Patents

Literature

56results about How to "Large deposition area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

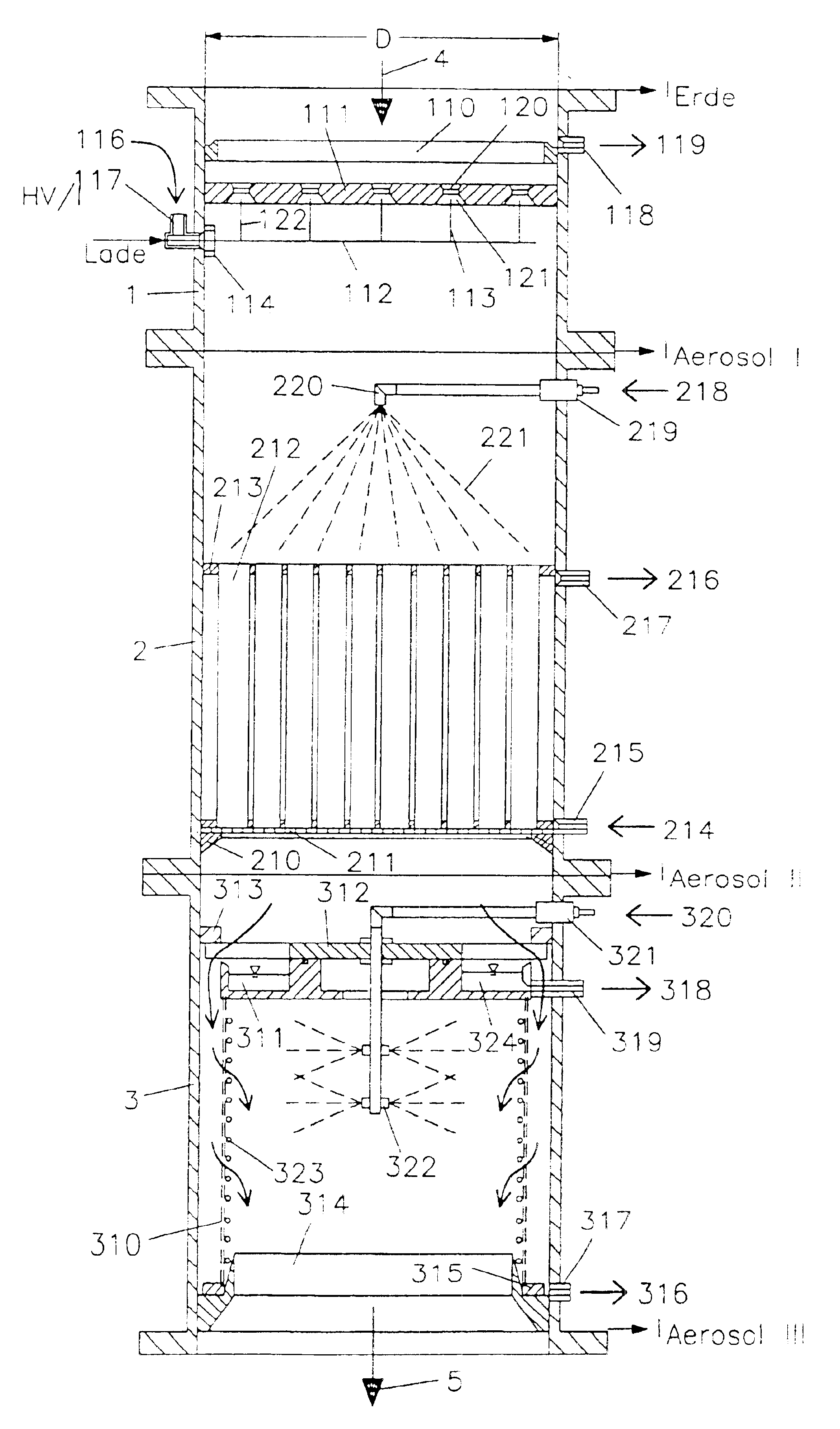

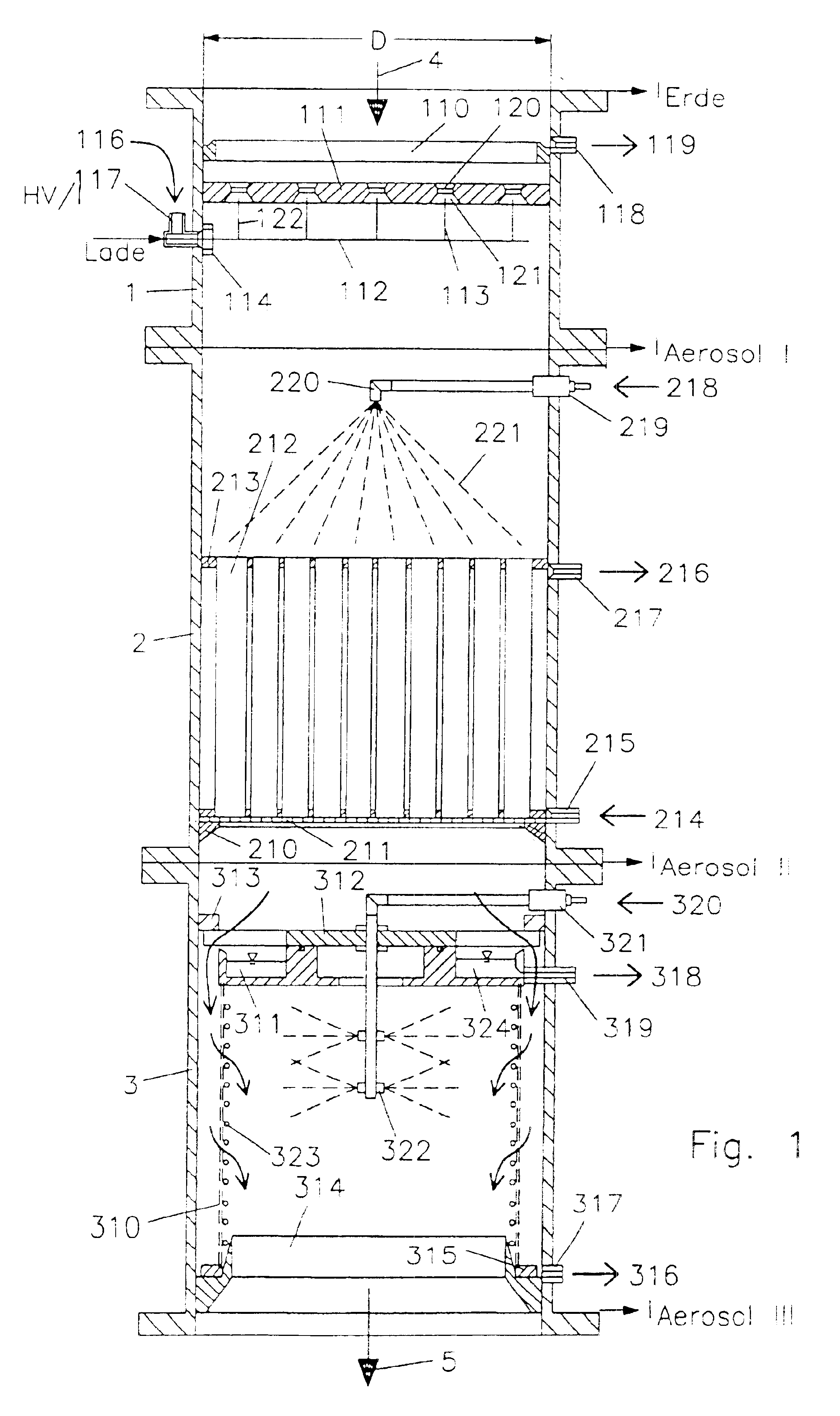

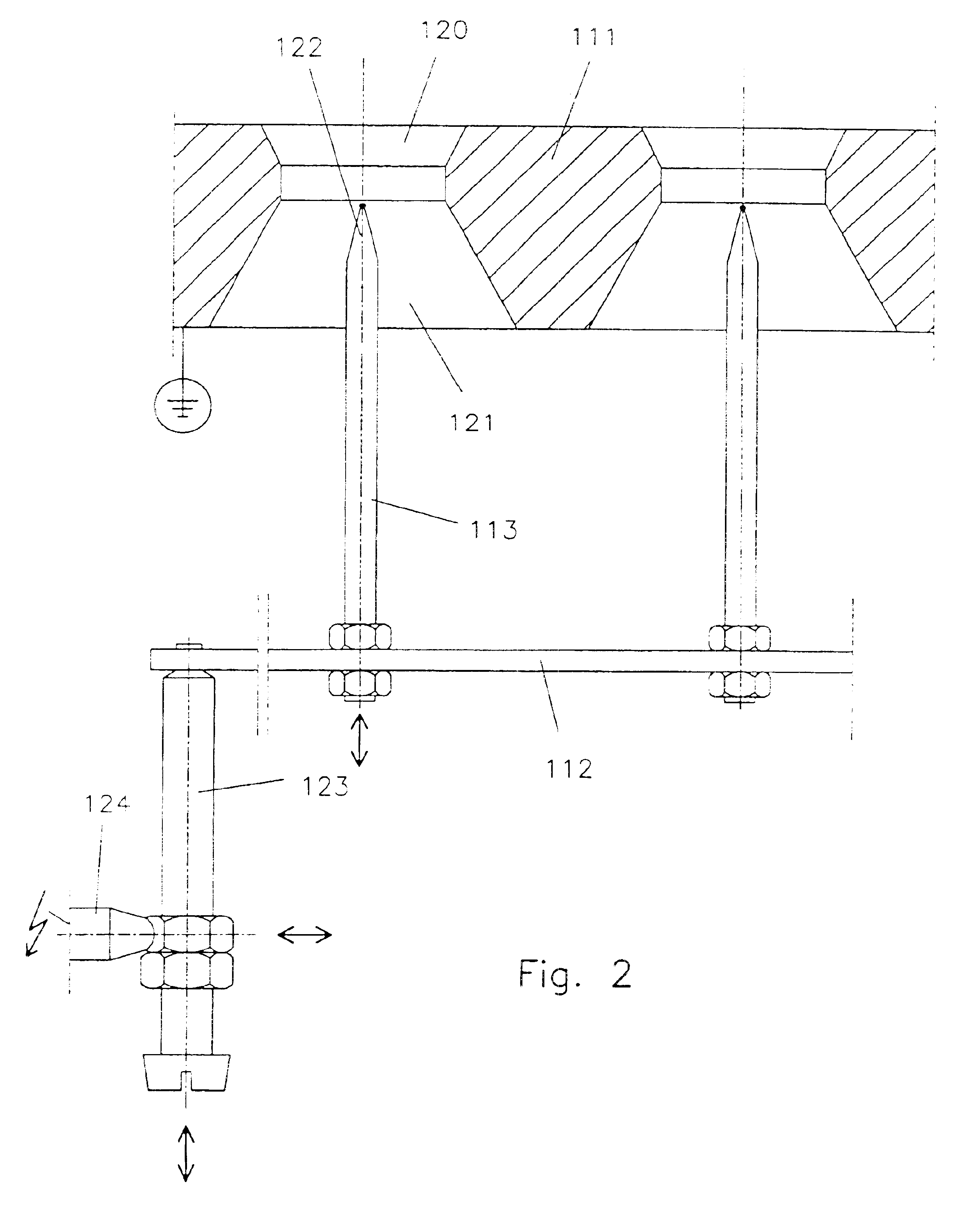

Apparatus for the electrostatic cleaning of gases and method for the operation thereof

InactiveUS6858064B2Improve efficiencyImprove heat transfer performanceElectrostatic separation housingDispersed particle filtrationProduct gasEngineering

In an apparatus for the purification of a gas which apparatus includes a three section conduit withan ionization and cleaning section in which particles contained in water-saturated air are ionized and then conducted through a chamber with grounded walls so that part of the particles are deposited on these walls,an additional cleaning section which includes grounded tubes past which the gas is conducted to remove additional charged particles anda filter section in which dry remaining fine particles are removed from the gas stream,the deposited particles are flushed from all three sections and the flushing water including the particles is cleaned and recycled.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

Method for self-assembling photonic crystal

ActiveCN101338447AIncrease profitLarge deposition areaFrom gel stateColloidal chemistry detailsPhotonic crystalPhotonic-crystal fiber

A self-assembling photonic crystal method relates to a preparation method of photonic crystal. The invention solves the problems existing in the current method that the photo crystal with large area can not be prepared and the prepared photonic crystal can not be bent. The method comprises the procedures as follows: (1) the surface of a base plate is treated: (2) colloidal solution is prepared: and (3) the base plate is put into a vessel and the colloidal solution is added into the vessel; the colloidal solution volatilizes under the constant temperature of 20 DEG C to 70 DEG C; the photonic crystal is taken out until no substance volatilizes, and the photonic crystal is made. The self-assembling photonic crystal can make the single or double sides of the photonic crystal deposit on the base plate, thus making the photonic crystal deposit on the base plate to a maximum.

Owner:HARBIN INST OF TECH +1

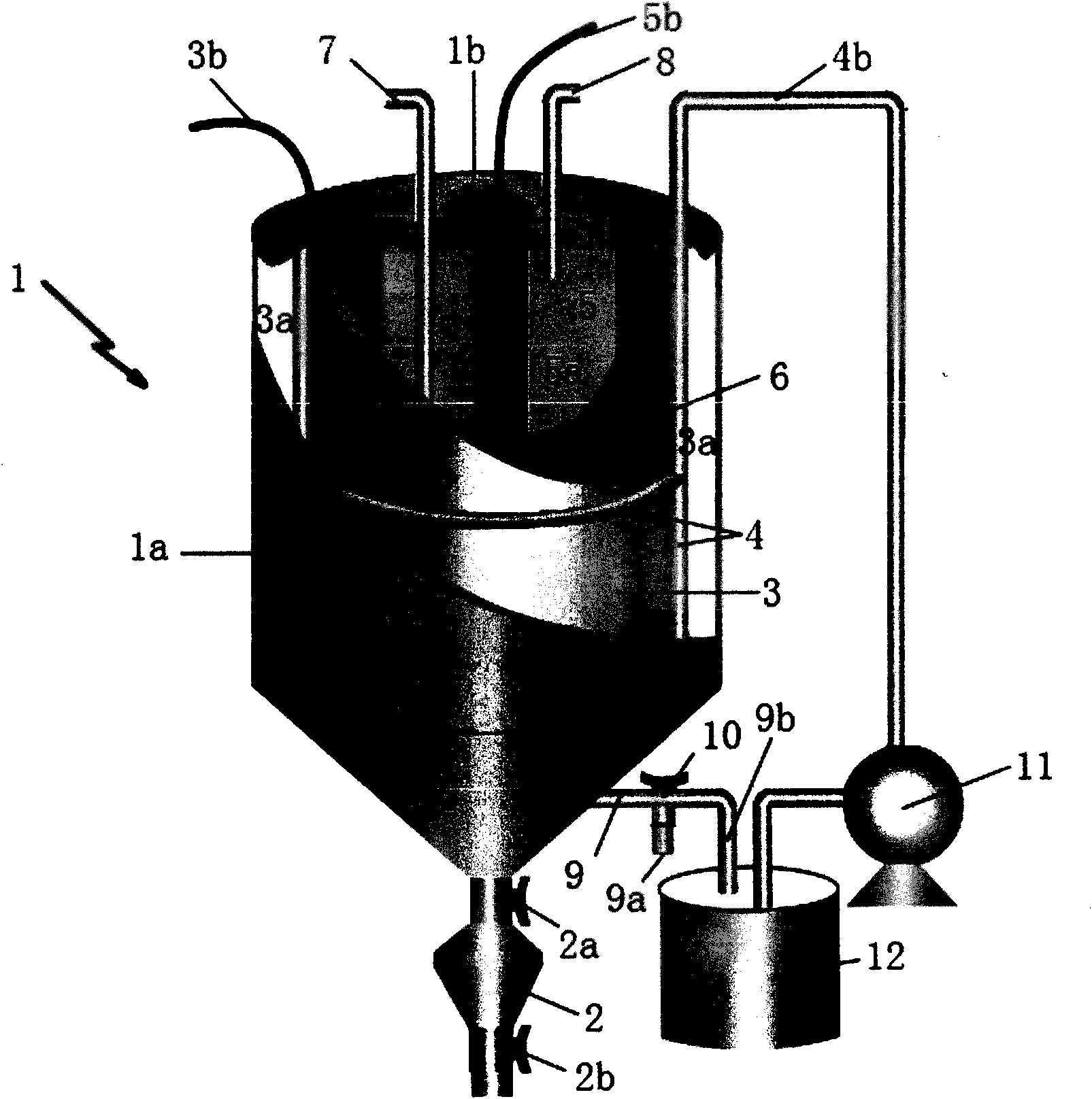

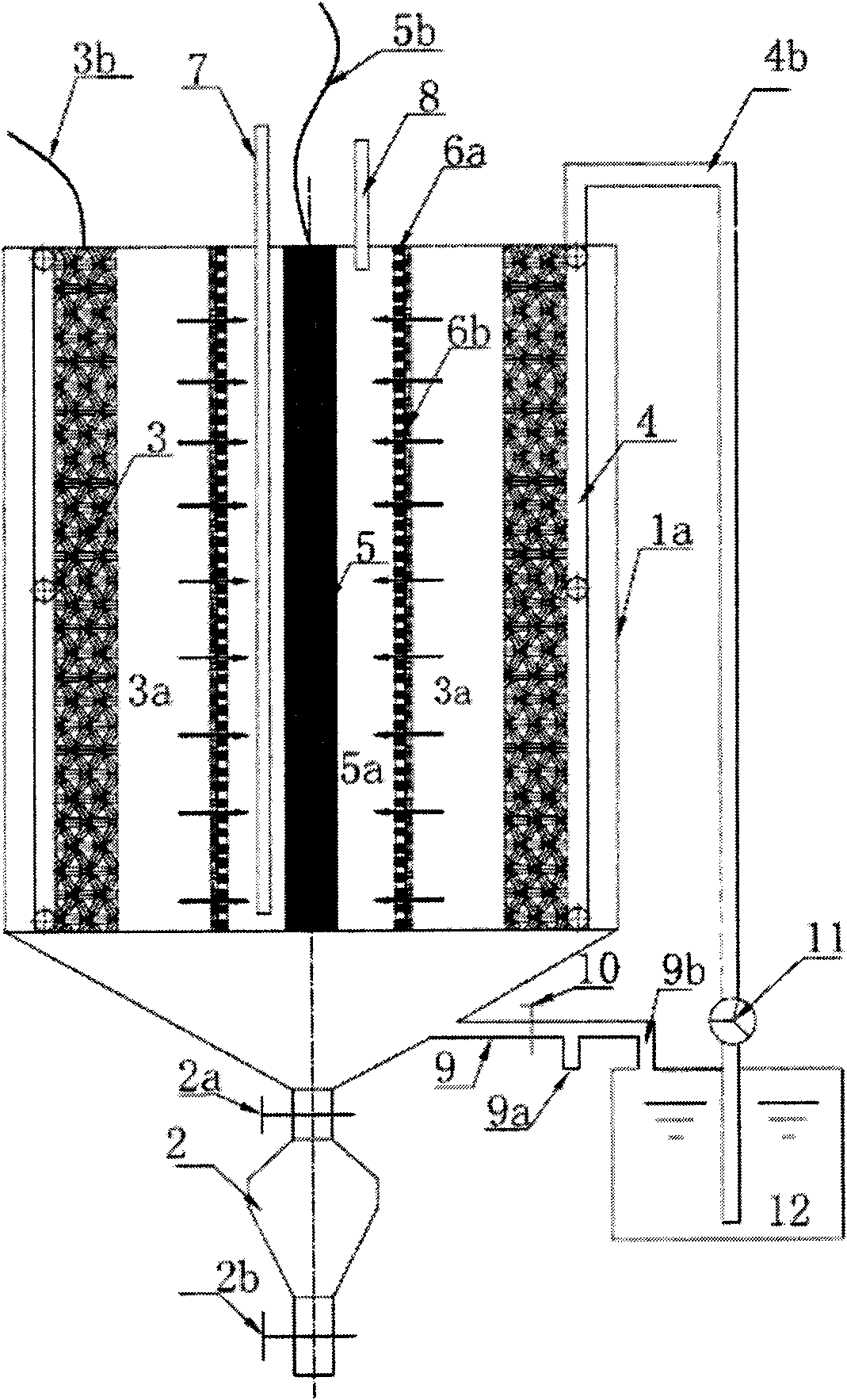

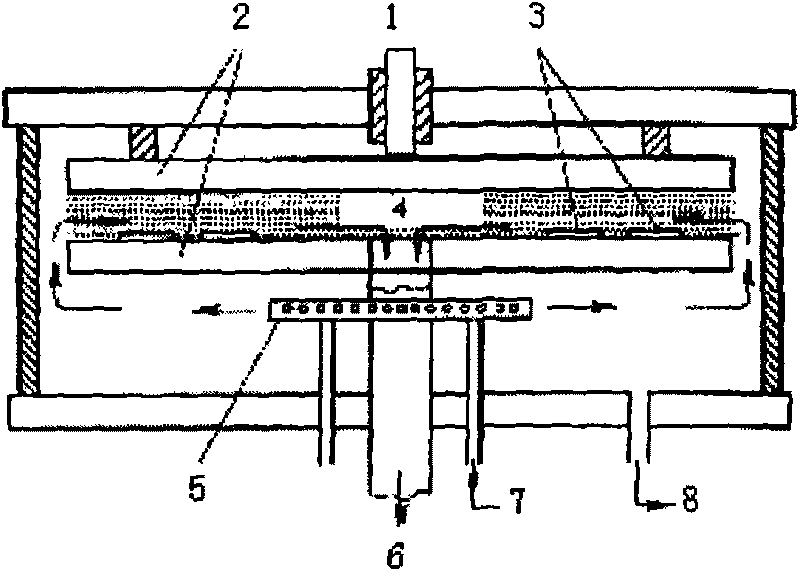

Electrolysis unit for efficiently recovering heavy metal ions

ActiveCN101538723ALarge deposition areaReduce current densityCellsIon-exchange membranesHigh pressure

The invention discloses an electrolysis unit for efficiently recovering heavy metal ions, which comprises an electrolytic cell, a cathode, a cathode anchor, an anode, an anion exchange membrane module, a deionization inlet pipe, an anolyte outlet pipe, a catholyte outlet, an extract (electrolyte) storage tank and a high pressure pump. The cell body takes the shape of a cylinder, and the bottom takes the shape of a taper and is provided with a metal powder storing hopper. The cathode and the anion exchange membrane module are distributed in a concentric circle; the anode is arranged in the center of the electrolytic cell and enclosed by the anion exchange membrane module, thus forming an anode chamber; the periphery of the anion exchange membrane module, and the cathode and the inner side of the electrolytic cell form a cathode chamber. The cathode is a multidimensional net structure consisting of stainless steel wires and is supported by the cathode anchor (a back washing system) consisting of PVC pipes. The whole device adopts an online detection device for controlling the treatment and discharging of liquid containing heavy metal and can realize the automation of the electrolytic process.

Owner:深圳龙澄高科技环保股份有限公司

Method for preparing lithium ion solid electrolyte film with large area

InactiveCN1447473AStable inorganic electrolyteImprove ionic conductivityFinal product manufactureVacuum evaporation coatingLithiumRadio frequency magnetron sputtering

The film of lithium, phosphor, oxygen and nitrogen (LiPON) is deposited by using the combination of the electron beam heating method and the mitrogen ion source generator. Comparing with the method of radio frequency magnetron sputtering, the deposited area is increased nearly 10 times. The conductivity of Li ion of the LiPON film prepared by the invention can reach 2-5X10 to the power -6 s / cm. Combining with electrodes of the thin film of Ag0.5V2O5 etc. and the metal Li film electrodes, thin film Li ion battery in full solid state can be assembled.

Owner:FUDAN UNIV

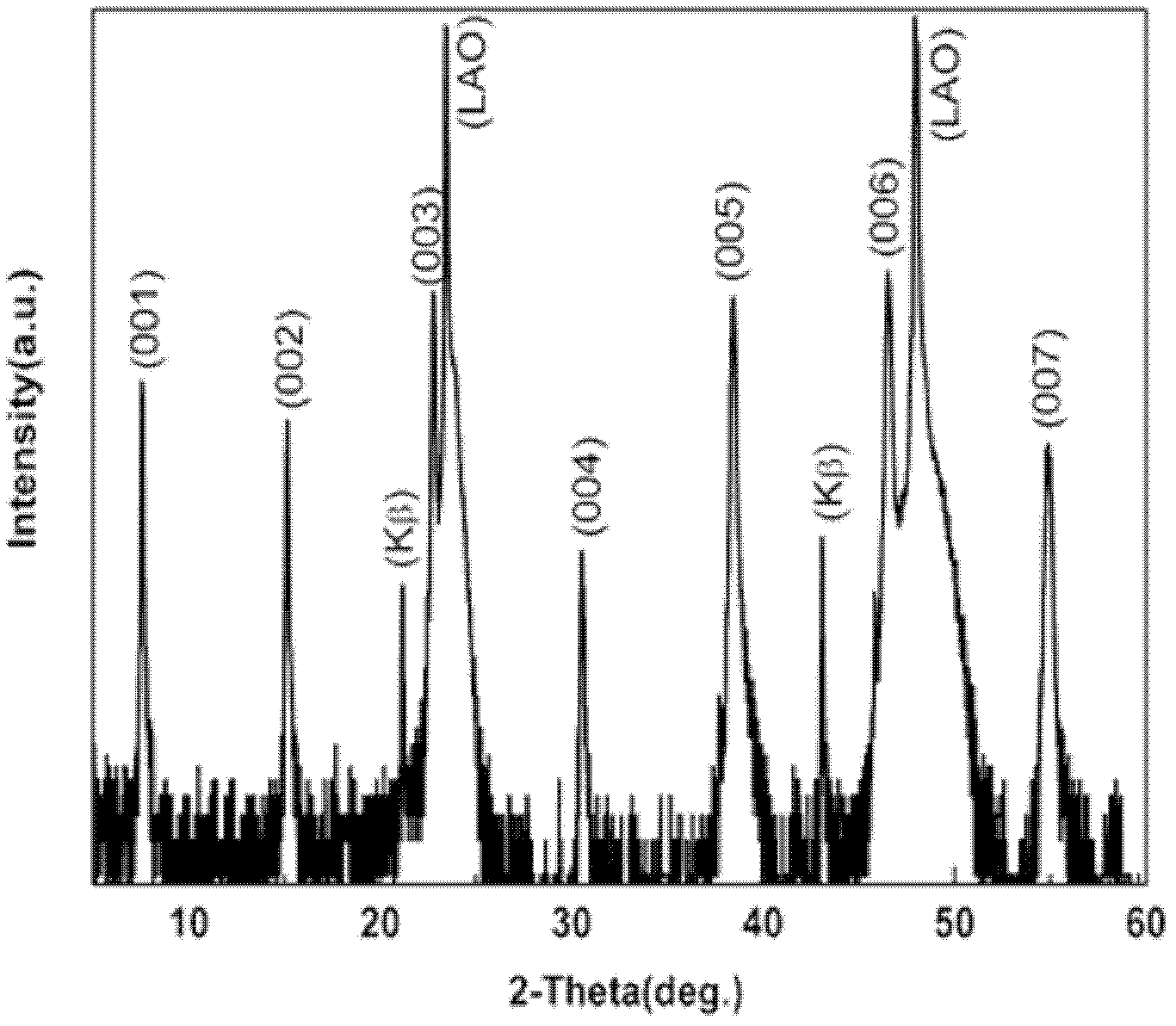

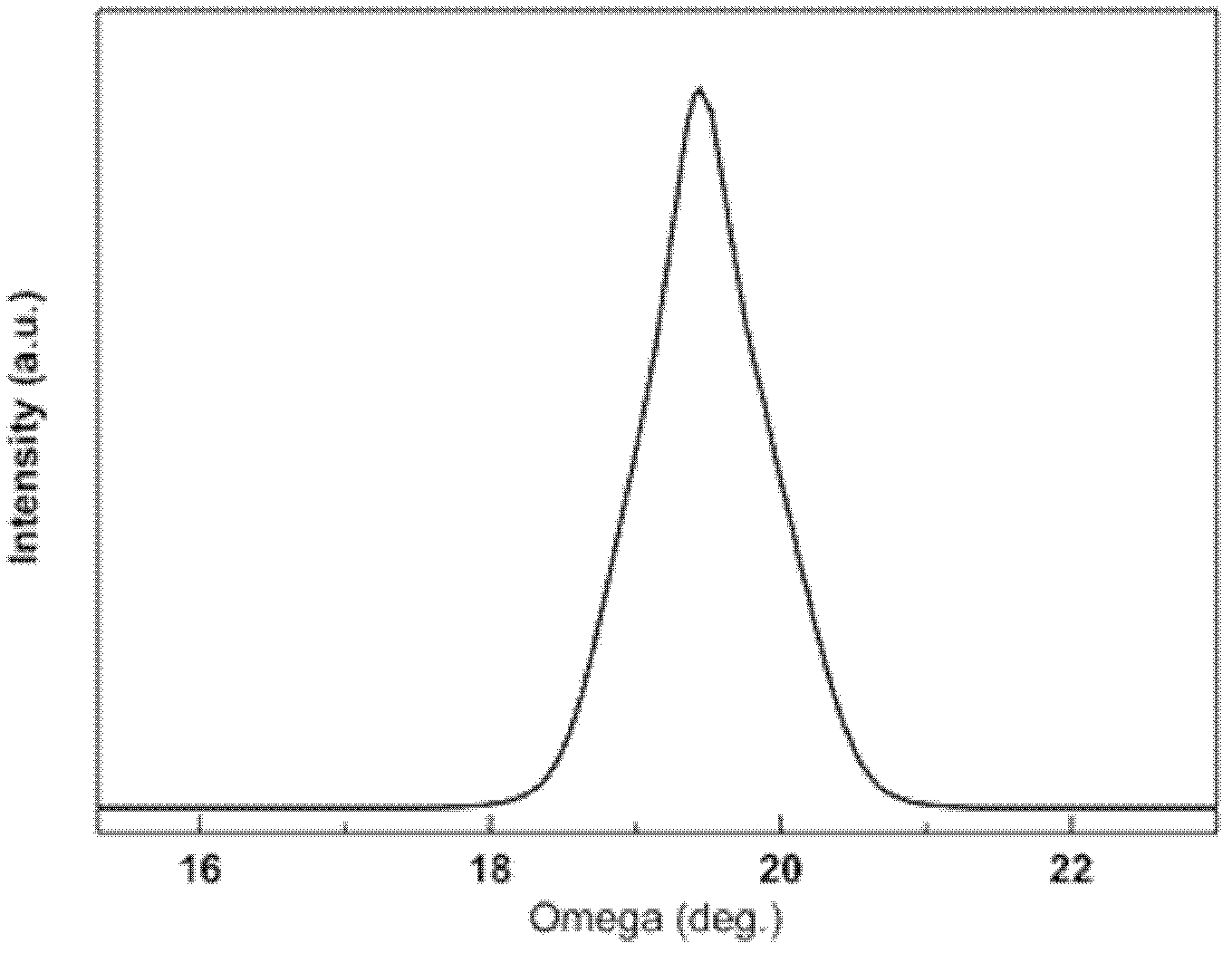

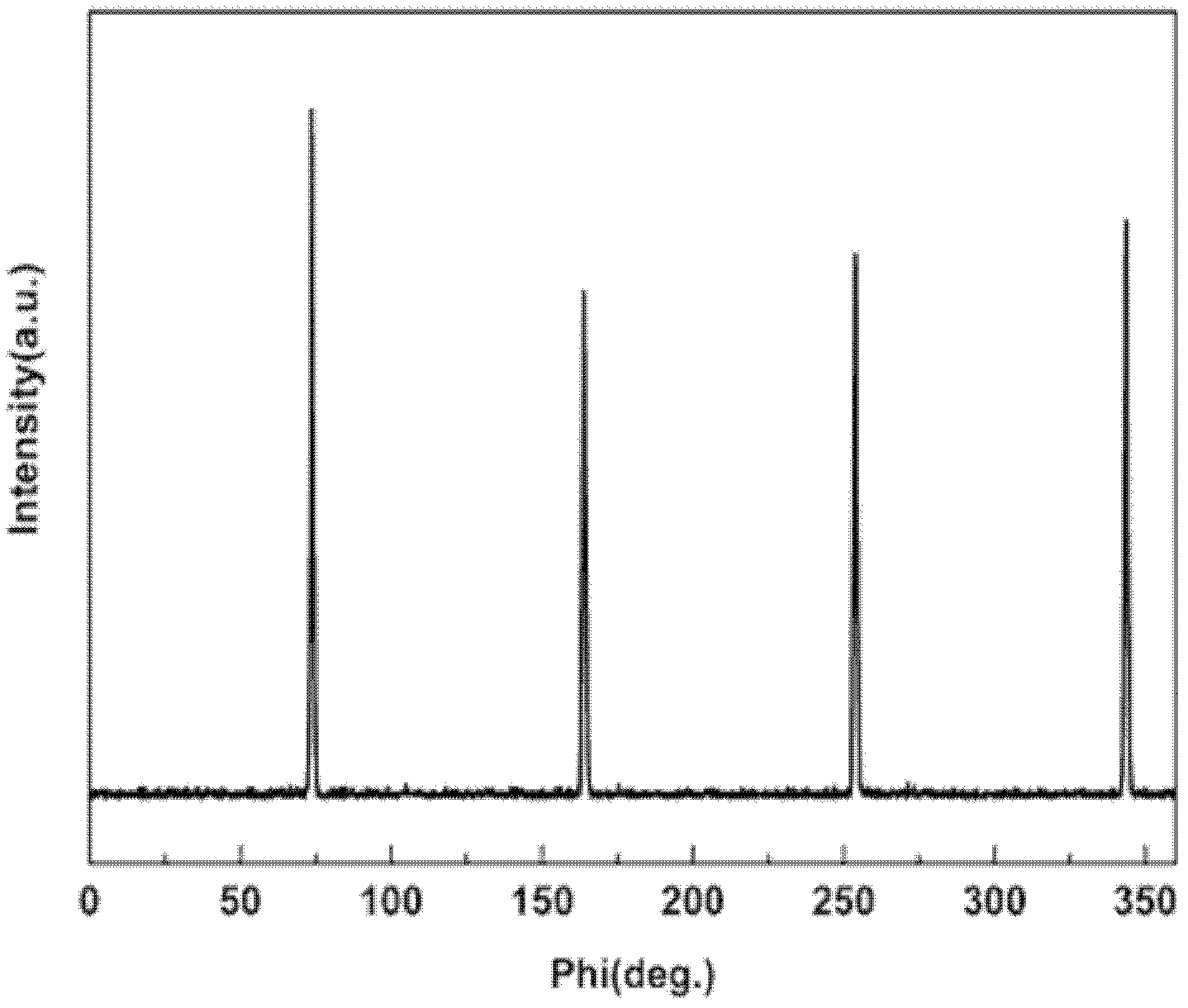

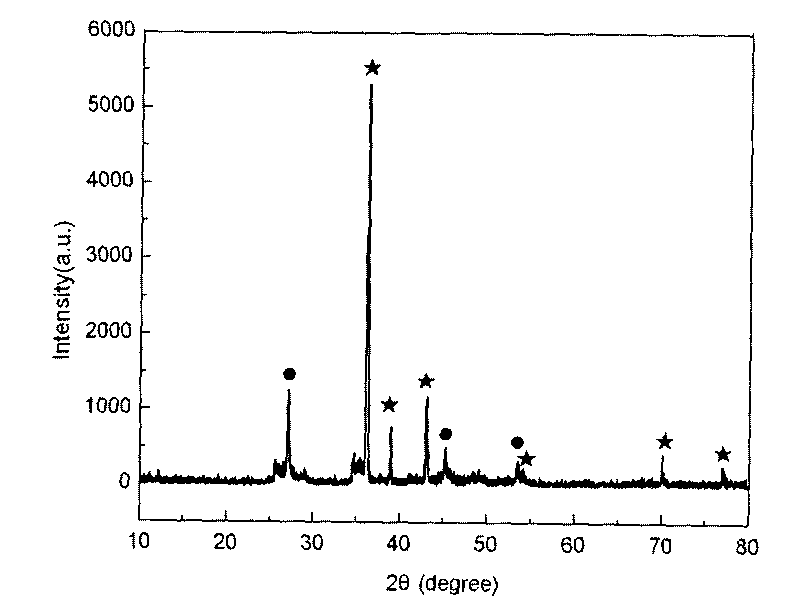

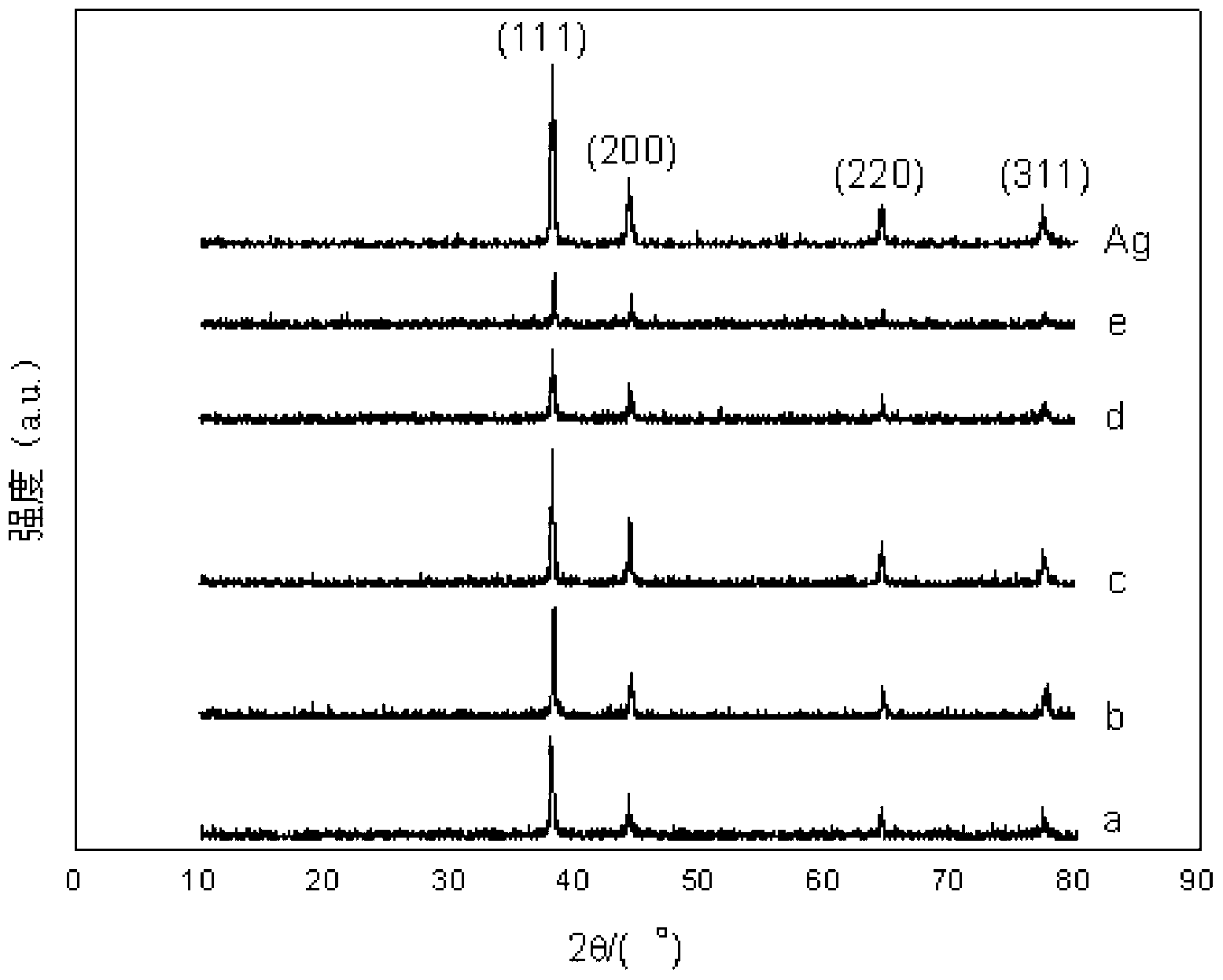

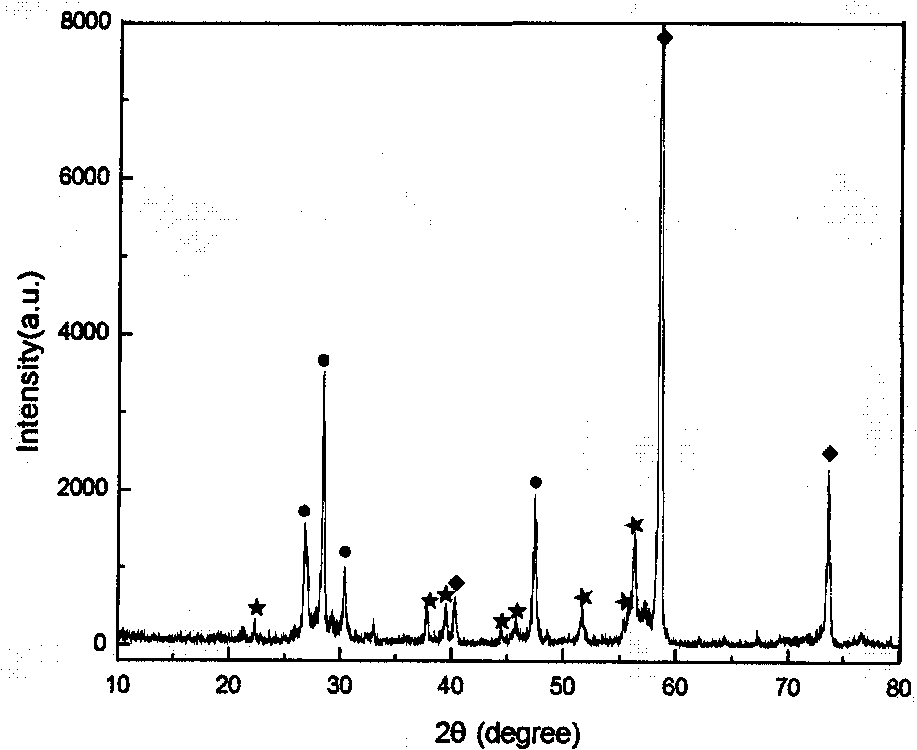

Yttrium barium copper oxide superconducting thin film mixed with samarium and manufacture method thereof

InactiveCN102491740AGood c-axis textureGood in-plane and out-of-plane textureYttrium barium copper oxideChemical composition

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

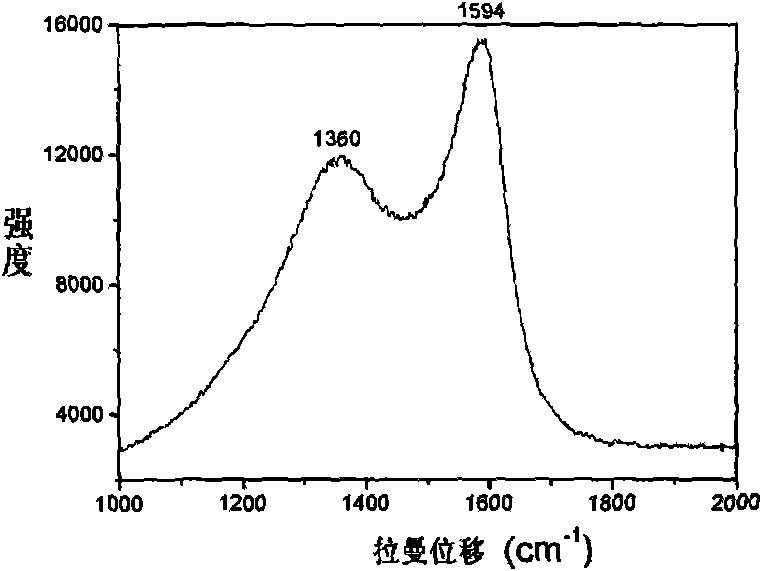

Method for preparing diamond-like film on germanium substrate

ActiveCN101736313AFast depositionLarge deposition areaChemical vapor deposition coatingRadio frequencyCapacitance

The invention relates to a method for preparing diamond-like film by depositing plasma activated chemical vapor on a germanium substrate, comprising the following steps: (1) placing germanium substrate on a cavity negative plate; (2) vacuumizing cavity, introducing CH4 gas, regulating cavity air pressure, and balancing for 3-5 minutes; (3) building up luminance to the radio frequency power, and regulating power; (4) regulating working air pressure to be 30-45 Pa, CH4 gas flow to be 20-30sccm, and regulating the matching capacitance to lead the reflection power to reach the minimum value; (5) depositing for 14-18min, and closing the radio frequency power; (6) cooling for 10min, taking out the germanium (Ge) substrate, and clearing the cavity; (7) placing the germanium (Ge) substrate again, vacuumizing the cavity, building up luminance to the radio frequency power, closing the radio frequency power after bombarding the sample for 70-90s, closing the radio frequency power, and continuously pumping high vacuum; and (8) repeating secondary deposition. The method has rapid deposition rate, large deposition area and relatively simple and convenient process. The diamond-like film obtained by the method has good anti-reflection and protection effect on germanium (Ge) substrate.

Owner:GRIMAT ENG INST CO LTD

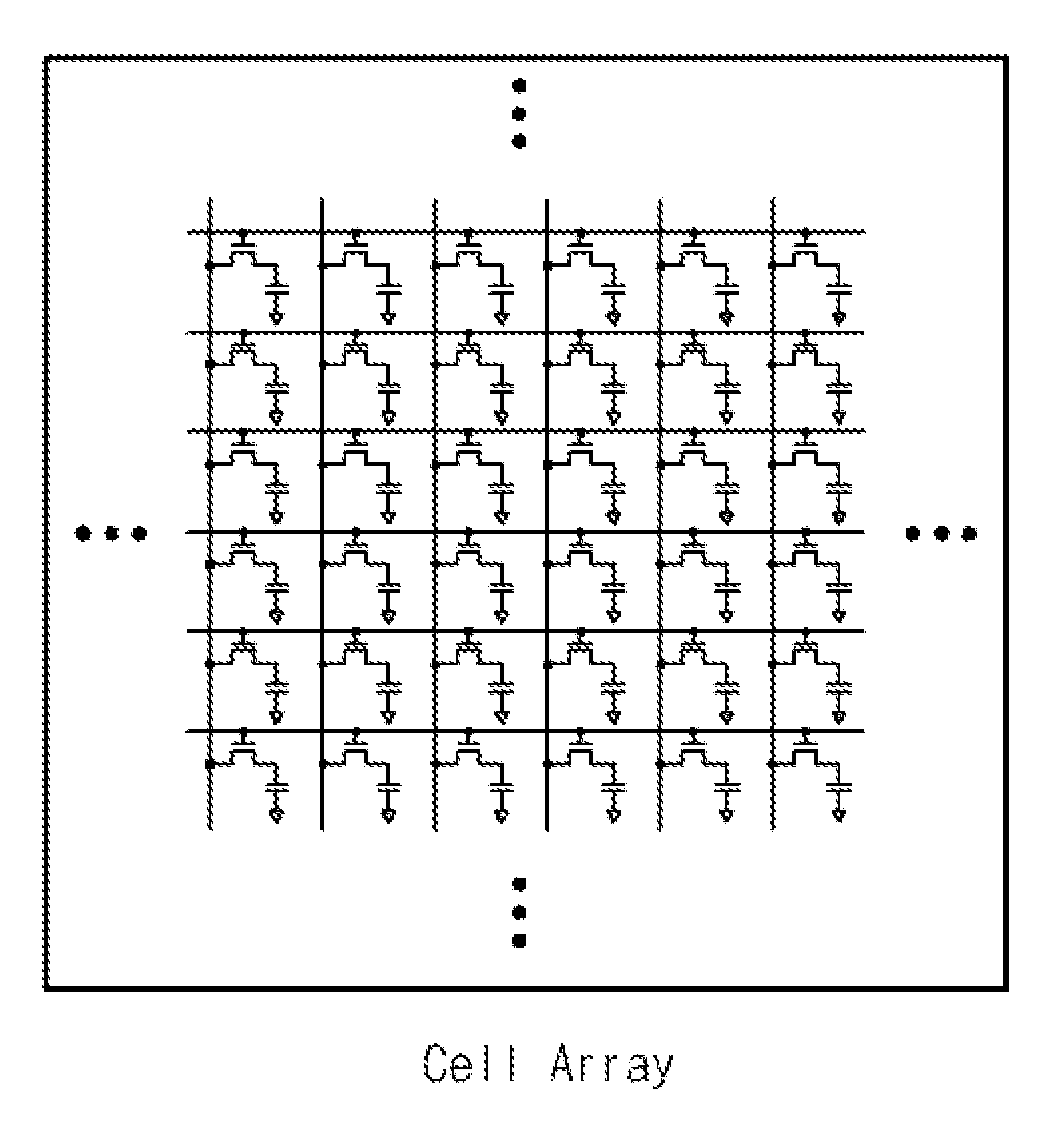

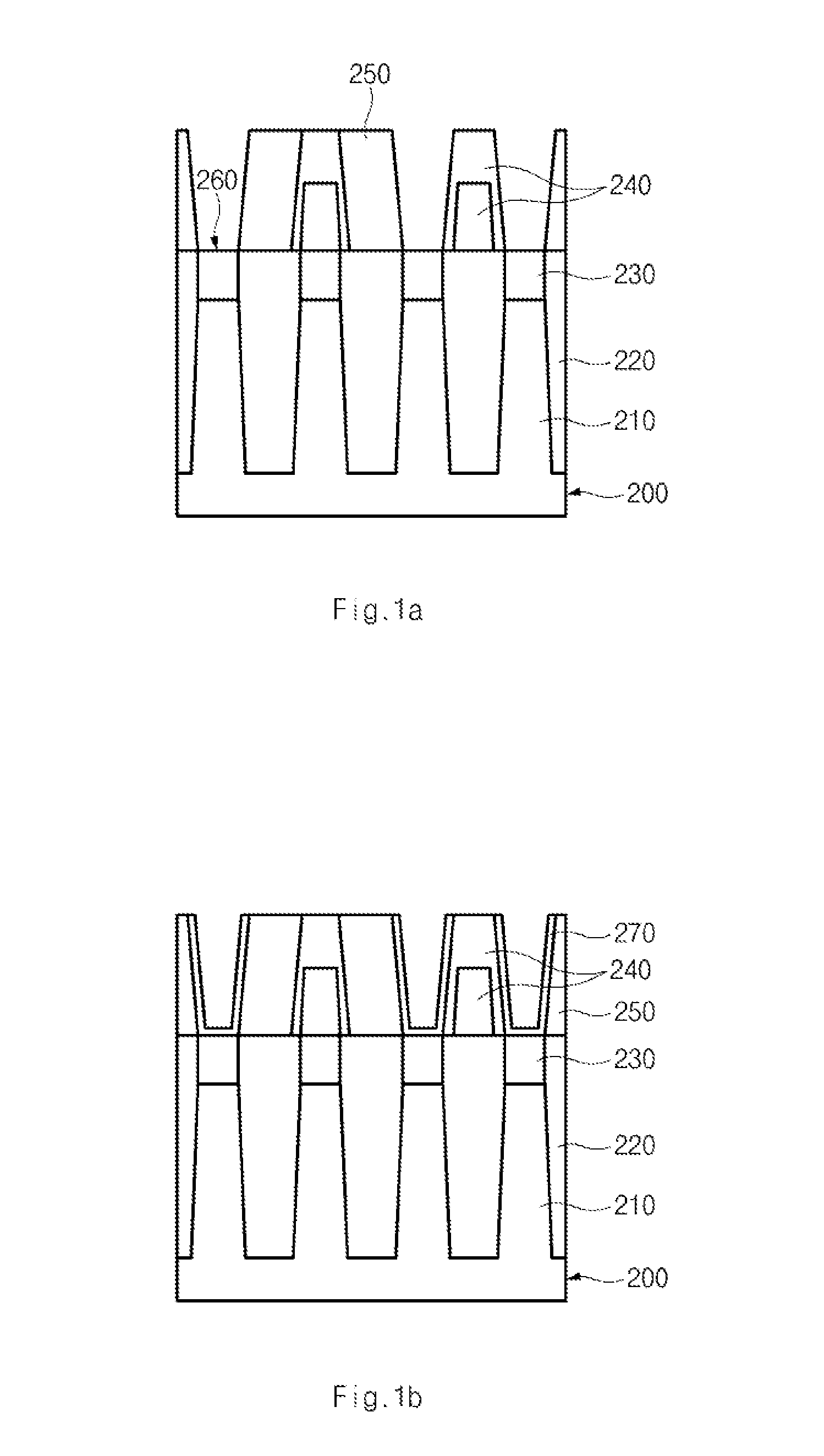

Semiconductor device and method for manufacturing the same

InactiveUS20130001744A1Capacitance of capacitor is guaranteedLarge deposition areaSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceCapacitance

In a semiconductor device, a polysilicon layer of a lower electrode contact plug is removed by a strip process such that the deposition area of a dielectric film is increased and capacitance of a capacitor is assured. A method for manufacturing the semiconductor device is also disclosed.

Owner:SK HYNIX INC

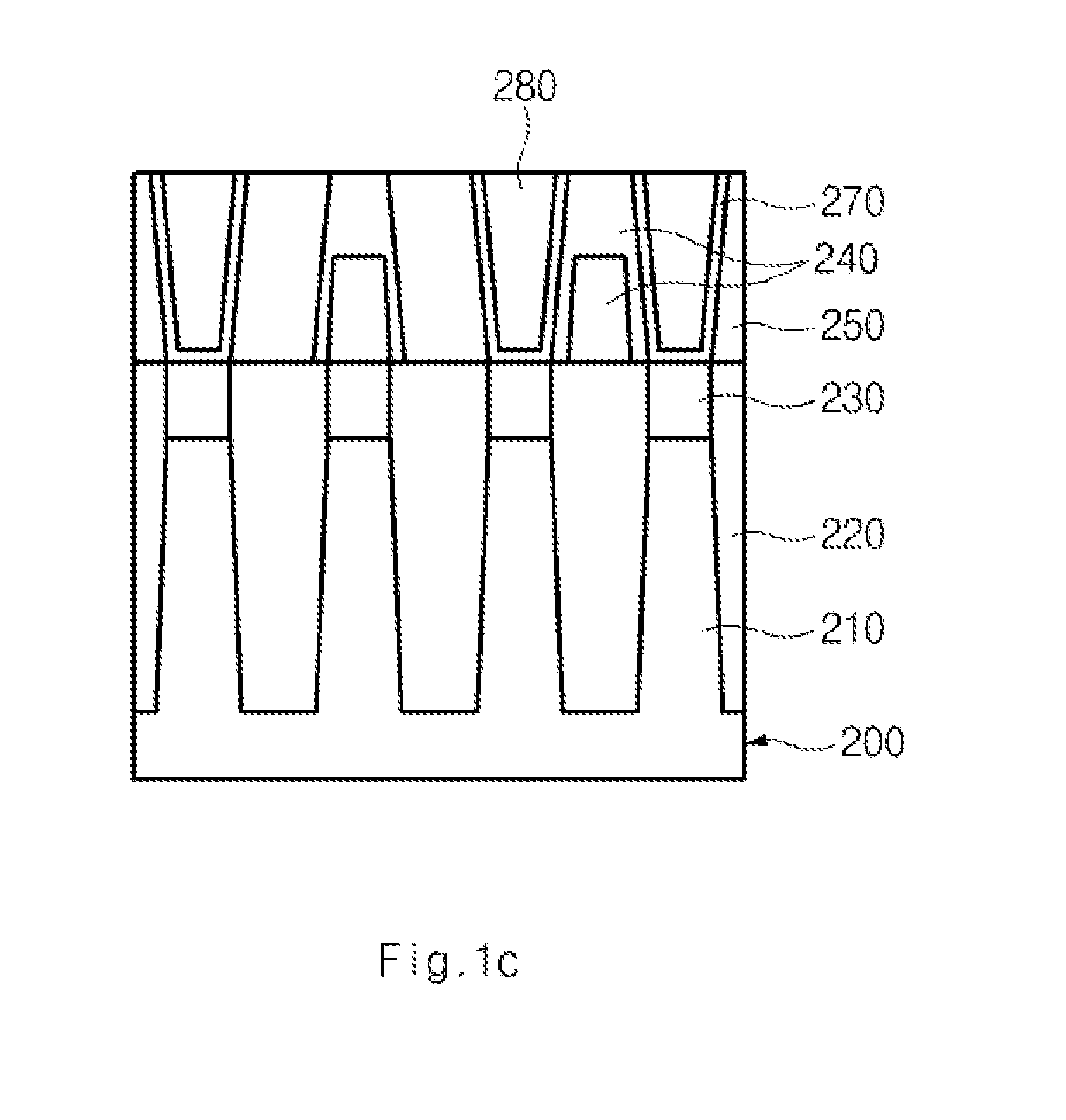

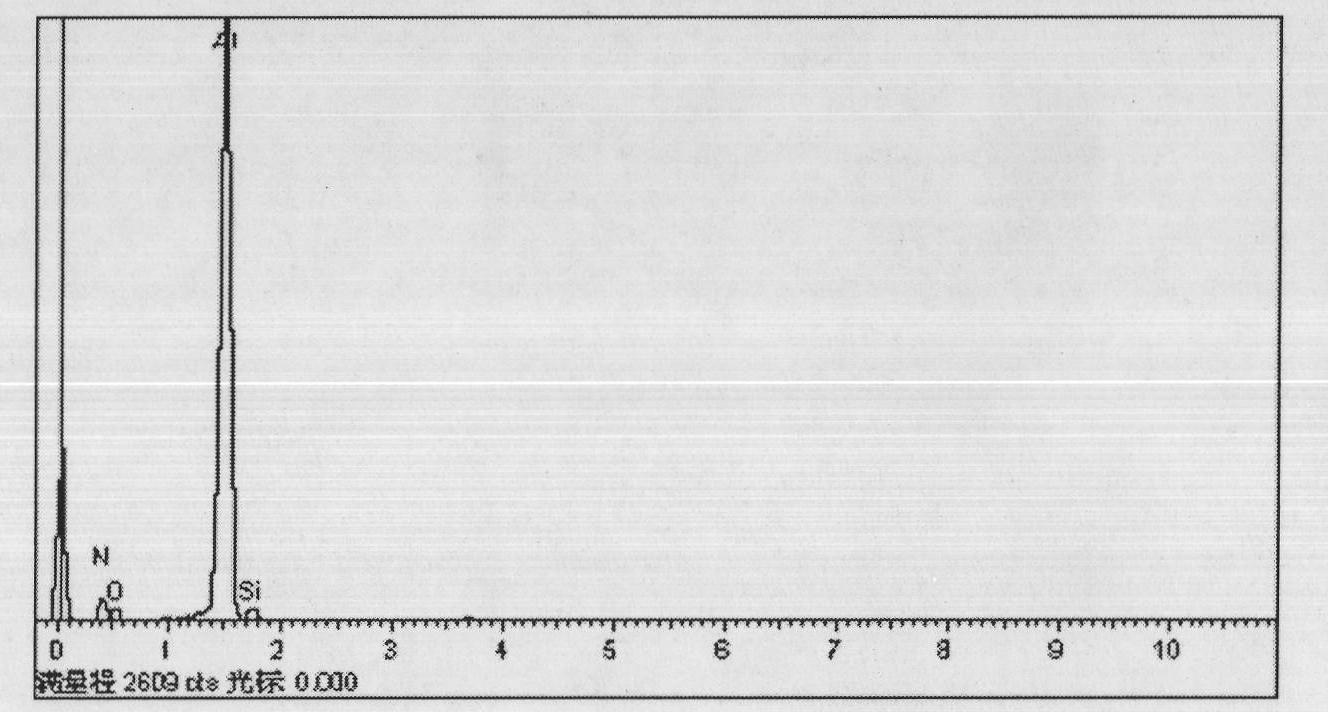

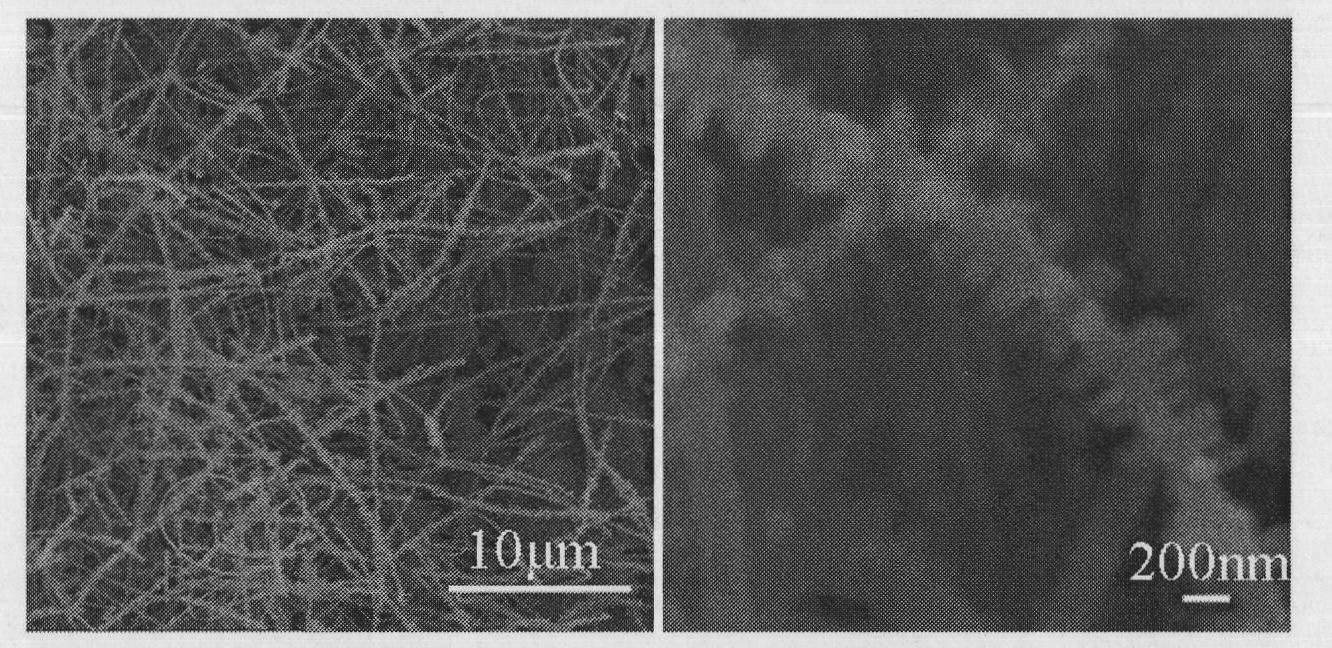

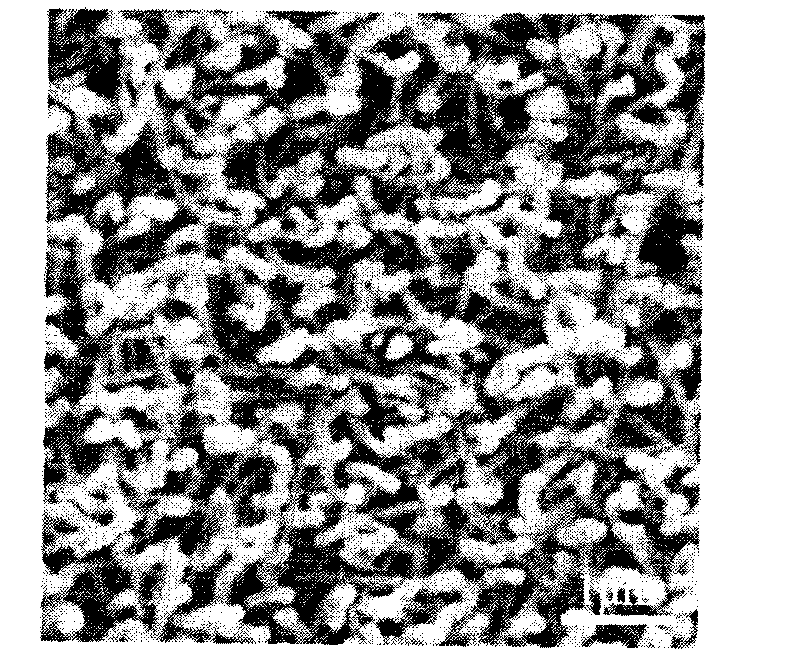

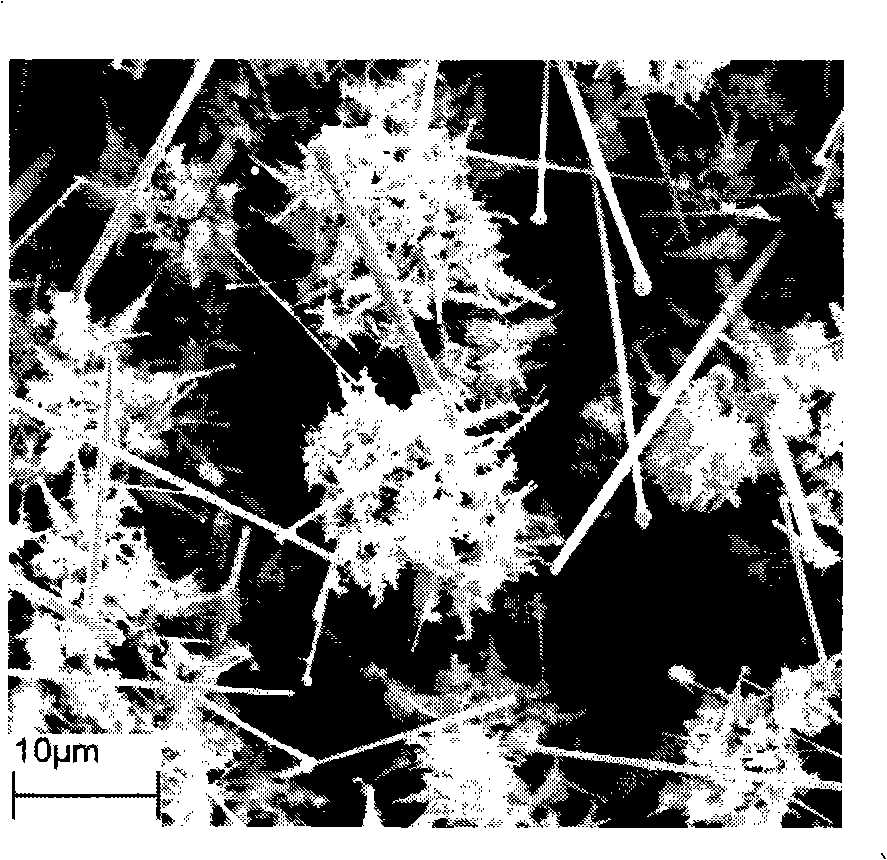

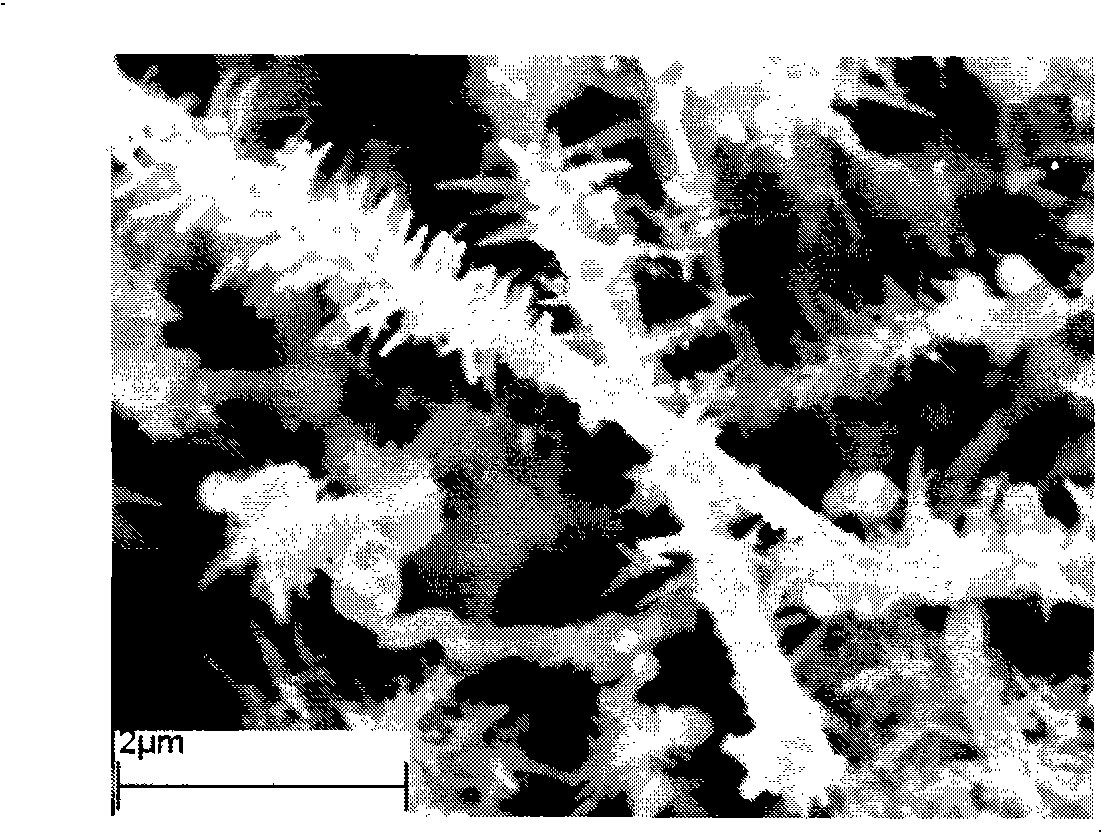

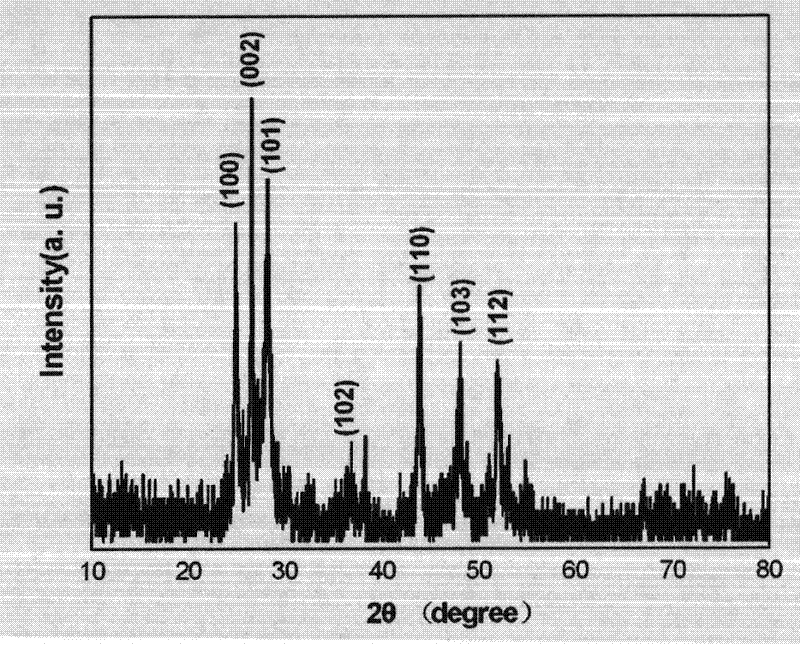

Method for preparing AlN mono-crystal nanobelts and nano-branch structure

InactiveCN101851781AUniform shapeLarge deposition areaPolycrystalline material growthFrom chemically reactive gasesAl powderFurnace temperature

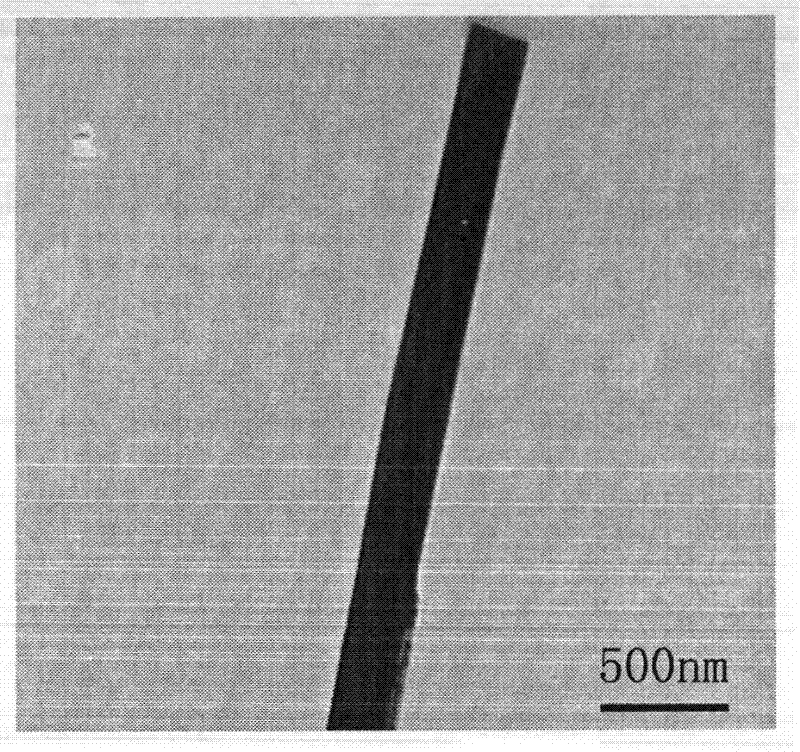

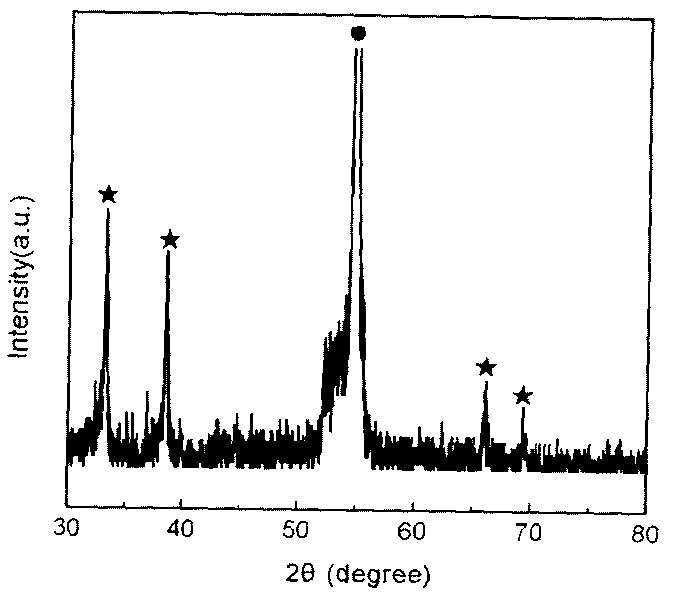

The invention discloses a method for growing AlN mono-crystal nanobelts and a nano-branch structure of III-V group semiconductor compounds by using a catalyst-free enhanced chemical vapor deposition method. The method is implemented by the following processes of: putting 0.2 grams of Al powder with a purity of 99.99 percent into a ceramic boat; converting a polycrystal Al2O3 substrate which is ultrasonically washed with alcohol and deionized water and serves as a substrate 5 mm directly above a source; placing the ceramic boat in a central region of a tubular furnace; starting to vacuumize after a container is sealed; introducing argon at a flow rate of 200 cm<3> / min (sccm) into a system when the vacuum degree of an alundum tube system is up to 1*10<-2> Pa; heating the system; introducingammonia gas at the flow rate of 30 sccm when a furnace temperature is up to 1,400 DEG C; keeping the temperature for 1 hour; stopping heating the system and turning off the ammonia gas when the temperature is reduced to 800 DEG C; and naturally cooling to room temperature in a protective atmosphere of the argon. The nanobelts and the nano-branch structure prepared by the method are of AlN in a monocrystal state. The AlN nanobelts and the nano-branch structure obtained by the method have the characteristics of uniform appearance and large deposition area. The method has the characteristics of no use of any catalyst, simple method and easy popularization.

Owner:XINJIANG UNIVERSITY

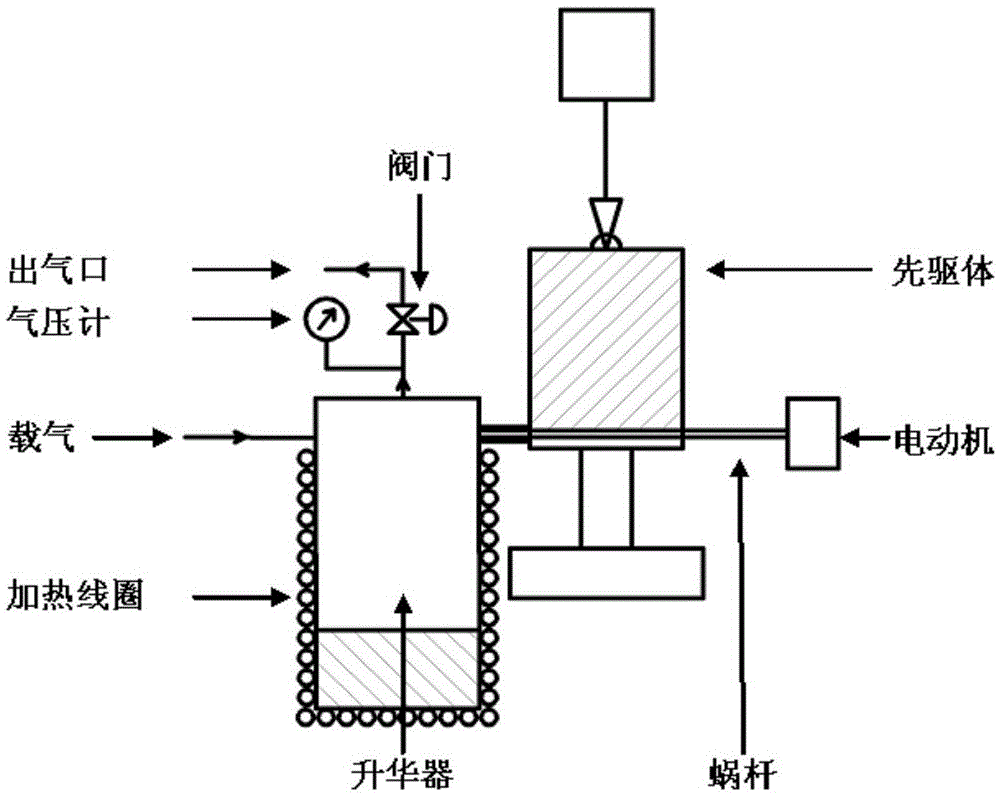

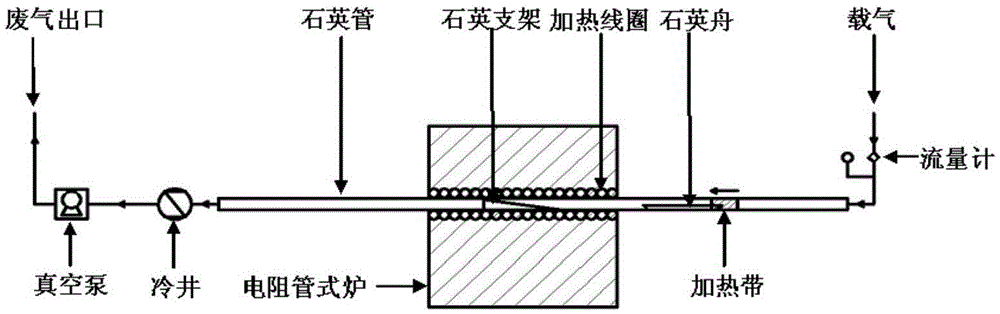

Method for manufacturing ceramic matrix composite boron nitride interface coating

ActiveCN105463403AEasy to form stoichiometric ratioStoichiometric ratio is betterChemical vapor deposition coatingLow temperature depositionReaction temperature

The invention relates to a method for manufacturing a ceramic matrix composite boron nitride interface coating, in particular to manufacturing of boron nitride coatings on a fiber surface and a substrate surface and belongs to the technical field of ceramic matrix composite toughness improvement. According to the method, a single component NH3BH3 containing B and N at the same time is selected as a precursor of a BN interface, the precursor is free of toxin and pollution, unlikely to burn or explode and capable of easily forming BN at the stoichiometric ratio of B:N=1:1, it is guaranteed that the manufactured BN is good in stoichiometric ratio, the problem that B and N in a double-component precursor are disproportionate is avoided, and no corrosive gas is generated in the manufacturing process. The method can be used for manufacturing the coating at the reaction temperature from 400 DEG C to 900 DEG C through a low-temperature chemical vapor deposition method, the temperature from 700 DEG C to 900 DEG C is preferred to increase the yield of BN, and the content of the obtained deposition product BN is over 97%. The strength retention rate of fibers can be increased as much as possible through low-temperature deposition, the strength retention rate is over 90% after deposition, and the strength retention rate is over 70% after high-temperature thermal treatment.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

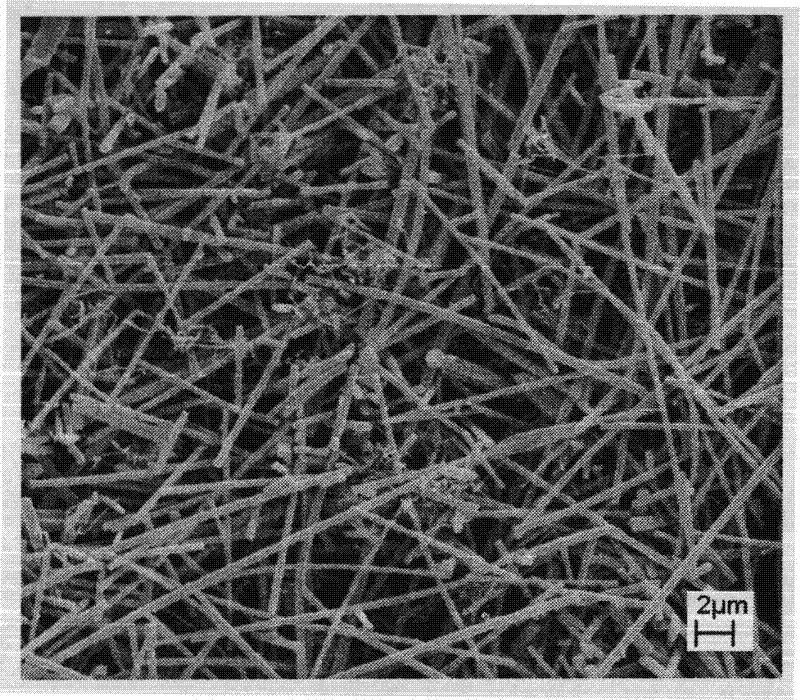

Method for growing ZnSe monocrystal nanowire

InactiveCN101693528AImprove resolutionLarge deposition areaNanostructure manufactureBinary selenium/tellurium compoundsNanowireEvaporation

The invention discloses a method for growing a ZnSe monocrystal nanowire by vacuum thermal evaporation under the assistance of a catalyst, comprising the following processes: evenly mixing ZnSe power and metallic Bi powder according to the mol ratio of 1 0.008-1: 0.06 to prepare raw material: putting into a resistance heating boat made of molybdenum sheets, and placing various substrates at the position 1.0cm-3.0cm above the boat; closing an evaporating furnace, preserving for 5-15 minutes when the vacuum degree of the vacuum evaporating furnace reaches 3*10-2-6*10-3Pa and the electric current of the resistance heating boat is 110-140A, and then obtaining the ZnSe monocrystal nanowire. The prepared cadmium oxide nano rod is ZnSe with a crystalline cubic phase structure; and the invention has the advantages that the obtained cadmium oxide nanowire bundle is suitable for a plurality of substrates and large-scale industrial production, and has large deposition area, evener appearance, simple method and easy popularization.

Owner:XINJIANG UNIVERSITY

Growth method of CdTe nanorod by catalyst assistant vacuum heat evaporation

InactiveCN101328615AEasy to operateLarge deposition areaPolycrystalline material growthFrom condensed vaporsNano structuringEvaporation

The invention discloses a method for preparing a CdTe nano structure of a II-VI series semiconductor compound through catalyst assistance and vacuum thermal evaporation. The method comprises the following steps that: by adoption of metallic Bi powder as a catalyst and CdTe powder as a raw material, the raw material undergoes thermal evaporation under the vacuum environment with a vacuum degree of 2x10<-2>-2x10<-3>Pa, and a CdTe film with the nano structure is grown on a substrate through catalysis. The method is simple and easy to operate, does not require carrier gas, and has the characteristics of large deposition area, uniform appearance, and suitability for various substrates.

Owner:XINJIANG UNIVERSITY

A method for preparing cds/zns nanowire heterojunction

InactiveCN102263036AAvoid influenceLarge deposition areaVacuum evaporation coatingSputtering coatingElectrical resistance and conductanceHeterojunction

The invention belongs to the field of nanowire heterojunction preparation, and relates to a method for growing CdS nanowires by a vacuum thermal evaporation method with the assistance of a catalyst and coating ZnS in its radial direction. The specific implementation process is as follows: first step, uniformly mix CdS and Bi powder at a ratio of 1:0.05mol as raw materials, place them in a resistance heating boat made of molybdenum sheets, and place a substrate at 1.0cm-2.0cm above the boat. During the evaporation process, the vacuum degree in the evaporation furnace is kept at 5×10-3Pa-5×10-2Pa, the heating current is 100A-120A, and the deposition time is 2min-10min to prepare CdS nanowires. In the second step, ZnS powder is used as a raw material, placed in a boat, and CdS nanowires are used as a substrate. Place the substrate at 1.0cm-2.0cm above the boat. During the evaporation process, the vacuum degree in the evaporation furnace is kept at 5×10-3Pa-5×10-2Pa, the deposition current is 120A-140A, and the deposition time is 2min-10min. Coating ZnS on CdS nanowires. Finally, CdS / ZnS nanowire radial heterojunction is obtained. The CdS / ZnS nanowire heterojunction obtained by the invention has the characteristics of good optical properties, uniform appearance, etc.; and the method is simple, easy to popularize, and suitable for large-scale industrial production.

Owner:XINJIANG UNIVERSITY

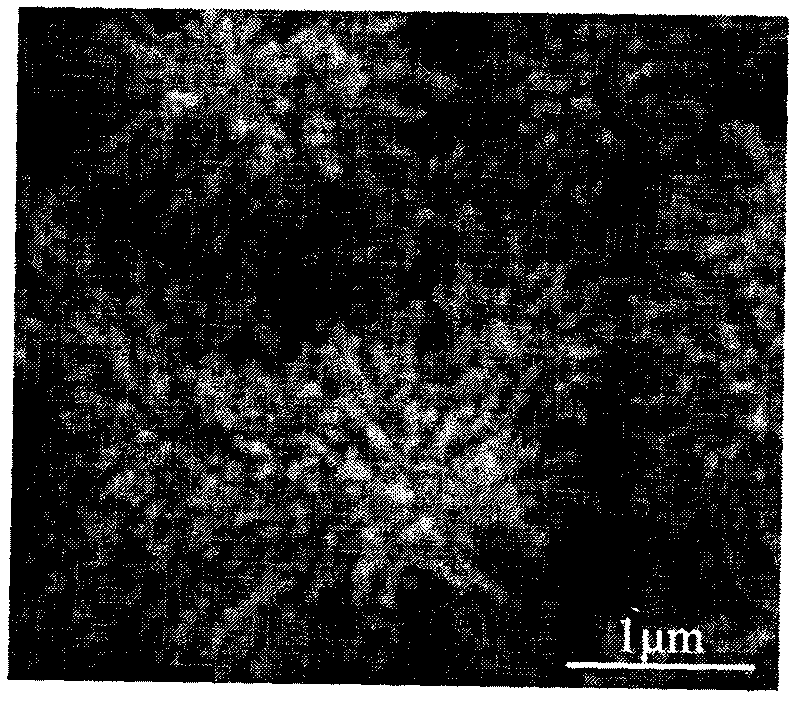

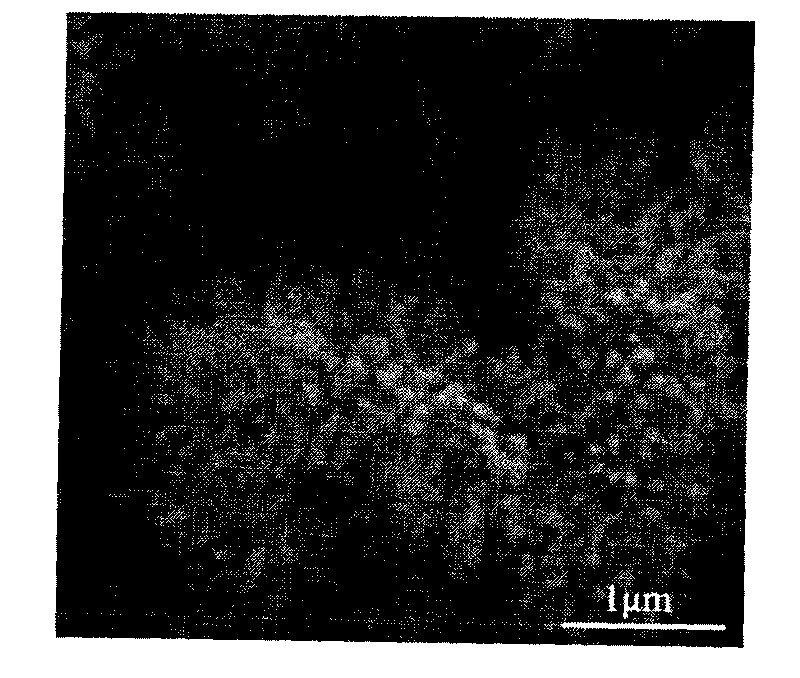

Method for growing CdO nanowire bundle

InactiveCN101693550ALarge deposition areaUniform shapeNanostructure manufactureCadmium compoundsCadmium oxideSemiconductor

The invention discloses a method for growing a group II-VI semiconductor compound CdO nanowire bundle by vacuum thermal evaporation under the assistance of a catalyst, comprising the following processes: evenly mixing CdO power and metallic Bi powder according to the mol ratio of 1: 0.02-1: 0.3 to prepare raw material; putting into a resistance heating boat made of molybdenum sheets, and placing various substrates at the position 3mm-4cm above the boat; closing an evaporating furnace, electrifying the resistance heating boat with the electric current of 110-180A after a cavity of the vacuum vaporizing furnace in which an evaporation deposition system is arranged reaches a vacuum environment of 2*10-2-5*10-3Pa, and preserving for 5-15 minutes, and then carrying out evaporation deposition. The prepared cadmium oxide nano rod is CdO with a crystalline cubic phase structure; in addition, the obtained cadmium oxide nanowire bundle is suitable for a plurality of substrates and has the advantages of large deposition area and evener appearance; and the method is simple, easy to popularize and suitable for large-scale industrial production.

Owner:XINJIANG UNIVERSITY

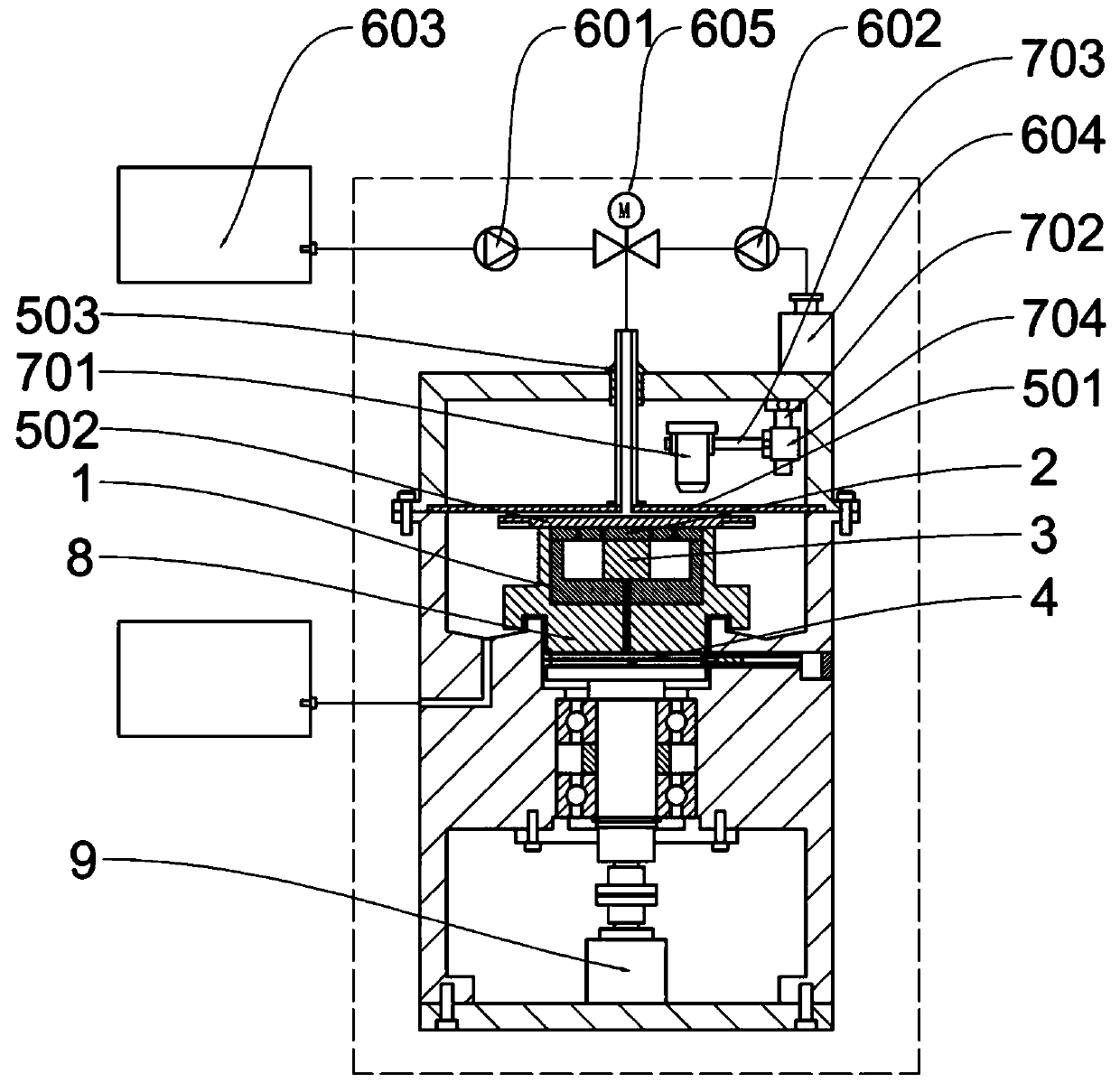

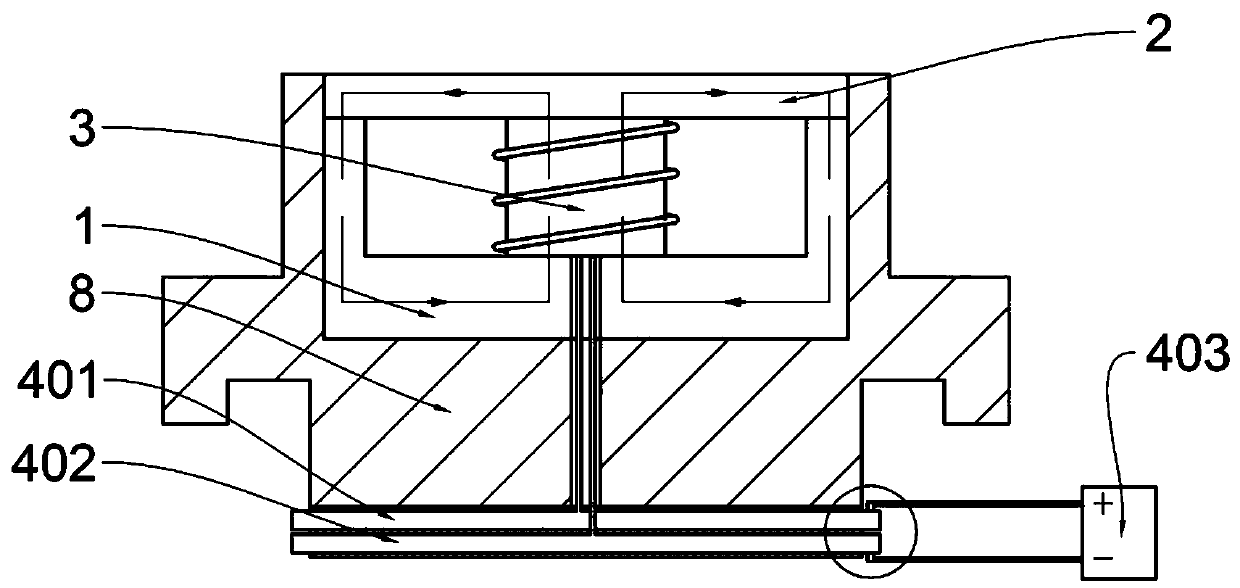

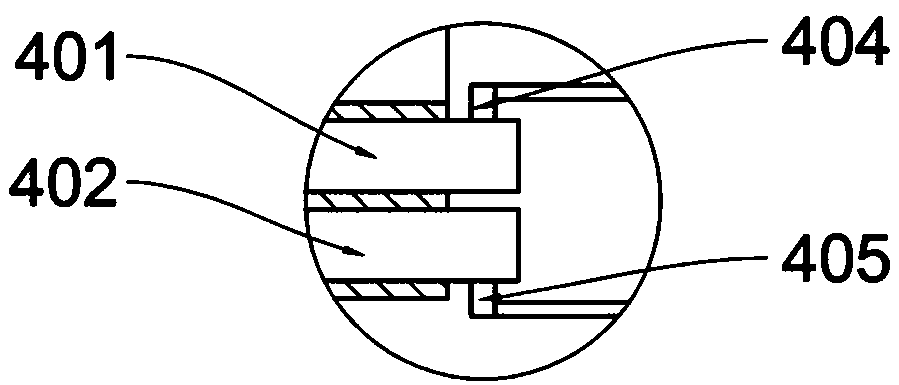

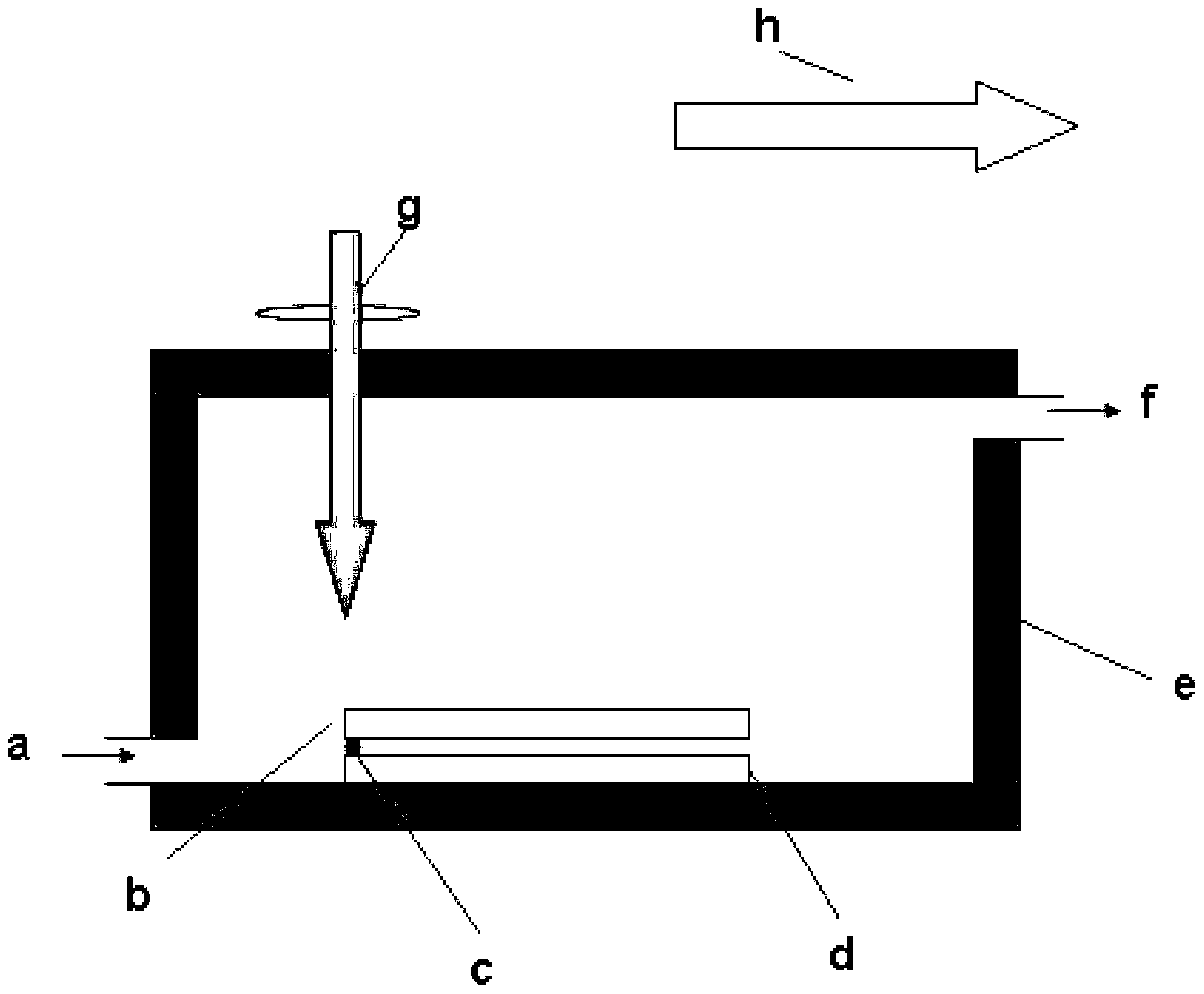

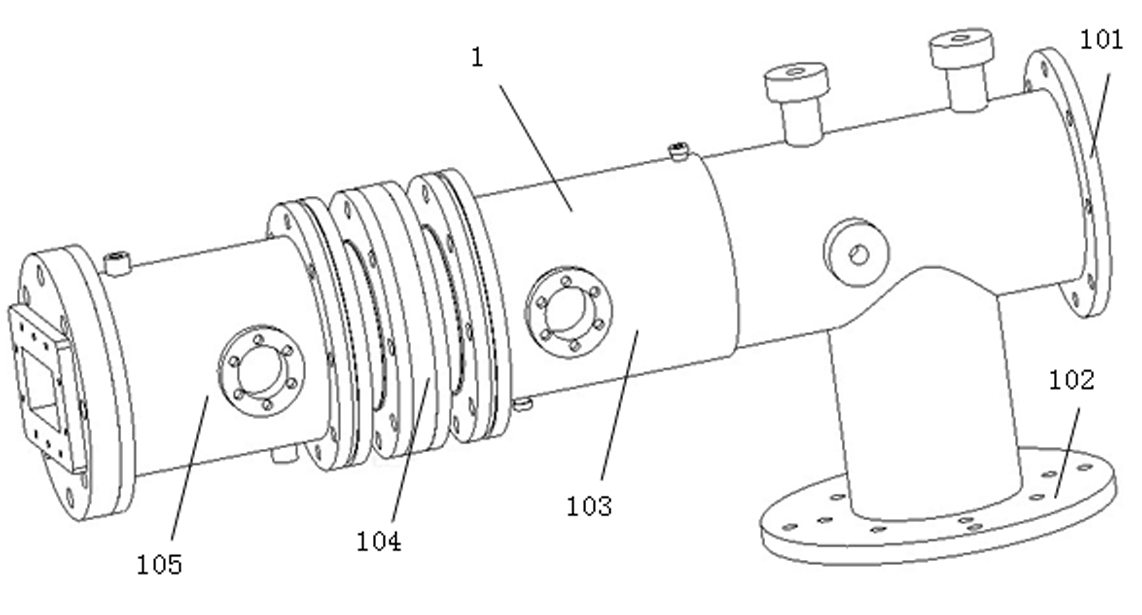

Online rotary ferrograph and equipment oil online monitoring method

PendingCN110595963AReduce gravitational effectsEasy to cleanParticle size analysisIndividual particle analysisImaging qualityBarrel Shaped

The invention discloses an online rotary ferrograph and an equipment oil online monitoring method. The online rotary ferrograph comprises an abrasive particle deposition spectrum forming module and amagnetic head module, wherein the magnetic head module comprises a rotatable magnetic head; the magnetic head comprises a barrel-shaped magnetic conductive bottom block, a pole shoe connected to an opening in the upper end of the magnetic conductive bottom block in a covering mode, and an electromagnet column located at the axis of the magnetic conductive bottom block; one end of the electromagnetcolumn is connected with the bottom surface of the magnetic bottom block and the other end is connected with the pole shoe to form a closed magnetic loop; the magnetic head module further comprises aconductive slip ring used for supplying power to the rotating electromagnet column; the abrasive particle deposition spectrum forming module is positioned above the pole shoe; and a to-be-detected liquid is placed in the abrasive particle deposition spectrum forming module for deposition and spectrum forming. Residual oil and pollutants in a deposition region can be cleaned and thrown away by means of the online rotary ferrograph, thus the online monitoring image quality is improved; two annular deposition surfaces with different diameters can be formed, and due to the fact that the magneticinduction intensities of the two annular deposition surfaces are different, the size ranges of abrasive particles deposited on the two annular deposition surfaces are different, and the spectrum forming monitoring efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

Preparation method of glass-substrate/silver nano-film/polyaniline electrochromic film

The invention discloses a preparation method of a glass-substrate / silver nano-film / polyaniline electrochromic film, relates to a preparation method of electrochromic films, and solves the technical problems that electrochromic devices are high in preparation cost because of taking ITO (indium tin oxide) glass as a conductive substrate, and the existing method is poor in uniformity of prepared metal films and complex in operation. The method comprises the following steps: 1, preparing a glass sheet to which a silver nano film is attached; 2, preparing a polyaniline (PANI) solution; and 3, vertically inserting the glass sheet to which the silver nano film is attached into the PANI solution, dipping 30 minutes, sequentially washing the glass sheet by using deionized water and a dilute hydrochloric acid, and carrying out natural airing on the glass sheet, thereby obtaining the glass-substrate / silver nano-film / polyaniline electrochromic film. The silver nano-film prepared by using the method disclosed by the invention is good in uniformity and electrical conductivity, and the color conversion effect of the glass-substrate / silver nano-film / polyaniline electrochromic film is better than that of an ITO / PANI film. The method disclosed by the invention belongs to the preparation field of electrochromic films.

Owner:HEILONGJIANG UNIV

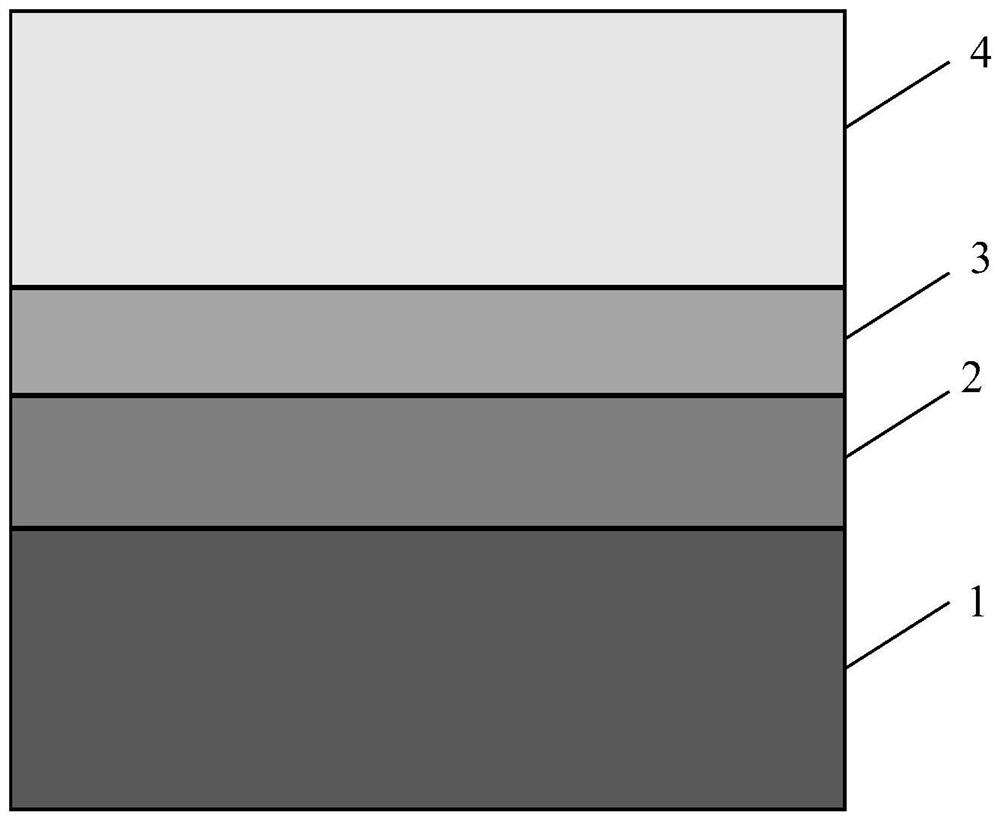

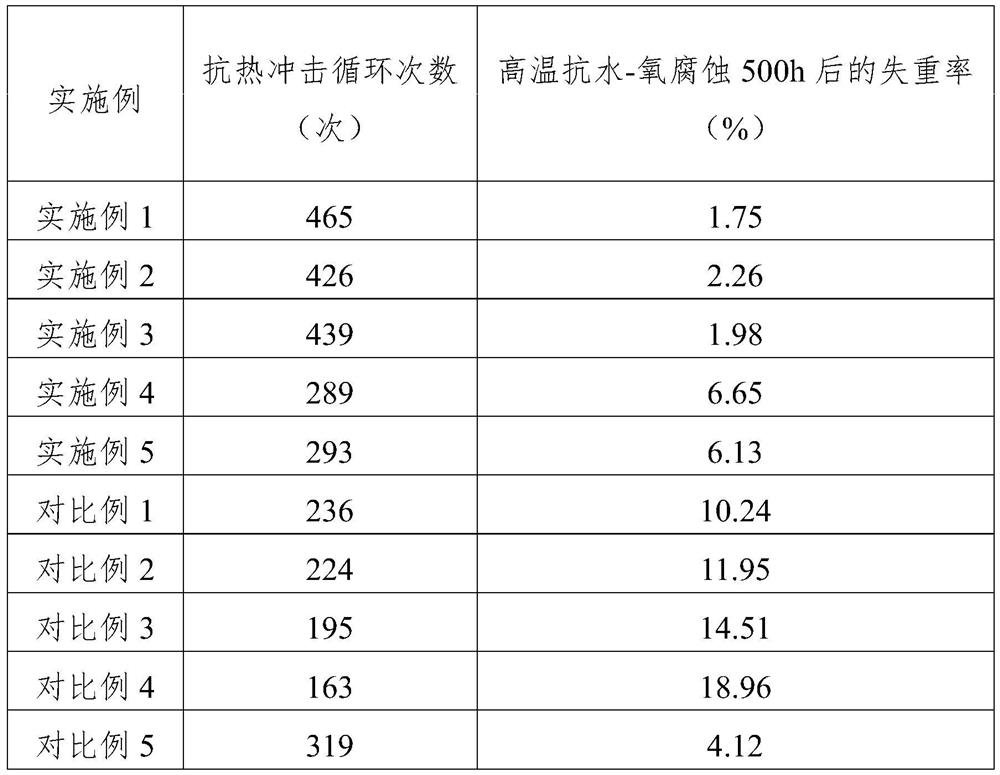

Multiphase environmental barrier coating formed on base material and preparation method thereof

ActiveCN111876714AImprove the performance of high temperature water-oxygen corrosion resistanceAlleviate thermal expansion mismatchMolten spray coatingEfficient propulsion technologiesLutetiumLutetium oxyorthosilicate

The invention relates to a multiphase environmental barrier coating formed on a base material and a preparation method thereof. The multiphase environmental barrier coating sequentially comprises a silicon bonding layer, a mullite layer and a Lu2SiO5-Sc2Si2O7 multiphase ceramic layer from the base material to the outside, wherein the Lu2SiO5-Sc2Si2O7 multiphase ceramic layer is formed by mixing lutetium silicate and scandium silicate. The method comprises the following steps: filling silicon powder, mullite powder and mixed powder formed by mixing lutetium silicate powder and scandium silicatepowder into a powder feeder of ultra-low pressure plasma spraying equipment and carrying out drying treatment; fixing the base material to a rotating table in a spraying cabin; and sequentially preparing the silicon bonding layer, the mullite layer and the Lu2SiO5-Sc2Si2O7 multiphase ceramic layer on the surface of the base material to prepare the multiphase environmental barrier coating. The multiphase environmental barrier coating is long in thermal shock resistance life and excellent in high-temperature water-oxygen corrosion resistance; and the method provided by the invention can be usedfor rapidly and integrally preparing the multiphase environmental barrier coating at low cost in an ultra-low pressure environment.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

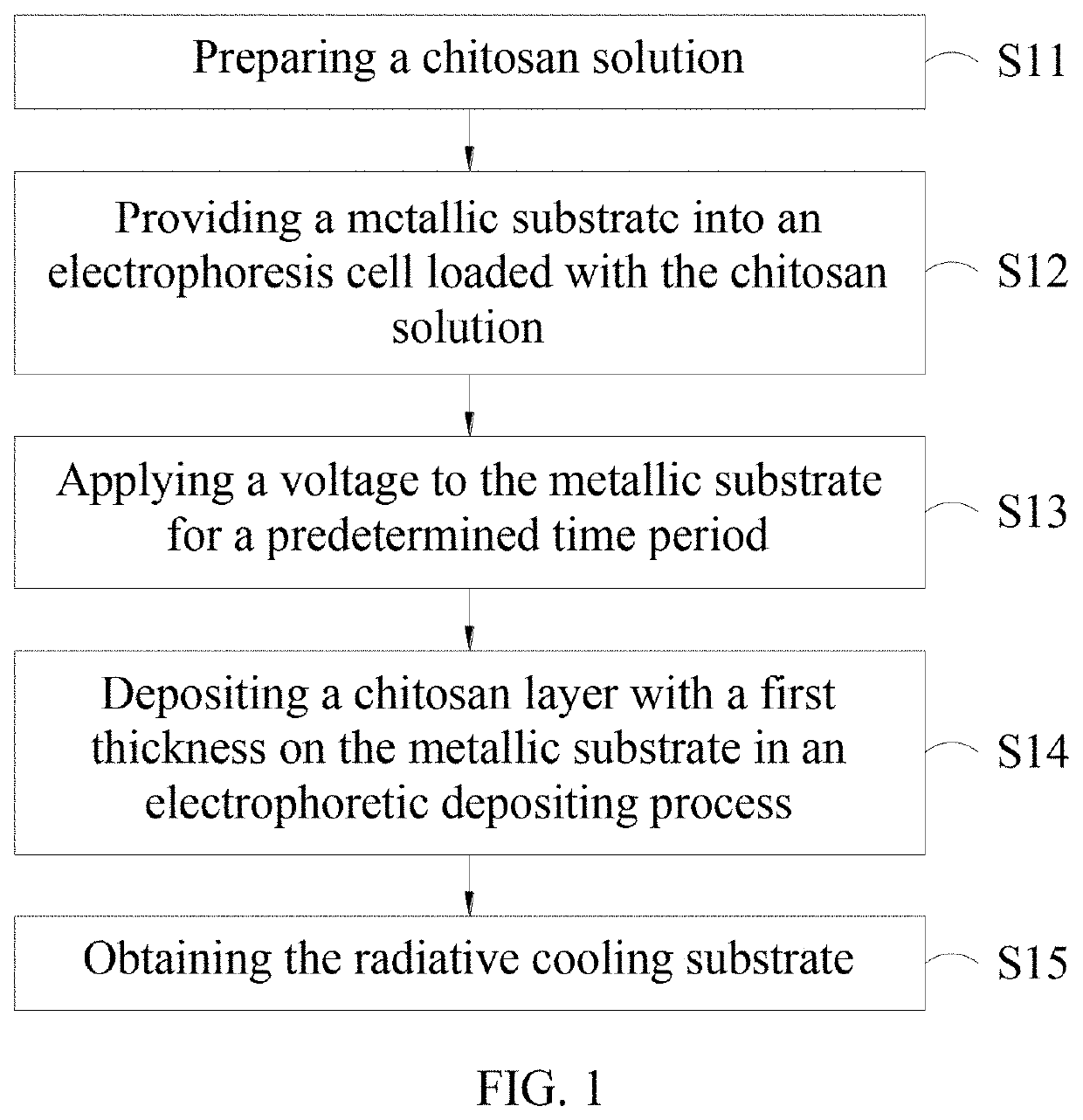

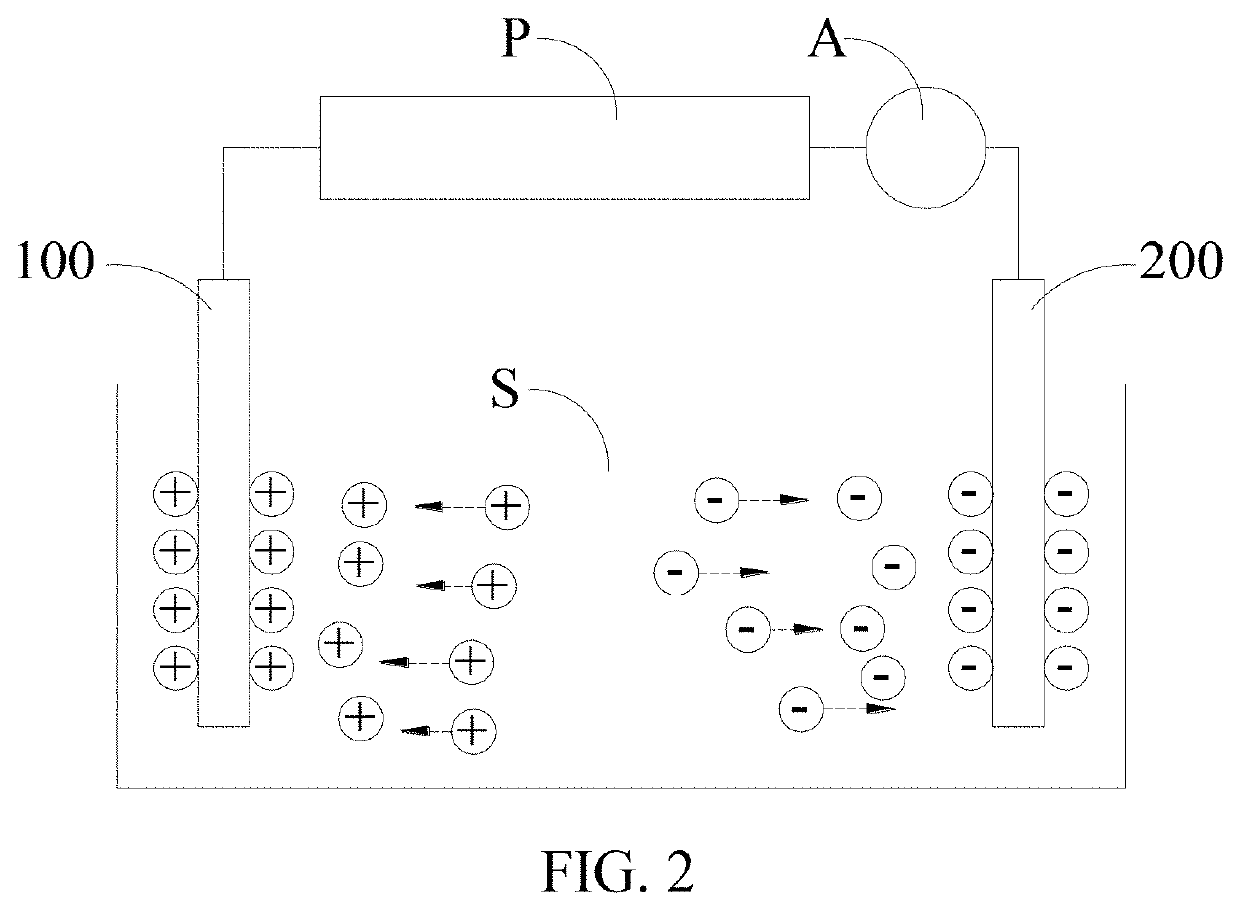

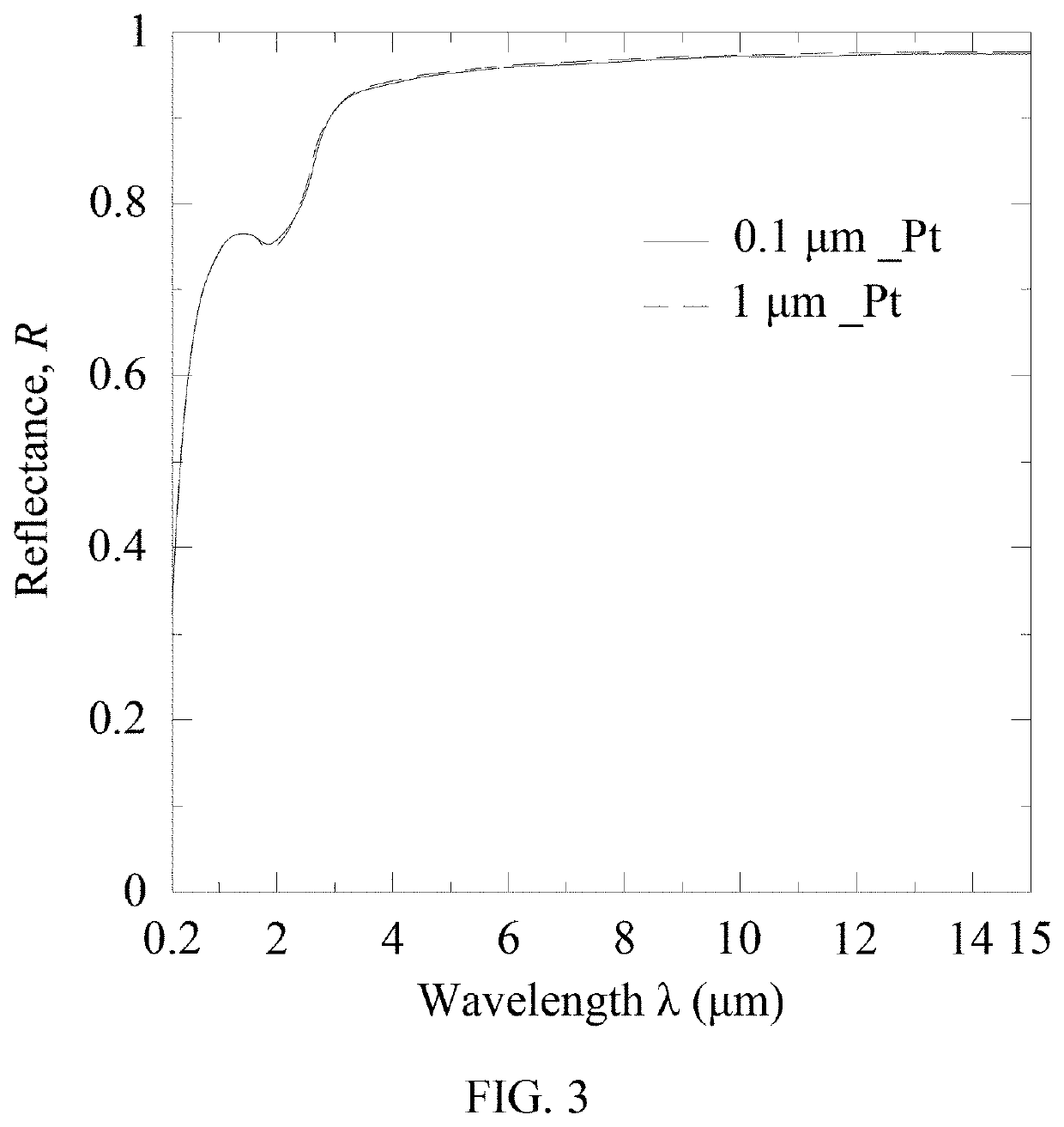

Radiative cooling substrate and manufacturing method of the same

ActiveUS11078593B2High emissivityLarge deposition areaElectrophoretic coatingsPaints for electrolytic applicationsPhysical chemistryWave band

Owner:NATIONAL TSING HUA UNIVERSITY

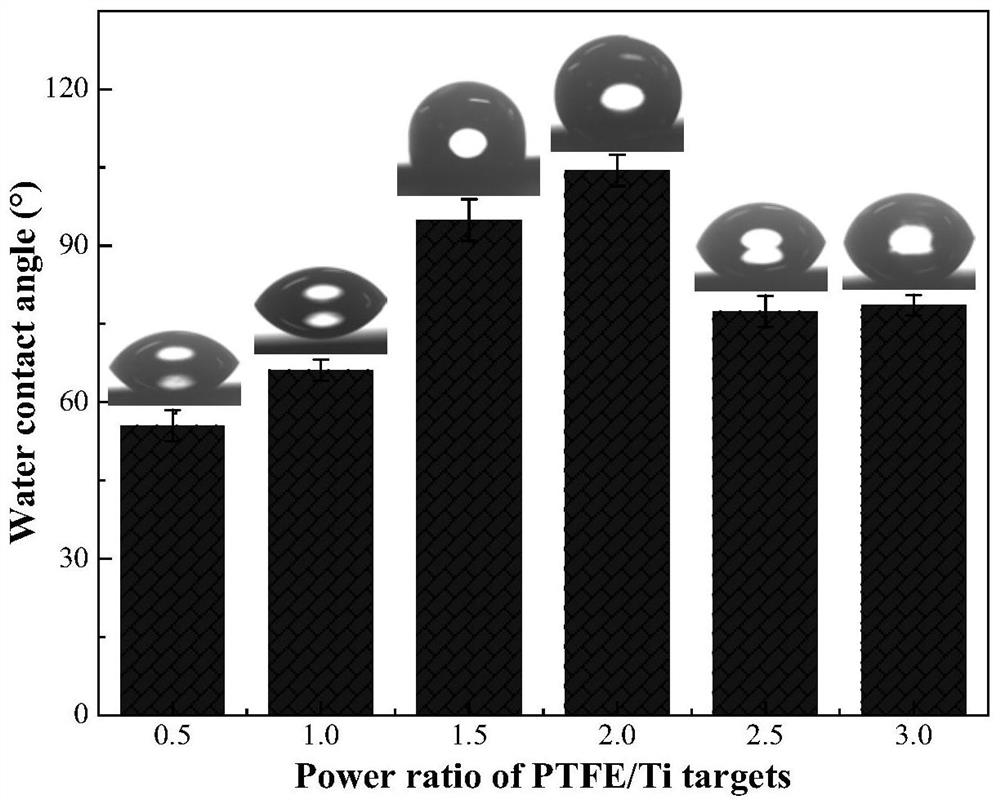

Organic-metal nano composite film as well as preparation method and application thereof

ActiveCN112030108AHigh purityLarge deposition areaVacuum evaporation coatingSputtering coatingComposite filmThin membrane

The invention discloses an organic-metal nano composite film as well as a preparation method and application thereof, and belongs to the technical field of composite materials. The organic-metal nanocomposite film is composed of a substrate layer and a fluorocarbon-titanium composite film layer. The preparation method comprises the following steps: grinding a polytetrafluoroethylene target material and a titanium target material, and cleaning; then carrying out pre-sputtering; depositing a fluorocarbon-titanium composite film on the surface of the substrate layer by virtue of co-sputtering; and then carrying out high-temperature annealing to obtain the product. According to the preparation method of the organic-metal nano composite film, the change of the deposition state of the film is changed by adopting the radio-frequency direct-current co-sputtering, so that nanoscale surface appearance and chemical component contents are regulated and controlled; and the crystallinity of the film is regulated and controlled by adjusting a high-temperature annealing process, so that the prepared composite film shows different infiltration properties and secondary electron emission characteristics, and has the advantages of high purity, large deposition area, high controllability of a phase structure and the like, thereby being wide in application and having remarkable popularization and practical values.

Owner:CHONGQING UNIV

Method for depositing semiconductor film on flexible substrate

InactiveCN102477549ALarge deposition areaTake advantage ofFinal product manufactureLiquid/solution decomposition chemical coatingEngineeringSemiconductor

The invention relates to a method for depositing a semiconductor film on a flexible substrate, which comprises the following steps: (1) preparing a reaction tank material; (2) mounting a part on a reaction tank base plate; (3) fixedly mounting four side plates around the reaction tank base plate to form a case body; (4) mounting a flexible substrate; (5) transferring the flexible substrate which is completely soaked in a reaction solution from one scroll to another scroll so as to allow the end surface of the flexible substrate to be snake-shaped. According to the invention, the flexible substrate is winded into a fixed shaft with a snake-shaped end surface; the scroll is driven by a motor, and the flexible substrate is transferred from one scroll to another scroll through snake-shaped movement in the reaction solution; thereby the substrate disposed in the reaction tank is as long as possible; the deposition area of the substrate is effectively increased; the reaction solution is made full use of; the flexible substrate is deposited completely in the reaction solution so as to form a semiconductor film with good uniformity; the device has a simple structure; the manufacturing cost is low; and the method has the characteristic of large-scale production.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

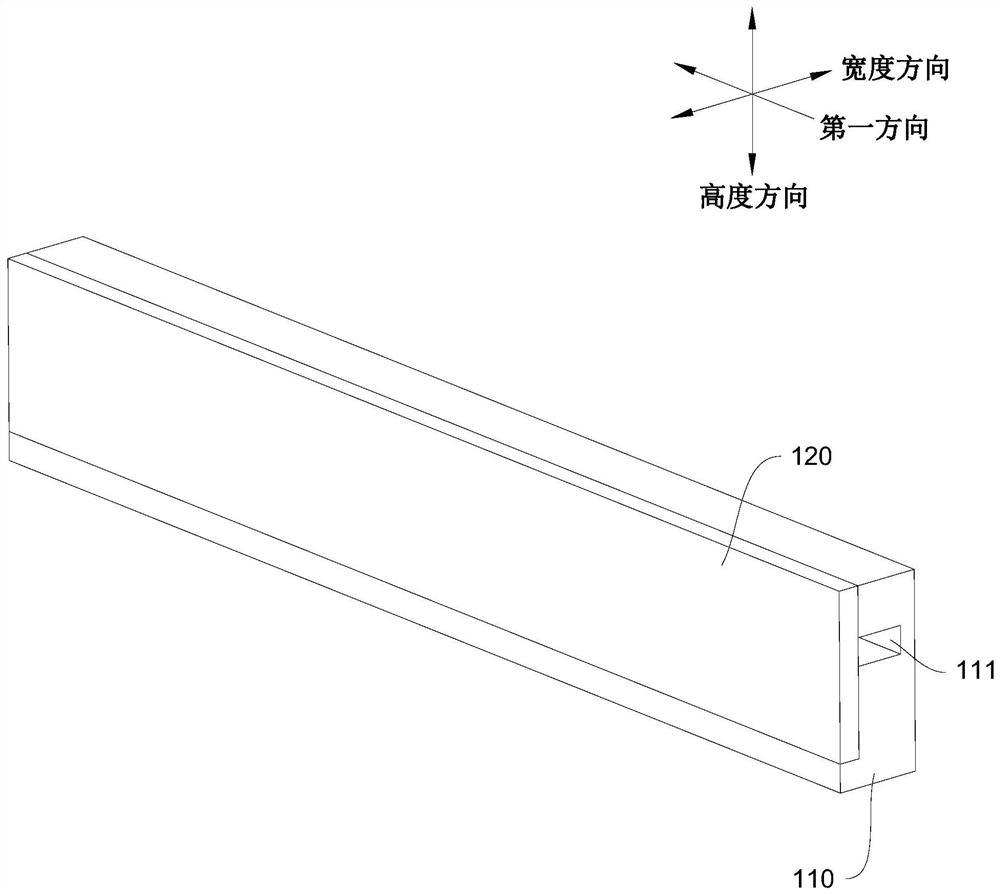

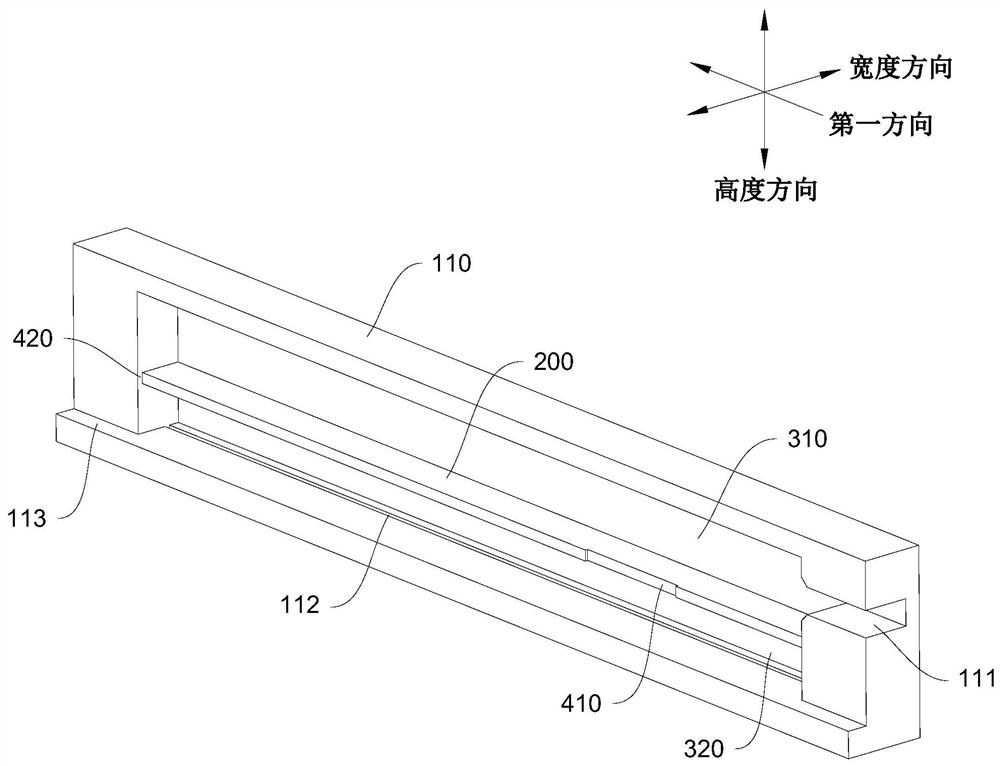

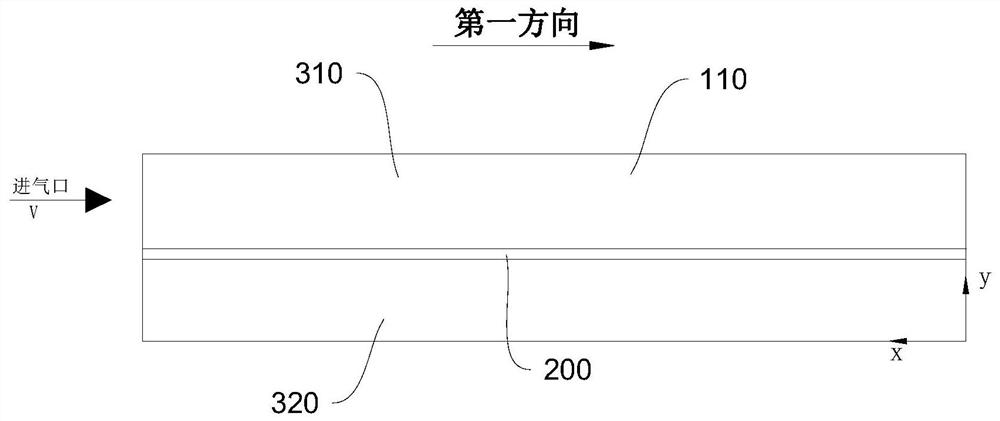

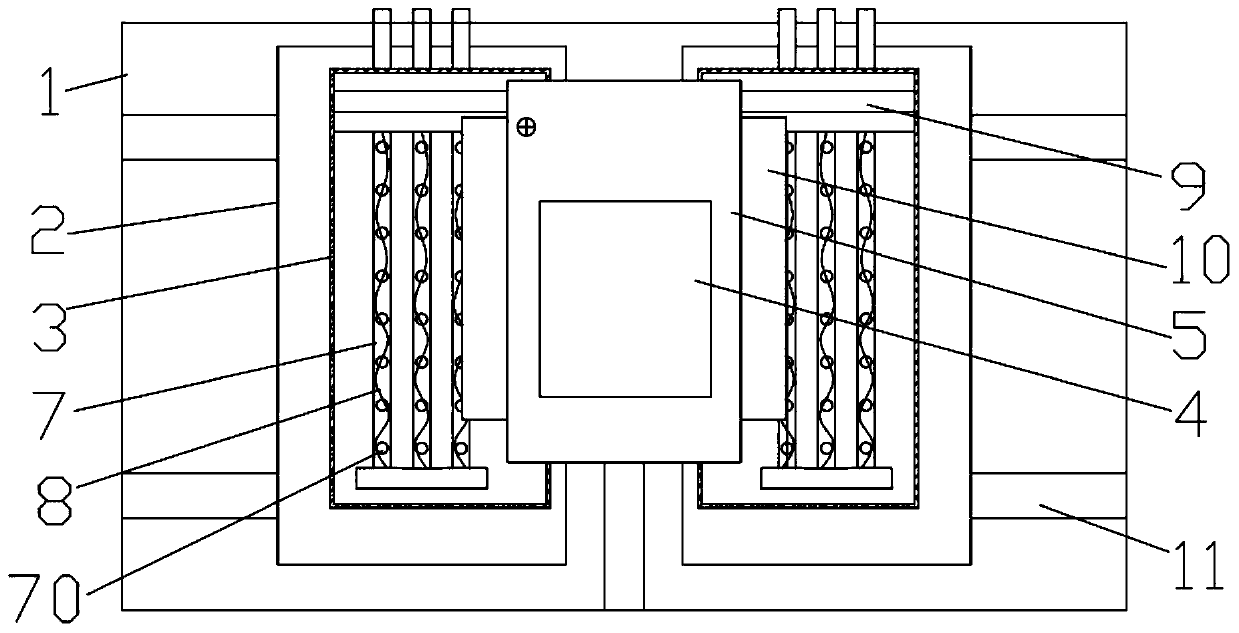

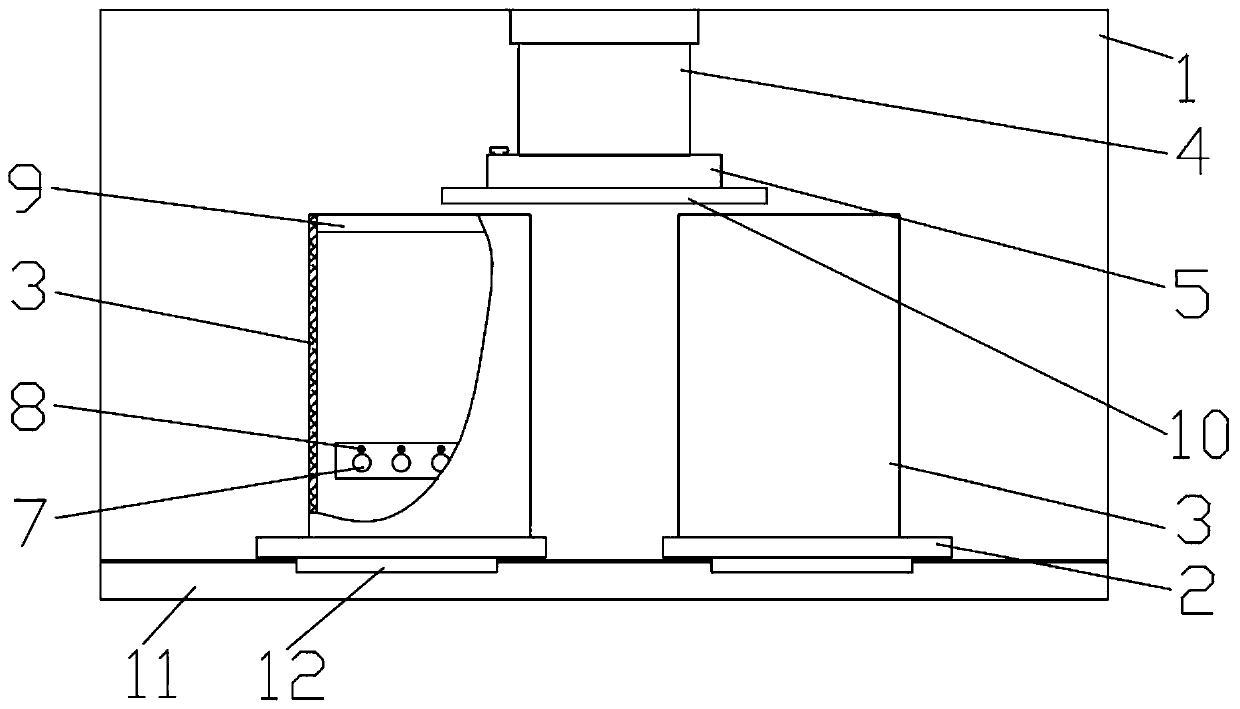

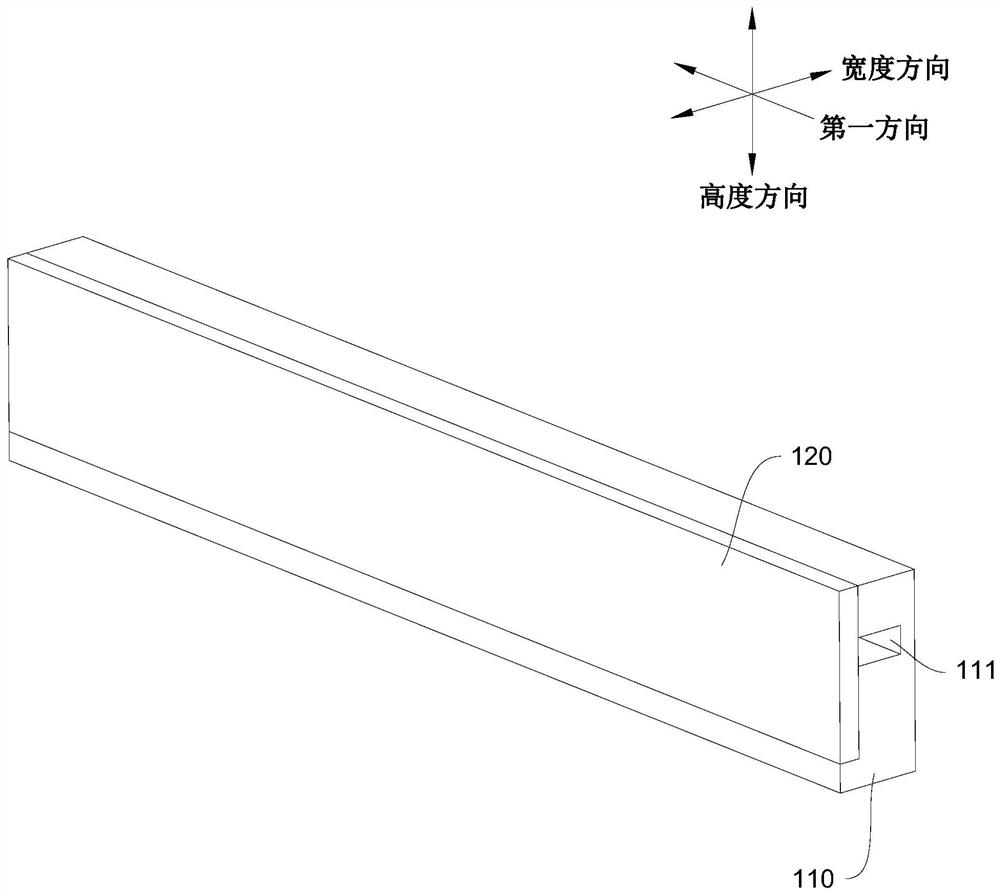

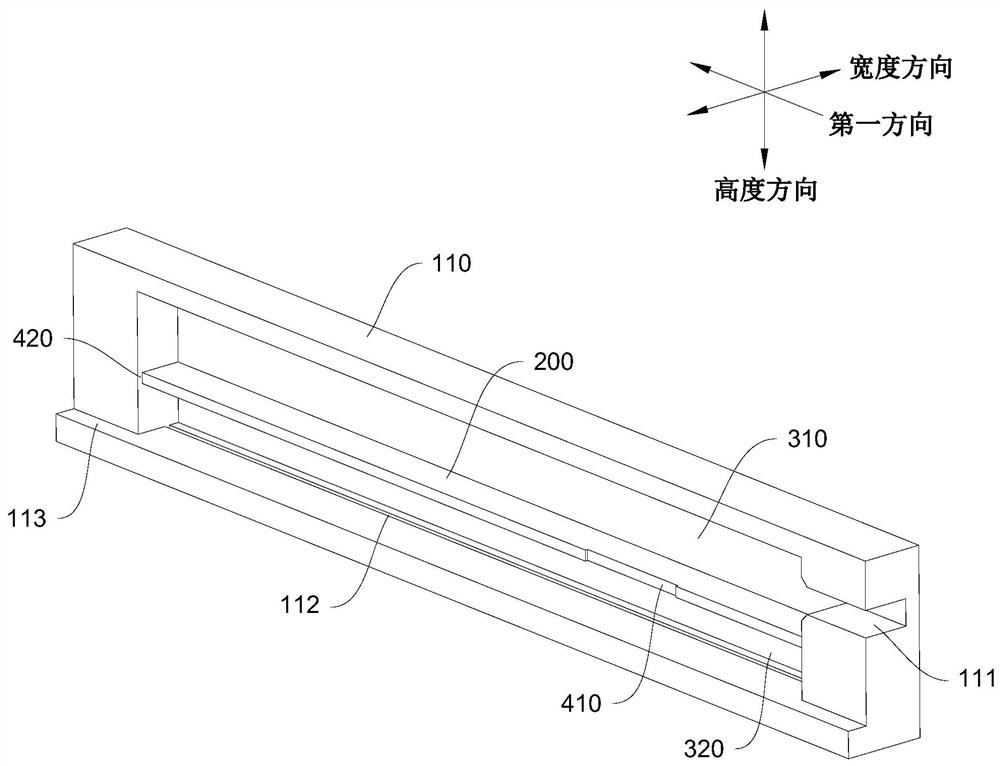

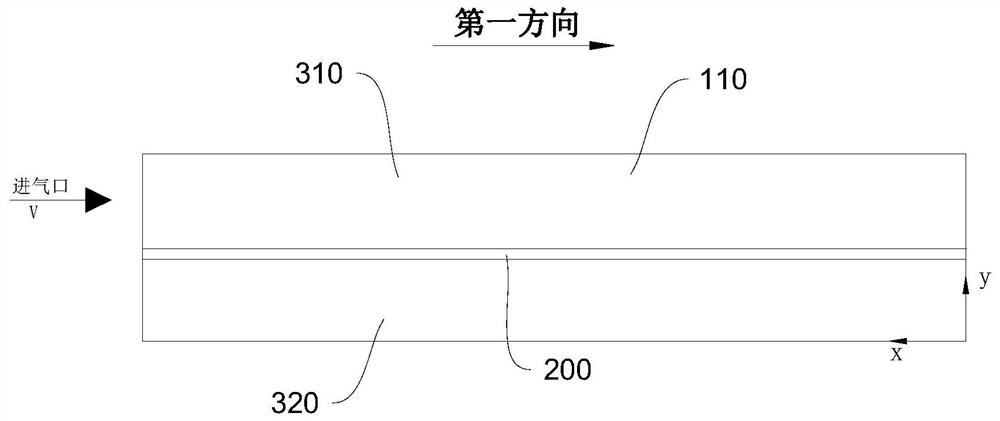

Spatial isolation atomic layer deposition device

ActiveCN113846315AUniform flowEven amountChemical vapor deposition coatingEngineeringMechanical engineering

The invention relates to a spatial isolation atomic layer deposition device. The spatial isolation atomic layer deposition device comprises a shell, a partition plate, an air inlet and an air outlet, wherein the interior of the shell is hollow to form an air duct; the partition plate is located in the shell; the portion, located on one side of the partition plate, in the air duct is a main air duct, and the portion, located on the other side of the partition plate, in the air duct is a static pressure chamber; a slit is formed in the partition plate, and the main air duct communicates with the static pressure chamber through the slit; the flowing direction of air in the length direction of the main air duct serves as the first direction, and the slit comprises a plurality of intervals in the first direction; the air inlet is formed in the shell and communicates with the main air duct; the air outlet is formed in the shell and communicates with the static pressure chamber, and the air outlet extends in the first direction; and in the area close to the tail end in the first direction, the width of the slit in at least part of the intervals is larger than that of the slit in the next interval, so that the amount of gas flowing into the static pressure chamber through the slit in the main air duct in all the intervals is equal.

Owner:HUAZHONG UNIV OF SCI & TECH

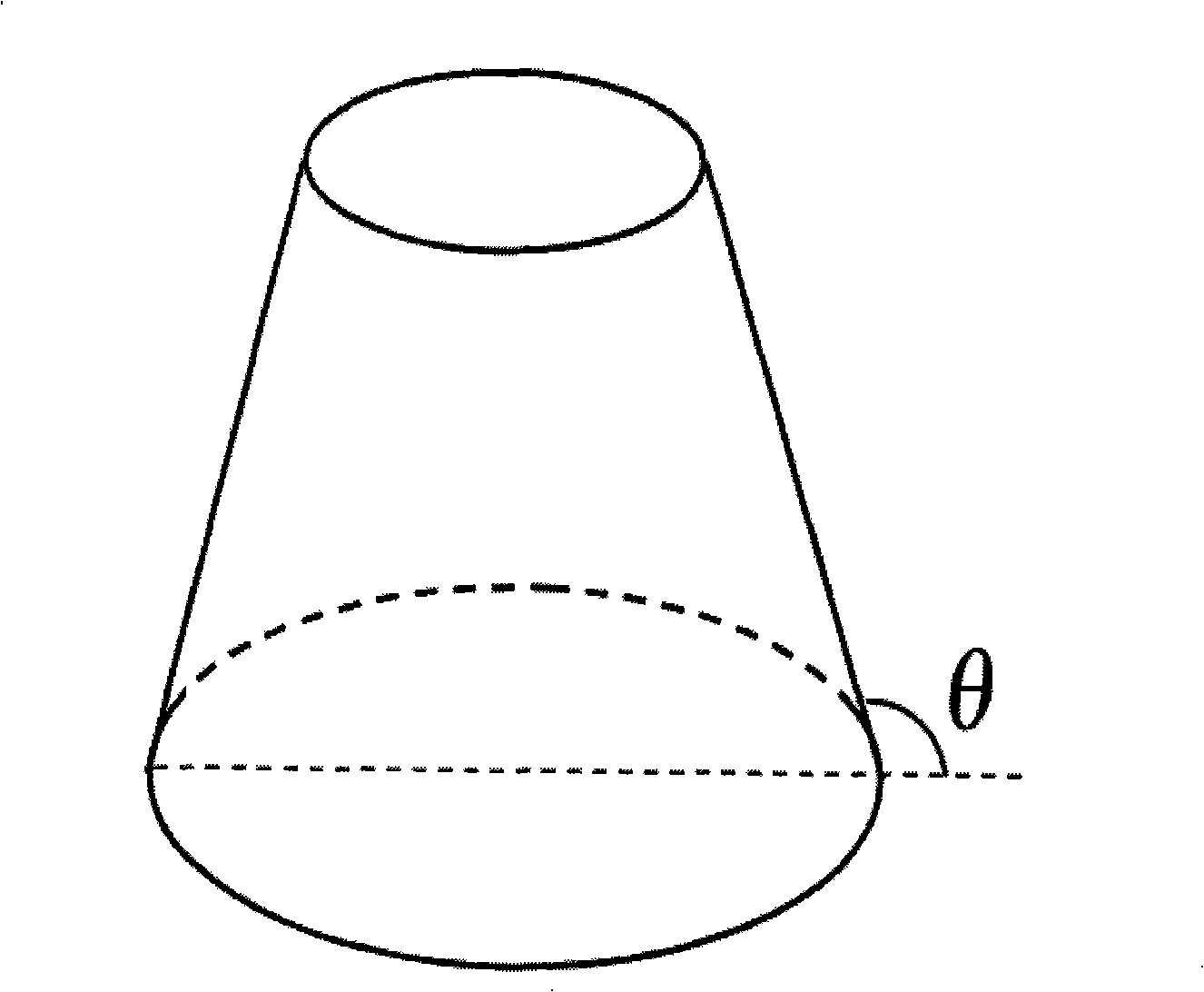

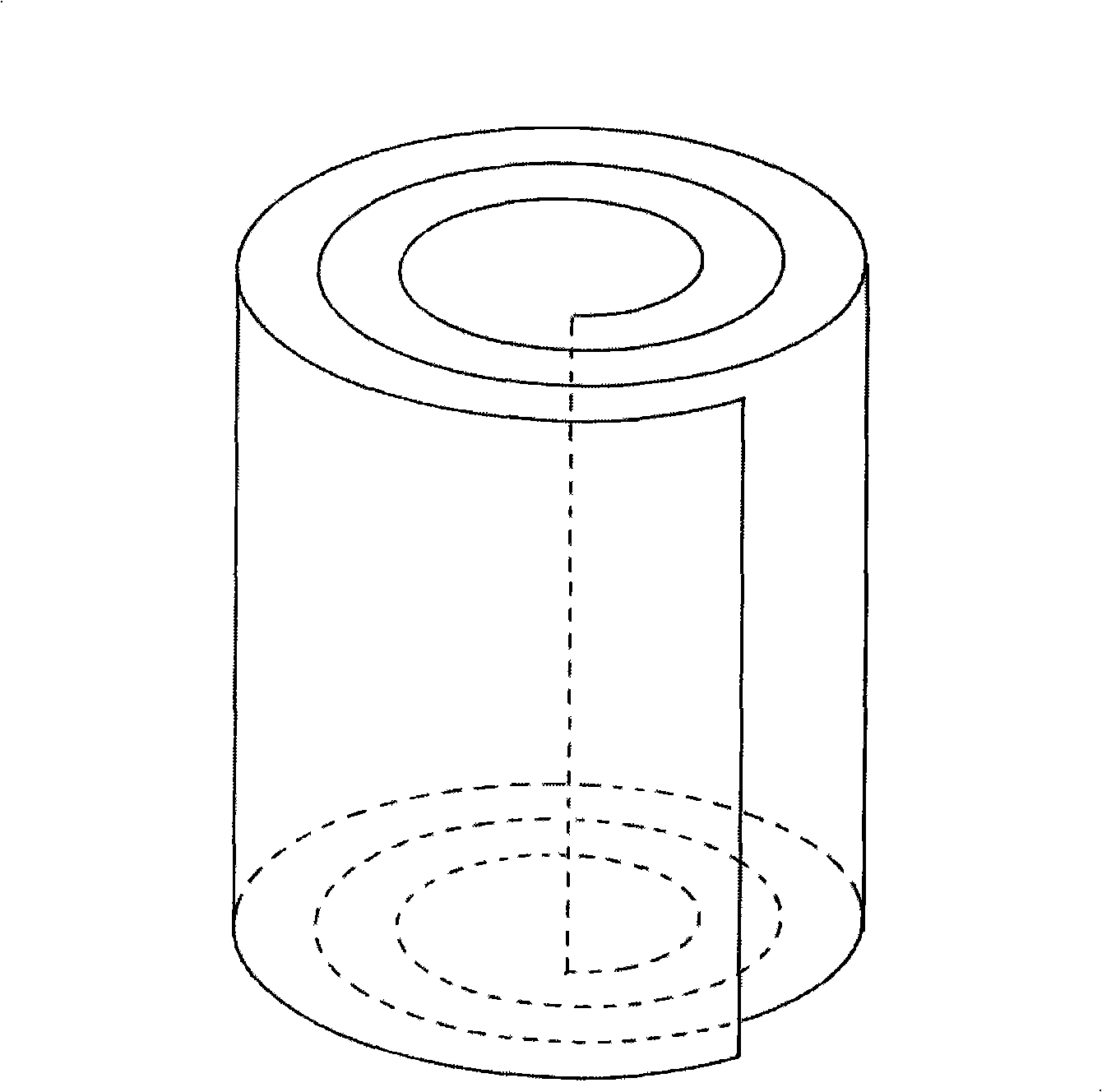

Multi-mode non-cylindrical resonant cavity MPCVD device with conical reflection top surface

PendingCN114196946ASimple structureScientific and reasonable designPolycrystalline material growthFrom chemically reactive gasesResonant cavityPlasma etching

The invention discloses a multi-mode non-cylindrical resonant cavity MPCVD device with a conical reflection top surface, and solves the technical problems of low synthetic power and slow growth speed of diamond limited by the existing resonant cavity structure. The device comprises a microwave generating device used for microwave emission and a growth cavity connected with the microwave generating device and used for diamond synthesis. An annular quartz window is arranged in the growth cavity, a water-cooling copper table antenna is arranged above the annular quartz window, a threaded molybdenum table for placing a diamond crystal is arranged above the water-cooling copper table antenna, plasma is arranged above the threaded molybdenum table, and a conical reflecting surface is arranged on the top surface in the growth cavity. The device is simple in structure, scientific and reasonable in design and convenient to use, the microwave power can be greatly enhanced, the growth speed can be increased, and silicon pollution caused by plasma etching can be greatly reduced.

Owner:成都稳正科技有限公司

Improved electric compressor for new energy automobile

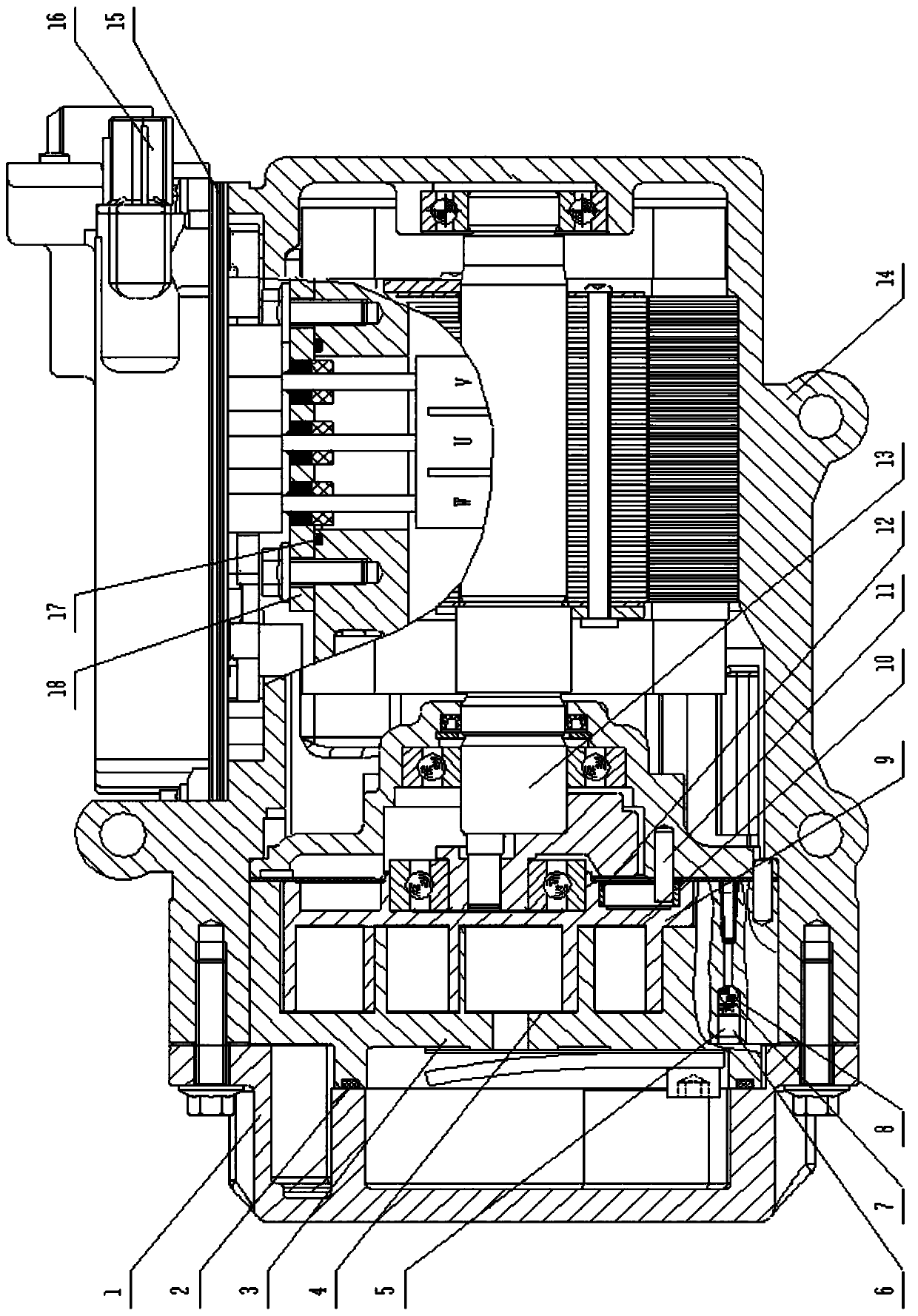

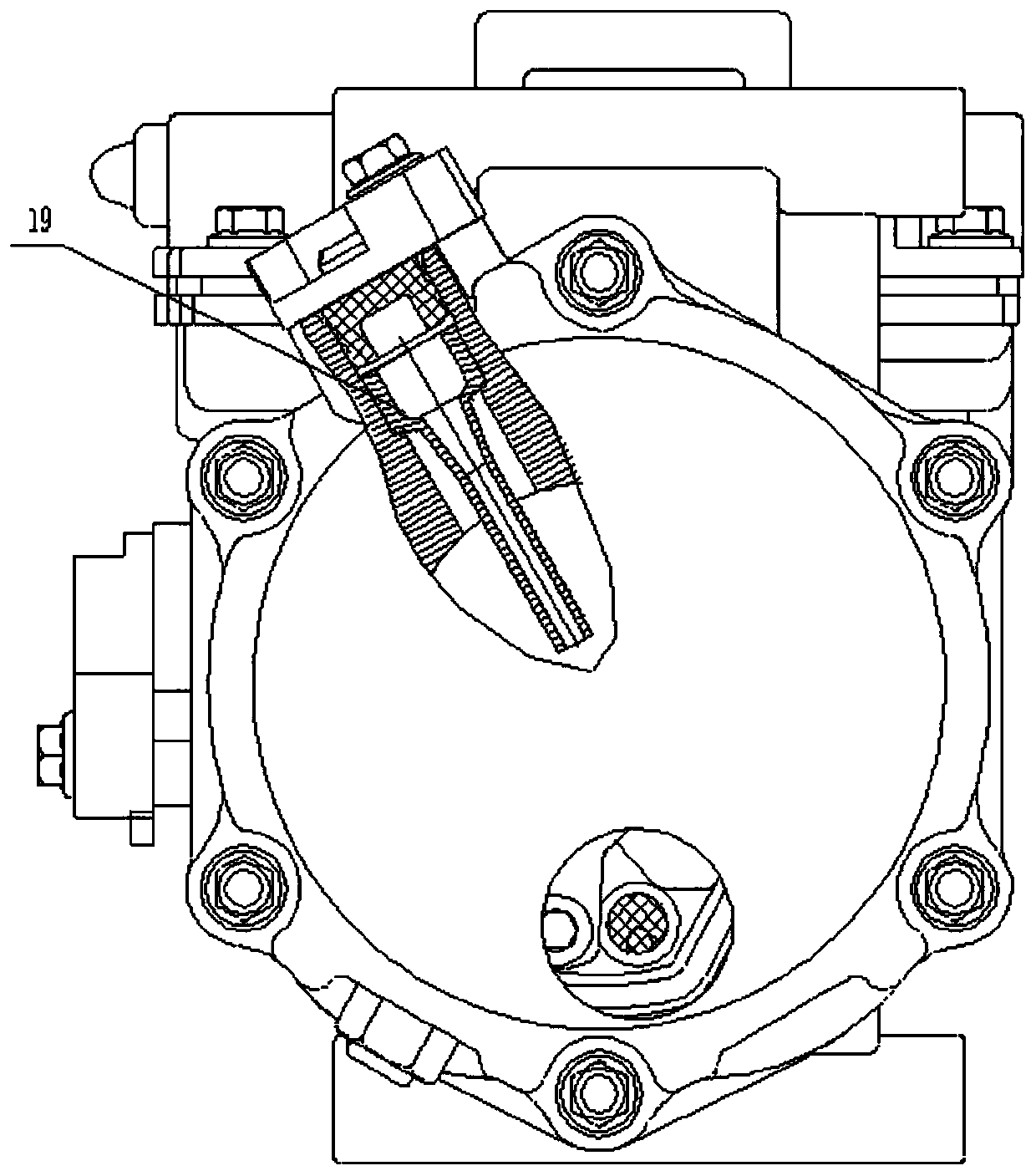

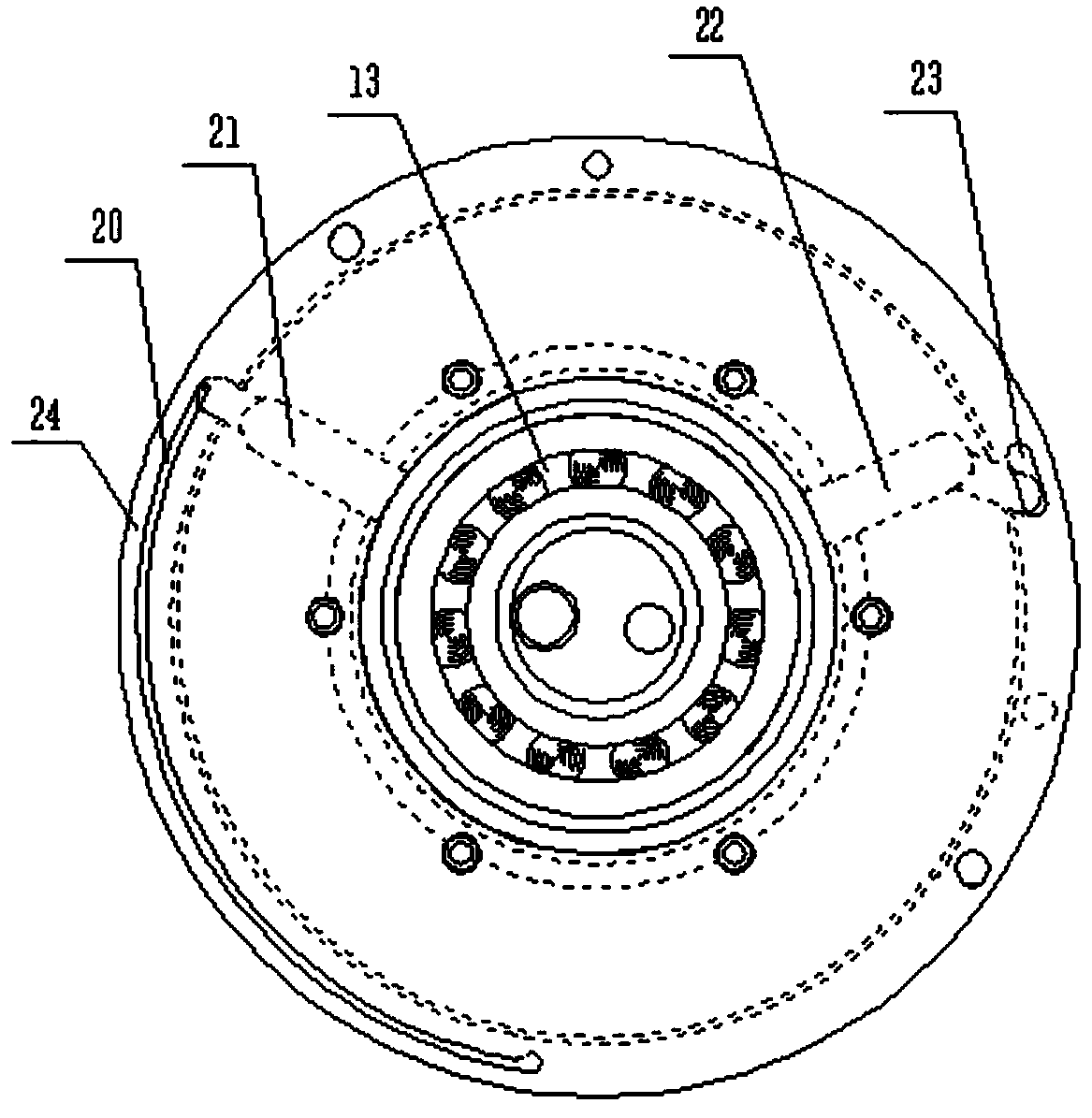

PendingCN111255683AReduce leak failure ratePrevent overcompressionRotary/oscillating piston combinations for elastic fluidsSealing arrangement for pumpsNew energyElectric machinery

The invention provides an improved electric compressor for a new energy automobile. The electric compressor comprises a rear cover part, a static scroll plate part, a movable scroll plate, a bearing seat part, a motor shell part and a controller part, an integrally closed cavity is formed between the rear cover part and the motor shell part, the rear cover part comprises a rear cover and a separation pipe, and a special-shaped sinking cavity is formed in the inner side of the rear cover, an exhaust step hole is formed in the rear cover, and a separation pipe is arranged in the exhaust step hole, a heat dissipation protruding block is arranged on the outer side of the top end of a motor shell in the motor shell component, the controller component comprises a controller shell and a heat dissipation plate, limiting cylinders are arranged at the four corners of the bottom end of the controller shell, a controller sealing gasket is arranged between the controller component and the motor shell component, and the heat dissipation plate is connected with the heat dissipation protruding block in an attached mode. According to the electric compressor, the oil return effect can be effectivelyimproved, the damage to the cross section of the scroll plate is prevented, the leakage failure rate of the whole machine is reduced, the installation failure rate of the controller is reduced, and the sealing effect is improved.

Owner:无锡双鸟科技股份有限公司

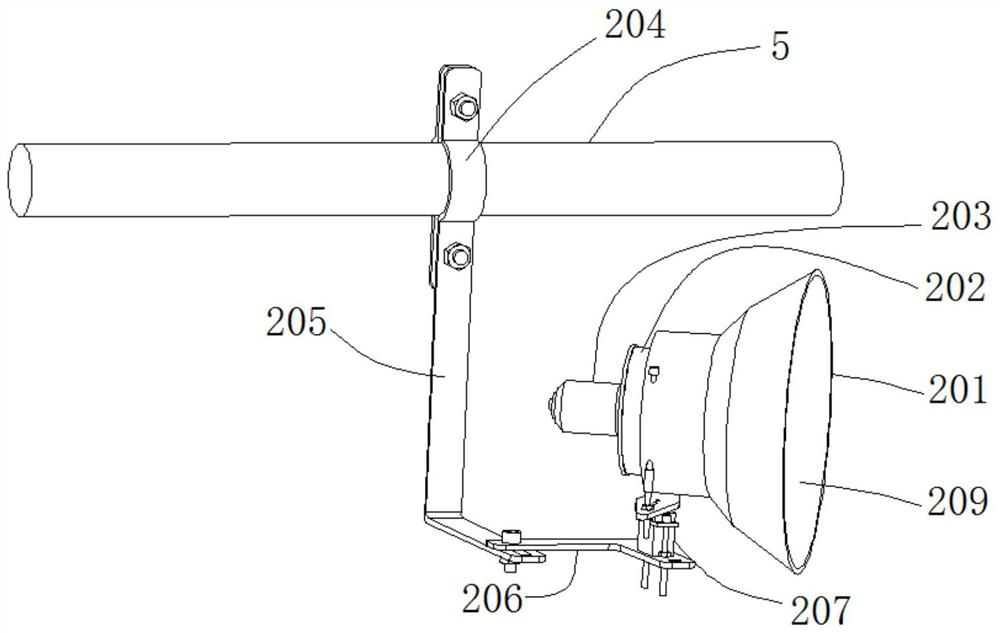

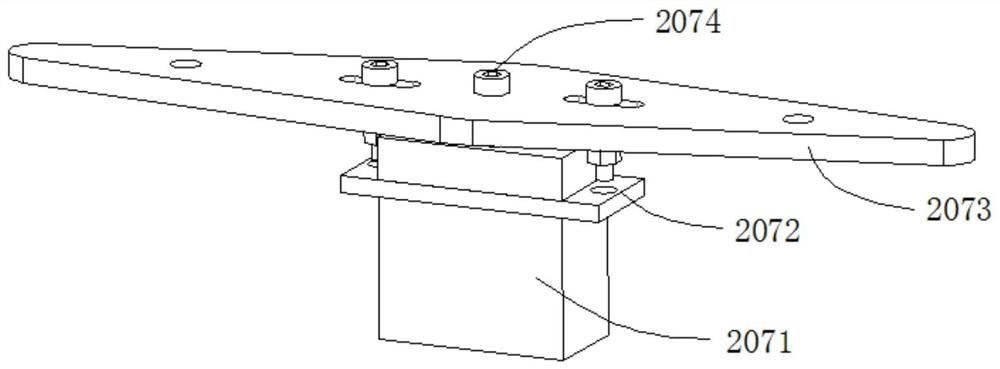

Air-assisted spraying device based on unmanned aerial vehicle

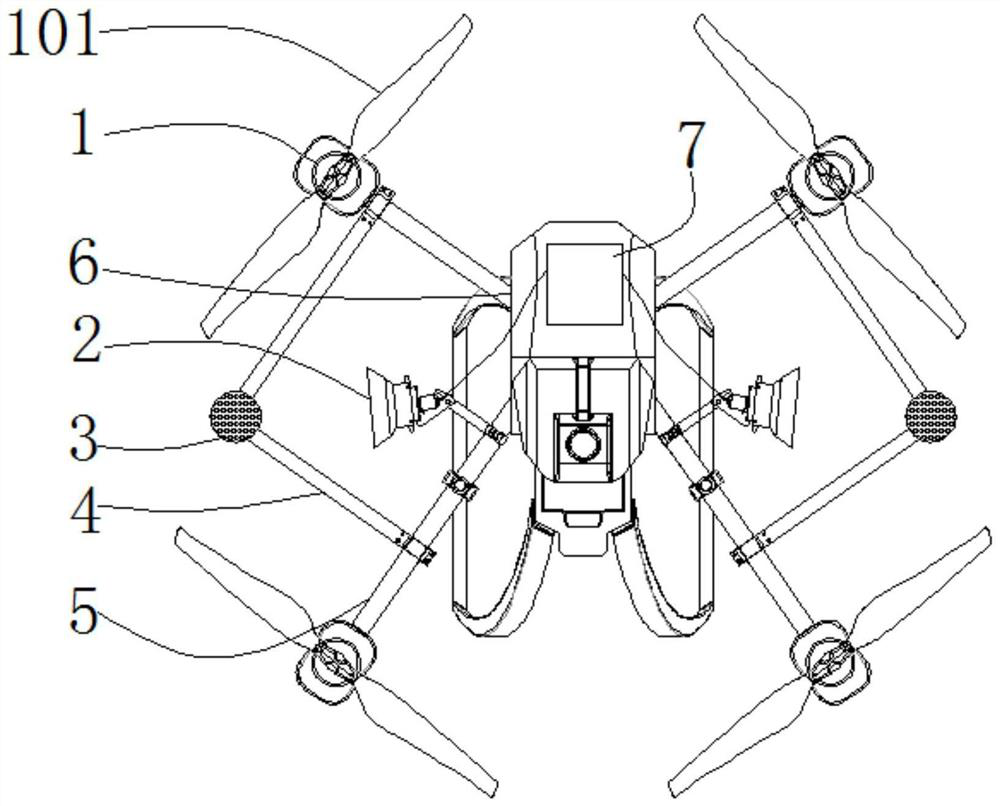

ActiveCN112776986AExtended stayLarge deposition areaAircraft componentsRotocraftSpray driftControl system

The invention discloses an air supply spraying device based on an unmanned aerial vehicle. The device comprises a flight mechanism, a connecting rod, a nozzle and a liquid storage cavity, wherein the nozzle is fixed on the flight mechanism through the connecting rod, the nozzle is connected with the liquid storage cavity, the liquid storage cavity is installed on the flight mechanism, and the air supply spraying device further comprises a control system and an air supply mechanism, the air supply mechanism is connected with a connecting arm of the flight mechanism, the nozzle and the air supply mechanism are both located between two groups of rotors of the flight mechanism, the air supply mechanism comprises a duct, an air duct, a steering engine set and a supporting frame, the duct is connected with the air duct, the lower end of the air duct is connected with the steering engine set, and the steering engine set is connected with the connecting arm through the supporting frame; and the duct and the steering engine set are connected with the control system. According to the air supply spraying device, under the interaction of existing rotor airflows of the air supply mechanism and the flight mechanism, when the spray head sprays, a steering engine set in the air supply mechanism rotates back and forth, so that liquid spray drifts obviously in the air, the residence time of the spray in the air is prolonged, and the deposition area of the spray is increased.

Owner:SOUTH CHINA AGRI UNIV

A ZnS monocrystal nanowire growing method

InactiveCN101514482AAvoid impurities and other by-productsLarge deposition areaPolycrystalline material growthFrom condensed vaporsHexagonal phaseSemiconductor

The invention discloses a method for catalyst growing monocrystal II-VI group semiconductor compound ZnS nanowire with support of a vacuum thermal evaporation method, which comprises the following steps: evenly mixing ZnS power and metal Bi power or Sn power according to the mol ratio of 1:0.005-1:0.057 as raw materials, placing the mixted raw materials in a resistance heating boat, arranging various substrates at the position of 1.0 cm-3.5 cm above from the boat, closing a vaporizing furnace, when the pressure of the vacuum vaporizing furnace cavity reaches 2x10-7x10 Pa, and the current of the heating boat reaches 120A-140A, the condition is maintained for 5-15 min for sedimentation. The ZnS nanowire prepared by the invention as a monocrystal ZnS with hexagonal phase has advantages of large sedimentation area, uniform appearance, and is applicable for various substrates. The method of the invention is simple, easy to popularize and suitable for large-scale commercial production.

Owner:XINJIANG UNIVERSITY

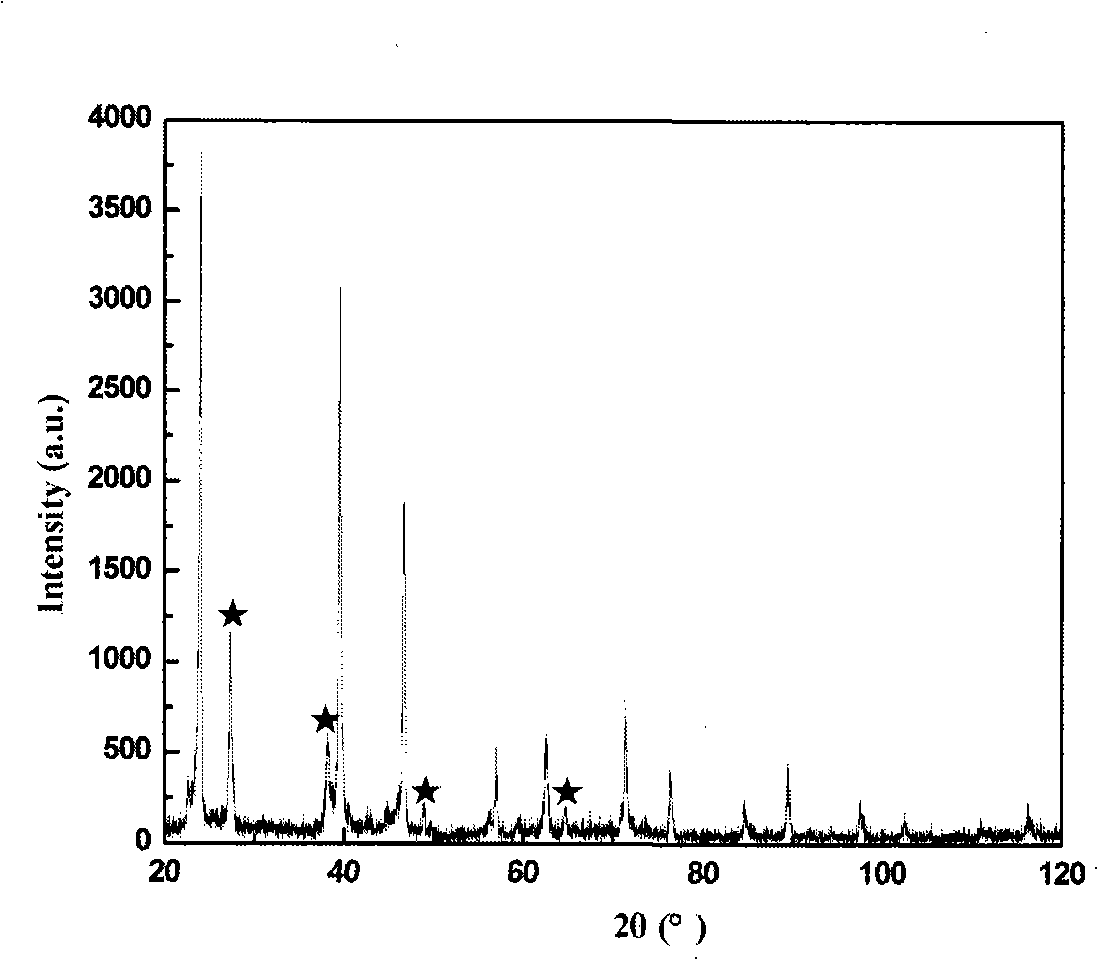

Method for preparing lithium ion solid electrolyte film with large area

InactiveCN1191654CLarge deposition areaImprove deposition efficiencyFinal product manufactureVacuum evaporation coatingLithiumRadio frequency magnetron sputtering

The film of lithium, phosphor, oxygen and nitrogen (LiPON) is deposited by using the combination of the electron beam heating method and the mitrogen ion source generator. Comparing with the method of radio frequency magnetron sputtering, the deposited area is increased nearly 10 times. The conductivity of Li ion of the LiPON film prepared by the invention can reach 2-5X10 to the power -6 s / cm. Combining with electrodes of the thin film of Ag0.5V2O5 etc. and the metal Li film electrodes, thin film Li ion battery in full solid state can be assembled.

Owner:FUDAN UNIV

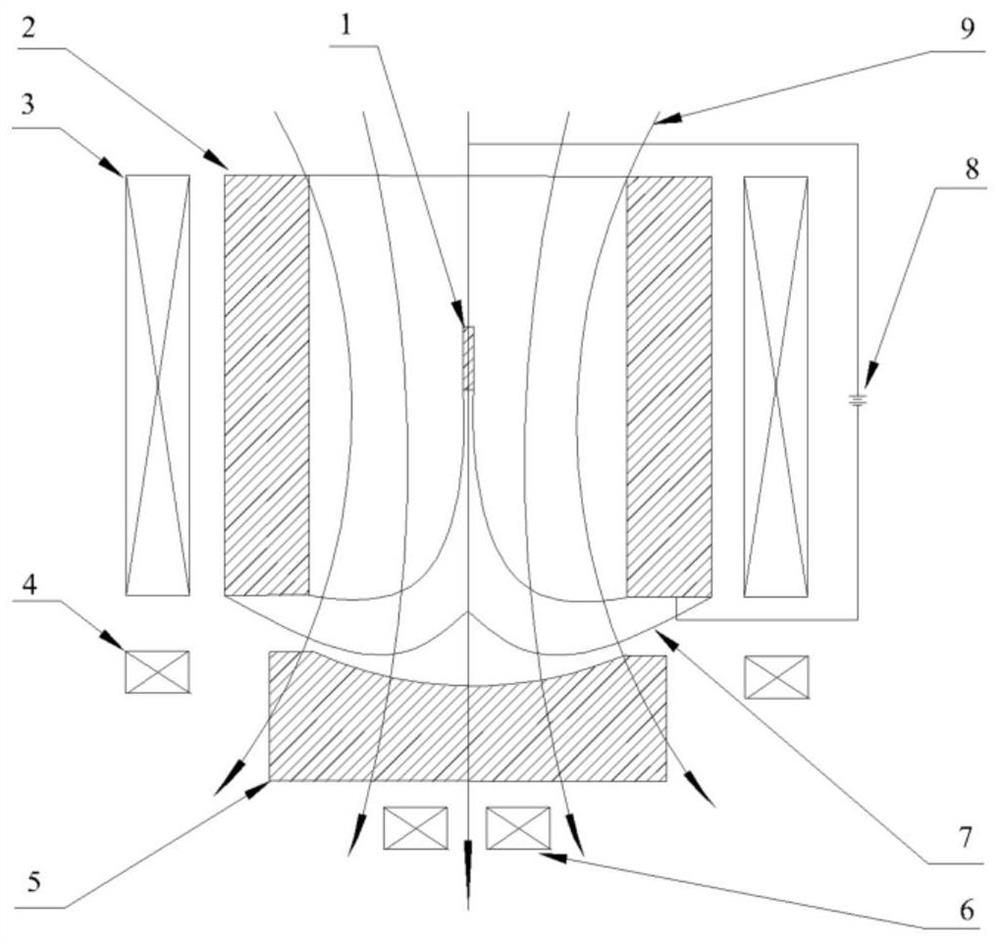

Device and method for plasma arc deposition of diamond film

ActiveCN111005065BGuaranteed uptimeHigh-speed heat dissipationPolycrystalline material growthFrom chemically reactive gasesHeat sinkCondensed matter physics

The invention discloses a plasma arc deposition device and method for a diamond film, and belongs to the technical field of diamond material preparation. A large-area conformal diamond film is deposited by adopting a direct-current arc plasma device with multi-stage magnetic field control; stable control on a rotating plasma arc is realized through a magnetic field generated by an arc-stabilizingmagnetic field coil; an extended arc coil further stabilizes the arc, and the extended rotating arc adapts to the size of a substrate, so that the large-area stable rotating guide of the arc to the substrate is realized. Meanwhile, a guide magnetic field coil at the bottom of the substrate realizes movement of the plasma arc towards the concave part of the substrate, and uniform deposition of diamonds on the surface of the conformal substrate is realized. Three magnetic field coils expand and guide the electric arc to enlarge the diamond deposition area while achieving generation and stabilization of the rotating electric arc, interference of anode carbon deposition on the electric arc is avoided, and long-term stable growth of a diamond film with a uniform thickness is achieved. The obtained conformal diamond film can be used as a heat sink or window material with high heat flux and rapid heat dissipation.

Owner:UNIV OF SCI & TECH BEIJING

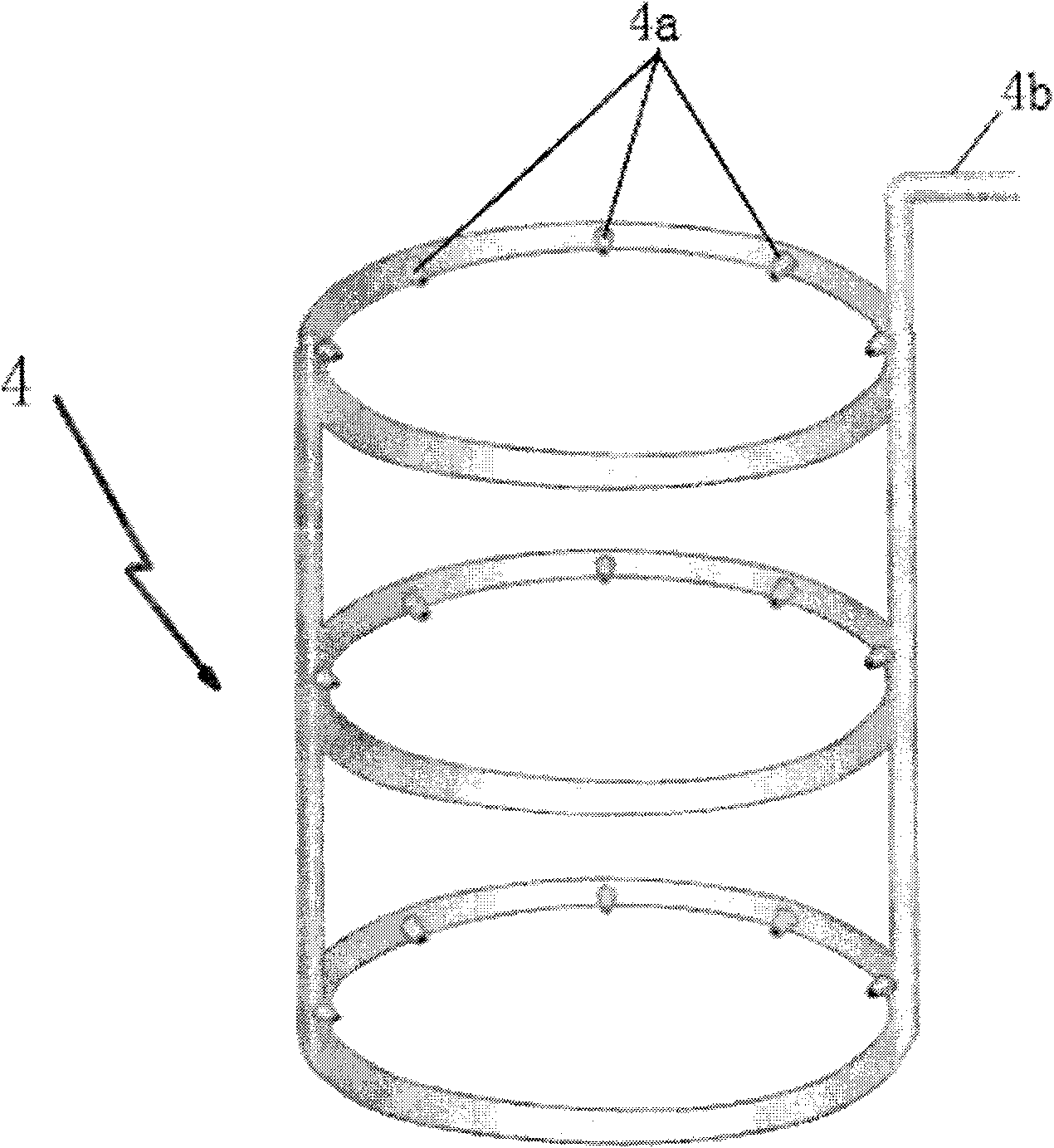

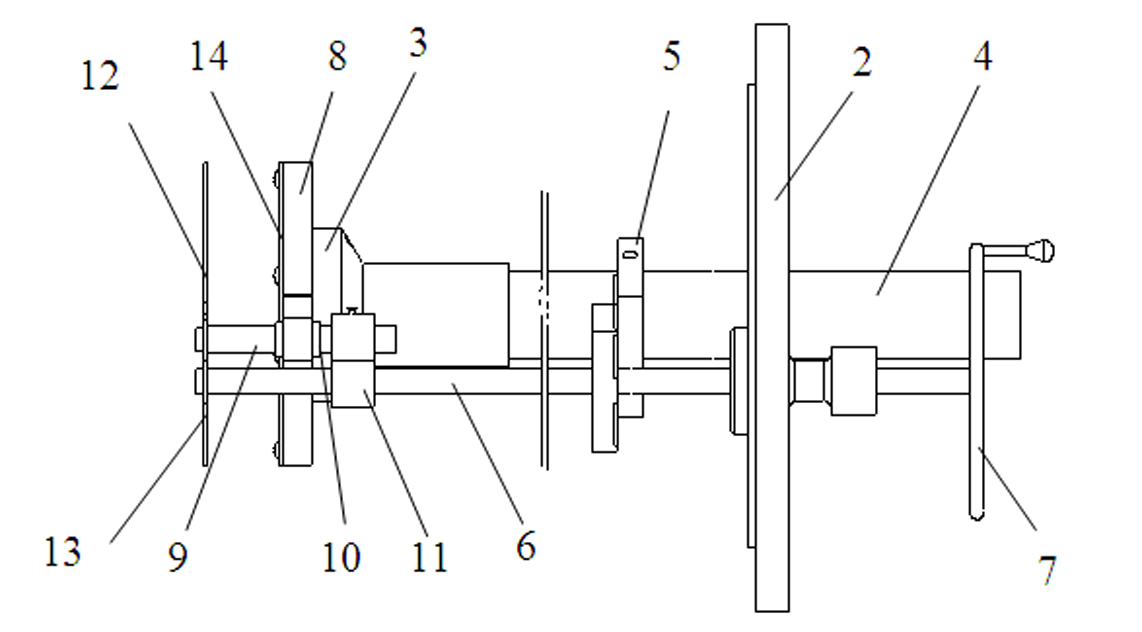

Basal plate retainer for ECR (Equivalent Continuous Rating) plasma sputtering device

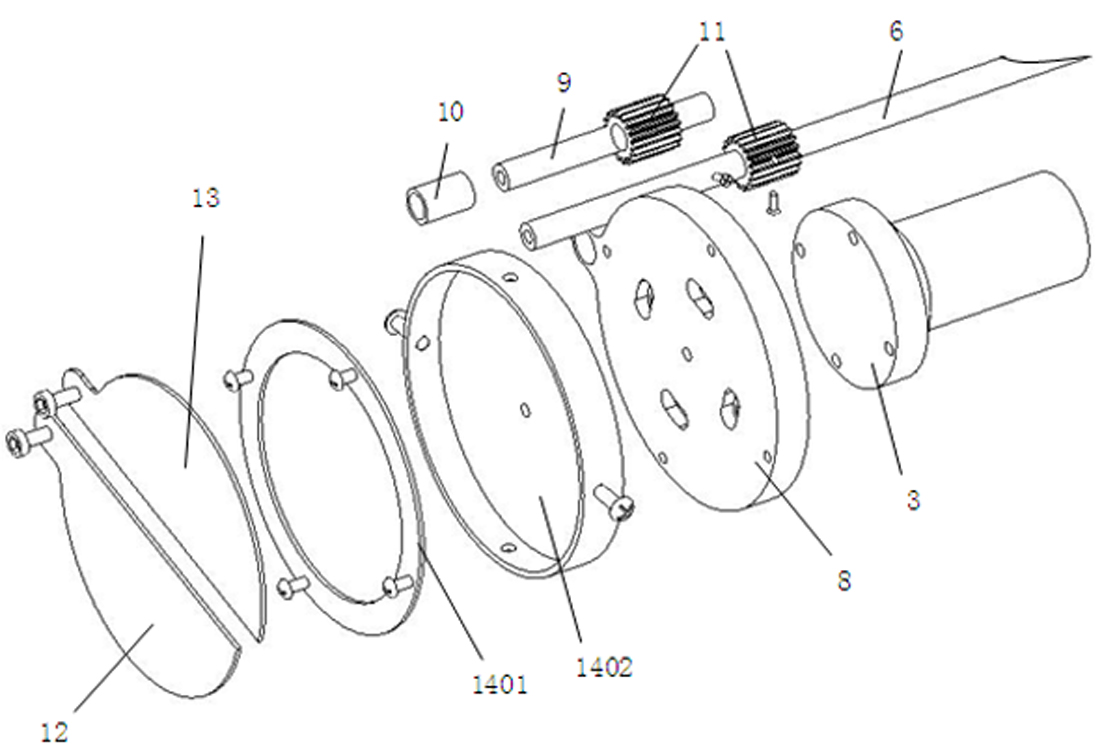

InactiveCN101831617APrecise time controlIncrease the areaVacuum evaporation coatingSputtering coatingDrive shaftVacuum chamber

The invention discloses a basal plate retainer for an ECR (Equivalent Continuous Rating) plasma sputtering device, comprising an original basal plate (3), a fixed shaft (4) connected with the original basal plate (3), a supporting plate (5) and a fixed flange (2) for connecting a vacuum chamber which are sequentially and axially arranged on the fixed shaft (4), wherein a driving shaft (6) parallel to the fixed shaft (4) passes through the supporting plate (5) and the fixed flange (2), and the outer end part of the driving shaft (6) is provided with a rotating handle(7). The basal plate retainer is characterized in that the original basal plate (3) is provided with an expanded basal plate (8), a driven shaft (9) passes vertically through the expanded basal plate (8), the driven shaft (9) and the driving shaft (6) are respectively provided with a gear, and the gears are meshed mutually, the inner end parts of the driven shaft (9) and the driving shaft (6) are respectively fixed with an upper baffle plate (12) and a lower baffle plate (13); and the driven shaft (9) passes through the position of the expanded basal plate (8) and is near to the periphery of the expanded basal plate (8).

Owner:XI AN JIAOTONG UNIV

Method for self-assembling photonic crystal

ActiveCN101338447BIncrease profitLarge deposition areaFrom gel stateColloidal chemistry detailsPhotonic crystalPhotonic-crystal fiber

A self-assembling photonic crystal method relates to a preparation method of photonic crystal. The invention solves the problems existing in the current method that the photo crystal with large area can not be prepared and the prepared photonic crystal can not be bent. The method comprises the procedures as follows: (1) the surface of a base plate is treated: (2) colloidal solution is prepared: and (3) the base plate is put into a vessel and the colloidal solution is added into the vessel; the colloidal solution volatilizes under the constant temperature of 20 DEG C to 70 DEG C; the photonic crystal is taken out until no substance volatilizes, and the photonic crystal is made. The self-assembling photonic crystal can make the single or double sides of the photonic crystal deposit on the base plate, thus making the photonic crystal deposit on the base plate to a maximum.

Owner:HARBIN INST OF TECH +1

Multi-group hot filament reaction equipment

PendingCN111501022AAvoid wastingImprove work efficiencyChemical vapor deposition coatingThin membraneMechanical engineering

The invention discloses multi-group hot filament reaction equipment, and belongs to the technical field of hot filament vapor deposition. The multi-group hot filament reaction equipment includes a shell, a plurality of mobile platforms are arranged side by side along the length direction in the shell, and the mobile platforms are all arranged in the shell through a sliding mechanism. The mobile platforms are all fixedly provided with reaction chambers, and the reaction chambers are all internally provided with hot filament vapor deposition reaction assemblies; a heating device is fixedly arranged at the top in the shell, and a substrate tray is arranged at the bottom of the heating device, and the substrate tray is used for installing substrates. According to the the multi-group hot filament reaction equipment, different types of hot filaments can be placed in the multiple reaction chambers, and when different types of films need to be deposited, the problem of wasting time due to frequent replacement of hot filaments can be avoided; and the multiple reaction chambers can work at the same time to realize the simultaneous deposition of the same or different kinds of film materials on the same substrate, the reaction rate is greatly improved, the deposition area is enlarged, and operation is facilitated.

Owner:SOUTHWEST PETROLEUM UNIV

Spatially isolated atomic layer deposition apparatus

ActiveCN113846315BUniform flowEven amountChemical vapor deposition coatingEngineeringMechanical engineering

The invention relates to a space isolation atomic layer deposition device, comprising: a casing, the interior of which is hollow to form an air duct; a baffle, the baffle is located in the casing, and the main air duct in the air duct is located on one side of the baffle, The static pressure chamber is located on the other side of the partition plate in the air duct, and a slit is formed at the partition plate. The main air duct and the static pressure chamber are connected through the slit, and the direction of the gas flowing in the length direction of the main air duct is the first direction, along the first direction, the slit includes a plurality of sections; the air inlet, the air inlet is arranged on the casing, and the air inlet is communicated with the main air duct; the air outlet, the air outlet is arranged on the casing, and the outlet The air port is communicated with the static pressure chamber, and the air outlet extends along the first direction; in the area close to the end along the first direction, the width of the slit in at least part of the interval is larger than the width of the slit in the next interval, so that the main air in each interval The amount of gas flowing into the static plenum through the slit in the channel is equal.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com