Light or colorless polyamide composite material for laser welding

A technology of laser welding and composite materials, which is applied in the field of modified polymer composite materials and composite materials, can solve the problems of unobtainable and difficult to approach the strength of the body, and achieve the effect of high strength retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

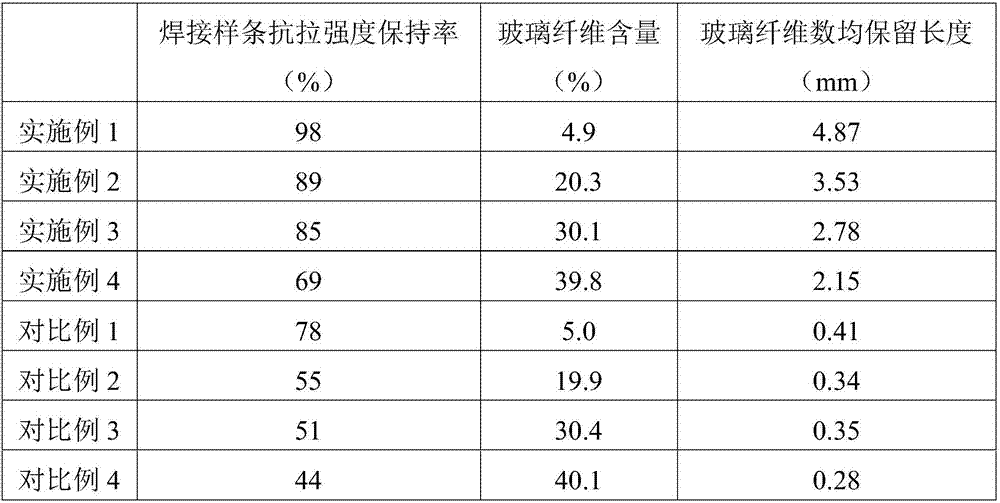

Examples

specific Embodiment 1

[0027] Laser absorption part: 85 parts of PA66, 5 parts of copper hydroxide phosphate, 0.05 part of cuprous iodide, 1 part of sodium bromide, 10 parts of PA66-LG50;

[0028] Transmission laser part: 85 parts of PA66, 0.05 parts of cuprous iodide, 1 part of sodium bromide, 10 parts of PA66-LG50.

specific Embodiment 2

[0030] Laser absorption part: 60 parts of PA66, 2 parts of copper phosphate, 0.5 parts of copper bromide, 2 parts of potassium iodide, 10 parts of glass fiber, 20 parts of PA66-LG50;

[0031] Transmission laser part: 60 parts of PA66, 0.5 parts of copper bromide, 2 parts of potassium iodide, 10 parts of glass fiber, 20 parts of PA66-LG50.

specific Embodiment 3

[0033] Laser absorption part: 50 parts of PA66, 1 part of sodium phosphate, 2 parts of cuprous iodide, 5 parts of sodium bromide, 20 parts of glass fiber, 20 parts of PA66-LG50;

[0034] Transmission laser part: 50 parts of PA66, 2 parts of cuprous iodide, 5 parts of sodium bromide, 20 parts of glass fiber, 20 parts of PA66-LG50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com