Method for prolonging service life of thermal barrier coating based on platinum-aluminum bonding layer

A technology of thermal barrier coating and bonding layer, which is applied in the direction of coating, superimposed layer plating, metal material coating process, etc., can solve the problem of film and ceramic coating peeling off, etc., to improve life and prolong service time , anti-oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The base material is directionally solidified nickel-based superalloy DD5.

[0038] Its chemical composition is as follows (mass percentage): Co: 7.5%, Cr: 7%, W: 5%, Mo: 1.5%, Al: 6.2%, Ta: 6.5%, Re: 3%, Ni: the balance. The DD5 superalloy rod with a diameter of 13mm is processed into a disc with a thickness of 2mm by wire cutting, and a round hole of Φ3mm is cut in the middle of the top of the disc to facilitate the suspension during electroplating and vapor deposition.

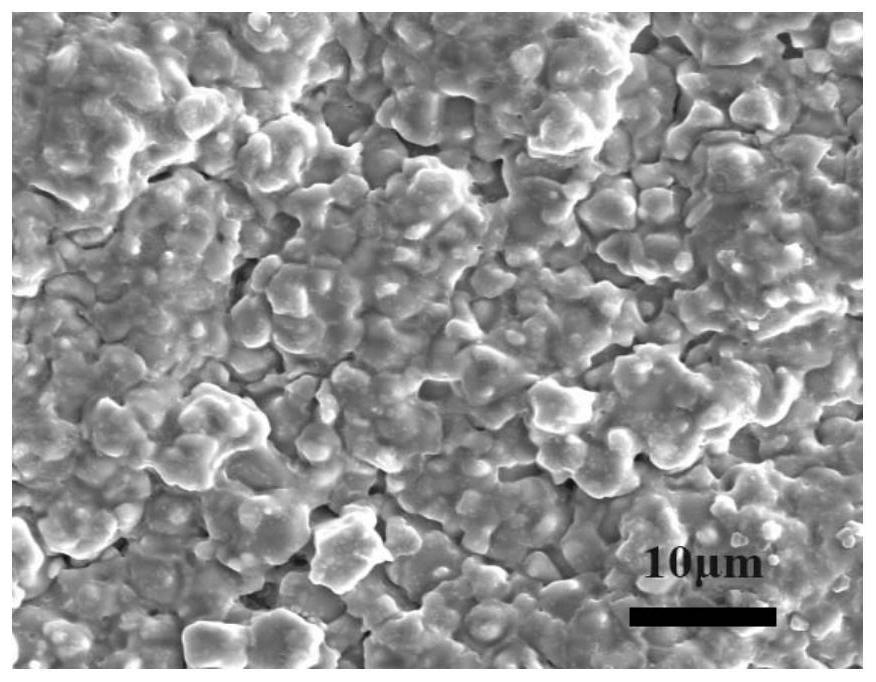

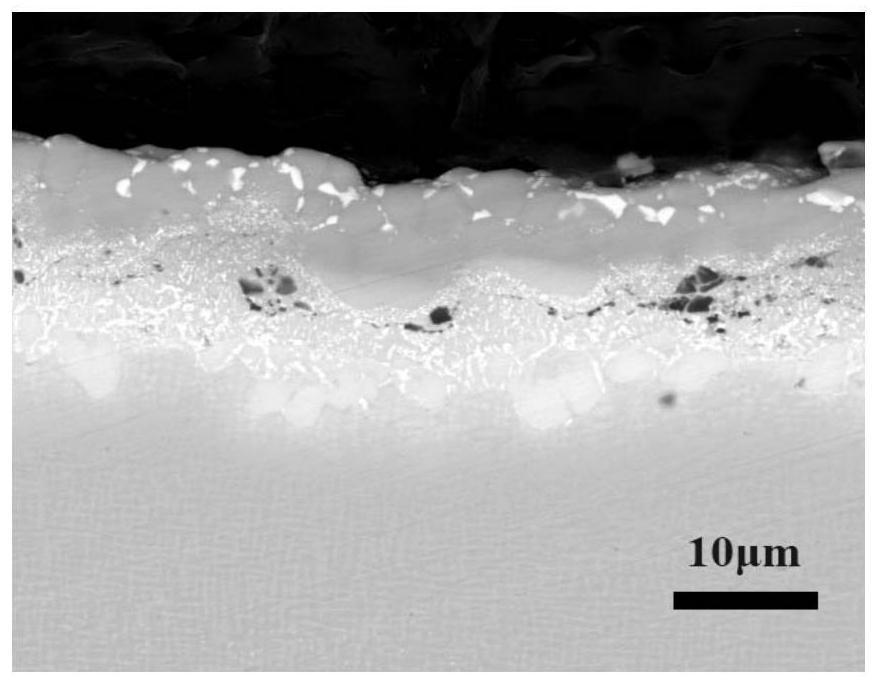

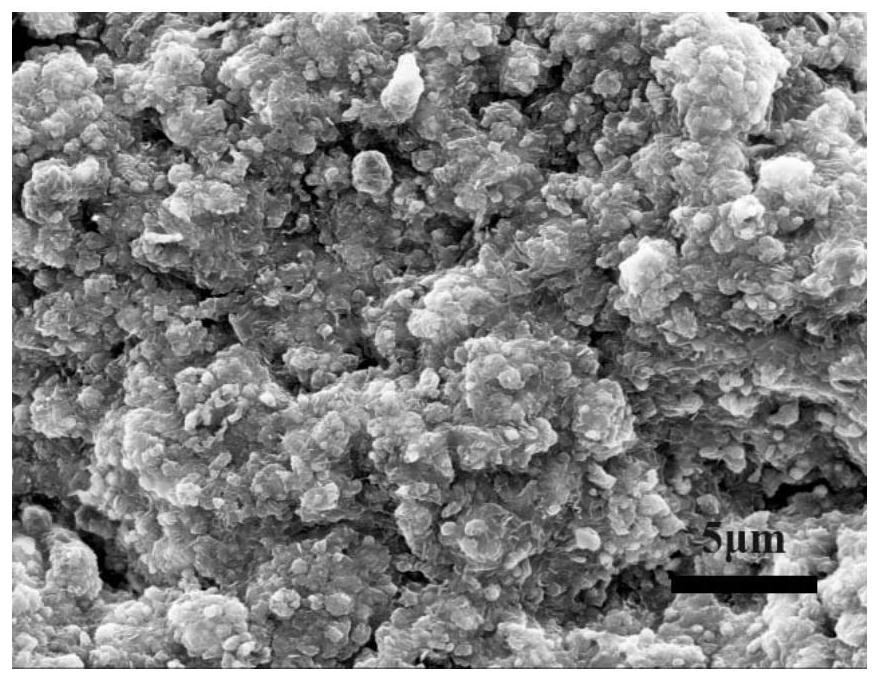

[0039] The platinum layer was prepared by electroplating, and then aluminum ions were introduced by CVD. The prepared platinum-aluminum coating was 30 μm, and the surface and cross-sectional morphology were as follows: figure 1 and figure 2 shown. The content of Pt at 1 / 3 of the outer layer of the platinum-aluminum coating is 10-40wt%, the content of Ni is 30-40wt%, and the content of Al is 20-40wt%.

[0040] Put the prepared platinum-aluminum-coated alloy sample into the tube furnace, and inject...

Embodiment 2

[0047] The substrate is made of DD5 superalloy, and the superalloy rod with a diameter of 13 mm is processed into a disc with a thickness of 2 mm by wire cutting, and a round hole of Φ3 mm is cut in the middle of the top of the disc to facilitate the process of electroplating and vapor deposition suspension.

[0048] A 30 μm platinum-aluminum coating was prepared by electroplating and chemical vapor deposition, the surface and cross-section are as follows figure 1 and figure 2 shown;

[0049] In the tube furnace, argon gas is used to wash the furnace. After the washing is completed, vacuum is carried out. When the pressure in the furnace reaches 1.5×10 -1 At Pa, start heating to 900°C at a speed of 10-15°C / min;

[0050] After reaching the temperature, feed 99.99% pure oxygen with a flow rate of 35ml / min, and keep it at 900°C for 5 hours for oxidation, and the pressure in the furnace is about 15Pa at this time;

[0051] After the oxidation is finished, stop feeding oxygen,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com