Non-aluminium 1.3 micron indium arsenic/gallium arsenic quantum point laser

A quantum dot and laser technology, applied in the field of aluminum-free 1.3μm indium arsenide/gallium arsenide quantum dot lasers, can solve the problems of deterioration of QDs laser temperature characteristics, lowering of limiting barriers, device application limitations, etc., to achieve low defect concentration and Effect of Surface Recombination Rate, Interdiffusion Inhibition, and Device Quality Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

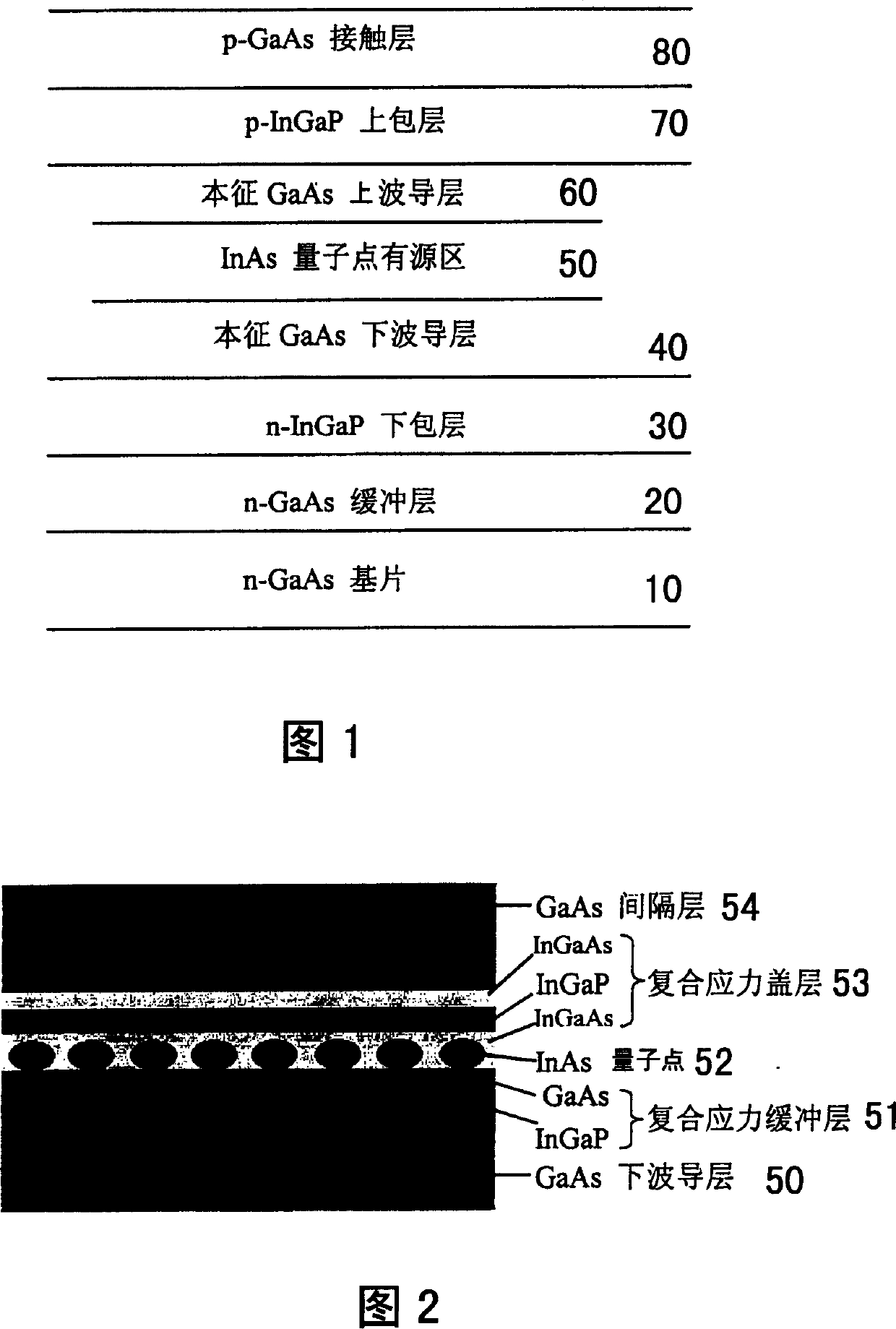

[0052] See Figure 1 and Figure 2:

[0053]1) The washed GaAs substrate 10 is placed in an MOCVD reaction chamber, and a GaAs buffer layer 20 of about 500 nanometers is grown (the reaction chamber temperature is 600 degrees Celsius);

[0054] 2) On the GaAs buffer layer 20, grow n-doped indium gallium phosphide (In 0.49 Ga 0.51 P) The lower cladding layer 30 is grown at a temperature of 530-570 degrees Celsius, and then a 100 nm undoped GaAs lower waveguide layer 40 is grown at the same temperature.

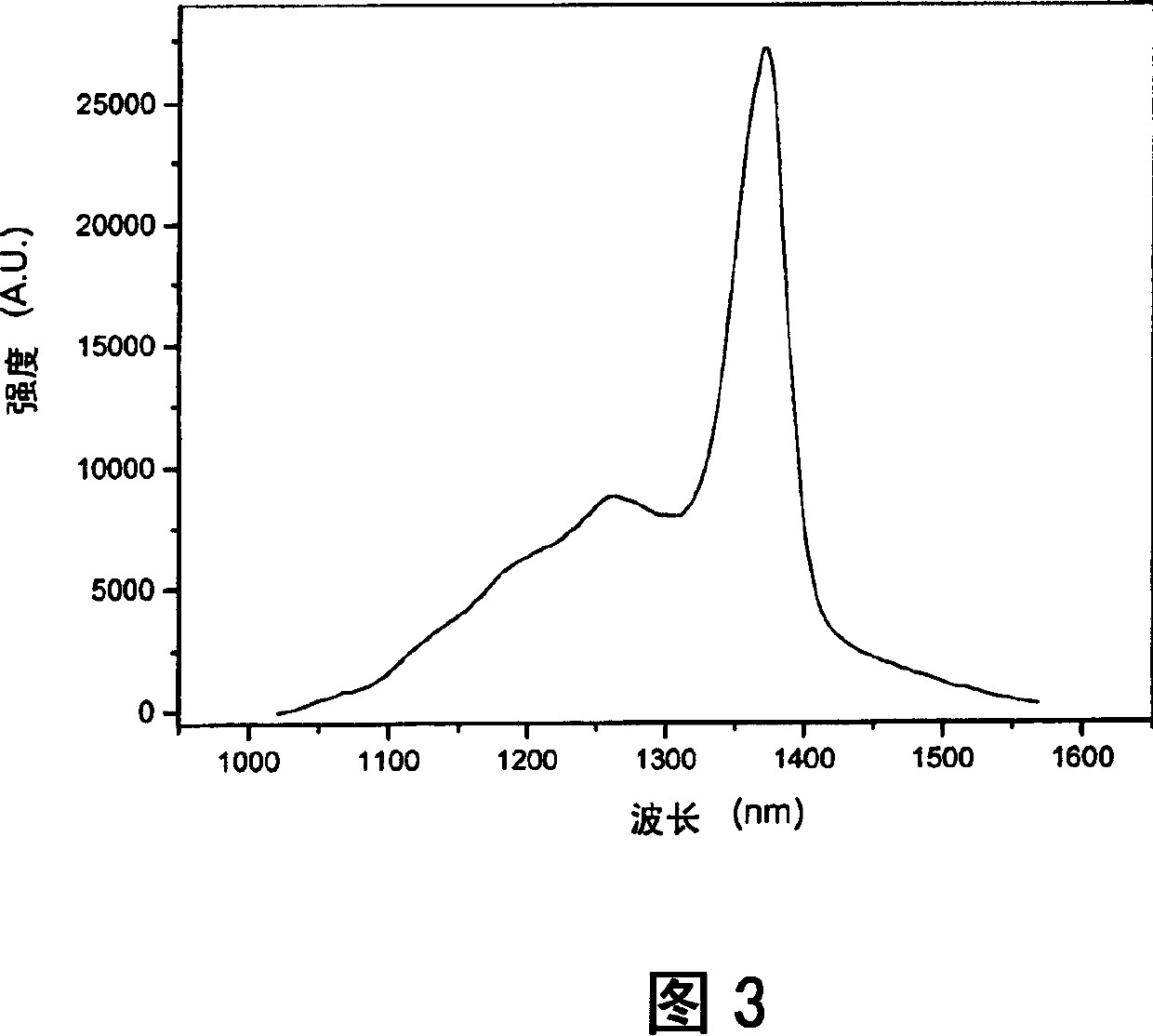

[0055] 3) Epitaxially growing the QDs active region 50 on the lower waveguide layer. The active region 50 is InAS quantum dots 52 of 3-5 periods separated by a 30 nm thick GaAs layer, and the growth temperature is 50

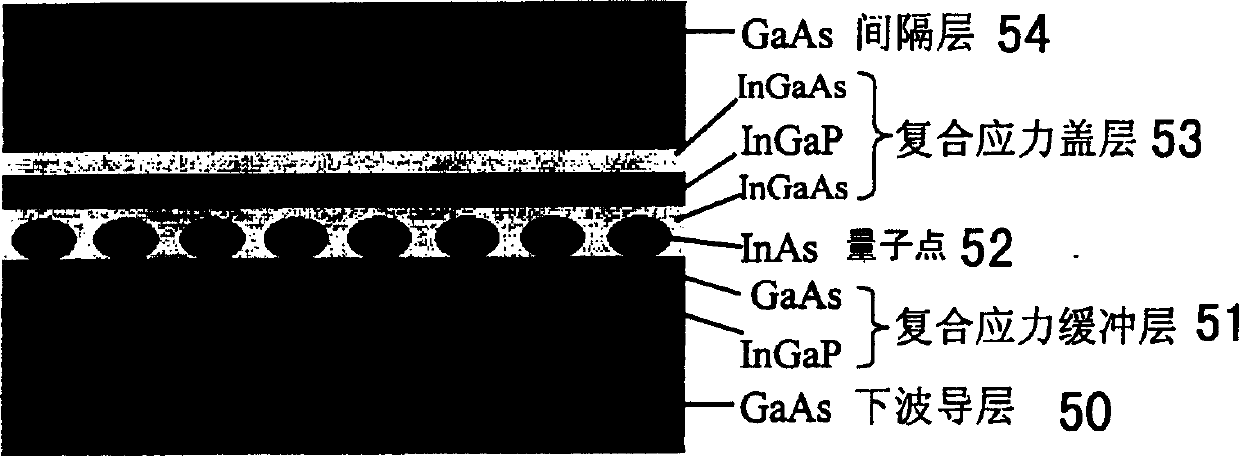

[0056] 0-515 degrees Celsius. In order to extend the emission wavelength of the quantum dots 52 and increase the confinement barrier to increase the characteristic temperature of the device, an InGaP / GaAs composite stress buffer layer 51 and an InGaP / InGaAs comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com