Method for preparing anti-oxidation permeated layer on surface of molybdenum or molybdenum alloy

A molybdenum alloy, anti-oxidation technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of insufficient oxidation resistance, fast degradation of the permeation layer, complicated preparation process, etc., to achieve Improved low-temperature oxidation resistance, quick layer deposition, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment includes the following steps:

[0027] Step 1, polishing the surface of the molybdenum to remove the surface scale, drying after ultrasonic cleaning for 30 minutes; the molybdenum is a pure molybdenum matrix (mass purity greater than 99%);

[0028] Step 2. Prepare the embedding agent, which is made by ball milling the following raw materials in mass percentage: 12% silicon powder, 6% aluminum powder, 3% boron powder, 6% catalyst, and the balance is alumina powder body; the catalyst is ammonium fluoride powder, and the mixing time of the ball mill is 3 hours; the particle size of the silicon powder, aluminum powder, boron powder, catalyst and alumina powder is not less than 100 mesh, and the silicon powder The mass purity of aluminum powder, boron powder, catalyst and alumina powder is not less than 98%;

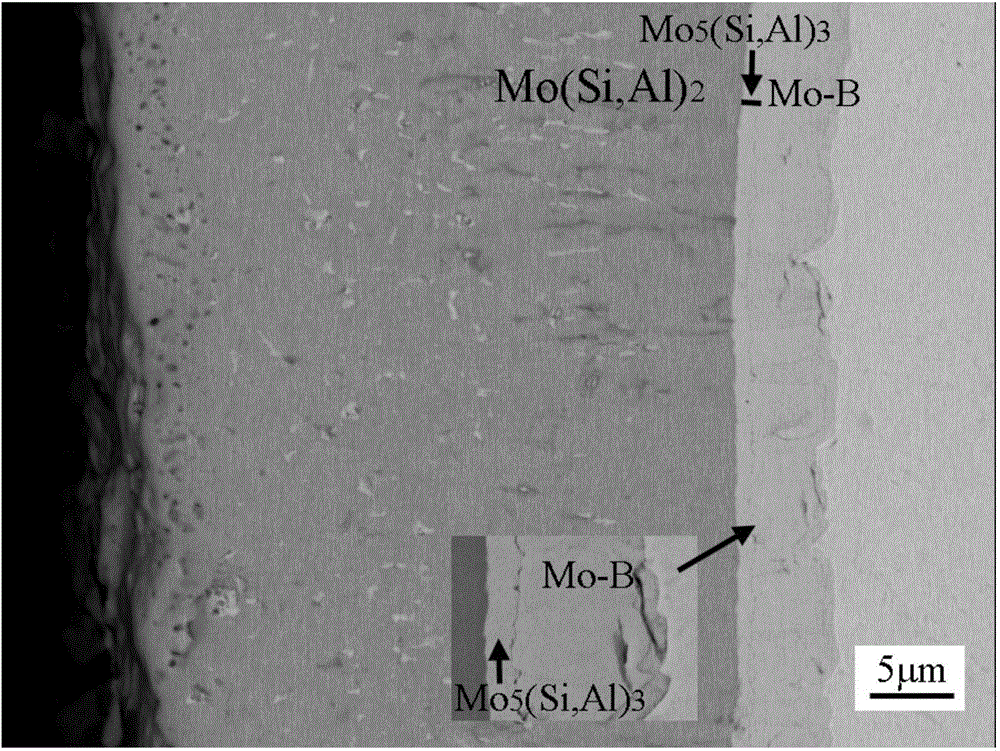

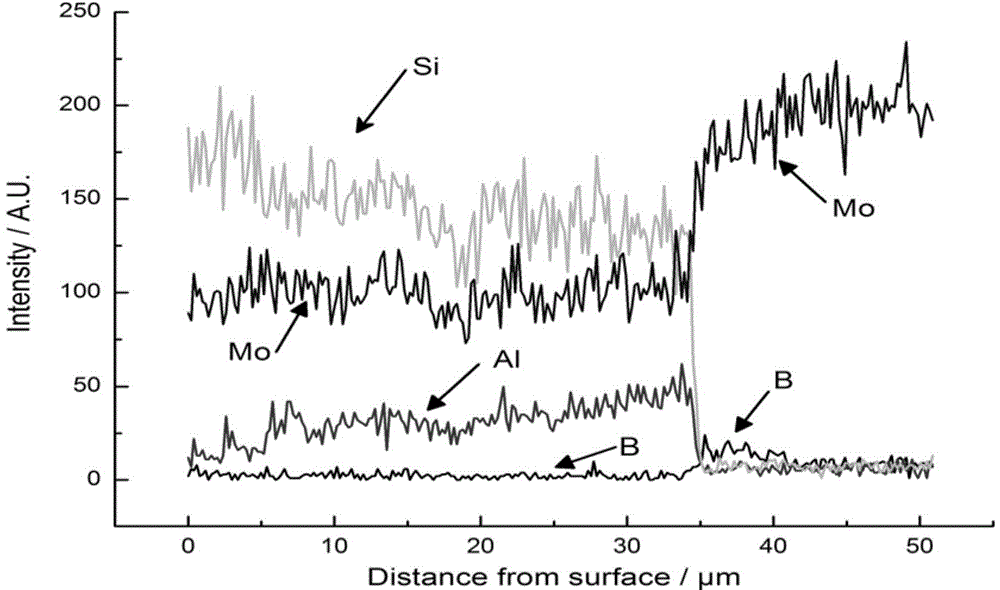

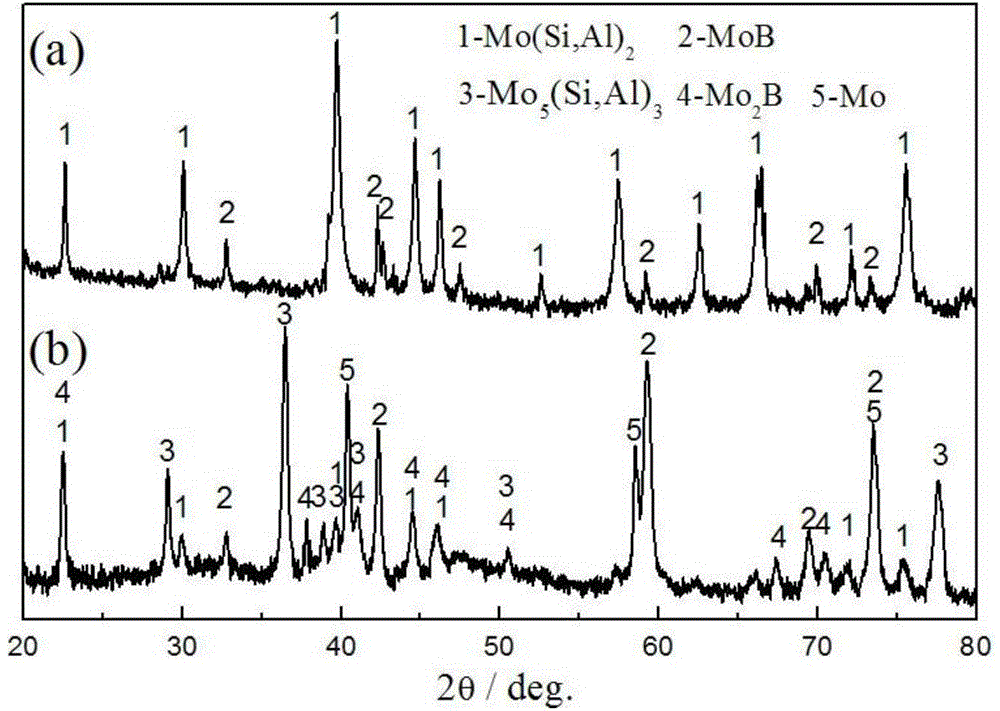

[0029] Step 3, embedding the dried molybdenum in step 1 in the corundum crucible containing the infiltration agent described in step 2, then sealing t...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] Step 1, polishing the surface of the molybdenum to remove the surface scale, drying after ultrasonic cleaning for 30 minutes; the molybdenum is a pure molybdenum matrix (mass purity greater than 99%);

[0043] Step 2. Prepare the osmotic agent for embedding. The osmotic agent is made by ball milling the following raw materials in mass percentage: 20% of silicon powder, 12% of aluminum powder, 4% of boron powder, 6% of catalyst, and the balance is alumina powder body; the catalyst is sodium fluoride powder, the mixing time of the ball mill is 6h; the particle size of the silicon powder, aluminum powder, boron powder, catalyst and alumina powder is not less than 100 mesh, the silicon powder The mass purity of aluminum powder, boron powder, catalyst and alumina powder is not less than 98%;

[0044] Step 3, embedding the dried molybdenum in step 1 in a graphite crucible equipped with the infiltration agent described in...

Embodiment 3

[0048] This embodiment includes the following steps:

[0049] Step 1. Grinding the surface of the molybdenum alloy to remove the surface scale, ultrasonic cleaning for 30 minutes and then drying; the molybdenum alloy is TZM molybdenum alloy;

[0050] Step 2. Prepare the embedding agent, which is made by ball milling the following raw materials in mass percentage: 12% silicon powder, 3% aluminum powder, 10% boron powder, 10% catalyst, and the balance is alumina powder body; the catalyst is ammonium chloride powder, and the mixing time of the ball mill is 5h; the particle size of the silicon powder, aluminum powder, boron powder, catalyst and alumina powder is not less than 100 mesh, and the silicon powder The mass purity of aluminum powder, boron powder, catalyst and alumina powder is not less than 98%;

[0051] Step 3, embedding the dried molybdenum alloy in step 1 in a graphite crucible filled with the infiltration agent described in step 2, then sealing the graphite crucibl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com