Method for carrying out interface modification on alumina fiber three-dimensional fabric and modified alumina fiber three-dimensional fabric prepared by same

A technology of alumina fiber and three-dimensional fabric, which is applied in fiber processing, textile material processing, physical processing, etc., can solve the problems of short cost cycle and achieve the effects of low cost, high strength retention rate, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

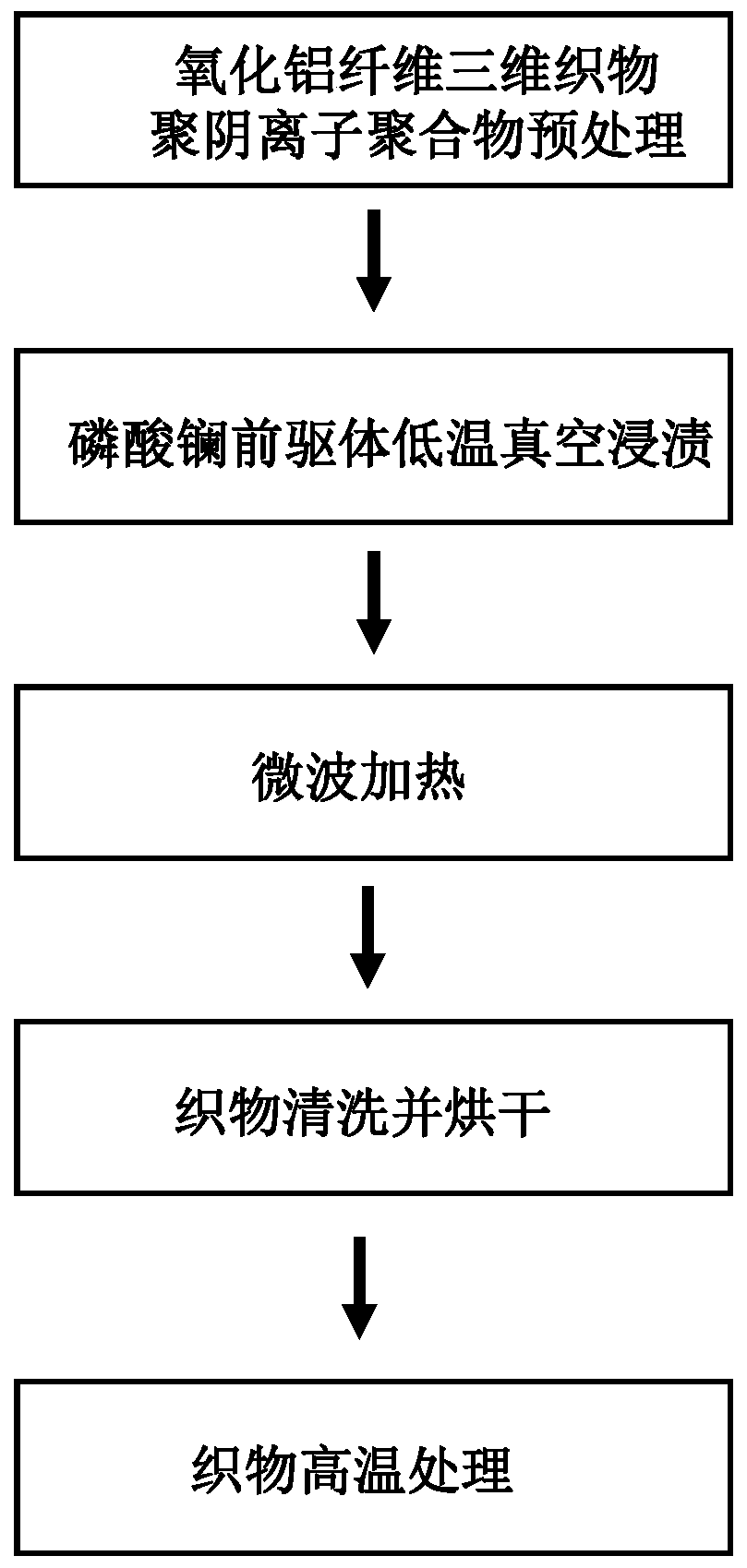

Method used

Image

Examples

Embodiment 1

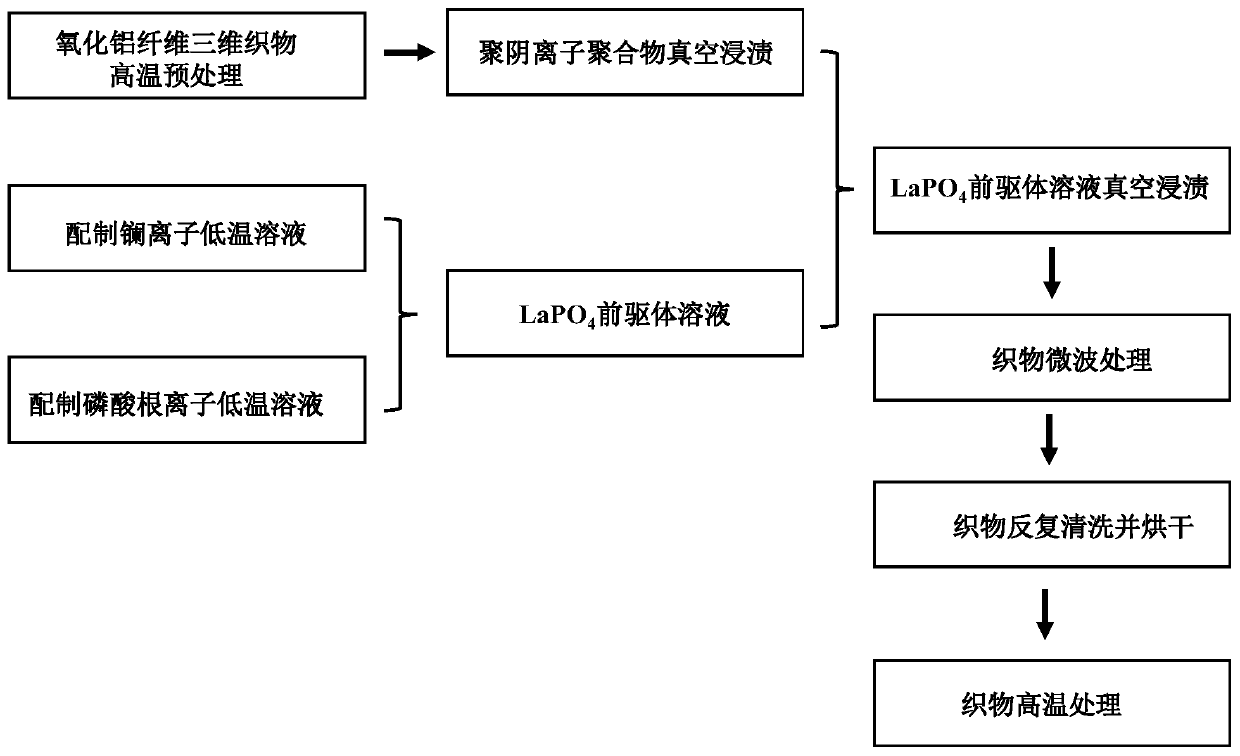

[0067] ①Treat the alumina fiber three-way orthogonal fabric at 500°C for 1 hour in an air atmosphere, and then place it in a vacuum container with a glue inlet. Inject into a vacuum container to completely soak the alumina fiber three-way orthogonal fabric. After standing at room temperature for 10 hours, take out the fabric, wash it once with distilled water, and dry it in an oven at 100°C for 1 hour to obtain polyanionic polymer pretreated alumina. Fiber three-way orthogonal fabric.

[0068] ②Dissolve lanthanum nitrate hexahydrate and EDTA in water at 1°C, adjust the pH value of the solution to 5 with concentrated ammonia water, prepare the final concentration of lanthanum ions in the solution to be 0.4M (0.4mol / L), and the final concentration of EDTA to be 0.8M (0.8mol / L), the final temperature of the solution is maintained at about 1°C to obtain a lanthanum ion solution; dissolve concentrated phosphoric acid in water at 1°C, adjust the pH value of the solution to 5 with co...

Embodiment 2

[0075] ① Treat the alumina fiber stitched fabric at 500°C for 1 hour in an air atmosphere, then place it in a vacuum container with a glue inlet, and inject a polyacrylic acid solution with a mass fraction of 5 wt% and a pH of 5 into the vacuum container under vacuum conditions In the process, the alumina fiber seamed fabric was completely soaked, and after standing at room temperature for 10 hours, the fabric was taken out, washed once with distilled water, and dried in an oven at 100°C for 1 hour to obtain a polyanionic polymer pretreated alumina fiber seamed fabric.

[0076] ② Dissolve lanthanum nitrate hexahydrate and EDTA in water at 1°C, adjust the pH value of the solution to 5 with concentrated ammonia water, prepare the final concentration of lanthanum ions in the solution to 0.4M, the final concentration of EDTA to 0.8M, and the final temperature of the solution Keep it at about 1°C to obtain a lanthanum ion solution; dissolve concentrated phosphoric acid in water at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com