High-damp-heat-resistance heat-conducting structural adhesive for power battery bonding, preparation and application

A heat-conducting structure and power battery technology, applied in the direction of adhesives, epoxy resin glue, adhesive types, etc., can solve problems such as reduced bonding performance, achieve low elastic modulus, avoid agglomeration, meet heat dissipation and bonding fixation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The processing steps are:

[0053] The first step: powder treatment, 1g of coupling agent is made into alcohol solution and added to the surface of 100g of heat-conducting powder, reacted at 85°C and then dried at 100°C.

[0054] Step 2: Add the materials in the formula to the planetary disperser one by one, stir and mix for 60 minutes at a stirring paddle speed of 50-150 r / min, and continue stirring for 60 minutes under vacuum to obtain the A and B components of the structural adhesive.

[0055] Step 3: Mix the obtained AB components with a static mixer, and test the properties after curing at room temperature for 7 days.

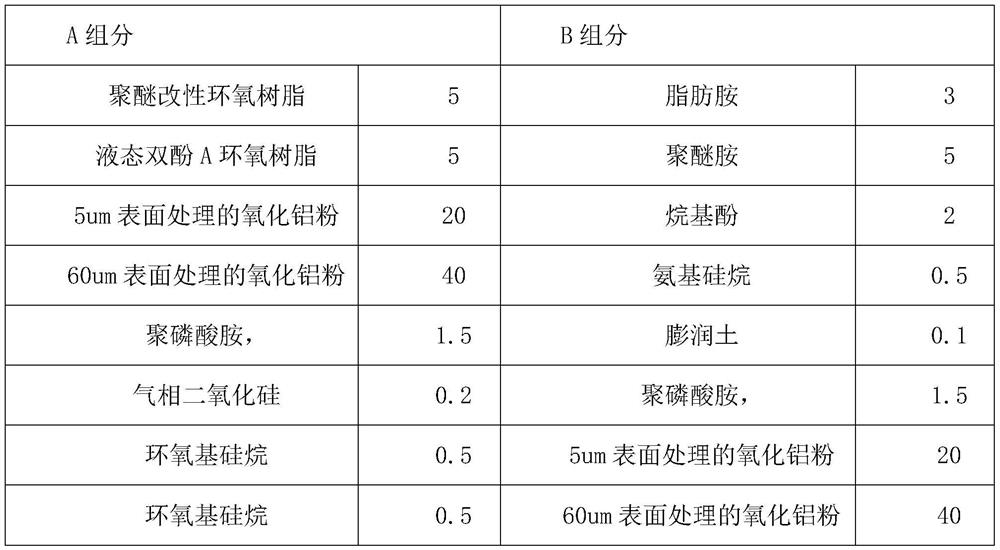

[0056] Component ratio table in embodiment 1

[0057]

Embodiment 2

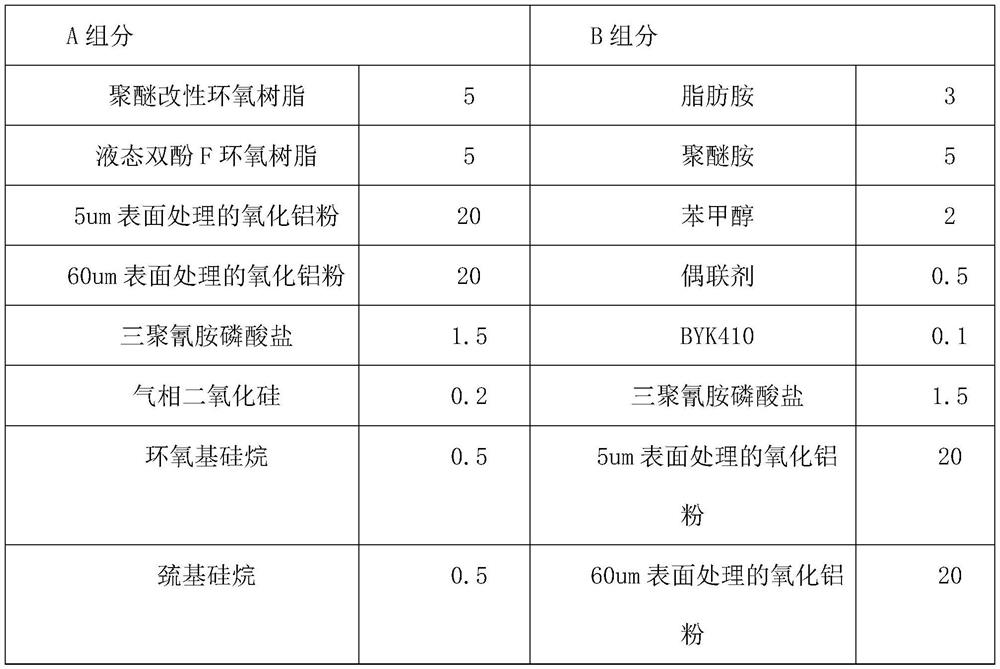

[0059] With reference to the technique in embodiment 1, the adjustment component proportioning table is

[0060]

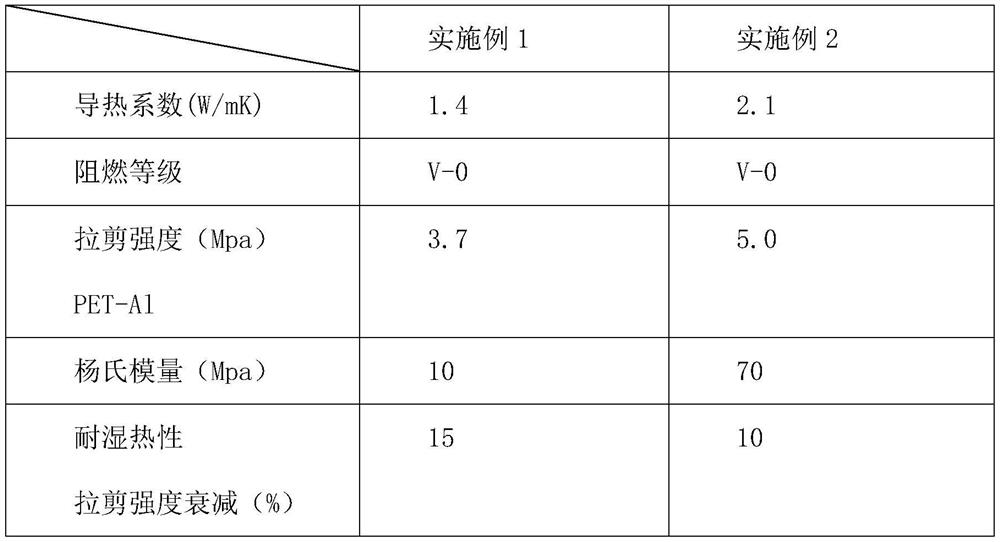

[0061] The test data sheet of embodiment 1 and embodiment 2

[0062]

[0063] Based on the content of the present invention and the content in the embodiment, the present invention has the following beneficial effects:

[0064] 1. By matching a specific compound amine cross-linking agent with a flexible modified epoxy resin, the cross-linking point structure with a long and smooth long molecular chain structure and short molecular chain concentration is controlled, and the polymer network structure Forming a microscopic phase separation, that is, a two-phase network structure between dense phase and loose phase, which overcomes the decrease in water absorption and heat resistance caused by the excessive free volume in the polymer network of the adhesive itself, and helps to reduce the hardness and elastic modulus of the cured product. At the same time, it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com