Antioxidation polyphenylene sulfide/modified nano silicon dioxide composite fiber and preparation method thereof

A nano-silica, polyphenylene sulfide technology, applied in the direction of fiber chemical characteristics, single-component synthetic polymer rayon, rayon manufacturing, etc., can solve the problems of anti-oxidation effect to be discussed, shorten the preparation process, etc., to achieve Effects of improved anti-oxidation performance, good dispersibility, and increased strength retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

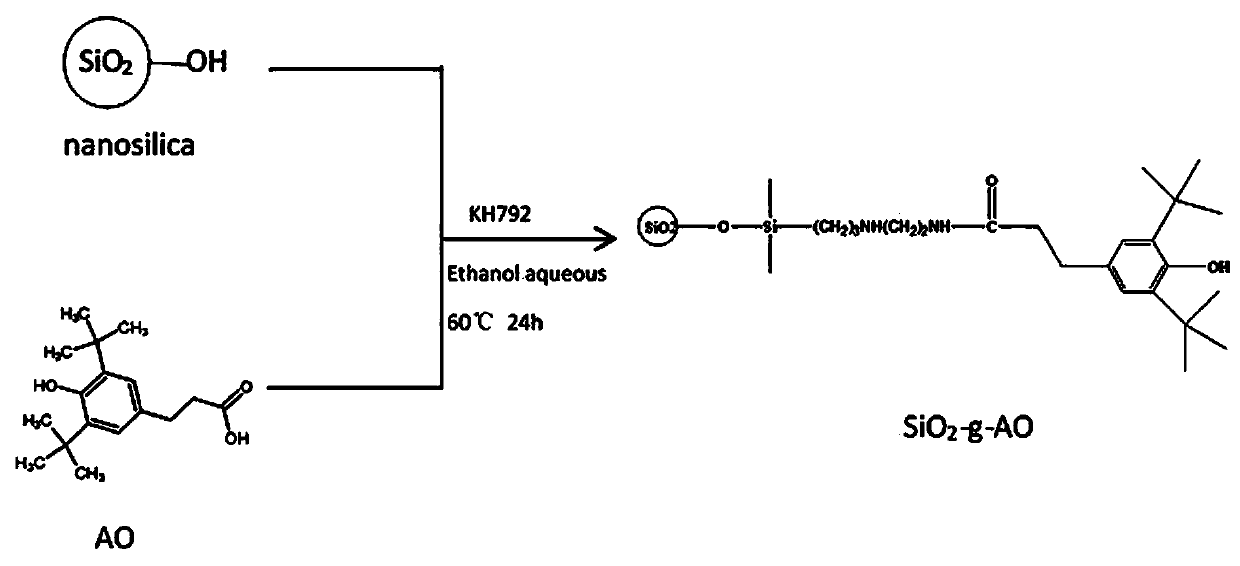

[0030] Embodiment 1: the preparation process of modified nano silicon dioxide is as follows figure 1 shown. Weigh 2g of nano-silica and pour it into a 250ml three-neck flask, then add 150ml of ethanol aqueous solution (ethanol: water = 3:1); the frequency of ultrasonic vibration is 40 kHz ultrasonic vibration for 60 min, put it into a heating mantle to heat and stir; Slowly add 0.3 g of KH792 dropwise into the three-necked flask, adjust the pH to 3 with hydrochloric acid; add 2 g of 3,5 di-tert-butyl-4-hydroxyphenylpropionic acid (AO) into the three-necked flask. Set the temperature to 70°C, condense to reflux, and stir for 12 h. After the reaction, put the product in a centrifuge and centrifuge at a speed of 6500 r / min for 5 min; wash and centrifuge repeatedly with ethanol solution until the pH of the solution is neutral, put it in a vacuum drying oven, and dry it at 110 °C After 10 h, the modified nano-silica was obtained.

[0031] Put the polyphenylene sulfide resin into...

Embodiment 2

[0042] Embodiment 2: the preparation process of modified nano silicon dioxide is as follows figure 1 shown. Weigh 2g of nano-silica and pour it into a 250ml three-neck flask, then add 100ml of ethanol aqueous solution (ethanol: water = 1:1); the frequency of ultrasonic vibration is 45 kHz ultrasonic vibration for 30 min, put it into a heating mantle to heat and stir; Slowly add 0.2 g KH792 dropwise to the three-necked flask, adjust the pH to 3 with hydrochloric acid; add 1.0 g of 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid (AO) to the three-necked flask. Set the temperature at 50°C, condense to reflux, and stir for 15 h. After the reaction, put the product in a centrifuge and centrifuge at a speed of 6500 r / min for 5 min; wash and centrifuge repeatedly with ethanol solution until the pH of the solution is neutral, put it in a vacuum drying oven, and dry it at 80°C After 12 h, the modified nano-silica was obtained.

[0043] Put the polyphenylene sulfide resin into a vacu...

Embodiment 3

[0049] Embodiment 3: the preparation process of modified nano silicon dioxide is as follows figure 1 shown. Weigh 2g of nano-silica and pour it into a 250ml three-neck flask, then add 200ml of ethanol aqueous solution (ethanol: water = 2:1); the frequency of ultrasonic vibration is 50 kHz ultrasonic vibration for 40 min, put it into a heating mantle to heat and stir; Slowly add 1 g of KH792 dropwise to the three-necked flask, adjust the pH to 3 with hydrochloric acid; add 4 g of 3,5-di-tert-butyl-4-hydroxyphenylpropionic acid (AO) to the three-necked flask. Set the temperature to 80°C, condense to reflux, and stir for 10 h. After the reaction, put the product in a centrifuge and centrifuge at a speed of 6500 r / min for 5 min; wash and centrifuge repeatedly with ethanol solution until the pH of the solution is neutral, put it in a vacuum drying oven, and dry it at 100 °C 8 h to obtain modified nano-silica.

[0050] Put the polyphenylene sulfide resin into a vacuum drum dryer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com