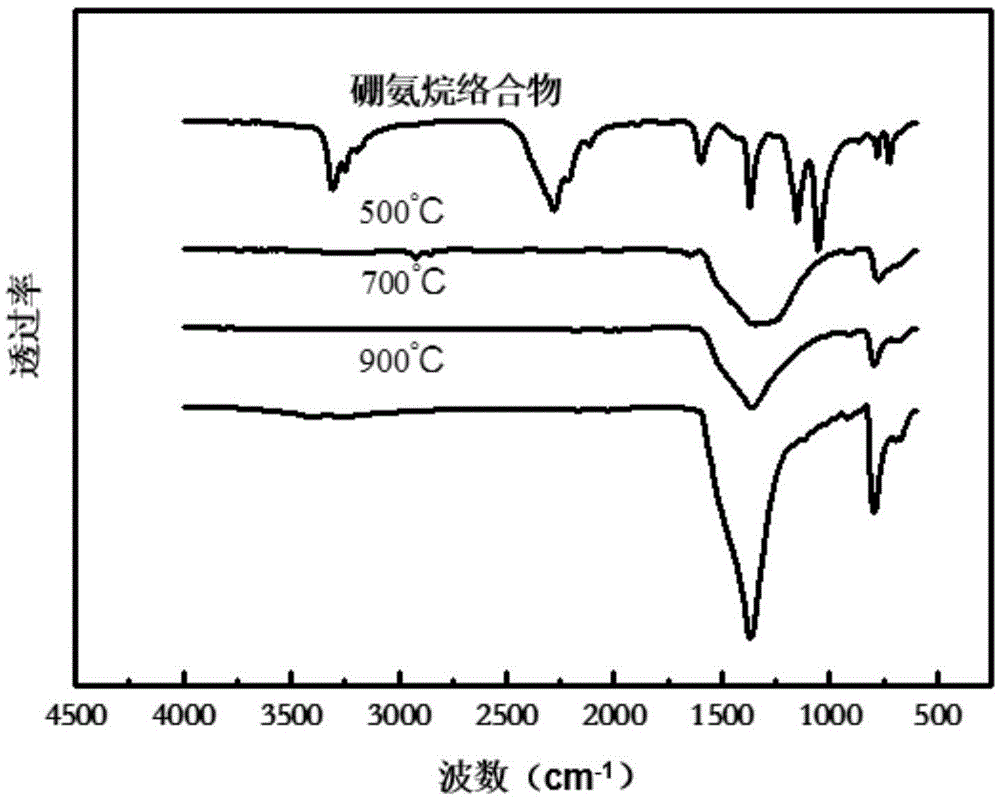

Method for manufacturing ceramic matrix composite boron nitride interface coating

ActiveCN105463403AEasy to form stoichiometric ratioStoichiometric ratio is betterChemical vapor deposition coatingLow temperature depositionReaction temperature

The invention relates to a method for manufacturing a ceramic matrix composite boron nitride interface coating, in particular to manufacturing of boron nitride coatings on a fiber surface and a substrate surface and belongs to the technical field of ceramic matrix composite toughness improvement. According to the method, a single component NH3BH3 containing B and N at the same time is selected as a precursor of a BN interface, the precursor is free of toxin and pollution, unlikely to burn or explode and capable of easily forming BN at the stoichiometric ratio of B:N=1:1, it is guaranteed that the manufactured BN is good in stoichiometric ratio, the problem that B and N in a double-component precursor are disproportionate is avoided, and no corrosive gas is generated in the manufacturing process. The method can be used for manufacturing the coating at the reaction temperature from 400 DEG C to 900 DEG C through a low-temperature chemical vapor deposition method, the temperature from 700 DEG C to 900 DEG C is preferred to increase the yield of BN, and the content of the obtained deposition product BN is over 97%. The strength retention rate of fibers can be increased as much as possible through low-temperature deposition, the strength retention rate is over 90% after deposition, and the strength retention rate is over 70% after high-temperature thermal treatment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Molded-in insert and method for fiber reinforced thermoplastic composite structure

ActiveUS9180631B2High strength retentionMeet actual needsNutsSecuring devicesEngineeringThermoplastic composites

In an embodiment of the disclosure, there is provided a molded-in insert for high strength retention in a fiber reinforced thermoplastic composite structure. The insert has a cylindrical body and at least one circumferential groove formed in the cylindrical body, the groove having a substantially concave configuration, having a groove radius of 0.025 inch or greater, and having the groove radius greater than or equal to a groove depth.

Owner:THE BOEING CO

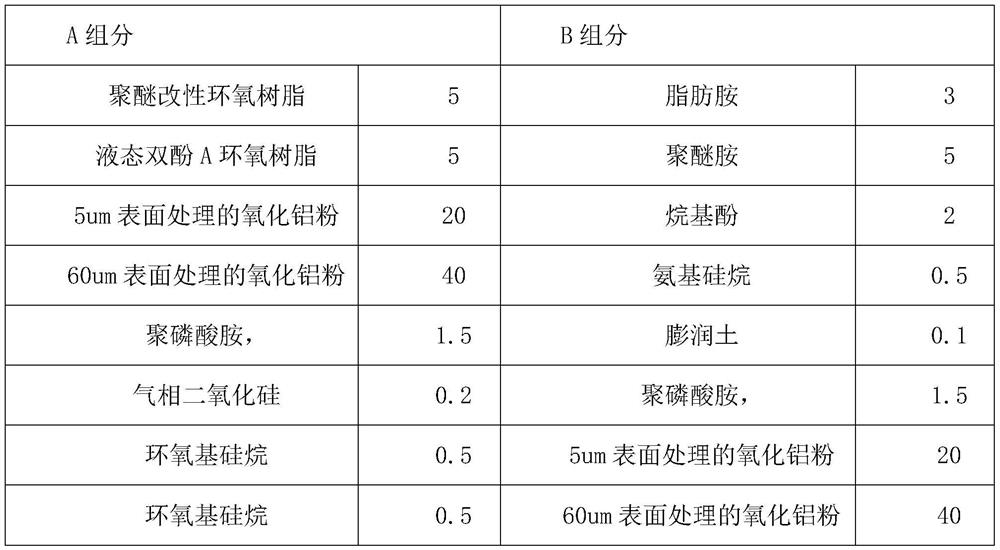

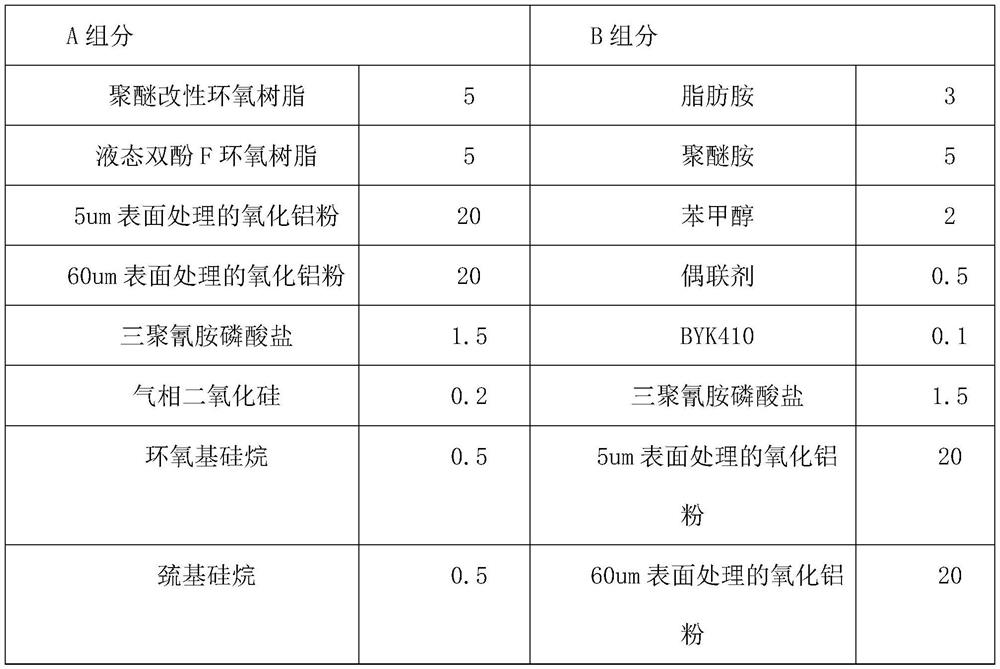

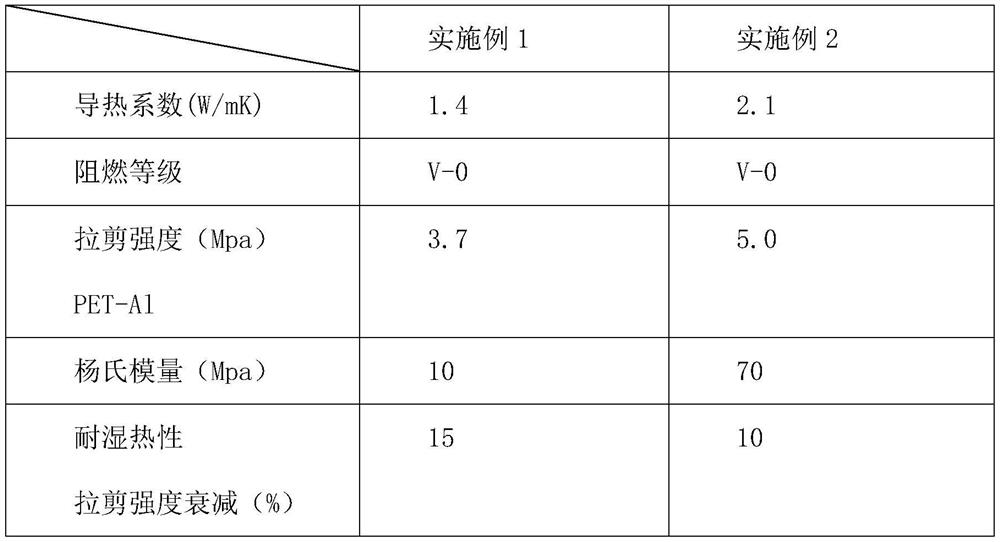

High-damp-heat-resistance heat-conducting structural adhesive for power battery bonding, preparation and application

PendingCN112778951AEasy to absorb water and reduce heat and humidity resistanceReduce hardnessNon-macromolecular adhesive additivesEpoxy resin adhesivesAdhesive cementPower battery

The invention relates to the technical field of adhesives, in particular to a high-damp-heat-resistance heat-conducting structural adhesive for power battery bonding, which comprises a component A and a component B mixed according to a volume ratio, wherein the component A comprises 5-50 parts of modified epoxy resin, 5-50 parts of liquid epoxy resin containing a reactive diluent, 5-100 parts of heat-conducting powder subjected to surface treatment by a specific coupling agent, 0.1-5 parts of a flame retardant, 0.1-5 parts of an anti-settling agent and 0.1-5 parts of a coupling agent; and the component B comprises 1-50 parts of an amine curing agent, 1-50 parts of a catalyst, 0.1-5 parts of a coupling agent, 0.1-5 parts of an anti-settling agent, 0.1-5 parts of a flame retardant and 5-100 parts of heat-conducting powder subjected to surface treatment by a specific coupling agent. The structural adhesive has the advantages of low elastic modulus, high heat conductivity, high adhesion, high flame retardance and high heat and damp resistance.

Owner:JONES TECH +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com