Method for manufacturing ceramic matrix composite boron nitride interface coating

A technology of interface coating and boron nitride, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of high preparation temperature, blockage of pipelines, damage of fiber mechanical properties, etc., and reach the deposition area Large, improved strength retention rate, uniform and dense interface coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

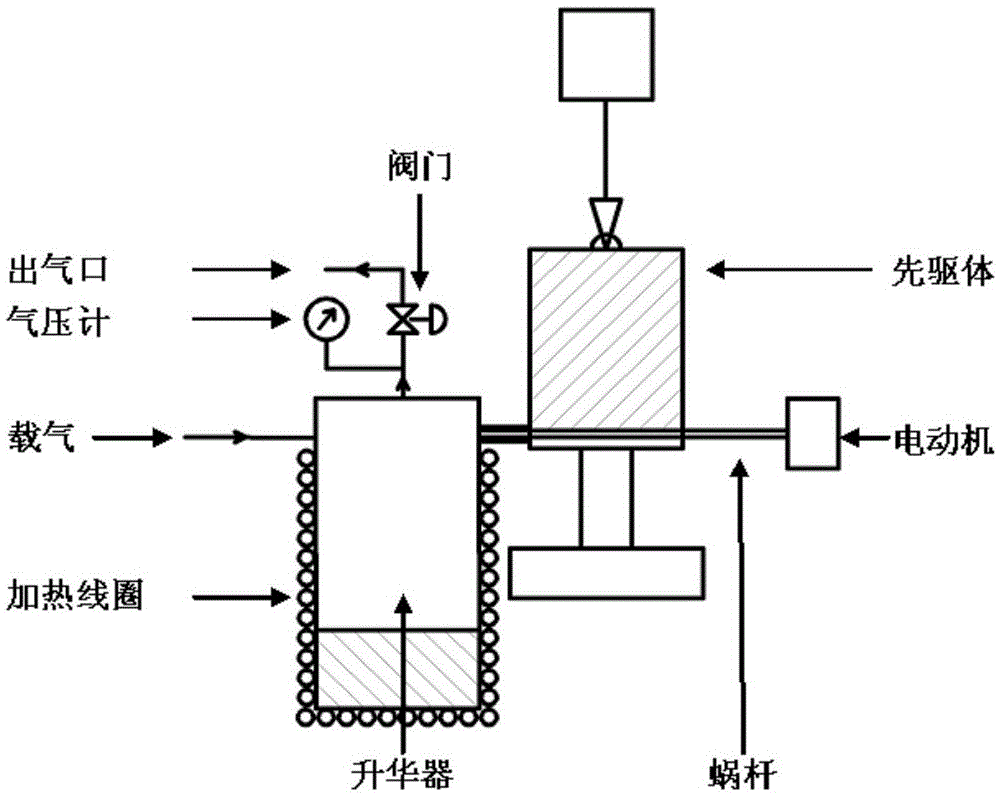

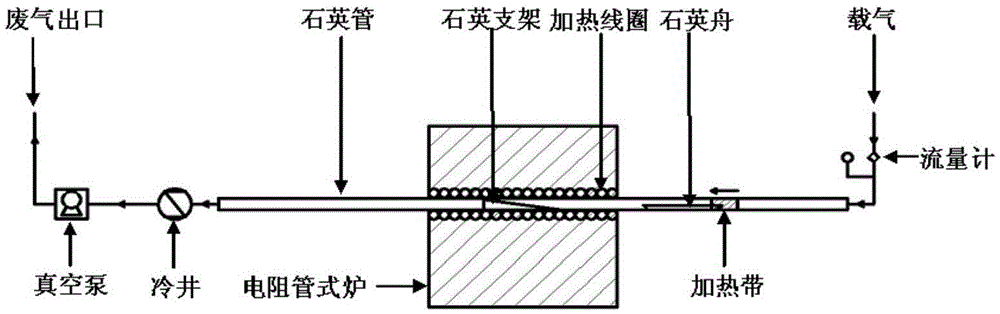

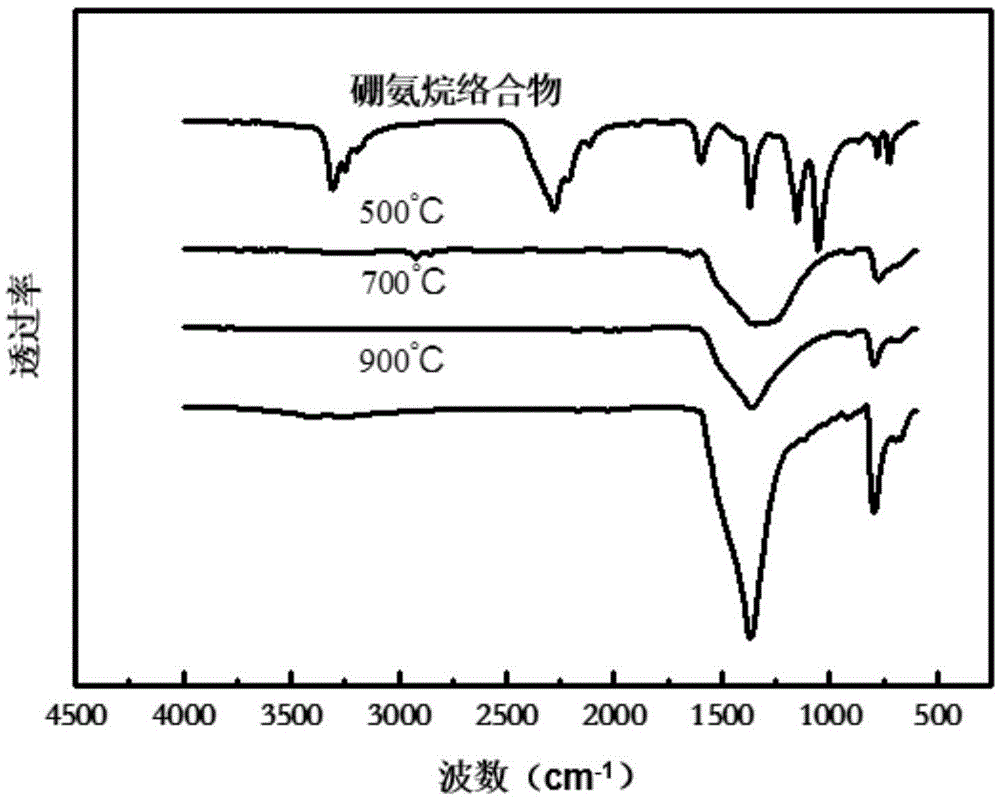

Method used

Image

Examples

Embodiment 1

[0047] A preparation method of boron nitride interface coating on the surface of alumina fiber, the steps are:

[0048] (1) Purify and pretreat 10 bundles of alumina fibers with a length of 14cm and 500 / bundle. The pretreatment process is as follows: first put them in acetone and ultrasonically clean them for 50 minutes, and then place them in a muffle furnace in an air atmosphere. Heating, the heating temperature is 500°C, the heating time is 2h, and the furnace cools down to room temperature to remove the glue on the surface of the alumina fiber;

[0049] (2) The alumina fiber obtained in step (1) is fixed on a solid quartz support with a right-angled triangle in cross section. The inclined plane of the support is 15 cm long and the inclination angle is 5 °. Then the solid quartz support is placed on a horizontally placed hot wall In the deposition tube reaction chamber in the CVD deposition furnace, the total length of the quartz tube (quartz deposition tube) is 1.2m, and i...

Embodiment 2

[0057] A preparation method of silicon nitride fiber boron nitride interface coating, the steps are:

[0058] (1) Purify and pretreat 10 bundles of silicon nitride fibers with a length of 14cm and 500 strands per bundle. The pretreatment process is as follows: first put them in acetone for ultrasonic cleaning for 50 minutes, and then place them in a muffle furnace in an air atmosphere Heating, the heating temperature is 500°C, the heating time is 2h, and the furnace cools down to room temperature to remove the surface coating of the silicon nitride fiber;

[0059](2) the silicon nitride fiber that step (1) is obtained is fixed on the solid quartz support that cross section is a right triangle, and the inclined plane of support is long 15cm, and the inclination angle is 5 °, then solid quartz support is placed in the heat that places horizontally In the reaction chamber of the deposition tube in the wall CVD deposition furnace, the total length of the deposition tube is 1.2m, a...

Embodiment 3

[0067] A preparation method of boron nitride interface coating on the surface of alumina fiber, the steps are:

[0068] (1) Purify and pretreat 10 bundles of alumina fibers with a length of 10 cm and 500 fibers per bundle. The pretreatment process is as follows: first put them in acetone and ultrasonically clean them for 50 minutes, and then place them in a muffle furnace in an air atmosphere. Heating, the heating temperature is 500°C, the heating time is 2h, and the furnace cools down to room temperature to remove the glue on the surface of the alumina fiber;

[0069] (2) The alumina fiber obtained in step (1) is fixed on a solid quartz support whose cross section is a right triangle. The inclined plane of the support is 11 cm long and the inclination angle is 8 °. Then the solid quartz support is placed on a horizontally placed hot wall In the reaction chamber of the deposition tube in the CVD deposition furnace, the total length of the deposition tube is 1.2m, and its cente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com