Patents

Literature

39results about How to "Suppressed interdiffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

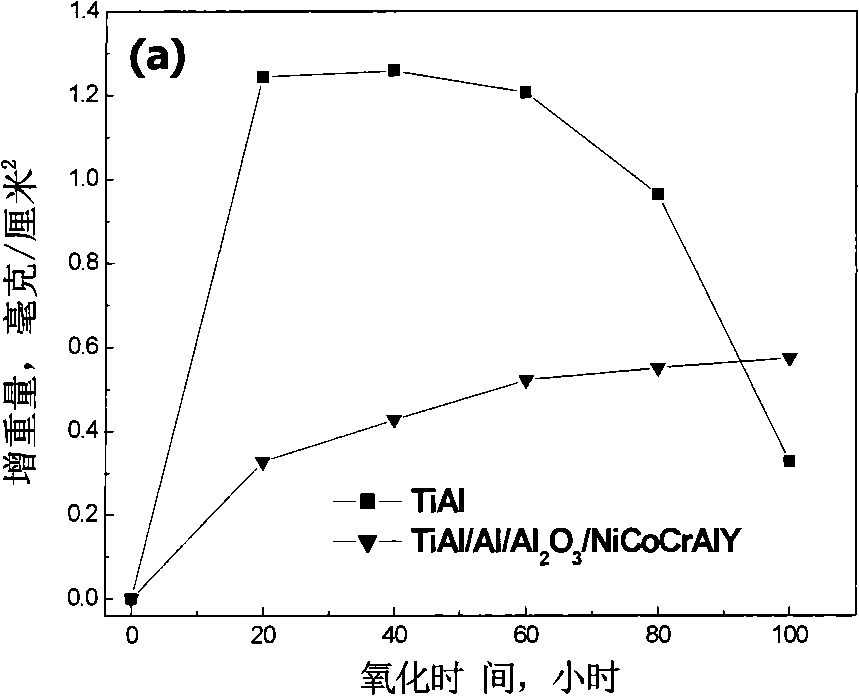

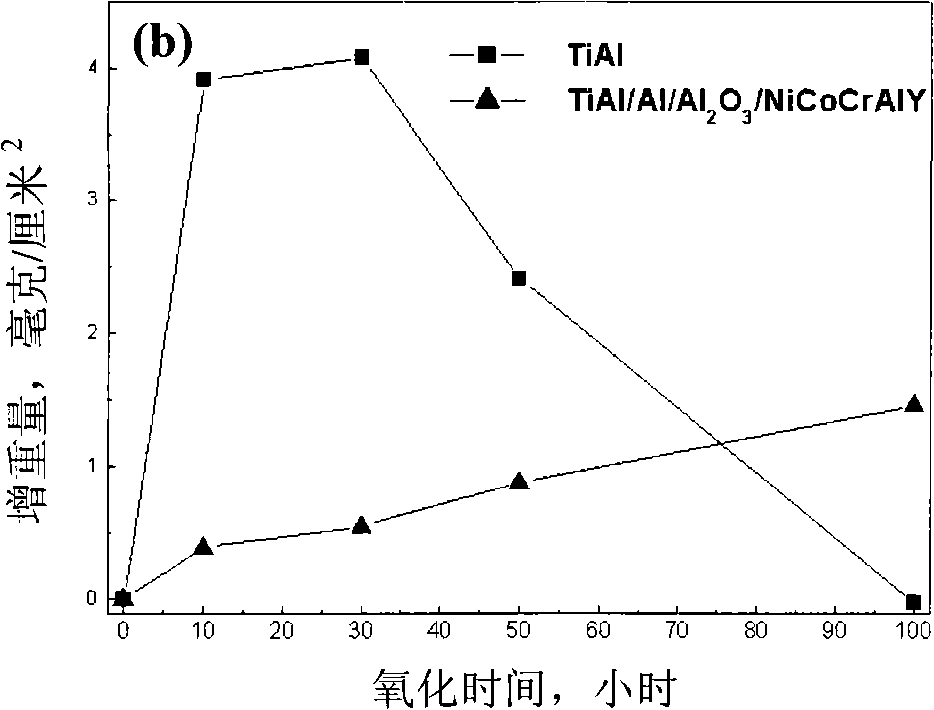

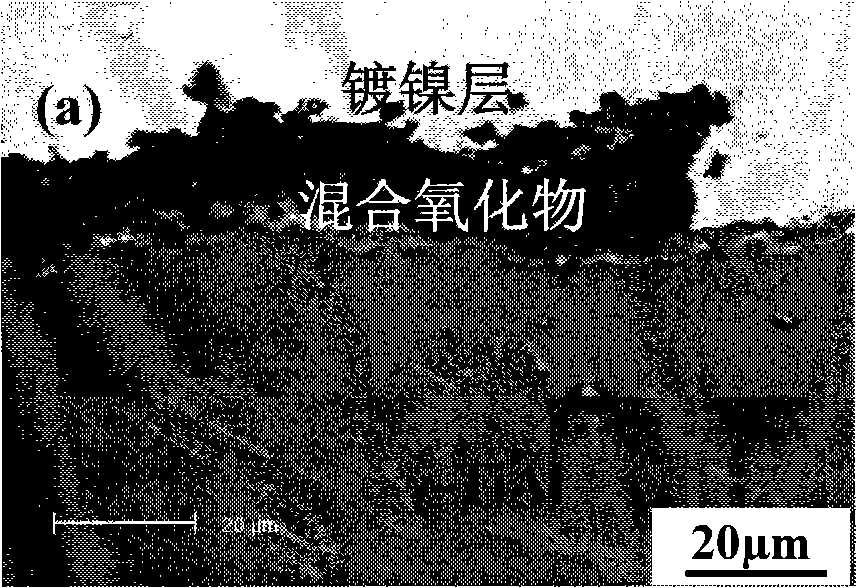

Aluminum/aluminum oxide/Ni-base superalloy composite coating for titanium-aluminum alloy and preparation method thereof

InactiveCN101310969AImprove high temperature stabilityBlocking interdiffusionVacuum evaporation coatingSputtering coatingSuperalloyIon plating

The invention relates to the coating technique, in particular to an Al / Al2O3 / MCrAlY composite coating used in Ti-Al alloy and a preparation method thereof, which aims at improving the high-temperature oxidation resistance of the Ti-Al alloy, guaranteeing the serviceability of the Ti-Al alloy in the high-temperature environment and solving the problem of non-matching between the MCrAlY coating and the Ti-Al alloy and is used for the high-temperature protection of the Ti-Al alloy. The composite coating comprises an Al / Al2O3 diffusion impervious layer and an MCrAlY alloy protective coating which are deposited on a substrate of the alloy in sequence; the thickness ratio among an Al film, an Al2O3 film and the MCrAlY protective coating is (1 to 5): (1 to 5): (20 to 50); in the MCrAlY alloy, M indicates Ni, Co or Ni plus Co. The arc ion plating technique is adopted to deposit the Al / Al2O3 diffusion impervious layer and then the MCrAlY coating on the substrate of the alloy. The composite coating of the invention has good high-temperature oxidation resistance as well as good bonding strength and high-temperature stability and can provide good high-temperature protection to the Ti-Al alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

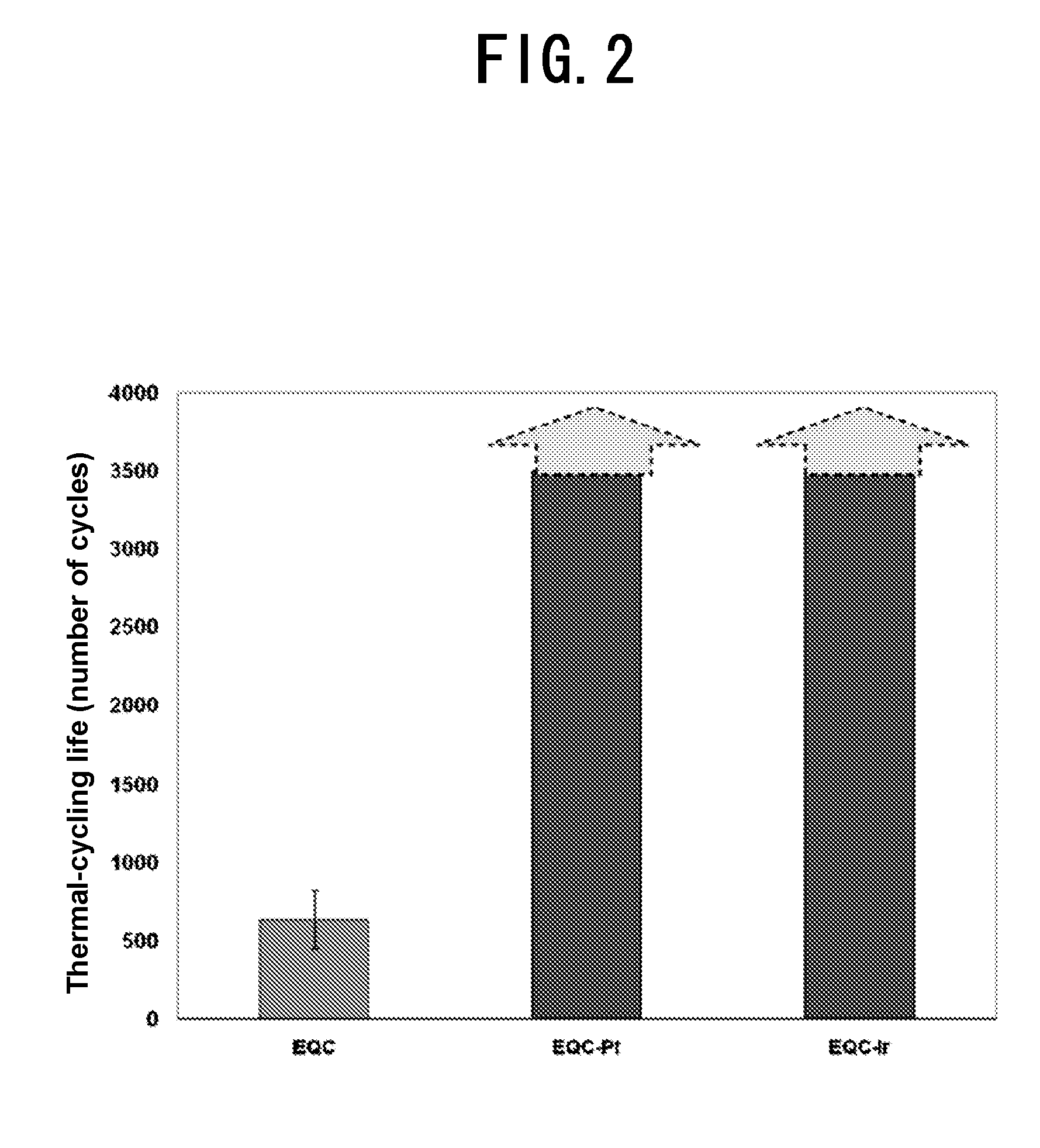

Heat-resistant component

ActiveUS20130095346A1Maintain interface stabilitySuppressed interdiffusionBlade accessoriesEfficient propulsion technologiesChemical compositionBond coat

A Ni-based superalloy component includes a bond coat layer having a chemical composition not allowing interdiffusion to occur on a Ni-base superalloy substrate, and by allowing the bond coat layer to have Pt and / or Ir content equal to or higher than 0.2% but not exceeding 15% by mass, generation of an SRZ, which occurs at an interface between the Ni-base superalloy substrate and the bond coat layer in a high-temperature oxidizing atmosphere, can be suppressed, and at the same time adhesion at the interface between a ceramic thermal barrier coat layer and the bond coat layer is improved. Thus, a long-life Ni-based superalloy component with suppressed elemental interdiffusion between the Ni-base superalloy substrate and the bond coat layer even at temperatures exceeding 1100° C. is provided.

Owner:NAT INST FOR MATERIALS SCI

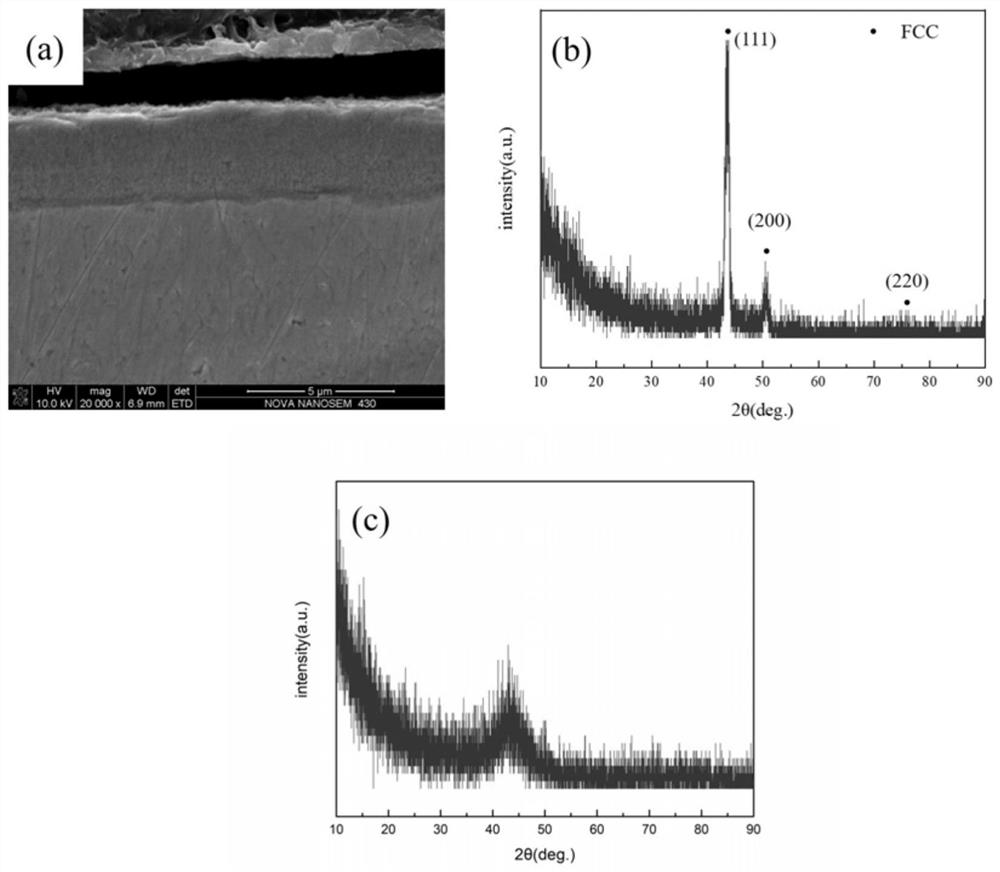

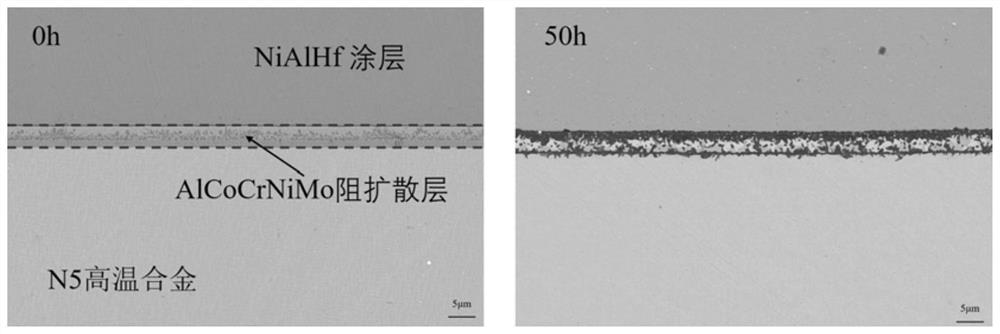

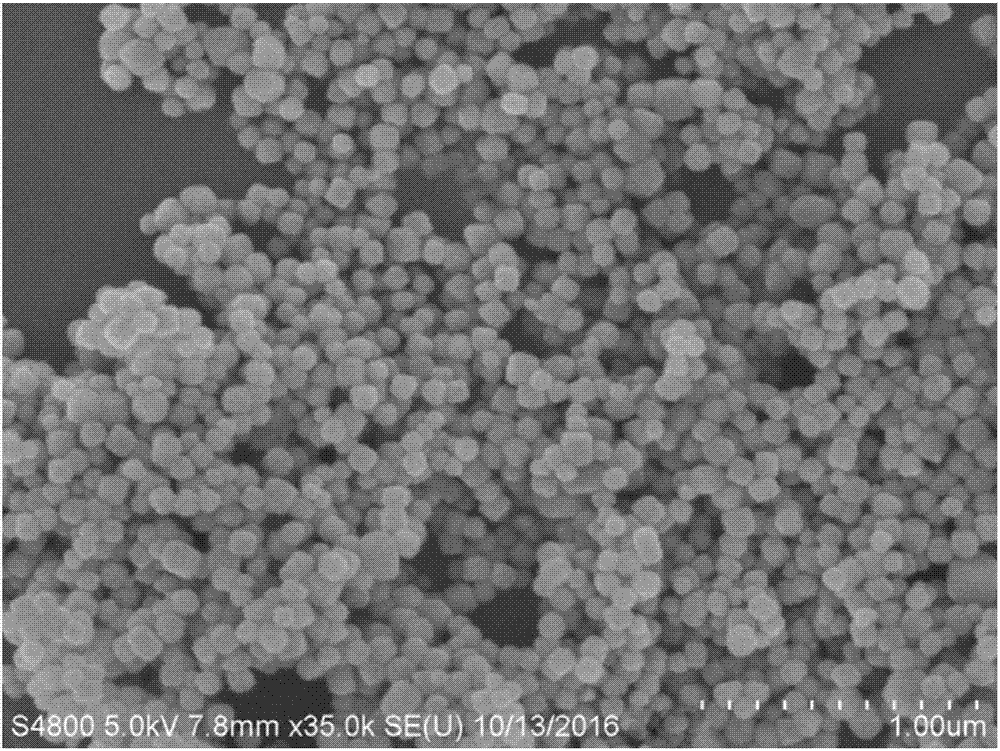

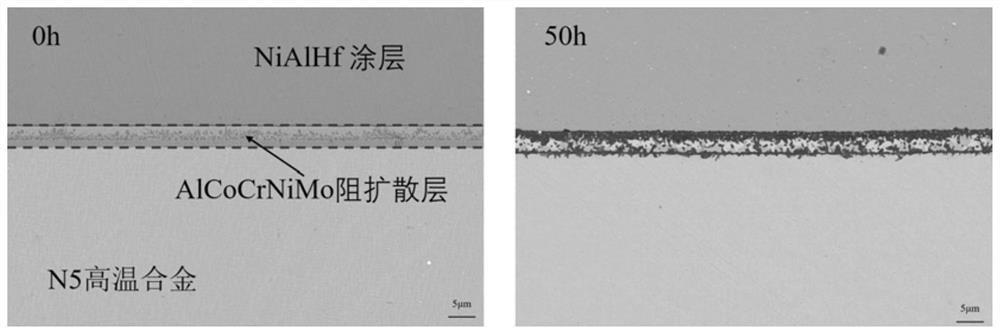

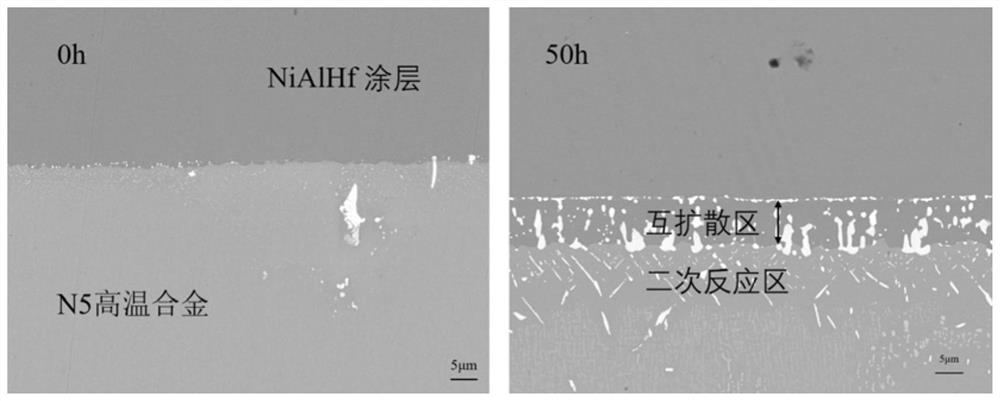

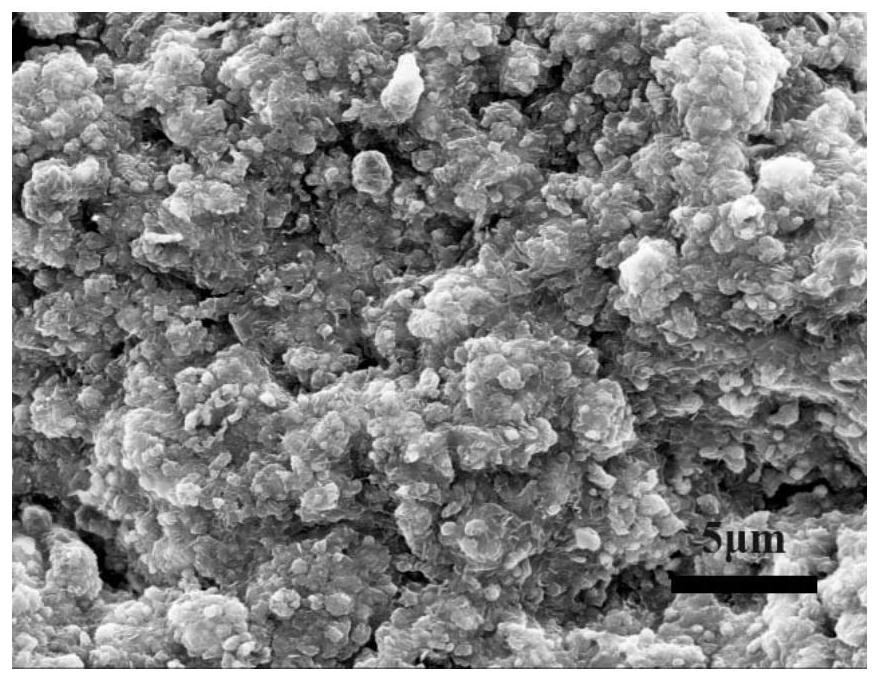

Diffusion-resistant high-entropy alloy coating material, high-temperature-resistant coating material as well as preparation method and application thereof

ActiveCN112064024AImprove high temperature oxidation resistanceSmall mechanical propertiesVacuum evaporation coatingSputtering coatingAlloy coatingHigh heat

The invention discloses a diffusion-resistant high-entropy alloy coating material, a high-temperature-resistant coating material as well as a preparation method and application thereof, and relates tothe technical field of coating preparation. The diffusion-resistant high-entropy alloy coating material comprises a base material and a diffusion-resistant high-entropy alloy coating, wherein elements of the diffusion-resistant high-entropy alloy coating comprise Al, Co, Cr, Ni and Mo. According to the high-temperature-resistant coating material and the preparation method thereof, the diffusion-resistant high-entropy alloy coating is formed on the base material and then serves as a material body to form a high-temperature-resistant coating, the specific slow diffusion effect of the diffusion-resistant high-entropy alloy coating is utilized, and the diffusion-resistant high-entropy alloy coating has good physical and chemical matching performance with the base material and the high-temperature-resistant coating; and mutual diffusion of alloy components between the base material and the coating and precipitation of interface harmful phases can be effectively inhibited, and the high-temperature oxidation resistance of the coating is improved. The high-temperature-resistant coating material can be applied to preparation of hot-end parts of aero-engines or gas turbines, the service life of the parts is prolonged, and the working reliability of the parts is improved.

Owner:GUANGDONG INST OF NEW MATERIALS

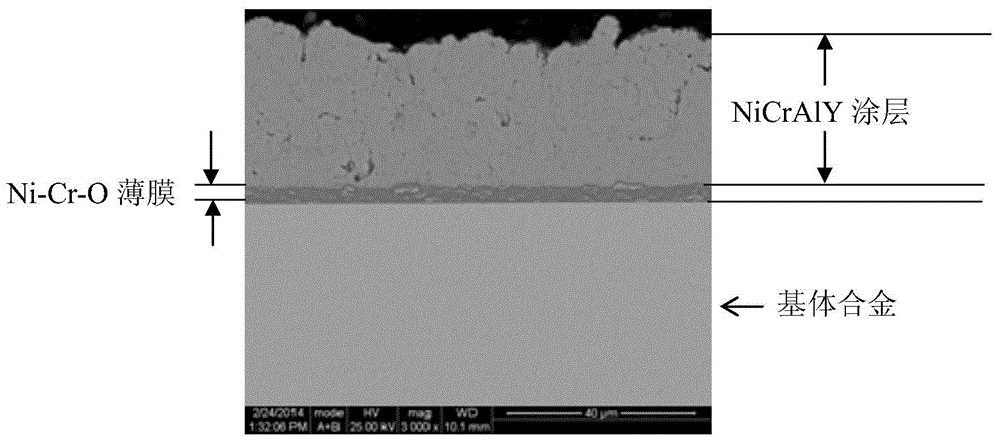

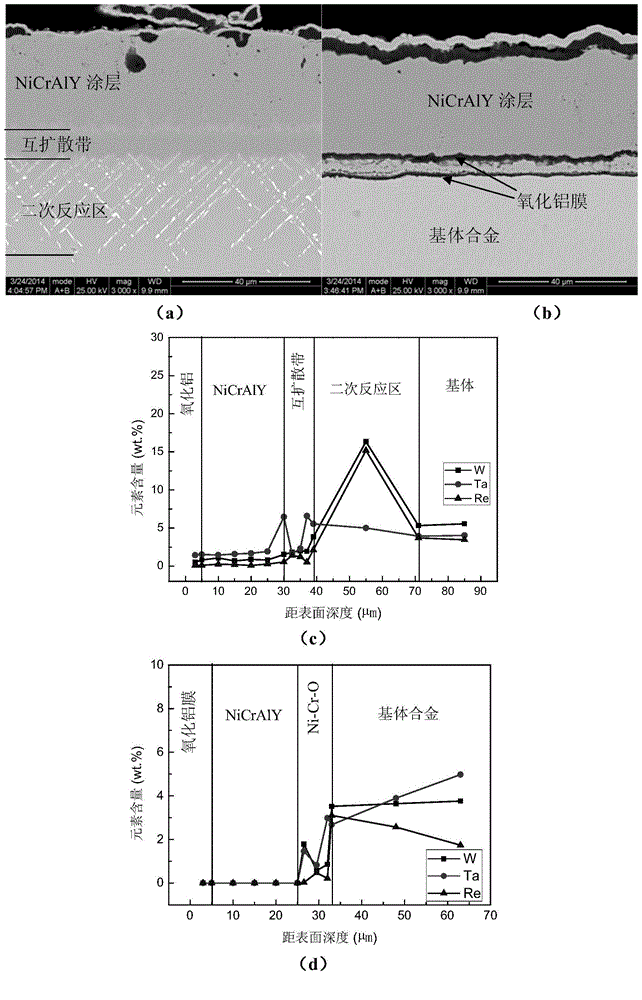

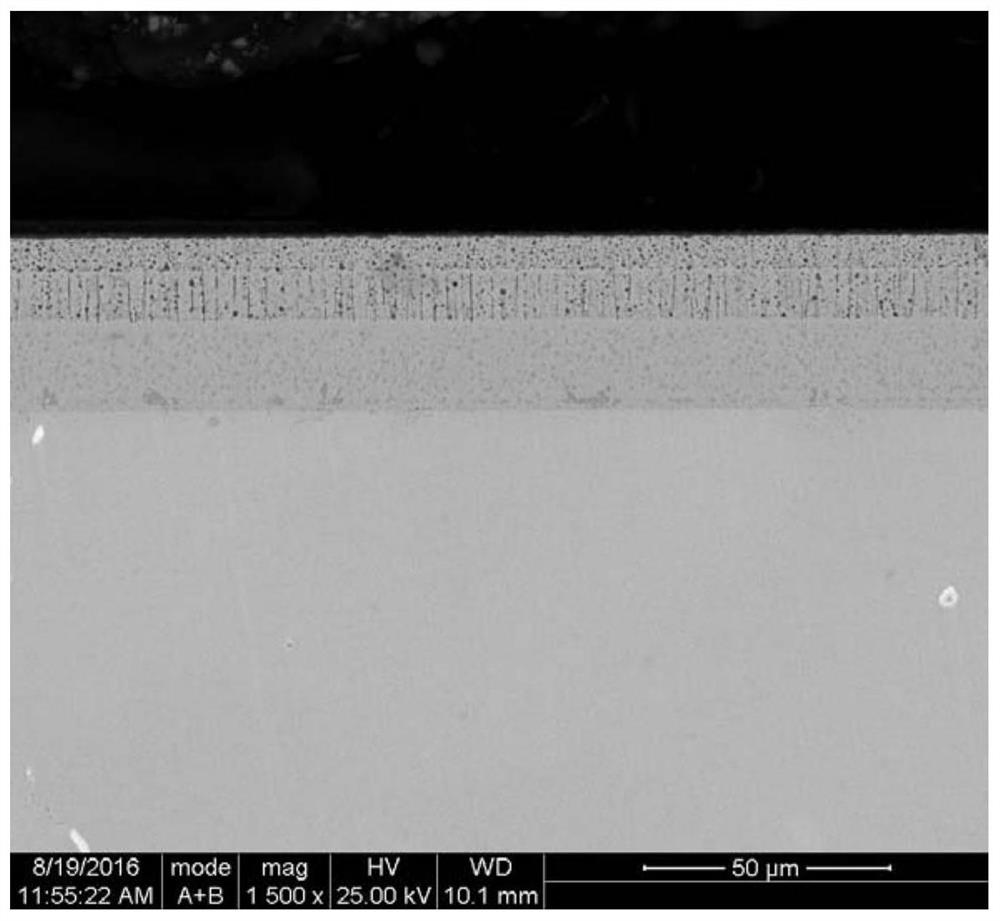

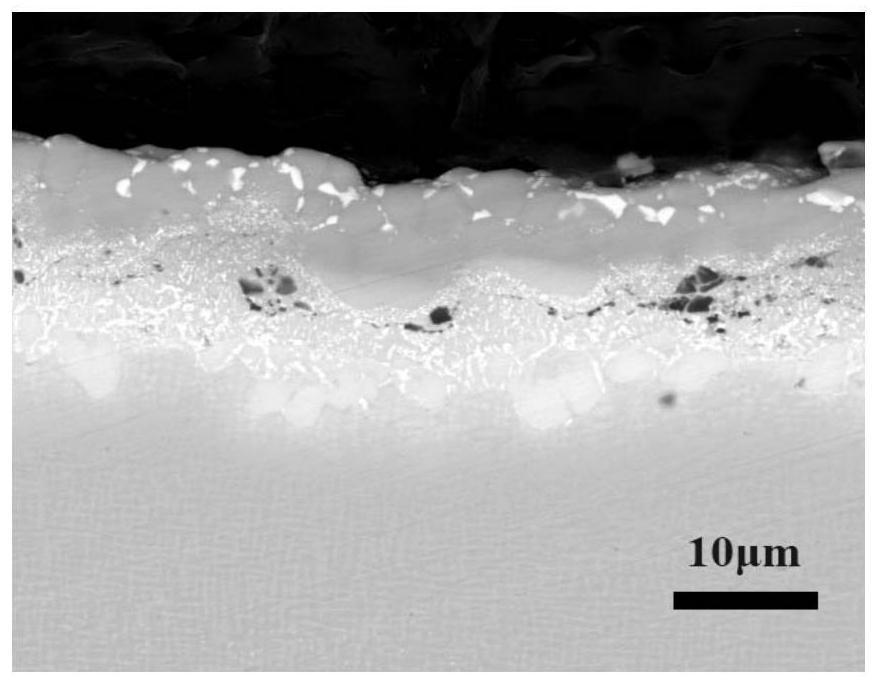

High-temperature coating comprising nickel-chromium-oxygen active diffusion barrier layer and preparation method

ActiveCN104401089AImprove the bonding strength of the interfaceHigh strengthMetal layered productsOxygenProtection layer

The invention relates to a high-temperature coating technology, in particular to a high-temperature coating comprising a nickel-chromium-oxygen active diffusion barrier layer and a preparation method. The high-temperature protection coating comprises a nickel-chromium-oxygen active diffusion barrier inner layer and a high-temperature oxidation protection outer layer. The nickel-chromium-oxygen inner layer can be spontaneously transformed into an alumina / metal / alumina multilayer film structure in a use process, prevent mutual diffusion between the high-temperature oxidation protection outer layer and a metal matrix and has good bonding strength and thermostability, so that effective oxidation resistance components in the high-temperature oxidation protection outer layer are prevented from diffusion to the matrix, the service life of the high-temperature coating is prolonged, and mechanical properties of the matrix are not damaged. The preparation method comprises the steps of preparing the nickel-chromium-oxygen layer on the surface of the matrix by a multi-arc ion plating physical vapor deposition method, and then preparing the high-temperature oxidation protection layer on the active diffusion barrier layer by one or a combination of a vacuum physical vapor deposition method, chemical vapor deposition method, a hot spraying method and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Application of diffusion barrier material, high-temperature coating and preparation method and application thereof, and gas turbine hot end part

ActiveCN111334759ABlocking interdiffusionImprove high temperature stabilityMolten spray coatingVacuum evaporation coatingThermal dilatationAlloy

The invention provides application of a diffusion barrier material, a high-temperature coating and a preparation method and application thereof, and a gas turbine hot end part, and belongs to the technical field of high-temperature protective coatings. The components of the diffusion barrier material include MeSi2, and Me includes Cr or Mo. The diffusion barrier material is compact in crystal structure and good in high-temperature-oxidation-resistant property, and has good thermal expansion compatibility with a base material; the high-temperature coating comprises an outer layer and an inner layer with the diffusion barrier material; the high-temperature coating can inhibit mutual diffusion of alloy components between a base body and the coating, the high-temperature-oxidation-resistant capacity of the coating is improved, meanwhile the situation that the mechanical property of the base body is lowered due to mutual diffusion is avoided, and the service life of parts is prolonged; andthe preparation method of the high-temperature coating is mature and reliable and good in repeatability, and large-area industrial production is easy to implement; and both the diffusion barrier material and the high-temperature coating can be used for machining the gas turbine hot end part, and the gas turbine hot end part containing the diffusion barrier material or the high-temperature coatinghas the long service life and high working reliability.

Owner:GUANGDONG INST OF NEW MATERIALS

Non-aluminium 1.3 micron indium arsenic/gallium arsenic quantum point laser

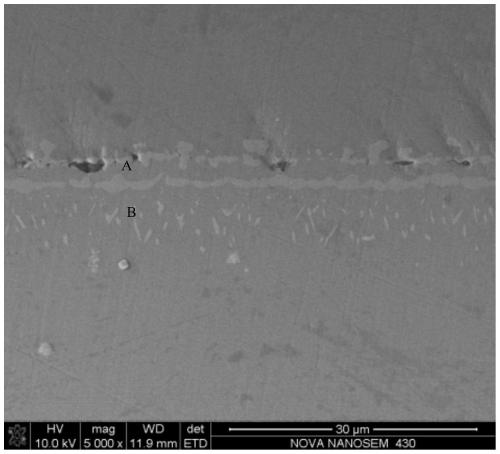

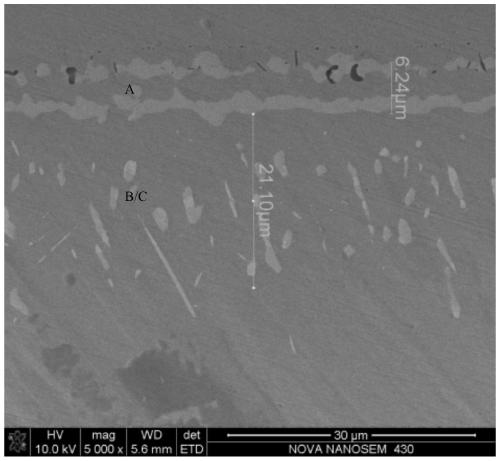

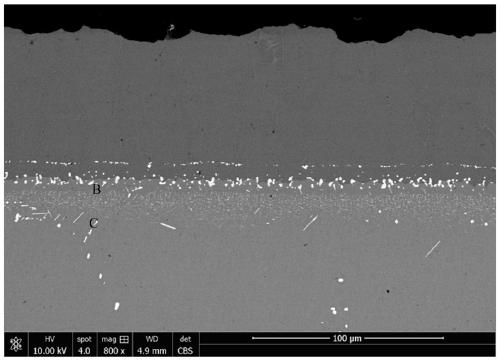

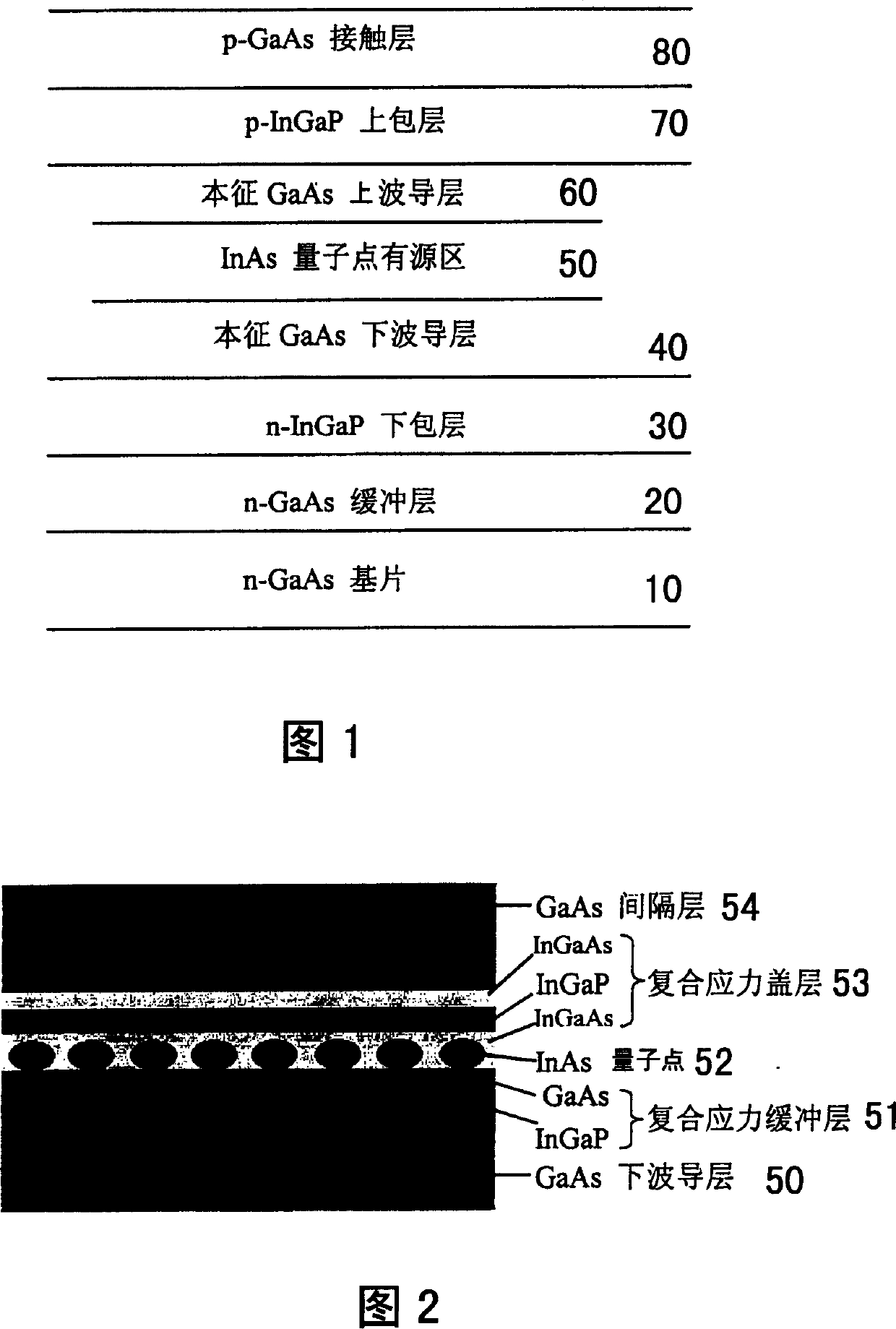

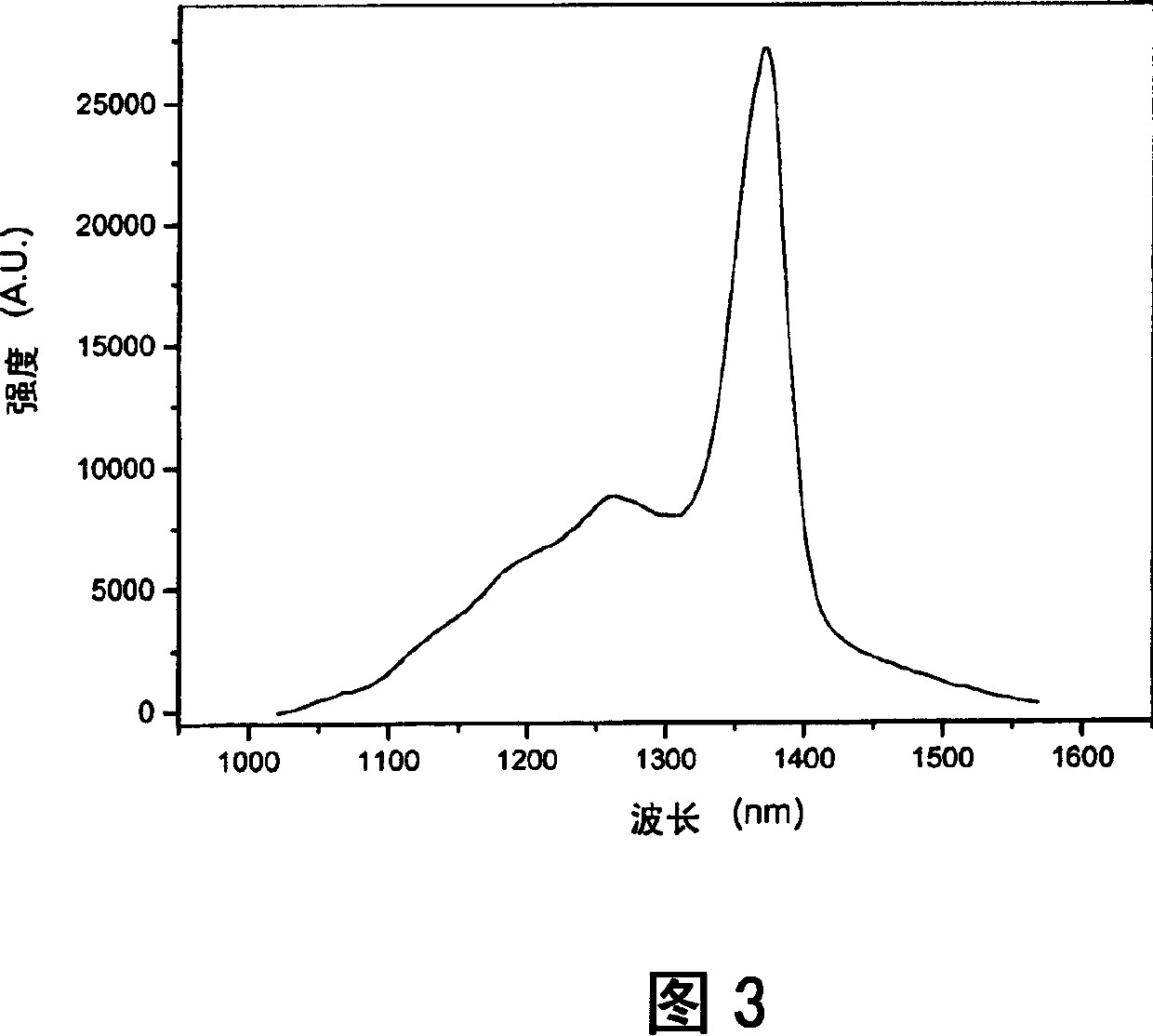

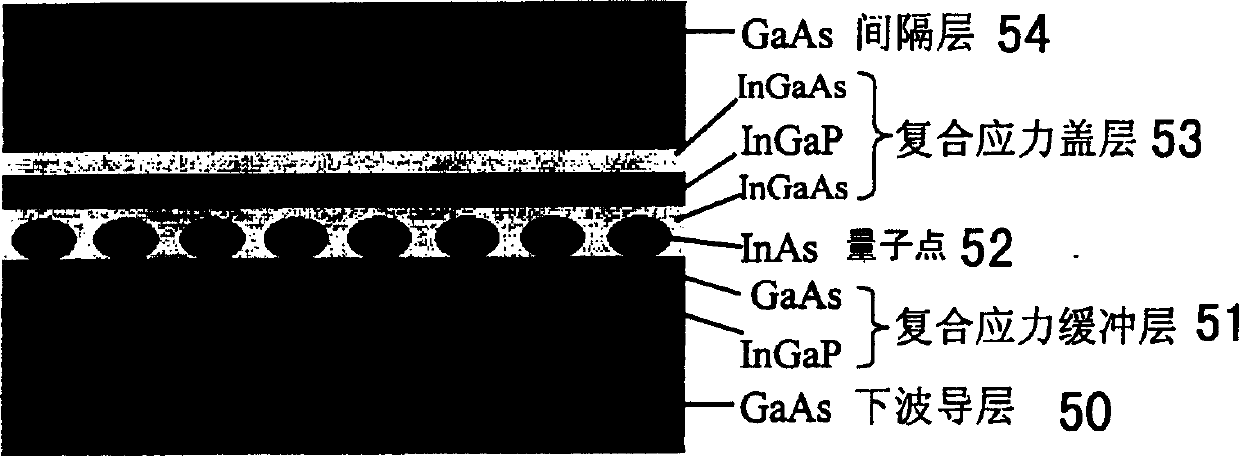

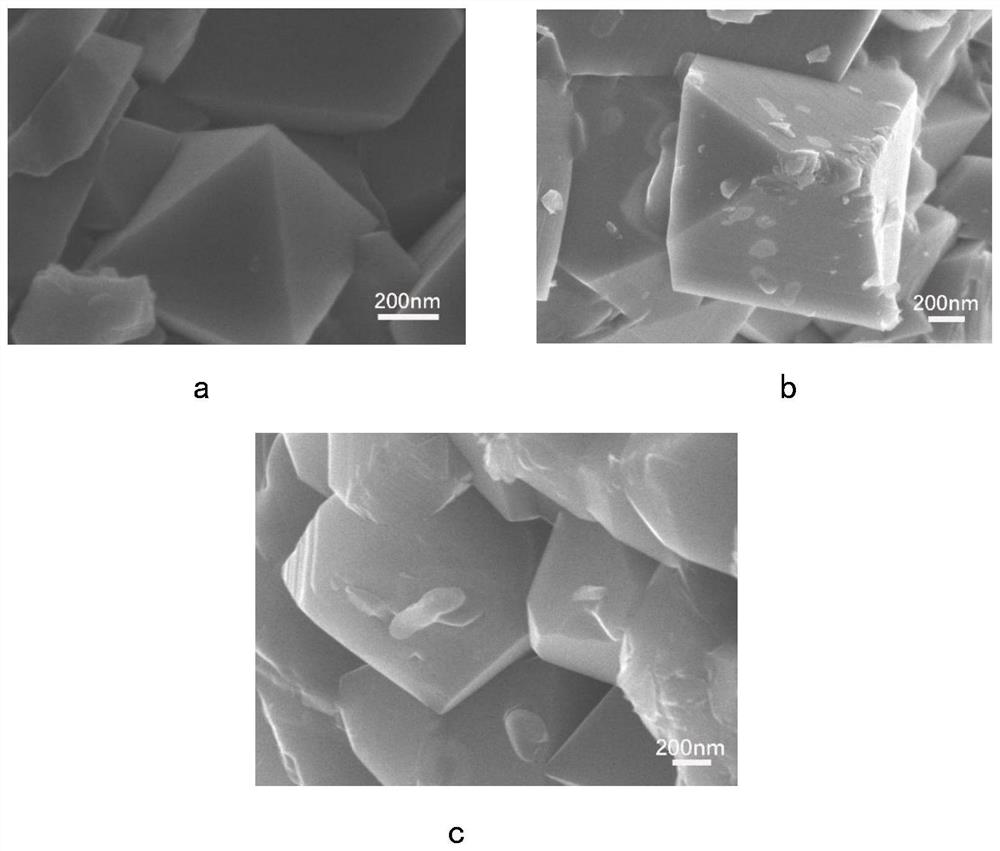

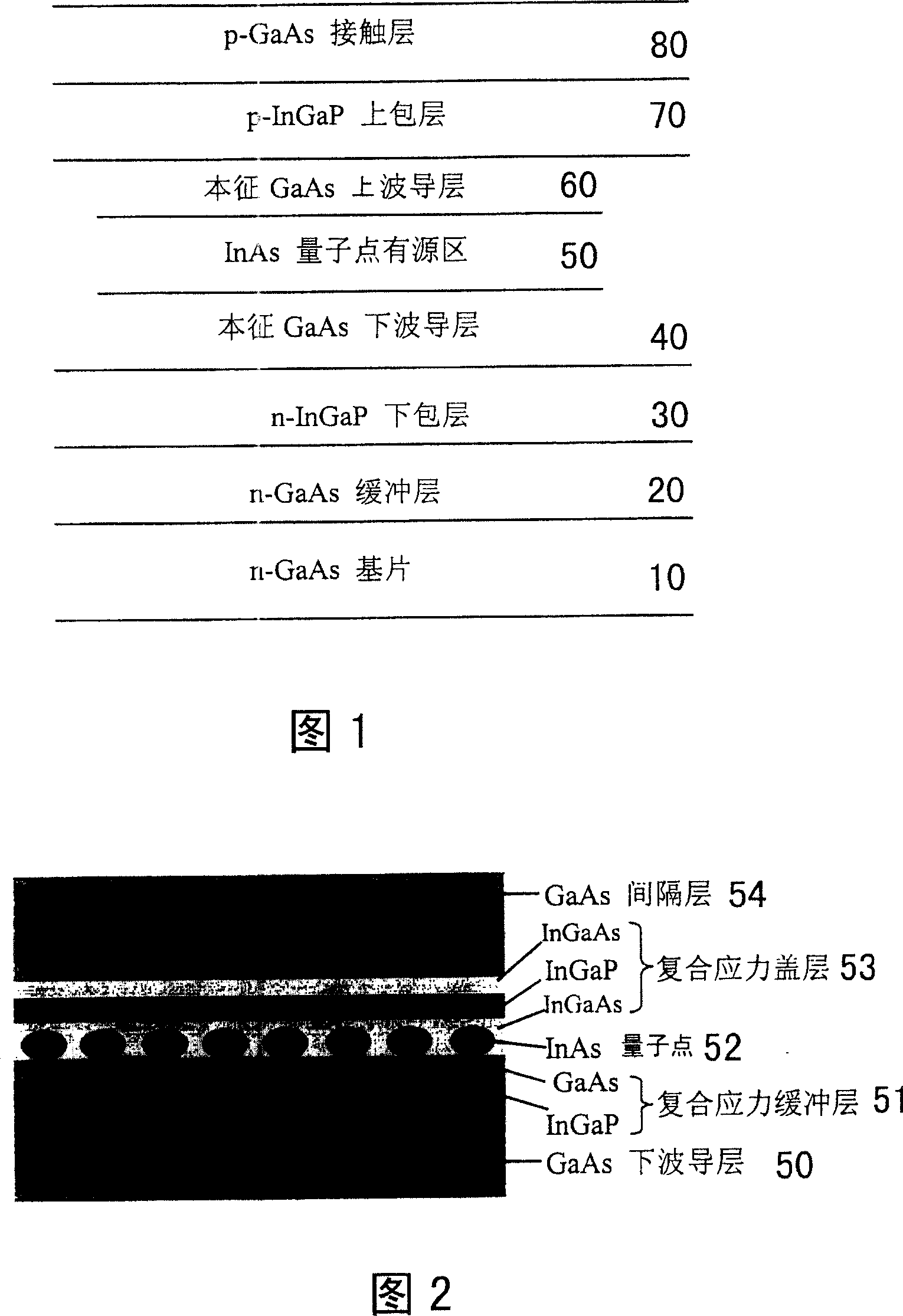

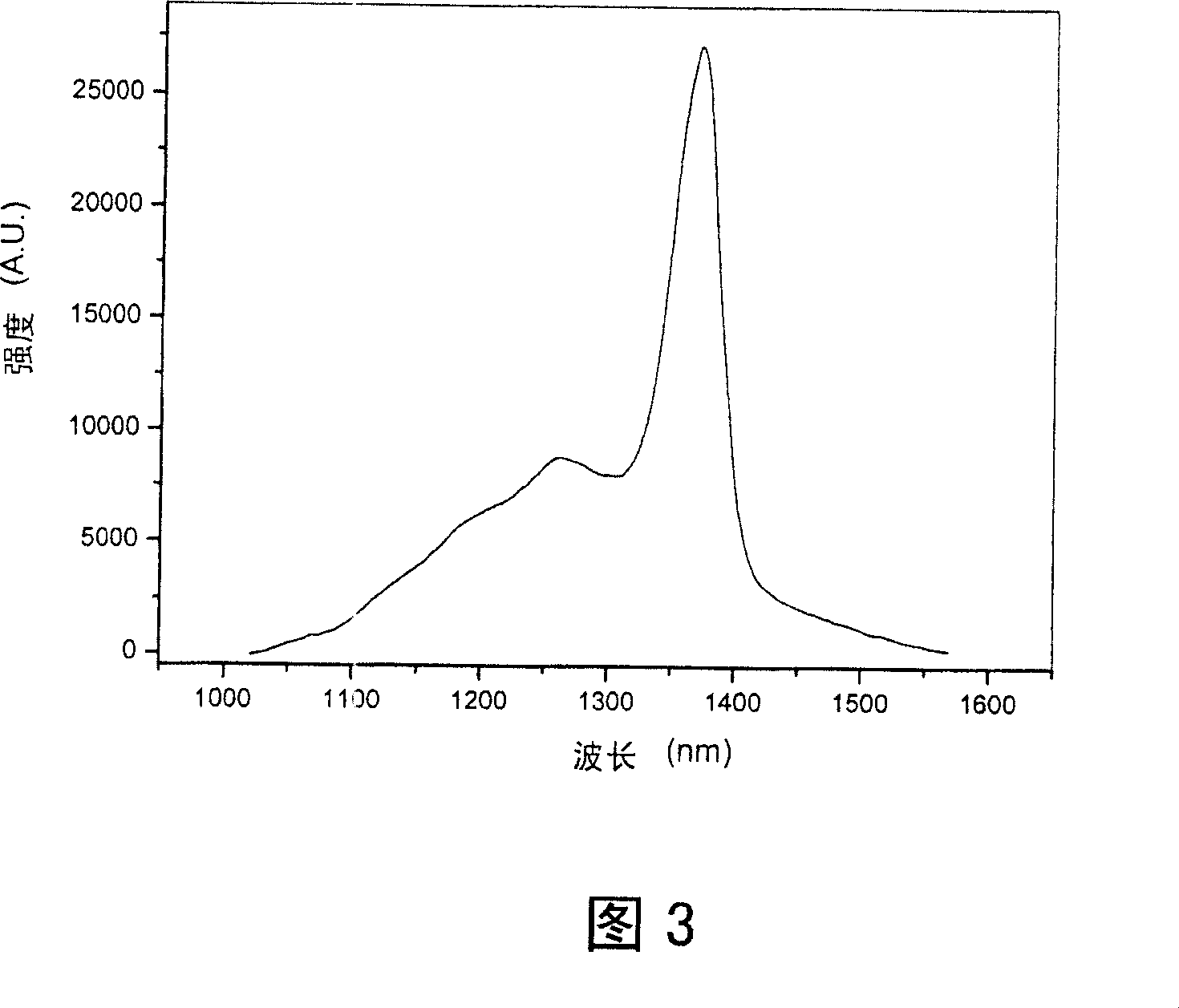

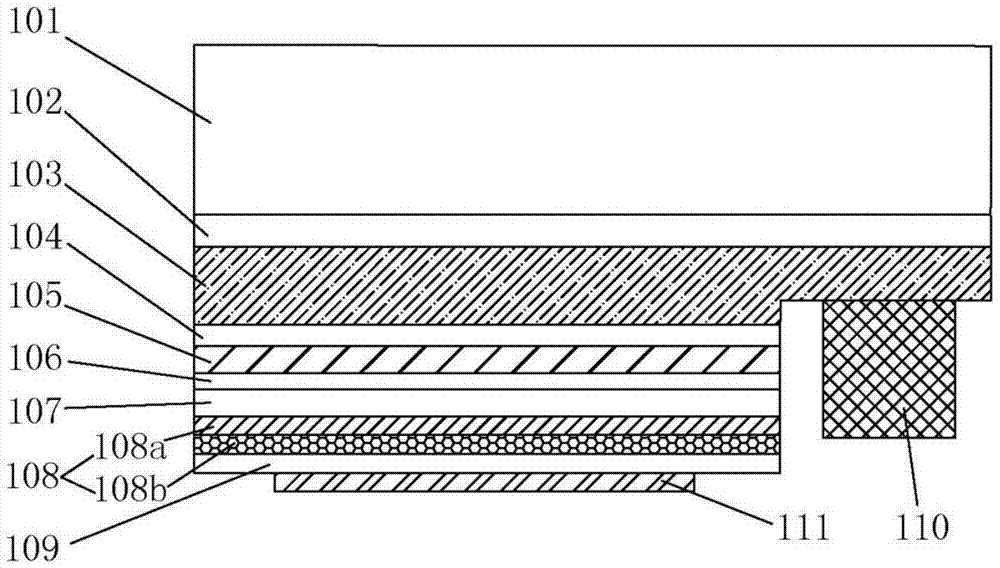

InactiveCN1825722ARaise device characteristic temperatureSuppressed interdiffusionLaser detailsSemiconductor lasersMaterial qualityIndium

This invention relates to a 1.3mum InAs / GaAs quantum dot laser without Al including a chip, a buffer layer processed on the chip, a lower cladding made on the buffer layer, a lower waveguide layer set on the lower cladding, a quantum dot active region set on the lower waveguide layer, an upper waveguide layer prepared on the active region of the quantum dot, an upper cladding prepared on the upper waveguide layer under low temperature, a contact layer prepared on the upper cladding. Since high quality of the InGaP can be got under low growing temperature, the blue shift of the quantum dots is controlled effectively in the growing process of the cladding.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

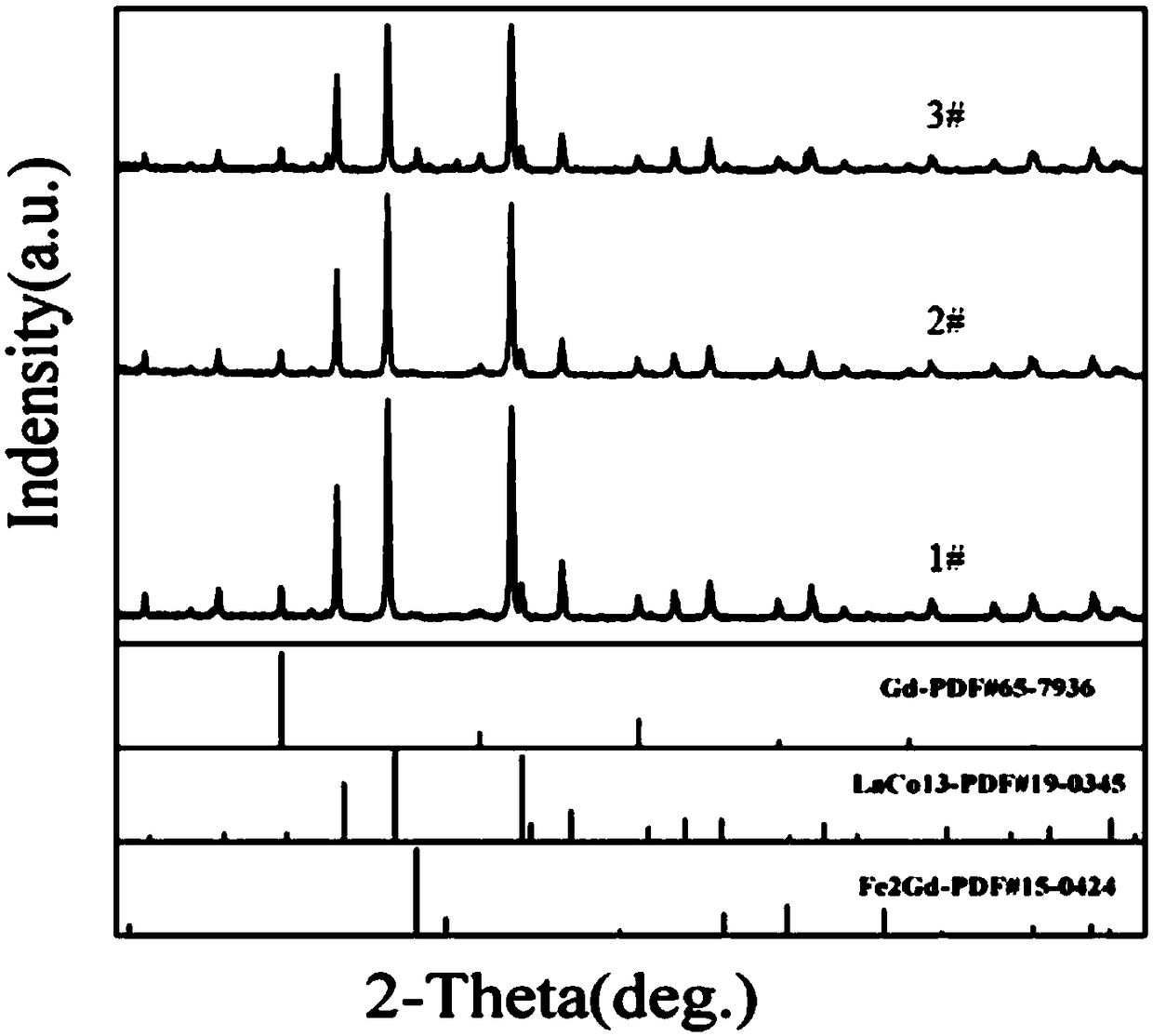

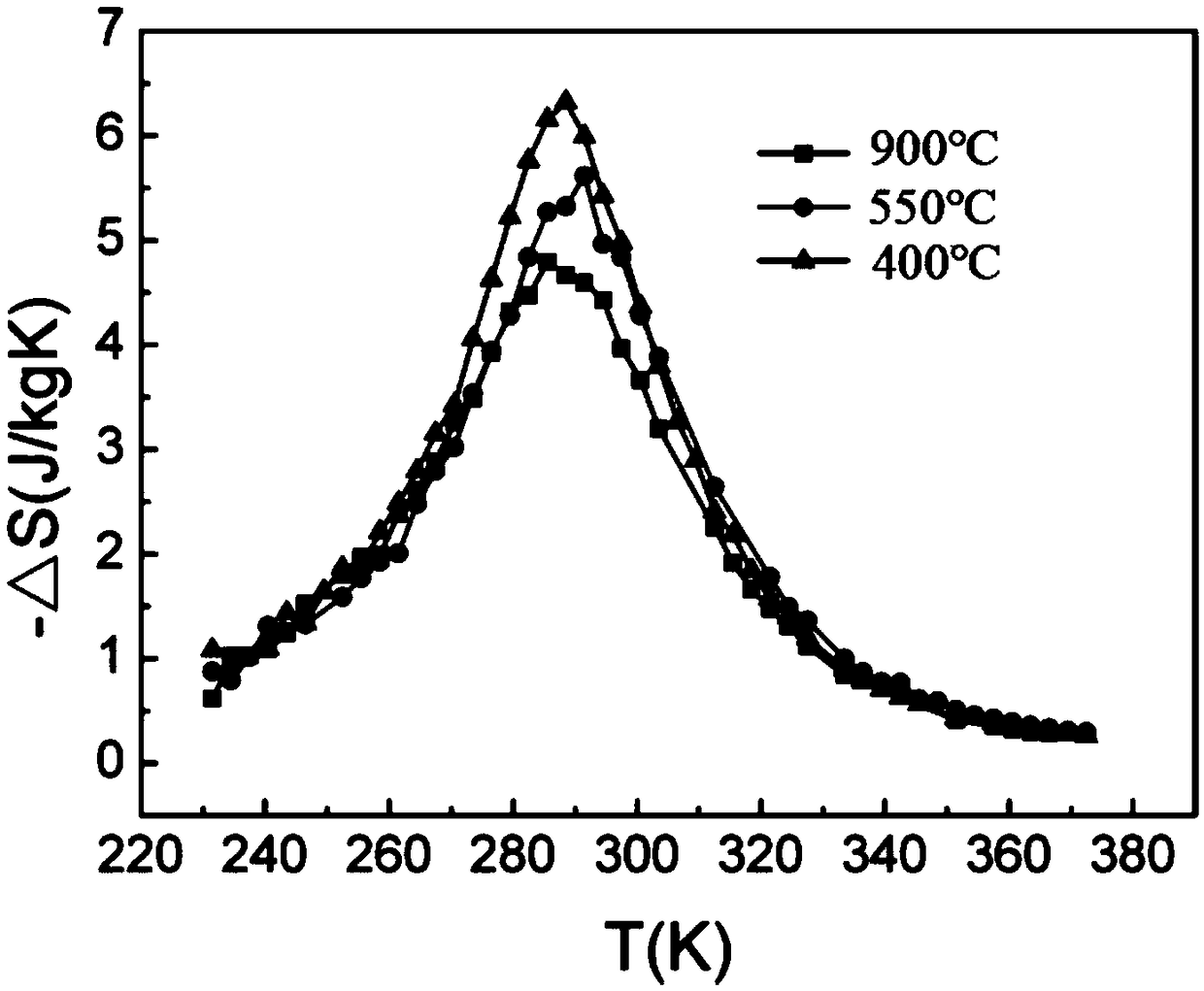

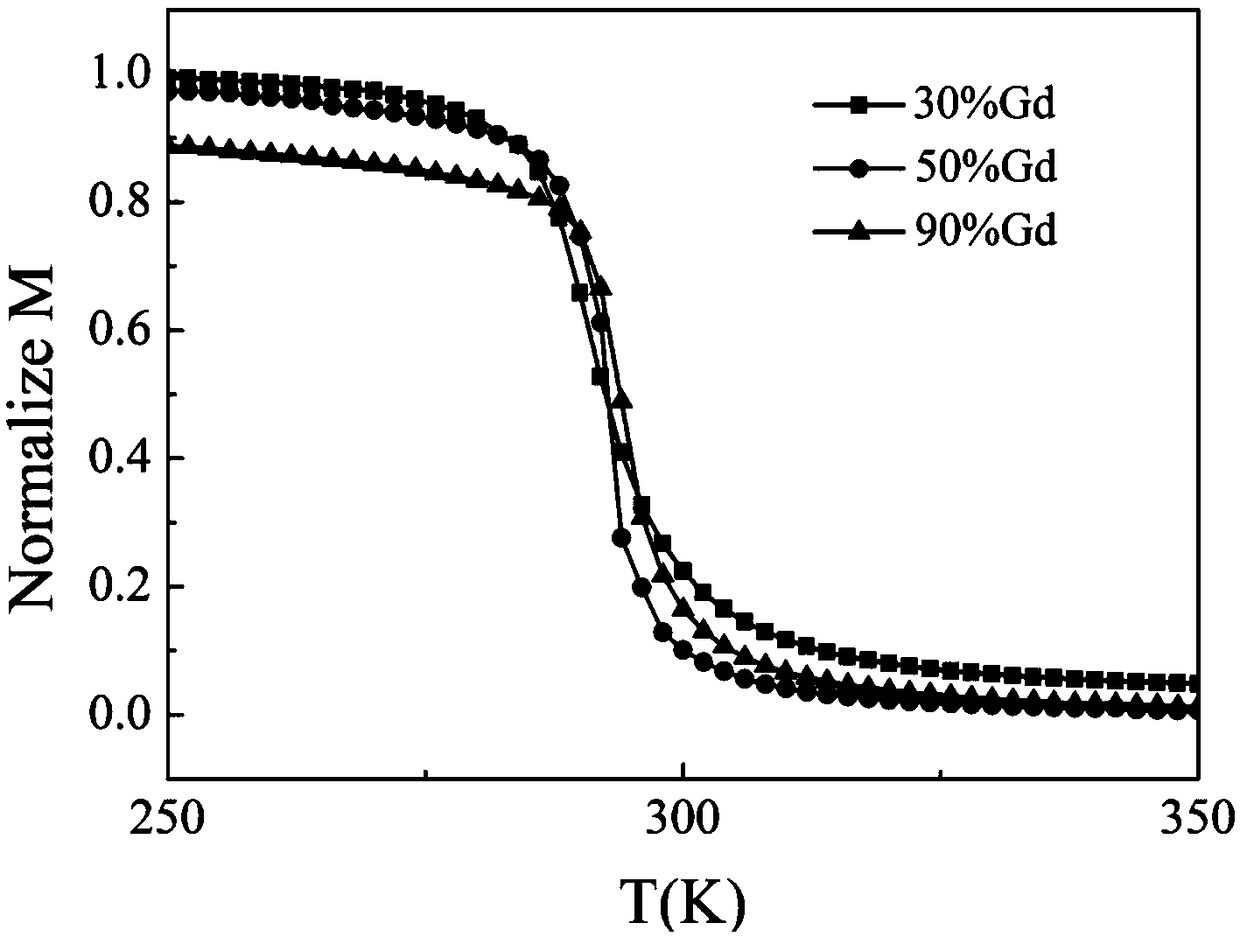

Lanthanum-iron-silicon/gadolinium composite magnetic refrigeration material and preparation technology thereof

ActiveCN108735411AImprove mechanical propertiesAvoid destructionInorganic material magnetismIncreasing energy efficiencyLanthanumMagnetic refrigeration

The invention discloses a lanthanum-iron-silicon / gadolinium composite magnetic refrigeration material and a preparation technology thereof and belongs to the field of magnetic refrigeration materialsin magnetic functional materials. A La-Fe-Si / Gd composite magnetic refrigeration material with high strength and high performance is obtained by adopting metal Gd particles as a second magnetic refrigeration material of playing a bonding role and La-Fe-Si series alloy through hot pressing sintering. The invention further discloses a preparation method and application of the La-Fe-Si / Gd composite magnetic refrigeration material. The La-Fe-Si series alloy and Gd are magnetic refrigeration materials with excellent performance, so that the mechanical properties are complementary. Through additionof Gd elemental particles, the mechanical property of the La-Fe-Si series alloy is greatly strengthened, and furthermore, the damage to the magnetic refrigeration performance caused by use of other binders is avoided. The obtained magnet has good magnetic refrigeration performance and relatively high strength, is simple in equipment, simple in operation and relatively low in cost in an implementation process, is high in economic value and has important application significance in the field of magnetic refrigeration, and mass production is easy to implement.

Owner:BEIJING UNIV OF TECH

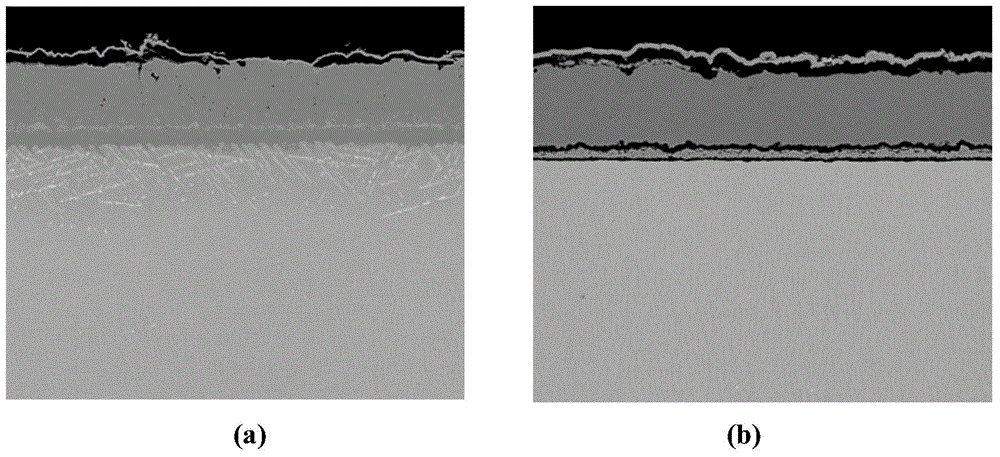

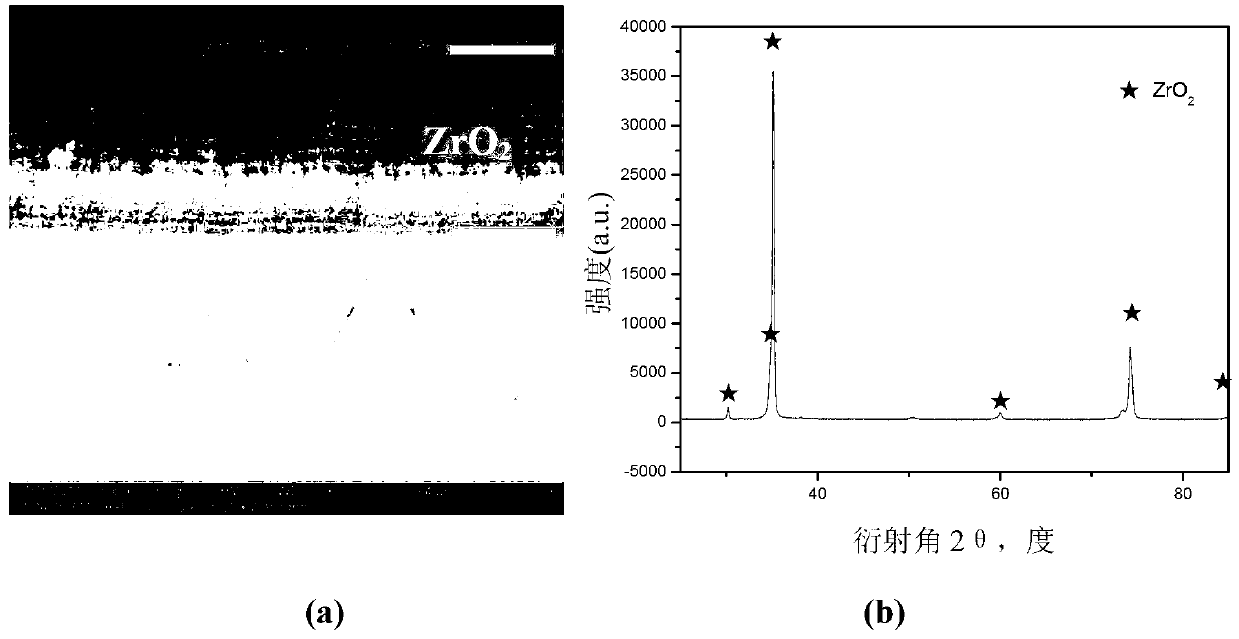

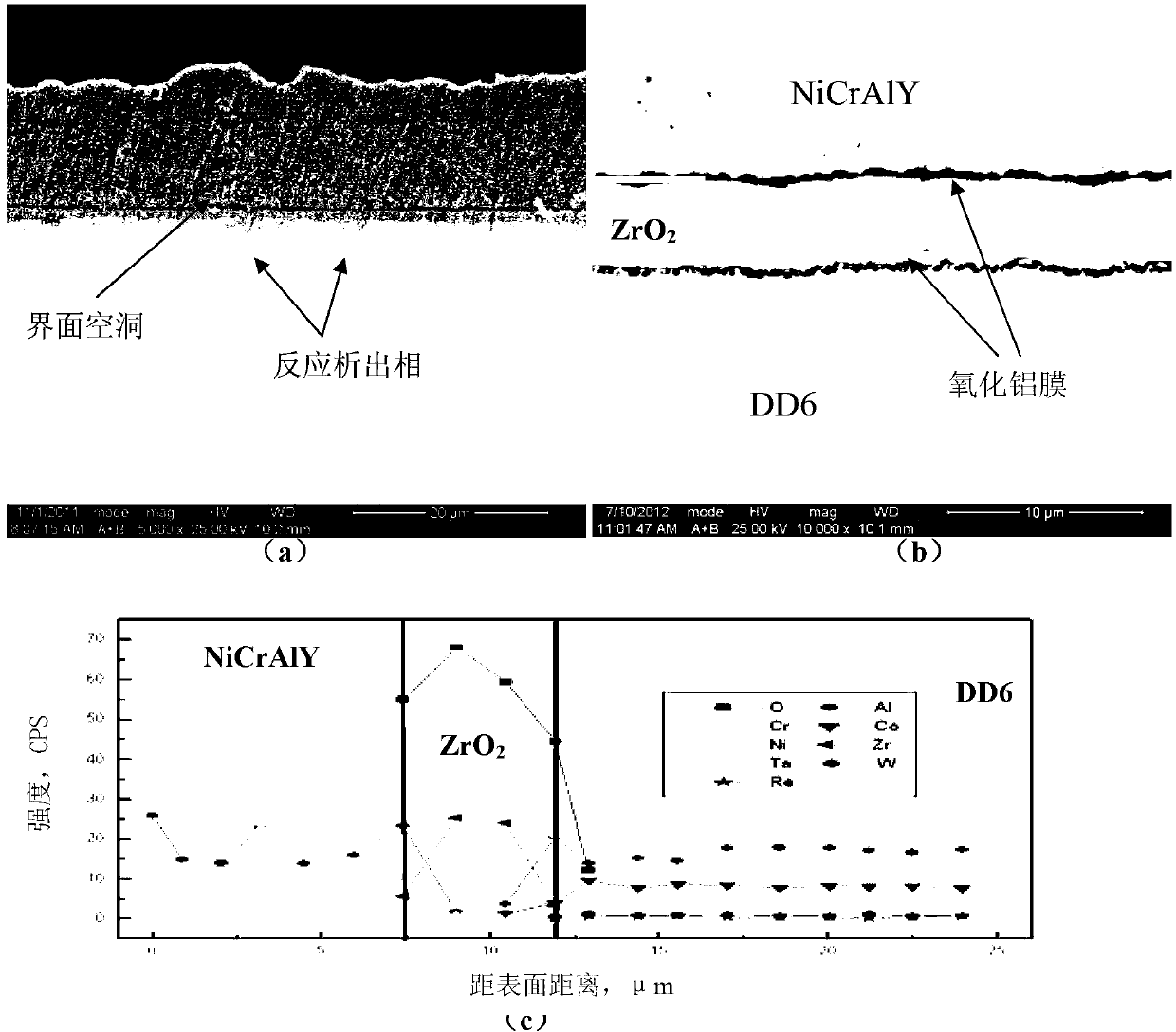

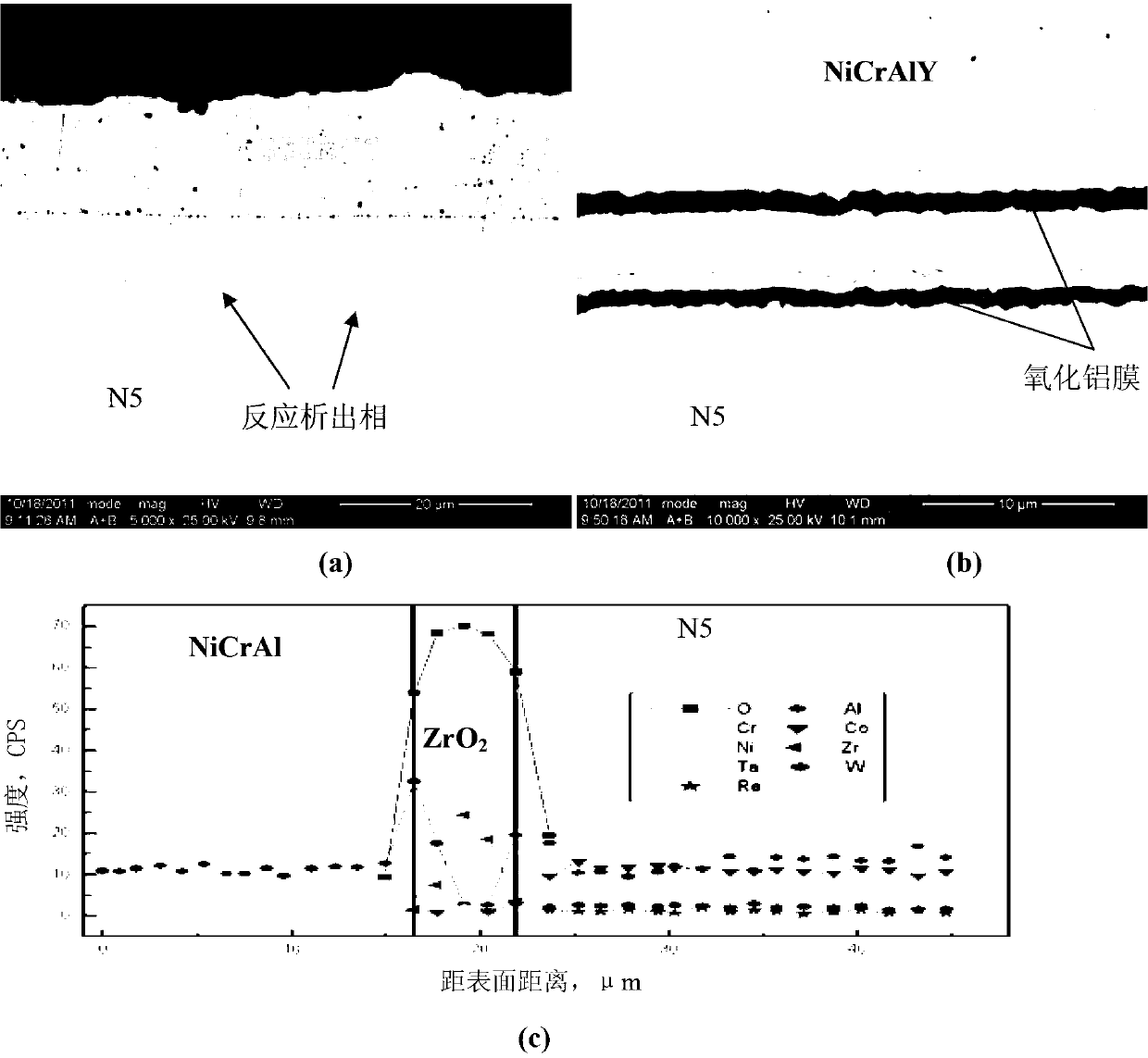

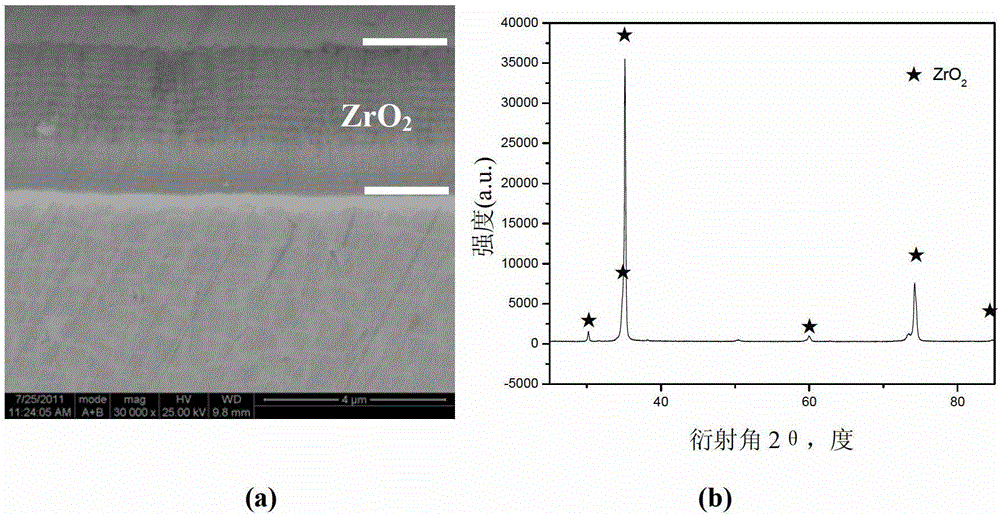

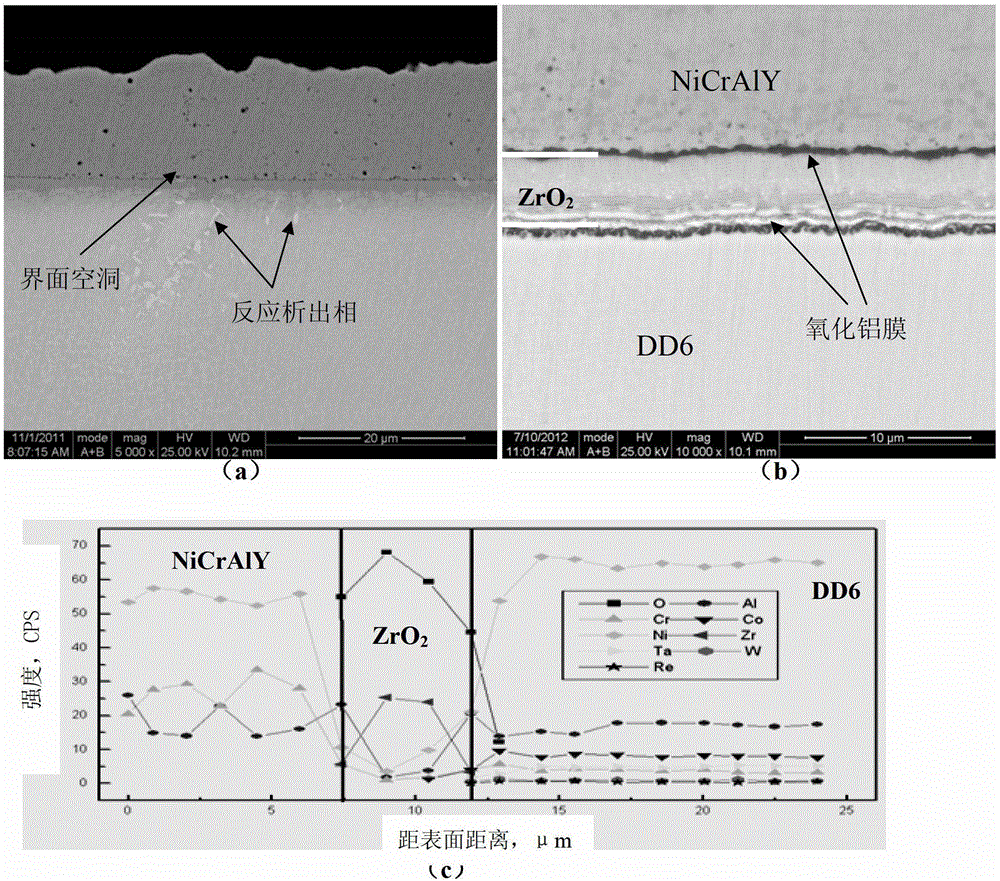

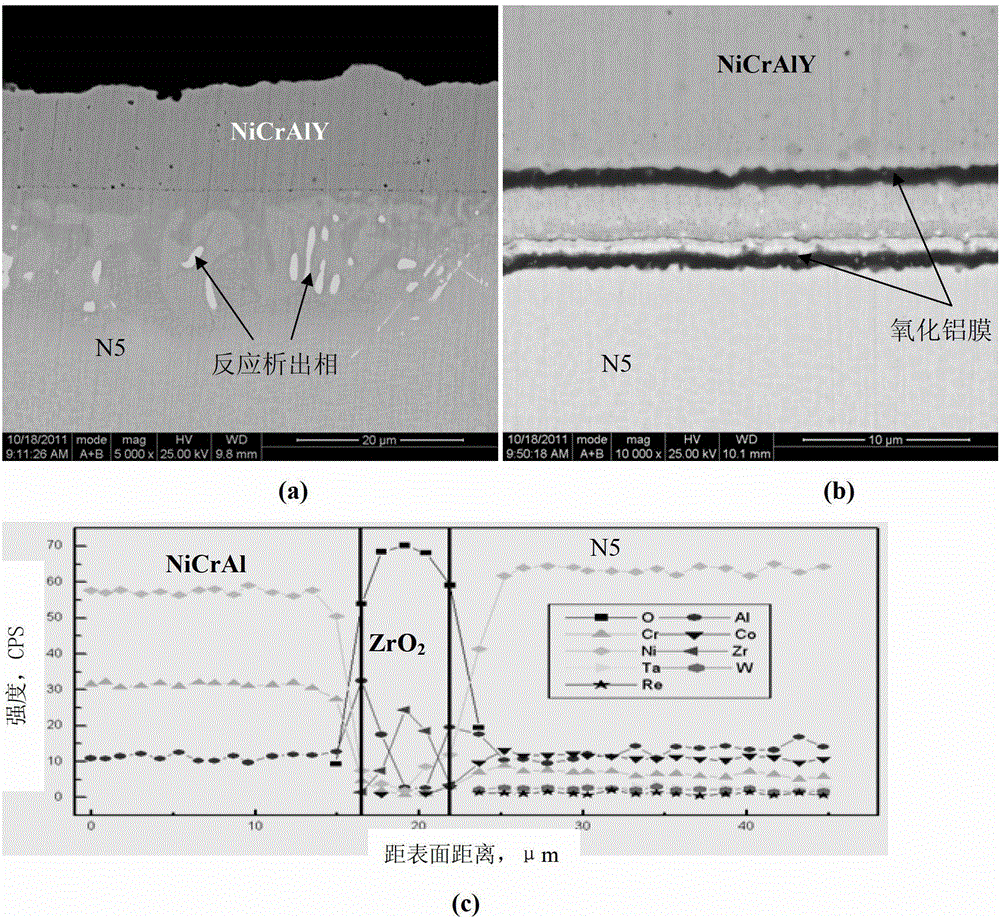

High temperature coating containing zirconium oxide active diffusing barrier and preparation method thereof

ActiveCN103342016AImprove the bonding strength of the interfaceHigh strengthMetal layered productsOxidation resistantMechanical properties of carbon nanotubes

The invention relates to the high temperature coating technology, and in particular relates to a high temperature coating containing zirconium oxide active diffusing barrier and a preparation method thereof. The high temperature protective coating comprises a zirconium oxide active diffusing inner layer and an anti-high temperature oxidizing protective layer. The zirconium oxide inner layer can be spontaneously converted into a multilayer film structure comprising aluminum oxide / metal / aluminum oxide in the using process, so that mutual diffusion between the anti-high temperature oxidizing protective layer and a base body can be resisted, and the coating has good binding strength and thermal stability, so that effective antioxidant components in the anti-high temperature oxidizing protective layer are prevented from diffusing to the base body, and therefore, the service life of the high temperature coating is prolonged, and the mechanical performance of the base body is not damaged. The preparation method comprises the following steps of: first, preparing a zirconium oxide layer on the surface of the base body by an electron beam physical vapor deposition method; and then, preparing the anti-high temperature oxidizing protective layer on the active diffusing barrier by one of a vacuum physical vapor deposition method, a chemical vapor deposition method, a thermal spraying method and the like or combination thereof.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

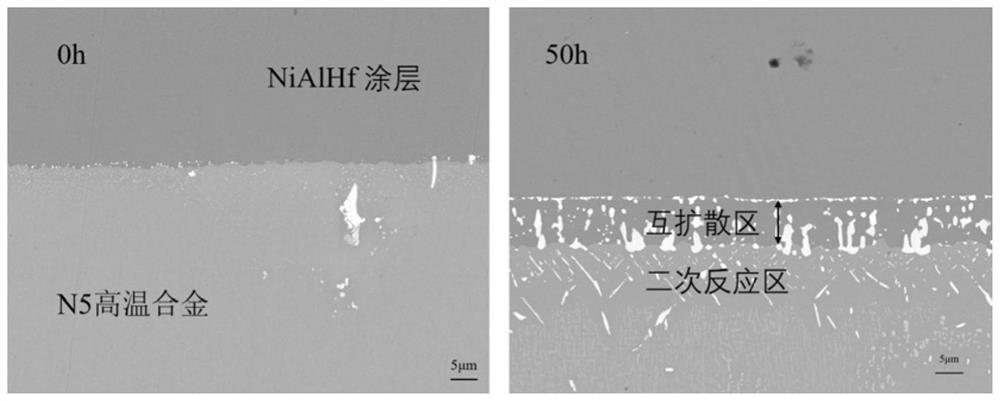

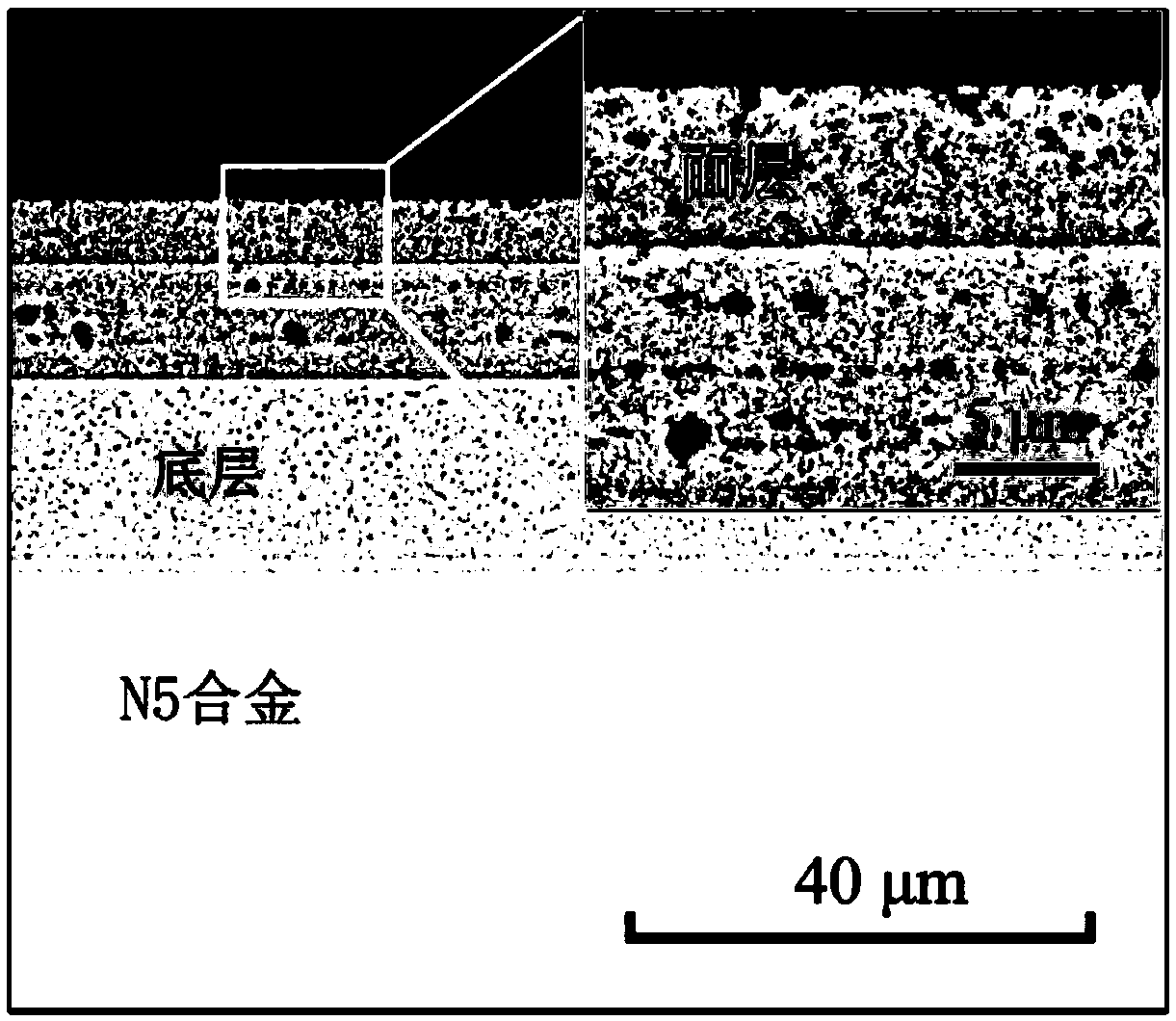

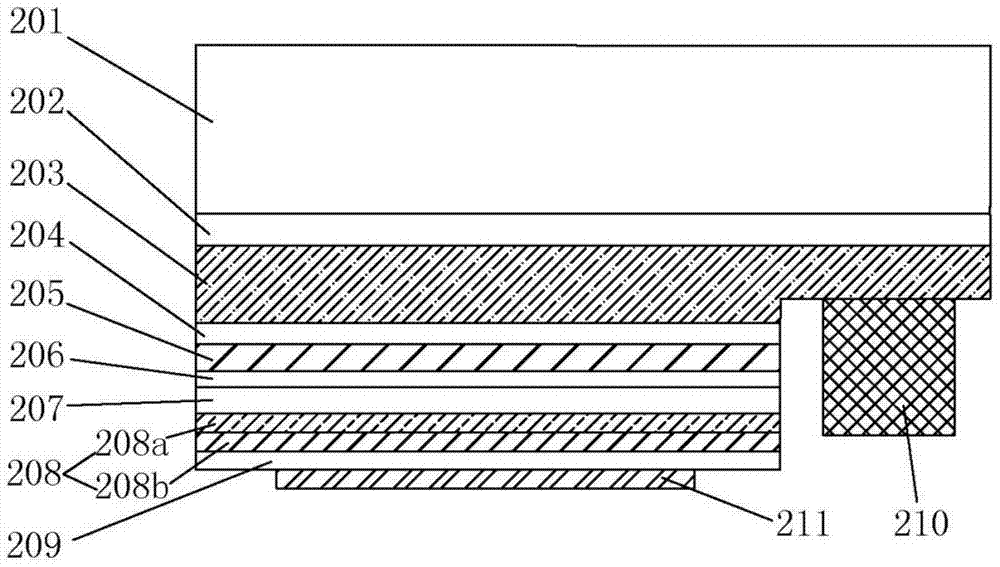

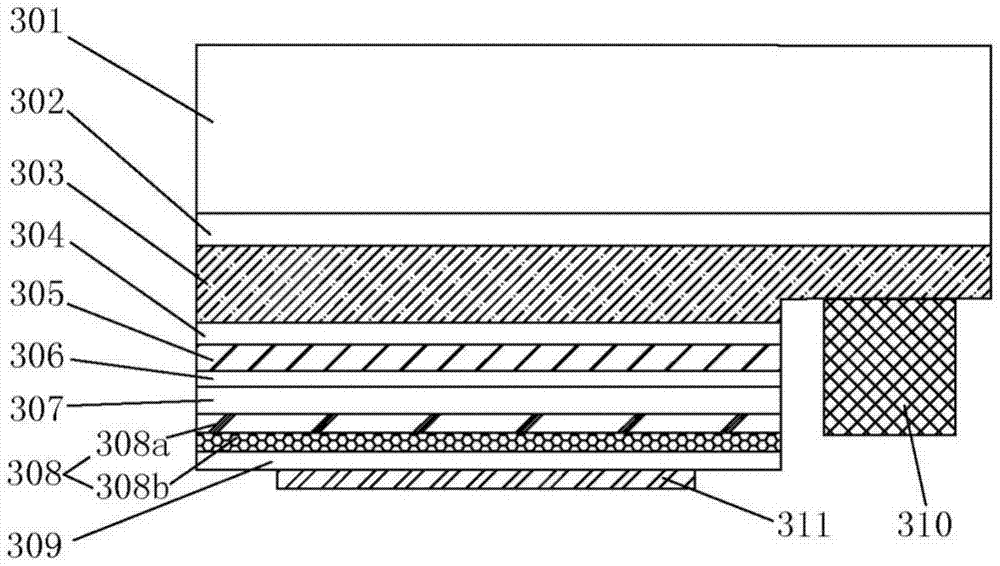

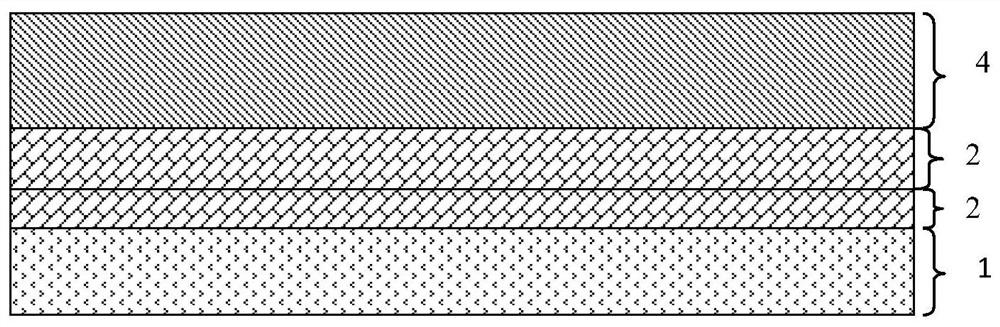

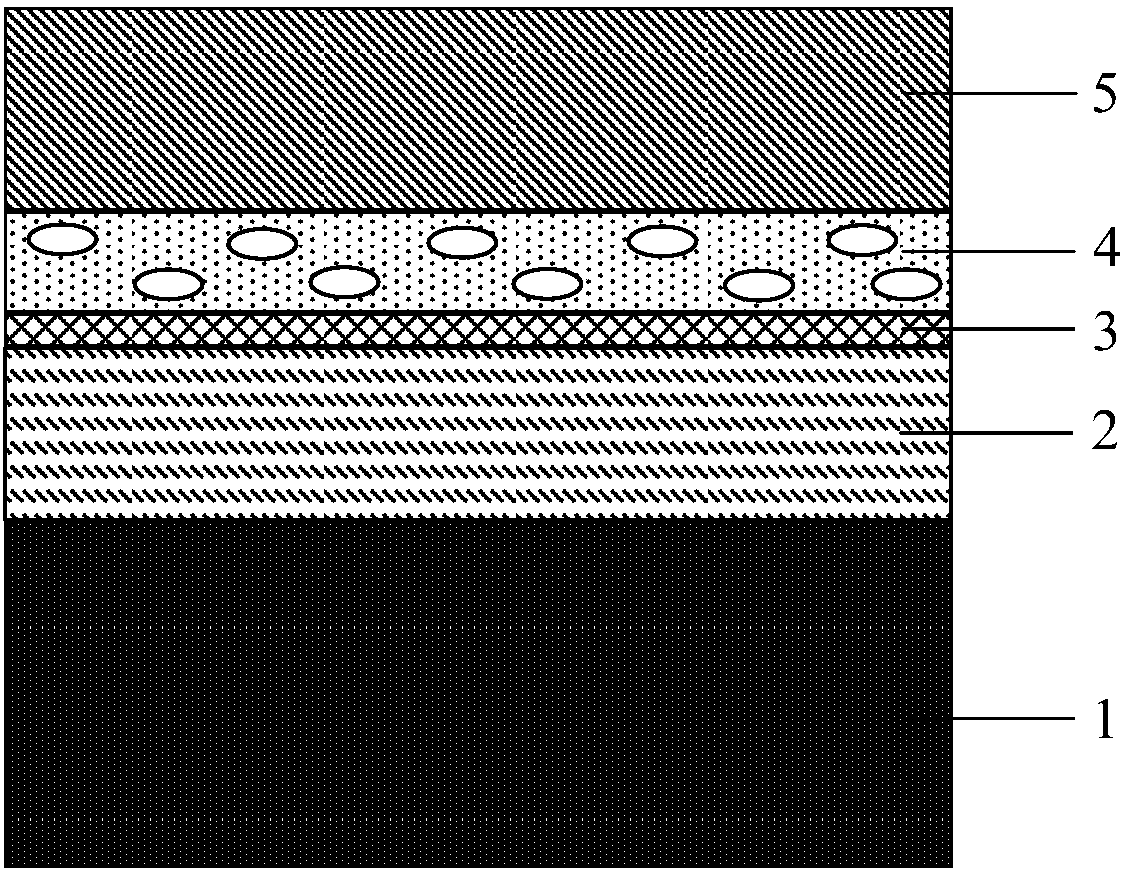

Thermal barrier coating for single crystal superalloy thermal protection and preparation method thereof

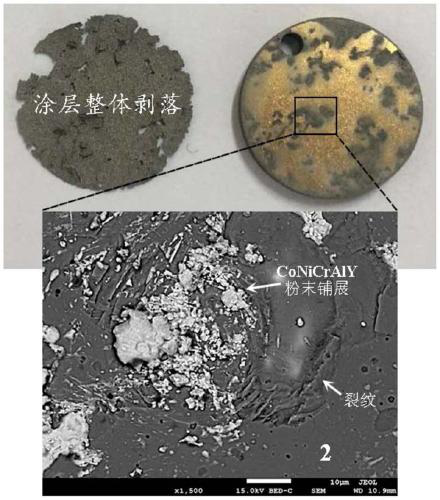

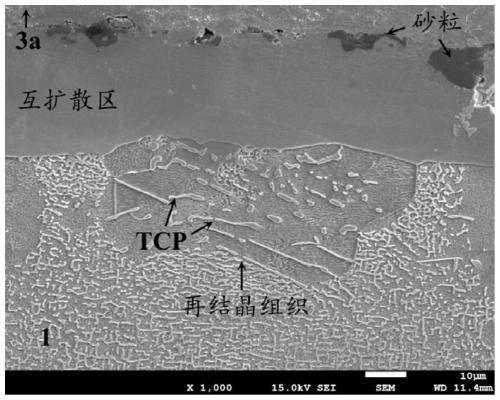

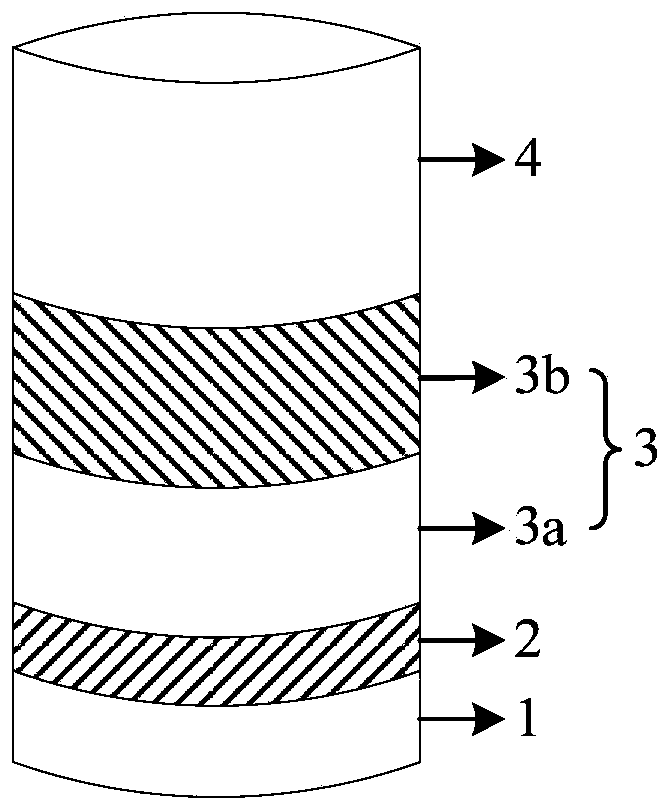

ActiveCN110079770ASuppressed interdiffusionGuaranteed Interface CompatibilityMolten spray coatingVacuum evaporation coatingThermal sprayingSingle crystal superalloy

The invention relates to a thermal barrier coating for single crystal superalloy thermal protection and a preparation method thereof, and belongs to the technical field of material thermal protection.The thermal barrier coating adopts single crystal superalloy as a substrate, a thermal barrier layer formed by sequentially stacking a barrier layer, a lower bonding layer prepared through a vapor deposition process, an upper bonding layer prepared thruogh a thermal spraying process, and a ceramic layer is arranged on the substrate, through the barrier coating, interdiffusion of elements betweenthe substrate and the bonding layers can be suppressed, and recrystallization of the single crystal superalloy substrate caused by a sandblasting process is avoided. The preparation process of the thermal barrier coating mature processes, operation is simple, and large-scale production can be achieved easily.

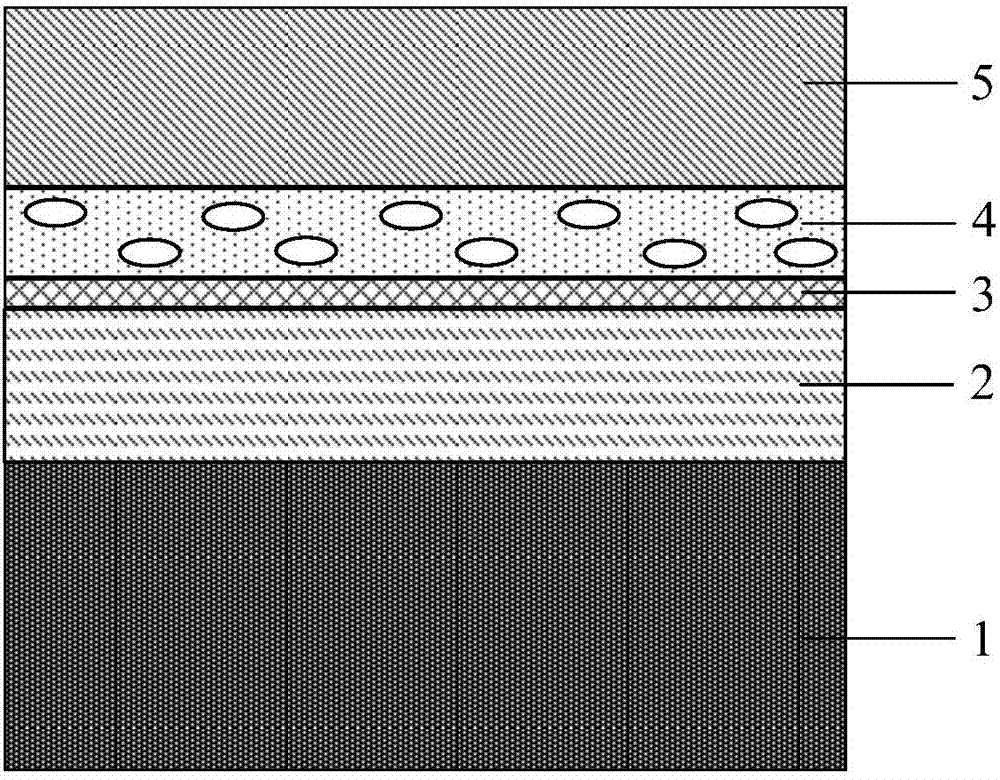

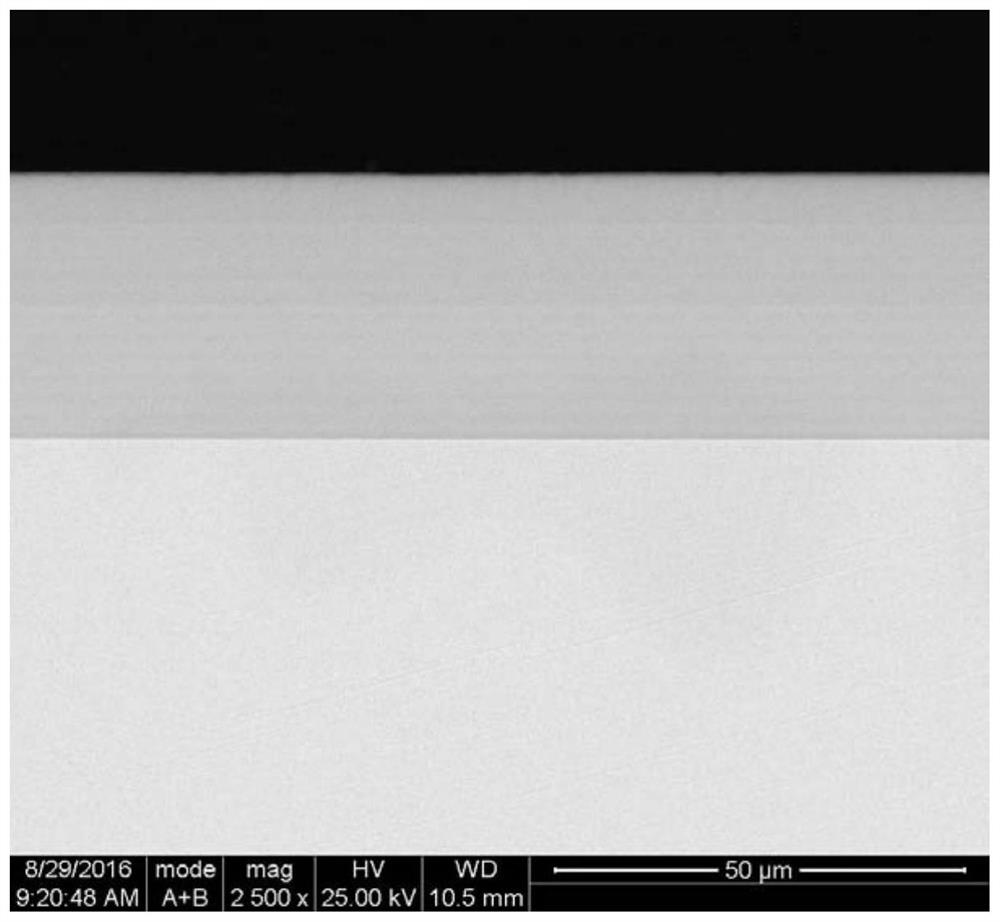

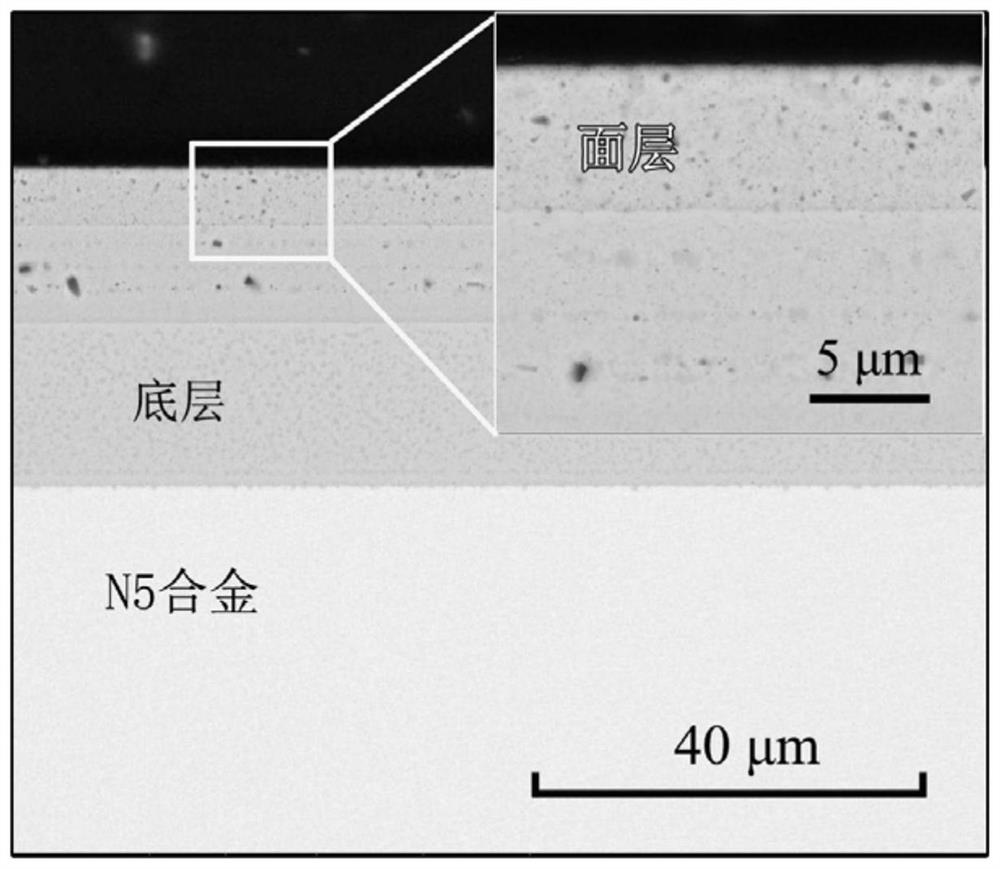

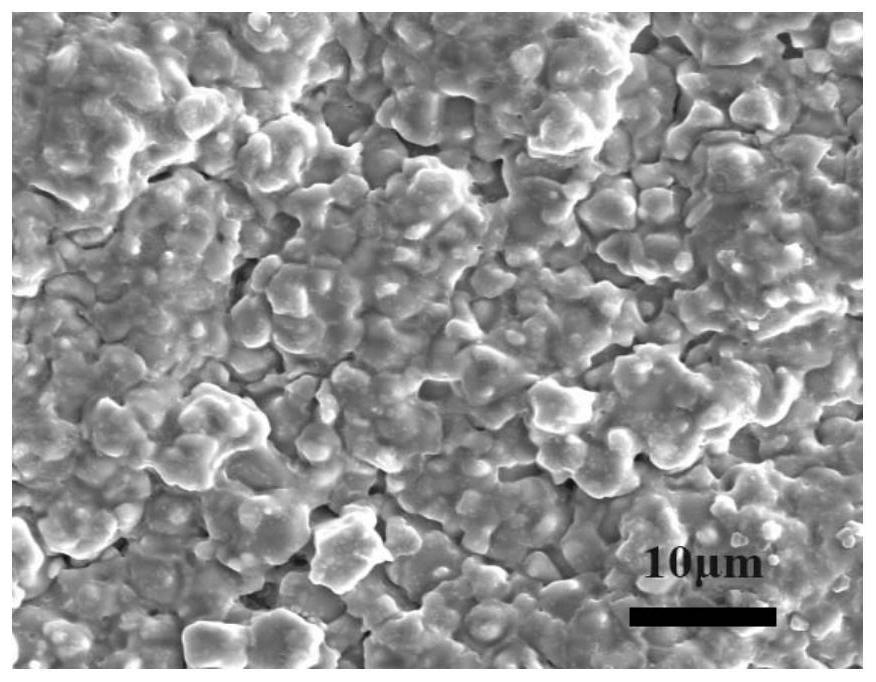

Composite metal ceramic coating for high-temperature alloy protection and preparing method of composite metal ceramic coating

ActiveCN108796461AAlleviate thermal expansion coefficient differencesReduce thermal stressVacuum evaporation coatingSputtering coatingSputteringCrystal structure

The invention discloses a composite metal ceramic coating for high-temperature alloy protection and a preparing method of the composite metal ceramic coating. The coating comprises a face layer and abottom layer with a nano columnar crystal structure. The face layer comprises at least two metal ceramic sub layers, and a metal parent phase and a dispersed distribution nitride ceramic phase are specifically included. In the direction from the surface of the composite metal ceramic coating to an alloy matrix, the doping amount of the nitride ceramic phase is gradually reduced, and the distribution interval of the volume fraction of the nitride ceramic phase is 0.1-60%. According to the preparing method of the coating, magnetic control sputtering is adopted for preparing a bottom layer coating, and then, non-balance reaction magnetic control sputtering is utilized for preparing the face layer of the doped ceramic phase. Through the structure, the heat expansion coefficient of the coatingis gradually increased from top to bottom, jumping changes of the heat expansion coefficient on the coating / oxide film interface are reduced, accordingly, the heat stress in an oxide film in the heatcirculation process is relieved, and the capability of oxide film peeling resisting of the coating in the heat circulation is enhanced.

Owner:JINAN UNIVERSITY

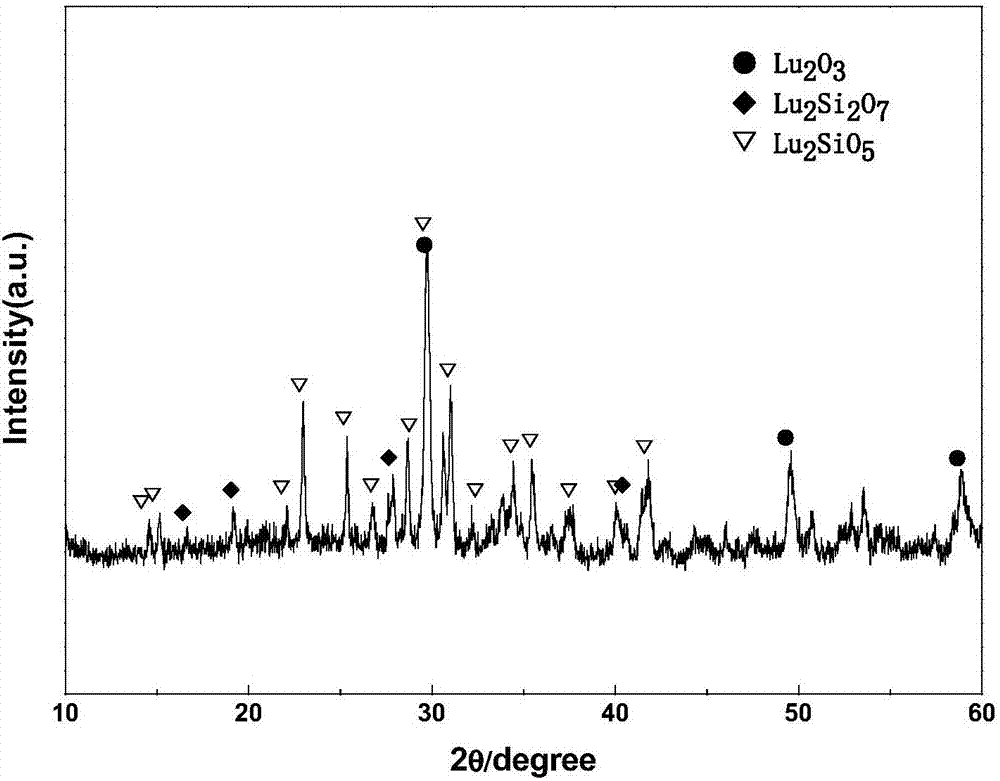

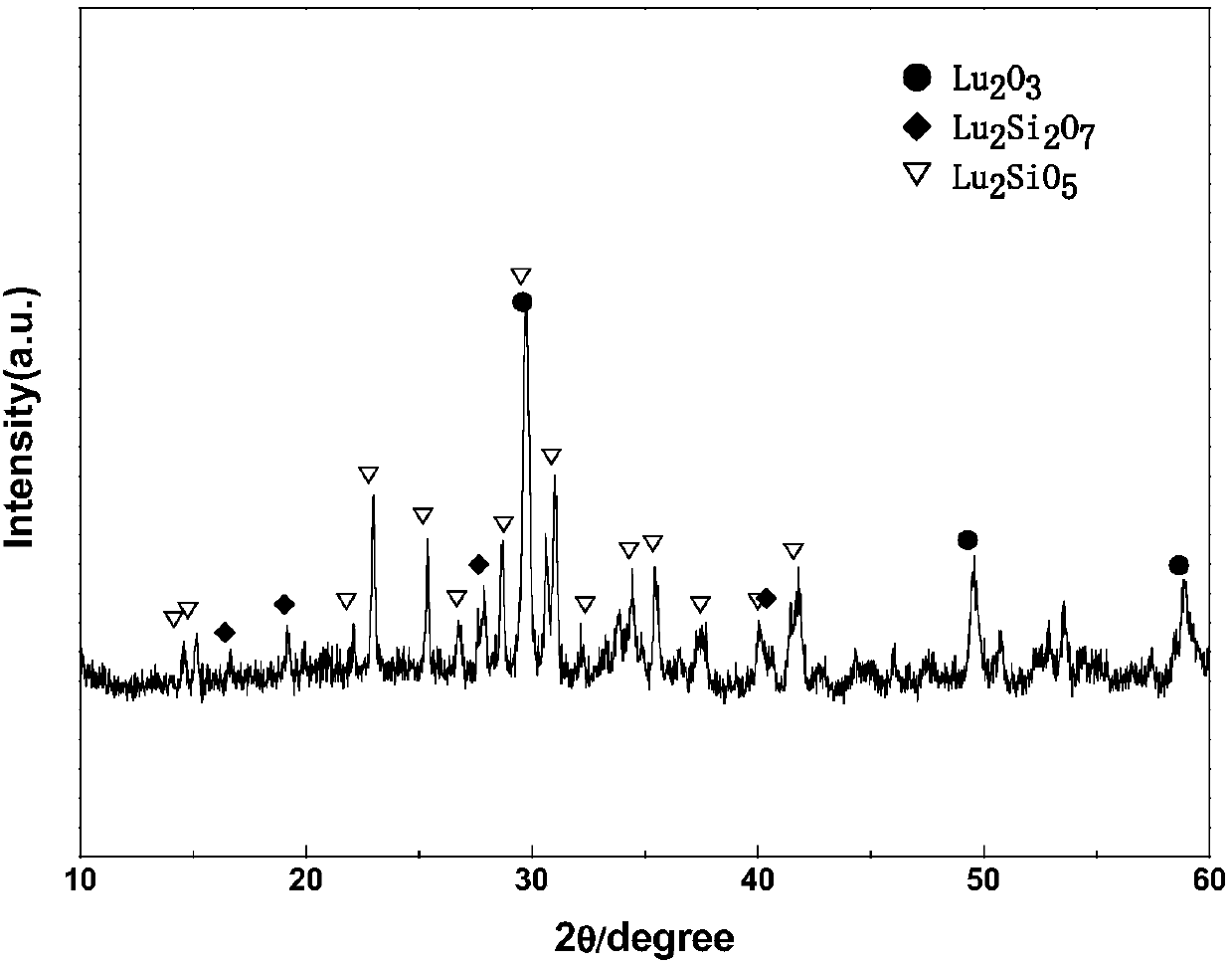

Rare-earth-based T/EBC ceramic matrix composite environmental barrier coating and preparation method thereof

ActiveCN107032831AGood resistance to high temperature water and oxygen corrosionProtective serviceBlade accessoriesMachines/enginesMulliteRare earth

The invention relates to a rare-earth-based T / EBC ceramic matrix composite environmental barrier coating and a preparation method thereof. A ceramic matrix is made of a silicon carbide fiber reinforcement silicon carbide ceramic matrix composite material, the environmental barrier coating sequentially comprises a water oxygen corrosion resistant layer, a chemical barrier layer, an energy dissipation layer and a thermal protecting and shielding layer from inside to outside, and the water oxygen corrosion resistant layer is prepared on the surface of the ceramic matrix, wherein materials of the water oxygen corrosion resistant layer comprise mullite and lutetium orthosilicate; a material of the chemical barrier layer comprises zirconium nitride; a material of the energy dissipation layer comprises yttrium aluminum garnet; a material of the thermal protecting and shielding layer comprises lanthanum zirconate. The ceramic matrix composite environmental barrier coating has excellent comprehensive performance, the interfacial strength, fracture toughness and hardness of the coating can be improved, the service life of the coating is significantly prolonged, the thermal conductivity of the coating is reduced, and therefore the Sicf / Sic ceramic matrix can keep stable in comprehensive performance after recycling utilization for multiple circles under the high-temperature environment of 1900 k or above.

Owner:BEIHANG UNIV

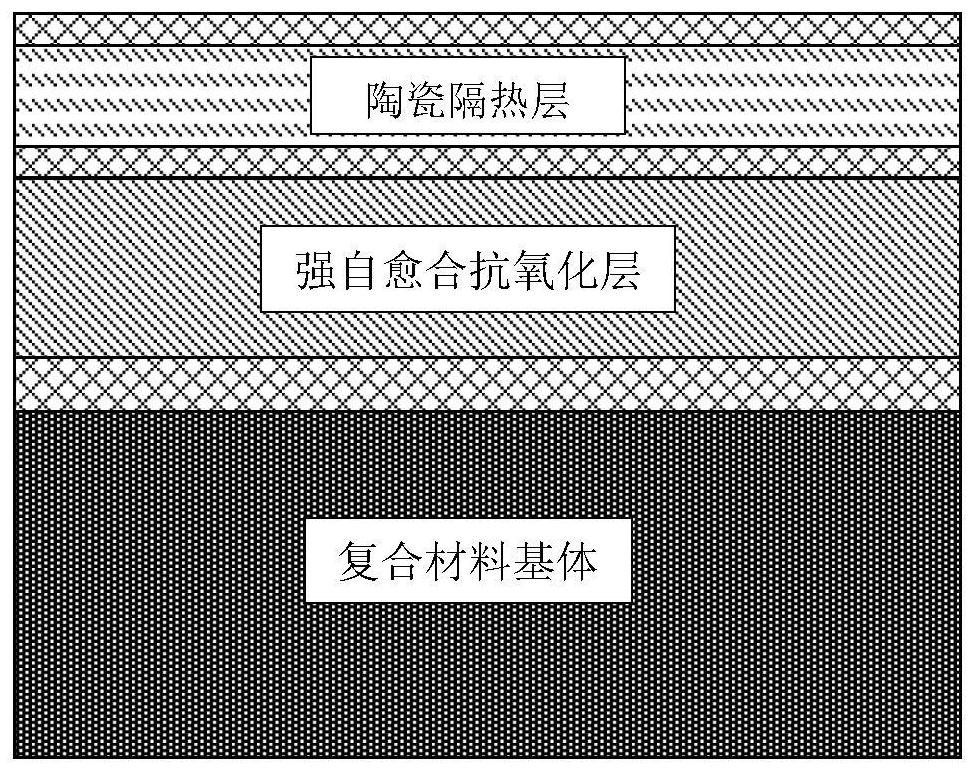

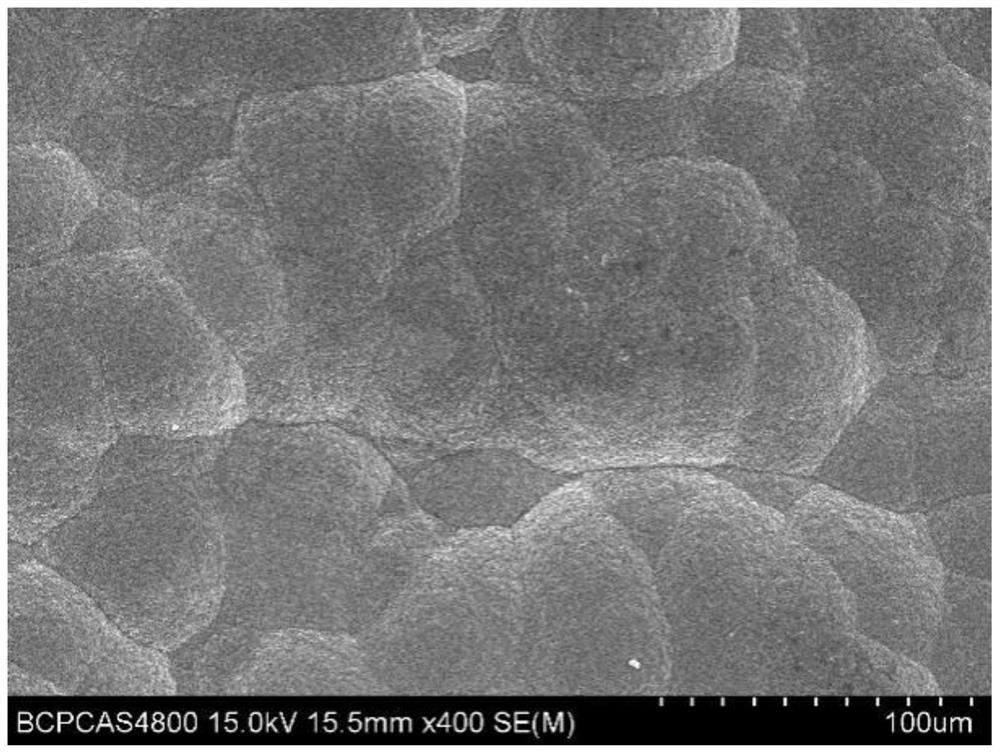

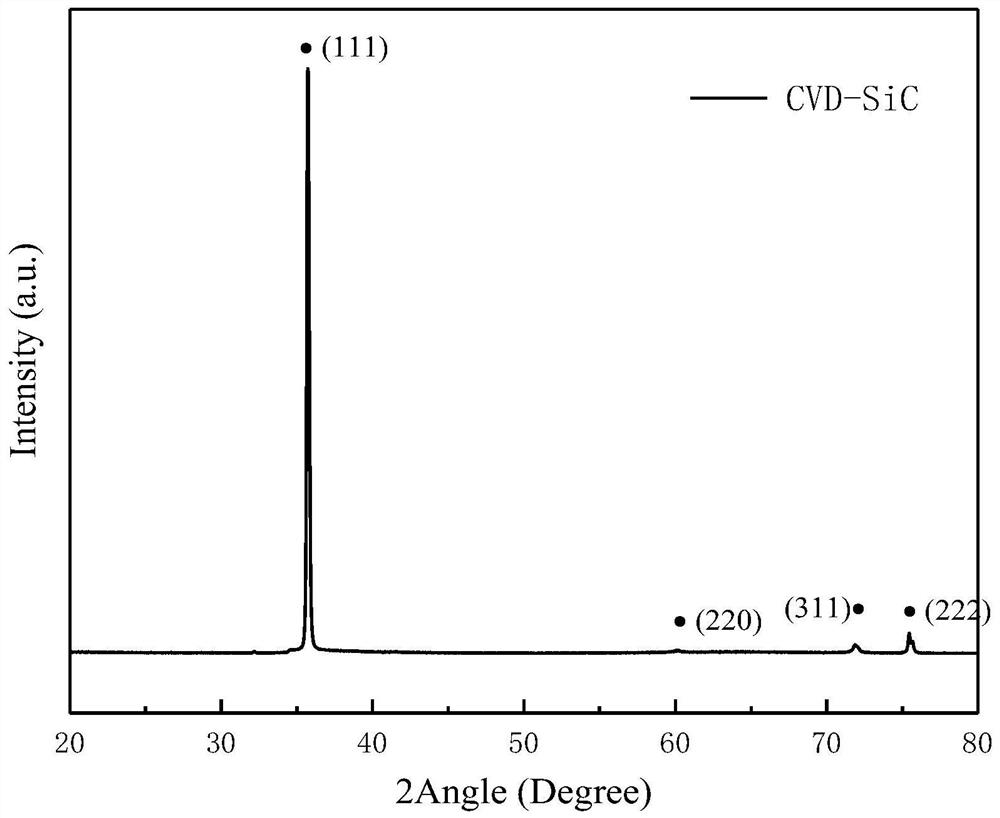

Multi-layer ceramic-based composite thermal protection coating as well as preparation method and application thereof

ActiveCN113800955ASmall difference in coefficient of thermal expansionInhibited DiffusionCosmonautic thermal protectionThermal insulationMullite

The invention provides a multi-layer ceramic-based composite thermal protection coating and a preparation method and an application thereof, and the multi-layer composite thermal protection coating is prepared by a combined process of preparing three layers by a chemical vapor deposition method and preparing two layers by a brushing sintering method, and the coating sequentially comprises a buffer layer, a high-strength self-healing anti-oxidation layer, a middle chemical barrier layer, a ceramic thermal insulation layer and a reinforced isolation layer from inside to outside. The inner buffer layer, the middle chemical barrier layer and the outer reinforced isolation layer are all made of chemical vapor deposition silicon carbide; the strong self-healing anti-oxidation layer of the secondary inner layer is made of silicon powder / zirconium silicide / silicon hexaboride multiphase ceramic; and the material of the ceramic thermal insulation layer on the secondary outer layer is silicon powder / lanthanum hexaboride / mullite / zirconium boride multiphase ceramic. The composite material has excellent thermal protection performance such as oxidation resistance, corrosion resistance and thermal shock resistance, the service life of the material under high-temperature chemical oxidation and corrosion conditions can be remarkably prolonged, and the ceramic-based or carbon-based composite material keeps stable comprehensive performance after being recycled for multiple weeks in the high-temperature environment of 1,500 K or above.

Owner:湖北瑞宇空天高新技术有限公司

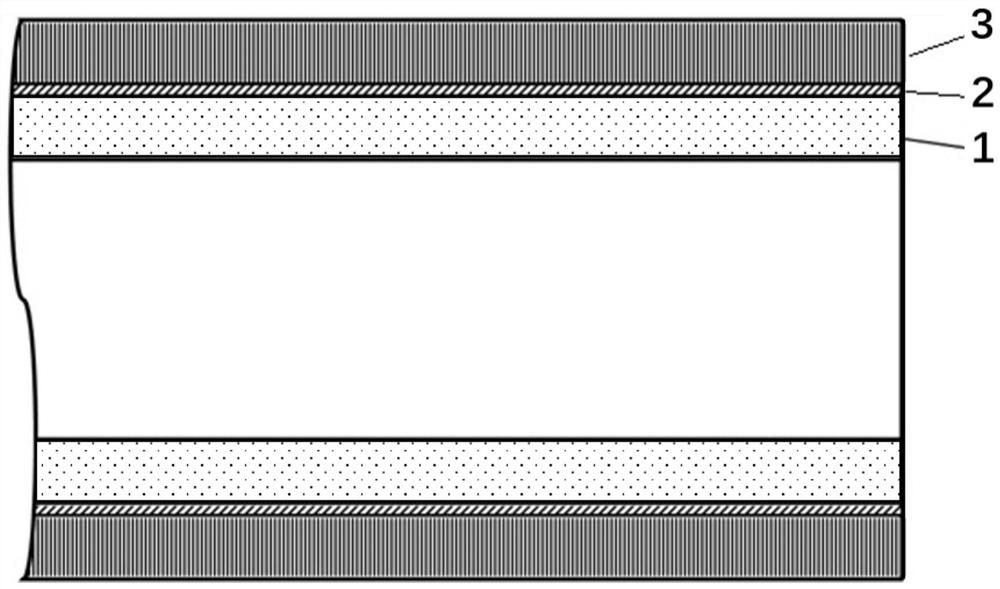

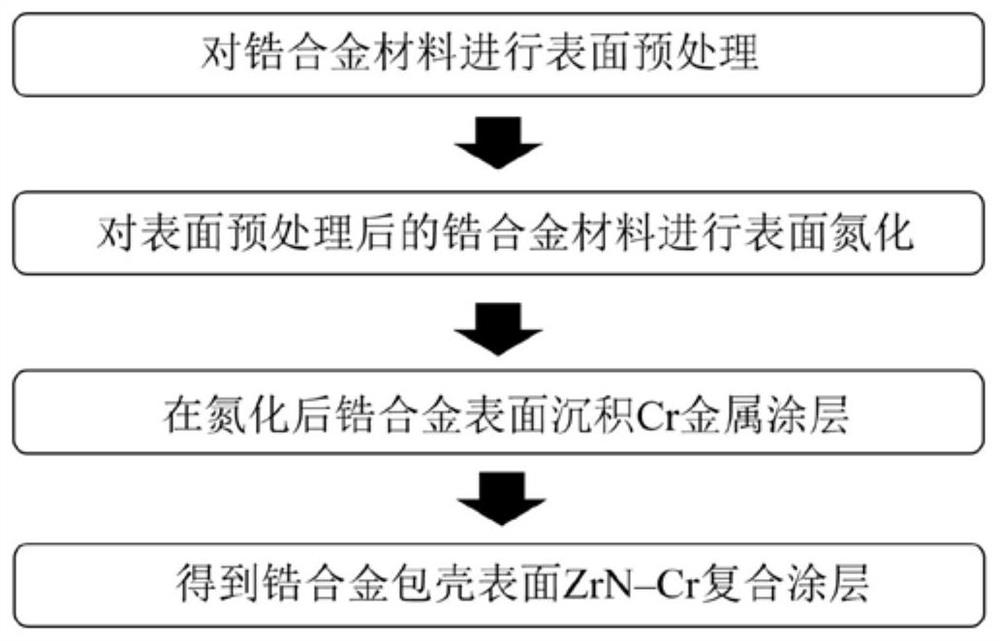

Coating for outer surface of zircalloy cladding tube and manufacturing method

PendingCN113293374AImprove corrosion resistanceImprove bindingOptical rangefindersNuclear energy generationThermal dilatationQuenching

The invention discloses a coating for the outer surface of a zircalloy cladding tube and a manufacturing method. According to the coating, a zircalloy cladding tube base body is sequentially coated with a ZrN transition layer and a Cr working layer; the thickness of the ZrN transition layer is 0.12 micron to 2 microns; and the main component of the Cr working layer is yttrium oxide doped stable zirconium oxide working layer. According to the method, mutual diffusion of elements between the Cr working layer and the zirconium alloy base body can be effectively inhibited, and mutual diffusion of the elements between the Cr working layer and the base body at high temperature is avoided; and under the quenching condition, the ZrN layer generates twin crystals under the stress effect, stress generated due to mismatching of thermal expansion coefficients between the coating and the base body can be effectively released, the binding force of the coating and the base body is enhanced, and cracking and failure of the coating are avoided.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

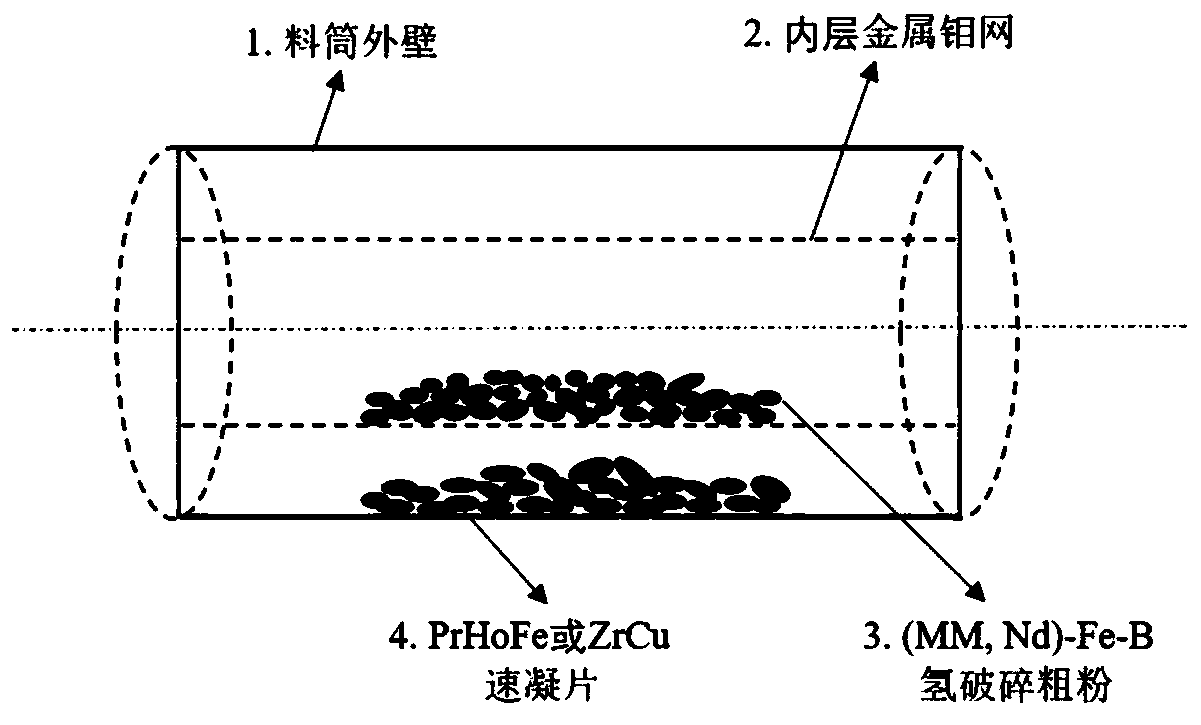

Method for preparing high-performance double-main-phase sintered mixed rare earth iron boron magnet through two-step diffusion method

ActiveCN110853854ARealize comprehensive utilizationReduce pollutionMagnetsInductances/transformers/magnets manufactureAlloyMagnet

The invention discloses a method for preparing a high-performance double-main-phase sintered mixed rare earth iron boron magnet through a two-step diffusion method, and belongs to the technical fieldof rare earth magnetic material preparation. Components of two main-phase alloys are RE-Fe-B (RE is Nd or Pr) and (Nd, MM)-Fe-B respectively, MM being mixed rare earth. The method is characterized inthat, to begin with, with a PrHoFe alloy quick-setting sheet serving as a diffusion source, the surfaces of (Nd, MM)-Fe-B hydrogen decrepitation powder particles are uniformly coated with a layer PrHo-rich compound, thereby improving the coercive force by utilizing higher anisotropic fields of Pr2Fe14B and Ho2Fe14B; and then, with a ZrCu alloy quick-setting sheet serving as the diffusion source, the surfaces of the powder particles subjected to the first-step diffusion are evenly coated with a Zr-rich layer to prevent growth of MM-containing main phase grains and suppress mutual diffusion withthe other main phase in the two main phases in the sintering process, thereby obtaining high coercive force.

Owner:BEIJING UNIV OF TECH

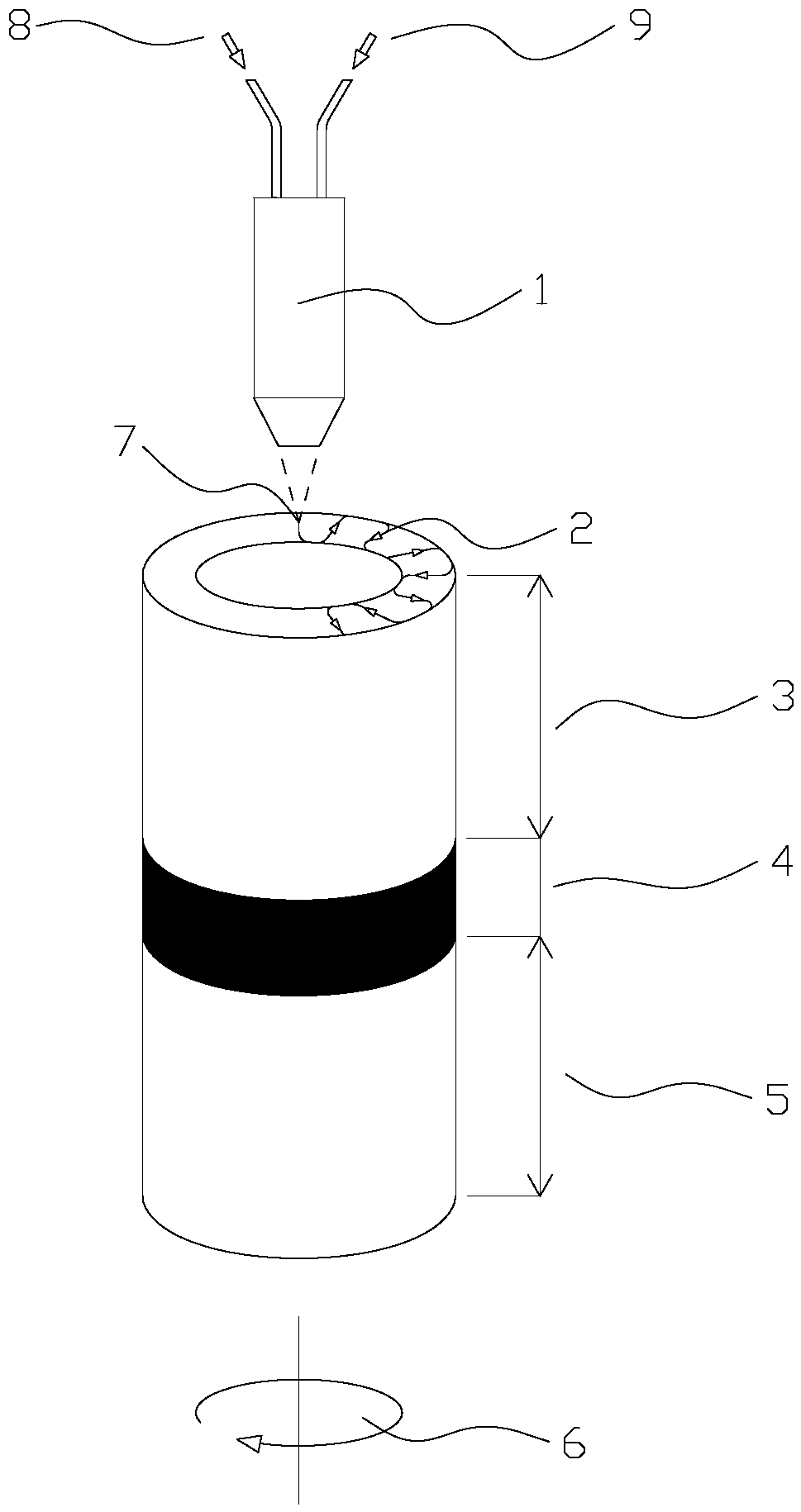

Additive manufacturing method for heterogeneous steel pipe joints

PendingCN109277699AReduce the difference in physical properties such as expansion coefficientSuppressed interdiffusionAdditive manufacturing apparatusWelding/soldering/cutting articlesMelting tankManufacturing technology

The invention relates to the field of laser additive manufacturing, in particular to an additive manufacturing method for heterogeneous steel pipe joints. The direct welding and manufacturing of existing heterogeneous steel pipe joints have problems such as low weld fusion surface strength, cracks in welded joints and heat affected zones, and performance degradation after long-term service. According to the additive manufacturing method for heterogeneous steel pipe joints, by adoption of the laser-coaxial powder feeding additive manufacturing technology, spherical powders of two alloys A and Bare put into two powder feeders; and the powder feeding ratio and the laser power are continuously changed during the melting process to change chemical components in a micro-zone of a molten pool, so that heterogeneous steel pipe joints with the chemical components transitioning from A to B in order are formed; the difference in physical properties, such as the expansion coefficient, of the twosides of the heterogeneous steel pipe joints is reduced; the thermal stress under high temperature and high pressure is greatly reduced; the chemical component concentration gradient on both sides ofthe heterogeneous steel pipe joints is also reduced; the interdiffusion of the alloys A and B can be inhibited; high temperature properties are improved, and the and service life is prolonged; and themethod has significant safety and economic benefits.

Owner:ZHEJIANG ZHENENG TECHN RES INST

Mo-Si-B/TiN composite coating and preparation method thereof

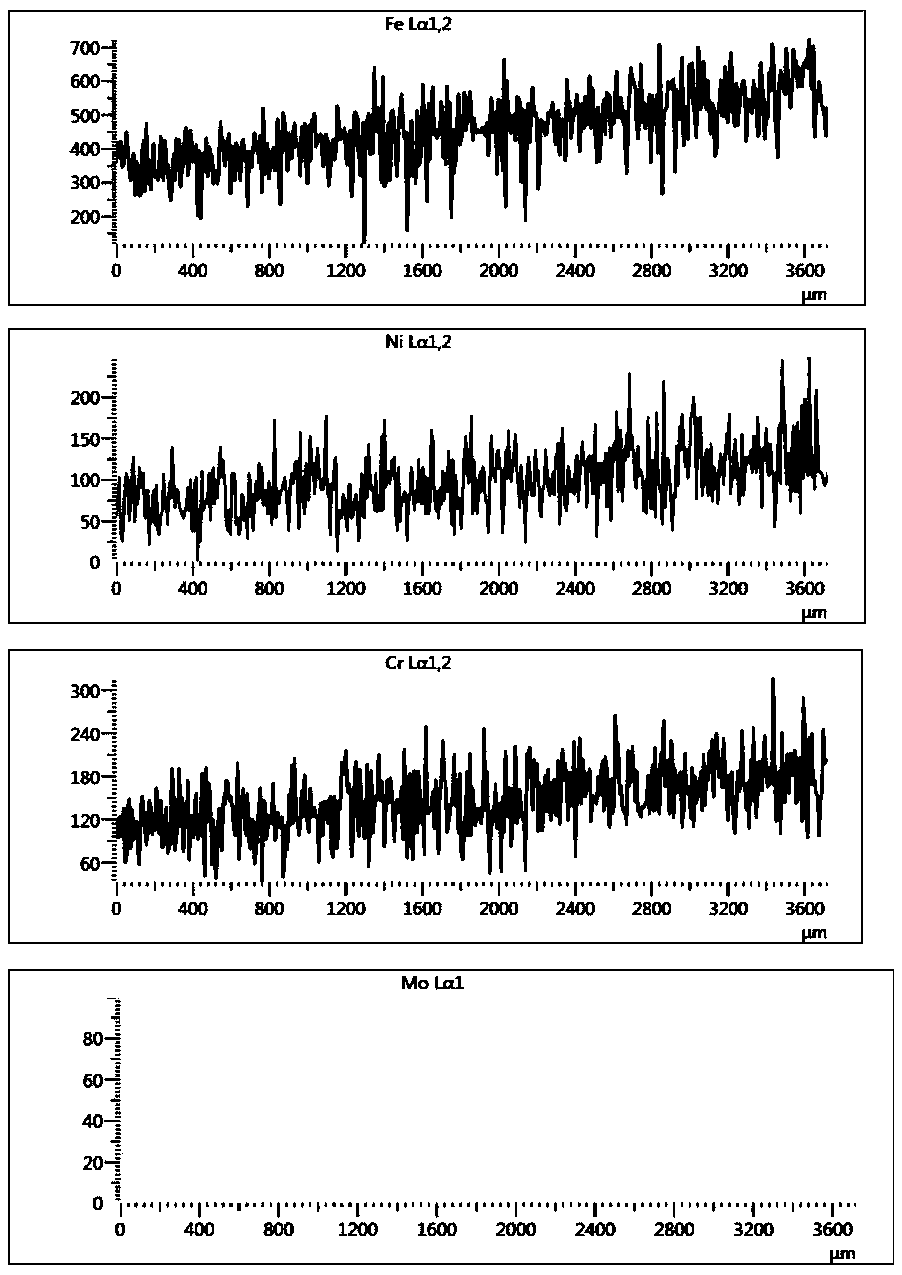

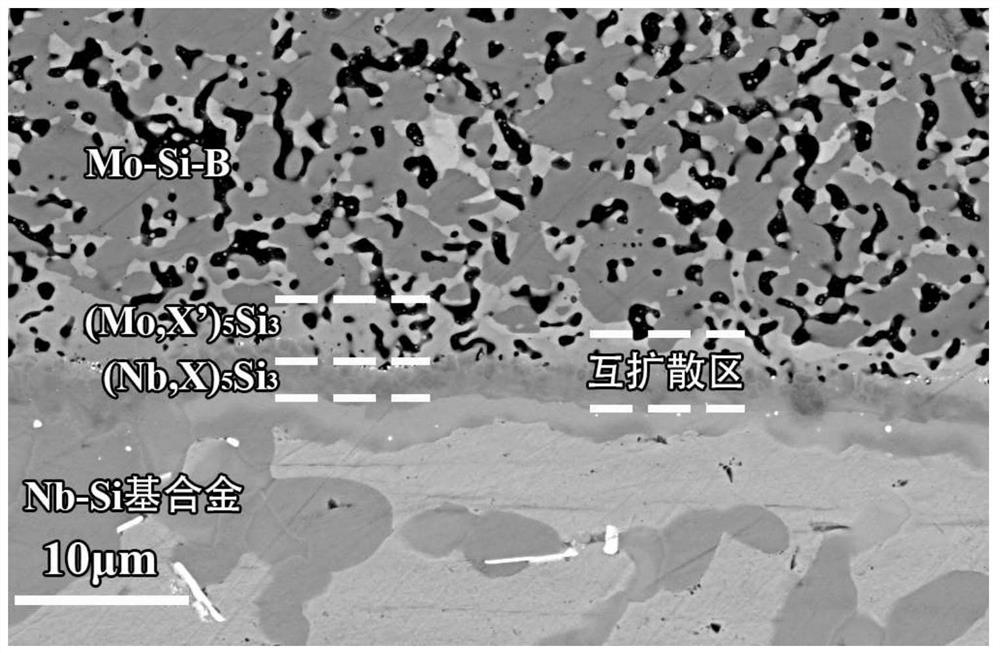

InactiveCN113046690ASufficient antioxidant elementsImprove antioxidant lifeVacuum evaporation coatingSputtering coatingDiffusion resistanceOxidation resistant

The invention discloses a Mo-Si-B / TiN composite coating and a preparation method thereof. The Mo-Si-B / TiN composite coating is composed of a TiN diffusion resistance layer and a Mo-Si-B mixed layer, and the TiN diffusion resistance layer can completely prevent mutual diffusion of elements in the coating and a matrix in the preparation process; and after oxidizing is carried out for 100 hours at the high temperature of 1200-1300 DEG C, the oxidation weight is increased by 0.52 mg / cm<3>-0.78 mg / cm<3>, a crystalline SiO2 and amorphous borosilicate mixed layer is formed on the surface of the Mo-Si-B mixed layer, the Mo-Si-B mixed layer can be prevented from being further oxidized, and the TiN diffusion resisting layer can effectively inhibit mutual diffusion between the Mo-Si-B mixed layer and the matrix in the oxidation process, so that it is guaranteed that the Mo-Si-B / TiN composite coating has enough antioxidant elements, and the anti-oxidation service life of the Mo-Si-B / TiN composite coating can be prolonged.

Owner:BEIHANG UNIV

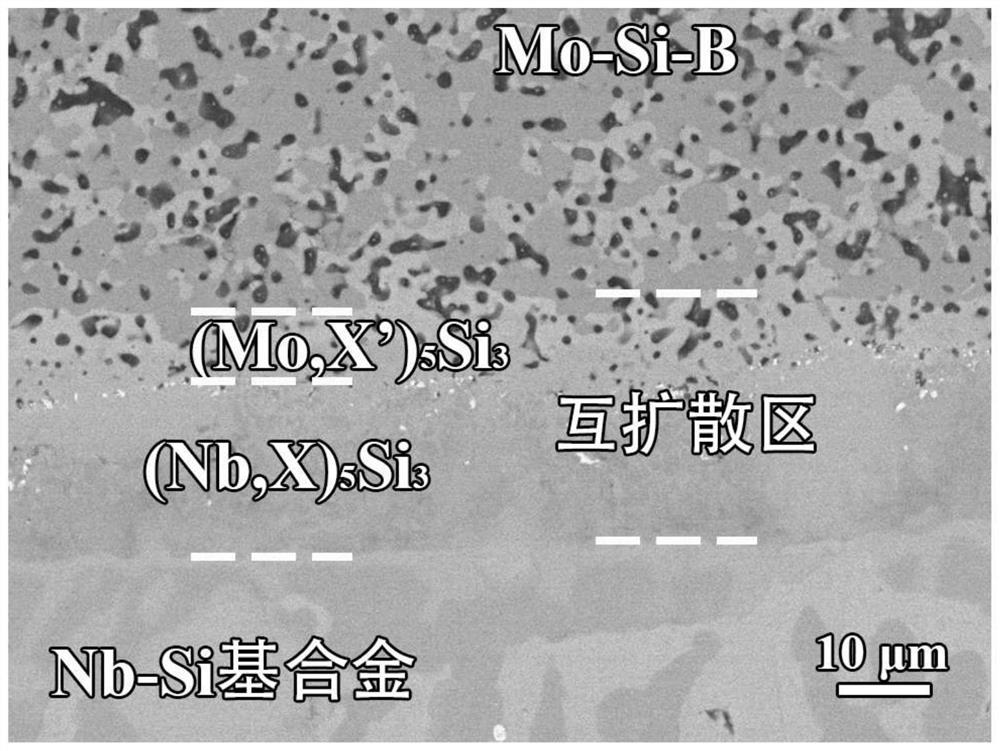

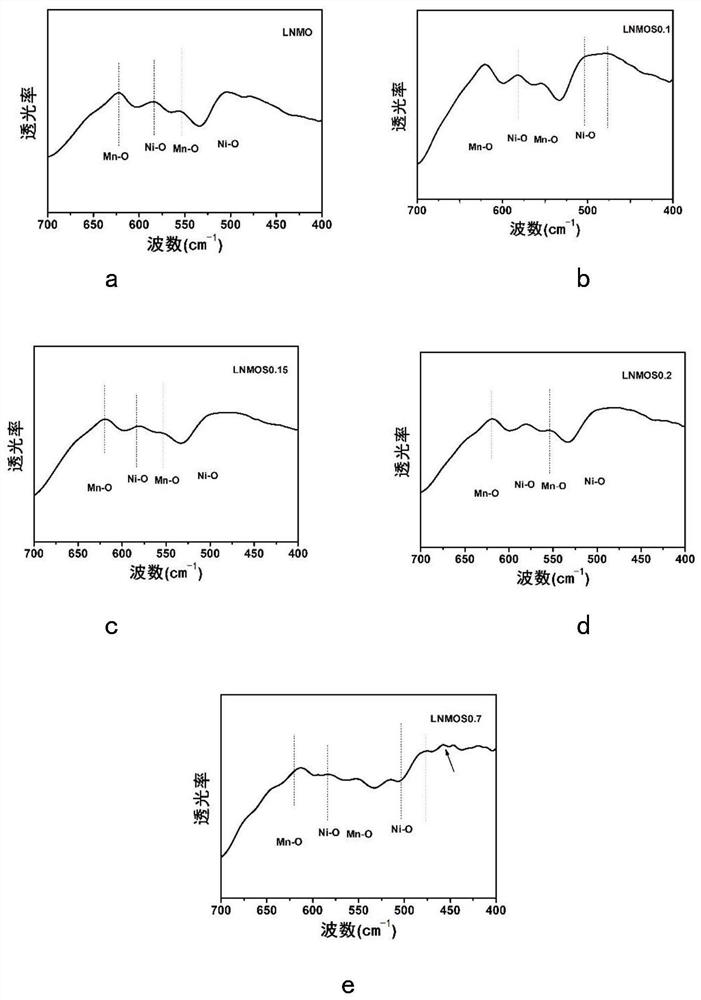

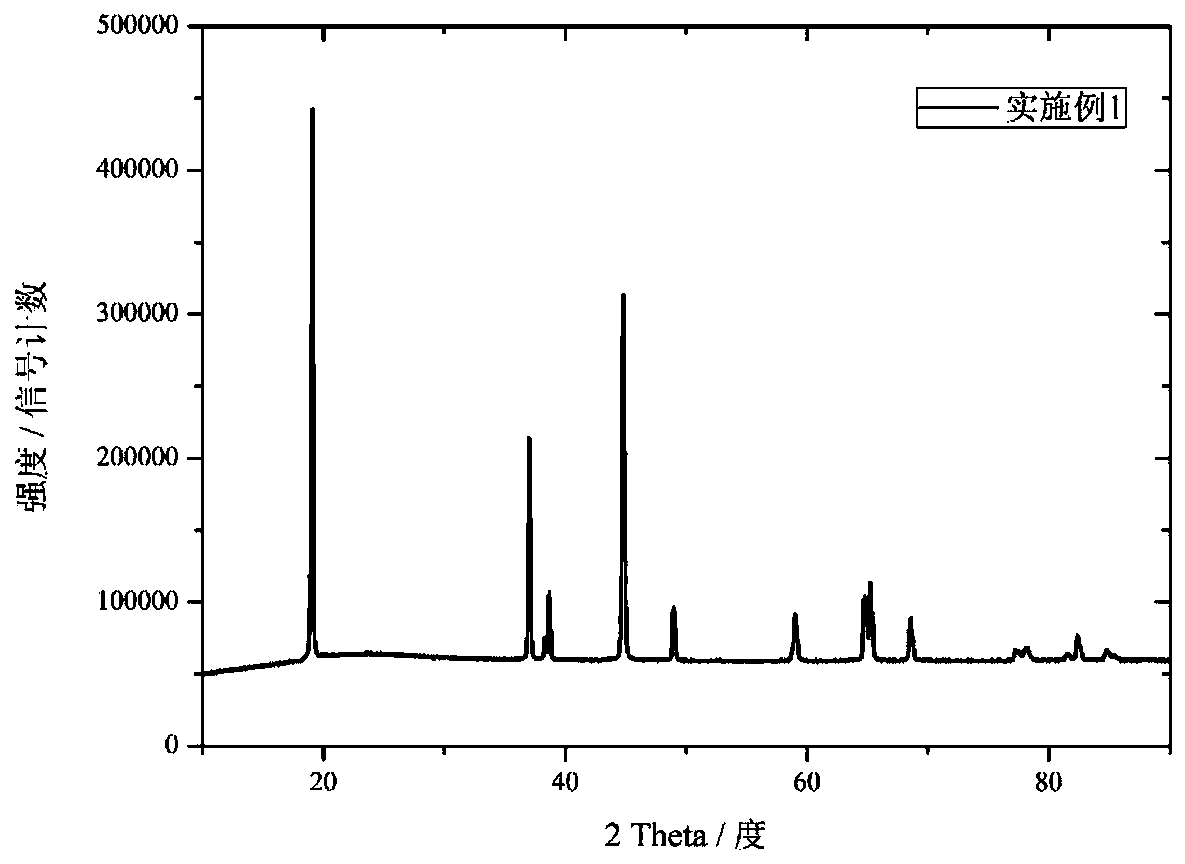

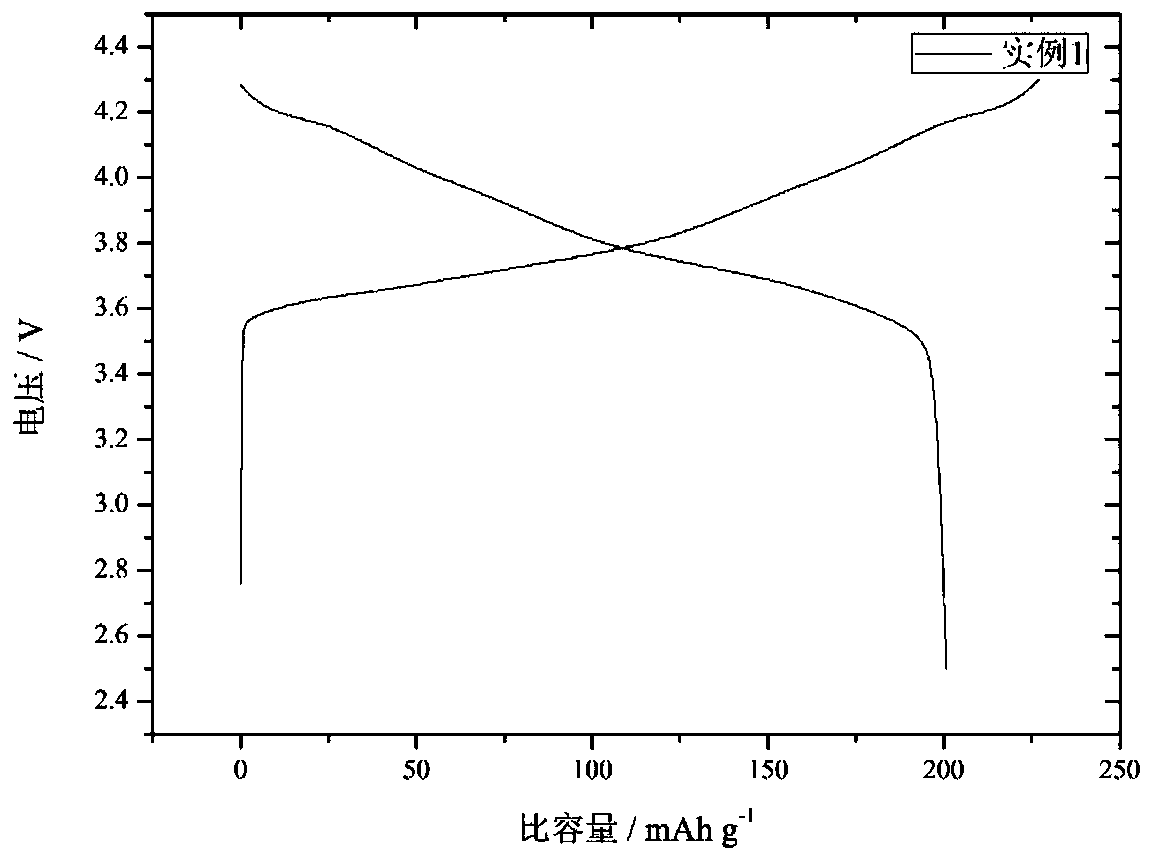

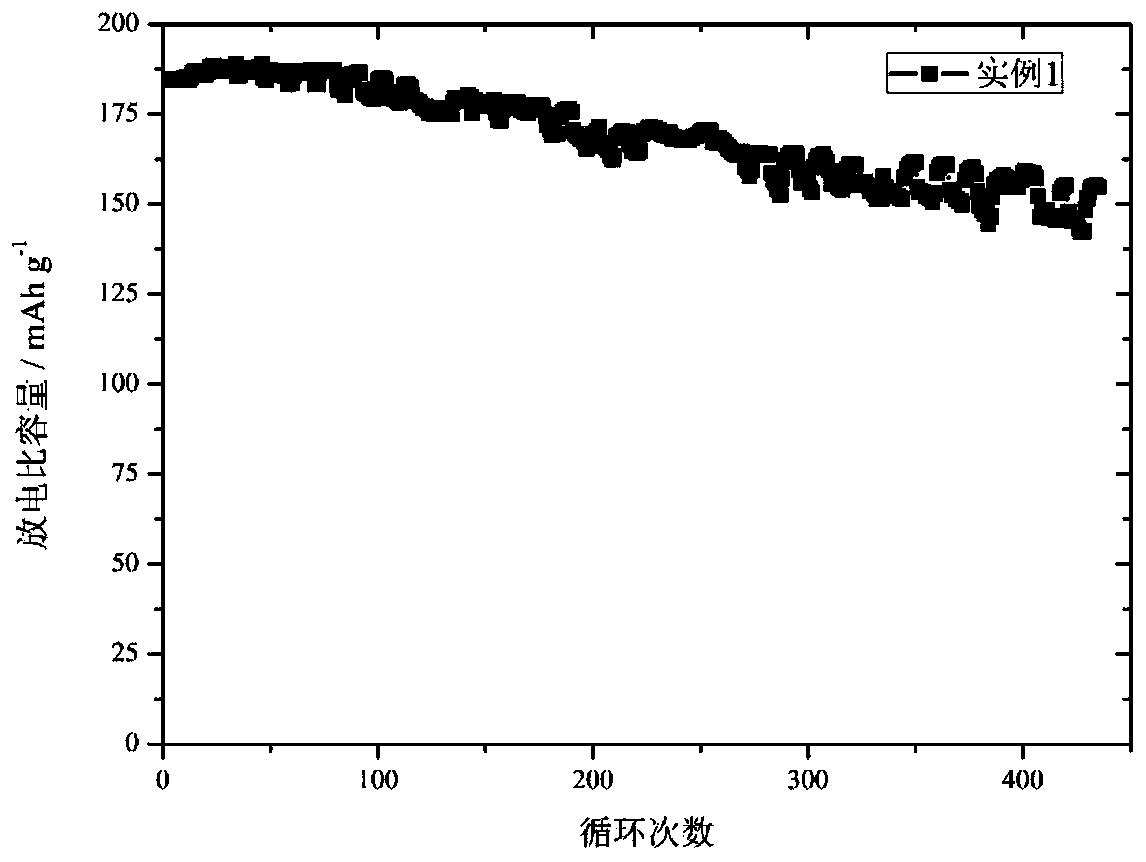

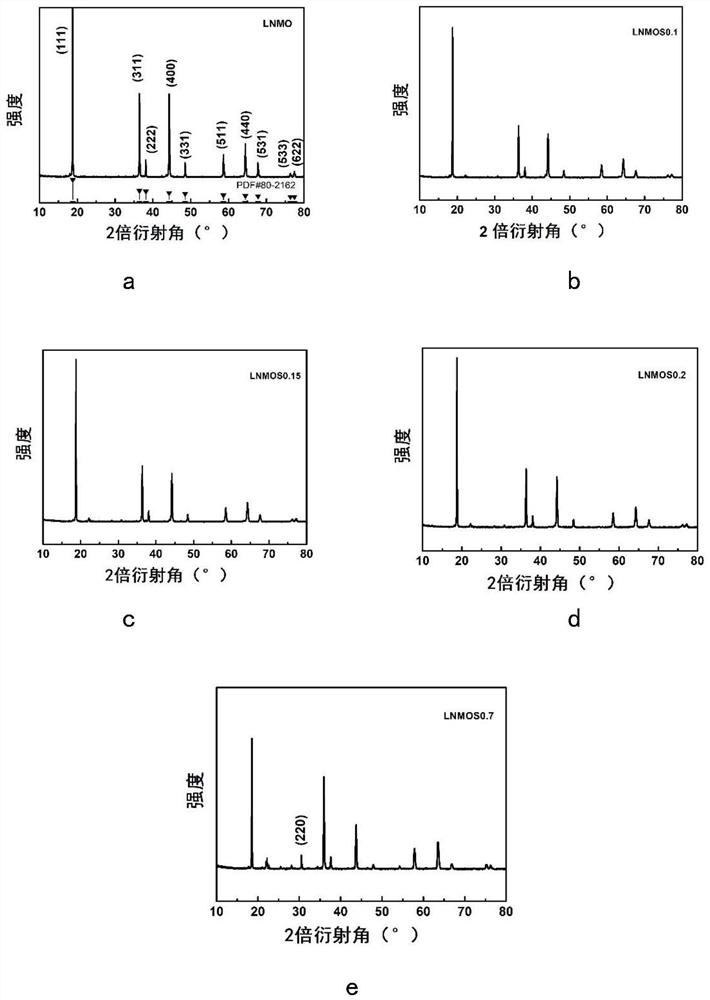

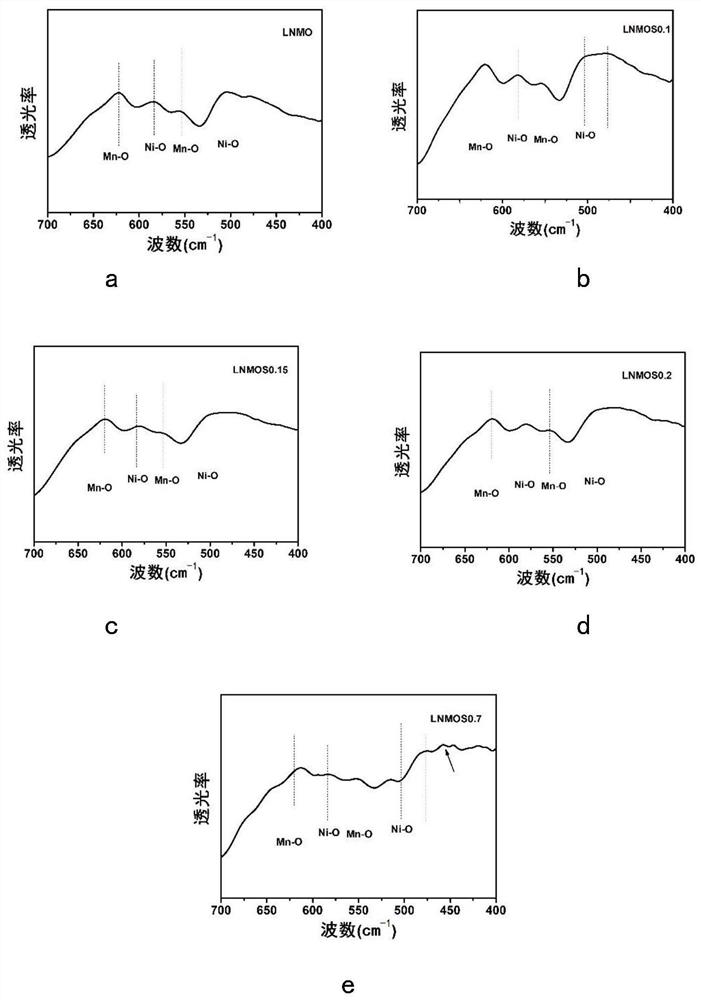

Positive electrode material for improving interface stability of sulfide electrolyte and application

ActiveCN113241435AImprove electrochemical performanceSuppressed interdiffusionSecondary cellsPositive electrodesDopingSulfide

The invention relates to a positive electrode material for improving the interface stability of sulfide electrolyte and application, wherein the chemical general formula of the positive electrode material is Li1-zZzNiaMnbM1cM2dM3eSxO4-x, z is more than or equal to 0 and less than 1, a is more than 0 and less than or equal to 0.5, b is more than 0 and less than or equal to1.5, c is more than or equal to 0 and less than2, d is more than or equal to 0 and less than or equal to 2, e is more than or equal to 0 and less than or equal to 2, x is more than or equal to 0.01 and less than0.65, a + b + c + d + e is equal to 2, Z is a positive ion doped at a Li site, the valence state of Z is +1 valence, M1, M2 and M3 are respectively positive ions doped at transition metal sites, and S is a sulfur element. According to the invention, the doping of the anion S can effectively inhibit the serious space charge layer effect and element mutual diffusion between the sulfurized electrolyte and the layered oxide positive electrode material, and reduce the interface electrochemical side reaction so as to improve the capacity, reducing the interface impedance and optimize the electrochemical performance of the material.

Owner:YANGTZE RIVER DELTA PHYSICS RES CENT CO LTD +2

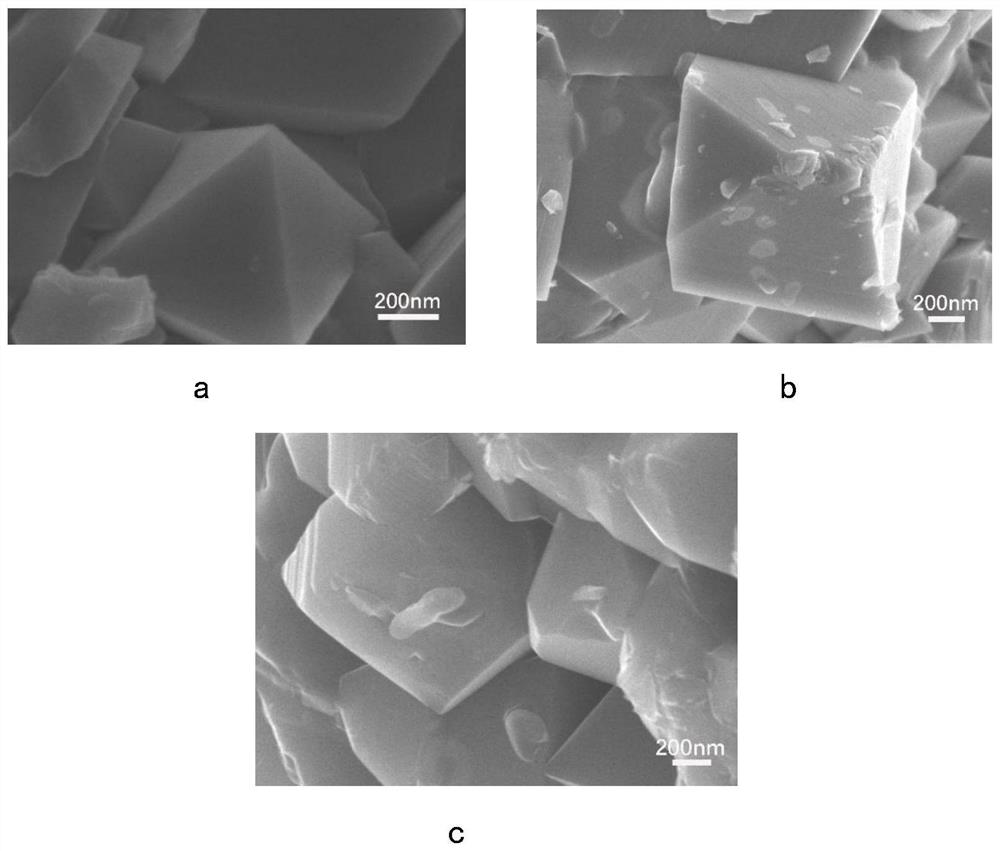

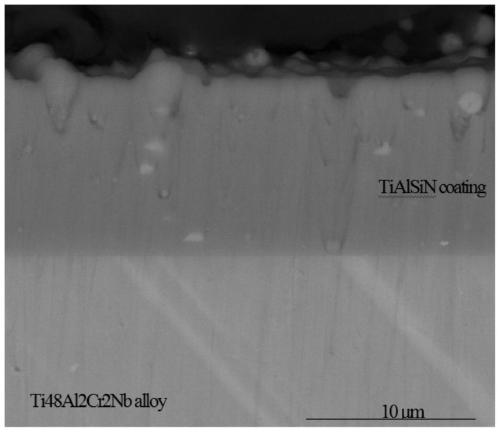

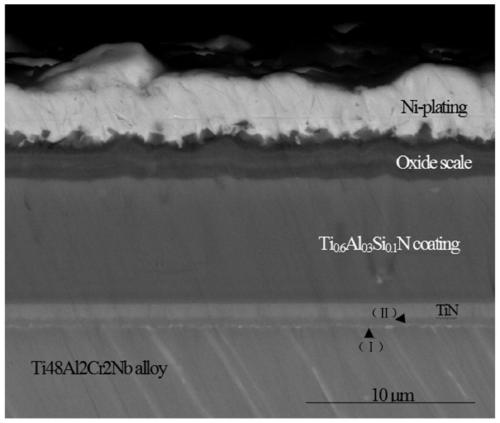

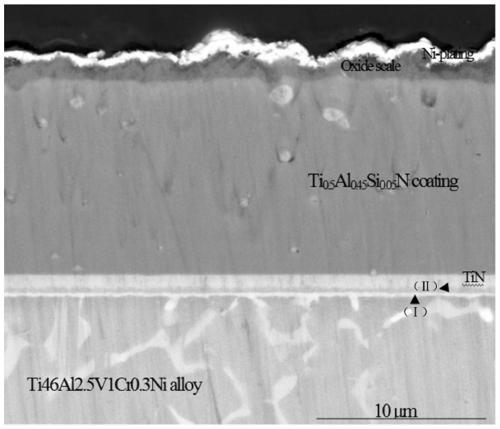

High temperature corrosion and ablation-resistant coating on surface of gamma-TiAl-based alloy and preparation method thereof

InactiveCN111485197AMeet the hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingCoated surfaceDiffusion barrier

The invention discloses a high temperature corrosion and ablation-resistant coating on the surface of a gamma-TiAl-based alloy and a preparation method thereof and belongs to the technical field of protective coatings. The coating is a TiAlSiN or CrAlSiN coating which is prepared by means of a vacuum physical vapor deposition method. A continuous Al2O3 layer can be formed in an oxidization film onthe surface of the coating in a high-temperature thermal exposure process of the coating, so that the coating has relatively good high-temperature oxidization resistance and ablation resistance. Moreover, the coating and a gamma-TiAl-based alloy interface can generate a diffusive barrier layer such as Ti5Si3 in situ at a high temperature, so that counterdiffusion between the coating and the alloyis quite slight and the service life of the coating is prolonged greatly.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of high-nickel ternary material with transition metal element concentration gradient and material prepared by preparation method

ActiveCN111092221ASuppressed interdiffusionPromote crystallizationCell electrodesSecondary cellsNickelRoasting

The invention discloses a preparation method of a high-nickel ternary positive electrode material with a transition metal element concentration gradient. The preparation method is characterized by comprising the following steps of: firstly, carrying out high-speed mechanical fusion on a precursor with a core-shell structure or an element concentration gradient structure and an additive, then mixing with lithium hydroxide, and preparing the high-nickel ternary positive electrode material with transition metal element concentration gradient distribution by controlling particle growth and elementdiffusion in a roasting process. Parameters in the roasting process are optimized, and the purposes of inhibiting abnormal growth of primary particles, inhibiting mutual diffusion of transition metalelements and the like are achieved.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

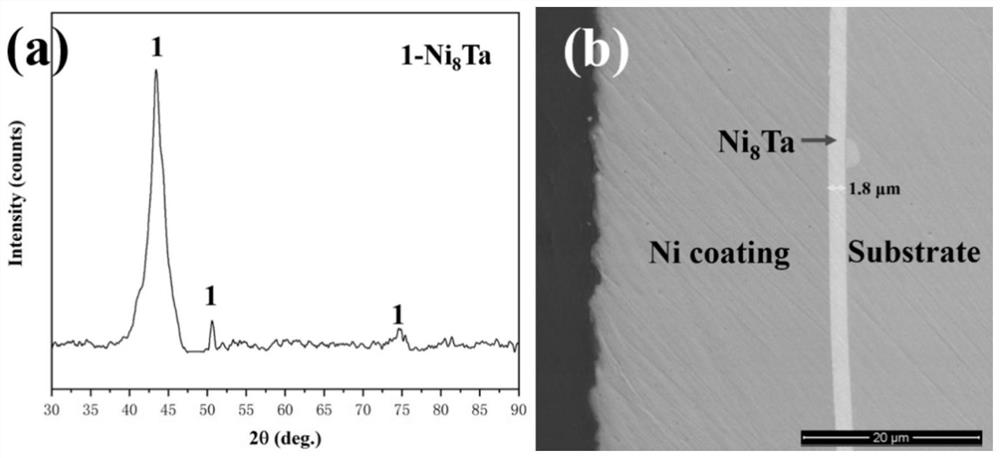

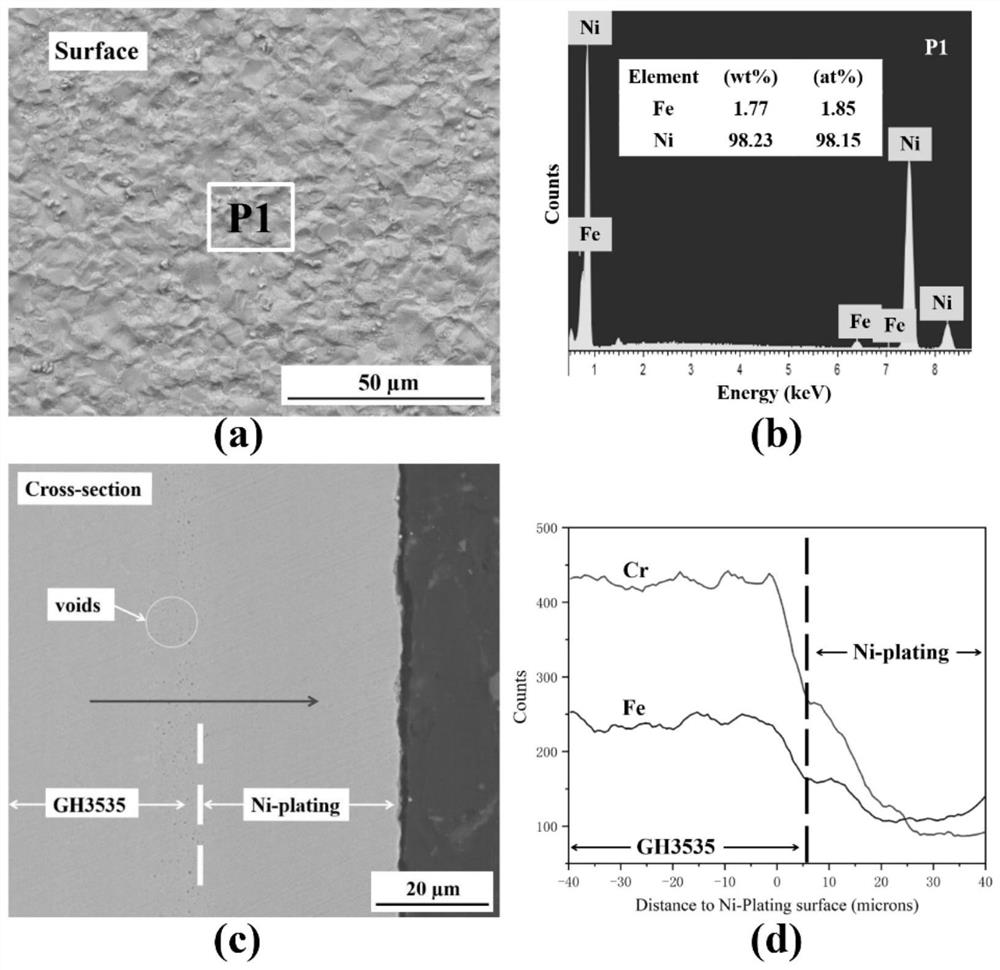

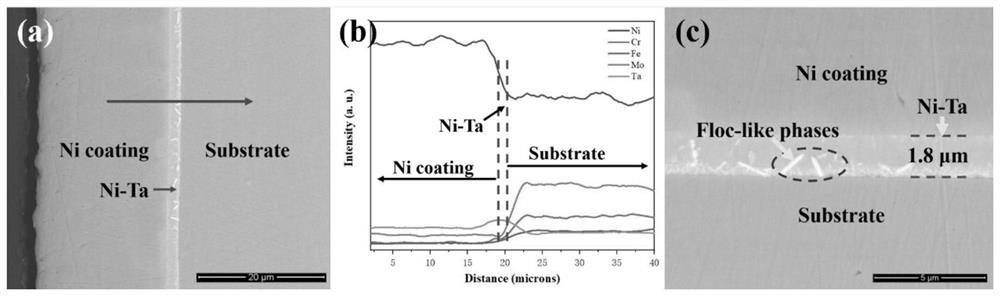

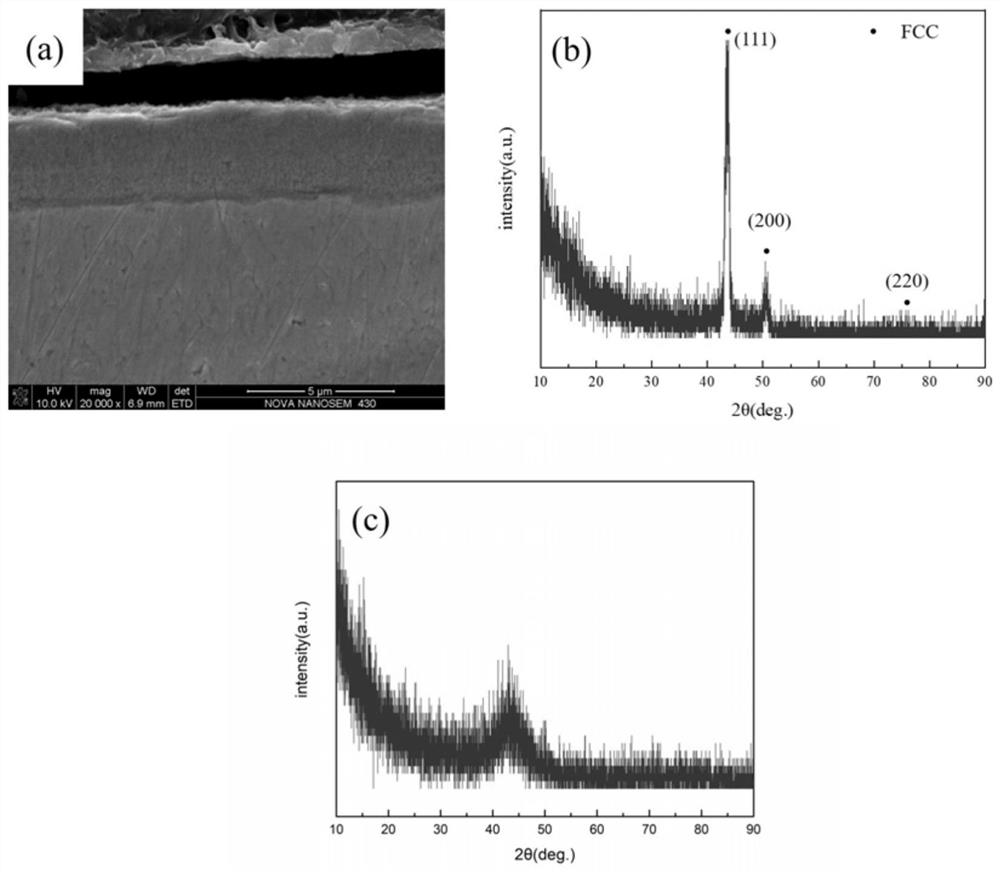

Molten salt corrosion resistant coating containing nickel-tantalum active diffusion barrier layer and preparation method

ActiveCN113106393ASuppressed interdiffusionNo damage to mechanical propertiesVacuum evaporation coatingSputtering coatingChemical platingMolten salt

The invention belongs to a molten salt corrosion resistant protective coating technology, and particularly relates to a molten salt corrosion resistant coating containing a nickel-tantalum active diffusion barrier layer and a preparation method. A high-temperature corrosion-resistant coating on a matrix comprises a nickel-tantalum inner layer and a pure nickel molten salt corrosion-resistant outer layer; and the nickel-tantalum diffusion barrier layer can react with alloy elements to form an intermetallic compound in a use process, can hinder mutual diffusion between the pure nickel outer layer and the matrix, and has good bonding strength. By means of the method for inhibiting mutual diffusion of alloy elements between the coating and the matrix; the service life of the coating can be prolonged; and the mechanical property of the matrix is not damaged. The preparation method comprises the following steps: firstly, preparing the nickel-tantalum layer on the surface of the matrix by using a physical vapor deposition (PVD) method; and then preparing the pure nickel molten salt corrosion resistant protective outer layer by using one or a combination of an electrodeposition preparation method, a physical vapor deposition preparation method and a chemical plating coating preparation method.

Owner:YANTAI UNIV

Diffusion-resistant high-entropy alloy coating material, high-temperature-resistant coating material, preparation method and application thereof

ActiveCN112064024BImprove high temperature oxidation resistanceSmall mechanical propertiesVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a diffusion-resistant high-entropy alloy coating material, a high-temperature-resistant coating material, a preparation method and an application thereof, and relates to the technical field of coating preparation. The diffusion-resistant high-entropy alloy coating material includes a base material and a diffusion-resistant high-entropy alloy coating, and the elements of the diffusion-resistant high-entropy alloy coating include Al, Co, Cr, Ni and Mo. The high-temperature-resistant coating material and its preparation method form the above-mentioned diffusion-resistant high-entropy alloy coating on the substrate, and then use this as the material body to form a high-temperature-resistant coating, and utilize the unique slow diffusion effect of the diffusion-resistant high-entropy alloy coating. And it has good physical and chemical matching with the substrate and the high-temperature resistant coating, which can effectively inhibit the interdiffusion of alloy components between the substrate and the coating and the precipitation of harmful phases at the interface, and improve the high-temperature oxidation resistance of the coating. The high-temperature-resistant coating material can be applied in the preparation of hot-end parts of aero-engines or gas turbines, thereby improving the service life and working reliability of the parts.

Owner:GUANGDONG INST OF NEW MATERIALS

Cathode materials and applications for improving the interfacial stability of sulfide electrolytes

ActiveCN113241435BImprove electrochemical performanceImprove Interface StabilitySecondary cellsPositive electrodesInterface impedanceSulfide

The invention relates to a positive electrode material and application for improving the interface stability of a sulfide electrolyte. The general chemical formula of the cathode material is: Li 1‑z Z z Ni a mn b M1 c M2 d M3 e S x o 4‑x ; where 0≤z<1, 0<a≤0.5, 0<b≤1.5, 0≤c<2, 0≤d≤2, 0≤e≤2, 0.01≤x<0.65, a+b+c+ d+e=2; wherein, Z is a cation doped with a Li site, and the valence is +1; M1, M2, and M3 are respectively cations doped with a transition metal site; S is sulfur. The doping of anion S can effectively suppress the serious space charge layer effect and interdiffusion of elements between the sulfurized electrolyte and the layered oxide cathode material, reduce the electrochemical side reaction at the interface, thereby increasing the capacity, reducing the interface impedance, and optimizing the electrical conductivity of the material. chemical properties.

Owner:YANGTZE RIVER DELTA PHYSICS RES CENT CO LTD +2

Non-aluminium 1.3 micron indium arsenic/gallium arsenic quantum point laser

InactiveCN100364193CRaise the characteristic temperatureIncreased limit barrierLaser detailsSemiconductor lasersIndiumQuantum dot

This invention relates to a 1.3mum InAs / GaAs quantum dot laser without Al including a chip, a buffer layer processed on the chip, a lower cladding made on the buffer layer, a lower waveguide layer set on the lower cladding, a quantum dot active region set on the lower waveguide layer, an upper waveguide layer prepared on the active region of the quantum dot, an upper cladding prepared on the upper waveguide layer under low temperature, a contact layer prepared on the upper cladding. Since high quality of the InGaP can be got under low growing temperature, the blue shift of the quantum dots is controlled effectively in the growing process of the cladding.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Ultraviolet semiconductor light-emitting device and manufacturing method thereof

ActiveCN104810455BReduce thermal resistanceHigh light efficiencySemiconductor devicesQuantum efficiencyNanoparticle

The invention discloses an ultraviolet semiconductor light emitting device and a manufacturing method thereof. The device comprises an epitaxial layer composed of an n-type layer, a quantum well layer and a p-type layer, a p-type electrode and an n-type electrode. The p-type layer is further provided with a graphene-Ag nanocomposite layer and a conductive reflecting layer sequentially, and the graphene-Ag nanocomposite layer and the p-type layer are in ohmic contact. Furthermore, the graphene-Ag nanocomposite layer includes an Ag nano material layer formed on the p-type layer, and the Ag nano material layer comprises Ag nano points and / or Ag nano lines and a graphene film covering the Ag nano material layer; or, graphene quantum points load an Ag nanoparticle composite layer. The device has the advantages of high external quantum efficiency, high light emitting efficiency, low start voltage, fine heat radiation and high stability, the manufacturing process is simple and controllable, cost is low, and the device is adaptive to industrial production.

Owner:NANJING UNIV

Composite cermet coating for superalloy protection and preparation method thereof

ActiveCN108796461BHigh coefficient of thermal expansionImprove peel performanceVacuum evaporation coatingSputtering coatingThermal dilatationSputtering

The invention discloses a composite metal ceramic coating for high-temperature alloy protection and a preparing method of the composite metal ceramic coating. The coating comprises a face layer and abottom layer with a nano columnar crystal structure. The face layer comprises at least two metal ceramic sub layers, and a metal parent phase and a dispersed distribution nitride ceramic phase are specifically included. In the direction from the surface of the composite metal ceramic coating to an alloy matrix, the doping amount of the nitride ceramic phase is gradually reduced, and the distribution interval of the volume fraction of the nitride ceramic phase is 0.1-60%. According to the preparing method of the coating, magnetic control sputtering is adopted for preparing a bottom layer coating, and then, non-balance reaction magnetic control sputtering is utilized for preparing the face layer of the doped ceramic phase. Through the structure, the heat expansion coefficient of the coatingis gradually increased from top to bottom, jumping changes of the heat expansion coefficient on the coating / oxide film interface are reduced, accordingly, the heat stress in an oxide film in the heatcirculation process is relieved, and the capability of oxide film peeling resisting of the coating in the heat circulation is enhanced.

Owner:JINAN UNIVERSITY

Method for prolonging service life of thermal barrier coating based on platinum-aluminum bonding layer

PendingCN114059066ASuppressed interdiffusionExtend service timeSolid state diffusion coatingSuperimposed coating processCoated surfacePlatinum

The invention discloses a method for prolonging the service life of a thermal barrier coating based on a platinum-aluminum bonding layer, and belongs to the technical field of high-temperature protective coatings. Through a pre-oxidation method, a layer of TGO oxidation film is prepared on the surface of a platinum-aluminum coating in advance to serve as a bottom bonding layer of a TBC coating. The platinum-aluminum coating bonding layer is bonded with a TBCs thermal barrier coating top layer YSZ mainly depending on an oxide film TGO generated on the surface, the thickness increase of the TGO oxide film is in a parabolic growth mode due to the diffusion rate of O and Al atoms, and when the TGO cracks and falls off due to stress concentration generated by the thickness increase of the TGO, the TBC coating loses efficacy. Due to the fact that a layer of compact oxidation film TGO can be generated on the surface of the platinum-aluminum bonding layer in advance through a low-pressure pre-oxidation technology, the growth speed of the TGO is slowed down, and the service life of the TBCs thermal barrier coating can be prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A high-temperature coating comprising an active diffusion barrier layer of zirconia and its preparation method

ActiveCN103342016BImprove the bonding strength of the interfaceHigh strengthMetal layered productsElectron beam physical vapor depositionThermal spraying

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Thermal barrier coating for inhibiting matrix/thermal barrier coating bonding layer element mutual diffusion

PendingCN114058999ASuppressed interdiffusionPerformance is not affectedMolten spray coatingBond coatGas turbines

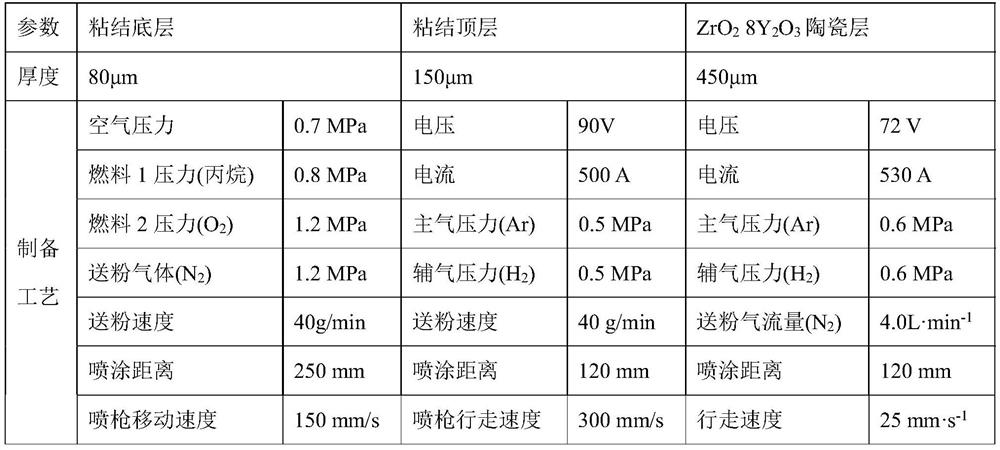

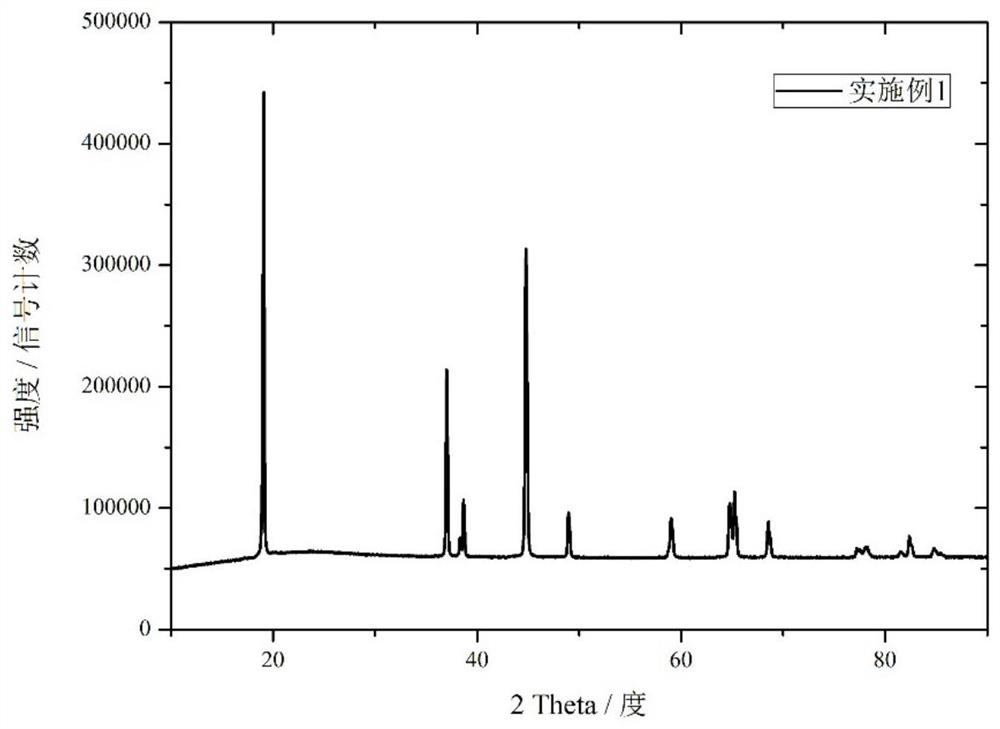

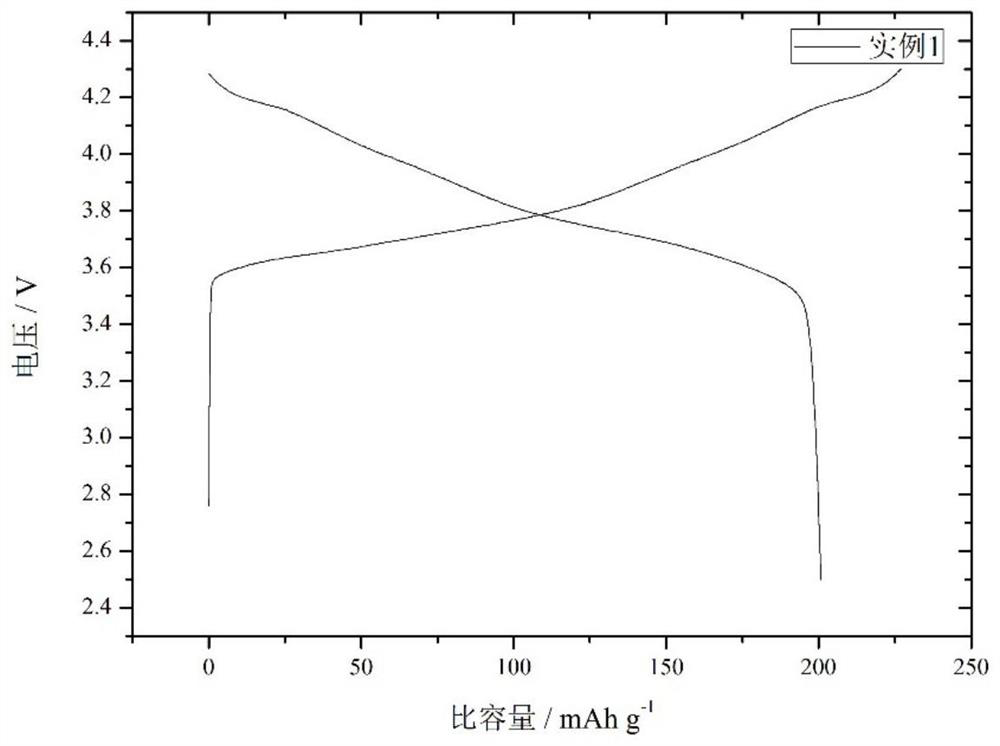

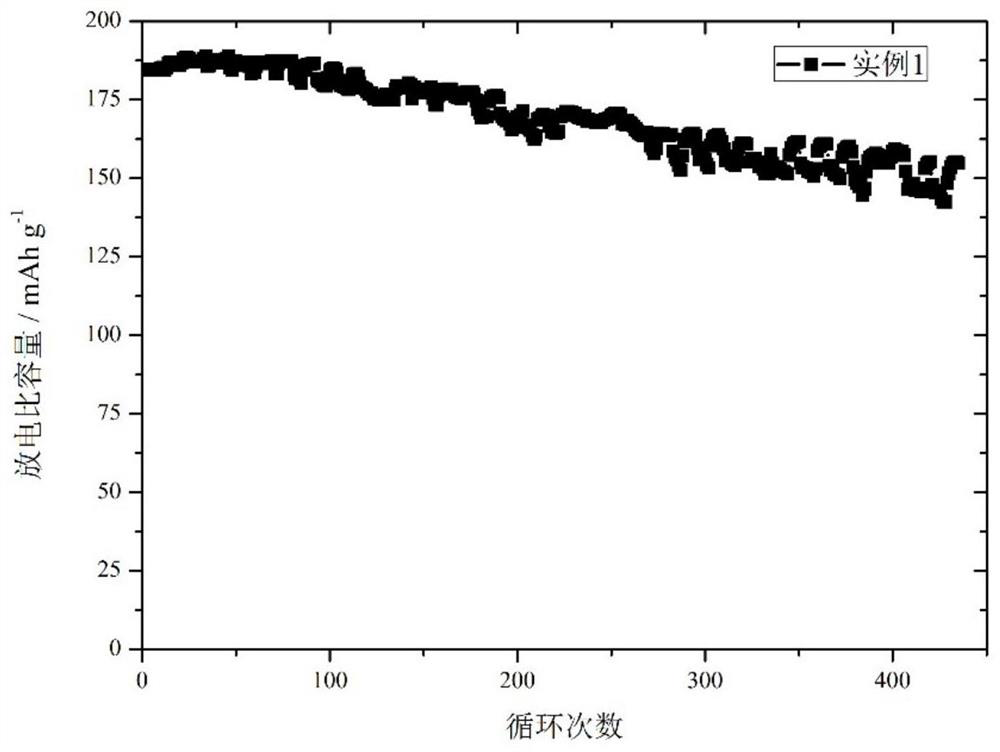

The invention discloses a thermal barrier coating for inhibiting matrix / thermal barrier coating bonding layer element mutual diffusion, which comprises an MCrAlY metal bonding layer and a ZrO2-6-8Y2O3 ceramic layer which are sequentially arranged on a matrix from inside to outside, and M is Ni or Co or Ni + Co; the metal bonding layer is composed of a bottom bonding layer and a top bonding layer, the components of the bottom bonding layer are completely the same as the components of the matrix, and the elements have no concentration gradient; the top bonding layer is MCrAlY, and the content of Al and Cr elements is higher than that of a base body. According to the thermal barrier coating, mutual diffusion of bonding layer / matrix elements in a traditional coating is effectively avoided, the production process is simple, efficiency is high, performance is excellent and stable, and the thermal barrier coating is suitable for being applied to hot end components of aero-engines and gas turbines on a large scale.

Owner:XIAN THERMAL POWER RES INST CO LTD

A preparation method of a high-nickel ternary material with a transition metal element concentration gradient and the prepared material

ActiveCN111092221BSuppressed interdiffusionPromote crystallizationCell electrodesSecondary cellsParticle growthRoasting

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

A kind of rare earth series t/ebc ceramic matrix composite environmental barrier coating and preparation method thereof

ActiveCN107032831BGood resistance to high temperature water and oxygen corrosionProtective serviceBlade accessoriesMachines/enginesMulliteRare earth

The invention relates to a rare-earth-based T / EBC ceramic matrix composite environmental barrier coating and a preparation method thereof. A ceramic matrix is made of a silicon carbide fiber reinforcement silicon carbide ceramic matrix composite material, the environmental barrier coating sequentially comprises a water oxygen corrosion resistant layer, a chemical barrier layer, an energy dissipation layer and a thermal protecting and shielding layer from inside to outside, and the water oxygen corrosion resistant layer is prepared on the surface of the ceramic matrix, wherein materials of the water oxygen corrosion resistant layer comprise mullite and lutetium orthosilicate; a material of the chemical barrier layer comprises zirconium nitride; a material of the energy dissipation layer comprises yttrium aluminum garnet; a material of the thermal protecting and shielding layer comprises lanthanum zirconate. The ceramic matrix composite environmental barrier coating has excellent comprehensive performance, the interfacial strength, fracture toughness and hardness of the coating can be improved, the service life of the coating is significantly prolonged, the thermal conductivity of the coating is reduced, and therefore the Sicf / Sic ceramic matrix can keep stable in comprehensive performance after recycling utilization for multiple circles under the high-temperature environment of 1900 k or above.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com