Preparation method for alumina/quartz glass composite fiber

A quartz glass and composite fiber technology is applied in the field of preparation of alumina/quartz glass composite fibers, which can solve the problems of affecting the long-term performance and strength stability of composite materials, losing the reinforcing effect of concrete, affecting high-temperature service performance, etc. Convenience, stable performance, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

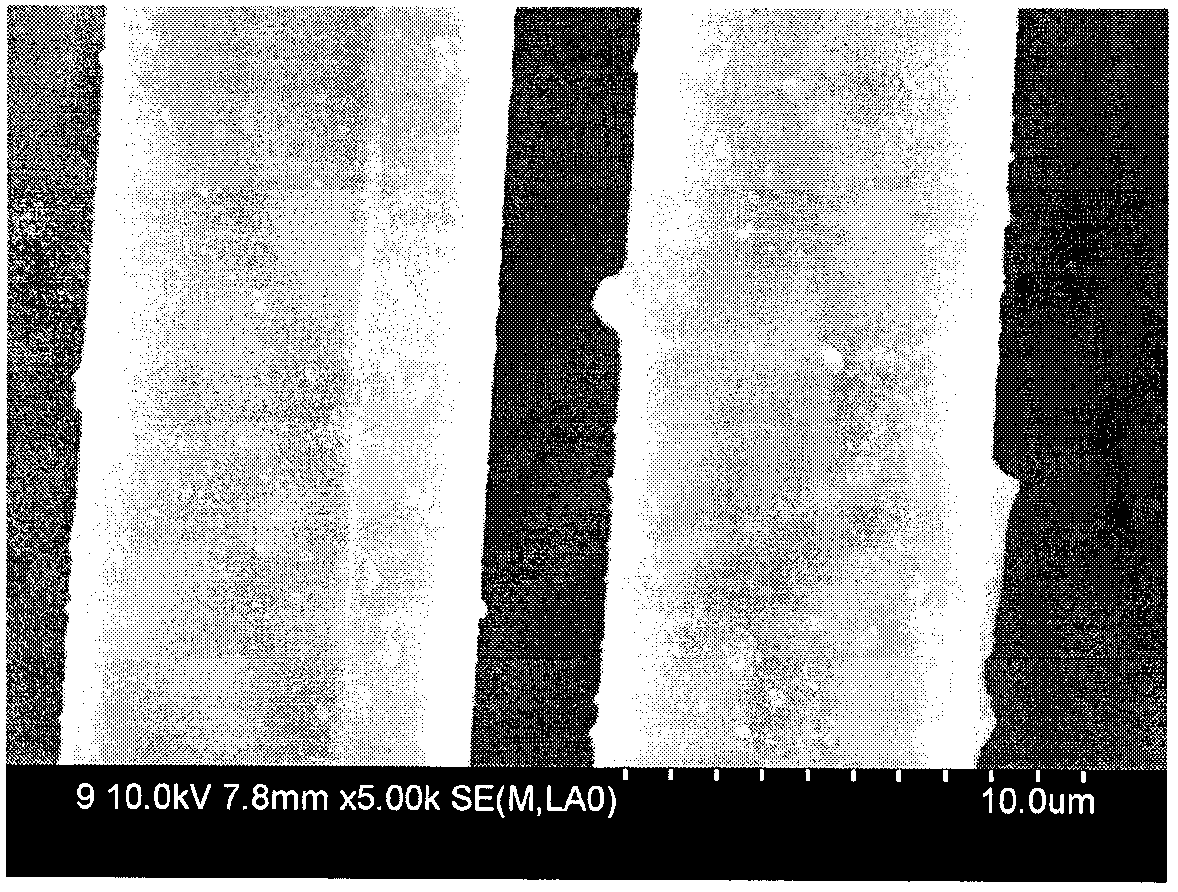

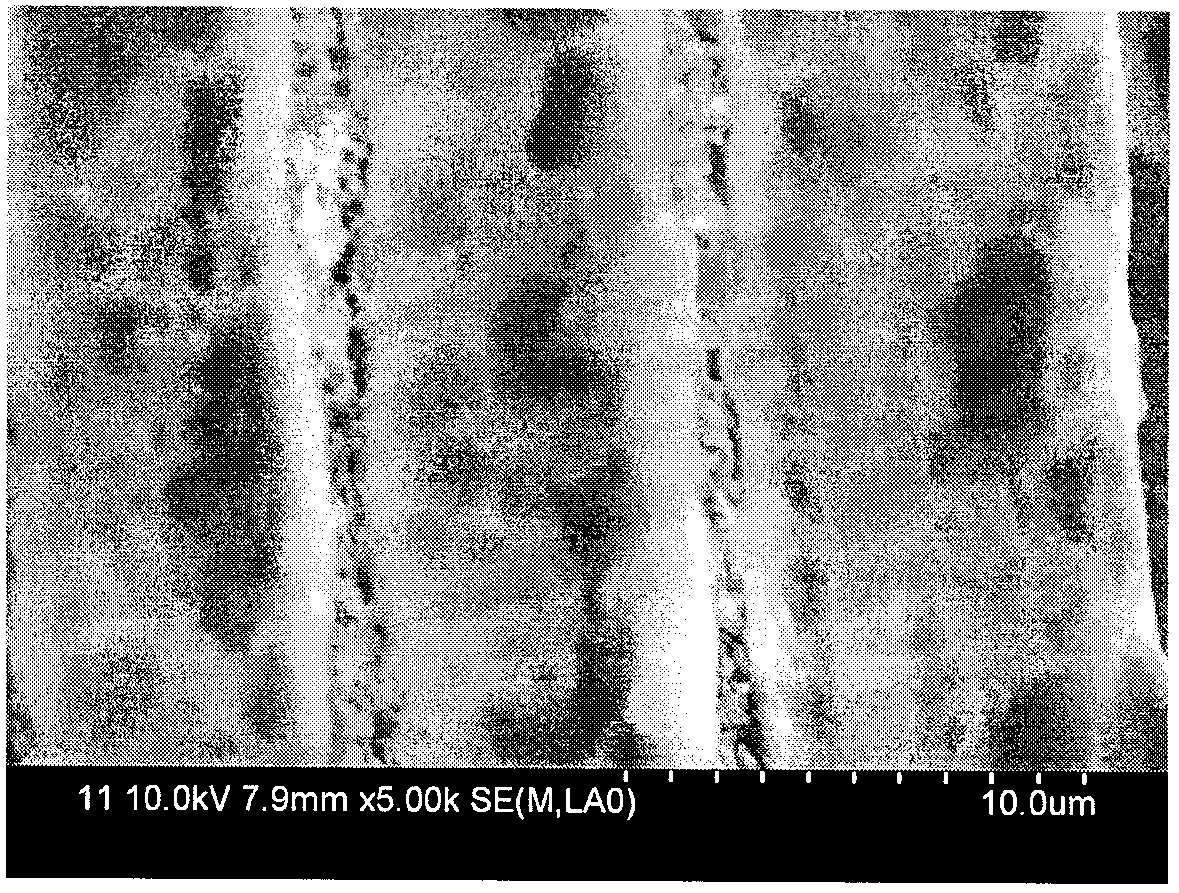

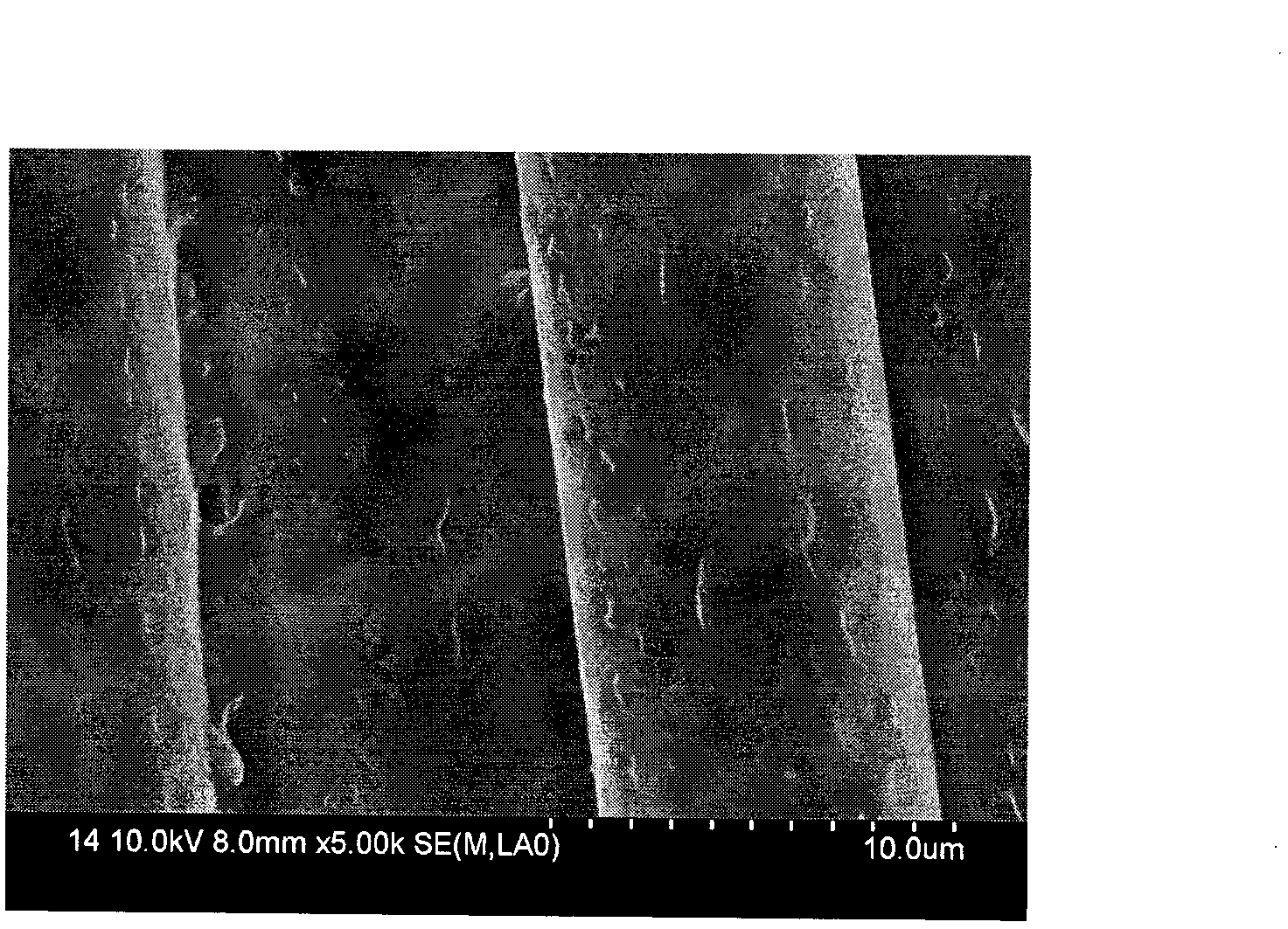

Image

Examples

Embodiment 1

[0031] A preparation method of alumina / quartz glass composite fiber, the method steps are as follows:

[0032] (1) Quartz fiber surface pretreatment;

[0033] The acid etching pretreatment process is used to pretreat the fiber surface to remove the sizing agent on the fiber surface. Take a certain amount of quartz fibers and put them into dilute sulfuric acid solution with a mass fraction of 2%, soak them for 1 hour at a constant temperature of 98°C, take them out and cool them, wash them with deionized water until they are neutral, dry them in an oven at 80°C, and then Natural cooling to room temperature;

[0034] (2) preparing boehmite sol;

[0035] ① Weigh the raw materials, and the AlCl 3 ·6H 2 Dissolve O in water, add aluminum powder, AlCl after fully hydrolyzed 3 ·6H 2 The molar ratio of O and metal Al powder is 1:2, in a constant temperature water bath at 100°C, mechanically stirred and refluxed for 10h to form a colloidal mother liquor;

[0036] ② Filter the mot...

Embodiment 2

[0041] A preparation method of alumina / quartz glass composite fiber, the method steps are as follows:

[0042] (1) Quartz fiber surface pretreatment;

[0043] The acid etching pretreatment process is used to pretreat the fiber surface to remove the sizing agent on the fiber surface. Take a certain amount of quartz fibers and put them into dilute sulfuric acid solution with a mass fraction of 6%, soak them for 1 hour at a constant temperature of 98°C, take them out and cool them, wash them with deionized water until they are neutral, dry them in an oven at 80°C, and then Natural cooling to room temperature;

[0044] (2) preparing boehmite sol;

[0045] ① Weigh the raw materials, and the AlCl 3 ·6H 2 Dissolve O in water, add aluminum powder, AlCl after fully hydrolyzed 3 ·6H 2 The molar ratio of O and metal Al powder is 1:2.5, in a constant temperature water bath at 100°C, mechanically stirred and refluxed for 10 hours to form a colloidal mother liquor;

[0046] ② Filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com