Method for alleviating thermal stress of porous silicon nitride ceramic and transparent aluminum nitride ceramic in connection process

A technology of porous alumina and silicon nitride ceramics, applied in ceramic products, applications, and other household appliances, etc., can solve the problem of low fracture toughness of transparent aluminum oxynitride ceramics, cracking of transparent aluminum oxynitride ceramics, and difficulty in resisting crack propagation etc. to achieve the effects of reducing the difference in thermal expansion coefficient, reducing thermal stress, and alleviating thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Preparation of oxynitride glass solder. The invention selects rare earth oxide, aluminum oxide, silicon oxide and silicon nitride powder as raw materials to prepare oxynitride glass solder. The rare earth oxides include at least one of lutetium oxide, erbium oxide, yttrium oxide and ytterbium oxide. The raw materials of the oxynitride glass solder include 35-48wt% rare earth oxide, 23-33wt% aluminum oxide, 9-18wt% silicon oxide and 10-24wt% silicon nitride powder, and the sum of the mass percentages of each component is 100wt %.

[0034] Porous silicon nitride ceramics are bonded to transparent aluminum oxynitride ceramics. The connection sequence is to first connect the porous silicon nitride to the porous alumina transition layer, and then connect the porous alumina transition layer to the transparent aluminum oxynitride ceramics. This connection sequence is conducive to realizing the thermal expansion coefficient of the porous alumina buffer layer. Adaptive change...

Embodiment 1

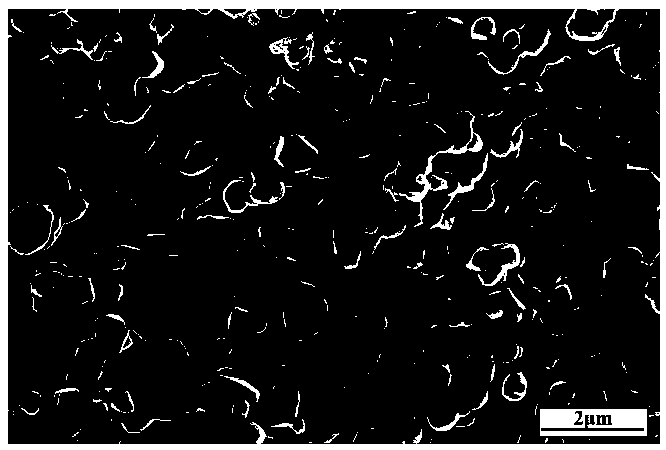

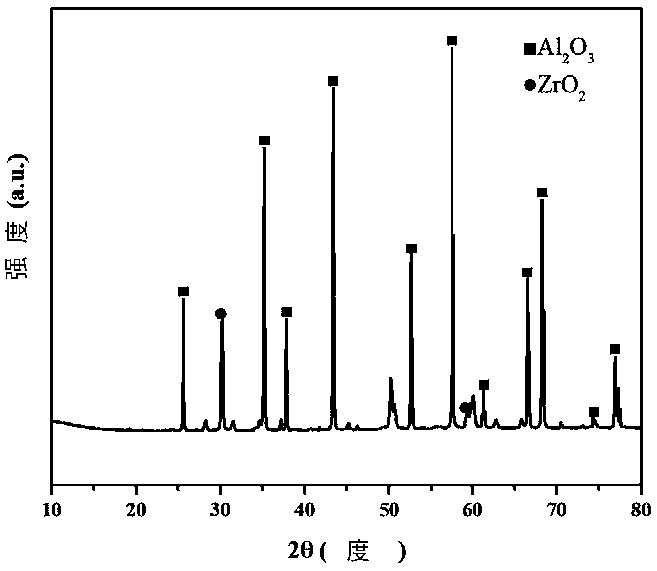

[0042] 84.9gAl 2 o 3 , 15 g ZrO 2 And 0.1gMgO total 100g, with 85g water as solvent, add 2g PVA, 0.3gTMAH, 0.5gPEG, 2g glycerin, it is made into the slurry that solid content is 22Vol%, with Al 2 o 3 100g of balls is the ball milling medium, mill for 4 hours, then filter out the balls and pour them into an aluminum mold, put them into a freeze drying equipment, freeze to -50°C, then slowly raise the temperature to 50°C, the whole process lasts for 40 hours, the vacuum degree is 1Pa. Slowly raise the temperature of the dried green body to 600°C at a rate of 1°C / min, and keep it warm for 2 hours to degrease. Sinter the degreased green body at 1500°C for 60min. Then the sintered alumina is processed into a porous alumina ceramic block with the same size as the welding surface and a thickness of 3mm, and the porosity of the obtained porous alumina ceramic block is 65%. After cleaning and drying the obtained porous alumina ceramic squares, use oxynitride glass solder to bond ...

Embodiment 2

[0044] 84.9gAl 2 o 3 , 15 g ZrO 2 And 0.1gMgO total 100g, with 53g water as solvent, add 2g PVA, 0.3gTMAH, 0.5gPEG, 2g glycerol, it is made into the slurry that solid content is 31Vol%, with Al 2 o 3 150g of balls is used as the ball milling medium, milled for 3 hours, then the balls are filtered out and poured into an aluminum mold, placed in a freeze-drying equipment, frozen to -40°C, and then slowly heated to 50°C, the whole process lasts for 50 hours, the vacuum degree is 20Pa. Slowly heat the dried green body to 600°C at a rate of 0.5°C / min, and keep it warm for 4 hours to degrease. Sinter the degreased green body at 1550°C for 90min. Then the sintered alumina is processed into a porous alumina ceramic square having the same length and width as the welding base material and a thickness of 4mm, and the porosity of the obtained porous alumina ceramic square is 50%. After cleaning and drying the obtained porous alumina ceramic squares, use oxynitride glass solder to bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com