Multi-layer ceramic-based composite thermal protection coating as well as preparation method and application thereof

A technology of multi-layer ceramics and thermal protection, which is applied in the direction of thermal protection devices of space vehicles, aerospace safety/emergency devices, etc., can solve the problems of accelerated material service performance attenuation, surface stability deterioration, heat transfer and load transfer stress, etc. , to enhance the interface bonding strength, improve stability and service life, and improve the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

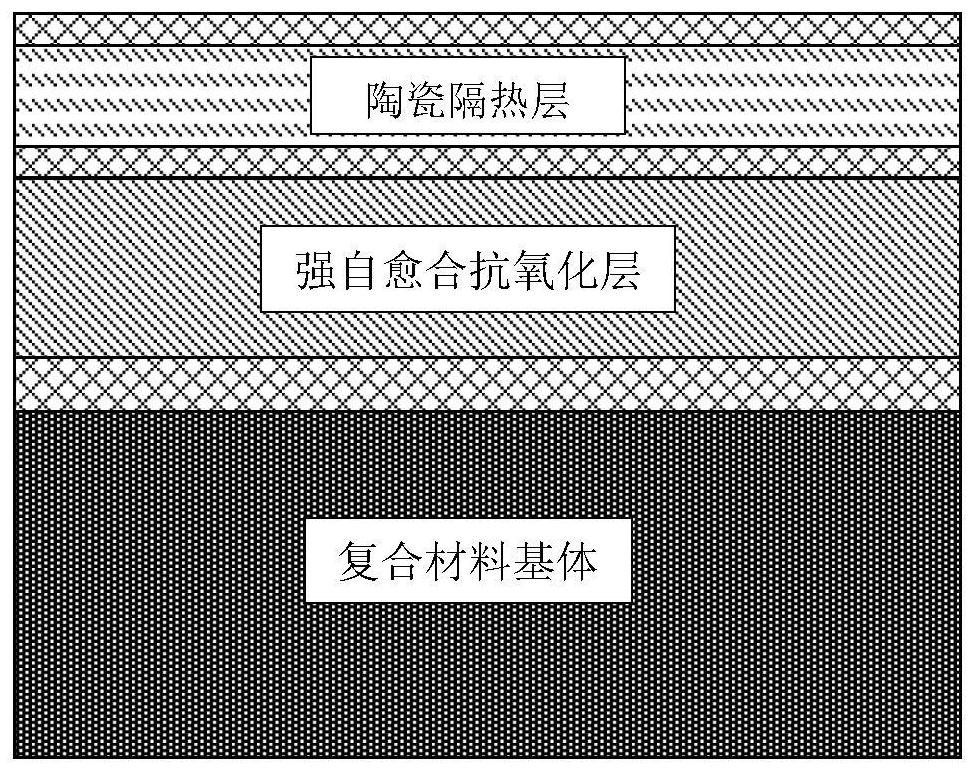

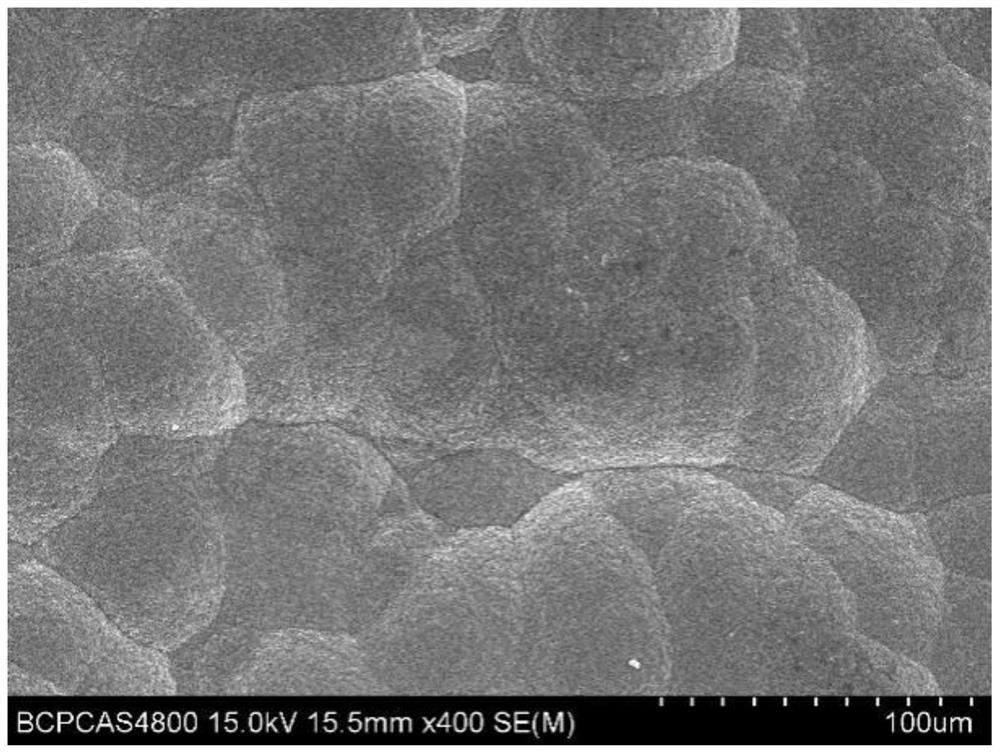

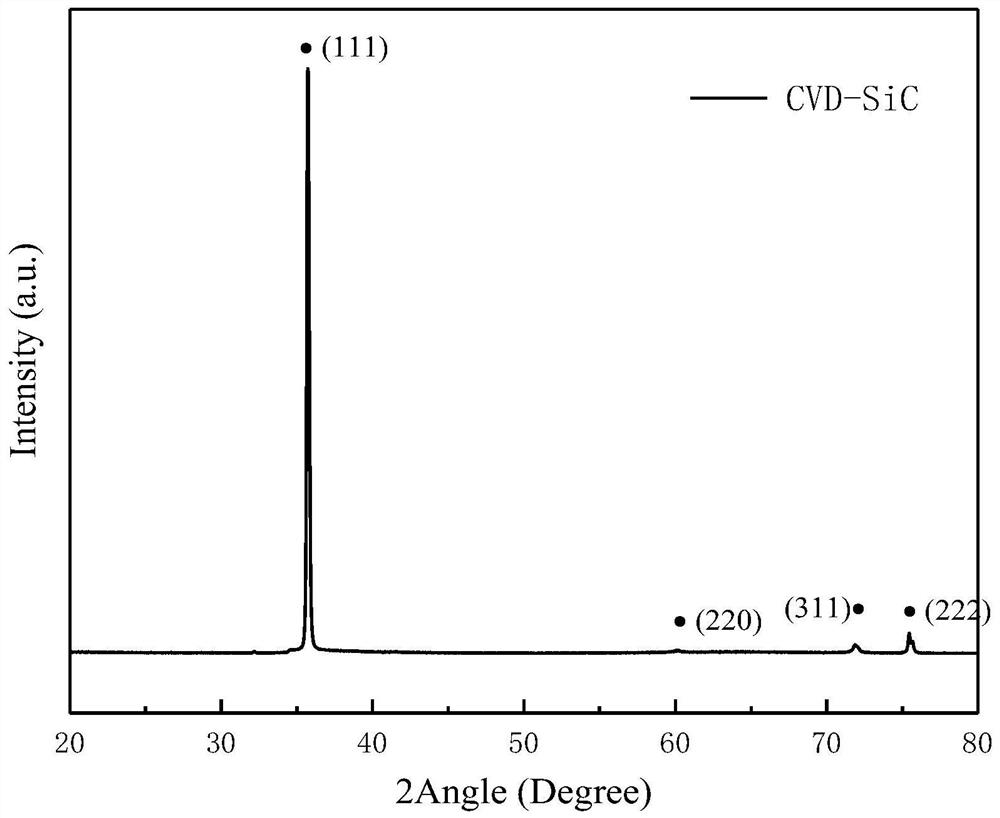

[0037] This embodiment provides a multilayer ceramic matrix composite thermal protective coating with strong self-healing ability, including a composite material matrix and a multilayer composite thermal protective coating, the material of the matrix is silicon carbide fiber reinforced silicon carbide ceramic matrix composite material (SiC f / SiC), the buffer layer is prepared on the surface of the substrate; from the inside to the outside, it includes a buffer layer, a strong self-healing anti-oxidation layer, an intermediate chemical barrier layer, a ceramic thermal insulation layer and a reinforced isolation layer, and the inner buffer layer is prepared on the surface of the composite material. surface. The material of the inner buffer layer, the middle chemical barrier layer and the outer reinforced isolation layer is chemical vapor deposited silicon carbide with a thickness of 50 μm, 30 μm and 30 μm respectively; the material of the strong self-healing anti-oxidation la...

Embodiment 2

[0046] This embodiment provides a multilayer ceramic matrix composite thermal protective coating with strong self-healing ability, comprising a composite material matrix and a multilayer composite thermal protective coating, the material of the matrix is carbon fiber reinforced silicon carbide ceramic matrix composite (C f / SiC), the buffer layer is prepared on the surface of the substrate; from the inside to the outside, it includes a buffer layer, a strong self-healing anti-oxidation layer, an intermediate chemical barrier layer, a ceramic thermal insulation layer and a reinforced isolation layer, and the inner buffer layer is prepared on the surface of the composite material. surface. The material of the inner buffer layer, the middle chemical barrier layer and the outer reinforced isolation layer is chemical vapor deposited silicon carbide with a thickness of 50 μm, 30 μm and 30 μm respectively; the material of the strong self-healing anti-oxidation layer of the second in...

Embodiment 3

[0055] This embodiment provides a multilayer ceramic-based composite thermal protective coating with strong self-healing ability, including a composite material matrix and a multilayer composite thermal protective coating, and the material of the matrix is a carbon fiber reinforced carbon matrix composite (C / C ), the buffer layer is prepared on the surface of the substrate; from the inside to the outside, it includes a buffer layer, a strong self-healing anti-oxidation layer, an intermediate chemical barrier layer, a ceramic heat insulation layer and a reinforced isolation layer, and the inner buffer layer is prepared on the surface of the composite material. The material of the inner buffer layer, the middle chemical barrier layer and the outer reinforced isolation layer is chemical vapor deposited silicon carbide with a thickness of 50 μm, 30 μm and 30 μm respectively; the material of the strong self-healing anti-oxidation layer of the second inner layer is silicon carbide w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com