Thermal barrier coating for inhibiting matrix/thermal barrier coating bonding layer element mutual diffusion

A technology of thermal barrier coating and bonding layer, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of reducing the service life of thermal barrier coating system, increasing the mutual diffusion rate, affecting the performance of the substrate, etc. , to achieve the effect of improving high temperature oxidation resistance, ensuring service life and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

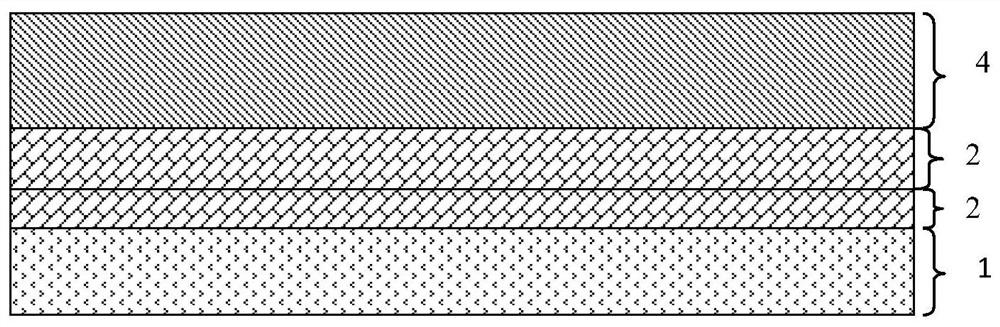

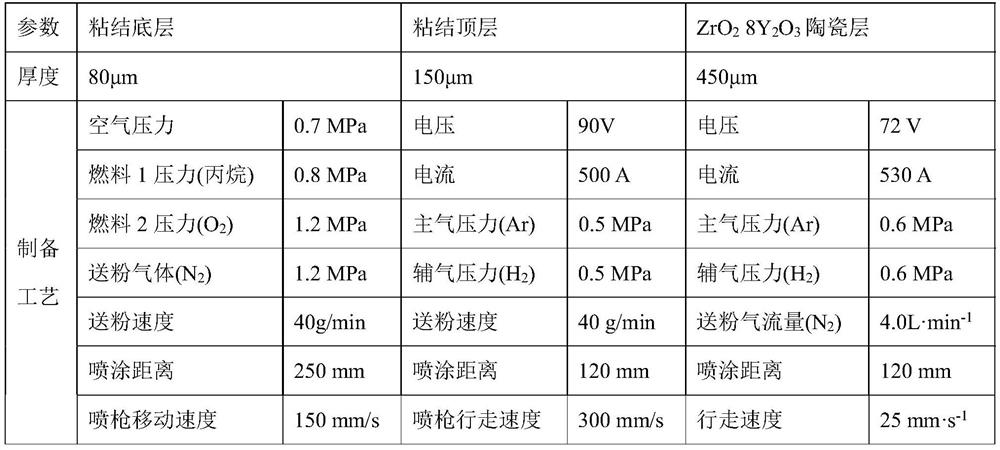

[0024] The matrix alloys of the two thermal barrier coatings in this embodiment are both DZ411 nickel-based superalloys, and the sample size is 30mm×10mm×1.5mm. Wherein thermal barrier coating 1 is the thermal barrier coating system designed by the present invention, adopts ZrO 2 8Y 2 o 3 (Metco204NS) ceramic powder is used as the raw material of the ceramic layer, Ni23Co17Cr12Al0.5Y (Amdry 365-1) nickel-based superalloy powder is used as the raw material of the top bonding layer, and Co in the raw material of the bottom bonding layer: 9.00~10.0wt .%, Al: 2.8-3.4wt.%, Cr: 13.5-14.3wt.%, Y: 0.5wt.%, and Ni is the balance. Thermal barrier coating 2 is a traditional thermal barrier coating system (only one bonding layer), using ZrO 2 8Y 2 o 3 (Metco 204NS) ceramic powder is used as the original material of the ceramic layer, and Ni23Co17Cr12Al0.5Y (Amdry 365-1) nickel-based superalloy powder is used as the original material of the bonding layer. The thickness and preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com