Method for preparing hydroxyapatite and bone collagen composite coating on surface of magnesium alloy

A technology of bone collagen and hydroxyapatite, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve the problems of low corrosion resistance, fast degradation speed, good corrosion resistance of magnesium alloys, etc. , to achieve the effect of good corrosion resistance, low degradation rate and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

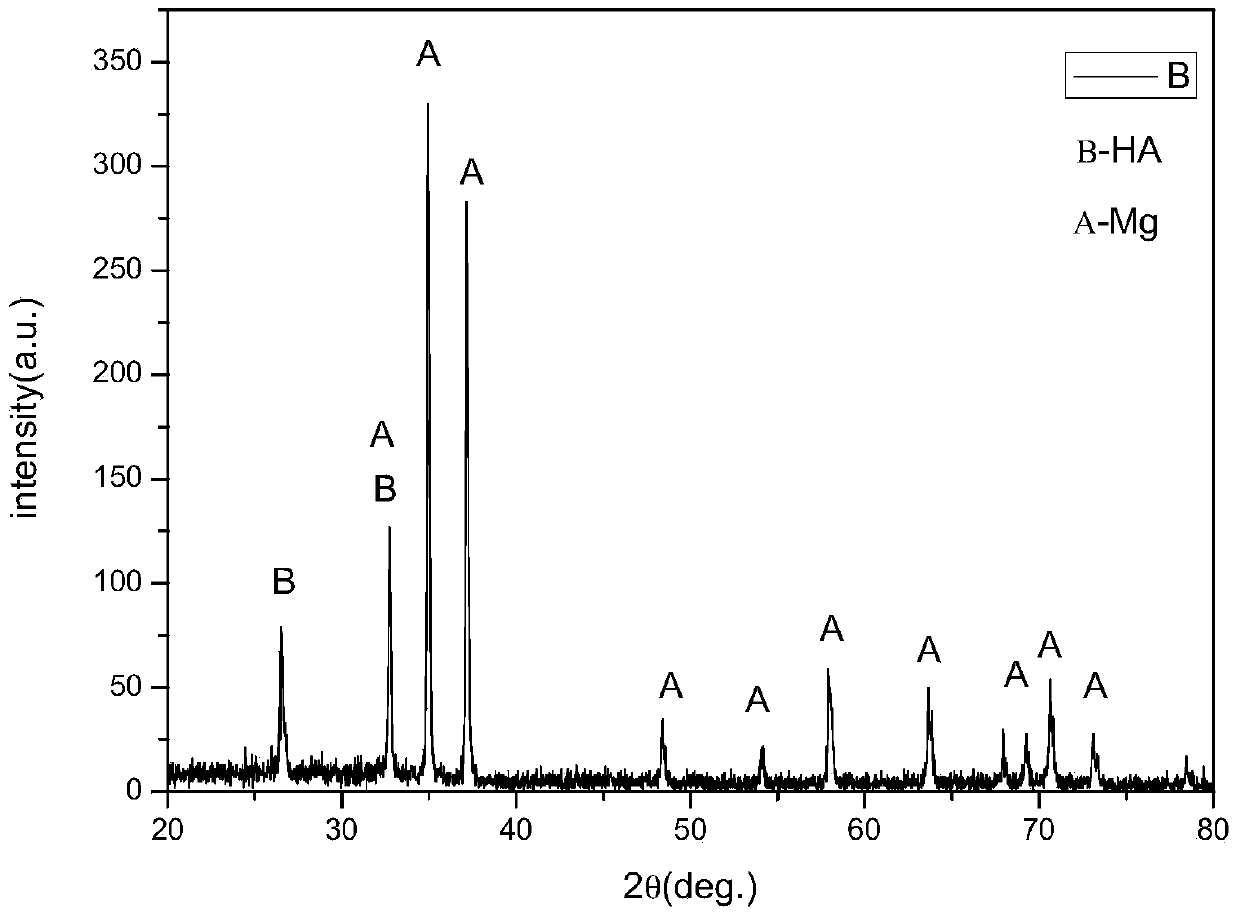

Embodiment 1

[0023] First, add 0.95g of calcium nitrate tetrahydrate into 180mL of distilled water, stir to dissolve it completely, then add 0.16g of sodium phosphate to obtain a turbid solution, then add nitric acid with a concentration of 65-68% and stir to clarify the turbid solution, then add 0.1g Add distilled water, and dropwise add a nitric acid solution with a concentration of 65-68% and a sodium hydroxide solution with a concentration of 1mol / L to adjust the pH value to 4.0, adjust the total volume of the solution to 200mL, and obtain a solution containing 0.02mol / L The deposition solution of L calcium nitrate, 0.002mol / L sodium phosphate and 0.5g / L bone collagen;

[0024] The biomedical magnesium alloy sheet was first polished with sandpaper and then ultrasonically cleaned with alcohol and acetone for 8 minutes each. The magnesium alloy sheet was immersed in a deposition solution heated to 40°C in a water bath for 24 hours of deposition. In the initial stage of deposition, the...

Embodiment 2

[0028] First, add 2.36g of calcium nitrate tetrahydrate into 180mL of distilled water, stir to dissolve it completely, then add 0.39g of sodium phosphate to obtain a cloudy solution, then add nitric acid with a concentration of 65-68% and stir to clarify the cloudy solution, add 0.2 g of bone collagen, add distilled water, and use a concentration of 65-68% nitric acid and a concentration of 1mol / L sodium hydroxide to adjust the pH value to 3.0, adjust the total volume of the solution to 200mL, and obtain a solution containing 0.05mol / L calcium nitrate, 0.005 Deposition solution of mol / L sodium phosphate and 1.0g / L bone collagen;

[0029] The biomedical magnesium alloy sheet was first polished with sandpaper, then ultrasonically cleaned with alcohol and acetone for 10 minutes each, and then the magnesium alloy sheet was immersed in a deposition solution heated to 40°C in a water bath for 8 hours of deposition. In the initial stage of deposition, the power was 150W. Ultrasonic v...

Embodiment 3

[0033] First, add 1.43g of calcium nitrate tetrahydrate into 180mL of distilled water, stir to dissolve it completely, then add 0.19g of sodium phosphate to obtain a cloudy solution, then add nitric acid with a concentration of 65-68% and stir to clarify the cloudy solution, add 0.2 g of collagen, add distilled water, and be 65-68% nitric acid and 1mol / L sodium hydroxide to adjust the pH value to 4.0 with a concentration of 65-68%, adjust the total volume of the solution to 200mL, and obtain 0.03mol / L calcium nitrate 0.0025mol / L sodium phosphate and 1.0g / L collagen deposition solution;

[0034] The biomedical magnesium alloy sheet was first polished with sandpaper and ultrasonically cleaned with alcohol and acetone for 10 minutes each, and then the magnesium alloy sheet was immersed in a deposition solution heated to 40°C in a water bath for 24 hours of deposition. In the initial stage of deposition, the power was 100W, and the frequency 40KHz ultrasonic vibration for 10min; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com