Method for preparing diamond-like film on germanium substrate

A diamond-like film, germanium-based technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problem of rough and uneven film surface, achieve fast deposition speed, anti-reflection and protection, and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

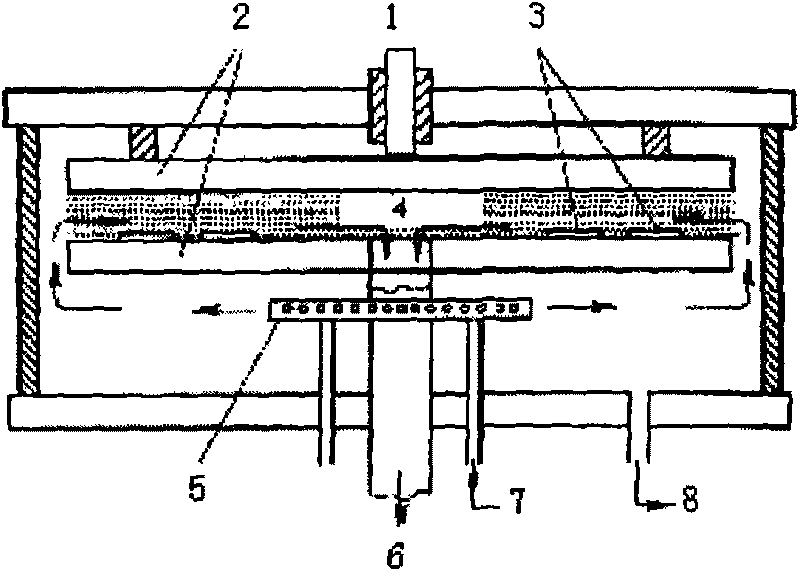

[0039] Diamond-like carbon films were prepared on larger Ge substrates by plasma chemical vapor deposition.

[0040] (1) Take a relatively large n-type single crystal Ge substrate 3 with a specification of φ200mm×5mm, and clean the substrate first to eliminate residues, oil stains and residual stress caused by optical cold processing of the substrate. The specific process Yes: put substrate 3 into acetone for 15 minutes of ultrasonic cleaning, and then dry it with a hair dryer.

[0041] (2) Place the Ge substrate on the lower plate 2, and then vacuum the cavity to less than 1×10 through the vacuum pump 6. -3 Pa, followed by CH 4 Gas 7, adjust the air pressure of the chamber to 45Pa, and equilibrate for 5 minutes.

[0042] (3) The radio frequency power supply 1 starts and adjusts the power to make it stable between 900W.

[0043](4) Stabilize other process parameters in the following range: working pressure 45Pa, CH 4 The flow rate of the gas 7 is controlled at 30 sccm, an...

Embodiment 2

[0052] Diamond-like carbon films were prepared on smaller Ge substrates by plasma chemical vapor deposition.

[0053] (1) Take a smaller n-type single crystal Ge substrate 3 with a specification of φ20mm×2.2mm, and clean the substrate first. The specific process is: put the substrate 3 in acetone for 10 minutes for ultrasonic cleaning, Then blow dry with a hair dryer.

[0054] (2) Place the Ge substrate on the lower plate 2, and then vacuum the cavity to less than 1×10 through the vacuum pump 6. -3 Pa, followed by CH 4 Gas 7, the purity of the methane gas used is 99.99%, the air pressure of the chamber is adjusted to 30Pa, and the balance is 3 minutes.

[0055] (3) The radio frequency power supply 1 starts and adjusts the power to make it stable at 800W.

[0056] (4) Stabilize other process parameters in the following ranges: working pressure 30Pa, CH 4 The flow rate of the gas 7 is controlled at 20 sccm, and the matching capacitor is adjusted to minimize the reflected po...

Embodiment 3

[0064] Diamond-like carbon films were prepared on medium Ge substrates by plasma chemical vapor deposition.

[0065] (1) Take a medium-sized n-type single crystal Ge substrate 3 with a specification of φ80mm×3.2mm, and clean the substrate first. The specific process is: put the substrate 3 in acetone for 10 minutes for ultrasonic cleaning, Then blow dry with a hair dryer.

[0066] (2) Place the Ge substrate on the lower plate 2, and then vacuum the cavity to less than 1×10 through the vacuum pump 6. -3 Pa, followed by CH 4 Gas 7, the purity of the methane gas used is 99.99%, the air pressure of the chamber is adjusted to 40 Pa, and the balance is 3 minutes.

[0067] (3) The radio frequency power supply 1 starts and adjusts the power to make it stable at 850W.

[0068] (4) Stabilize other process parameters in the following ranges: working pressure 40Pa, CH 4 The flow rate of the gas 7 is controlled at 25 sccm, and the matching capacitor is adjusted to minimize the reflect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com