A high-temperature coating comprising an active diffusion barrier layer of zirconia and its preparation method

A zirconia, high-temperature technology, applied in chemical instruments and methods, layered products, metal layered products, etc., can solve the problems of anti-oxidation coatings that have not been reported yet, and achieve excellent thermal stability, high thermal stability, The effect of avoiding the deterioration of the mechanical properties of the matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

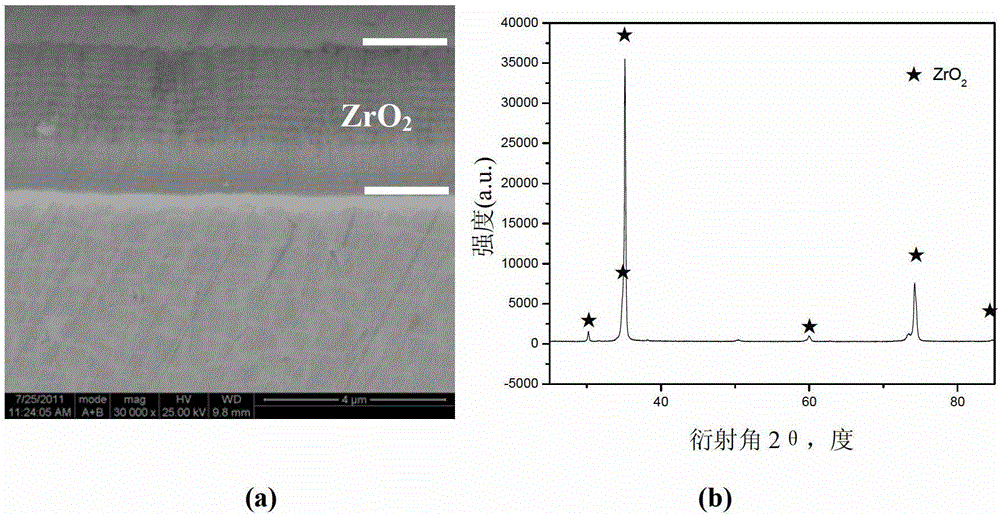

[0033] The substrate is DZ40M alloy, the substrate sample is 15mm×10mm×2.5mm, and the purity of the zirconia target is 99.95wt%. The matrix sample is loaded into the working room after surface cleaning; the working room is vacuumed to 3×10 -2 ~7×10 -2 Pa, heat the substrate with a heating gun, and start evaporating the target after the temperature of the substrate sample reaches 700-800°C. 3 μm. In this embodiment, the chemical composition and content of the zirconia inner layer are as follows: the zirconia content is 99.95wt%, and the rest is hafnium oxide.

[0034] Observing the cross-section of the deposited zirconia film, it can be seen that the structure of the film layer is dense and well combined with the alloy matrix, such as figure 1 Shown in a; X-ray diffraction analysis shows that its crystal form is a tetragonal structure, and the results are as follows figure 1 as shown in b.

Embodiment 2

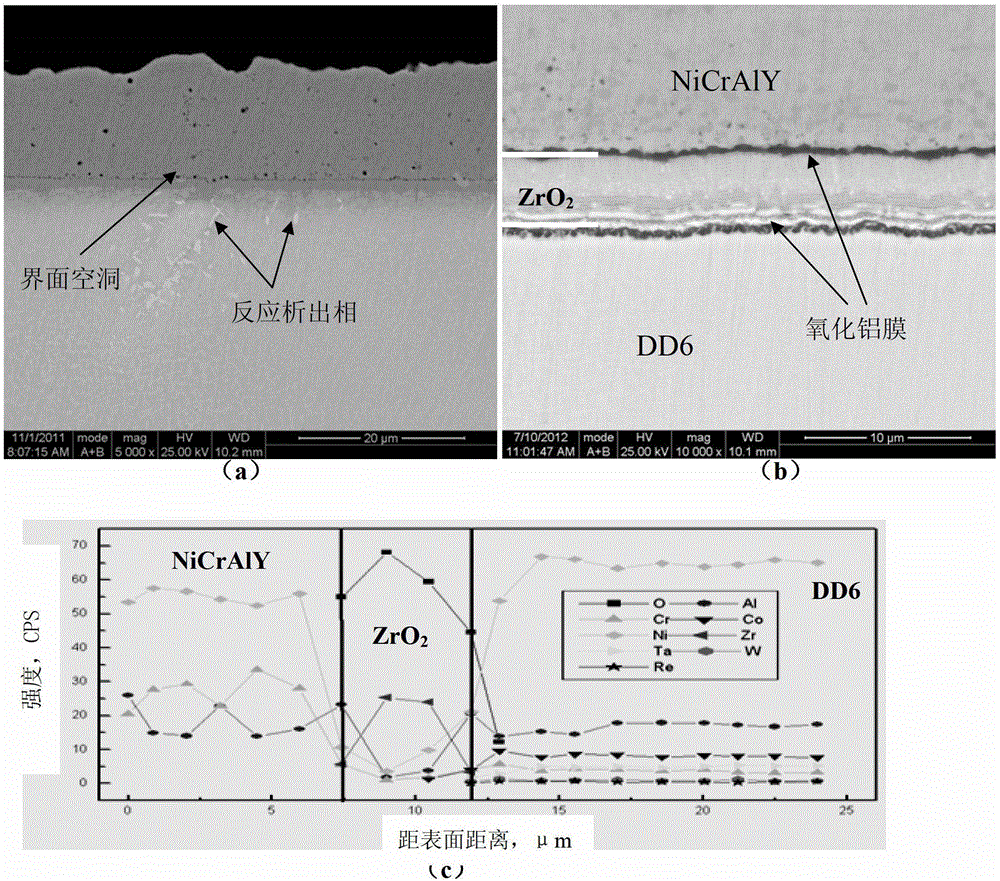

[0036] The substrate is DD6 superalloy, the substrate sample is 15mm×10mm×2.5mm, and the target is 6-10wt% yttria-stabilized zirconia. After the substrate sample is cleaned on the surface, it is loaded into the working room, and the working room is vacuumed to 7×10 -2 ~1.2×10 -1 Pa, heat the substrate with a heat gun, and start evaporating the target after the temperature of the substrate sample reaches 800-850°C. 4 μm. In this embodiment, the chemical composition and content of the zirconia inner layer are: 90wt% zirconia, and the rest is yttrium oxide. Using multi-arc ion plating technology to deposit a layer of NiCrAlY (Ni-25Cr-11Al-0.5Y, wt%) coating with a thickness of 20-30 μm on zirconia, the preparation parameters are Ar gas pressure 0.1-0.2Pa, substrate temperature 200 ~250℃, arc current 65~75A, DC bias voltage -10~-20V, duty cycle 20%, deposition for about 400min. Subsequently, the substrate / coating system was oxidized at 970° C. for 5 hours.

[0037] The cross-...

Embodiment 3

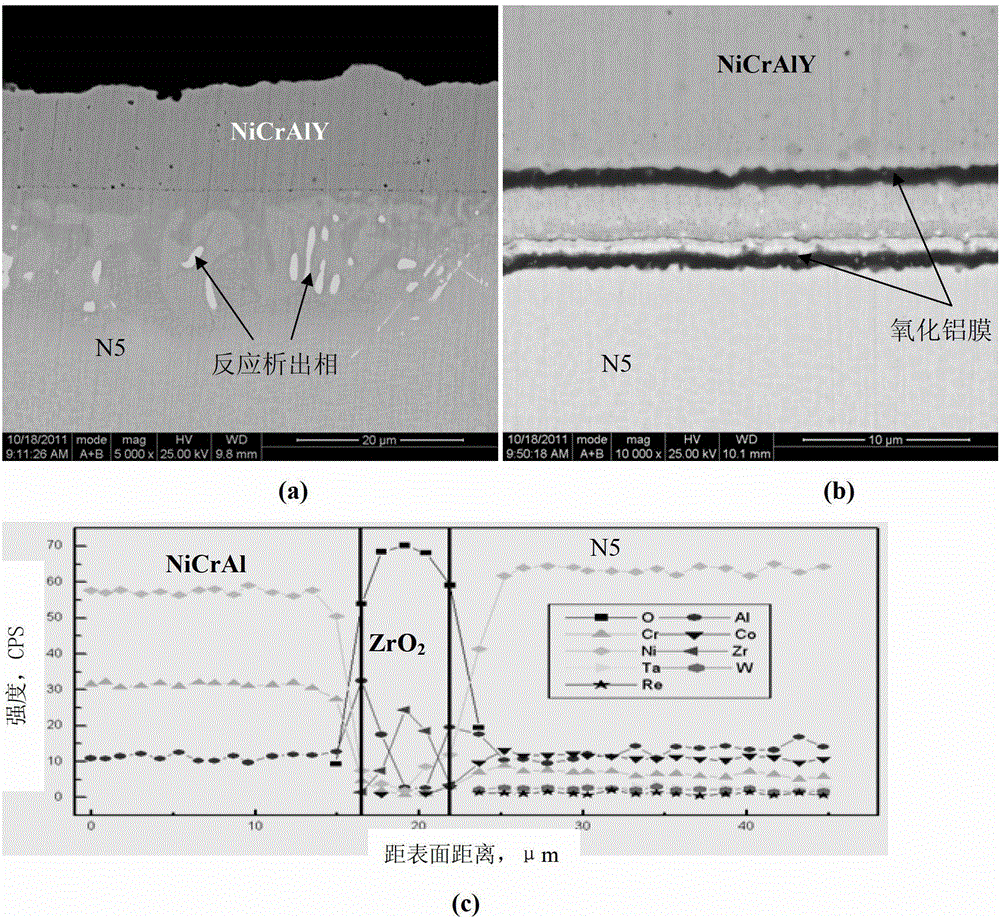

[0039] The substrate is made of ReneN5 superalloy, the substrate sample is 15mm×10mm×2.5mm, and the target material is zirconia stabilized with 6-10wt% hafnium oxide. The matrix sample is loaded into the working room after surface cleaning; the working room is vacuumed to 8×10 -2 ~2×10 -1 Pa, heat the substrate with a heat gun, and start evaporating the target after the temperature of the substrate sample reaches 850-900°C, the voltage of the evaporation gun is 17-24kV, the evaporation current is 1.6-2A, the deposition time is about 1min, and the thickness of the zirconia film is about 3μm ; In this embodiment, the chemical composition and content of the inner layer of zirconia are: 90wt% zirconia, and the rest is hafnium oxide. A layer of NiCoCrAlY (Ni-20Co-25Cr-11Al-0.5Y, wt%) coating with a thickness of 20-30 μm was deposited on zirconia by multi-arc ion plating technology. Subsequently, the substrate / coating system was oxidized at 1000°C for 100 hours.

[0040] The cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com